Solar Reflector Materials Degradation Due to the Sand Deposited on the Backside Protective Paints

Abstract

1. Introduction

2. Materials and Methods

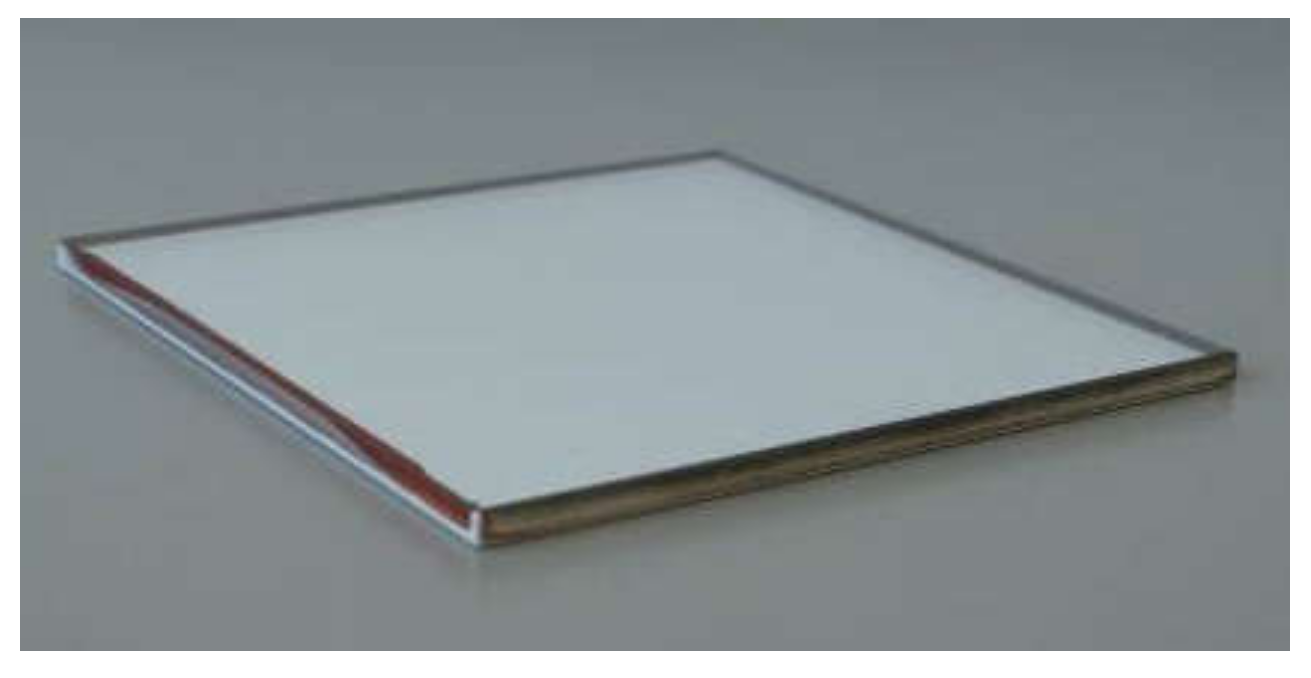

2.1. Reflector Samples

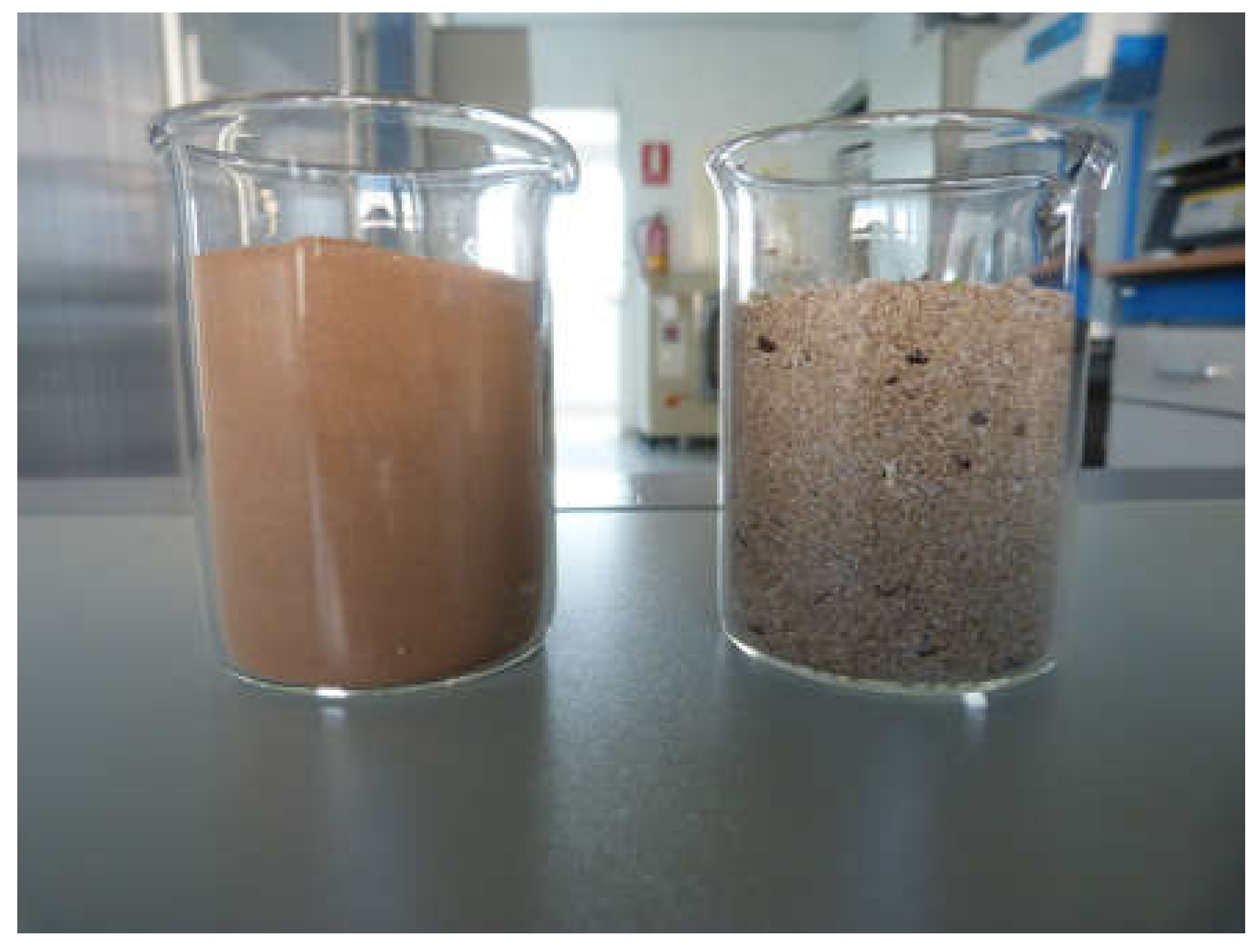

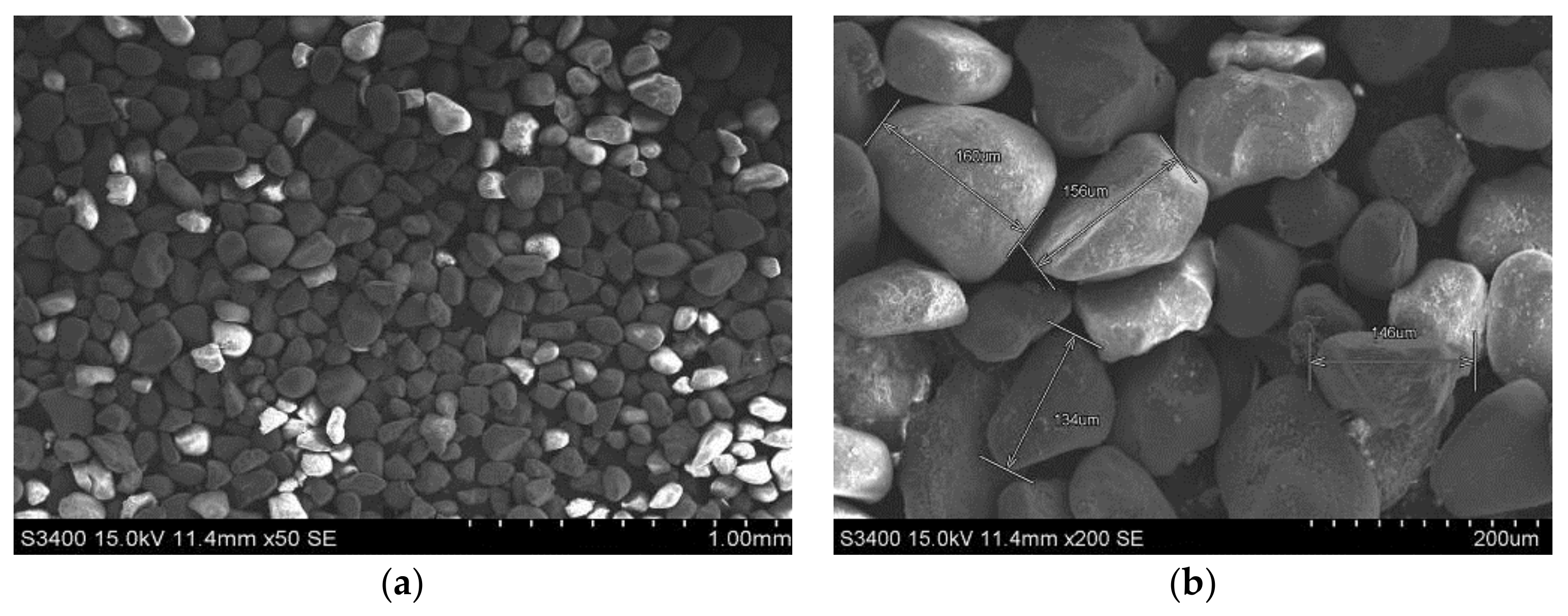

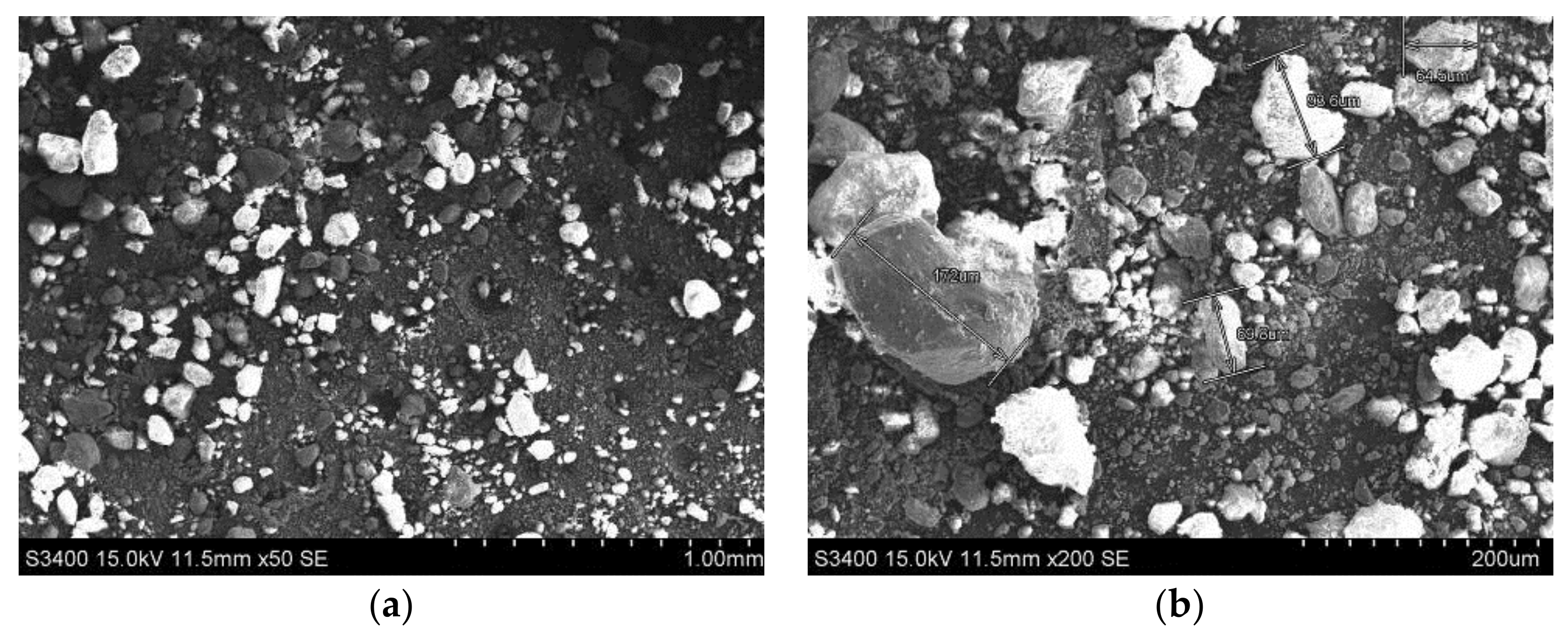

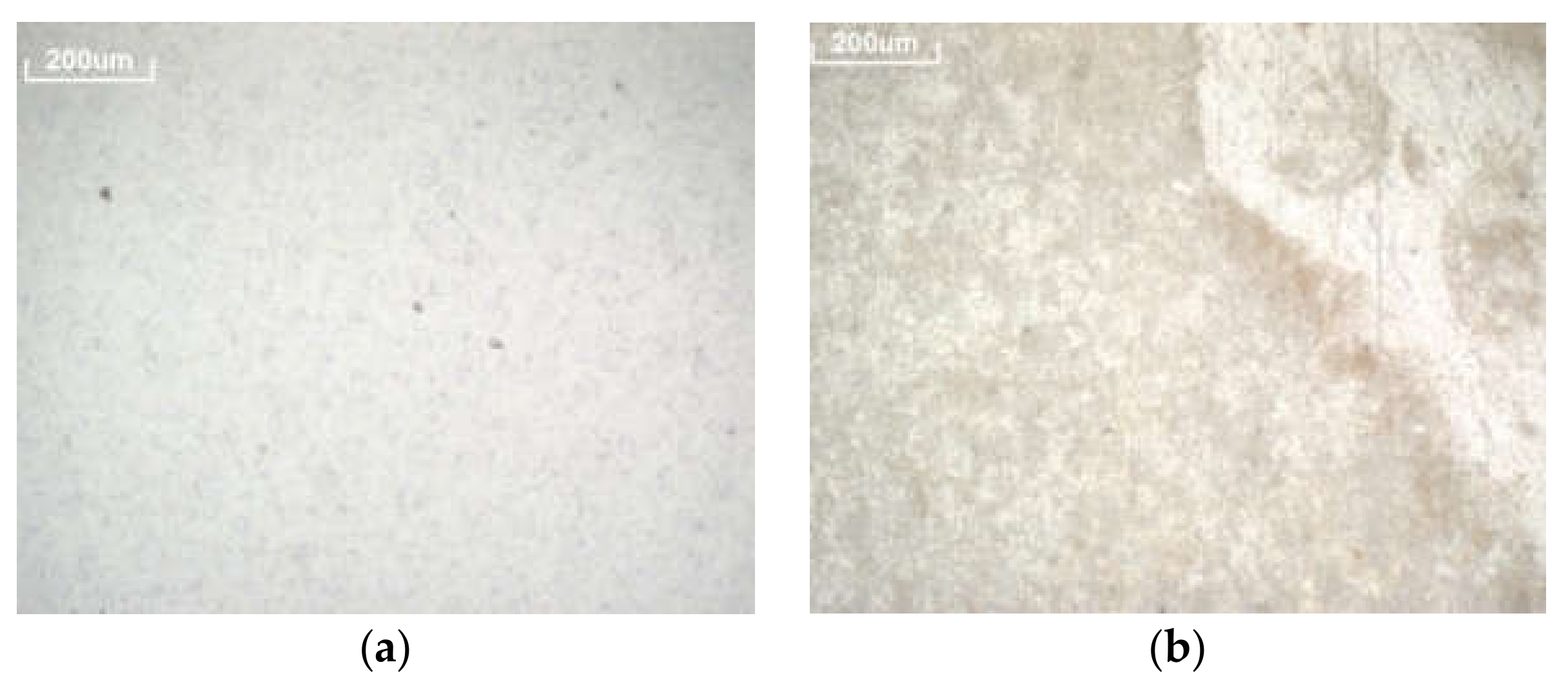

2.2. Sand Samples

2.3. Reflector Samples Preparation

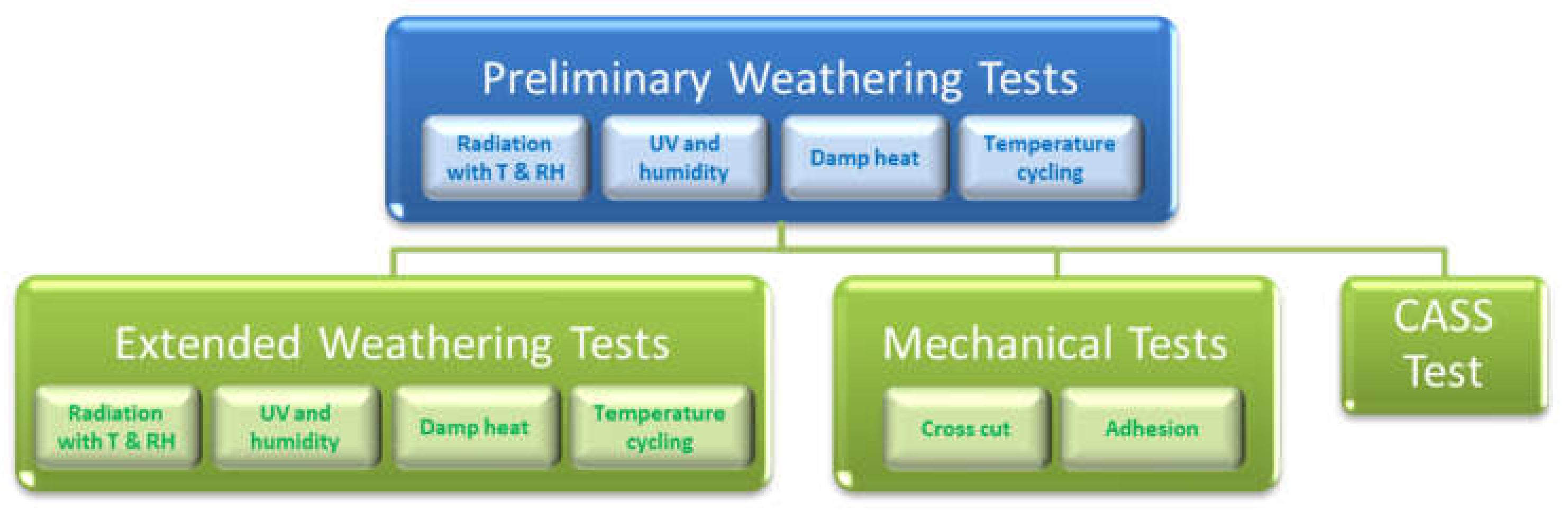

2.4. Testing Approach

- The first set of 12 samples continued with the four weathering tests, which was named the extended weathering test. The testing time was increased to check if a longer time in the accelerated aging chambers could report more relevant results. The sand was again deposited before the long-term weathering tests and then removed with demineralized water after the tests were complete.

- The second set of 12 samples was submitted to two mechanical tests (cross-cut and adhesion tests, see Section 2.5.5 and Section 2.5.6) that modified the backside paint layers to investigate how the weathering tests might affect the resistance of the backside paint layer and to provoke further weakness in the mechanically pre-damaged area. A reference sample (named Ref. 01) without any previous weathering test was included in the cross-cut and adhesion tests.

- The third set of 12 samples was directly exposed to the copper-accelerated acetic acid salt spray (CASS) test (see Section 2.5.7). This is the most suitable test to remark corrosion in the silver layer produced by a weakness point or area in the backside paint layers. A reference sample (named Ref. 02) without any previous weathering tests was also included.

2.5. Tests Description

2.5.1. Radiation with Temperature and Humidity Test

2.5.2. UV and Humidity Cycling

2.5.3. Damp Heat Test

2.5.4. Temperature Cycling

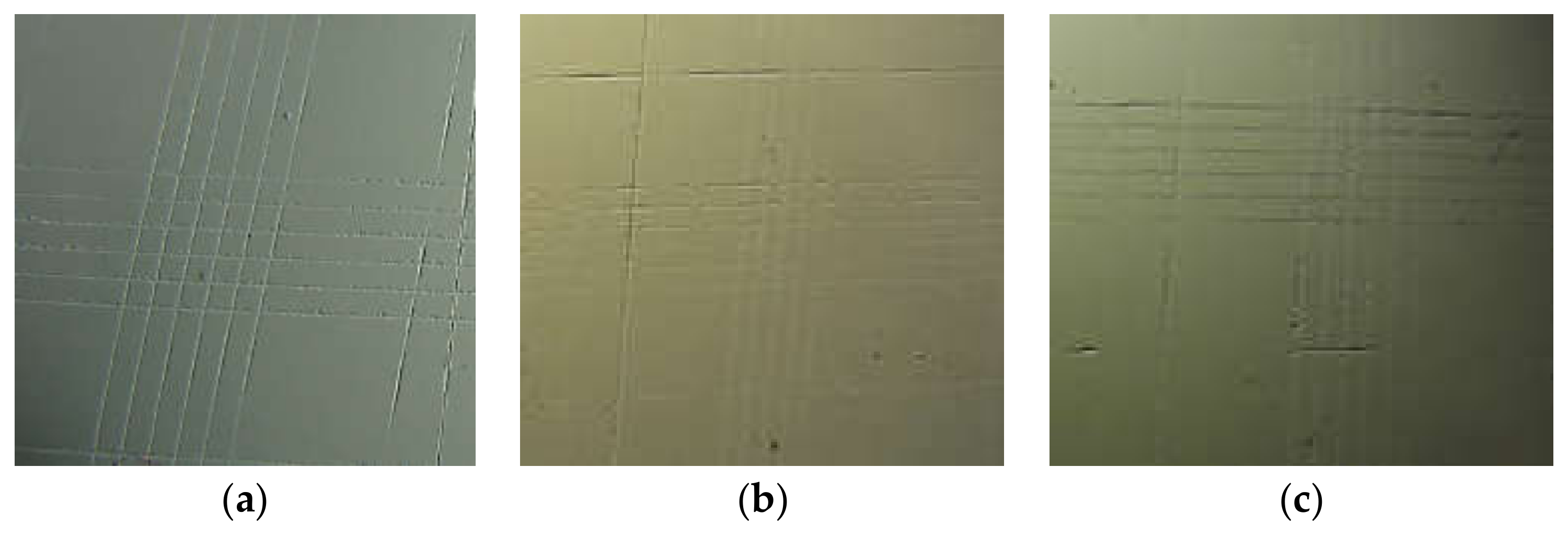

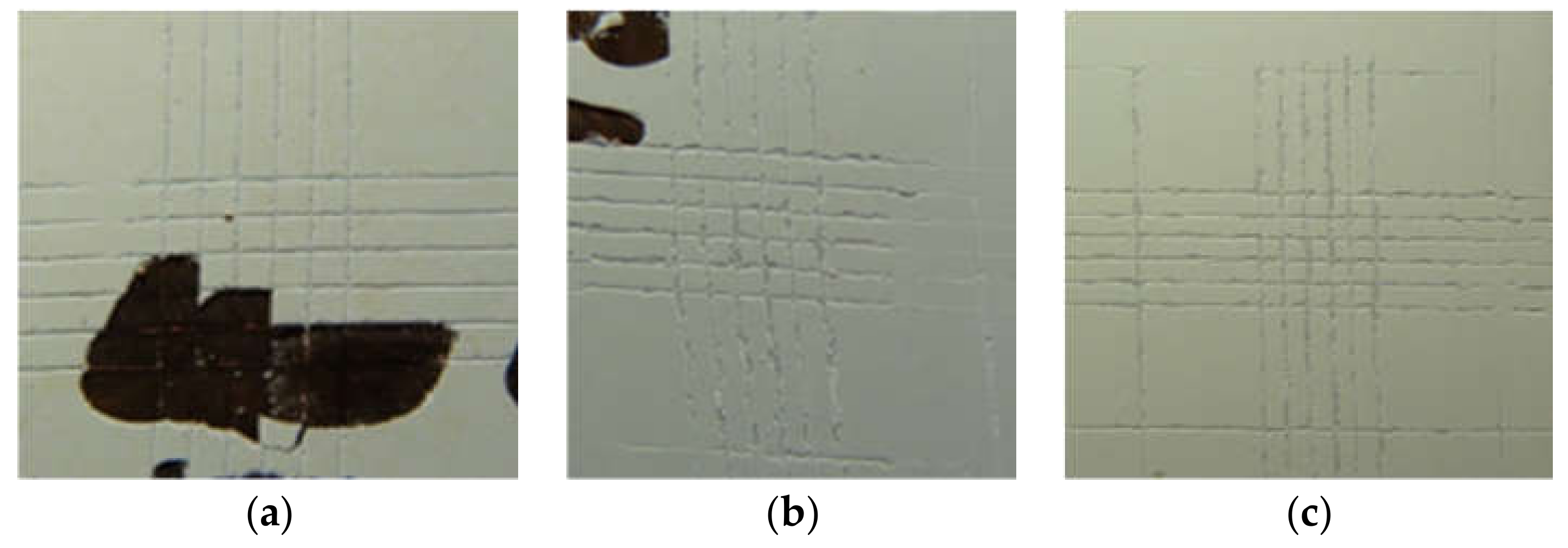

2.5.5. Cross-Cut Test

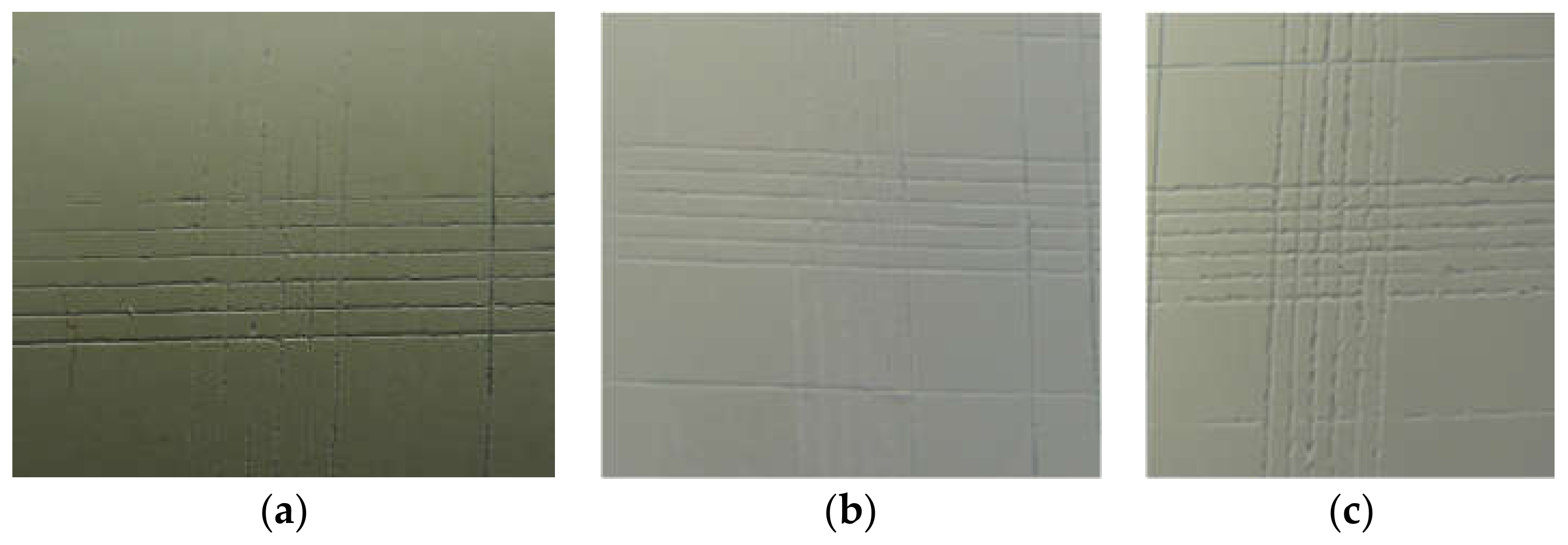

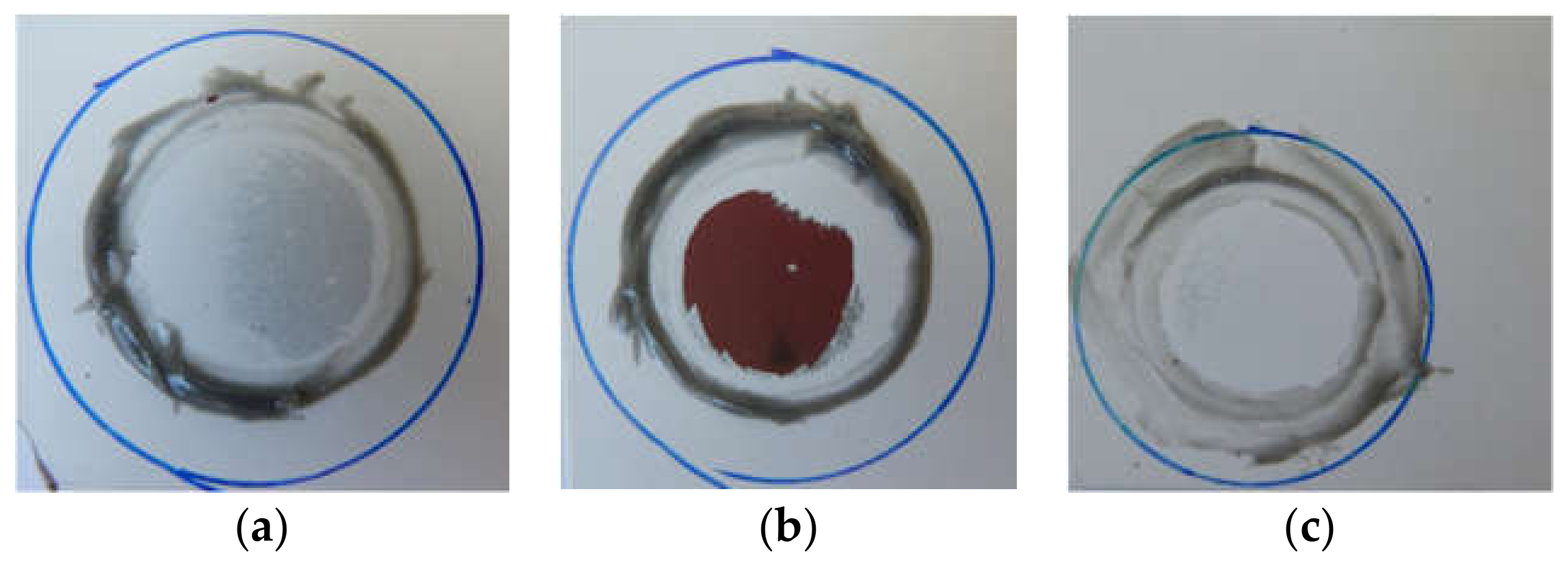

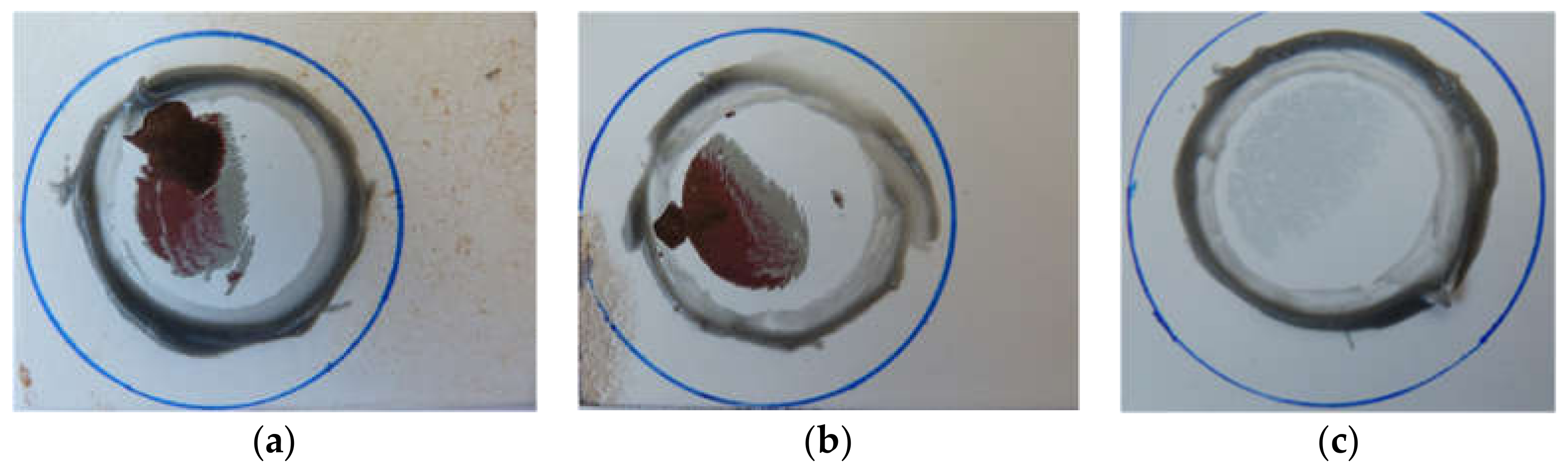

2.5.6. Adhesion Test

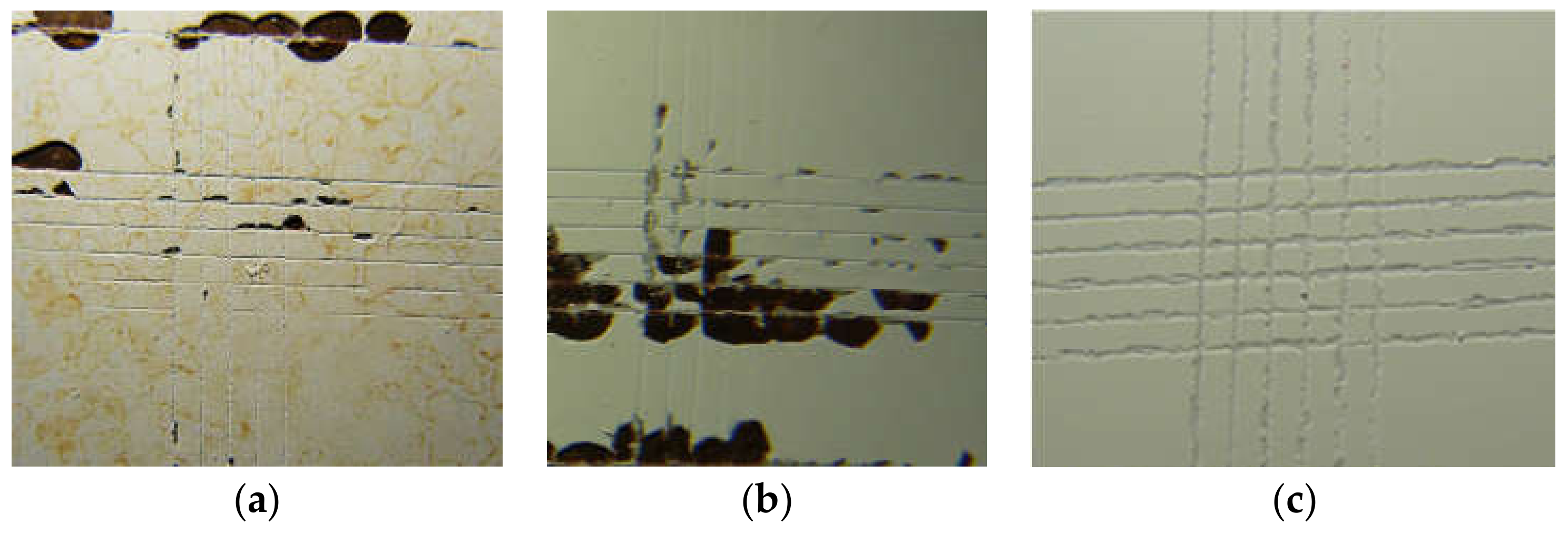

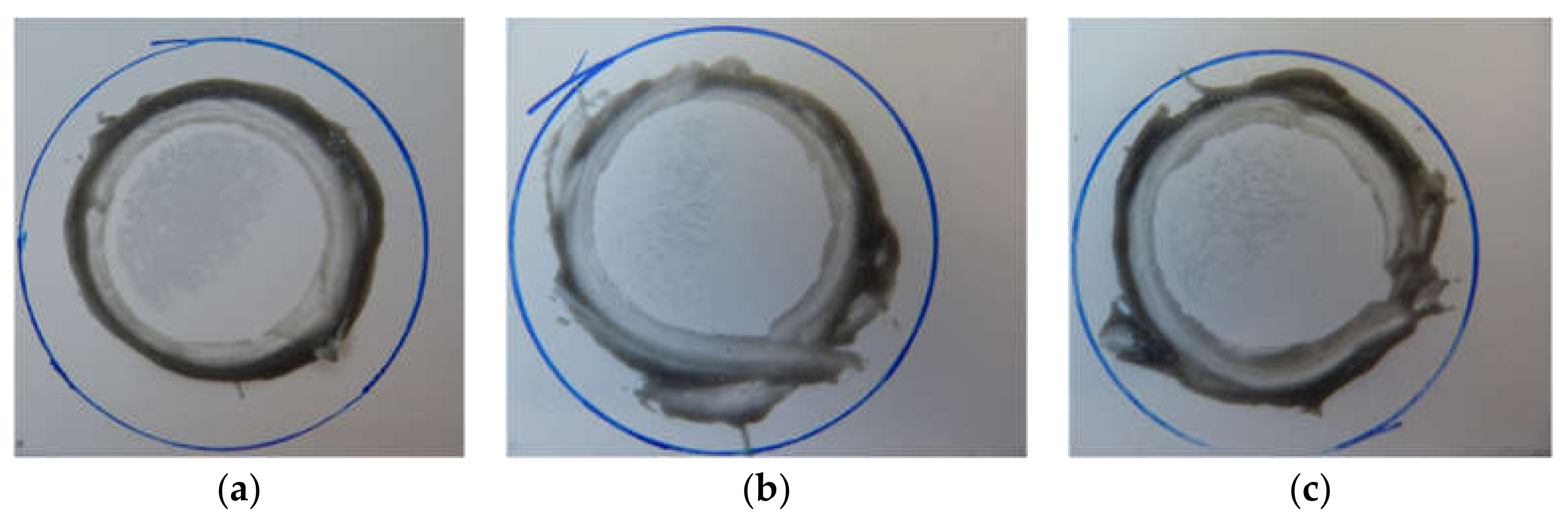

2.5.7. CASS Test

- (1)

- The test samples were located in the chamber room to avoid direct exposure to the spray from the nozzle.

- (2)

- The samples were located in the chamber room facing upwards at an angle close to 20° to the vertical.

- (3)

- The test samples were organized to avoid any contact with the chamber walls and to permit free circulation of the spray around the sample surfaces.

2.6. Experimental Evaluation

2.6.1. Spectrophotometer

2.6.2. Reflectometer

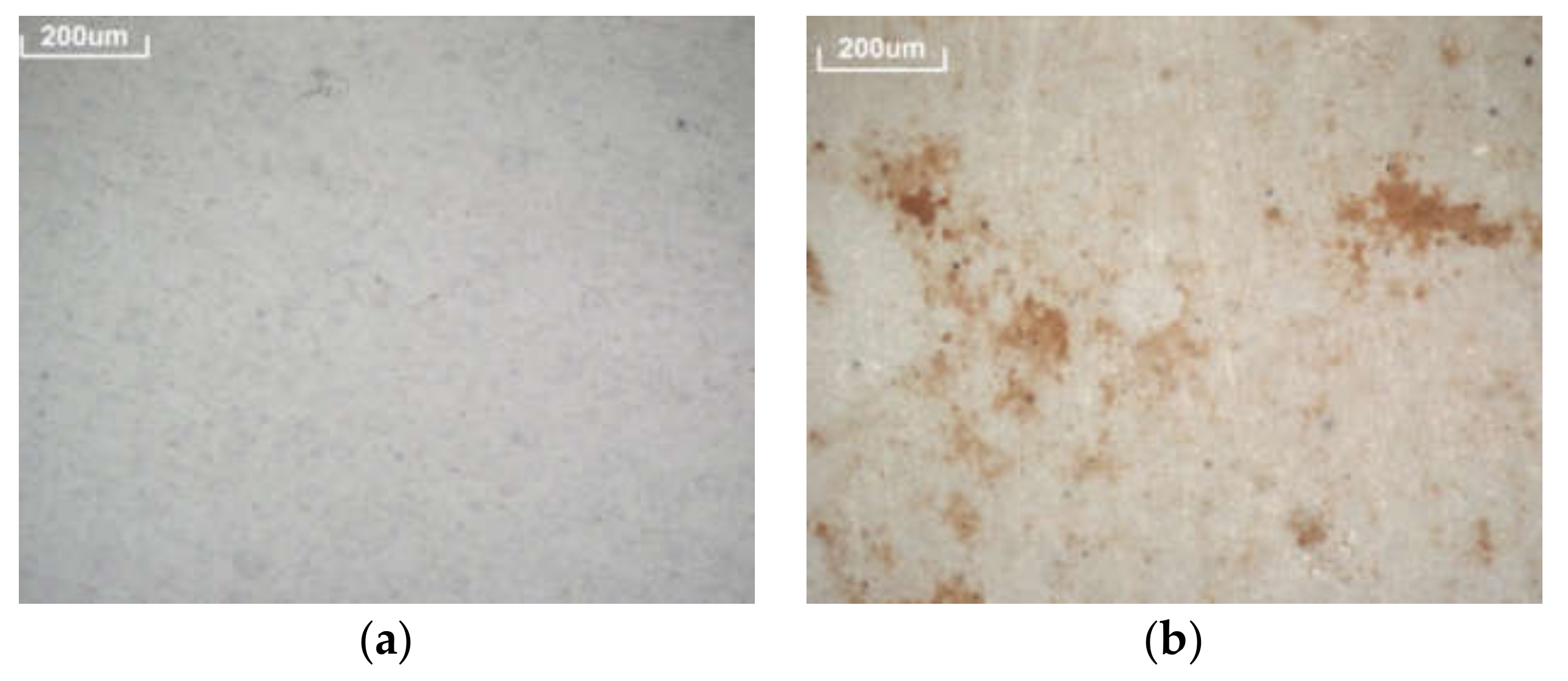

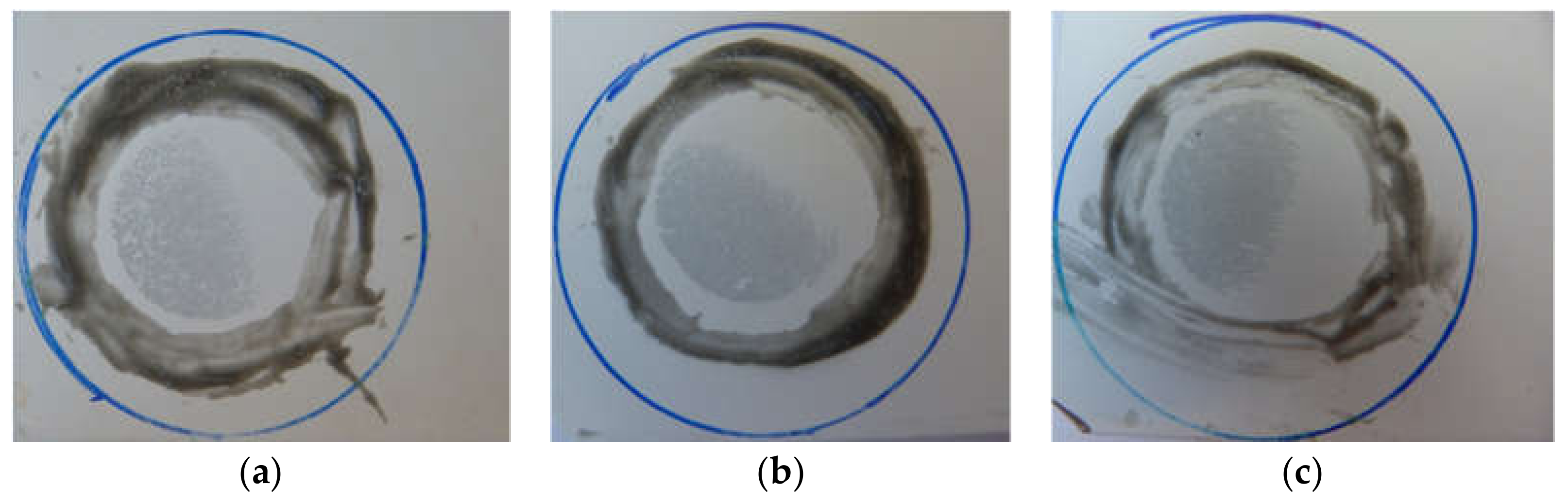

2.6.3. Optical Inspection

2.6.4. Scanning Electron Microscope

3. Results and Discussion

3.1. Preliminary Weathering Tests

3.2. Extended Weathering Tests

3.3. Mechanical Tests

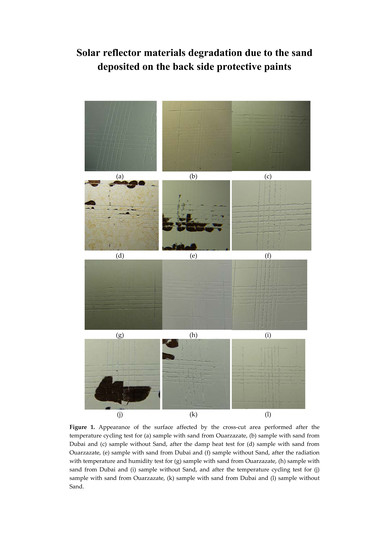

3.3.1. Cross-Cut Test

3.3.2. Adhesion Test

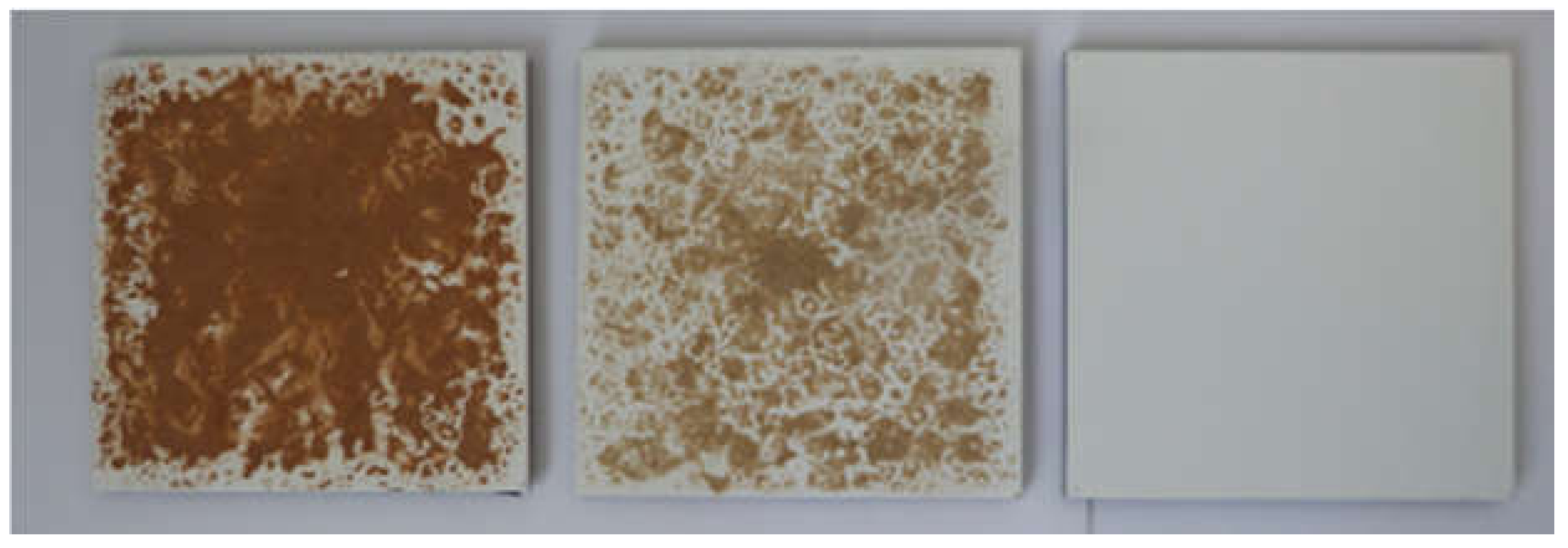

3.4. CASS Test

4. Conclusions

- The representative ambient conditions, simulated by radiation with temperature and humidity tests, did not show any degradation of the paint layers.

- The samples tested in the weathering experiments without sand were not affected at all by the cross-cut and adhesion tests. This means that the deterioration produced in the back-paint layers after the mechanical tests was clearly caused by the interaction between the deposited sand and the paint layers during the accelerated aging experiments.

- The accelerated conditions that produced the highest deterioration of the backside layers were those simulated by the damp heat test (high temperature in combination with high humidity), followed by the temperature cycling test with humidity (sharp temperature variations). In these cases, the sand from Ouarzazate was more aggressive than the sand from Dubai. This phenomenon was detected both in the preliminary and extended weathering tests, as well as in the mechanical tests (cross-cut and adhesion tests).

- The ambient conditions simulated by the UV and humidity test in combination with sand from Dubai also was shown to be destructive. This effect was noticed both in the extended weathering tests and the adhesion test.

- With respect to the testing protocol proposed in this work, all of the experiments performed generated significant conclusions, except the CASS test, which is not recommended for further studies focused on the backside paints. Therefore, for further similar studies it is advisable to apply the same testing protocol, avoiding the CASS test.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Symbols | |

| DU | Dubai |

| Gb | direct solar irradiance (W/m2) |

| h | hemispherical (−) |

| OU | Ouarzazate |

| RH | relative humidity (%) |

| s | specular (−) |

| T | temperature (°C) |

| θi | incidence angle (°) |

| λ | wavelength (nm) |

| ρ | reflectance (−) |

| ϕ | acceptance angle (mrad) |

| Acronyms | |

| CASS | copper-accelerated acetic acid salt spray (CASS) |

| CIEMAT | Centro de Investigaciones Energéticas Medioambientales y Tecnológicas (Energy, Environment and Technology Research Center, Spain) |

| CSP | concentrating solar power |

| DLR | Deutsches Zentrum für Luft- und Raumfahrt (German Aerospace Center, Germany) |

| DNI | direct normal irradiance |

| ESTELA | European Solar Thermal Electricity Association |

| IEA | International Energy Agency |

| MASENMENA | Moroccan Agency for Solar EnergyMiddle East and North Africa |

| O&M | operation and maintenance |

| OPAC | Optical Aging Characterization |

| PSA | Plataforma Solar de Almería (Spain) |

| PV | photovoltaics |

| SEM | scanning electron microscope |

| STC | solar thermal collector |

| STE | solar thermal electricity |

| UAE | United Arab Emirates |

References

- Baños, R.; Manzano-Agugliaro, F.; Montoya, F.G.; Gil, C.; Alcayde, A.; Gómez, J. Optimization methods applied to renewable and sustainable energy: A review. Renew. Sustain. Energy Rev. 2011, 15, 1753–1766. [Google Scholar] [CrossRef]

- El-Katiri, L. A Roadmap for Renewable Energy in the Middle East and North Africa; Oxford Institute for Energy Studies, University of Oxford: Oxford, UK, 2014; pp. 1–52. [Google Scholar]

- Jäger-Waldau, A. Photovoltaics and renewable energies in Europe. Renew. Sustain. Energy Rev. 2007, 11, 1414–1437. [Google Scholar] [CrossRef]

- Montoya, F.G.; Aguilera, M.J.; Manzano-Agugliaro, F. Renewable energy production in Spain: A review. Renew. Sustain. Energy Rev. 2014, 33, 509–531. [Google Scholar] [CrossRef]

- Kousksou, T.; Allouhi, A.; Belattar, M.; Jamil, A.; El Rhafiki, T.; Arid, A.; Zeraouli, Y. Renewable energy potential and national policy directions for sustainable development in Morocco, 2015. Renew. Sustain. Energy Rev. 2015, 47, 46–57. [Google Scholar] [CrossRef]

- Solangi, K.H.; Islam, M.R.; Saidur, R.; Rahim, N.A.; Fayaz, H. A review on global solar energy policy. Renew. Sustain. Energy Rev. 2011, 15, 2149–2163. [Google Scholar] [CrossRef]

- Ab Kadir, M.Z.A.; Rafeeu, Y.; Adam, N.M. Prospective scenarios for the full solar energy development in Malaysia. Renew. Sustain. Energy Rev. 2010, 14, 3023–3031. [Google Scholar] [CrossRef]

- Hernández-Escobedo, Q.; Rodríguez-García, E.; Saldaña-Flores, R.; Fernández-García, A.; Manzano-Agugliaro, R. Solar energy resource assessment in Mexican states along the Gulf of Mexico. Renew. Sustain. Energy Rev. 2015, 43, 216–238. [Google Scholar] [CrossRef]

- Porras-Prieto, C.J.; Benedicto-Schönemann, S.; Mazarrón, F.R.; Benavente, R.M. Profitability Variations of a Solar System with an Evacuated Tube Collector According to Schedules and Frequency of Hot Water Demand. Energies 2016, 9, 1053. [Google Scholar] [CrossRef]

- Manzano-Agugliaro, F.; Alcayde, A.; Montoya, F.G.; Zapata-Sierra, A.; Gil, C. Scientific production of renewable energies worldwide: An overview. Renew. Sustain. Energy Rev. 2013, 18, 134–143. [Google Scholar] [CrossRef]

- Kommalapati, R.; Kadiyala, A.; Shahriar, T.; Huque, Z. Review of the Life Cycle Greenhouse Gas Emissions from Different Photovoltaic and Concentrating Solar Power Electricity Generation Systems. Energies 2017, 10, 350. [Google Scholar] [CrossRef]

- Mills, D. Advances in solar thermal electricity technology. Sol. Energy 2004, 76, 19–31. [Google Scholar] [CrossRef]

- Pavlović, T.M.; Radonjić, I.S.; Milosavljević, D.D.; Pantić, L.S. A review of concentrating solar power plants in the world and their potential use in Serbia. Renew. Sustain. Energy Rev. 2012, 16, 3891–3902. [Google Scholar] [CrossRef]

- Py, X.; Azoumah, Y.; Olives, R. Concentrated solar power: Current technologies, major innovative issues and applicability to West African countries. Renew. Sustain. Energy Rev. 2013, 18, 306–315. [Google Scholar] [CrossRef]

- Technology Roadmap: Solar Thermal Electricity; Technology Report; OECD/IEA: Paris, France, 2014.

- Asim, N.; Sopian, K.; Ahmadi, S.; Saeedfar, K.; Alghoul, M.A.; Saadatian, O.; Zaidi, S.H. A review on the role of materials science in solar cells. Renew. Sustain. Energy Rev. 2012, 16, 5834–5847. [Google Scholar] [CrossRef]

- Vasconcelos Sampaio, P.G.; Aguirre González, M.O. Photovoltaic solar energy: Conceptual framework. Renew. Sustain. Energy Rev. 2017, 74, 590–601. [Google Scholar] [CrossRef]

- Zhao, J.; Ji, Y.; Yuan, Y.; Zhang, Z.; Lu, J. Energy-Saving Analysis of Solar Heating System with PCM Storage Tank. Energies 2018, 11, 237. [Google Scholar] [CrossRef]

- Kennedy, C.E.; Terwilliger, K. Optical Durability of Candidate Solar Reflectors. J. Sol. Energy Eng. 2005, 127, 262–269. [Google Scholar] [CrossRef]

- López Martín, R.; Cantos-Soto, M.E.; Fernández-García, A.; Alguacil-Algarrada, M.; Sutter, F. Competitive examination of solar reflectors durability under accelerated aging. In Proceedings of the SolarPACES, Marrakech, Morocco, 11–14 September 2012. [Google Scholar]

- Concentrating Solar Power, Renewable Energy Technologies: Cost Analysis Series, Volume 1: Power Sector; IRENA Working Paper; Issue 2/5; IRENA: Masdar City, UAE, June 2012.

- Fernández-García, A.; Zarza, E.; Valenzuela, L.; Pérez, M. Parabolic-trough solar collectors and their applications. Renew. Sustain. Energy Rev. 2010, 14, 1695–1721. [Google Scholar] [CrossRef]

- Sutter, F.; Meyen, S.; Fernández-García, A.; Heller, P. Spectral characterization of specular reflectance of solar mirrors. Sol. Energy Mater. Sol. Cells 2016, 145, 248–254. [Google Scholar] [CrossRef]

- Materials Roadmap Enabling Low-Carbon Energy Technologies; Technology Report 1609; European Commission: Brussels, Belgium, 2011.

- Kennedy, C.E. Advances in Concentrating Solar Power Collectors: Mirrors and Solar-Selective Coatings; Technology Report NREL/PR-550–43695; NREL: Golden, CO, USA, 2007.

- Kennedy, C.E.; Smilgys, R.V.; Kirkpatrick, D.A.; Ross, J.S. Optical performance and durability of solar reflectors protected by an alumina coating. Thin Solid Films 1997, 304, 303–309. [Google Scholar] [CrossRef]

- Kennedy, C.E.; Terwilliger, K.; Milbourne, M. Development and Testing of Solar Reflectors Technical Report; Technology Report NREL/CP-520-36582; NREL: Golden, CO, USA, 2004.

- Pitchumani, R. Concentrating Solar Power Program; Sunshot Grand Challenge and Peer Review; DOE: Anaheim, CA, USA, 2014. [Google Scholar]

- García-Segura, A.; Fernández-García, A.; Ariza, M.J.; Sutter, F.; Valenzuela, L. Durability studies of solar reflectors: A review. Renew. Sustain. Energy Rev. 2016, 62, 453–467. [Google Scholar] [CrossRef]

- Solar Thermal Electricity: Strategic Research Agenda 2020–2025; ESTELA: Brussels, Belgium, 2012.

- Costa, S.C.; Diniz, A.S.A.; Kazmerski, L.L. Dust and soiling issues and impacts relating to solar energy systems: Literature review update for 2012–2015. Renew. Sustain. Energy Rev. 2016, 63, 33–61. [Google Scholar] [CrossRef]

- Conceição, T.; Silva, H.G.; Mirão, J.; Collares-Pereira, M. Organic Soiling: The Role of Pollen in PV Module Performance Degradation. Energies 2018, 11, 294. [Google Scholar] [CrossRef]

- Wolfertstetter, F.; Pottler, K.; Geuder, N.; Affolter, R.; Merrouni, A.A.; Mezrhab, A.; Pitz-Paal, R. Monitoring of Mirror and Sensor Soiling with TraCS for Improved Quality of Ground based Irradiance Measurements. Energy Procedia 2014, 49, 2422–2432. [Google Scholar] [CrossRef]

- Bouaddi, S.; Ihlal, A.; Fernández-García, A. Soiled CSP solar reflectors modeling using dynamic linear models. Sol. Energy 2015, 122, 847–863. [Google Scholar] [CrossRef]

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Vivar, M.; Herrero, R.; Antón, I.; Martínez-Moreno, F.; Moretón, R.; Sala, G.; Blakers, A.W.; Smeltink, J. Effect of soiling in CPV systems. Sol. Energy 2010, 84, 1327–1335. [Google Scholar] [CrossRef]

- Cohen, G.E.; Kearney, D.W.; Kolb, G.J. Final Report on the Operation and Maintenance Improvement Program for Concentrating Solar Power Plants; Technology Report SAND99-1290; Sandia National Laboratories: Albuquerque, NM, USA, 1999. [Google Scholar]

- Fernández-García, A.; Álvarez-Rodrigo, L.; Martínez-Arcos, L.; Aguiar, R.; Márquez-Payés, J.M. Study of Different Cleaning Methods for Solar Reflectors Used in CSP Plants. Energy Procedia 2014, 49, 80–89. [Google Scholar] [CrossRef]

- Berg, R.S. Heliostat Dust Buildup and Cleaning Studies; Technology Report SAND-78-0510; Sandia National Laboratories: Albuquerque, NM, USA, 1978. [Google Scholar]

- Roth, E.P.; Pettit, R.B. The Effect of Soiling on Solar Mirrors and Techniques Used to Maintain High Reflectivity. In Solar Materials Science, 1st ed.; Academic Press: New York, NY, USA, 1980; Chapter 6; pp. 199–227. ISBN 978-0-12-511160-7. [Google Scholar]

- Morris, V.L. Cleaning agents and techniques for concentrating solar collectors. Sol. Energy Mater. 1980, 3, 35–55. [Google Scholar] [CrossRef]

- Biryukov, S.; Faiman, D.; Goldfeld, A. An Optical System for the Quantitative Study of Particulate Contamination on Solar Collector Surfaces. Sol. Energy 1999, 66, 371–378. [Google Scholar] [CrossRef]

- Pettit, R.B.; Freese, J.M.; Roth, E.P. Studies of Dust Accumulation on Solar-Mirror Materials; Technology Report SAND-81-0075C; Sandia National Laboratories: Albuquerque, NM, USA, 1981. [Google Scholar]

- Fernández-García, A. Estudio de la Reflectancia Especular en Plantas de Captadores Solares Cilindroparabólicos, 1st ed.; CIEMAT: Madrid, Spain, 2012; ISBN 9788478346721. [Google Scholar]

- Bethea, R.M.; Barriger, M.T.; Williams, P.F.; Chin, S. Environmental effects on solar concentrator mirrors. Sol. Energy 1981, 27, 497–511. [Google Scholar] [CrossRef]

- Heimsath, A.; Heck, M.; Morin, G.; Kiewitt, W.; Platzer, W. Soiling of aluminum and glass mirrors under different climatic conditions and techno-economic optimization of cleaning intervals. In Proceedings of the SolarPACES, Perpignan, France, 21–24 September 2010. [Google Scholar]

- Tahboub, Z.; Dahleh, B.; Goebel, O. Solar Mirrors Soiling Campaign Abu Dhabi. In Proceedings of the SolarPACES, Marrakech, Morocco, 11–14 September 2012. [Google Scholar]

- Deffenbaugh, D.M.; Green, S.T.; Svedeman, S.J. The effect of dust accumulation on line-focus parabolic trough solar collector performance. Sol. Energy 1986, 36, 139–146. [Google Scholar] [CrossRef]

- Bouaddi, S.; Ihlal, A.; Fernández-García, A. Comparative analysis of soiling of CSP mirror materials in arid zones. Renew. Energy 2017, 101, 437–449. [Google Scholar] [CrossRef]

- Roth, E.P.; Anaya, A.J. The Effect of Natural Soiling and Cleaning on the Size Distribution of Particles Deposited on Glass Mirrors. J. Sol. Energy Eng. 1980, 102, 248–256. [Google Scholar] [CrossRef]

- Bouaouadja, N.; Bouzid, S.; Hamidouche, M.; Bousbaa, C.; Madjoubi, M. Effects of sandblasting on the efficiencies of solar panels. Appl. Energy 2000, 65, 99–105. [Google Scholar] [CrossRef]

- Nelson, A. Understanding soil adhesion in Concentrating Solar Power Plants: A novel analysis of soil Characteristics. In Proceedings of the SolarPACES, Granada, Spain, 20–23 September 2011. [Google Scholar]

- Karim, M.; Naamane, S.; El Amrani EL Hassani, I.; Delord, C.; Belcadi, S.; Tochon, P.; Bennouna, A. Towards the prediction of CSP mirrors wear: Methodology of analysis of influencing parameters on the mirrors surface degradation: Application in two different sites in Morocco. Sol. Energy 2014, 108, 41–50. [Google Scholar] [CrossRef]

- Karim, M.; Naamane, S.; Delord, C.; Bennouna, A. Study of the Surface Damage of Glass Reflectors Used in Concentrated Solar Power Plants. Energy Procedia 2015, 69, 106–115. [Google Scholar] [CrossRef]

- Wiesinger, F.; Sutter, F.; Fernández-García, A.; Reinhold, J.; Pitz-Paal, R. Sand erosion on solar reflectors: Accelerated simulation and comparison with field data. Sol. Energy Mater. Sol. Cells 2016, 145, 303–313. [Google Scholar] [CrossRef]

- Wette, J.; Sutter, F.; Fernández-García, A.; Ziegler, S.; Dasbach, R. Comparison of Degradation on Aluminum Reflectors for Solar Collectors due to Outdoor Exposure and Accelerated Aging. Energies 2016, 9, 916. [Google Scholar] [CrossRef]

- Wiesinger, F.; Sutter, F.; Wolfertstetter, F.; Hanrieder, N.; Fernández-García, A.; Pitz-Paal, R.; Schmücker, M. Assessment of the erosion risk of sandstorms on solar energy technology at two sites in Morocco. Sol. Energy 2018, 162, 217–228. [Google Scholar] [CrossRef]

- Wiesinger, F.; San Vicente, G.; Fernández-García, A.; Sutter, F.; Morales, A.; Pitz-Paal, R. Sandstorm erosion testing of anti-reflective glass coatings for solar energy applications. Sol. Energy Mater. Sol. Cells 2018, 179, 10–16. [Google Scholar] [CrossRef]

- Bouzid, S.; Bouaouadja, N. Effect of impact angle on glass surfaces eroded by sand blasting. J. Eur. Ceram. Soc. 2000, 20, 481–488. [Google Scholar] [CrossRef]

- Holze, C.; Brucks, A. Sand abrasion testing: Characterization of abrasive resistance of optical surfaces in arid operational areas using standard and adapted methods. In Proceedings of the SolarPACES, Granada, Spain, 20–23 September 2011. [Google Scholar]

- Sansom, C.; Comley, P.; Bhattacharyya, D.; Macerol, N. A comparison of Polymer film and Glass Collectors for concentrating solar power. In Proceedings of the SolarPACES, Las Vegas, NV, USA, 17–20 September 2011. [Google Scholar]

- Sansom, C.; Comley, P.; King, P.; Almond, H.; Atkinson, C.; Endaya, E. Predicting the Effects of Sand Erosion on Collector Surfaces in CSP Plants. Energy Procedia 2015, 69, 198–207. [Google Scholar] [CrossRef]

- Sansom, C.; Fernández-García, A.; Sutter, F.; Almond, H.; King, P.; Martínez-Arcos, L. Soiling and Cleaning of Polymer Film Solar Reflectors. Energies 2016, 9, 1006. [Google Scholar] [CrossRef]

- Sutter, F.; Fernandez-García, A.; Wette, J.; Heller, P. Comparison and evaluation of accelerated aging tests for reflectors. Energy Procedia 2014, 49, 1718–1727. [Google Scholar] [CrossRef]

- Paints and Varnishes—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps; ISO 16474-3; ISO: Geneva, Switzerland, 2013.

- Concentrator Photovoltaic (cpv) Modules and Assemblies—Designed Modification and Type Approval; IEC 62108; International Electrochemical Commission (IEC): Geneva, Switzerland, 2007.

- Reflector Panels for Concentrating Solar Technologies; UNE 206016; AENOR: Madrid, Spain, 2018.

- Paints and Varnishes—Cross-Cut Test; ISO 2409; ISO: Geneva, Switzerland, 2007.

- Paints and Varnishes—Pull-off Test for Adhesion; ISO 4624; ISO: Geneva, Switzerland, 2016.

- Corrosion Tests in Artificial Atmospheres—Salt Spray Tests; ISO 9227; ISO: Geneva, Switzerland, 2006.

- Sutter, F.; Fernández-García, A.; Heller, P.; Anderson, K.; Wilson, G.; Schmückerd, M.; Marvig, P. Durability testing of silvered-glass mirrors. Energy Procedia 2015, 69, 1568–1577. [Google Scholar] [CrossRef]

- SolarPACES Reflectance Guideline. Parameters and Method to Evaluate the Reflectance Properties of Reflector Materials for Concentrating Solar Power Technology. Version 3.0. March 2018. Available online: http://www.solarpaces.org/wp-content/uploads/20180320_SolarPACES-Reflectance-Guidelines-V3.pdf (accessed on 30 March 2018).

- Fernández-García, A.; Sutter, F.; Martínez-Arcos, L.; Sansom, C.; Wolfertstetter, F.; Delord, C. Equipment and methods for measuring reflectance of concentrating solar reflector materials. Sol. Energy Mater. Sol. Cells 2017, 167, 28–52. [Google Scholar] [CrossRef]

- Solar Thermal Electric Plants. Terminology; UNE 206009; AENOR: Madrid, Spain, 2013. [Google Scholar]

- Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres; ASTM E903-82; ASTM: West Conshohocken, PA, USA, 2012.

- Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface; ASTM G173-03; ASTM: West Conshohocken, PA, USA, 2003.

| Compound | Dubai Sand Weight (%) | Ouarzazate Sand Weight (%) |

|---|---|---|

| CaO | 62.05 | 17.76 |

| SiO2 | 26.79 | 51.11 |

| MgO | 3.30 | 2.80 |

| Al2O3 | 3.08 | 14.70 |

| Fe2O3 | 2.03 | 8.02 |

| K2O | 0.66 | 3.39 |

| SO3 | 0.58 | 0.16 |

| Na2O | 0.38 | 0.19 |

| P2O5 | 0.38 | 0.52 |

| SrO | 0.35 | 0.05 |

| TiO2 | 0.15 | 0.97 |

| Cl | 0.15 | 0.03 |

| Others | 0.09 | 0.29 |

| Total | 100.00 | 100.00 |

| Test Name | UV and Humidity Cycling | Damp Heat | Radiation with Temperature and Humidity | Temperature Cycling | ||||

|---|---|---|---|---|---|---|---|---|

| Sand type | OU | DU | OU | DU | OU | DU | OU | DU |

| ρs,h ([280,2500] nm, 8°, h) (silver layer) | −0.001 | −0.002 | 0.000 | 0.000 | −0.002 | 0.000 | 0.000 | 0.000 |

| ρλ,h (660 nm, 8°, h) (silver layer) | −0.002 | −0.002 | 0.000 | 0.000 | −0.002 | 0.000 | 0.000 | 0.000 |

| ρλ,ϕ (660 nm, 15°, 12.5 mrad) (silver layer) | −0.002 | −0.002 | 0.000 | 0.000 | −0.002 | 0.000 | 0.000 | 0.000 |

| ρs,h ([280,2500] nm, 8°, h) (backside paint layer) | −0.011 | −0.009 | −0.033 | 0.000 | −0.011 | −0.010 | −0.025 | −0.005 |

| Test Name | UV and Humidity Cycling | Damp Heat | Radiation with Temperature and Humidity | Temperature Cycling | ||||

|---|---|---|---|---|---|---|---|---|

| Sand type | OU | DU | OU | DU | OU | DU | OU | DU |

| ρs,h ([280,2500] nm, 8°, h) (silver layer) | −0.001 | 0.000 | 0.000 | −0.001 | −0.001 | −0.001 | 0.000 | −0.001 |

| ρλ,h (660 nm, 8°, h) (silver layer) | −0.002 | −0.001 | 0.000 | −0.002 | 0.000 | 0.000 | 0.000 | −0.001 |

| ρλ,ϕ (660 nm, 15°, 12.5 mrad) (silver layer) | −0.001 | 0.000 | 0.000 | −0.003 | −0.001 | −0.001 | 0.000 | 0.000 |

| ρs,h ([280,2500] nm, 8°, h) (backside paint layer) | 0.000 | −0.009 | −0.009 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Preliminary Weathering Test | Sand Type | Classification | Interpretation |

|---|---|---|---|

| UV and humidity cycling | Ouarzazate | 0 | No detachment—none of the squares of the grid was detached |

| Dubai | 0 | ||

| Without sand | 0 | ||

| Damp heat | Ouarzazate | 2 | An area >5%, but <15% was affected |

| Dubai | 3 | Some squares detached partly or totally and an area <15%, but <35% was affected | |

| Without sand | 0 | No detachment—none of the squares of the grid was detached | |

| Radiation with temperature and humidity | Ouarzazate | 0 | No detachment—none of the squares of the grid was detached |

| Dubai | 0 | ||

| Without sand | 0 | ||

| Temperature cycling | Ouarzazate | 3 | Some squares detached partly or totally and an area <15%, but <35% was affected |

| Dubai | 1 | A cross-cut area <5% was affected | |

| Without sand | 0 | No detachment—none of the squares of the grid was detached | |

| No test | Without sand [1] | 0 | No detachment—none of the squares of the grid was detached |

| Test Name | UV and Humidity Cycling | Damp Heat | Radiation with Temperature and Humidity | Temperature Cycling | ||||

|---|---|---|---|---|---|---|---|---|

| Sand type | OU | DU | OU | DU | OU | DU | OU | DU |

| ρs,h ([280,2500] nm, 8°, h) (silver layer) | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| ρλ,h (660 nm, 8°, h) (silver layer) | −0.001 | 0.000 | 0.00 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| ρλ,ϕ (660 nm, 15°, 12.5 mrad) (silver layer) | 0.000 | 0.000 | 0.000 | −0.002 | 0.000 | 0.000 | 0.000 | 0.000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-García, A.; Juaidi, A.; Sutter, F.; Martínez-Arcos, L.; Manzano-Agugliaro, F. Solar Reflector Materials Degradation Due to the Sand Deposited on the Backside Protective Paints. Energies 2018, 11, 808. https://doi.org/10.3390/en11040808

Fernández-García A, Juaidi A, Sutter F, Martínez-Arcos L, Manzano-Agugliaro F. Solar Reflector Materials Degradation Due to the Sand Deposited on the Backside Protective Paints. Energies. 2018; 11(4):808. https://doi.org/10.3390/en11040808

Chicago/Turabian StyleFernández-García, Aránzazu, Adel Juaidi, Florian Sutter, Lucía Martínez-Arcos, and Francisco Manzano-Agugliaro. 2018. "Solar Reflector Materials Degradation Due to the Sand Deposited on the Backside Protective Paints" Energies 11, no. 4: 808. https://doi.org/10.3390/en11040808

APA StyleFernández-García, A., Juaidi, A., Sutter, F., Martínez-Arcos, L., & Manzano-Agugliaro, F. (2018). Solar Reflector Materials Degradation Due to the Sand Deposited on the Backside Protective Paints. Energies, 11(4), 808. https://doi.org/10.3390/en11040808