Enabling Large-Scale Carbon Capture, Utilisation, and Storage (CCUS) Using Offshore Carbon Dioxide (CO2) Infrastructure Developments—A Review

Abstract

:1. Introduction

- Section 2 points out the main differences between onshore and offshore CO2-EOR, gives a brief description of facilities needed for offshore CO2-EOR, summarizes current assessments of the global offshore CO2-EOR potential for additional oil production, using available analyses, and gives an overview of the basic economics of offshore CO2-EOR;

- Section 3 describes one existing offshore CO2-EOR project, two cases of desk studies, and one pilot test, pointing out the reasons for why these studies did not materialise into large scale projects;

- Section 4 identifies and describes technology solutions that may enable large scale CO2-EOR projects;

- Section 5 discusses monitoring, verification and accounting (MVA) approaches and points out similarities and differences between offshore and onshore CO2-EOR as well between offshore CO2-EOR and offshore storage projects;

- Section 6 addresses status regulatory issues;

2. Review of Offshore CO2-EOR Storage

2.1. Difference between Onshore and Offshore CO2-EOR

- Offshore, space and weight restrictions on platforms are more limited than they are for onshore projects;

- Offshore wells tend to be directional and farther apart than onshore wells;

- Offshore fields have often achieved higher recovery prior to the use of CO2-EOR than have onshore fields;

- Offshore, CO2 has to be delivered by ship or offshore pipeline, and both methods create additional costs compared to those of onshore solutions;

- Differences in reservoir management capability.

- Offshore leases will generally be authorized/granted by single licensing authorities, making offshore CO2-EOR projects less complex to plan and execute.

- Larger field sizes offshore may correspond to significant potential for higher production from CO2-EOR.

- The possibility of combining CO2-EOR and CO2 storage (volume) is potentially greater offshore.

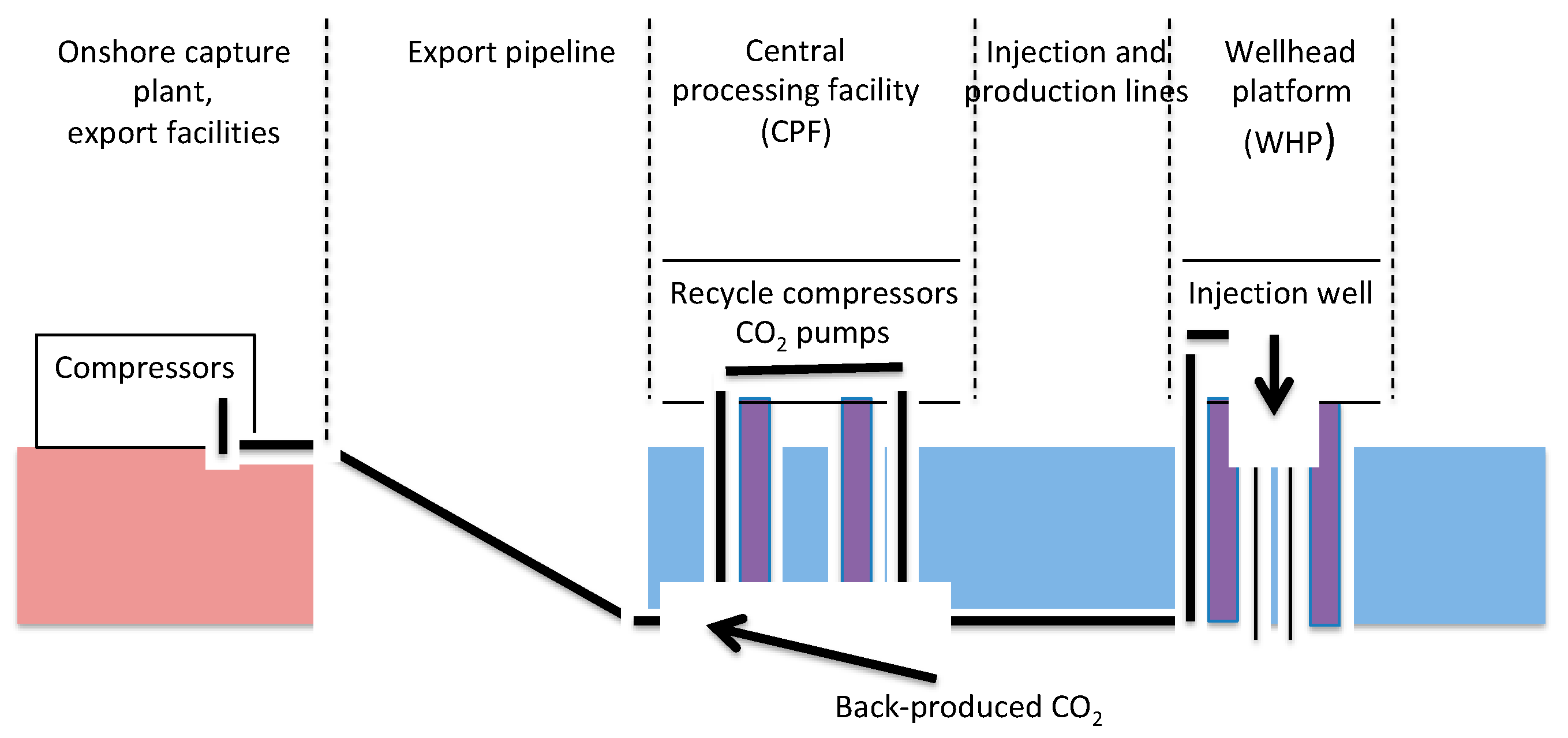

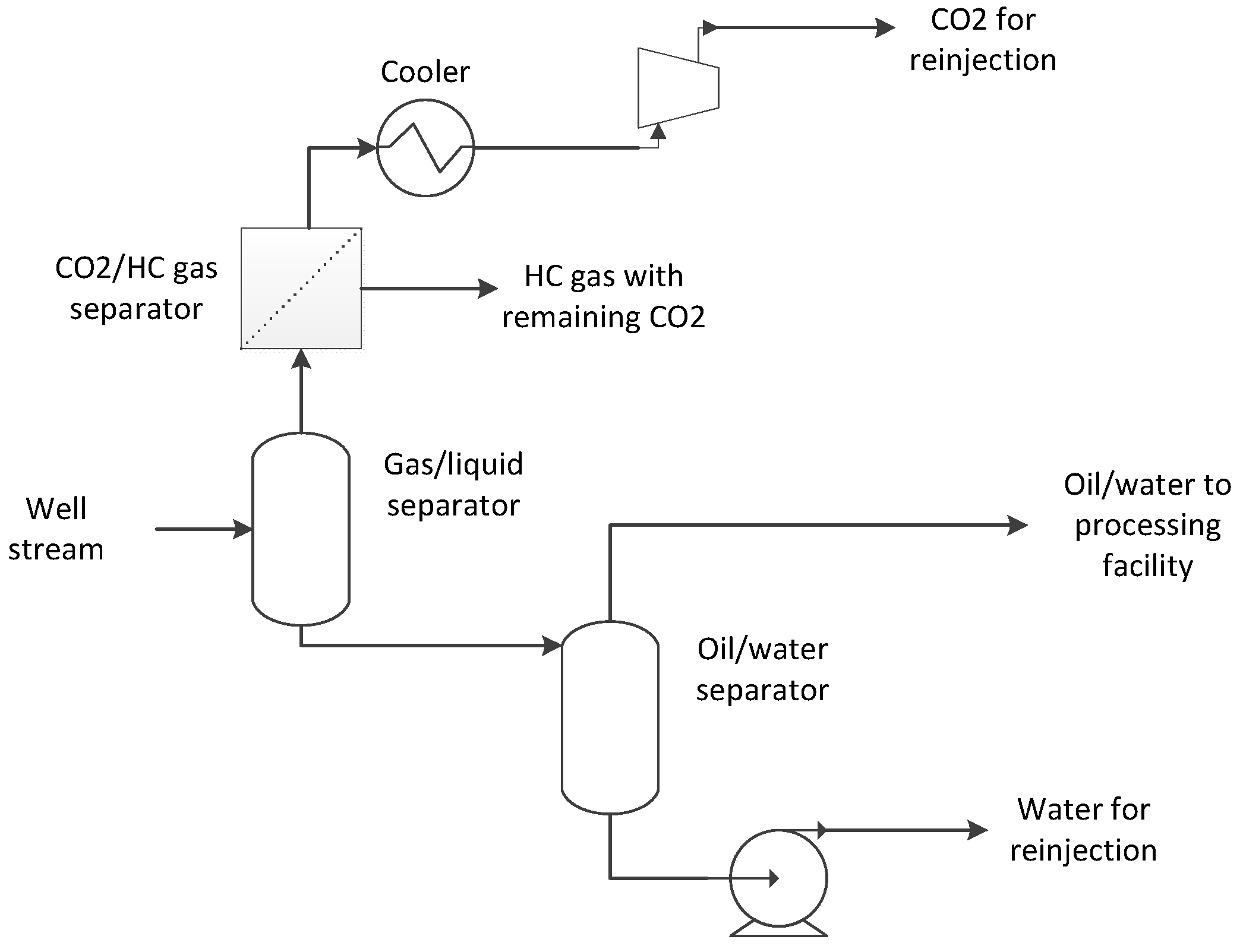

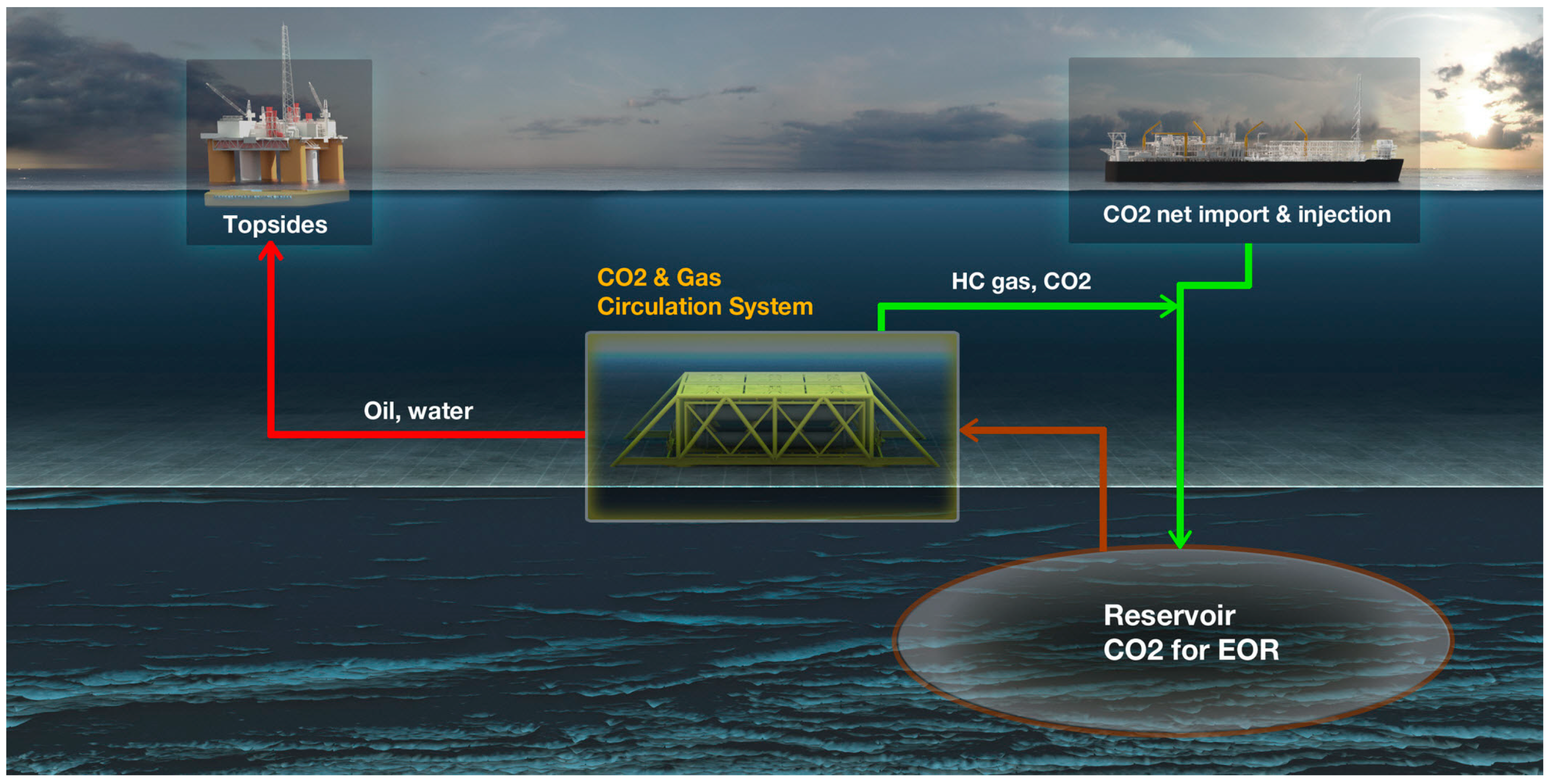

2.2. Facilities for Offshore CO2-EOR

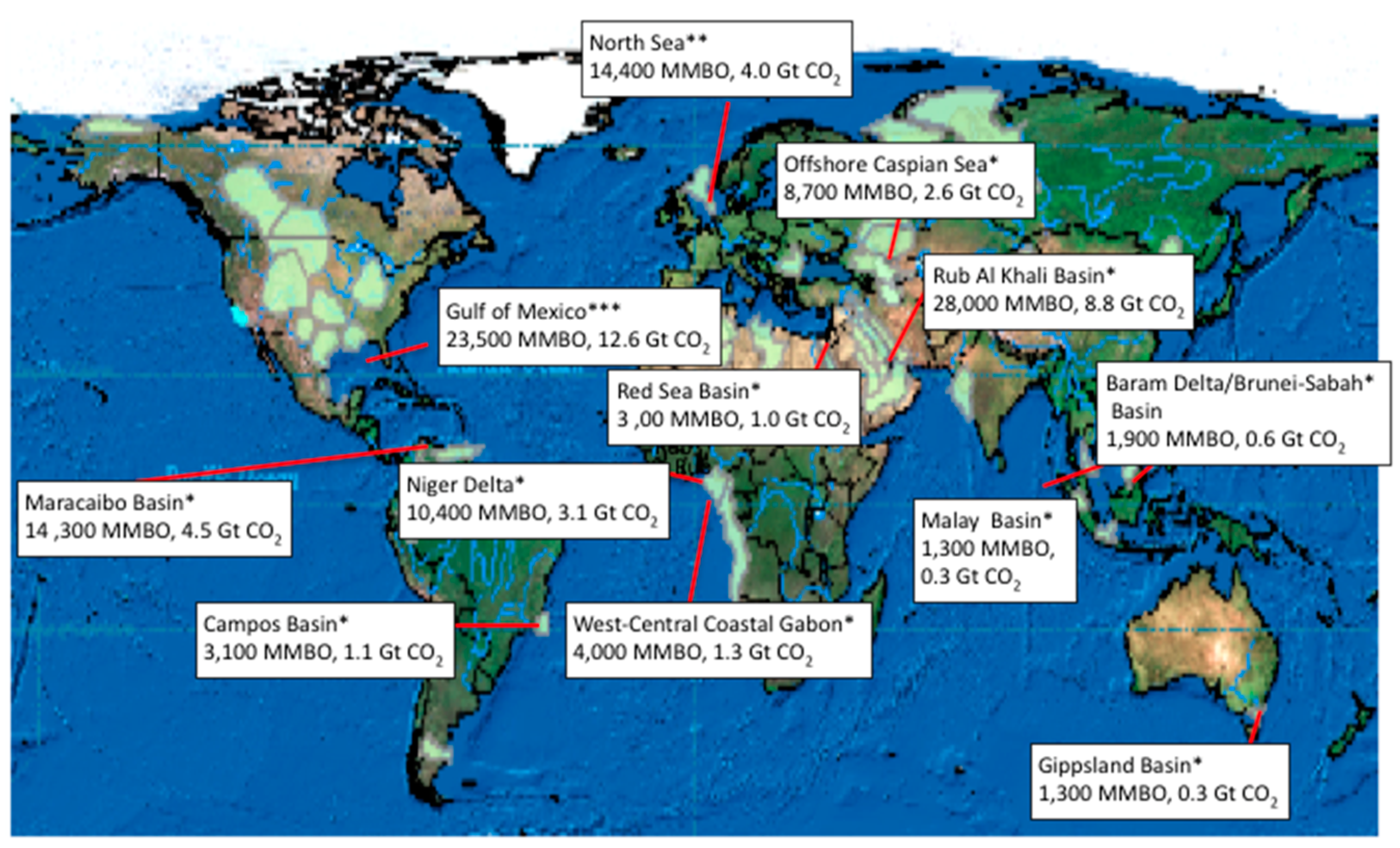

2.3. Global Tecchnical Potential for Incremental CO2-EOR Production and for CO2 Storage

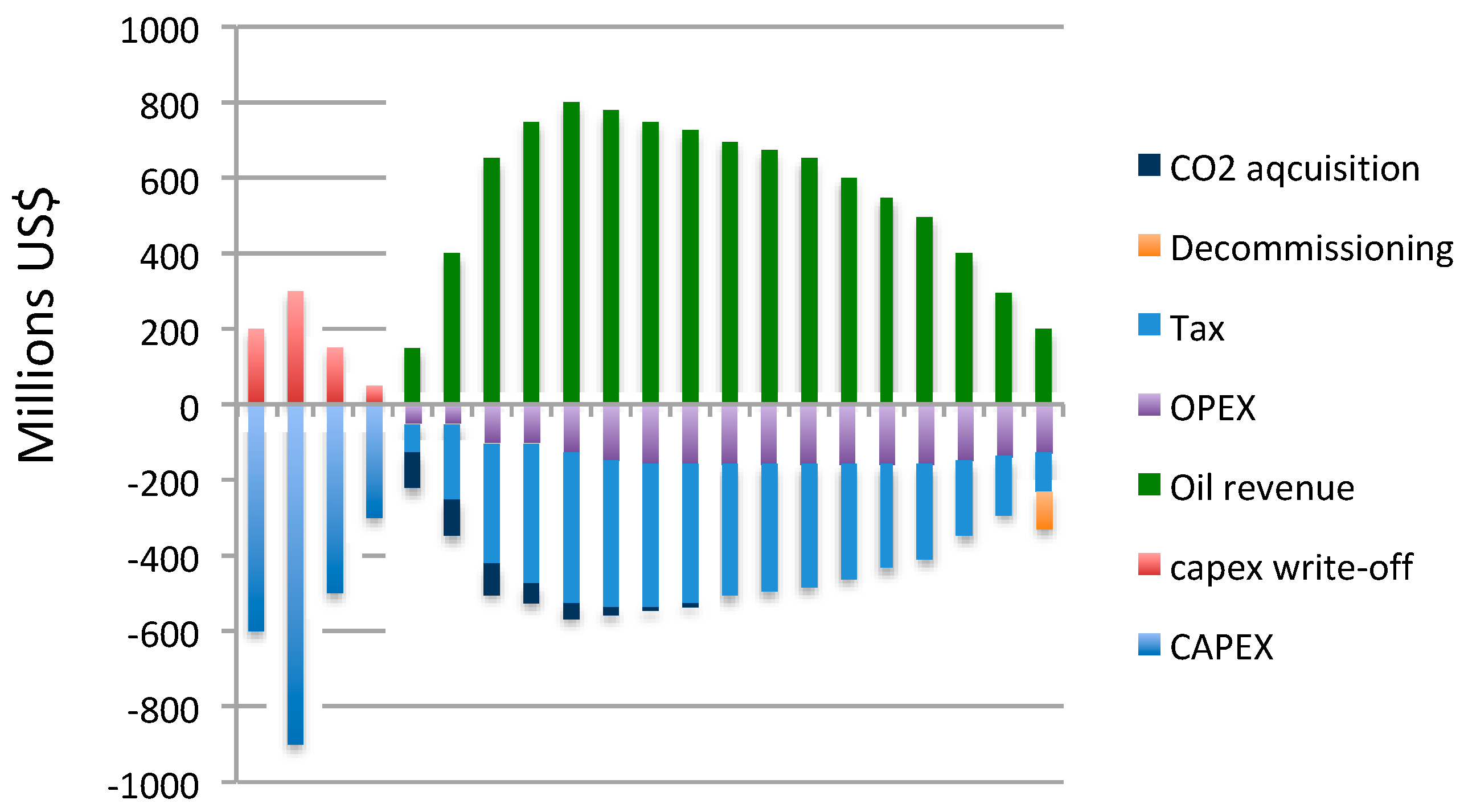

2.4. Economics of Offshore CO2-EOR

3. Case Studies

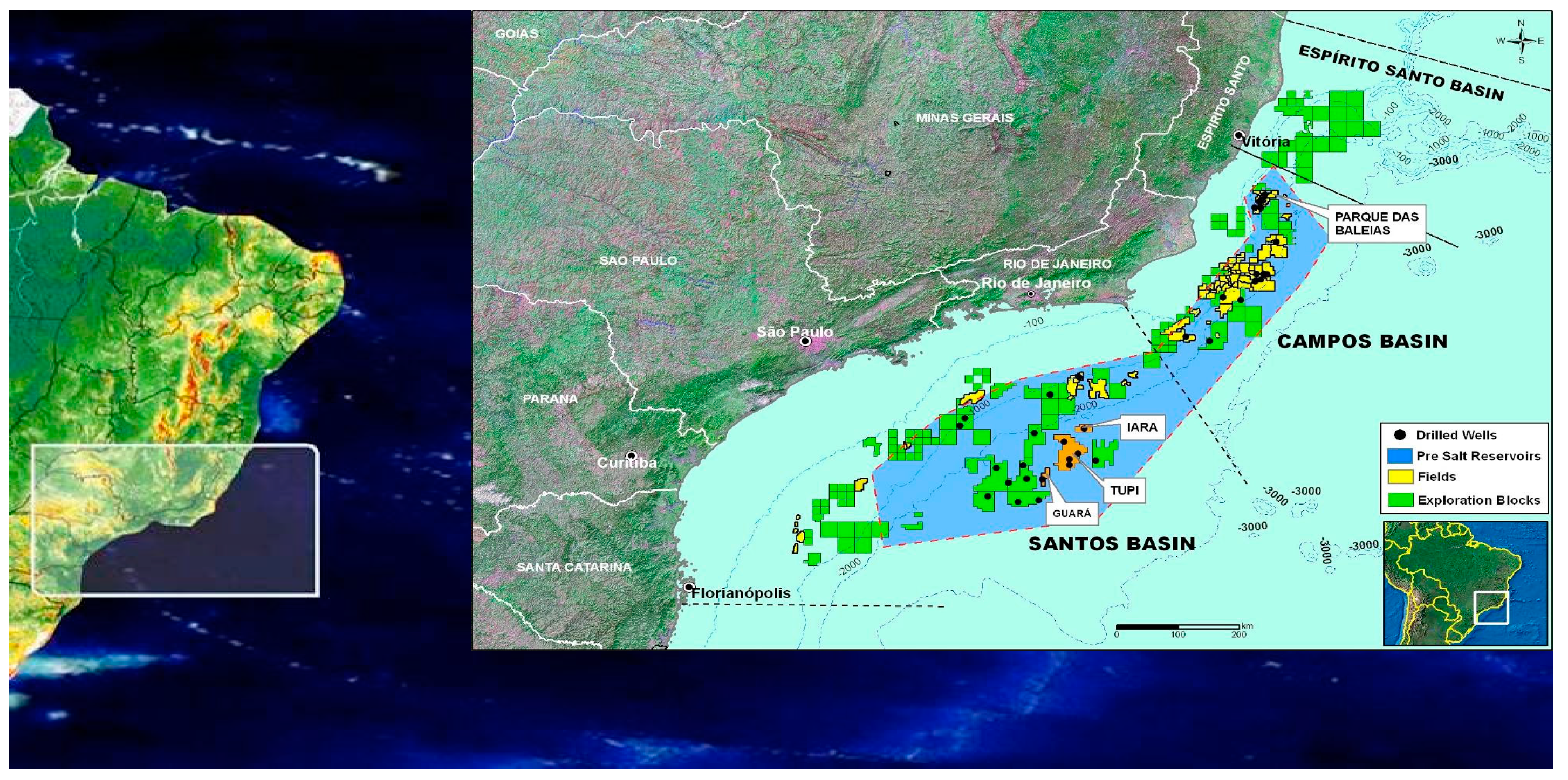

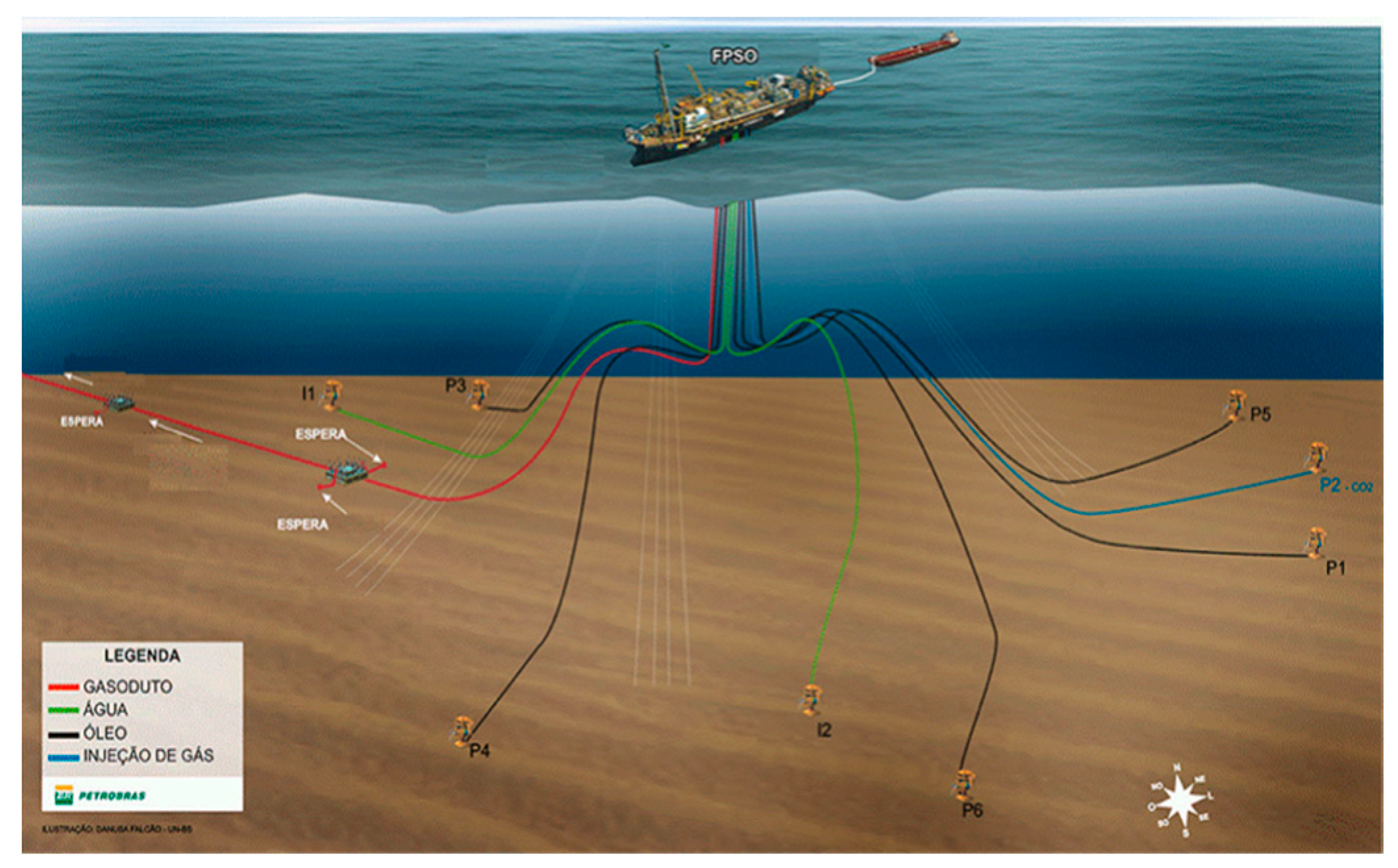

3.1. The Lula Project, Brazil

- Ultra-deep waters

- Heterogeneous carbonate reservoirs

- Presence of contaminants, mainly CO2, in the associated gas

- Thick salt layer and very deep reservoirs that create seismic imaging complexities and drilling difficulties.

3.2. Examples of Desk Studies that Did Not Materialise

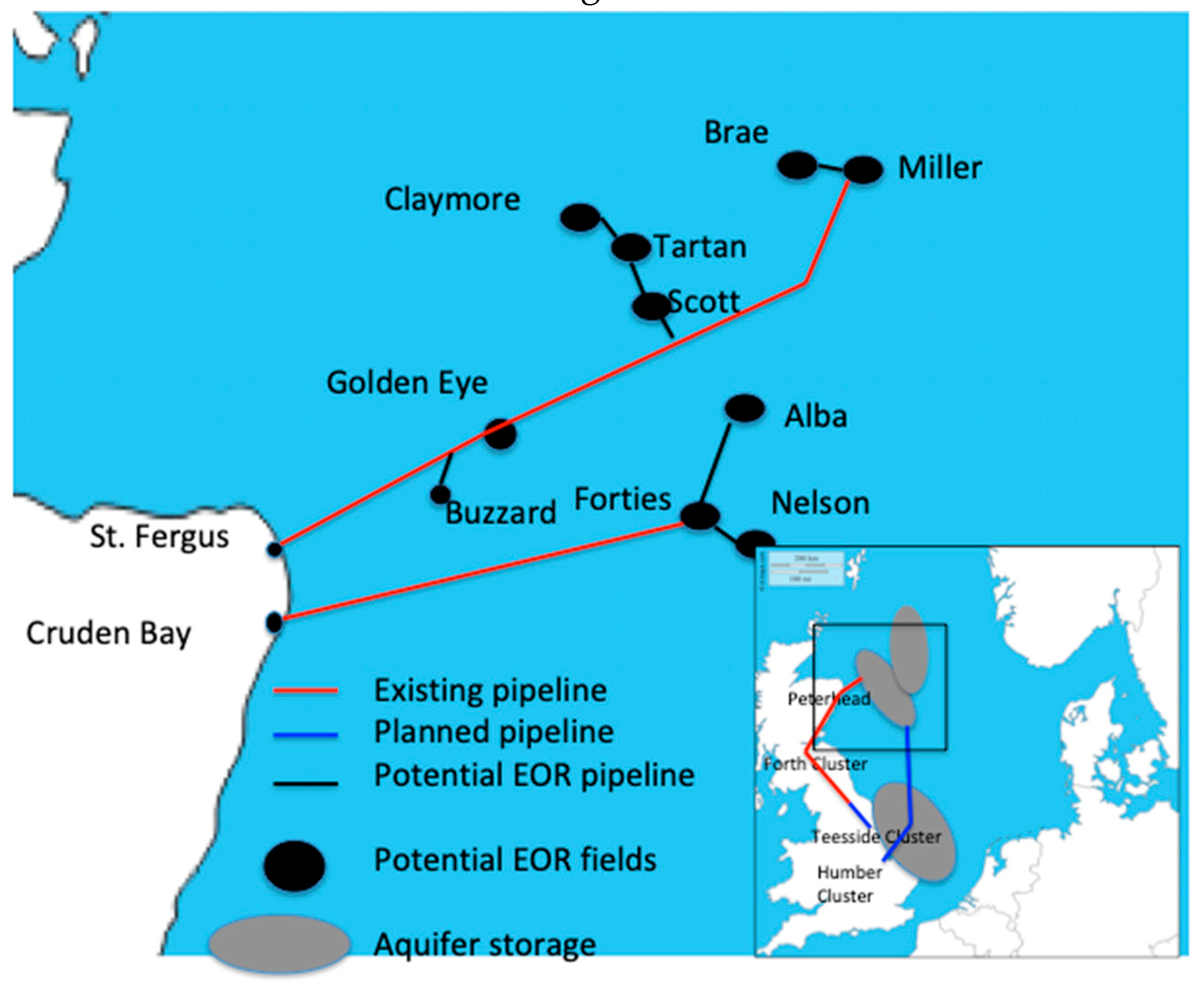

3.2.1. A UK Case

3.2.2. A Norwegian Case

- Five tonnes CO2/year transported CO2 by pipeline from two sources in Denmark to Gullfaks;

- Ship transport of 5 Mt CO2/year from various distributed sources to the Kårstø terminal and a pipeline to Gullfaks;

- Three and a half tonnes CO2/year from distributed sources by ship to Esbjerg, supplemented by 2 Mt CO2/year from a power station and transported by pipeline to Gullfaks.

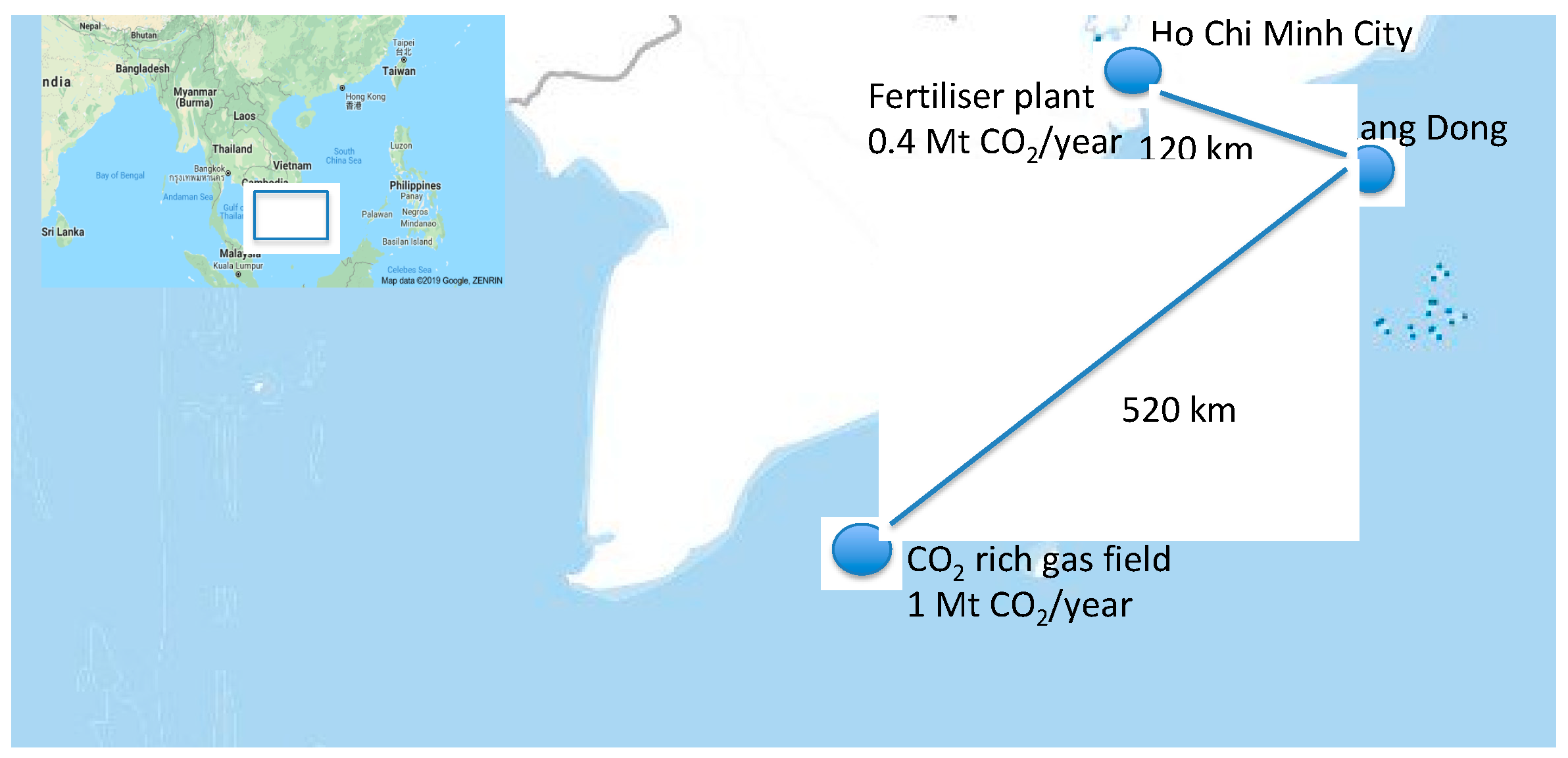

3.2.3. A Vietnamese Case

- CO2 injectivity confirmation

- Oil production increase

- Water-cut reduction

- Oil property changes by CO2 injection

- Oil saturation changes before/after CO2 injection

4. Approaches for Enabling Offshore CO2-EOR

4.1. Optimized and Smart Solutions

- The large investment costs associated with the conversion and adaption of offshore platform facilities;

- The lack of infrastructure to supply and handle sufficient volumes of CO2 to achieve a viable CO2-EOR project;

- Competition with other more attractive oilfield development options, such as gas injection.

- Using smart operational solutions for reducing project CAPEX and OPEX, e.g., by minimising the need for conversion of surface facilities and optimising the gas/CO2 recycling system [15].

- Using late-life oilfield infrastructure. In certain cases, relatively minor modifications could be made to late-life, and generally smaller, offshore field developments where some CO2 handling capabilities are already in place, e.g., the K12-B gas field in the Dutch sector of the North Sea [27].

- Using isolated oilfield satellite projects for dedicated CO2-EOR projects. There is considerable experience in the North Sea with subsea satellite field developments tied back to a main offshore oilfield project. There could be potential for using CO2-EOR on an isolated satellite field without incurring the larger conversion costs associated with a full field project.

- CO2-EOR reservoir modelling, simulation, and optimisation issues. Reservoir mathematical modelling and simulation is a broadly used tool in the oil industry. CO2-EOR is more complex than conventional recovery techniques, such as phase behaviour, reaction with reservoir rock, and multiphase flow in porous media, and oil stability need to be characterised and included in mathematical models/simulators.

4.2. Emerging Technical Solutions for Offshore CO2-EOR and Storage

- The need for treatment of well streams from an EOR flood. Existing offshore facilities generally have very limited space and weight reserves, and the materials utilised in existing processing systems are generally not suitable for streams with a high CO2 content.

- Lack of sufficient and timely CO2 supply.

- Insufficient additional oil recovery to cover the extra expenses.

- Subsea alternatives for topside CO2 processing modules used to separate CO2 for re-injection

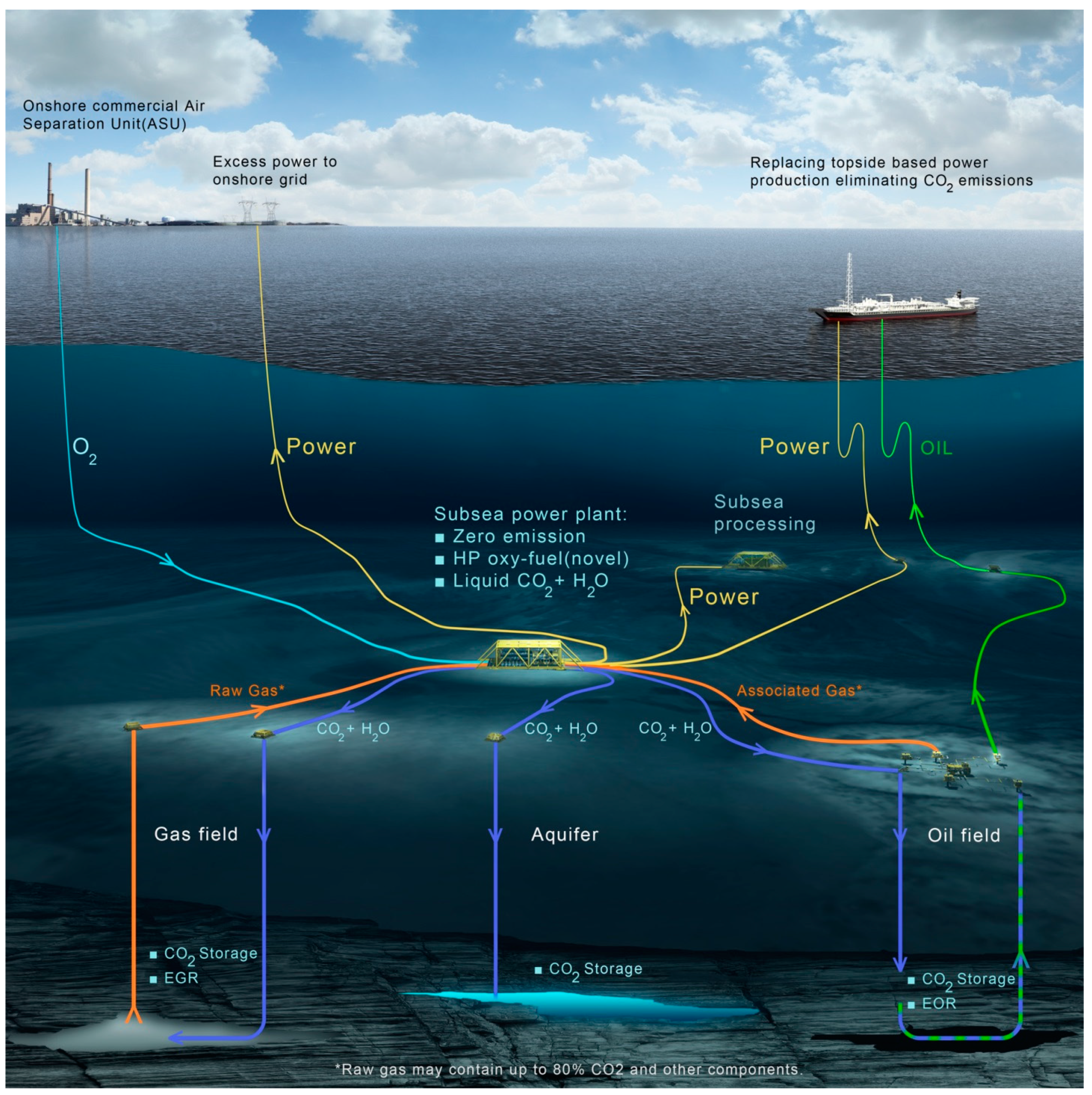

- Combined subsea production, power generation and CO2-EOR

- Improved mobility control using CO2 foam

- Solutions for enabling CO2 supply chains.

4.2.1. Subsea Solutions

4.2.2. Combined Subsea Production, Power Generation and CO2-EOR

- The robust oxy-fuel combustion process eliminates the need for pre-processing of the feed gas.

- The high pressure, naturally provided at the wellhead, combined with the necessary cooling provided by the cold seawater, eliminates the need for costly postprocessing of the flue gas for reinjection.

- The short distances to production and injection wells save much on costly piping infrastructure.

4.2.3. Mobility Control

4.2.4. CO2 Transport as Part of the Supply Chain

5. Monitoring, Verification, and Accounting (MVA)

5.1. Roles and Expectations of MVA for Offshore CO2-EOR

- EOR operational needs: MVA tools for onshore CO2-EOR projects are often targeted at optimising CO2 utilisation, and it is currently unclear how the optimisation will be conducted offshore; however, various types of oilfield surveillance have been widely used, such as wellhead and bottom-hole pressure gauges, injection and production profile logs, saturation logging using tools, such as pulsed neutron devices, 3-D and 4D geophysical surveys, cross-wells surveys, and tracer test programs [33]

- Drilling and operational regulatory requirements: Most hydrocarbon regulation focuses on the assurance of well integrity: These regulations are generally in place but may need modification for CO2-specific well integrity issues

- Greenhouse gas accounting requirements: Monitoring to document storage efficiency and to provide assurance of CO2 containment during and after project operation is likely to become more important over the coming years. However, many components of monitoring programs for CO2-EOR are similar to those detailed for greenhouse gas (GHG) accounting [34], so only incremental changes are expected. For CO2-EOR projects, accounting is needed for CO2 that is produced with hydrocarbons, and some guidance on how this can be included can be found in Reference [35]

- Risk and liability management: Risk management can be a major motivation for the implementation of monitoring and will be site specific in terms of site characteristics, operational condition, and local receptors. These parameters can be integrated into a risk assessment. for which. a framework is provided in Reference [33]

5.2. Differences between MVA for CO2-EOR and Storage of CO2

5.3. Differences between MVA for Onshore CO2-EOR and Offshore CO2-EOR

- Offshore, wells tend to have deviated, multilateral, and of newer construction than onshore wells. These factors might impact risk profiles and optimisation of MVA tools deployed. The wider well spacing might create larger areas of elevated pressure than is typical onshore.

- Onshore the traditional highest concern has been contamination of groundwater or surface water resources. Offshore, hydrocarbons may leak into marine environments, where concerns may be even higher than in onshore settings.

- It is not yet clear how the brine-handling options in an offshore setting will affect the operations for offshore CO2-EOR projects.

- On the more on the speculative side, offshore CO2-EOR may be deployed with a stronger initial emphasis on greenhouse-gas accounting, leading to high and constant rates of CO2 injection. High rates of CO2 injection might elevate offshore risk as compared to traditional onshore EOR by allowing CO2 and elevated pressure to migrate outside of the area of the field under control by production.

5.4. Transition CO2-EOR to Storage—Impact on Monitoring

6. Regulatory Issues

6.1. General

- Presently, CO2-EOR projects are not required to undertake the same extent of site analysis and evaluation —with respect to capacity, integrity and monitoring—as CO2 storage projects. CO2-EOR projects that are considered for transition to carbon capture storage (CCS) projects after cessation of oil production must bear this in mind.

- According to oil-field regulations, a CO2-EOR project ends when the oil production ceases and the field is abandoned. If seeking to transition to a CO2 storage project, issues around liability and CO2 ownership may arise.

- GHG emissions accounting requirements, including emissions connected to recycling and injection processes and the potential for CO2 losses during recycling may also be an issue.

6.2. Some Country and Region Specific Examples

7. Conclusions

- Related to the implementation of CCS in general (where politicians and other decision makers can contribute):

- ∘

- Lack of access to sufficient and timely supply of CO2

- ∘

- Lack of business models, especially for offshore CO2-EOR,

- Related to technology:

- ∘

- High investment costs, CAPEX and additional operational costs, OPEX

- ∘

- Loss of production while modifying facilities represents an additional up-front cost. Technology development can contribute to cost reduction, although the value is also dependent on the required rate of return.

- Related to revenue: Reservoir characteristics are usually well known for mature oil fields, but uncertainties still surround reservoir performance and the yield of addition oil. Uncertainties around the revenues, namely the oil price and the cost of CO2, include the following:

- ∘

- Volatile oil prices that may prevent operators from implementing offshore CO2-EOR unless new business models and/or changed tax regimes are implemented to de-risk investments.

- ∘

- Uncertainties around the price of CO2 that the oil-field operator must pay to the CO2 supplier, including the price of the CO2 itself and the transportation costs. The former will often be subject to negotiations between seller and buyer and could be influenced by CO2 prices in a trading scheme.

- Regulatory issues:

- ∘

- Global development of consistent regulatory regimes for CO2-EOR and the transition from CO2-EOR to CO2 storage in the offshore environment need to be developed globally.

- ∘

- Deciphering requirements that different jurisdictions will place on monitoring underground CO2. Although not being a barrier in itself, monitoring will require different considerations than those for offshore CO2 storage and to onshore CO2-EOR.

- ∘

- Clarity around long-term liability

8. Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- Ueda, Y.; Uchiyama, T.; Kawahara, Y.; Hatakeyama, A. CO2-EOR Huff ‘n’ Puff Pilot Test in Rang Dong Oilfield, offshore Vietnam. J. Jpn. Assoc. Pet. Technol. 2013, 78, 188–196. [Google Scholar] [CrossRef]

- Malone, T.; Kuuskraa, V.; DiPietro, P. CO2-EOR Offshore Resource Assessment, Report DOE/NETL-2014/1631. 2014; 90p. Available online: http://www.netl.doe.gov/energy-analyses/temp/FY14_CO2-EOROffshoreResourceAssessment_060114.pdf (accessed on 17 May 2019).

- Hustad, C.W.; Austell, J.M. Mechanisms and Incentives to Promote the Use and Storage of CO2 in the North Sea; European Energy Law Report: Cambridge, UK, 2004; pp. 355–380. [Google Scholar]

- Holt, T.; Lindberg, E.; Wessel-Berg, D. EOR and CO2 disposal—Economic and capacity potential in the North Sea. Energy Procedia 2009, 1, 4159–4166. [Google Scholar] [CrossRef]

- Pershad, H.; Durusut, E.; Crerar, A.; Black, D.; Mackay, E.; Olden, P. Economic Impacts of CO2-Enhanced oil Recovery for Scotland. Element Energy Report to Scottish Enterprise. 2013. Available online: https://www.scottish-enterprise.com/knowledge-hub/articles/publication/co2-enhanced-oil-recovery (accessed on 2 February 2017).

- Durust, E.; Pershad, H. CO2-EOR in the UK: Analysis of Fiscal Initiatives. Final Non-Technical Report, Element Energy 2014. Available online: http://www.element-energy.co.uk/wordpress/wp-content/uploads/2014/06/SCCS_CO2-EOR_JIP-TaxStudyNon-technicalReport.pdf (accessed on 17 May 2019).

- Norwegian Petroleum Directorate (NPD), 2014 CO2 Storage Atlas. Available online: https://www.regjeringen.no/en/aktuelt/CO2-storage-atlas-for-the-Norwegian-continental-shelf/id760077/ / (accessed on 17 May 2019).

- Energy Research Partnership. Prospects for CO2-EOR in the UKCS 2015. Available online: http://erpuk.org/wp-content/uploads/2015/10/ERP_CO2-EOR-Report-Oct-2015.pdf (accessed on 17 May 2019).

- Scottish Carbon Capture and Storage (SCCS). CO2 Storage and Enhanced Oil Recovery in the North Sea. Securing a Low-Carbon Future for the UK. CO2-EOR Joint Industry Project 2015. Available online: http://www.sccs.org.uk/expertise/reports/co2eor-joint-industry-project (accessed on 30 January 2017).

- Welkenhuysen, K.; Meyvis, B.; Piessens, K. Techno-Economic Evaluation of CO2-EOR in the North Sea. Scottish Carbon Capture and Storage (SCCS) CO2-EOR Joint Industry Project. 2015. Available online: https://pdfs.semanticscholar.org/f54c/49577acbb72d52ca06be06a499591afae5e5.pdf (accessed on 20 May 2019).

- Welkenhuysen, K.; Meyvis, B.; Piessens, K. A profitability study of CO2-EOR and subsequent CO2 storage in the North Sea under low oil market prices. Energy Procedia 2017, 114, 7060–7069. [Google Scholar] [CrossRef]

- IEAGHG. Regional Assessment of Barriers to CO2 Enhanced Oil Recovery in the North Sea, Russia and the GCC States. IEAGHG Report 2016/11. 2016. Available online: http://www.ieaghg.org/publications/technical-reports/129-publications/new-reports-list/718-2016-11 (accessed on 17 May 2019).

- Lindeberg, E.; Grimstad, A.-A.; Bergmo, P.; Wessel-Berg, D.; Torsæter, M.; Holt, T. Large-scale tertiary CO2 EOR in mature water flooded Norwegian oil fields. Energy Procedia 2017, 114, 7096–7106. [Google Scholar] [CrossRef]

- Carbon Sequestration Leadership Forum (CSLF) Technical Group. Task Force on Offshore CO2-EOR: Enabling Large-Scale CCS Using Offshore CO2 Utilization and Storage Infrastructure Developments. 2017. Available online: https://www.cslforum.org/cslf/sites/default/files/documents/OffshoreEORTaskForce-FinalReport.pdf (accessed on 17 May 2019).

- Goodyear, S.G.; Koster, M.P.; Marriott, K.A.; Paterson, A.; Sipkema, A.W.; Young, I.M. Moving CO2 EOR Offshore. SPE 144939. 2011. Available online: https://www.onepetro.org/conference-paper/SPE-144939-MS (accessed on 17 May 2019).

- IEAGHG. CO2 Storage in Depleted Oilfields: Global Application Criteria for Carbon Dioxide Enhanced Oil Recovery, Report 2009/12. 2009. Available online: http://www.ieaghg.org/docs/General_Docs/Reports/2009-12.pdf (accessed on 17 May 2019).

- Kemp, A.G.; Kasim, S. The economics of CO2-EOR cluster developments in the UK Central North Sea. Energy Policy 2013, 62, 1344–1355. [Google Scholar] [CrossRef]

- Vidas, H.; Hugman, B.; Chikkatur, A.; Venkatesh, B. Analysis of the Costs and Benefits of CO2 Sequestration on the U.S. Outer Continental Shelf; OCS Study BOEM 2012-100; U.S. Department of the Interior, Bureau of Ocean Energy Management: Herndon, VA, USA, 2012.

- Seabra, P.N.; Grava, W.M. Petrobras’ Offshore CO2 Management—Pre-Salt Development Management. Presented at the 2014 COP 20 Side Event, Lima, Peru, 6 December 2014; Available online: http://www.ieaghg.org/docs/presentations/COP_20_-_Side_Event_Petrobras_Public.pdf (accessed on 17 May 2019).

- Reid, W. A Selective Literature Review of CO2 EOR in the UK North Sea Continental Shelf; Aiken Reid Ltd: Aberdeen, UK, 2015. [Google Scholar]

- Ministry of Petroleum and Energy, Norway. Enhanced Recovery on the Norwegian Continental Shelf (in Norwegian). 2010. Available online: https://www.regjeringen.no/globalassets/upload/oed/pdf_filer/oktutvinning.pdf (accessed on 7 May 2019).

- Berger, B.; Kaarstad, O.; Haugen, H.A. Creating a Large-Scale CO2 Infrastructure for Enhanced Oil Recovery. Presented at the Seventh International Conference on Greenhouse Gas Control Technologies (GHGT-7), Vancouver, BC, Canada, 5–9 September 2004. [Google Scholar]

- Augustsson, H.; Grinestaf, G.H. A Study of IOR by CO2 Injection in the Gullfaks Field, Offshore Norway. Presented at the 13th European Symposium on Improved Oil Recovery, Budapest, Hungary, 25–27 April 2005. [Google Scholar]

- Uchiyama, T.; Mitsuishi, H.; Ueda, Y.; Nishizaki, A.; Okabe, H.; Takagi, S.; Mitsuishi, H.; Kawahara, Y.; Huy, L.; Trung, P.N.; et al. Evaluation of a Vietnam Offshore CO2 Huff-n-Puff Test. Presented at the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Ha, G.T.; Tran, N.D.; Vu, H.H.; Takagi, S.; Mitsuishi, H.; Hatakeyama, A.; Uchiyama, T.; Ueda, Y.; Nguyen, T.V.; Phan, T.N.; et al. Design & Implementation of CO2 Huff-n-Puff Operation in a Vietnam Offshore Field. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 11–14 November 2012. [Google Scholar]

- Kawahari, Y.; Hatakeyama, A. Offshore CO2-EOR Pilot Project in Vietnam. Presented at the Carbon Sequestration Leadership Forum (CSLF), Tokyo, Japan, 5 October 2016; Available online: https://www.cslforum.org/cslf/sites/default/files/documents/tokyo2016/Kawahara-VietnamEORProject-Workshop-Session1-Tokyo1016.pdf (accessed on 17 May 2019).

- Kreft, E.; Brouwer, G.K.; Hofstee, C.; Wildenborg, A.F.B.; Audigane, P.; Gozalpour, F.; Geel, C.R. Results of the Second Test Program in K12-B, a Site for CO2 Storage and Enhanced Gas Recovery. Presented at the 68th EAGE Conference and Exhibition, Incorporating SPE EUROPEC, Vienna, Austria, 12–15 June 2006. [Google Scholar]

- Melzer, L.S.; Kuuskraa, V.A.; Koperna, G.J. The Origin and Resource Potential of Residual Oil Zones. Presented at the SPE Annual Technical Conference and Exhibition 2006, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Harouaka, A.; Trentham, B.; Melzer, S. Long Overlooked Residual Oil Zones (ROZ’s) Are Brought to the Limelight. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 5–7 November 2013. [Google Scholar]

- IEAGHG. Assessment of Emerging CO2 Capture Technologies and Their Potential to Reduce Costs. 2014/TR4. 2014. Available online: http://www.ieaghg.org/docs/General_Docs/Reports/2014-TR4.pdf (accessed on 17 May 2019).

- Nazarian, B.; Cavanagh, A.; Ringrose, P.; Paasch, B. Composition Swing Injection for CO2 Storage and EOR. Presented at the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 10–13 November 2014. [Google Scholar]

- GCCSI. The Global Status of CCS; CCS Technologies: Melbourne, Australia, 2015. [Google Scholar]

- Cooper, C. (Ed.) A Technical Basis for CO2 Storage. CO2 Capture Project; CPL Press: Newbury, UK, 2009; Available online: www.co2captureproject.org (accessed on 17 May 2019).

- CSLF. Technical Barriers and R&D Opportunities for Offshore, Sub-Seabed Storage of CO2. 2015. Available online: https://www.cslforum.org/cslf/sites/default/files/documents/OffshoreStorageTaskForce_FinalCombinedReport.pdf (accessed on 17 May 2019).

- ISO. ISO 27916—Carbon Dioxide Capture, Transportation and Geological Storage—Carbon Dioxide Storage Using Enhanced Oil Recovery (CO2-EOR); International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Hill, B.; Hovorka, S.; Melzer, S. Geologic carbon storage through enhanced oil recovery. Energy Procedia 2013, 37, 6808–6830. [Google Scholar] [CrossRef]

- CSLF. Technical Challenges in the Cnversions of CO2-EOR Projects to CO2 Storage Projects. 2013. Available online: https://www.cslforum.org/cslf/sites/default/files/documents/CO2-EORtoCCS_FinalReport.pdf (accessed on 17 May 2019).

- Eidan, A.A.; Bachu, S.; Melzer, L.S.; Eide, L.I.; Ackiewicz, M. Technical Challenges in the Conversion of CO2 EOR Projects to Storage Projects. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 11–13 August 2015. [Google Scholar]

- CCP. Best Practice in Transitioning from CO2 EOR to CO2 Storage: Report for CCPS Policies and Incentives Group. 2016. Available online: http://www.co2captureproject.org/viewresult.php?downid=228 (accessed on 17 May 2019).

- Carruthers, K. Metal Mobility in Sandstones and the Potential Environmental Impacts of Offshore Geologic Storage. Ph.D. Dissertation, University of Edinburgh, Edinburgh, UK, 2016; 266p. [Google Scholar]

| Basin | Incremental Oil, Million Barrels | Stored CO2, Gt |

|---|---|---|

| Total | 106,600 | 38.4 |

| Parameter | Scale |

|---|---|

| CO2 availability and price, including transport | Regional/local/project specific, subject to negotiations |

| Oil price | Global |

| CO2 emission cost | Global/Regional |

| Reservoir characteristics, (including permeability, depth, API | Site specific |

| Timing of CO2-EOR operation (effect of CO2-EOR will be reduced as the field gets more mature) | Project specific |

| Project discount rate | Project specific |

| Lost production during the rebuild and delayed decommissioning cost | Project specific |

| Capital expenditure (CAPEX), including modifications, wells, recycling of CO2 | Project specific |

| Operational expenditures (OPEX), including separation and compression of CO2 | Project specific |

| Carbon capture storage (CCS) regulations, including monitoring, decommissioning, closure*, and liability | Project specific |

| Oil Recovery and CO2 Storage Potential | Current Technology | “Next Generation” Technology * |

|---|---|---|

| Total technical viable oil recovery (millions of barrels) | 23,500 | 53,900 |

| Total CO2 demand/storage capacity (Gt) | 12.64 | 15.1 |

| Risk Type | Storage Only (Saline) | EOR with Incremental Storage |

|---|---|---|

| Surface conditions | Greenfield (never used) | Brownfield—already impacted by past operations |

| CO2 management | Injection only | Injection, production, recycle |

| Pressure management | Significant risk, can be managed by water withdrawal | Pressure management is goal of EOR |

| CO2 trapping | Quality of seal is inferred | Quality of seal is proven |

| Solubility of CO2 in formation fluid | CO2 weakly soluble in brine | CO2 highly soluble in oil |

| Subsurface information density | Sparse information, few penetrations | Dense information from well penetrations and past operational history |

| Well failure | Few wells may lead to low risk | Abundant and older wells may increase risk * |

| Pore-space access | Requires new legal mechanisms | Can be built on existing oil and gas precedent |

| Revenue to offset capture cost | No | Yes |

| Public acceptance | Questionable | Public more familiar with oil production |

| Regulation for | USA (Onshore) | Canada (Onshore) | EU (Onshore and Offshore) | Australia (Onshore and Offshore) | Brazil (Onshore and Offshore) | ||

|---|---|---|---|---|---|---|---|

| Alberta | Saskatchewan | British Columbia | |||||

| CO2-EOR | In place | In place | In place | Discussions underway | In place | In place | In place |

| Transition | In development | Discussions underway | Discussions underway | No information | In place | No information | Discussions underway |

| CCS | In place | In place | In development | In development | In place | In place | Discussions underway |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eide, L.I.; Batum, M.; Dixon, T.; Elamin, Z.; Graue, A.; Hagen, S.; Hovorka, S.; Nazarian, B.; Nøkleby, P.H.; Olsen, G.I.; et al. Enabling Large-Scale Carbon Capture, Utilisation, and Storage (CCUS) Using Offshore Carbon Dioxide (CO2) Infrastructure Developments—A Review. Energies 2019, 12, 1945. https://doi.org/10.3390/en12101945

Eide LI, Batum M, Dixon T, Elamin Z, Graue A, Hagen S, Hovorka S, Nazarian B, Nøkleby PH, Olsen GI, et al. Enabling Large-Scale Carbon Capture, Utilisation, and Storage (CCUS) Using Offshore Carbon Dioxide (CO2) Infrastructure Developments—A Review. Energies. 2019; 12(10):1945. https://doi.org/10.3390/en12101945

Chicago/Turabian StyleEide, Lars Ingolf, Melissa Batum, Tim Dixon, Zabia Elamin, Arne Graue, Sveinung Hagen, Susan Hovorka, Bamshad Nazarian, Pål Helge Nøkleby, Geir Inge Olsen, and et al. 2019. "Enabling Large-Scale Carbon Capture, Utilisation, and Storage (CCUS) Using Offshore Carbon Dioxide (CO2) Infrastructure Developments—A Review" Energies 12, no. 10: 1945. https://doi.org/10.3390/en12101945

APA StyleEide, L. I., Batum, M., Dixon, T., Elamin, Z., Graue, A., Hagen, S., Hovorka, S., Nazarian, B., Nøkleby, P. H., Olsen, G. I., Ringrose, P., & Vieira, R. A. M. (2019). Enabling Large-Scale Carbon Capture, Utilisation, and Storage (CCUS) Using Offshore Carbon Dioxide (CO2) Infrastructure Developments—A Review. Energies, 12(10), 1945. https://doi.org/10.3390/en12101945