Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing

Abstract

1. Introduction

2. Materials and Methods

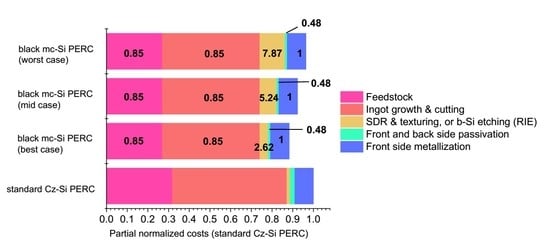

2.1. PERC Production Process

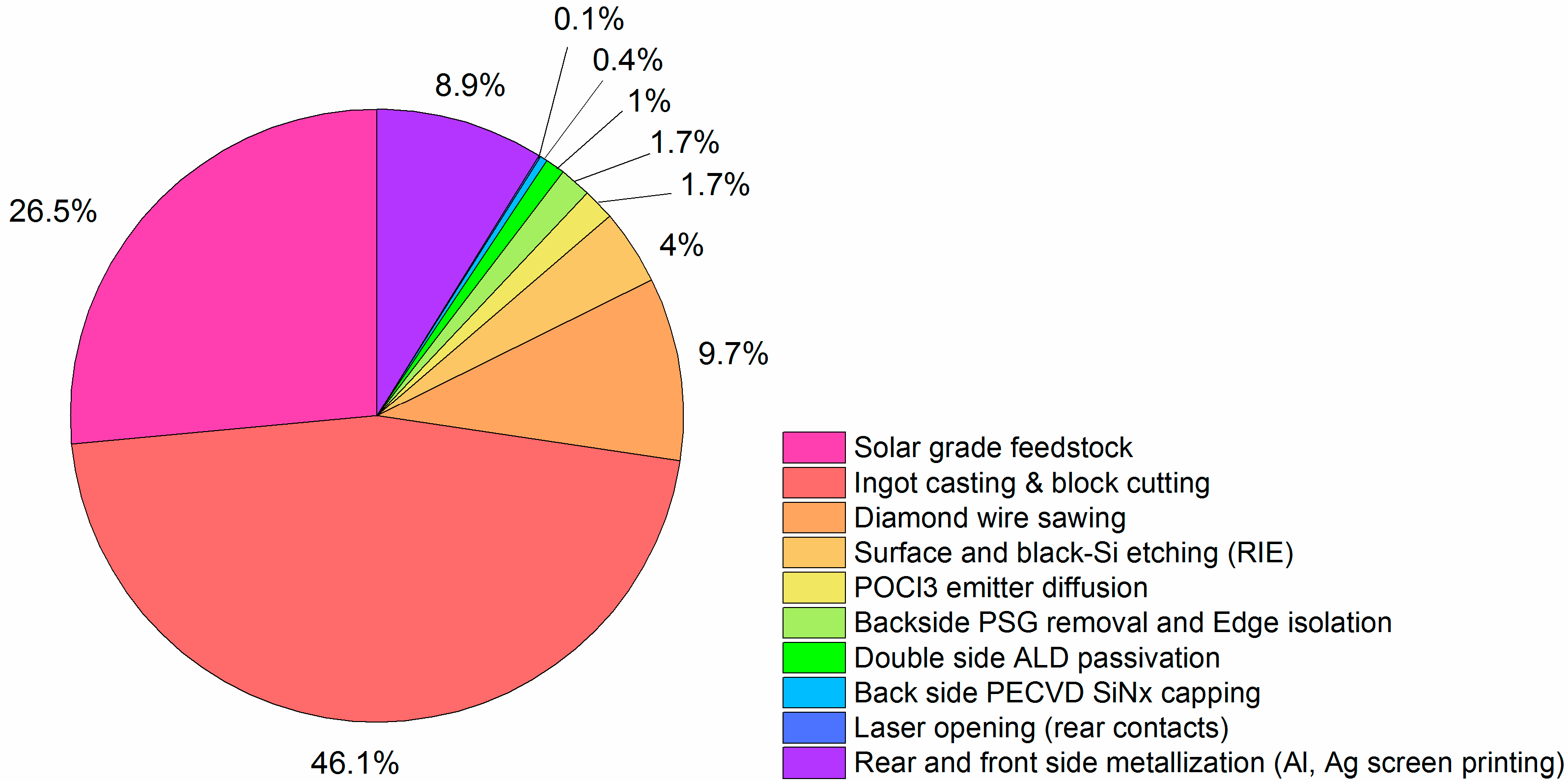

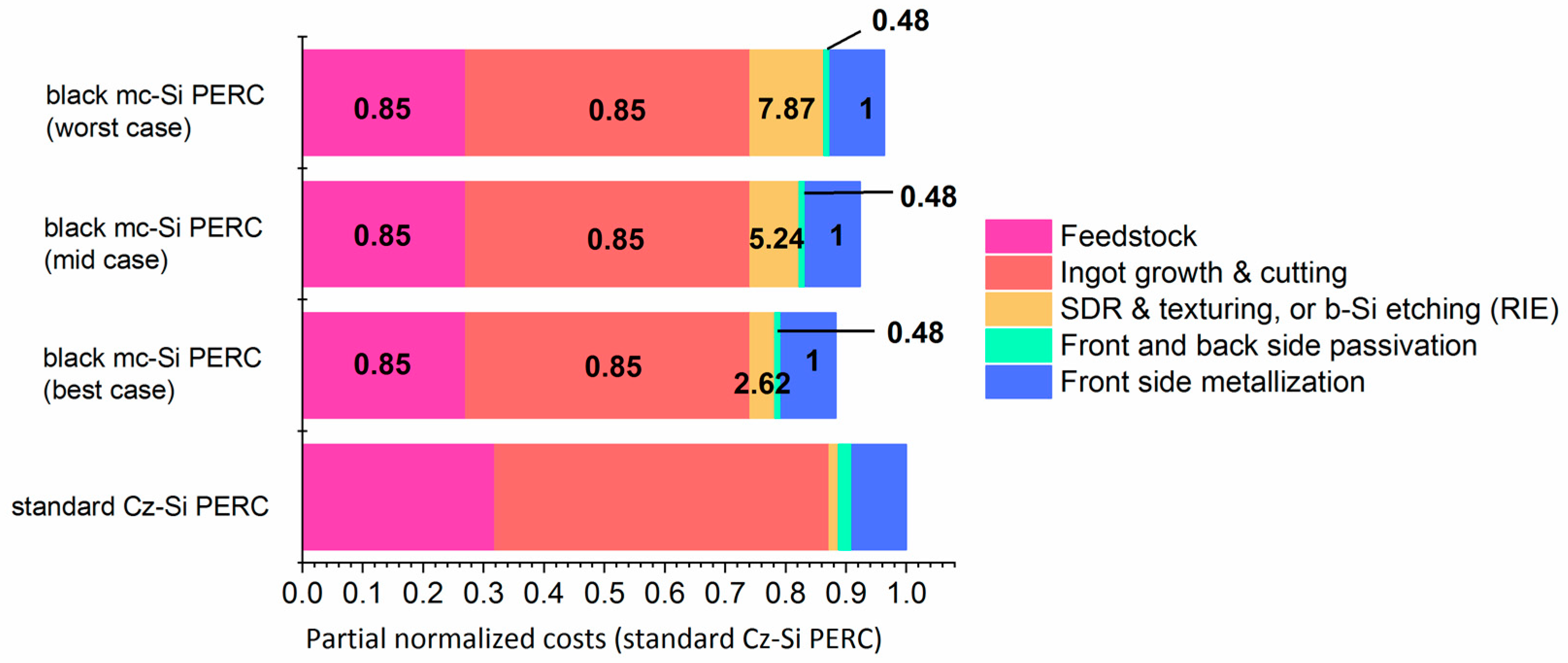

2.2. Costs and Sensitivity Calculations

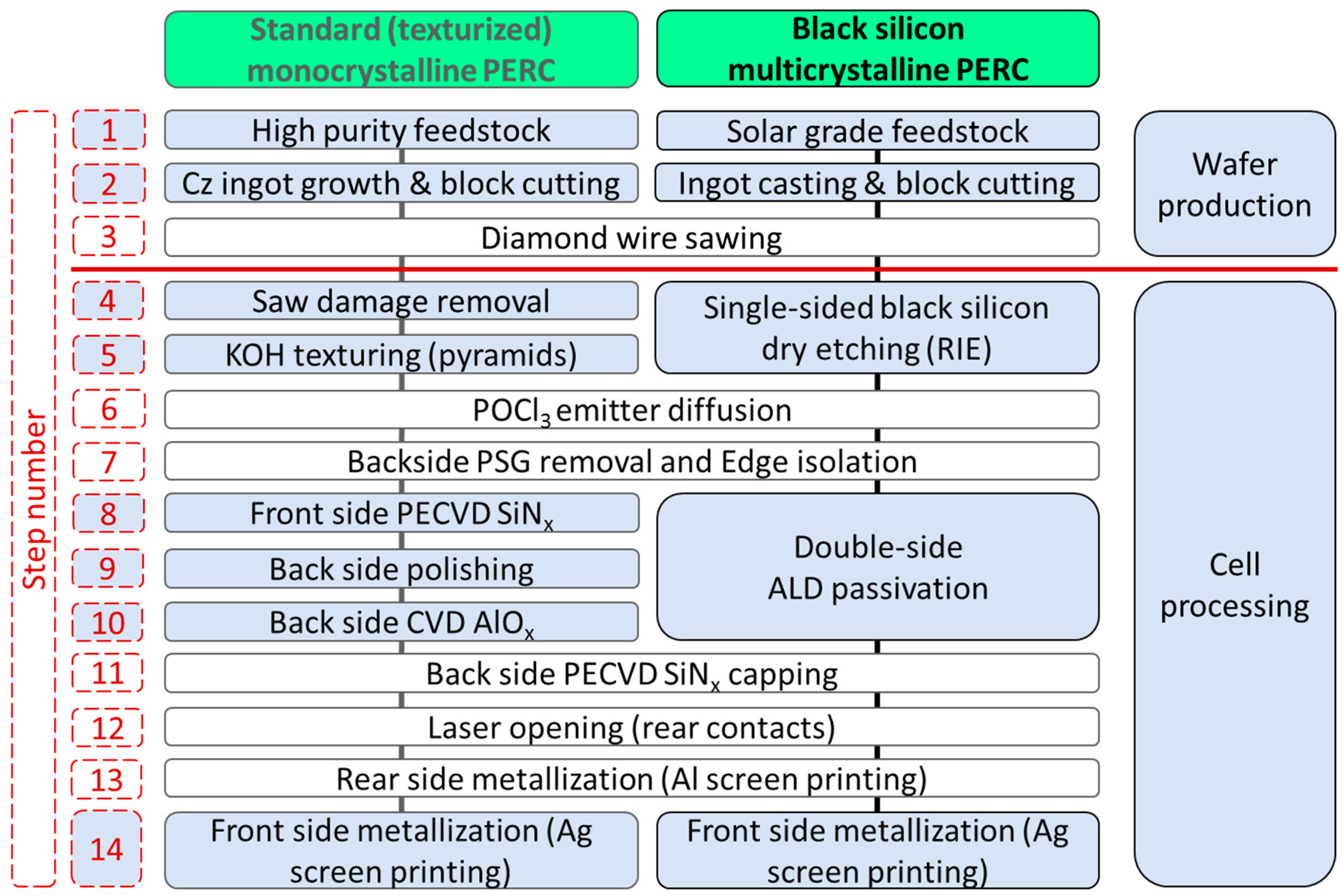

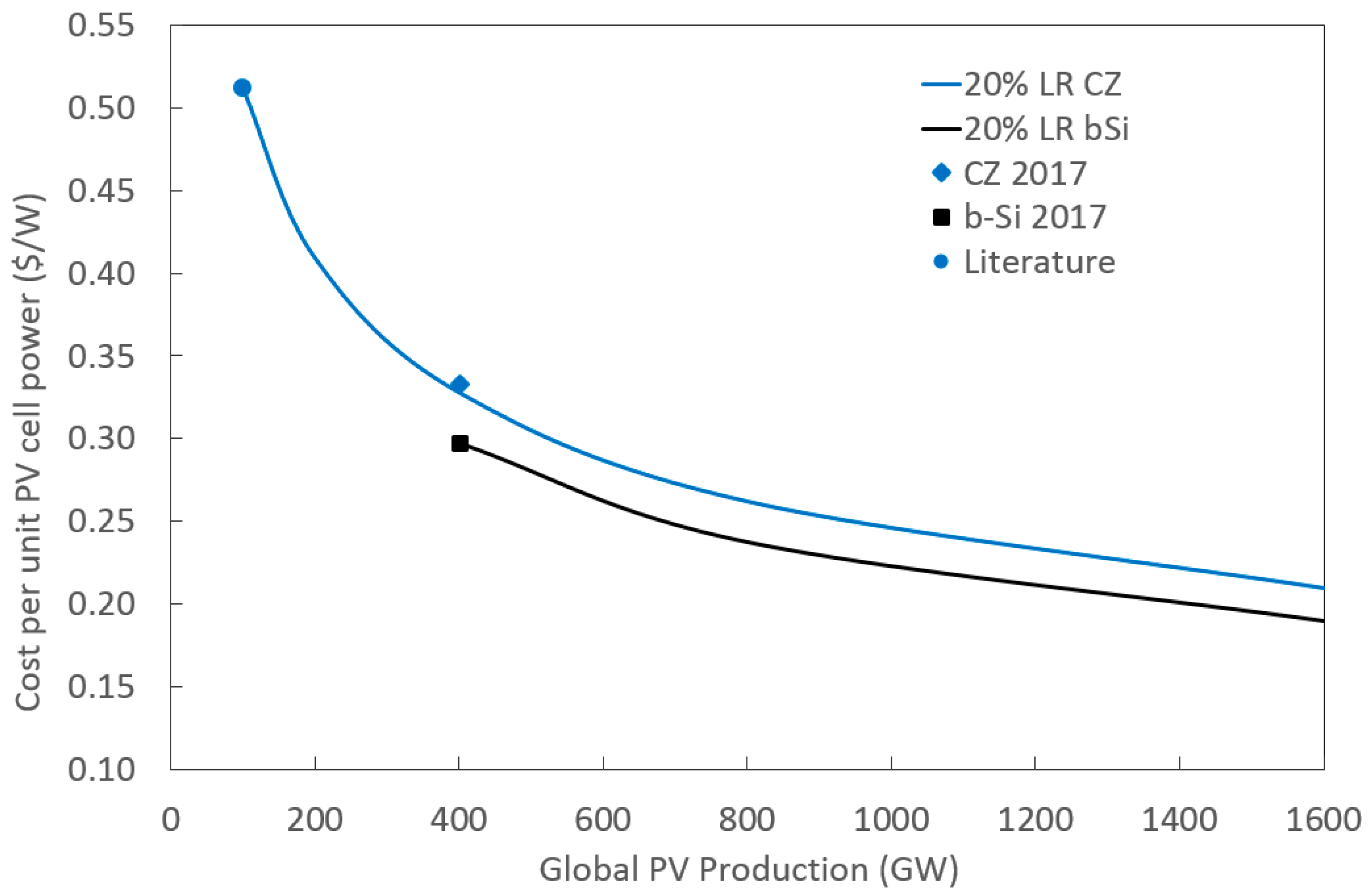

3. Results

4. Discussion

4.1. Black Silicon

4.2. Policies to Accelerate b-Si Deployment in the PV Industry

4.2.1. Policies for Research Support

4.2.2. Policies for Commercialization Support

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ADE | Atmospheric dry etching |

| Ag | Silver |

| Al | Aluminum |

| ALD | Atomic layer deposition |

| AlOx | Aluminum oxide |

| b-Si | Black silicon |

| CVD | Chemical vapor deposition |

| Cz | Czochralski |

| DRIE | Deep reactive ion etching |

| KOH | Potassium hydroxide |

| LID | Light induced degradation |

| MACE | Metal-assisted chemical etching |

| mc-Si | Multicrystalline silicon |

| PECVD | Plasma enhanced chemical vapor deposition |

| PERC | Passivated emitter rear cell |

| POCl3 | Phosphoryl chloride |

| PSG | Phosphosilicate glass |

| PV | Photovoltaic |

| RIE | Reactive ion etching |

| R&D | Research and development |

| ROI | Return on investment |

| SDR | Saw damage removal |

| SiNx | Silicon nitride |

| SME | Small and medium sized enterprises |

| TCO | Transparent conductive oxide |

Appendix A. Costs of All the Production Steps for Both the Standard (Texturized) Cz PERC and the Black Multicrystalline PERC.

| Process Step | Step Costs (US$/Wp) Standard (Texturized) Cz PERC | Source | Step Costs (US$/Wp) Black mc-Si PERC | Source |

|---|---|---|---|---|

| 1 * | 0.0925 | [68] | 0.0786 | [68] |

| 2 * | 0.1610 | [68] | 0.1369 | [68] |

| 3 * | 0.0287 | [68] | 0.0287 | [68] |

| 4+5 | 0.0045 | § | 0.0118 (best case) | § |

| 0.0236 (mid case) | ||||

| 0.0354 (worst case) | ||||

| 6 | 0.0050 | § | 0.0050 | § |

| 7 | 0.0049 | § | 0.0049 | § |

| 8 | 0.0049 | § | 0.0031 | § |

| 9 | 0.0000 | § | ||

| 10 | 0.0016 | § | ||

| 11 | 0.0028 | § | 0.0011 | § |

| 12 | 0.0003 | § | 0.0003 | § |

| 13+14 | 0.0263 | § | 0.0263 | § |

Appendix B

| Source | PERC Cell Architecture | Assumptions | ||

|---|---|---|---|---|

| Cell Size * | Cell Efficiency | Cell Output | ||

| [68] | Both | cm2 | % | Wp/cell |

| 237 | 22 | 5.204 | ||

| § | Standard (texturized) Cz PERC | 244 | 22 | 5.375 |

| Black mc-Si PERC | 246 | 22 | 5.405 | |

| § | Black mc-Si PERC | 243 | 22 | 5.204 |

| § | Black mc-Si PERC | 243 | 22 | 5.204 |

References

- Albrecht, J. The future role of photovoltaics: A learning curve versus portfolio perspective. Energy Policy 2007, 35, 2296–2304. [Google Scholar] [CrossRef]

- Yu, C.F.; van Sark, W.G.J.H.M.; Alsema, E.A. Unraveling the photovoltaic technology learning curve by incorporation of input price changes and scale effects. Renew. Sustain. Energy Rev. 2011, 15, 324–337. [Google Scholar] [CrossRef]

- Hong, S.; Chung, Y.; Woo, C. Scenario analysis for estimating the learning rate of photovoltaic power generation based on learning curve theory in South Korea. Energy 2015, 79, 80–89. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.V.; Tan, H.; Liu, P.H.Y.; Li, S.-J.; Lin, L.-C. The determinants of photovoltaic system costs: an evaluation using a hierarchical learning curve model. J. Clean. Prod. 2016, 112, 1709–1716. [Google Scholar] [CrossRef]

- Mauleón, I. Photovoltaic learning rate estimation: Issues and implications. Renew. Sustain. Energy Rev. 2016, 65, 507–524. [Google Scholar] [CrossRef]

- Feldman, D.; Barbose, G.; Margolis, R.; Wiser, R.; Darghout, N.; Goodrich, A. Photovoltaic (PV) Pricing Trends: Historical, Recent, and Near-term Projections; Technical Report; Lawrence Berkeley National Lab.: Berkeley, CA, USA, 2012. [Google Scholar]

- Barbose, G.L.; Darghouth, N.R.; Millstein, D.; LaCommare, K.; DiSanti, N.; Widiss, R. Tracking the Sun 10: The Installed Price of Residential and Non-Residential Photovoltaic Systems in the United States. Available online: https://emp.lbl.gov/publications/tracking-sun-10-installed-price (accessed on 25 July 2018).

- PVinsights. Available online: http://pvinsights.com/ (accessed on 25 July 2018).

- Reuters. Solar Costs to Fall Further, Powering Global Demand-Irena. Available online: https://www.reuters.com/article/singapore-energy-solar/solar-costs-to-fall-further-powering-global-demand-irena-idUSL4N1MY2F8 (accessed on 5 March 2018).

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Safi, M. Indian Solar Power Prices Hit Record Low, Undercutting Fossil Fuels. Available online: http://www.theguardian.com/environment/2017/may/10/indian-solar-power-prices-hit-record-low-undercutting-fossil-fuels (accessed on 5 March 2018).

- Drury, E.; Miller, M.; Macal, C.M.; Graziano, D.J.; Heimiller, D.; Ozik, J.; Perry, T.D., IV. The transformation of southern California’s residential photovoltaics market through third-party ownership. Energy Policy 2012, 42, 681–690. [Google Scholar] [CrossRef]

- Branker, K.; Shackles, E.; Pearce, J.M. Peer-to-peer financing mechanisms to accelerate renewable energy deployment. J. Sustain. Financ. Invest. 2011, 1, 138–155. [Google Scholar] [CrossRef]

- Alafita, T.; Pearce, J.M. Securitization of residential solar photovoltaic assets: Costs, risks and uncertainty. Energy Policy 2014, 67, 488–498. [Google Scholar] [CrossRef]

- Hede, S.; Nunes, M.J.L.; Ferreira, P. Credits trading mechanism for corporate social responsibility: An empirically grounded framework. Int. J. Technol. Learn. Innov. Dev. 2014, 7, 49–92. [Google Scholar] [CrossRef]

- Overholm, H. Spreading the rooftop revolution: What policies enable solar-as-a-service? Energy Policy 2015, 84, 69–79. [Google Scholar] [CrossRef]

- Ameli, N.; Kammen, D.M. Innovations in financing that drive cost parity for long-term electricity sustainability: An assessment of Italy, Europe’s fastest growing solar photovoltaic market. Energy Sustain. Dev. 2014, 19, 130–137. [Google Scholar] [CrossRef]

- Coughlin, J.; Cory, K.S. Solar Photovoltaic Financing: Residential Sector Deployment; Technical Report; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- International Energy Agency. Renewables 2017. Available online: https://www.iea.org/publications/renewables2017/ (accessed on 5 March 2018).

- Polman, A.; Knight, M.; Garnett, E.C.; Ehrler, B.; Sinke, W.C. Photovoltaic materials: Present efficiencies and future challenges. Science 2016, 352, aad4424. [Google Scholar] [CrossRef] [PubMed]

- Projected Market Share of Solar Photovoltaic Panels Worldwide in 2030, by Technology. Available online: https://www.statista.com/statistics/492755/solar-pv-panels-market-share-projection-by-cell-technology-globally/ (accessed on 5 March 2018).

- Powell, D.M.; Fu, R.; Horowitz, K.; Basore, P.A.; Woodhouse, M.; Buonassisi, T. The capital intensity of photovoltaics manufacturing: Barrier to scale and opportunity for innovation. Energy Environ. Sci. 2015, 8, 3395–3408. [Google Scholar] [CrossRef]

- Dullweber, T.; Schmidt, J. Industrial silicon solar cells applying the passivated emitter and rear cell (PERC) concept—A review. IEEE J. Photovolt. 2016, 6, 1366–1381. [Google Scholar] [CrossRef]

- Green, M.A. The Passivated Emitter and Rear Cell (PERC): From conception to mass production. Sol. Energy Mater. Sol. Cells 2015, 143, 190–197. [Google Scholar] [CrossRef]

- International Technology Roadmap for Photovoltaic Results 2016 incl. Maturity Report. Available online: http://www.itrpv.net/Reports/Downloads/ (accessed on 16 May 2018).

- Liu, X.; Coxon, P.R.; Peters, M.; Hoex, B.; Cole, J.M.; Fray, D.J. Black silicon: Fabrication methods, properties and solar energy applications. Energy Environ. Sci. 2014, 7, 3223–3263. [Google Scholar] [CrossRef]

- Pasanen, T.P.; Laine, H.S.; Vähänissi, V.; Schön, J.; Savin, H. Black silicon significantly enhances phosphorus diffusion gettering. Sci. Rep. 2018, 8, 1991. [Google Scholar] [CrossRef] [PubMed]

- Pasanen, T.P.; Modanese, C.; Vähänissi, V.; Laine, H.S.; Heikkinen, I.T.S.; Wolny, F.; Oehlke, A.; Kusterer, K.; Wagner, Mt.; Savin, H. Black-silicon eliminates light- and elevated-temperature induced degradation in industrial passivated emitter and rear cells. Prog. Photovolt. 2018. under review. [Google Scholar]

- Davidsen, R.S.; Ormstrup, J.; Ommen, M.L.; Larsen, P.E.; Schmidt, M.S.; Boisen, A.; Nordseth, Ø.; Hansen, O. Angle resolved characterization of nanostructured and conventionally textured silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 140, 134–140. [Google Scholar] [CrossRef]

- Koynov, S.; Brandt, M.S.; Stutzmann, M. Black nonreflecting silicon surfaces for solar cells. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef]

- Jura, M.P.; Miller, J.B.; Yim, J.W.L.; Forziati, J.; Murphy, B.; Chleboski, R.; Cooper, I.B.; Rohatgi, A.; Black, M.R. Conventionally-processed silicon nanowire solar cells demonstrating efficiency improvement over standard cells. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 598–600. [Google Scholar]

- Toor, F.; Miller, J.B.; Davidson, L.M.; Nichols, L.; Duan, W.; Jura, M.P.; Yim, J.; Forziati, J.; Black, M.R. Nanostructured silicon via metal assisted catalyzed etch (MACE): chemistry fundamentals and pattern engineering. Nanotechnology 2016, 27, 412003. [Google Scholar] [CrossRef] [PubMed]

- Toor, F.; Miller, J.B.; Davidson, L.M.; Duan, W.; Jura, M.P.; Yim, J.; Forziati, J.; Black, M.R. Metal assisted catalyzed etched (MACE) black Si: optics and device physics. Nanoscale 2016, 8, 15448–15466. [Google Scholar] [CrossRef] [PubMed]

- Beetz, B. Suntech’s Black Silicon Solar Cells Enter Mass Production. Available online: https://www.pv-magazine.com/2018/01/04/suntechs-black-silicon-solar-cells-enter-mass-production/ (accessed on 8 March 2018).

- Hutchins, M. Black is the New Black. Available online: https://www.pv-magazine.com/magazine-archive/black-is-the-new-black/ (accessed on 5 March 2018).

- Savin, H.; Repo, P.; Gastrow, G.V.; Ortega, P.; Calle, E.; Garín, M.; Alcubilla, R. Black silicon solar cells with interdigitated back-contacts achieve 22.1% efficiency. Nat. Nanotechnol. 2015, 10, 624–628. [Google Scholar] [CrossRef] [PubMed]

- Davidsen, R.S.; Li, H.; To, A.; Wang, X.; Han, A.; An, J.; Colwell, J.; Chan, C.; Wenham, A.; Schmidt, M.; et al. Black silicon laser-doped selective emitter solar cell with 18.1% efficiency. Sol. Energy Mater. Sol. Cells 2016, 144, 740–747. [Google Scholar] [CrossRef]

- Werner, S.; Lohmüller, E.; Saint-Cast, P.; Greulich, J.M.; Weber, J.; Schmidt, S.; Moldovan, A.; Brand, A.A.; Dannenber, T.; Mack, S.; et al. Key aspects for fabrication of p-type Cz-Si PERC solar cells exceeding 22% conversion efficiency. In Proceedings of the the 33rd European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

- NREL. Solar Spectra. Air Mass 1.5: ASTM G-173-03. Available online: http://rredc.nrel.gov/solar/spectra/am1.5/ (accessed on 5 March 2018).

- Energy Trend PV. Available online: https://pv.energytrend.com/ (accessed on 2 June 2018).

- Priolo, F.; Gregorkiewicz, T.; Galli, M.; Krauss, T.F. Silicon nanostructures for photonics and photovoltaics. Nat. Nanotechnol. 2014, 9, 19–32. [Google Scholar] [CrossRef] [PubMed]

- Venkatesan, R.; Arivalagan, M.K.; Venkatachalapathy, V.; Pearce, J.M.; Mayandi, J. Effects of silver catalyst concentration in metal assisted chemical etching of silicon. Mater. Lett. 2018, 221, 206–210. [Google Scholar] [CrossRef]

- Saint-Cast, P.; Kafle, B.; Pandey, R.; Ridoy, A.I.; Hofmann, M.; Clochard, L.; Schwarze, T.; Pittroff, M.; Rentsch, J.; Preu, R. Rear passivated mc-Si solar cells textured by atmospheric pressure dry etching. Energy Procedia 2017, 124, 260–266. [Google Scholar] [CrossRef]

- Repo, P.; Haarahiltunen, A.; Sainiemi, L.; Yli-Koski, M.; Talvitie, H.; Schubert, M.C.; Savin, H. Effective Passivation of Black Silicon Surfaces by Atomic Layer Deposition. IEEE J. Photovolt. 2013, 3, 90–94. [Google Scholar] [CrossRef]

- Pasanen, T.P.; Vähänissi, V.; Wolny, F.; Oehlke, A.; Wagner, M.; Juntunen, M.A.; Heikkinen, I.T.S.; Salmi, E.; Sneck, S.; Vahlman, H.; et al. Industrial applicability of AR-coating-free black silicon. In Proceedings of the 35th European PV Solar Energy Conference and Exhibition (EU PVSEC), Brussels, Belgium, 24–28 September 2018. [Google Scholar]

- Heikkinen, I.T.S.; Repo, P.; Vähänissi, V.; Pasanen, T.; Malinen, V.; Savin, H. Efficient surface passivation of black silicon using spatial atomic layer deposition. Energy Procedia 2017, 124, 282–287. [Google Scholar] [CrossRef]

- Dingemans, G.; Terlinden, N.M.; Verheijen, M.A.; van de Sanden, M.C.M.; Kessels, W.M.M. Controlling the fixed charge and passivation properties of Si(100)/Al2O3 interfaces using ultrathin SiO2 interlayers synthesized by atomic layer deposition. J. Appl. Phys. 2011, 110, 093715. [Google Scholar] [CrossRef]

- Terlinden, N.M.; Dingemans, G.; Vandalon, V.; Bosch, R.H.E.C.; Kessels, W.M.M. Influence of the SiO2 interlayer thickness on the density and polarity of charges in Si/SiO2/Al2O3 stacks as studied by optical second-harmonic generation. J. Appl. Phys. 2014, 115, 033708. [Google Scholar] [CrossRef]

- Pasanen, T.P.; Vähänissi, V.; Theut, N.; Savin, H. Surface passivation of black silicon phosphorus emitters with atomic layer deposited SiO2/Al2O3 Stacks. Energy Procedia 2017, 124, 307–312. [Google Scholar] [CrossRef]

- Loo, B.H.W.V.D.; Knoops, H.C.M.; Dingemans, G.J.M.; Lamers, M.W.P.E.; Romijn, I.G.; Weeber, A.W.; Kessels, W.M.M. ”Zero-charge” SiO2/Al2O3 stacks for the simultaneous passivation of n+ and p+ doped silicon surfaces by atomic layer deposition. Sol. Energy Mater. Sol. Cells 2015, 143, 450–456. [Google Scholar]

- Cui, J.; Wan, Y.; Chen, Y.; Verlinden, P.; Cuevas, A. Highly effective electronic passivation of silicon surfaces by atomic layer deposited hafnium oxide. Appl. Phys. Lett. 2017, 110, 021602. [Google Scholar] [CrossRef]

- Ingenito, A.; Isabella, O.; Zeman, M. Nano-cones on micro-pyramids: modulated surface textures for maximal spectral response and high efficiency solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 1649–1659. [Google Scholar] [CrossRef]

- Gastrow, G.V.; Alcubilla, R.; Ortega, P.; Yli-Koski, M.; Conesa-Boj, S.; Fontcuberta I Morral, A.; Savin, H. Analysis of the atomic layer deposited Al2O3 field-effect passivation in black silicon. Sol. Energy Mater. Sol. Cells 2015, 142, 29–33. [Google Scholar] [CrossRef]

- To, A.; Li, W.M.; Li, X.; Hoex, B. The effects of bifacial deposition of ALD AlOx on the contact properties of screen-printed contacts for p-type PERC solar cells. Energy Procedia 2017, 124, 914–921. [Google Scholar] [CrossRef]

- Müller, M.; Fischer, G.; Bitnar, B.; Steckemetz, S.; Schiepe, R.; Mühlbauer, M.; Köhler, R.; Richter, P.; Kusterer, C.; Oehlke, A.; et al. Loss analysis of 22% efficient industrial PERC solar cells. Energy Procedia 2017, 124, 131–137. [Google Scholar] [CrossRef]

- Wang, W.; Donw, J.; Ye, Q.; Yang, Y.; Cai, W.; Sheng, J.; Yang, J.; Zhang, C.; Zhou, X.; Dong, S. Industrially feasible PERC cells on diamond wire sawing multi-crystalline silicon wafers textured by RIE towards 20.78% efficiency. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 290–294. [Google Scholar]

- Repo, P.; Benick, J.; Gastrow, G.V.; Vähänissi, V.; Heinz, F.D.; Schön, J.; Schubert, M.C.; Savin, H. Passivation of black silicon boron emitters with atomic layer deposited aluminum oxide. Phys. Status Solidi RRL 2013, 7, 950–954. [Google Scholar] [CrossRef]

- Otto, M.; Kroll, M.; Käsebier, T.; Salzer, R.; Tünnermann, A.; Wehrspohn, R.B. Extremely low surface recombination velocities in black silicon passivated by atomic layer deposition. Appl. Phys. Lett. 2012, 100, 191603. [Google Scholar] [CrossRef]

- Pvbuzz Media. Get Read-The Price for Solar Power Will Drop Even Further. Available online: https://www.pvbuzz.com/price-for-solar-power-drop/ (accessed on 25 February 2018).

- Strupeit, L.; Neij, L. Cost dynamics in the deployment of photovoltaics: Insights from the German market for building-sited systems. Renew. Sustain. Energy Rev. 2017, 69, 948–960. [Google Scholar] [CrossRef]

- Nemet, G.F. Beyond the learning curve: factors influencing cost reductions in photovoltaics. Energy Policy 2006, 34, 3218–3232. [Google Scholar] [CrossRef]

- Parente, V.; Goldemberg, J.; Zilles, R. Comments on experience curves for PV modules. Prog. Photovolt. Res. Appl. 2002, 10, 571–574. [Google Scholar] [CrossRef]

- Candelise, C.; Winskel, M.; Gross, R.J.K. The dynamics of solar PV costs and prices as a challenge for technology forecasting. Renew. Sustain. Energy Rev. 2013, 26, 96–107. [Google Scholar] [CrossRef]

- Breyer, C.; Birkner, C.; Kersten, F.; Gerlach, A.; Goldschmidt, J.C.; Stryi-Hipp, G.; Fraile Montoro, D.; Riede, M. Research and Development Investments in PV–A Limiting Factor for a Fast PV Diffusion? In Proceedings of the 25th European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 6–10 September 2010. [Google Scholar]

- Tour, A.D.L.; Glachant, M.; Ménière, Y. Predicting the costs of photovoltaic solar modules in 2020 using experience curve models. Energy 2013, 62, 341–348. [Google Scholar] [CrossRef]

- Swanson, R.M. A vision for crystalline silicon photovoltaics. Prog. Photovolt. Res. Appl. 2006, 14, 443–453. [Google Scholar] [CrossRef]

- Ferioli, F.; van der Zwaan, B.C.C. Learning in Times of Change: A Dynamic Explanation for Technological Progress. Environ. Sci. Technol. 2009, 43, 4002–4008. [Google Scholar] [CrossRef] [PubMed]

- Goodrich, A.; Hacke, P.; Wang, Q.; Sopori, B.; Margolis, R.; James, T.L.; Woodhouse, M. A wafer-based monocrystalline silicon photovoltaics road map: Utilizing known technology improvement opportunities for further reductions in manufacturing costs. Sol. Energy Mate. Sol. Cells 2013, 114, 110–135. [Google Scholar] [CrossRef]

- Hill, J.S. Global Solar Market Demand Expected to Reach 100 Gigawatts in 2017, Says Solar Power Europe. Available online: https://cleantechnica.com/2017/10/27/global-solar-market-demand-expected-reach-100-gw-2017-solarpower-europe/ (accessed on 23 May 2018).

- Tamboli, A.C.; Bobela, D.C.; Kanevce, A.; Remo, T.; Alberi, K.; Woodhouse, M. Low-Cost CdTe/Silicon Tandem Solar Cells. IEEE J. Photovolt. 2017, 7, 1767–1772. [Google Scholar] [CrossRef]

- Liu, J.; Liu, B.; Shen, Z.; Liu, J.; Zhong, S.; Liu, S.; Li, C.; Xia, Y. Characterization of PIII textured industrial multicrystalline silicon solar cells. Sol. Energy 2012, 86, 3004–3008. [Google Scholar] [CrossRef]

- Yoo, J.; Yu, G.; Yi, J. Large-area multicrystalline silicon solar cell fabrication using reactive ion etching (RIE). Sol. Energy Mater. Sol. Cells 2011, 95, 2–6. [Google Scholar] [CrossRef]

- Juntunen, M.; Heinonen, J.; Vähänissi, V.; Repo, P.; Valluru, D.; Savin, H. Near-unity quantum efficiency of broadband black silicon photodiodes with an induced junction. Nat. Photonics 2016, 10, 777–781. [Google Scholar] [CrossRef]

- Huang, Z.; Carev, J.E.; Liu, M.; Mazur, E.; Campbell, J.C. Microstructured silicon photodetector. Appl. Phys. Lett. 2006, 89, 033506. [Google Scholar] [CrossRef]

- Boer, M.J.; Gardeniers, J.G.E.; Jansen, H.V.; Gilde, M.J.; Roelofs, G.; Sasserath, J.N.; Elwenspoek, M.C. Guidelines for etching silicon MEMS structures using fluorine high-density plasmas at cryogenic temperatures. J. Microelectromech. Syst. 2002, 11, 385–401. [Google Scholar] [CrossRef]

- Gesemann, B.; Wehrspohn, R.; Hackner, A.; Müller, G. Large-Scale Fabrication of Ordered Silicon Nanotip Arrays Used for Gas Ionization in Ion Mobility Spectrometers. IEEE Trans. Nanotechnol. 2011, 10, 50–52. [Google Scholar] [CrossRef]

- Joshi, M.; Verma, R. Black Silicon Photovoltaics: Fabrication methods and properties. Int. J. Res. Eng. Sci. 2017, 5, 62–72. [Google Scholar]

- Lv, J.; Zhang, T.; Zhang, P.; Zhao, Y.; Li, S. Review application of nanostructured black silicon. Nanoscale Res. Lett. 2018, 13, 110. [Google Scholar] [CrossRef] [PubMed]

- Kafle, B.; Schön, J.; Fleischmann, C.; Werner, S.; Wolf, A.; Clochard, L.; Duffy, E.; Hofmann, M.; Rentsch, J. On the emitter formation in nanotextured silicon solar cells to achieve improved electrical performances. Sol. Energy Mater. Sol. Cells 2016, 152, 94–102. [Google Scholar] [CrossRef]

- Repo, P.; Benick, J.; Vähänissi, V.; Schön, J.; von Gastrow, G.; Steinhauser, B.; Schubert, M.C.; Hermle, M.; Savin, H. N-type Black Silicon Solar Cells. Energy Procedia 2013, 38, 866–871. [Google Scholar] [CrossRef]

- Peyronnet, R.; Fischer, G.; Blevin, T.; Johnson, E.V.; Drahi, E.; Lemiti, M. Texturing optimization for bifacial n-PERT: Are pyramids and/or black silicon the way to go for thinner devices? Energy Procedia 2017, 124, 250–259. [Google Scholar] [CrossRef]

- What is Horizon 2020? Available online: https://ec.europa.eu/programmes/horizon2020/en/what-horizon-2020 (accessed on 25 April 2018).

- Griliches, Z. Research Costs and Social Returns: Hybrid Corn and Related Innovations. J. Political Econ. 1958, 66, 419–431. [Google Scholar] [CrossRef]

- Griliches, Z. The Search for R&D Spillovers. Available online: http://www.nber.org/papers/w3768 (accessed on 25 July 2018).

- Lenoir, T. Revolution from above: The role of the state in creating the german research system, 1810–1910. Am. Econ. Rev. 1998, 88, 22–27. [Google Scholar]

- Jones, C.I.; Williams, J.C. Measuring the Social Return to R&D. Q. J. Econ. 1998, 113, 1119–1135. [Google Scholar] [CrossRef]

- Hall, B.H. The Financing of Research and Development. Oxf. Rev. Econ. Policy 2002, 18, 35–51. [Google Scholar] [CrossRef]

- Hall, B.H.; Lerner, J. Chapter 14-The Financing of R&D and Innovation. Handb. Econ. Innov. 2010, 1, 609–639. [Google Scholar]

- Levin, R.C.; Klevorick, A.K.; Nelson, R.R.; Winter, S.G.; Gilbert, R.; Griliches, Z. Appropriating the Returns from Industrial Research and Development. Brook. Pap. Econ. Act. 1987, 3, 783–831. [Google Scholar] [CrossRef]

- Mamuneas, T.P.; Ishaq Nadiri, M. Public R&D policies and cost behavior of the US manufacturing industries. J. Public Econ. 1996, 63, 57–81. [Google Scholar] [CrossRef]

- Becker, B. Public R&D Policies and Private R&d Investment: A Survey of the Empirical Evidence. J. Econ. Surv. 2015, 29, 917–942. [Google Scholar] [CrossRef]

- SENTECH: Home of Thin Film Measurement. Available online: https://www.sentech.com/en/site__2235/ (accessed on 29 May 2018).

- InPassion ALD. Available online: http://www.solaytec.com/products/inpassion-ald (accessed on 29 May 2018).

- Lotus Applied Technology. Applications. Available online: http://lotusat.com/roll-to-roll-ald/applications/ (accessed on 29 May 2018).

- Tseng, M.-H.; Yu, H.-H.; Chou, K.-Y.; Jou, J.-H.; Lin, K.-L.; Wang, C.-C.; Tsai, F.-Y. Low-temperature gas-barrier films by atomic layer deposition for encapsulating organic light-emitting diodes. Nanotechnology 2016, 27, 295706. [Google Scholar] [CrossRef] [PubMed]

- Maydannik, P.S.; Kääriäinen, T.O.; Lahtinen, K.; Cameron, D.C.; Söderlund, M.; Soininen, P.; Johansson, P.; Kuusipalo, J.; Moro, L.; Zeng, X. Roll-to-roll atomic layer deposition process for flexible electronics encapsulation applications. J. Vac. Sci. Technol. A 2014, 32, 051603. [Google Scholar] [CrossRef]

- Yersak, A.S.; Sharma, K.; Wallas, J.M.; Dameron, A.A.; Li, X.; Yang, Y.; Hurst, K.E.; Ban, C.; Tenent, R.C.; George, S.M. TEMAZ/O3 atomic layer deposition process with doubled growth rate and optimized interface properties in metal–insulator–metal capacitors. J. Vac. Sci. Technol. A 2018, 36, 01A123. [Google Scholar] [CrossRef]

- Tassey, G. Competing in Advanced Manufacturing: The Need for Improved Growth Models and Policies. J. Econ. Perspect. 2014, 28, 27–48. [Google Scholar] [CrossRef]

- Bloom, N.; Griffith, R.; Van Reenen, J. Do R&D tax credits work? Evidence from a panel of countries 1979–1997. J. Public Econ. 2002, 85, 1–31. [Google Scholar] [CrossRef]

- Rao, N. Do tax credits stimulate R&D spending? The effect of the R&D tax credit in its first decade. J. Public Econ. 2016, 140, 1–12. [Google Scholar] [CrossRef]

- Czarnitzki, D.; Hanel, P.; Rosa, J.M. Evaluating the impact of R&D tax credits on innovation: A microeconometric study on Canadian firms. Res. Policy 2011, 40, 217–229. [Google Scholar] [CrossRef]

- Ali-Yrkkö, J. Impact of Public R&D Financing on Private R&D: Does Financial Constraint Matter? 2004. The Research Institute of the Finnish Economy (ETLA). Available online: https://www.etla.fi/wp-content/uploads/2012/09/dp943.pdf (accessed on 25 July 2018).

- Wilcox, J.A. Do Government Loan Guarantees Lower, Or Raise, Banks’ Non-Guaranteed Lending? Available online: http://siteresources.worldbank.org/INTFR/Resources/WilcoxYasuda_PCG%26JapaneseBanks_FINAL.pdf (accessed on 25 July 2018).

- Zhang, H.; Li, L.; Zhou, D.; Zhou, P. Political connections, government subsidies and firm financial performance: Evidence from renewable energy manufacturing in China. Renew. Energy 2014, 63, 330–336. [Google Scholar] [CrossRef]

- Branker, K.; Pearce, J.M. Financial return for government support of large-scale thin-film solar photovoltaic manufacturing in Canada. Energy Policy 2010, 38, 4291–4303. [Google Scholar] [CrossRef]

- Bartik, T.J. Who Benefits from State and Local Economic Development Policies? Upjohn Press: Kalamazoo, MI, USA, 1991. [Google Scholar] [CrossRef]

- Goodrich, A.C.; Powell, D.M.; James, T.L.; Woodhouse, M.; Buonassisi, T. Assessing the drivers of regional trends in solar photovoltaic manufacturing. Energy Environ. Sci. 2013, 6, 2811–2821. [Google Scholar] [CrossRef]

- Fialka, J. Why China Is Dominating the Solar Industry. Available online: https://www.scientificamerican.com/article/why-china-is-dominating-the-solar-industry/ (accessed on 2 May 2018).

- Zhang, F.; Gallagher, K.S. Innovation and technology transfer through global value chains: Evidence from China’s PV industry. Energy Policy 2016, 94, 191–203. [Google Scholar] [CrossRef]

- Jäger-Waldau, A. PV Status Report. 2017. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC108105/kjna28817enn.pdf (accessed on 25 July 2018).

- Baily, M.; Lawrence, R. Tax Incentives for R&D: What do the Data Tell Us? Council on Research and Technology: Washington, DC, USA, 1992. [Google Scholar]

- Hall, B.H. R&D Tax Policy during the 1980s: Success or Failure? Tax Policy Econ. 1993, 7, 1–35. [Google Scholar] [CrossRef]

- Hines, J.R. No Place like Home: Tax Incentives and the Location of R&D by American Multinationals. Tax Policy Econ. 1994, 8, 65–104. [Google Scholar] [CrossRef]

- Harju, J.; Kari, S.; Koivisto, A.; Kuusi, T.; Matikka, T.; Määttänen, N.; Pajarinen, M.; Ropponen, O.; Rouvinen, P.; Valkonen, T. Yritysverotus, Investoinnit Ja Tuottavuus. Available online: http://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/160322/Yritysverotus%20investoinnit%20ja%20tuottavuus.pdf (accessed on 25 July 2018).

- Kuusi, T.; Pajarinen, M.; Rouvinen, P.; Valkonen, T. Tutkimuksen Ja Tuotekehityksen Verotuet. Available online: http://pub.etla.fi/ETLA-Muistio-Brief-31.pdf (accessed on 25 July 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modanese, C.; Laine, H.S.; Pasanen, T.P.; Savin, H.; Pearce, J.M. Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies 2018, 11, 2337. https://doi.org/10.3390/en11092337

Modanese C, Laine HS, Pasanen TP, Savin H, Pearce JM. Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies. 2018; 11(9):2337. https://doi.org/10.3390/en11092337

Chicago/Turabian StyleModanese, Chiara, Hannu S. Laine, Toni P. Pasanen, Hele Savin, and Joshua M. Pearce. 2018. "Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing" Energies 11, no. 9: 2337. https://doi.org/10.3390/en11092337

APA StyleModanese, C., Laine, H. S., Pasanen, T. P., Savin, H., & Pearce, J. M. (2018). Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies, 11(9), 2337. https://doi.org/10.3390/en11092337