Cogging Torque Reduction Based on a New Pre-Slot Technique for a Small Wind Generator

Abstract

1. Introduction

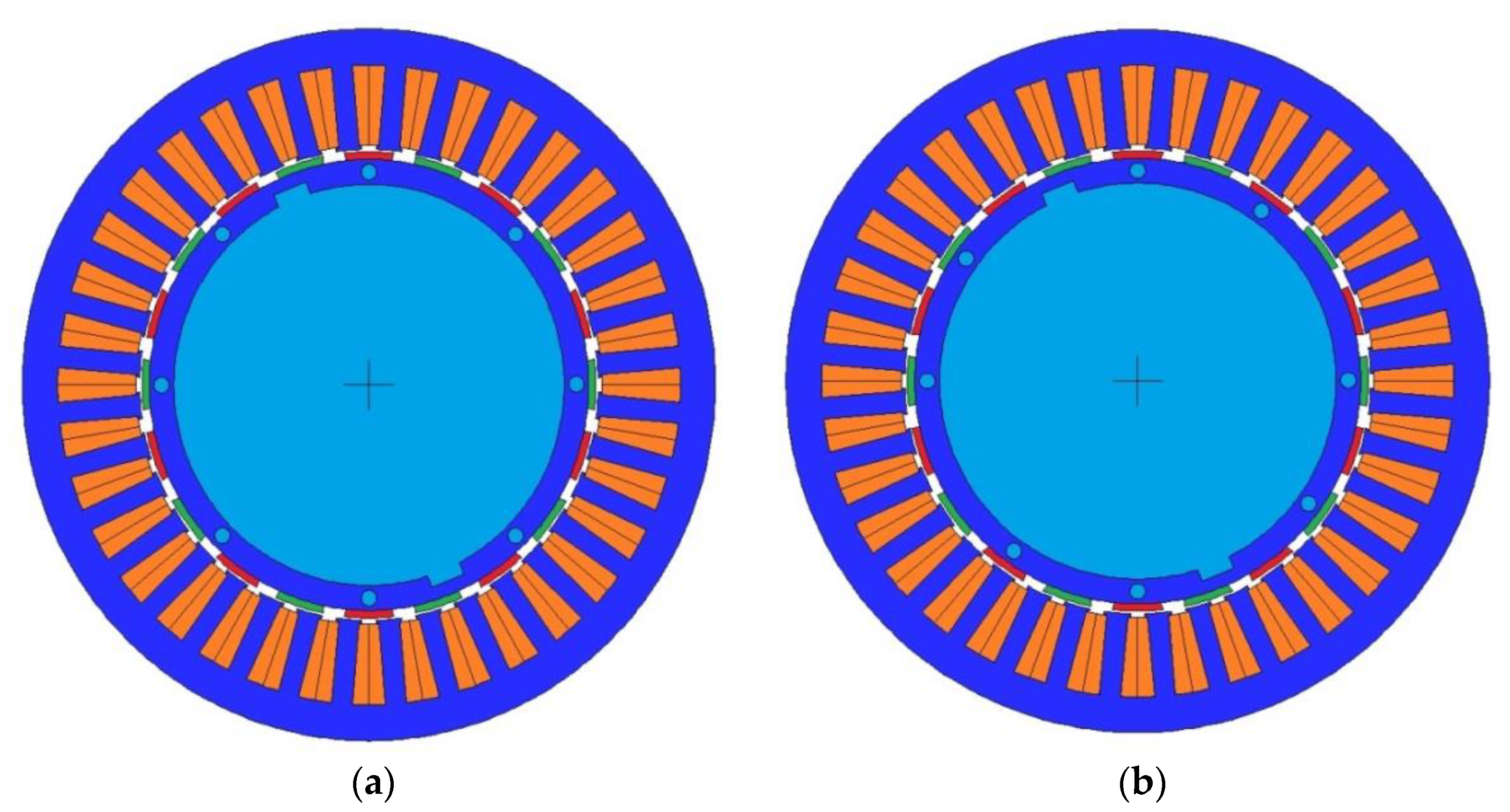

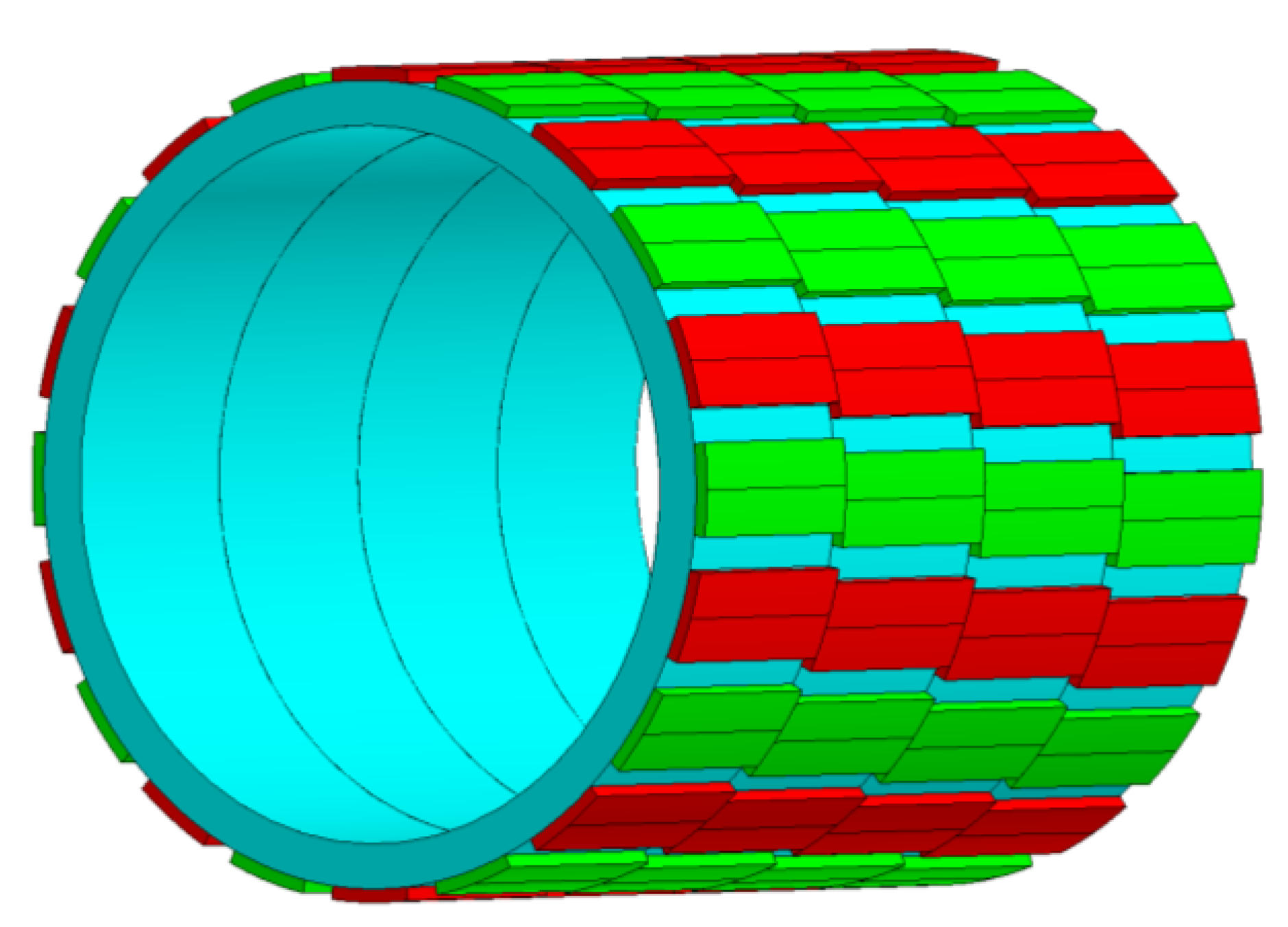

2. Machine Type and Main Parameters

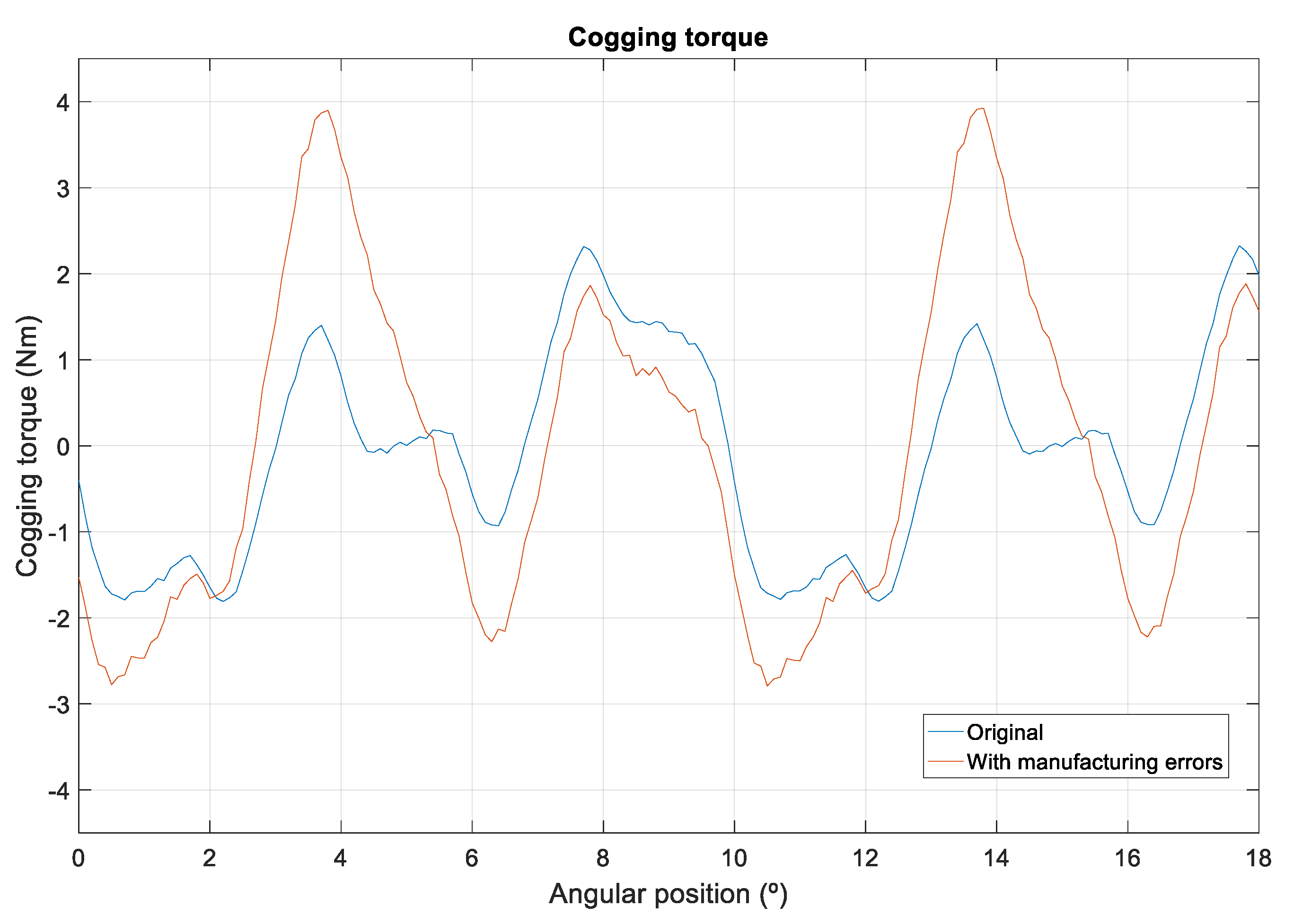

3. Cogging Torque

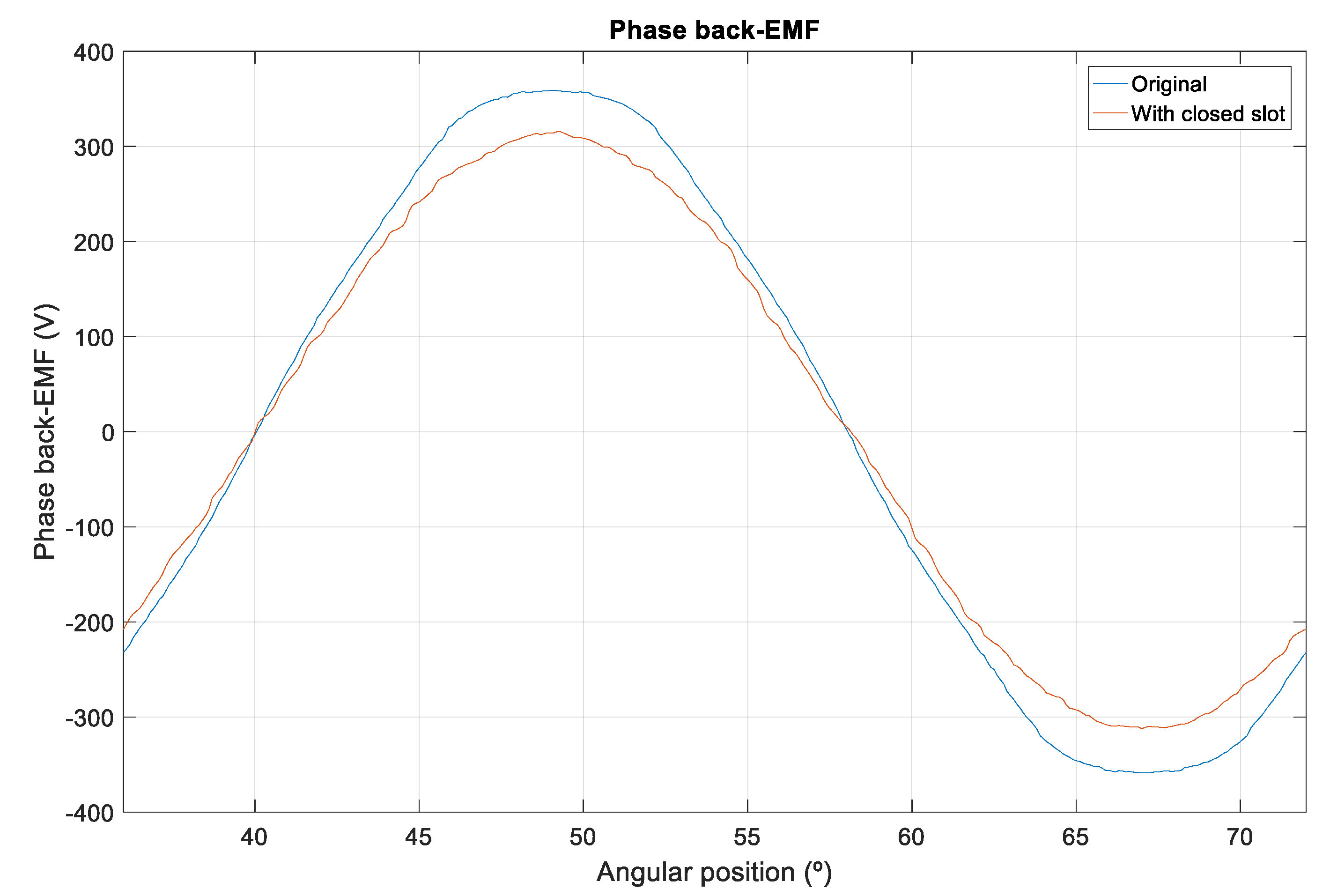

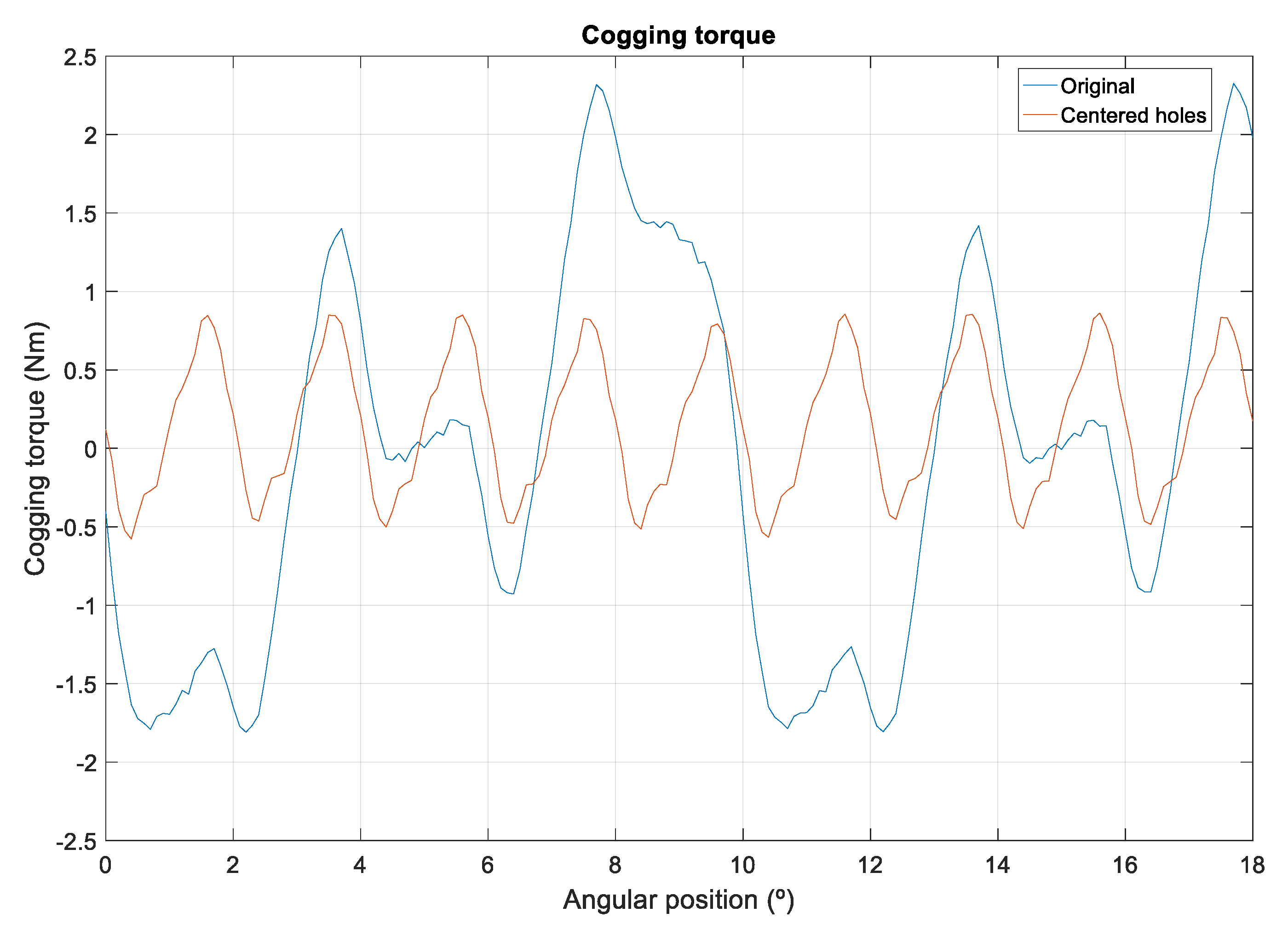

4. Cogging Torque Measurement

5. Cogging Torque Reduction Methods

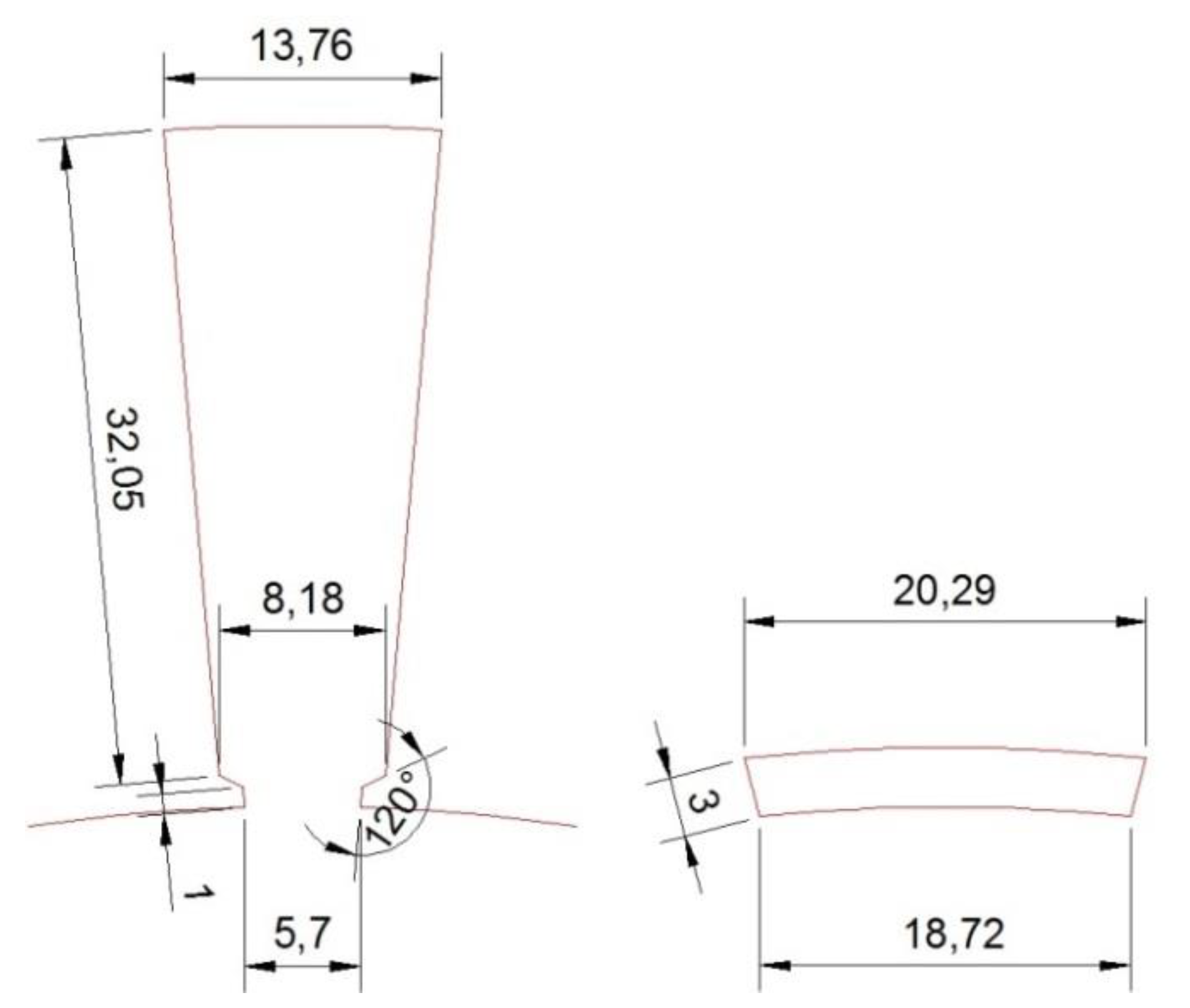

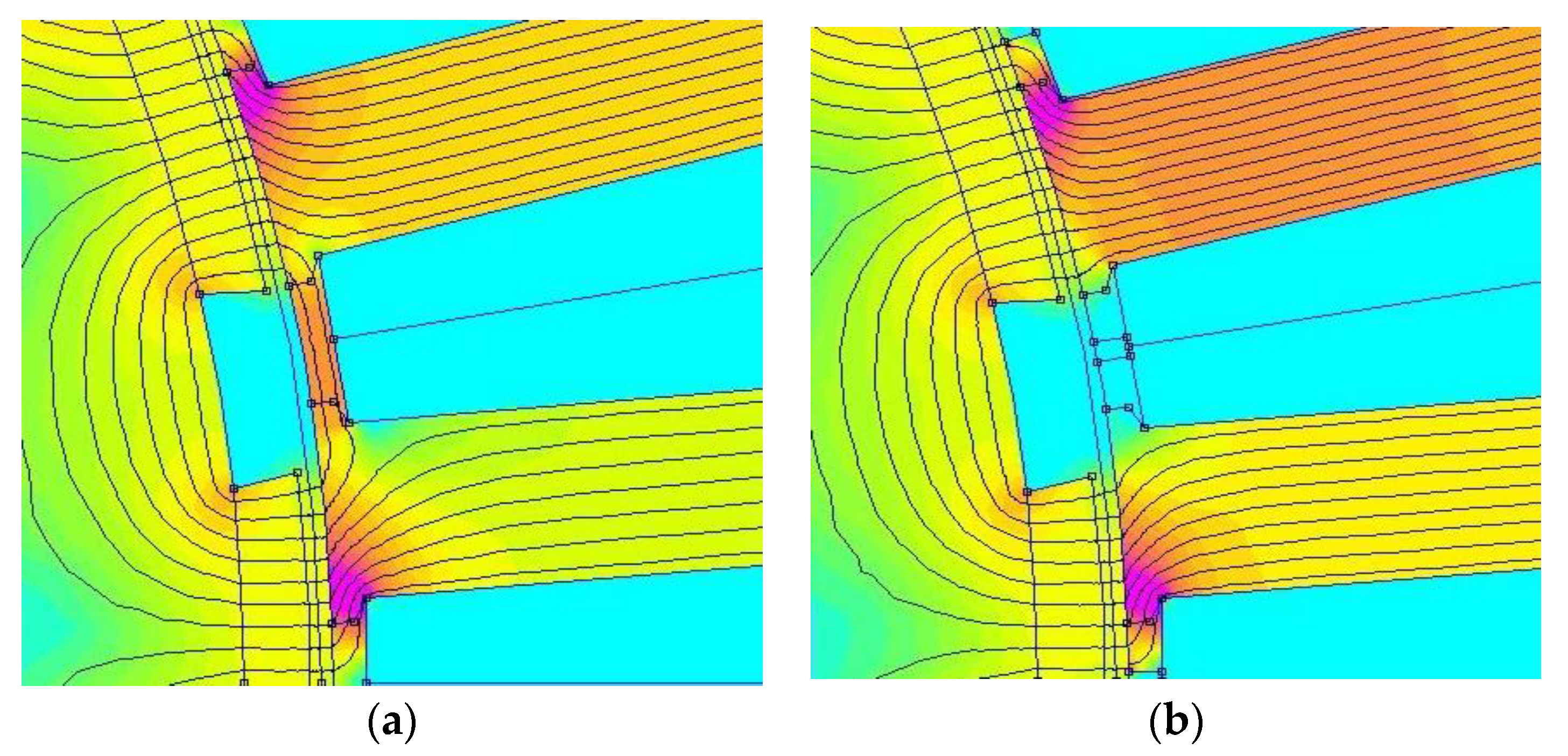

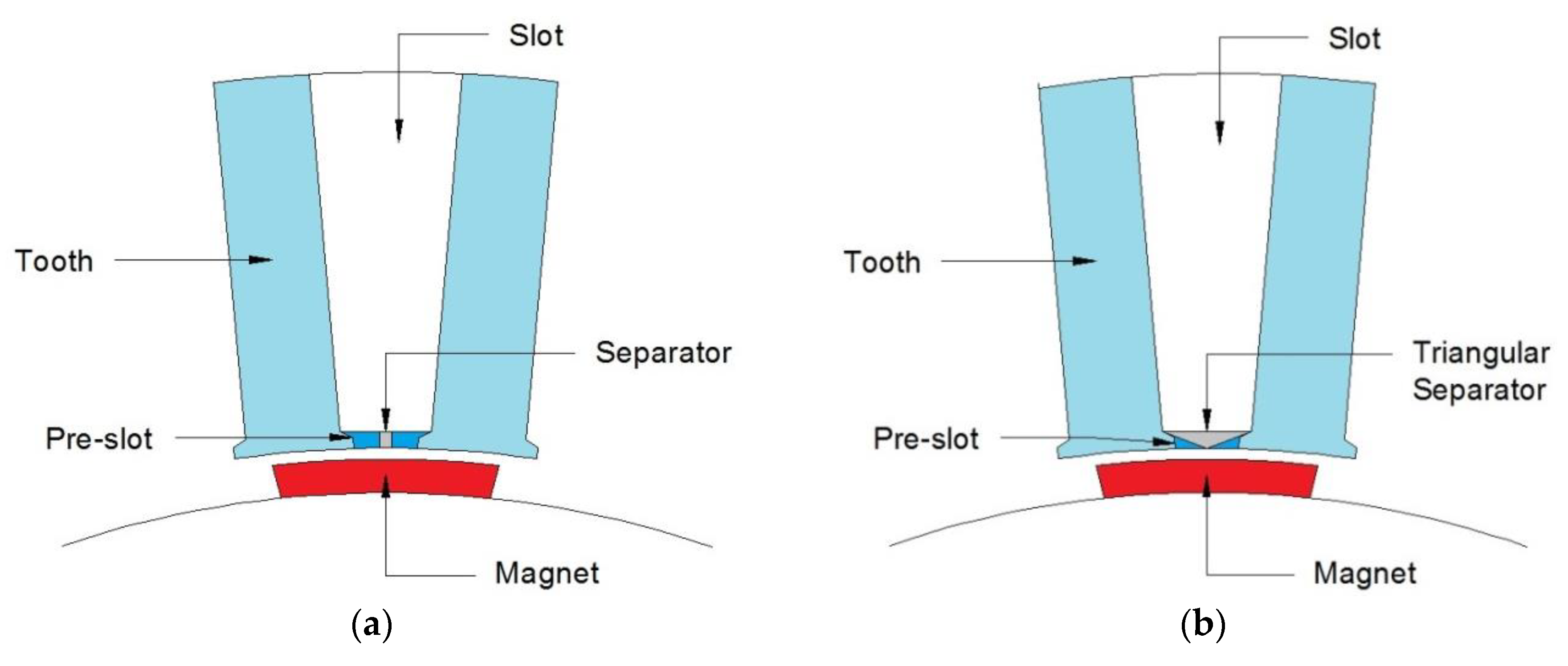

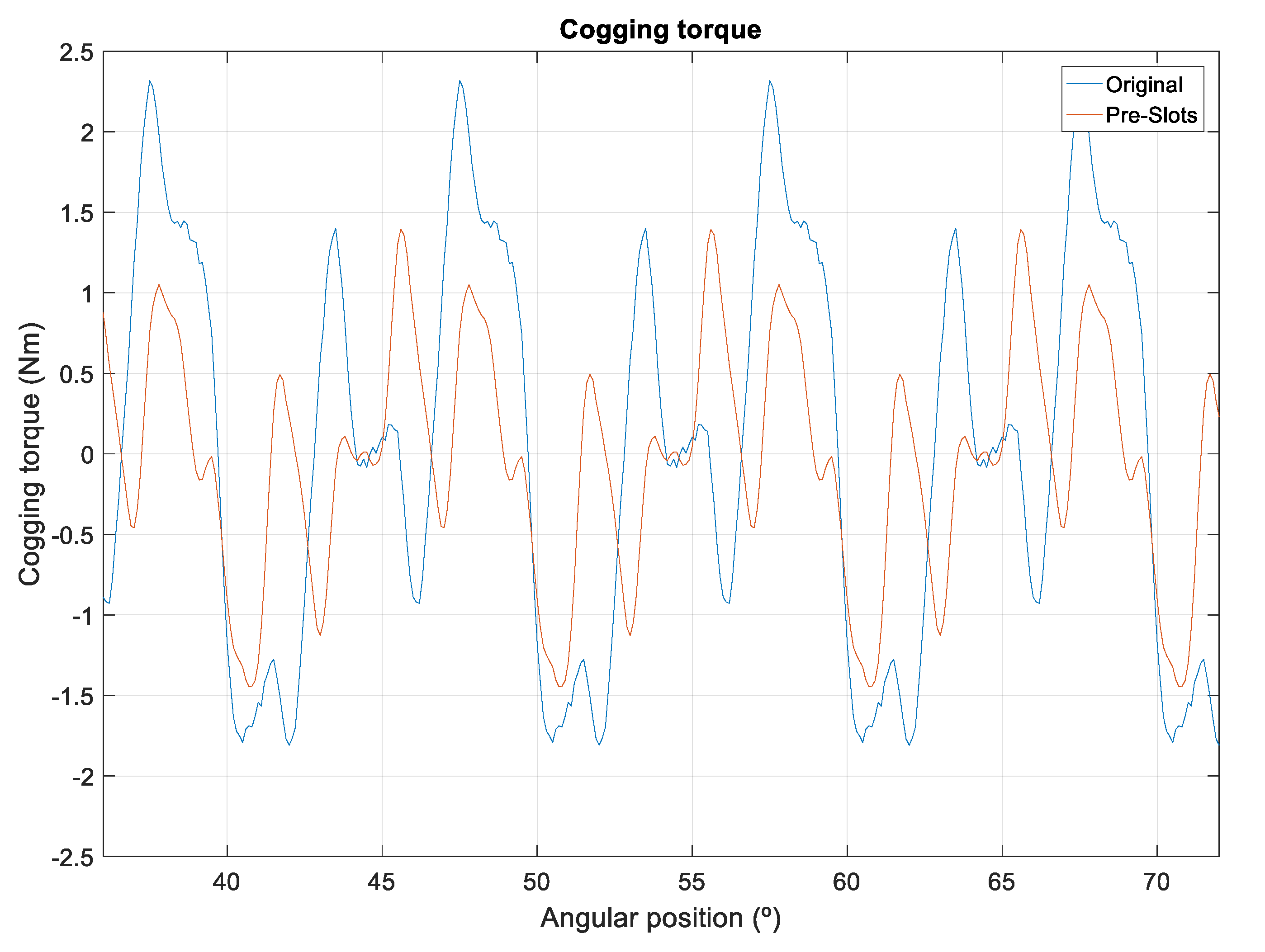

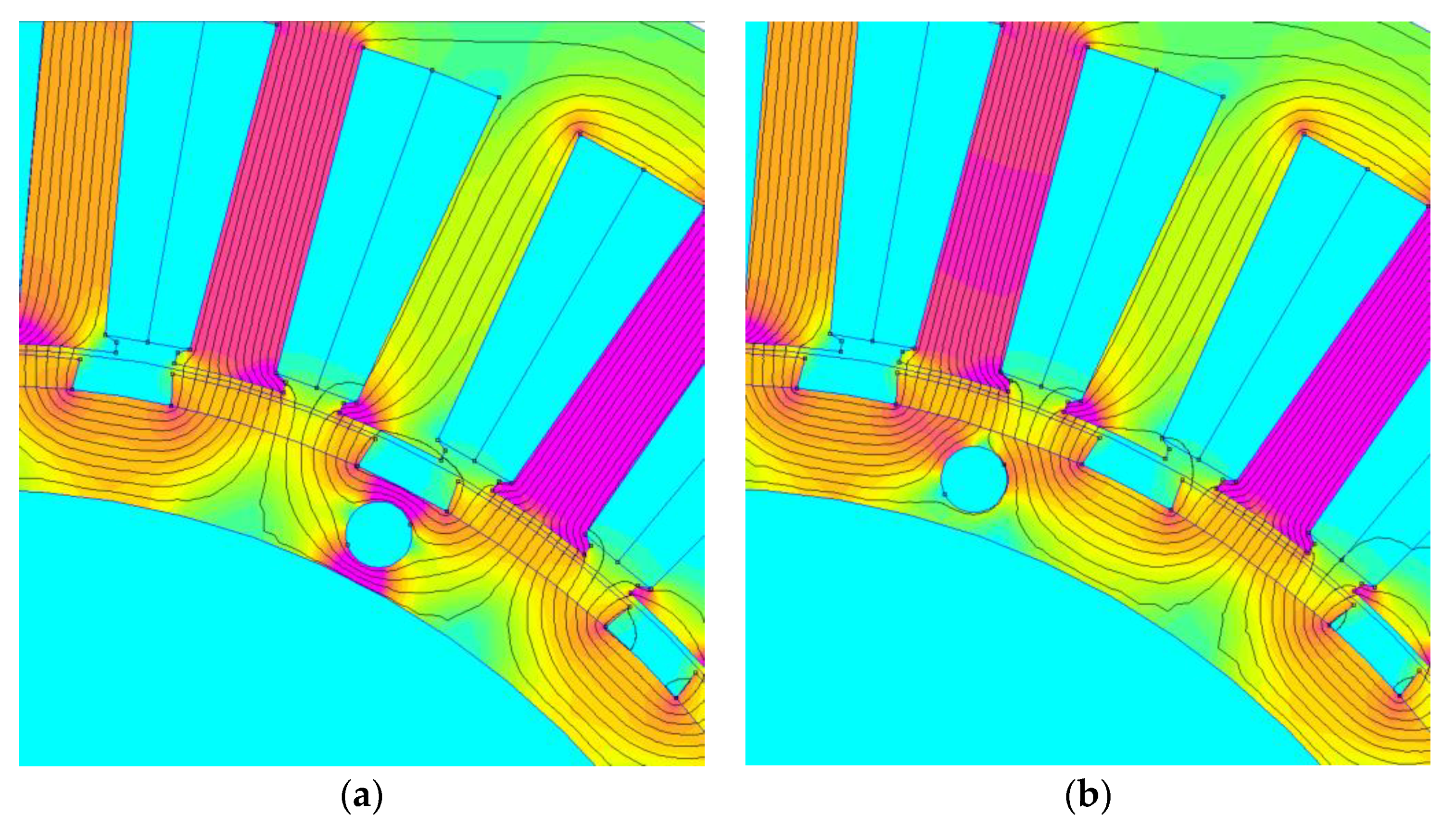

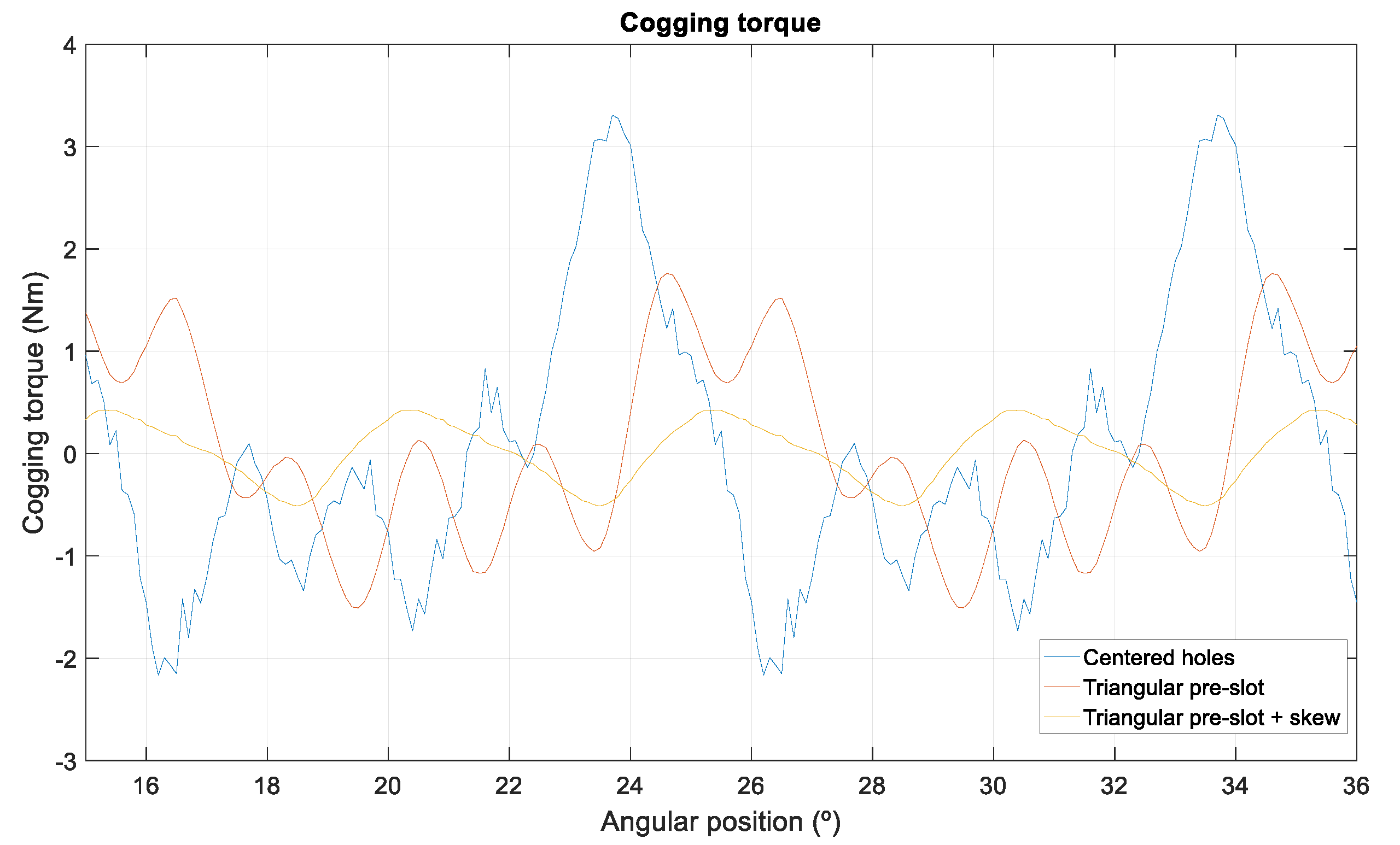

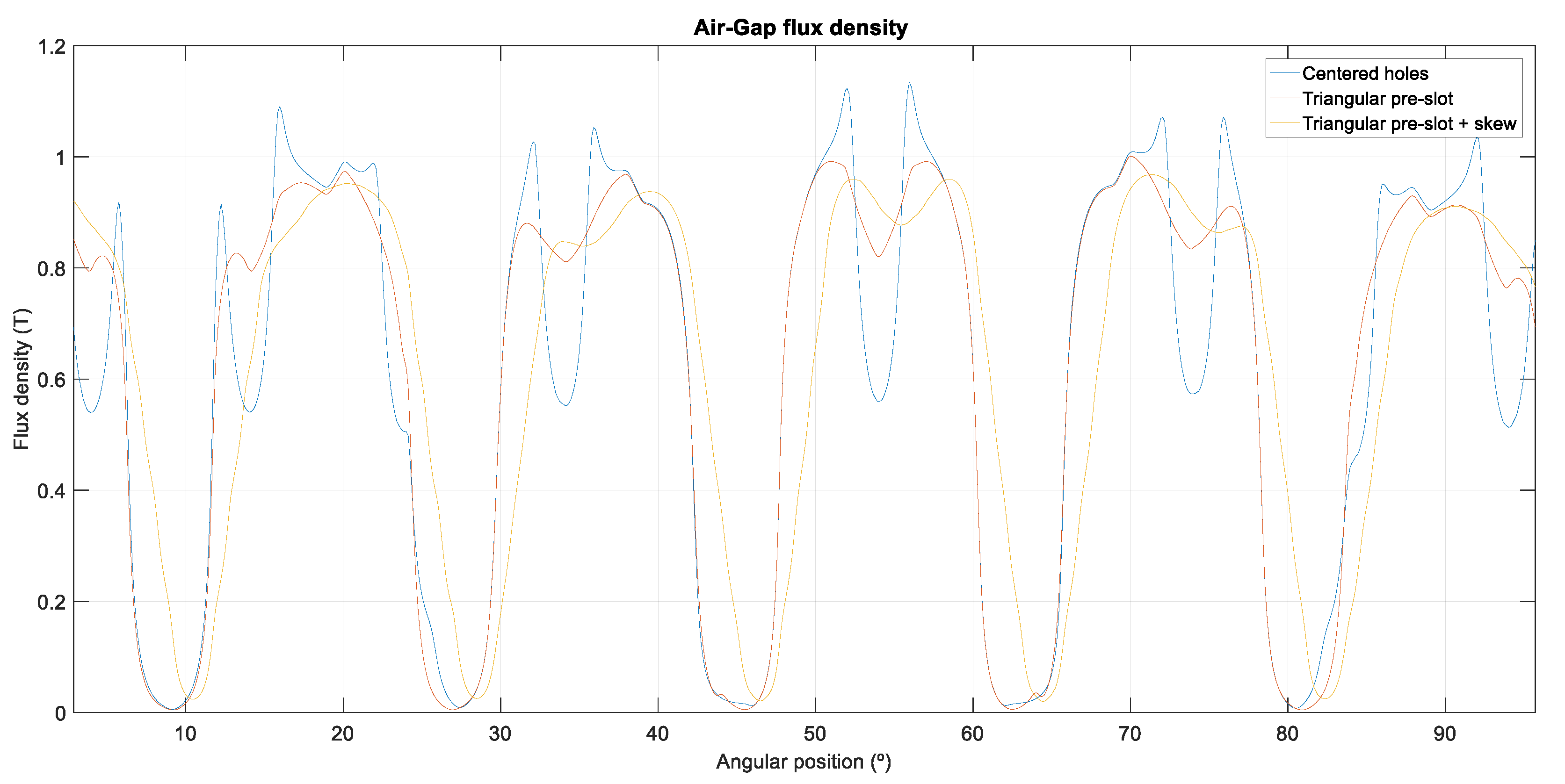

5.1. Pre-Slot Method

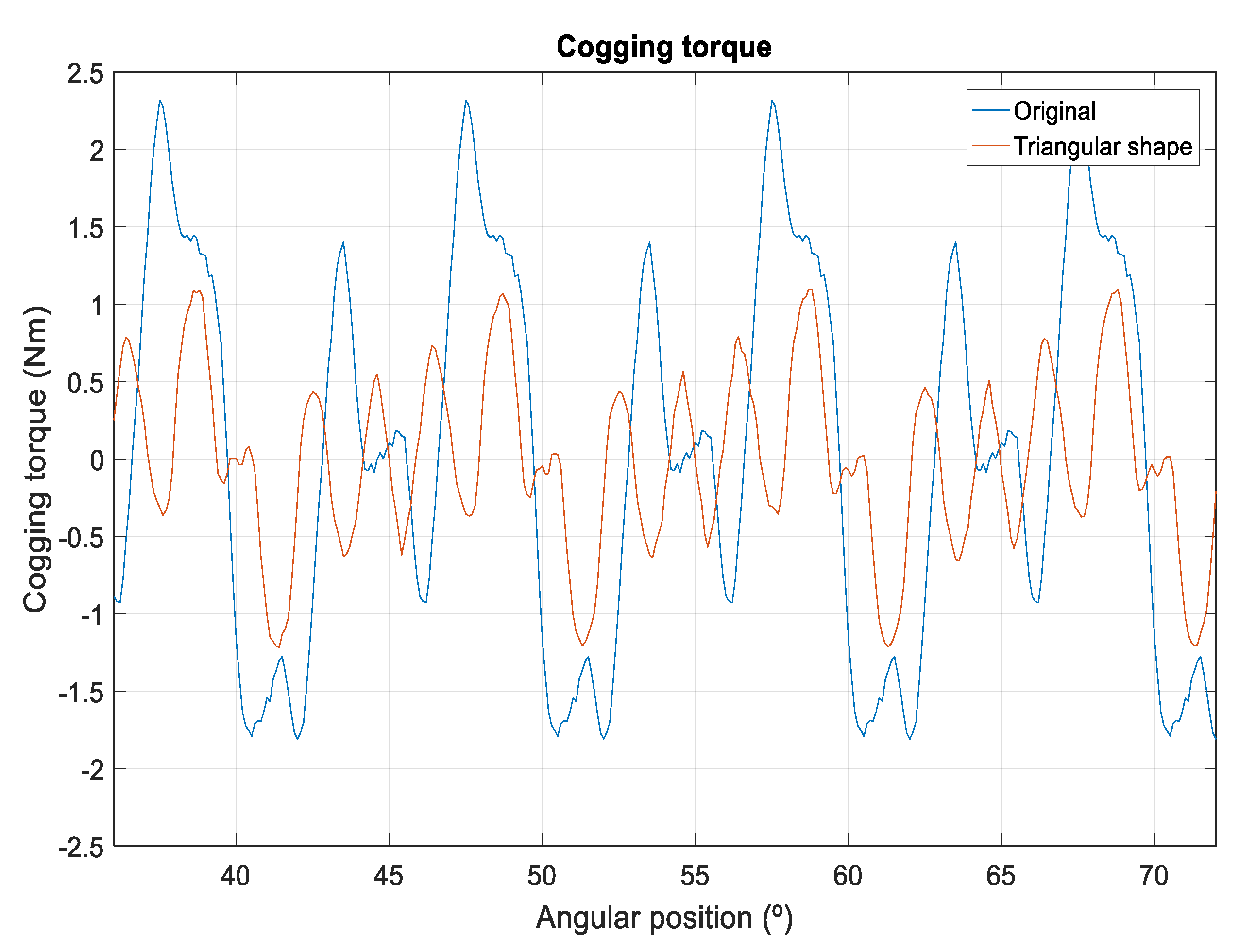

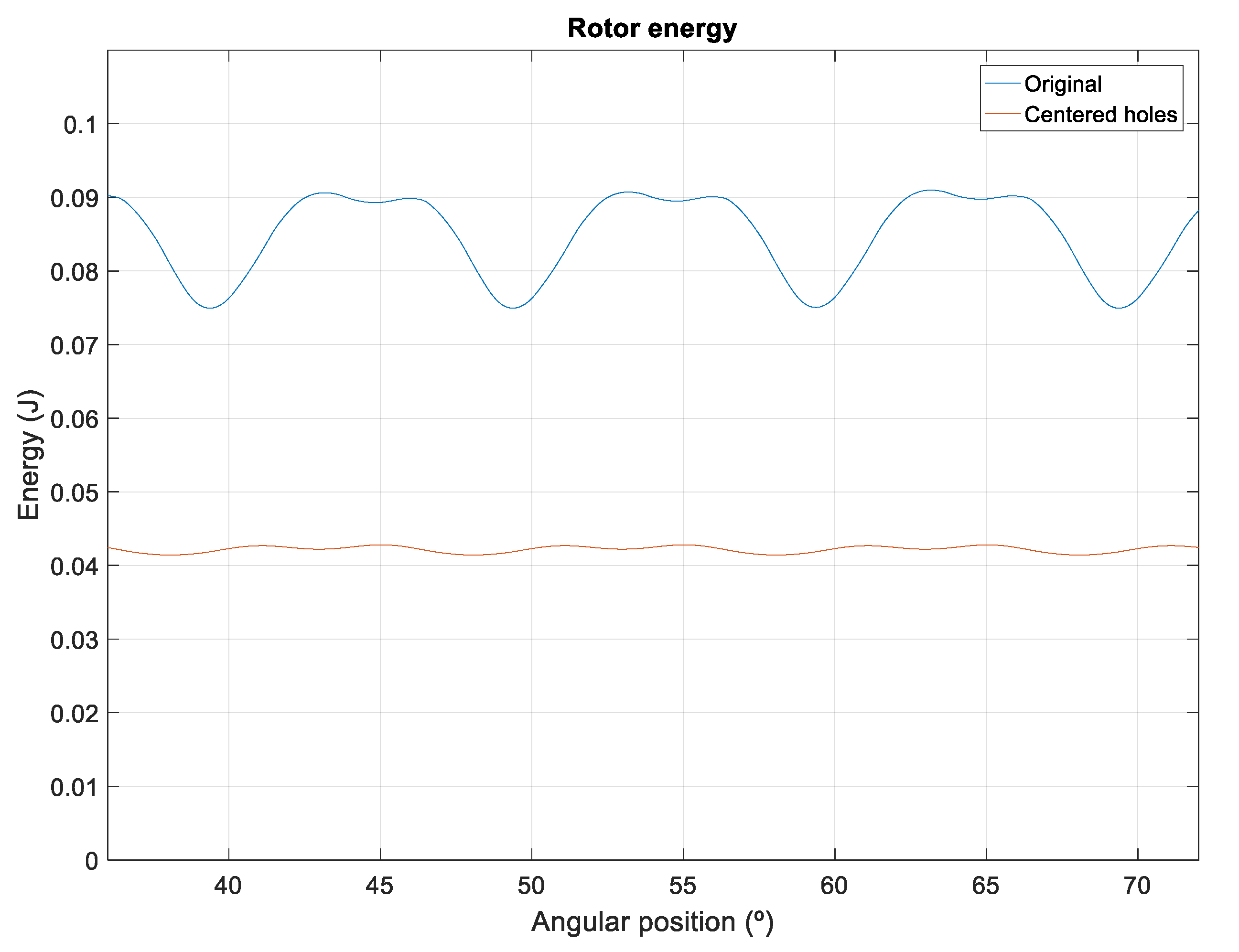

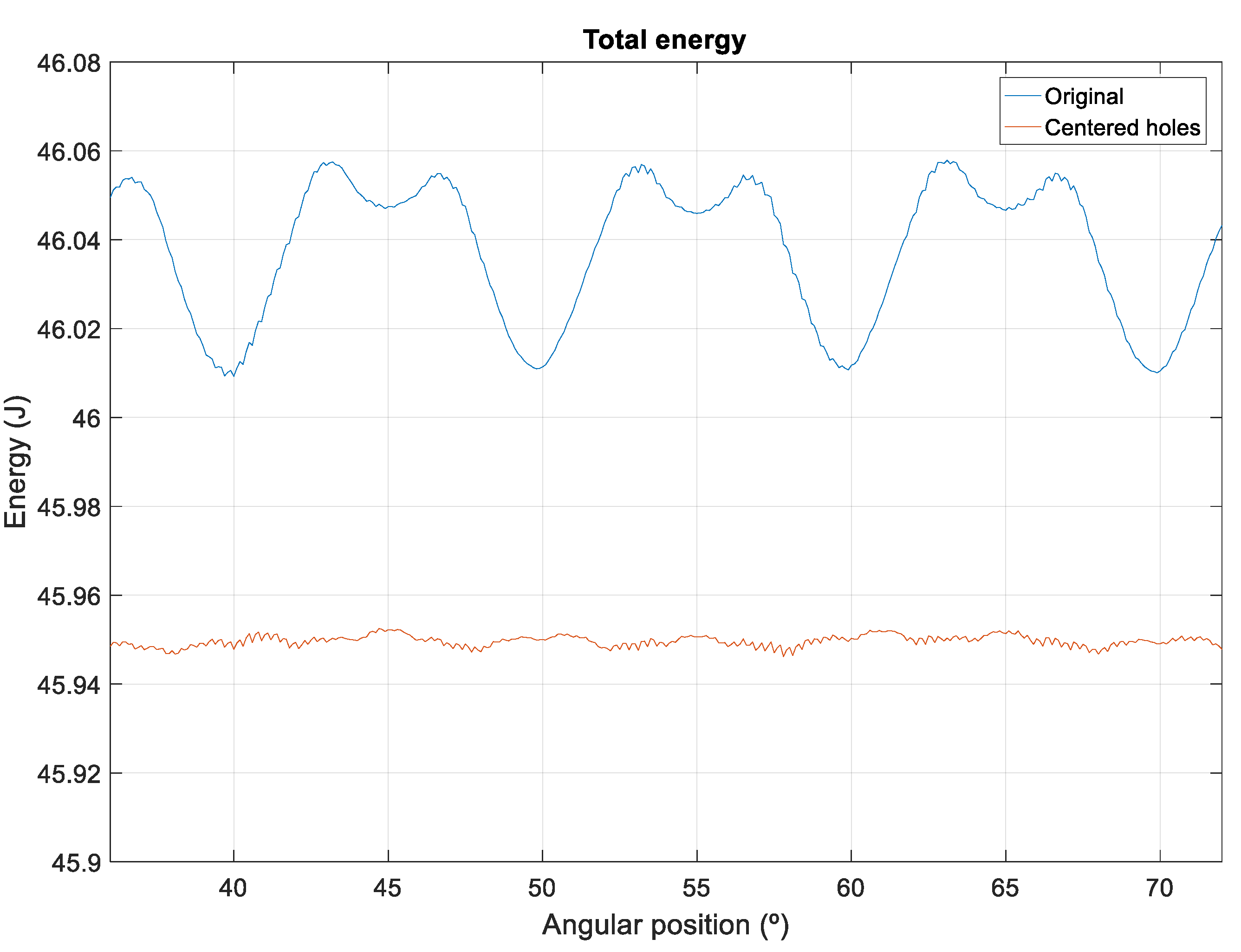

5.2. Manufacturing Aspects to Reduce the Cogging Torque

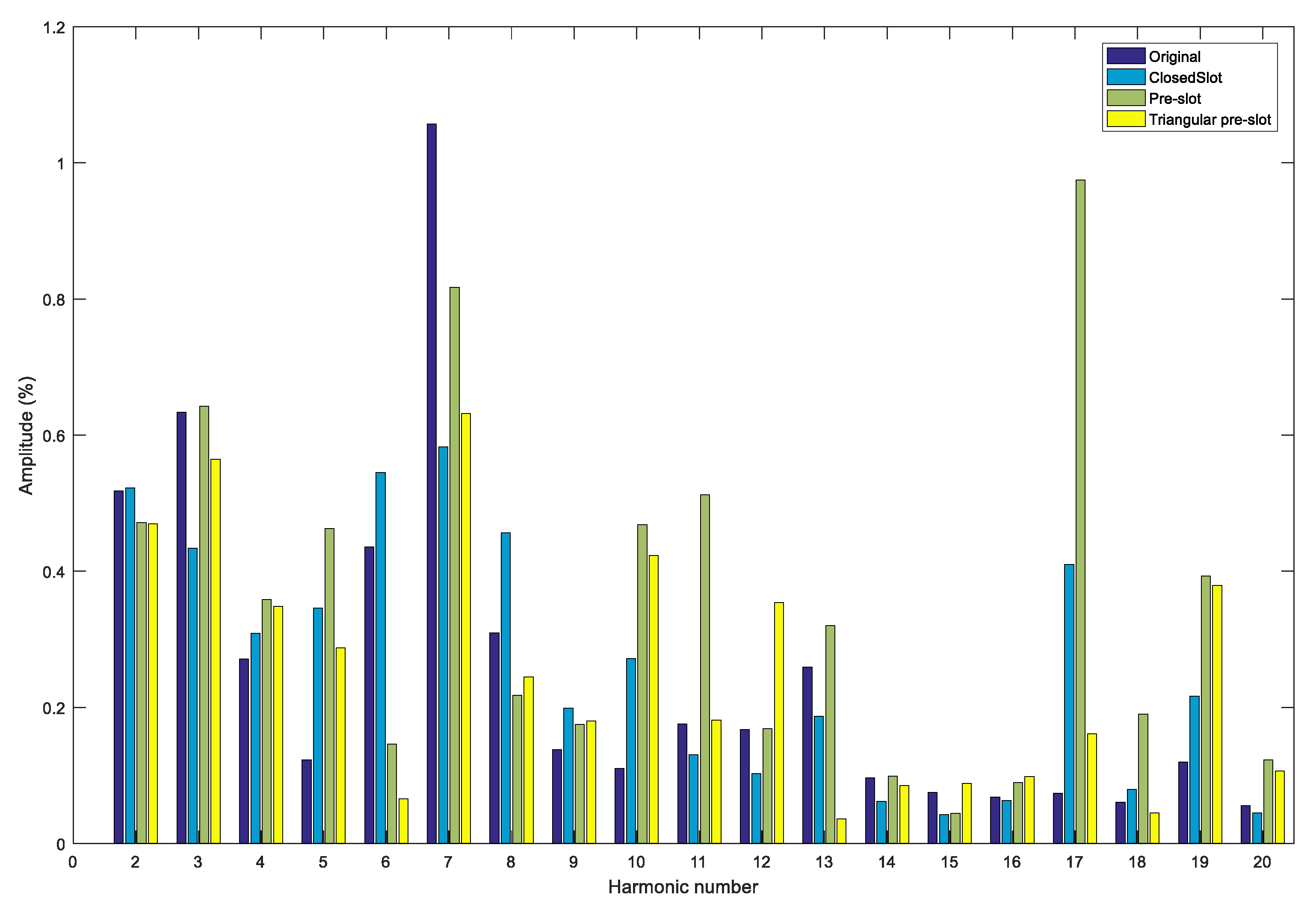

5.3. Comparative Results

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fei, W.; Zhu, Z.Q. Comparison of Cogging Torque Reduction in Permanent Magnet Brushless Machines by Conventional and Herringbone Skewing Techniques. IEEE Trans. Energy Convers. 2013, 28, 664–674. [Google Scholar] [CrossRef]

- Ose-zala, B.; Pugachov, V. Methods to Reduce Cogging Torque of Permanent Magnet Synchronous Generator Used in Wind Power Plants. Elektron. Elektrotechnika 2017, 23, 43–48. [Google Scholar] [CrossRef]

- Leijon, J.; Sjölund, J.; Ekergård, B.; Boström, C.; Eriksson, S.; Temiz, I.; Leijon, M. Study of an Altered Magnetic Circuit of a Permanent Magnet Linear Generator for Wave Power. Energies 2018, 11, 84. [Google Scholar] [CrossRef]

- Lejerskog, E.; Leijon, M. Detailed Study of Closed Stator Slots for a Direct-Driven Synchronous Permanent Magnet Linear Wave Energy Converter. Machines 2014, 2, 73–86. [Google Scholar] [CrossRef]

- Raihan, M.A.H.; Smith, K.J.; Almoraya, A.A.; Khan, F. Interior Permanent Magnet Synchronous Machine (IPMSM) design for environment friendly Hybrid Electric Vehicle (HEV) Applications. In Proceedings of the Humanitarian Technology Conference IEEE Region 10, Dhaka, Bangladesh, 21–23 December 2017. [Google Scholar]

- Öztürk, N.; Dalcali, A.; Çelik, E.; Sakar, S. Cogging Torque Reduction by Optimal Design of PM Synchronous Generator for Wind Turbines. Int. J. Hydrog. Energy 2017, 42, 17593–17600. [Google Scholar] [CrossRef]

- Ozoglu, Y. New Stator Tooth for Reducing Torque Ripple in Outer Rotor Permanent Magnet Machine. Adv. Electr. Comput. Eng. 2016, 16, 49–56. [Google Scholar] [CrossRef]

- Liu, C.; Lu, J.; Wang, Y.; Lei, G.; Zhu, J.; Guo, Y. Techniques for Reduction of the Cogging Torque in Claw Pole Machines with SMC Cores. Energies 2017, 10, 1541. [Google Scholar] [CrossRef]

- Ito, T.; Akatsu, K. Electromagnetic Force Acquisition Distributed in Electric Motor to Reduce Vibration. IEEE Trans. Ind. Appl. 2017, 53, 1001–1008. [Google Scholar] [CrossRef]

- Chen, Y.S.; Zhu, Z.Q.; Howe, D. Vibration of PM Brushless Machines Having a Fractional Number of Slots per Pole. IEEE Trans. Magn. 2006, 42, 3395–3397. [Google Scholar] [CrossRef]

- Min, S.G.; Bramerdorfer, G.; Sarlioglu, B. Analytical Modeling and Optimization for Electromagnetic Performances of Fractional-Slot PM Brushless Machines. IEEE Trans. Ind. Electron. 2017, 65, 4017–4027. [Google Scholar] [CrossRef]

- Tseng, W.; Chen, W. Design Parameters Optimization of a Permanent Magnet Synchronous Wind Generator. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016. [Google Scholar]

- Levin, N.; Orlova, S.; Pugachov, V.; Ose-Zala, B.; Jakobsons, E. Methods to Reduce the Cogging Torque in Permanent Magnet Synchronous Machines. Electron. Electr. Eng. 2013, 19, 23–26. [Google Scholar] [CrossRef]

- Ma, G.; Li, G.; Zhou, R.; Guo, X.; Ju, L.; Xie, F. Effect of Stator and Rotor Notches on Cogging Torque of Permanent Magnet Synchronous Motor. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sidney, Australia, 11–14 August 2017. [Google Scholar]

- Liu, T.; Huang, S.; Gao, J.; Lu, K. Cogging Torque Reduction by Slot-Opening Shift for Permanent Magnet Machines. IEEE Trans. Magn. 2013, 49, 4028–4031. [Google Scholar] [CrossRef]

- Dajaku, G.; Gerling, D. New Methods for Reducing the Cogging Torque and Torque Ripples of PMSM. In Proceedings of the 2014 4th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 September–1 October 2014. [Google Scholar]

- Hsiao, C.; Yeh, S.; Hwang, J. A novel cogging torque simulation method for permanent-magnet synchronous machines. Energies 2011, 4, 2166–2179. [Google Scholar] [CrossRef]

- Imamori, S.; Ohguchi, H.; Shuto, M.; Toba, A. Relation between Magnetic Properties of Stator Core and Cogging Torque in 8-Pole 12-Slot SPM Synchronous Motors. IEEJ J. Ind. Appl. 2015, 4, 696–702. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, Z.Q.; Chu, W.Q. Iron Loss in Surface-Mounted PM Machines Considering Tooth-Tip Local Magnetic Saturation. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2011. [Google Scholar]

- Wu, D.; Zhu, Z.Q. On-Load Voltage Distortion in Fractional Slot Surface-Mounted Permanent Magnet Machines Considering Local Magnetic Saturation. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Li, Y.X.; Li, G.J. Influence of Stator Topologies on Average Torque and Torque Ripple of Fractional-Slot SPM Machines with Fully Closed Slots. IEEE Trans. Ind. Appl. 2018, 54, 2151–2164. [Google Scholar] [CrossRef]

- De Donato, G.; Capponi, F.G.; Caricchi, F. On the Use of Magnetic Wedges in Axial Flux Permanent Magnet Machines. IEEE Trans. Ind. Electron. 2013, 11, 4831–4840. [Google Scholar] [CrossRef]

- Todorov, G.; Stoev, B.; Savov, G.; Kyuchukov, P. Effects of Cogging Torque Reduction Techniques Applied to Surface Mounted PMSMs with Distributed Windings. In Proceedings of the 2017 15th International Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–3 June 2017. [Google Scholar]

- Galfarsoro, U.; Parra, J.; McCloskey, A.; Zarate, S.; Hernández, X. Analysis of Vibration Induced by Cogging Torque in Permanent-Magnet Synchronous Motors. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and Their Application to Mechatronics (ECMSM), Donostia-San Sebastian, Spain, 24–26 May 2017. [Google Scholar]

| Parameter | Value |

|---|---|

| Phase | 3 |

| Pole number | 20 |

| Slot number | 36 |

| Rated speed | 232 rpm |

| Rated power | 6300 W |

| Rated voltage | 256.4 V |

| Rated torque | 102 Nm |

| Air gap | 1 mm |

| Thickness of PM | 3 mm |

| Rotor diameter | 180 mm |

| Material of steel | M330-50A |

| Material of PM | NdFeB |

| Model | THD (%) |

|---|---|

| Original design | 1.54 |

| Design with closed slot | 1.39 |

| Design with pre-slot | 1.88 |

| Design with triangular pre-slot | 1.33 |

| Model | Without Manufacturing Errors | Considering Manufacturing Errors | ||

|---|---|---|---|---|

| Nm | Reduction (%) | Nm | Reduction (%) | |

| Original Design (without Centered Holes) | ||||

| Prototype | 3.70 | - | - | - |

| Original design | 2.32 | - | 3.92 | - |

| Pre-slot with separation | 1.44 | 37.9 | 2.03 | 48.2 |

| Triangular pre-slot | 1.21 | 47.8 | 1.90 | 51.5 |

| Design with all Holes Centered | ||||

| Original design | 0.86 | - | 3.31 | - |

| Pre-slot with separation | 0.61 | 29.1 | 1.80 | 45.6 |

| Triangular pre-slot | 0.59 | 31.4 | 1.76 | 46.8 |

| Model | Without Manufacturing Errors | Considering Manufacturing Errors | ||

|---|---|---|---|---|

| Nm | Reduction (%) | Nm | Reduction (%) | |

| Design with centered holes | 0.86 | - | 3.31 | - |

| Design with centered holes + Triangular pre-slot | 0.59 | 31.4 | 1.76 | 46.8 |

| Design with centered holes + Skewing | 0.31 | 64.0 | 1.34 | 59.5 |

| Design with centered holes + Triangular pre-slot + Skewing | 0.03 | 96.5 | 0.51 | 84.6 |

| Model | EMF (V) (p.u.) | Cogging Torque (Nm) | |

|---|---|---|---|

| Design with centered holes | 241.52 | 1.000 | 3.31 |

| Design with centered holes + Skewing | 229.47 | 0.950 | 1.34 |

| Design with centered holes + Triangular pre-slot | 247.73 | 1.026 | 1.76 |

| Design with centered holes + Triangular pre-slot + Skewing | 233.04 | 0.965 | 0.51 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Gracia, M.; Jiménez Romero, Á.; Herrero Ciudad, J.; Martín Arroyo, S. Cogging Torque Reduction Based on a New Pre-Slot Technique for a Small Wind Generator. Energies 2018, 11, 3219. https://doi.org/10.3390/en11113219

García-Gracia M, Jiménez Romero Á, Herrero Ciudad J, Martín Arroyo S. Cogging Torque Reduction Based on a New Pre-Slot Technique for a Small Wind Generator. Energies. 2018; 11(11):3219. https://doi.org/10.3390/en11113219

Chicago/Turabian StyleGarcía-Gracia, Miguel, Ángel Jiménez Romero, Jorge Herrero Ciudad, and Susana Martín Arroyo. 2018. "Cogging Torque Reduction Based on a New Pre-Slot Technique for a Small Wind Generator" Energies 11, no. 11: 3219. https://doi.org/10.3390/en11113219

APA StyleGarcía-Gracia, M., Jiménez Romero, Á., Herrero Ciudad, J., & Martín Arroyo, S. (2018). Cogging Torque Reduction Based on a New Pre-Slot Technique for a Small Wind Generator. Energies, 11(11), 3219. https://doi.org/10.3390/en11113219