Influence of Fertilization and Rootstocks in the Biomass Energy Characterization of Prunus dulcis (Miller)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Study

2.2. Vegetal Material and Treatments

2.3. Laboratory Analysis

2.3.1. Proximate Analysis

2.3.2. Determination of Gross Calorific Value and Elemental Composition Analysis

3. Results and Discussion

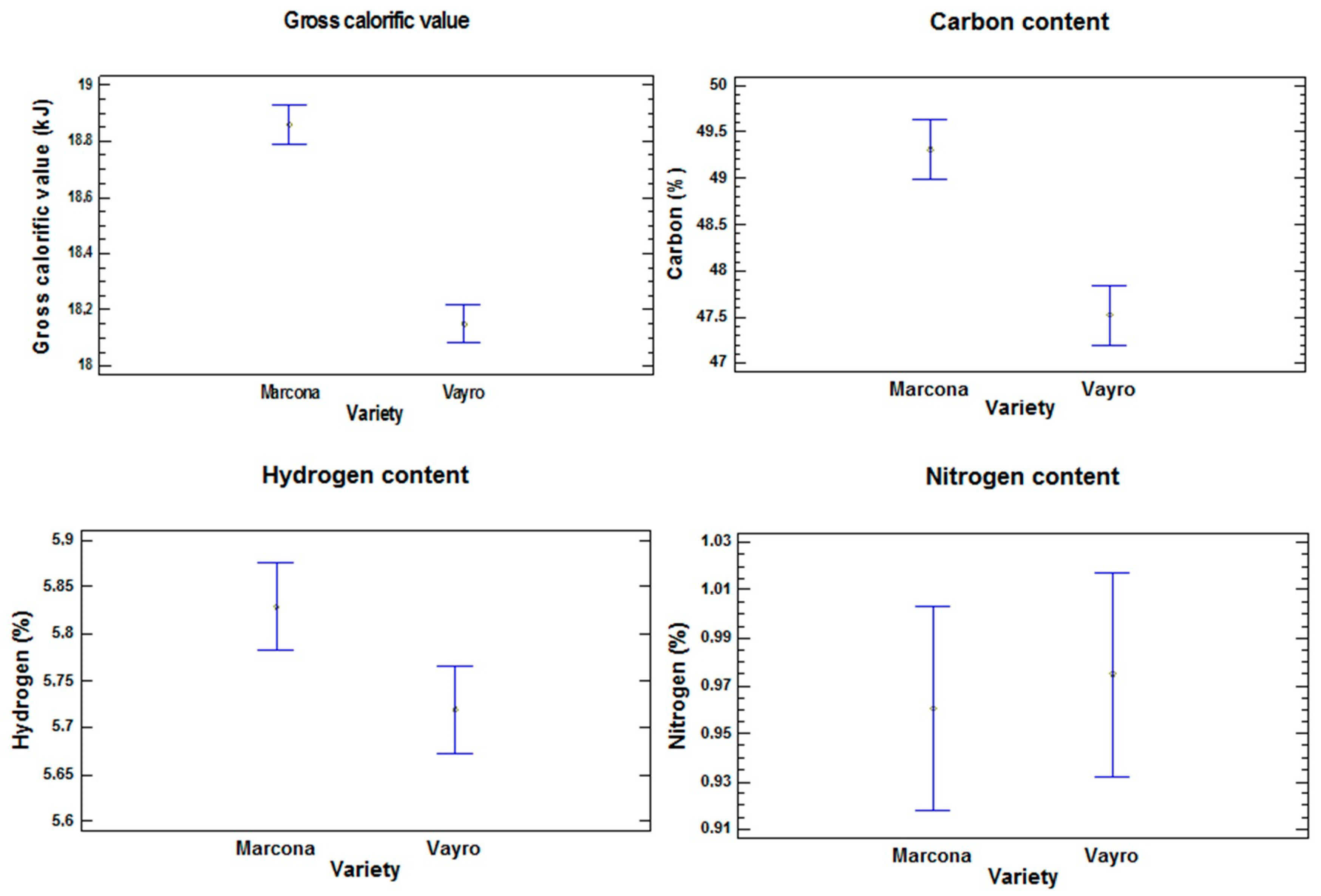

3.1. The Variety Factor

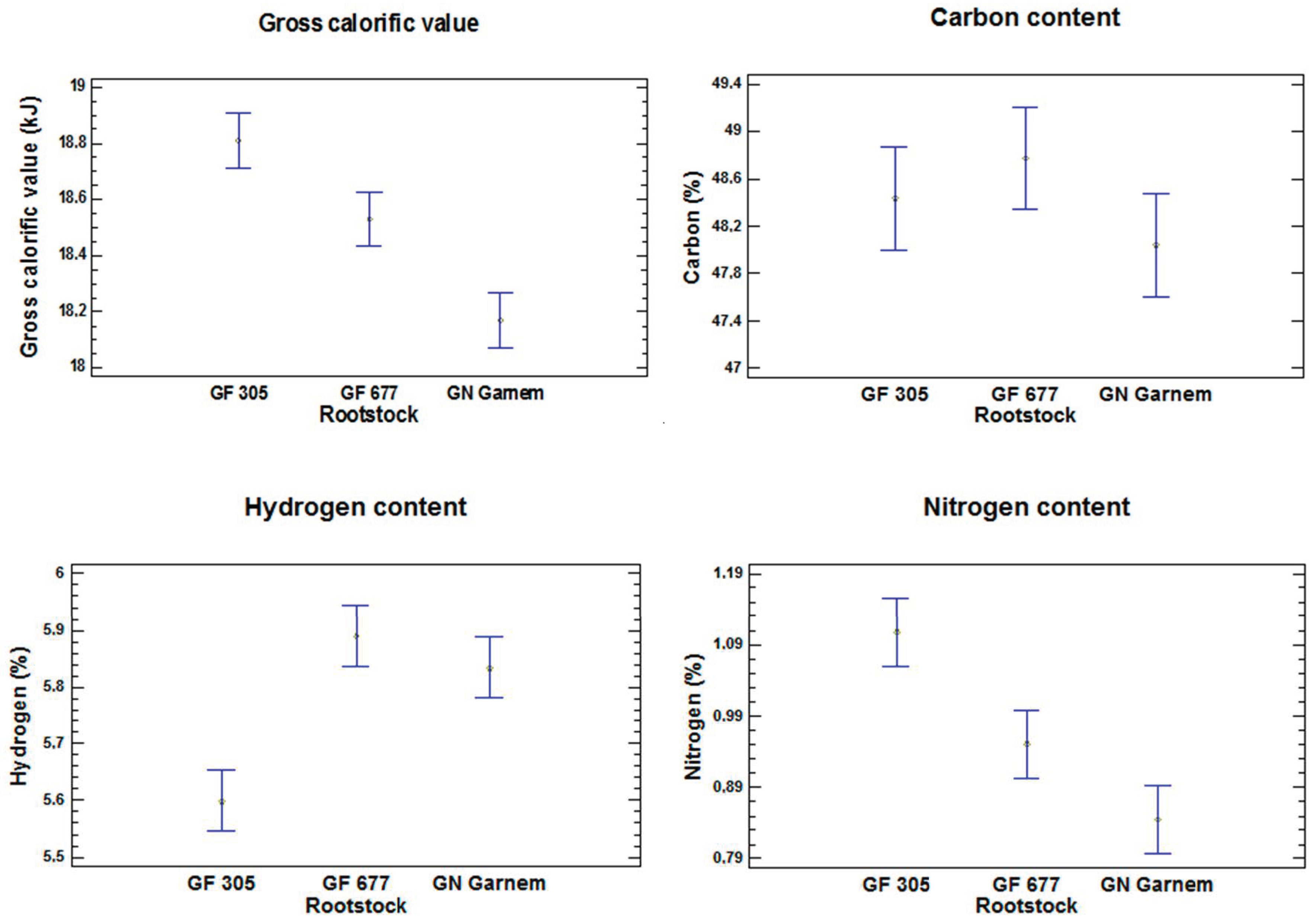

3.2. The Rootstock Factor

3.3. The Combination Variety-Rootstock Factor

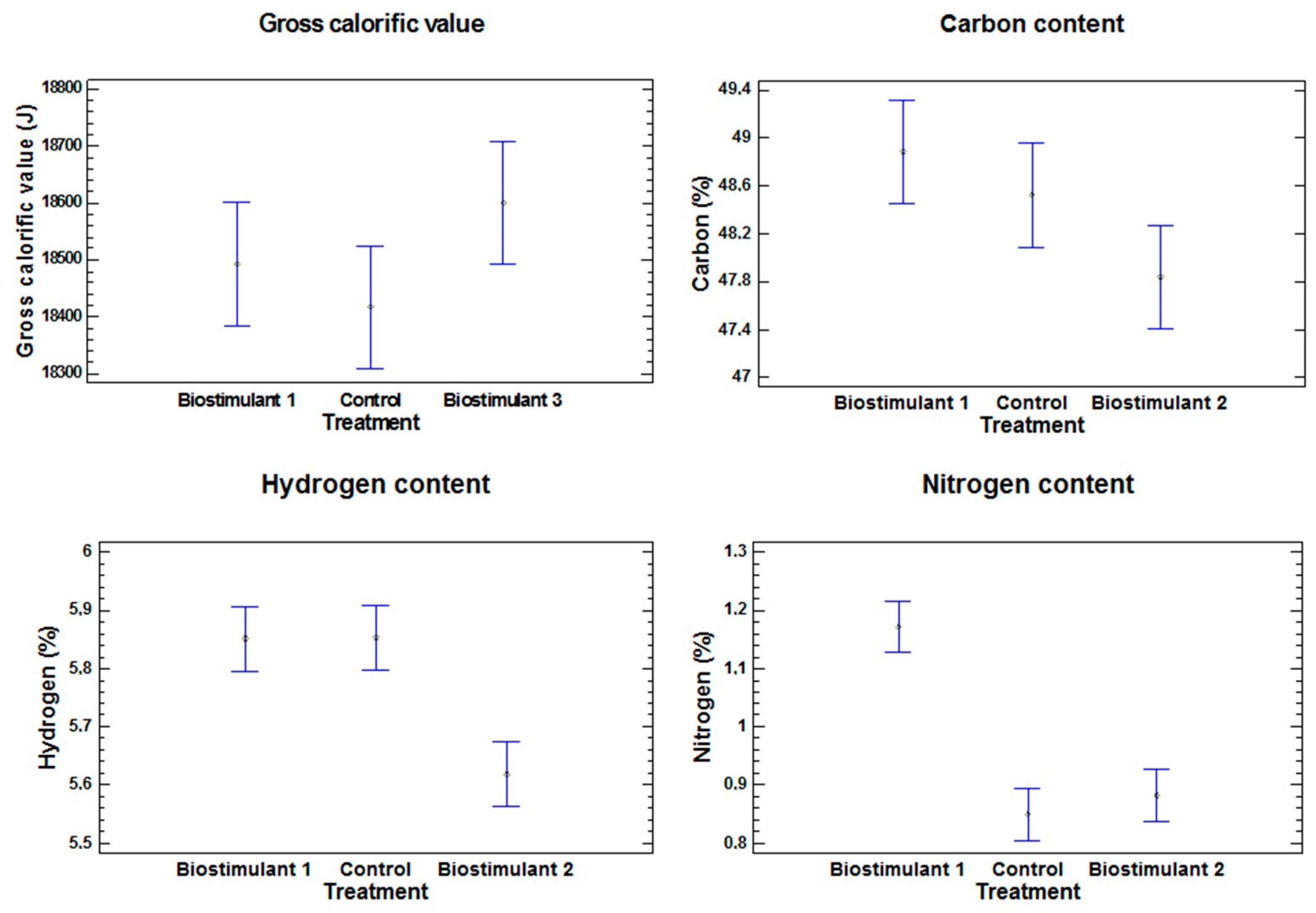

3.4. The Treatment Factor

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fernández-García, A.; Rojas, E.; Pérez, M.; Silva, R.; Hernández-Escobedo, Q.; Manzano-Agugliaro, F. A parabolic-trough collector for cleaner industrial process heat. J. Clean. Prod. 2015, 89, 272–285. [Google Scholar] [CrossRef]

- Jacobsson, S.; Johnson, A. The diffusion of renewable energy technology: An analytical framework and key issues for research. Energy Policy 2000, 28, 625–640. [Google Scholar] [CrossRef]

- Cruz-Peragon, F.; Palomar, J.M.; Casanova, P.J.; Dorado, M.P.; Manzano-Agugliaro, F. Characterization of solar flat plate collectors. Renew. Sustain. Energy Rev. 2012, 16, 1709–1720. [Google Scholar] [CrossRef]

- Perea-Moreno, A.J.; Perea-Moreno, M.Á.; Hernandez-Escobedo, Q.; Manzano-Agugliaro, F. Towards forest sustainability in Mediterranean countries using biomass as fuel for heating. J. Clean. Prod. 2017, 156, 624–634. [Google Scholar] [CrossRef]

- Esteban, L.S.; Carrasco, J.E. Biomass resources and costs: Assessment in different eu countries. Biomass Bioenergy 2011, 35, S21–S30. [Google Scholar] [CrossRef]

- Sajdak, M.; Velázquez-Martí, B.; López-Cortés, I.; Fernández-Sarría, A.; Estornell, J. Prediction models for estimating pruned biomass obtained from Platanus hispanica Münchh. used for material surveys in urban forests. Renew. Energy 2014, 66, 178–184. [Google Scholar] [CrossRef]

- Sajdak, M.; Velazquez-Marti, B. Estimation of pruned biomass form dendrometric parameters on urban forests: Case study of sophora japonica. Renew. Energy 2012, 47, 188–193. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- MacFarlane, D.W. Potential availability of urban wood biomass in Michigan: Implications for energy production, carbon sequestration and sustainable forest management in the U.S.A. Biomass Bioenergy 2009, 33, 628–634. [Google Scholar] [CrossRef]

- Proskurina, S.; Junginger, M.; Heinimö, J.; Tekinel, B.; Vakkilainen, E. Global biomass trade for energy—Part 2: Production and trade streams of wood pellets, liquid biofuels, charcoal, industrial roundwood and emerging energy biomass. Biofuels Bioprod. Biorefining 2018. [Google Scholar] [CrossRef]

- Prando, D.; Renzi, M.; Gasparella, A.; Baratieri, M. Monitoring of the energy performance of a district heating CHP plant based on biomass boiler and ORC generator. Appl. Therm. Eng. 2015, 79, 98–107. [Google Scholar] [CrossRef]

- Artese, C.; Schenone, G.; Bartolelli, V. Biomass Boilers for Household Heating. RES& RUE Dissemination Project. Available online: http://www.itabia.it/testi%20digitali/Dossier%20Caldaie%20a%20Biomassa.pdf (accessed on 12 October 2016). (In Spanish).

- VYC. Industrial Biomass Boilers. Available online: http://vycindustrial.com/es/calderas/productos/calderas-industriales-de-biomasa/ (accessed on 16 October 2016). (In Spanish).

- Uris, M.; Linares, J.I.; Arenas, E. Techno-economic feasibility assessment of a biomass cogeneration plant based on an Organic Rankine Cycle. Renew. Energy 2014, 66, 707–713. [Google Scholar] [CrossRef]

- Uris, M.; Linares, J.I.; Arenas, E. Feasibility assessment of an Organic Rankine Cycle (ORC) cogeneration plant (CHP/CCHP) fueled by biomass for a district network in mainland Spain. Energy 2017, 133, 969–985. [Google Scholar] [CrossRef]

- Haseli, Y.; van Oijen, J.A.; de Goey, L.P.H. Modeling biomass particle pyrolysis with temperature-dependent heat of reactions. J. Anal. Appl. Pyrolysis 2011, 90, 140–154. [Google Scholar] [CrossRef]

- Morgan, H.M., Jr.; Bu, Q.; Liang, J.; Liu, Y.; Mao, H.; Shi, A.; Lei, H.; Ruan, R. A review of catalytic microwave pyrolysis of lignocellulosic biomass for value-added fuel and chemicals. Bioresour. Technol. 2017, 230, 112–121. [Google Scholar] [CrossRef] [PubMed]

- Oh, W.D.; Lisak, G.; Webster, R.D.; Liang, Y.-N.; Veksha, A.; Giannis, A.; Moo, J.G.S.; Lim, Y.-W.; Lim, T.-T. Insights into the thermolytic transformation of lignocellulosic biomass waste to redox-active carbocatalyst: Durability of surface active sites. Appl. Catal. B 2018, 233, 120–129. [Google Scholar] [CrossRef]

- Fernández-González, E. Análisis de los procesos de producción de biomasa residual procedente del cultivo de frutales mediterráneos. Cuantificación, cosecha y caracterización. Ph.D. Thesis, Universitat Politècnica de València, Valencia, Spain, 2010. [Google Scholar]

- Velázquez-Martí, B.; López-Cortés, I.; Salazar-Hernández, D.; Callejón-Ferre, Á.J. Modeling the Calorific Value of Biomass from Fruit Trees Using Elemental Analysis Data. In Biomass Volume Estimation and Valorization for Energy; InTech: London, UK, 2017. [Google Scholar] [CrossRef]

- Toklu, E. Biomass energy potential and utilization in Turkey. Renew. Energy 2017, 107, 235–244. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean almond groves. Renew. Energy 2011, 36, 621–626. [Google Scholar] [CrossRef]

- Winzer, F.; Kraska, T.; Elsenberger, C.; Kötter, T.; Pude, R. Biomass from fruit trees for combined energy and food production. Biomass Bioenergy 2017, 107, 279–286. [Google Scholar] [CrossRef]

- Callejón-Ferre, A.J.; Carreño-Sánchez, J.; Suárez-Medina, F.J.; Pérez-Alonso, J.; Velázquez-Martí, B. Prediction models for higher heating value based on the structural analysis of the biomass of plant remains from the greenhouses of Almería (Spain). Fuel 2014, 116, 377–387. [Google Scholar] [CrossRef]

- Barco, A.; Maucieri, C.; Borin, M. Root system characterization and water requirements of ten perennial herbaceous species for biomass production managed with high nitrogen and water inputs. Agric. Water Manag. 2018, 196, 37–47. [Google Scholar] [CrossRef]

- Yin, C.-Y. Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 2011, 90, 1128–1132. [Google Scholar] [CrossRef]

- Vargas-Moreno, J.M.; Callejón-Ferre, A.J.; Pérez-Alonso, J.; Velázquez-Martí, B. A review of the mathematical models for predicting the heating value of biomass materials. Renew. Sustain. Energy Rev. 2012, 16, 3065–3083. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Sajdak, M.; López-Cortés, I.; Callejón-Ferre, A.J. Wood characterization for energy application proceeding from pruning Morus alba L., Platanus hispanica Münchh. and Sophora japonica L. in urban areas. Renew. Energy 2014, 62, 478–483. [Google Scholar] [CrossRef]

- Bychkov, A.L.; Denkin, A.I.; Tikhova, V.D.; Lomovsky, O.I. Prediction of higher heating values of plant biomass from ultimate analysis data. J. Therm. Anal. Calorim. 2017, 130, 1399–1405. [Google Scholar] [CrossRef]

- Osman, A.I.; Abdelkader, A.; Johnston, C.R.; Morgan, K.; Rooney, D.W. Thermal Investigation and Kinetic Modeling of Lignocellulosic Biomass Combustion for Energy Production and Other Applications. Ind. Eng. Chem. Res. 2017, 56, 12119–12130. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J.L.T. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Álvarez, A.; Pizarro, C.; García, R.; Bueno, J.L. Spanish biofuels heating value estimation based on structural analysis. Ind. Crop. Prod. 2015, 77, 983–991. [Google Scholar] [CrossRef]

- Agencia Estatal de Meteorología. Available online: http://www.aemet.es/es/serviciosclimaticos/datosclimatologicos (accessed on 20 October 2017).

- Salazar, D.M.; Melgarejo-Moreno, P. Cultivos leñosos: Frutales de zonas áridas. El cultivo del almendro; Mundi-Prensa: Madrid, Spain, 2002. [Google Scholar]

- Vargas, F.; Romero, M.; Clavé, J.; Vergés, J.; Santos, J.; Batlle, I. ‘Vayro’, ‘Marinada’, ‘Constantí’, and ‘Tarraco’ almonds. HortScience 2008, 43, 535–537. [Google Scholar]

- Carrera, M.; Gomez-Aparasi, J. Rootstock influence on the performance of the peach variety ‘Catherine’. In Proceedings of the IV International Peach Symposium, Bordeaux, France, 22–26 June 1997; pp. 573–578. [Google Scholar]

- Bernhard, R.; Grasselly, C. Les pêchers x amandiers. Arboric. Fruit 1981, 328, 37–42. [Google Scholar]

- Mondragón-Valero, A.; Lopéz-Cortés, I.; Salazar, D.M.; de Córdova, P.F. Physical mechanisms produced in the development of nursery almond trees (Prunus dulcis Miller) as a response to the plant adaptation to different substrates. Rhizosphere 2017, 3, 44–49. [Google Scholar] [CrossRef]

- ISO 18134-2:2017. Solid Biofuels–Determination of Moisture Content–Oven Dry Method–Part 2: Total Moisture–Simplified Method; ISO: Geneva, Switzerland, 2017.

- ISO 18122:2015. Solid Biofuels—Determination of Ash Content; ISO: Geneva, Switzerland, 2015.

- ISO 18123:2015. Solid Biofuels—Determination of the Content of Volatile Matter; ISO: Geneva, Switzerland, 2015.

- ISO 18125:2017. Solid Biofuels. Determination of Calorific Value; ISO: Geneva, Switzerland, 2017.

- ISO 16948:2015. Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen; Instrumental Methods; ISO: Geneva, Switzerland, 2015.

- Nhuchhen, D.R.; Abdul Salam, P. Estimation of higher heating value of biomass from proximate analysis: A new approach. Fuel 2012, 99, 55–63. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate analysis, backwards stepwise regression between gross calorific value, ultimate and chemical analysis of wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef] [PubMed]

- Özçimen, D.; Ersoy-Meriçboyu, A. Characterization of biochar and bio-oil samples obtained from carbonization of various biomass materials. Renew. Energy 2010, 35, 1319–1324. [Google Scholar] [CrossRef]

- Jenkins, B.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.C.; Champagne, P. Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Callejón-Ferre, A.J.; Velázquez-Martí, B.; López-Martínez, J.A.; Manzano-Agugliaro, F. Greenhouse crop residues: Energy potential and models for the prediction of their higher heating value. Renew. Sustain. Energy Rev. 2011, 15, 948–955. [Google Scholar] [CrossRef]

- Obernberger, I.; Biedermann, F.; Widmann, W.; Riedl, R. Concentrations of inorganic elements in biomass fuels and recovery in the different ash fractions. Biomass Bioenergy 1997, 12, 211–224. [Google Scholar] [CrossRef]

- Nordin, A. Chemical elemental characteristics of biomass fuels. Biomass Bioenergy 1994, 6, 339–347. [Google Scholar] [CrossRef]

- Ercisli, S.; Esitken, A.; Orhan, E.; Ozdemir, O. Rootstocks used for temperate fruit trees in Turkey: An overview. Sodininkyste ir Darzininkyste 2006, 25, 27–33. [Google Scholar]

- Demirbaş, A. Relationships between lignin contents and heating values of biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Kuhlbusch, T.A.; Lobert, J.M.; Crutzen, P.J.; Warneck, P. Molecular nitrogen emissions from denitrification during biomass burning. Nature 1991, 351, 135–137. [Google Scholar] [CrossRef]

- Owen, A.G.; Jones, D.L. Competition for amino acids between wheat roots and rhizosphere microorganisms and the role of amino acids in plant N acquisition. Soil Biol. Biochem. 2001, 33, 651–657. [Google Scholar] [CrossRef]

- Ercoli, L.; Mariotti, M.; Masoni, A.; Bonari, E. Effect of irrigation and nitrogen fertilization on biomass yield and efficiency of energy use in crop production of Miscanthus. Field Crop. Res. 1999, 63, 3–11. [Google Scholar] [CrossRef]

- Mantineo, M.; D’Agosta, G.M.; Copani, V.; Patanè, C.; Cosentino, S.L. Biomass yield and energy balance of three perennial crops for energy use in the semi-arid Mediterranean environment. Field Crop. Res. 2009, 114, 204–213. [Google Scholar] [CrossRef]

| Factor | Number of Levels | Levels |

|---|---|---|

| Variety | 2 | Marcona Vayro |

| Rootstock | 3 | GF 305 GF 677 GN Garnem |

| Fertilization | 3 | Biostimulant 1 Control Biostimulant 2 |

| Average | Standard Deviation | Standard Skewness | Standard Kurtosis | Minimum | Maximum | |

|---|---|---|---|---|---|---|

| Carbon (%) | 48.41 | 2.22 | −1.99 | 2.01 | 41.50 | 53.50 |

| Hidrogen (%) | 5.77 | 0.30 | −4.81 | 4.96 | 4.83 | 6.60 |

| Nitrogen (%) | 0.97 | 0.27 | 1.62 | −0.59 | 0.44 | 1.67 |

| C/H | 8.40 | 0.38 | −1.53 | 0.70 | 7.29 | 9.26 |

| GCV (joule/g) | 18503.44 | 555.99 | −6.73 | 7.99 | 17067.37 | 19628.39 |

| Moisture content (%) | 8.36 | 1.83 | 1.87 | 0.98 | 5.78 | 12.84 |

| Ash (%) | 3.41 | 0.80 | 2.05 | −1.39 | 2.15 | 5.01 |

| Volatile compounds (%) | 82.89 | 5.48 | −1.88 | 0.58 | 69.59 | 92.74 |

| Variety | Rootstock | Interaction Variety/Rootstock | Treatment | C | H | N | C/H | GCV | Moisture Content (%) | Ash (%) | Volatile Compounds (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Variety | 0 | 0.9869 * | 0 | −0.4053 * | −0.1831 | 0.027 | −0.1983 * | −0.6465 * | −0.2160 * | 0.2163 * | −0.1180 | |

| Rootstock | 0 | 0.1612 | 0 | −0.072 | 0.3213 * | −0.4055 * | −0.4346 * | −0.4769 * | −0.3373 * | −0.2213 * | 0.6926 * | |

| Interaction variety/rootstock | 0.9869 * | 0.1612 | 0 | −0.4116 * | −0.1289 | −0.0387 | −0.2658 * | −0.7149 * | −0.2675 * | 0.1778 | −0.0049 | |

| Treatment | 0 | 0 | 0 | −0.1932 | −0.3167 * | −0.4427 * | 0.1606 | 0.0797 | 0.1503 | 0.2787 * | 0.1605 | |

| C | −0.4053 * | −0.072 | −0.4116 * | −0.1932 * | 0.5593 * | 0.1868 * | 0.3581 * | 0.4168 * | −0.0617 | −0.0048 | 0.2528 * | |

| H | −0.1831 | 0.3213 * | −0.1289 | −0.3167 * | 0.5593 * | −0.1143 | −0.5722 * | 0.0851 | −0.2663 * | −0.1574 | 0.4891 * | |

| N | 0.0270 | −0.4055 * | −0.0387 | −0.4427 * | 0.1868 * | −0.1143 | 0.3199 * | 0.2552 * | 0.2706 * | 0.2334 * | −0.4033 * | |

| C/H | −0.1983 * | −0.4346 * | −0.2658 * | 0.1606 | 0.3581 * | −0.5722 * | 0.3199 * | 0.3118 * | 0.2426 * | 0.1688 | −0.3013 * | |

| GCV | −0.6465 * | −0.4769 * | −0.7149 * | 0.0797 | 0.4168 * | 0.0851 | 0.2552 * | 0.3118 * | 0.2781 * | 0.2354 * | −0.0938 | |

| Moisture content (%) | −0.216 * | −0.3373 * | −0.2675 * | 0.1503 | −0.0617 | −0.2663 * | 0.2706 * | 0.2426 * | 0.2781 * | 0.0584 | −0.4015 * | |

| Ash (%) | 0.2163 * | −0.2213 * | 0.1778 | 0.2787 * | −0.0048 | −0.1574 | 0.2334 * | 0.1688 | 0.2354 * | 0.0584 | 0.2146 * | |

| Volatile compounds (%) | −0.118 | 0.6926* | −0.0049 | 0.1605 | 0.2528 * | 0.4891 * | −0.4033 * | −0.3013 * | −0.0938 | −0.4015 * | 0.2146 * |

| Interaction Variety-Rootstock | GCV (J) | Carbon (%) | Hydrogen (%) | Nitrogen (%) |

|---|---|---|---|---|

| Marcona 305 | 19270.66 ± 266.47 e | 50.45 ± 1.77 c | 5.77 ± 0.19 b | 1.10 ± 0.14 d |

| Marcona 677 | 18807.45 ± 204.93 d | 48.80 ± 1.07 b | 5.87 ± 0.20 b | 0.83 ± 0.30 ab |

| Marcona GN | 18497.88 ± 375.76 c | 48.68 ± 0.83 b | 5.83 ± 0.24 b | 0.94 ± 0.15 bc |

| Vayro 305 | 18349.76 ± 90.33 bc | 46.41 ± 3.50 a | 5.41 ± 0.39 a | 1.11 ± 0.16 d |

| Vayro 677 | 18255.92 ± 238.11 b | 48.73 ± 1.77 b | 5.90 ± 0.14 b | 1.06 ± 0.34 dc |

| Vayro GN | 17839.02 ± 565.84 a | 47.40 ± 0.80 a | 5.83 ± 0.26 b | 0.74 ± 0.19 a |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mondragón-Valero, A.; Velázquez-Martí, B.; Salazar, D.M.; López-Cortés, I. Influence of Fertilization and Rootstocks in the Biomass Energy Characterization of Prunus dulcis (Miller). Energies 2018, 11, 1189. https://doi.org/10.3390/en11051189

Mondragón-Valero A, Velázquez-Martí B, Salazar DM, López-Cortés I. Influence of Fertilization and Rootstocks in the Biomass Energy Characterization of Prunus dulcis (Miller). Energies. 2018; 11(5):1189. https://doi.org/10.3390/en11051189

Chicago/Turabian StyleMondragón-Valero, Alba, Borja Velázquez-Martí, Domingo M. Salazar, and Isabel López-Cortés. 2018. "Influence of Fertilization and Rootstocks in the Biomass Energy Characterization of Prunus dulcis (Miller)" Energies 11, no. 5: 1189. https://doi.org/10.3390/en11051189

APA StyleMondragón-Valero, A., Velázquez-Martí, B., Salazar, D. M., & López-Cortés, I. (2018). Influence of Fertilization and Rootstocks in the Biomass Energy Characterization of Prunus dulcis (Miller). Energies, 11(5), 1189. https://doi.org/10.3390/en11051189