Utilization of Energy Crops and Sewage Sludge in the Process of Co-Gasification for Sustainable Hydrogen Production

Abstract

1. Introduction

2. Materials and Methods

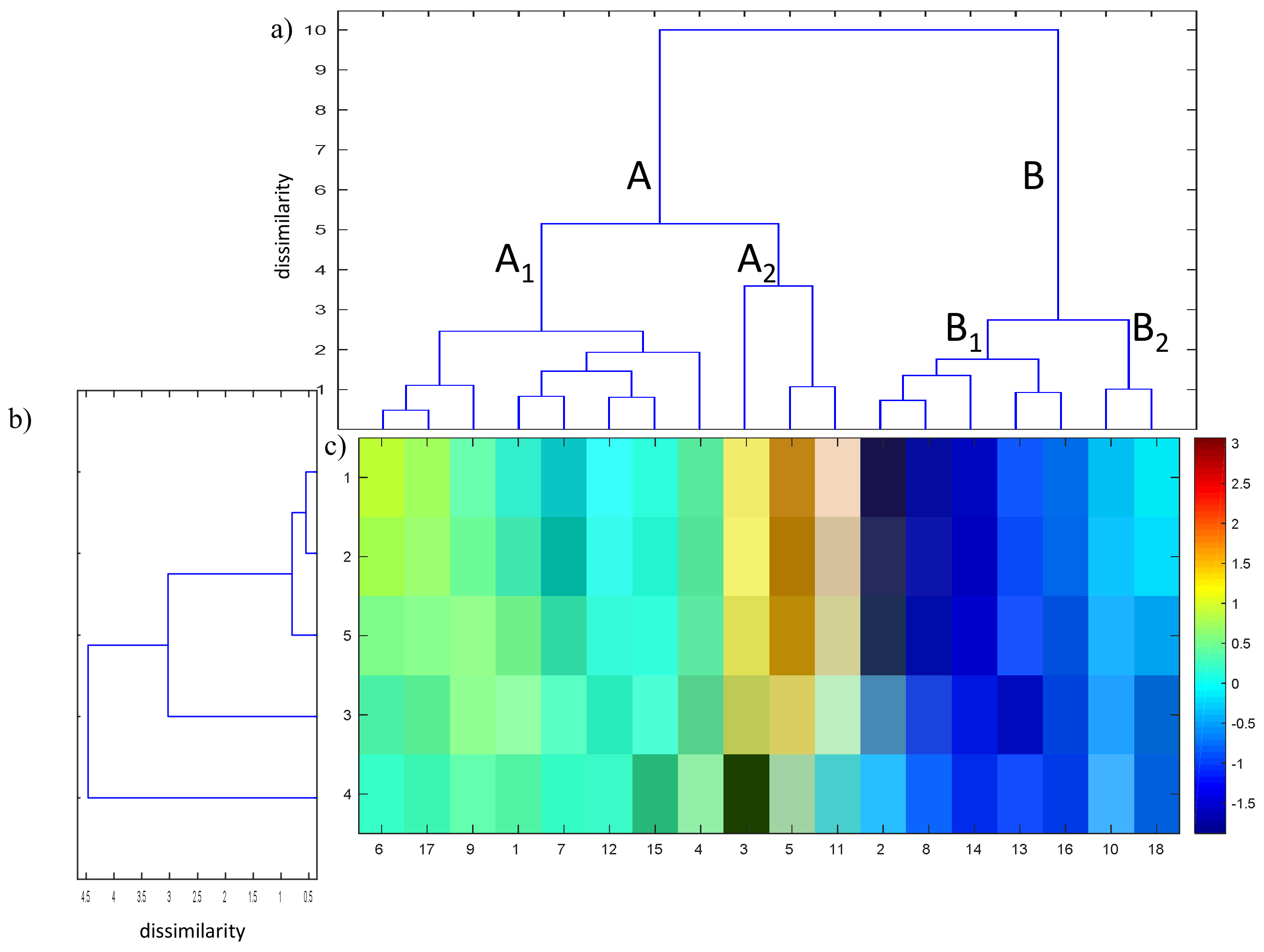

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Singh, R.P.; Agrawal, M. Potential benefits and risks of land application of sewage sludge. Waste Manag. 2008, 28, 347–358. [Google Scholar] [CrossRef] [PubMed]

- Camargo, F.P.; Tonello, P.S.; dos Santos, A.C.A.; Silveira Duarte, I.C. Removal of Toxic Metals from Sewage Sludge Through Chemical, Physical, and Biological Treatments—A Review. Water Air Soil Pollut. 2016, 227, 433. [Google Scholar] [CrossRef]

- Garrido-Baserba, M.; Molinos-Senante, M.; Abelleira-Pereira, J.M.; Fdez-Güelfo, L.A.; Poch, M.; Hernandez-Sancho, F. Selecting sewage sludge treatment alternatives in modern wastewater treatment plants using environmental decision support systems. J. Clean. Prod. 2015, 107, 410–419. [Google Scholar] [CrossRef]

- Kokalj, F.; Arbiter, B.; Samec, N. Sewage sludge gasification as an alternative energy storage model. Energy Convers. Manag. 2017, 149, 738–747. [Google Scholar] [CrossRef]

- Ramos, A.; Monteiro, E.; Silva, V.; Rouboa, A. Co-gasification and recent developments on waste-to-energy conversion: A Review. Renew. Sustain. Energy Rev. 2018, 81, 380–398. [Google Scholar] [CrossRef]

- Skoglund, N.; Bäfver, L.; Fahlströmd, J.; Holmén, E.; Renström, C. Fuel design in co-combustion of demolition wood chips and municipal sewage sludge. Fuel Process. Technol. 2016, 141, 196–201. [Google Scholar] [CrossRef]

- Liu, J.; Huang, L.; Buyukada, M.; Evrendilek, F. Response surface optimization, modeling and uncertainty analysis of mass loss response of co-combustion of sewage sludge and water hyacinth. Appl. Therm. Eng. 2017, 125, 328–335. [Google Scholar] [CrossRef]

- Xiao, Z.; Yuan, X.; Jiang, L.; Chen, X.; Li, H.; Zeng, G.; Leng, L.; Wang, H.; Huang, H. Energy recovery and secondary pollutant emission from the combustion of co-pelletized fuel from municipal sewage sludge and wood sawdust. Energy 2015, 91, 441–450. [Google Scholar] [CrossRef]

- Lin, Y.; Liao, Y.; Yu, Z.; Fang, S.; Ma, X. The investigation of co-combustion of sewage sludge and oil shale using thermogravimetric analysis. Thermochim. Acta 2017, 653, 71–78. [Google Scholar] [CrossRef]

- Niu, S.; Chen, M.; Li, Y.; Song, J. Co-combustion characteristics of municipal sewage sludge and bituminous coal. J. Therm. Anal. Calorim. 2018, 131, 1821–1834. [Google Scholar] [CrossRef]

- Deng, S.; Tan, H.; Wang, X.; Yang, F.; Cao, R.; Wang, Z.; Ruan, R. Investigation on the fast co-pyrolysis of sewage sludge with biomass and the combustion reactivity of residual char. Bioresour. Technol. 2017, 239, 302–310. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Du, G.; Li, J.; Fang, Y.; Hou, L.; Chen, G.; Ma, D. Supercritical water pyrolysis of sewage sludge. Waste Manag. 2017, 59, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yuan, C.; Xu, J.; Yang, X. Beneficial synergetic effect on gas production during co-pyrolysis of sewage sludge and biomass in a vacuum reactor. Bioresour. Technol. 2015, 183, 255–258. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Gao, L.; Chen, Z.; Ma, C.; Zhou, Y.; Chen, J.; Ma, S.; Laghari, M.; Xiao, B.; Zhang, B.; et al. Syngas production by catalytic in-situ steam co-gasification of wet sewage sludge and pine sawdust. Energy Convers. Manag. 2016, 111, 409–416. [Google Scholar] [CrossRef]

- Gai, C.; Chen, M.; Liu, T.; Peng, N.; Liu, Z. Gasification characteristics of hydrochar and pyrochar derived from sewage sludge. Energy 2016, 113, 957–965. [Google Scholar] [CrossRef]

- Zhu, J.G.; Yao, Y.; Lu, Q.G.; Gao, M.; Ouyang, Z.Q. Experimental investigation of gasification and incineration characteristics of dried sewage sludge in a circulating fluidized bed. Fuel 2015, 150, 441–447. [Google Scholar] [CrossRef]

- Pinto, F.; Andre, R.N.; Lopes, H.; Dias, M.; Gulyurtlu, I.; Cabrita, I. Effect of experimental conditions on gas quality and solids produced by sewage sludge cogasification. Sewage sludge mixed with biomass. Energy Fuel 2008, 22, 2314–2325. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Huo, C.; Hu, M.; Guo, D.; Xiao, B. Effect of bioleaching on hydrogen-rich gas production by steam gasification of sewage sludge. Energy Convers. Manag. 2015, 106, 1212–1218. [Google Scholar] [CrossRef]

- Chao, G.; Guo, Y.; Liu, T.; Peng, N.; Liu, Z. Hydrogen-rich gas production by steam gasification of hydrochar derived from sewage sludge. Int. J. Hydrog. Energy 2016, 41, 3363–3372. [Google Scholar]

- Chiang, K.Y.; Lu, C.H.; Liao, C.K.; Hsien-Ruen, R. Characteristics of hydrogen energy yield by co-gasified of sewage sludge and paper-mill sludge in a commercial scale plant. Int. J. Hydrogen Energy 2016, 41, 21641–21648. [Google Scholar] [CrossRef]

- Methling, T.; Armbrust, N.; Haitz, T.; Speidel, M.; Poboss, N.; Braun-Unkhoff, M.; Dieter, H.; Kempter-Regel, B.; Kraaij, G.; Schliessmann, U.; et al. Power generation based on biomass by combined fermentation and gasification—A new concept derived from experiments and modelling. Bioresour. Technol. 2014, 169, 510–517. [Google Scholar] [CrossRef] [PubMed]

- Speidel, M.; Kraaij, G.; Wörner, A. A new process concept for highly efficient conversion of sewage sludge by combined fermentation and gasification and power generation in a hybrid system consisting of a SOFC and a gas turbine. Energy Convers. Manag. 2015, 98, 259–267. [Google Scholar] [CrossRef]

- Smoliński, A.; Howaniec, A. Co-gasification of coal/sewage sludge blends to hydrogen-rich gas with the application of simulated high temperature reactor excess heat. Energy 2016, 41, 8154–8158. [Google Scholar] [CrossRef]

- Cormos, C.C. Hydrogen and power co-generation based on coal and biomass/solid wastes co-gasification with carbon capture and storage. Int. J. Hydrogen Energy 2012, 37, 5637–5648. [Google Scholar] [CrossRef]

- Smoliński, A.; Howaniec, N. Thermal Utilization of Sewage Sludge in the Process of Steam Co-Gasification with Coal to Hydrogen-Rich Gas. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference SGEM 2017, SGEM2017 Vienna GREEN Conference proceedings, Vienna, Austria, 27–29 November 2017; Volume 17, pp. 829–836. [Google Scholar]

- Howaniec, N.; Smoliński, A. Effect of fuel blend composition on the efficiency of hydrogen-rich gas. Fuel 2014, 128, 442–450. [Google Scholar] [CrossRef]

- Howaniec, N.; Smoliński, A. Influence of fuel blend ash components on steam co-gasification of coal and biomass—Chemometric study. Energy 2014, 78, 814–825. [Google Scholar] [CrossRef]

- Smoliński, A. Coal char reactivity as a fuel selection criterion for coal-based hydrogen-rich gas production in the process of steam gasification. Energy Convers. Manag. 2011, 52, 37–45. [Google Scholar] [CrossRef]

- Kaufman, L.; Rousseeuw, P.J. Finding Groups in Data; an Introduction to Cluster Analysis; Wiley: New York, NY, USA, 1990. [Google Scholar]

- Romesburg, H.C. Cluster Analysis for Researchers; Lifetime Learning Publications: Belmont, CA, USA, 1984. [Google Scholar]

- Howaniec, N.; Smoliński, A.; Cempa-Balewicz, M. Experimental study of nuclear high temperature reactor excess heat use in the coal and energy crops co-gasification process to hydrogen-rich gas. Energy 2015, 84, 455–461. [Google Scholar] [CrossRef]

- Massart, D.L.; Kaufman, L. The Interpretation of Analytical Data by the Use of Cluster Analysis; Wiley: New York, NY, USA, 1983. [Google Scholar]

| Parameter | Helianthus tuberosus L. | Miscanthus x giganteus | Sewage sludge |

|---|---|---|---|

| Total moisture, % | 8.81 | 6.78 | 2.24 |

| Ash, % | 3.18 | 1.60 | 35.39 |

| Volatiles, % | 69.24 | 76.00 | 54.96 |

| Heat of combustion, kJ/kg | 15,989 | 16,546 | 14,230 |

| Calorific value, kJ/kg | 14,543 | 14,942 | 13,410 |

| Sulfur, % | 0.04 | 0.05 | 1.2 |

| Carbon, % | 46.62 | 53.71 | 34.52 |

| Hydrogen, % | 5.64 | 6.59 | 4.98 |

| Nitrogen, % | <0.01 | <0.01 | 8.80 |

| Oxygen, % | 35.71 | 31.27 | 12.87 |

| Fixed carbon, % | 18.77 | 15.62 | 7.41 |

| No | Sample | Temperature, °C |

|---|---|---|

| 1 | HTL | 700 |

| 2 | MXG | 700 |

| 3 | HTL | 800 |

| 4 | MXG | 800 |

| 5 | HTL | 900 |

| 6 | MXG | 900 |

| 7 | HTL + 10%SS | 700 |

| 8 | MXG + 10%SS | 700 |

| 9 | HTL + 10%SS | 800 |

| 10 | MXG + 10%SS | 800 |

| 11 | HTL + 10%SS | 900 |

| 12 | MXG + 10%SS | 900 |

| 13 | HTL + 20%SS | 700 |

| 14 | MXG + 20%SS | 700 |

| 15 | HTL + 20%SS | 800 |

| 16 | MXG + 20%SS | 800 |

| 17 | HTL + 20%SS | 900 |

| 18 | MXG + 20%SS | 900 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smoliński, A.; Howaniec, N.; Bąk, A. Utilization of Energy Crops and Sewage Sludge in the Process of Co-Gasification for Sustainable Hydrogen Production. Energies 2018, 11, 809. https://doi.org/10.3390/en11040809

Smoliński A, Howaniec N, Bąk A. Utilization of Energy Crops and Sewage Sludge in the Process of Co-Gasification for Sustainable Hydrogen Production. Energies. 2018; 11(4):809. https://doi.org/10.3390/en11040809

Chicago/Turabian StyleSmoliński, Adam, Natalia Howaniec, and Andrzej Bąk. 2018. "Utilization of Energy Crops and Sewage Sludge in the Process of Co-Gasification for Sustainable Hydrogen Production" Energies 11, no. 4: 809. https://doi.org/10.3390/en11040809

APA StyleSmoliński, A., Howaniec, N., & Bąk, A. (2018). Utilization of Energy Crops and Sewage Sludge in the Process of Co-Gasification for Sustainable Hydrogen Production. Energies, 11(4), 809. https://doi.org/10.3390/en11040809