Poly(imide-co-siloxane) as a Thermo-Stable Binder for a Thin Layer Cathode of Thermal Batteries

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Preparation of Polyimide

2.3. In Situ PIS Gel Formation and Preparation of FeS2/PIS Cathode Composites

2.4. Thermal Battery Cell Fabrication and Discharge Measurements

2.5. Electrical Conductivity Measurement

2.6. Electrical Properties of the FeS2/PIS Cathode Layer

3. Results and Discussion

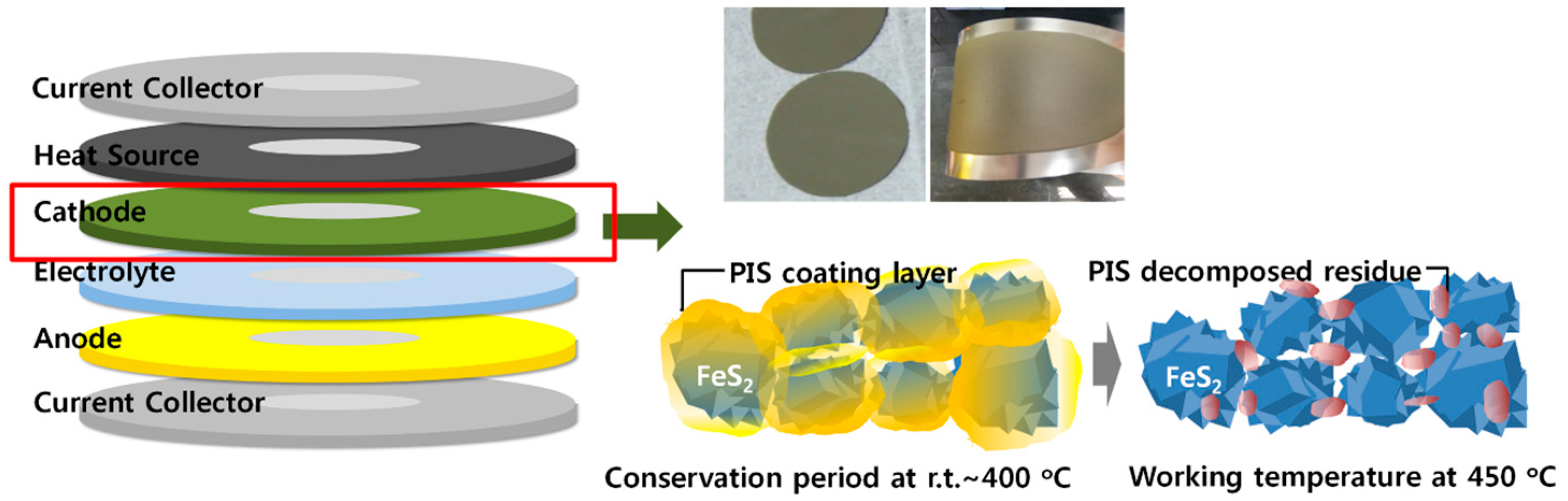

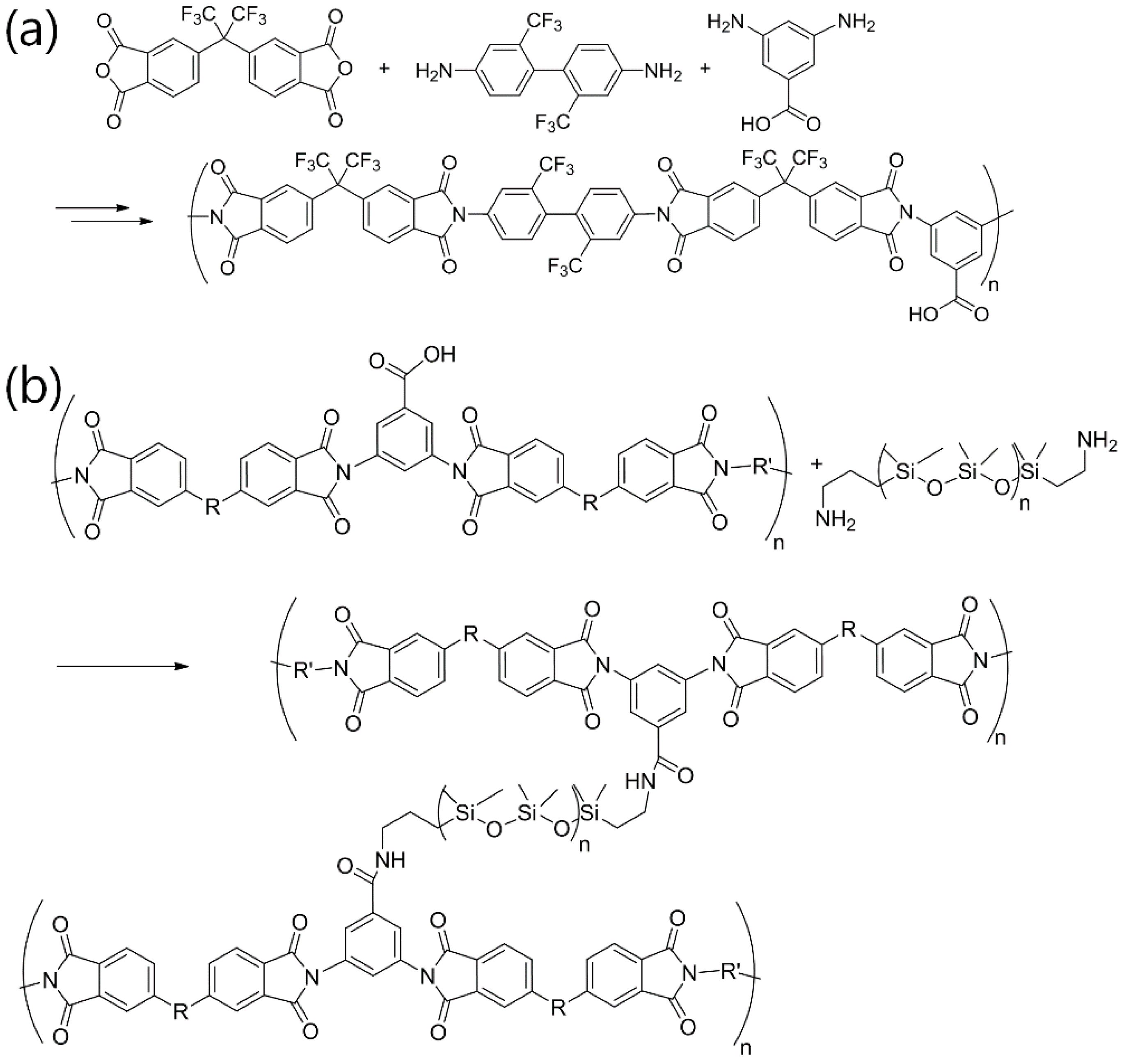

3.1. Synthesis of Polyimide and the Formation of Cross-Linked PIS

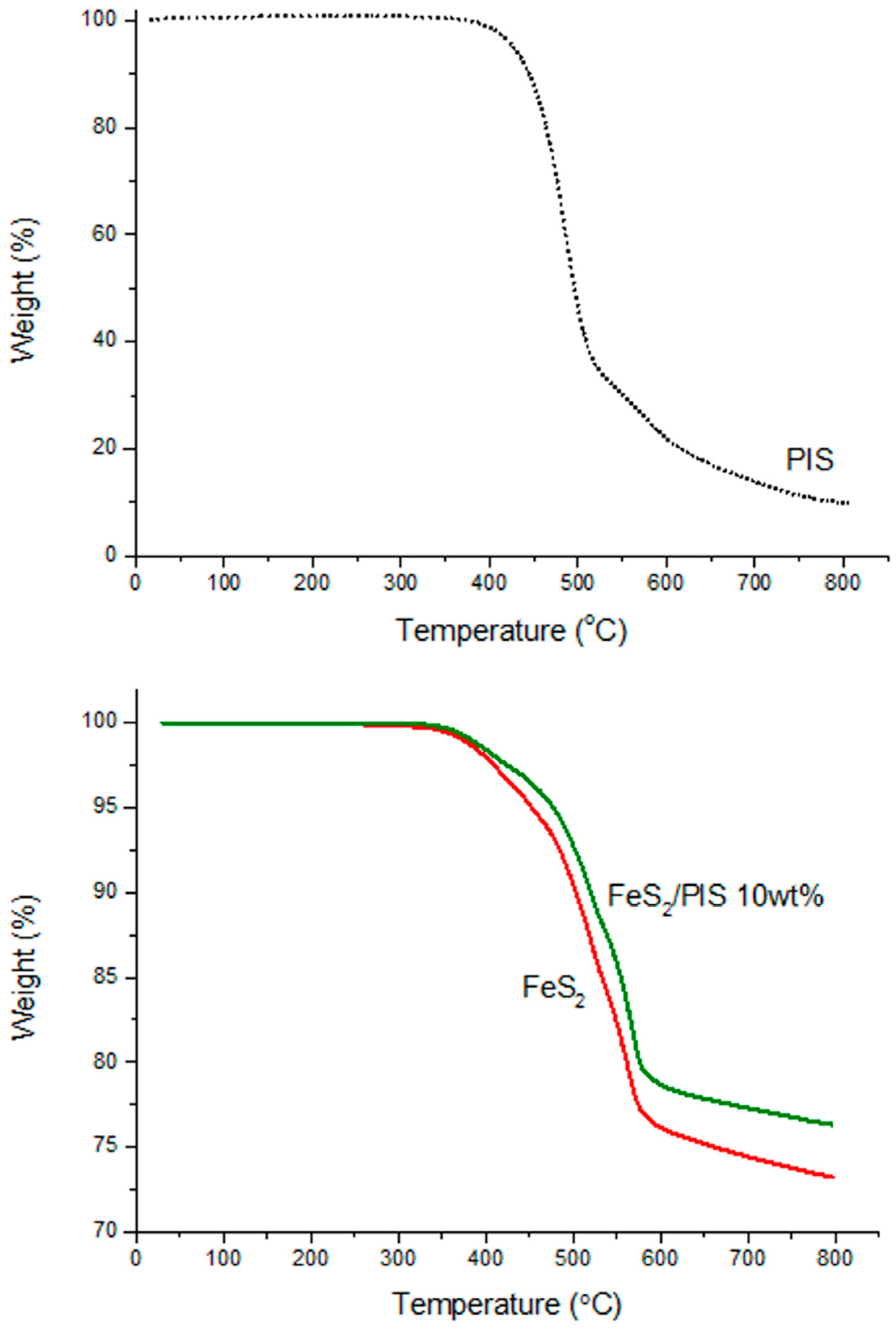

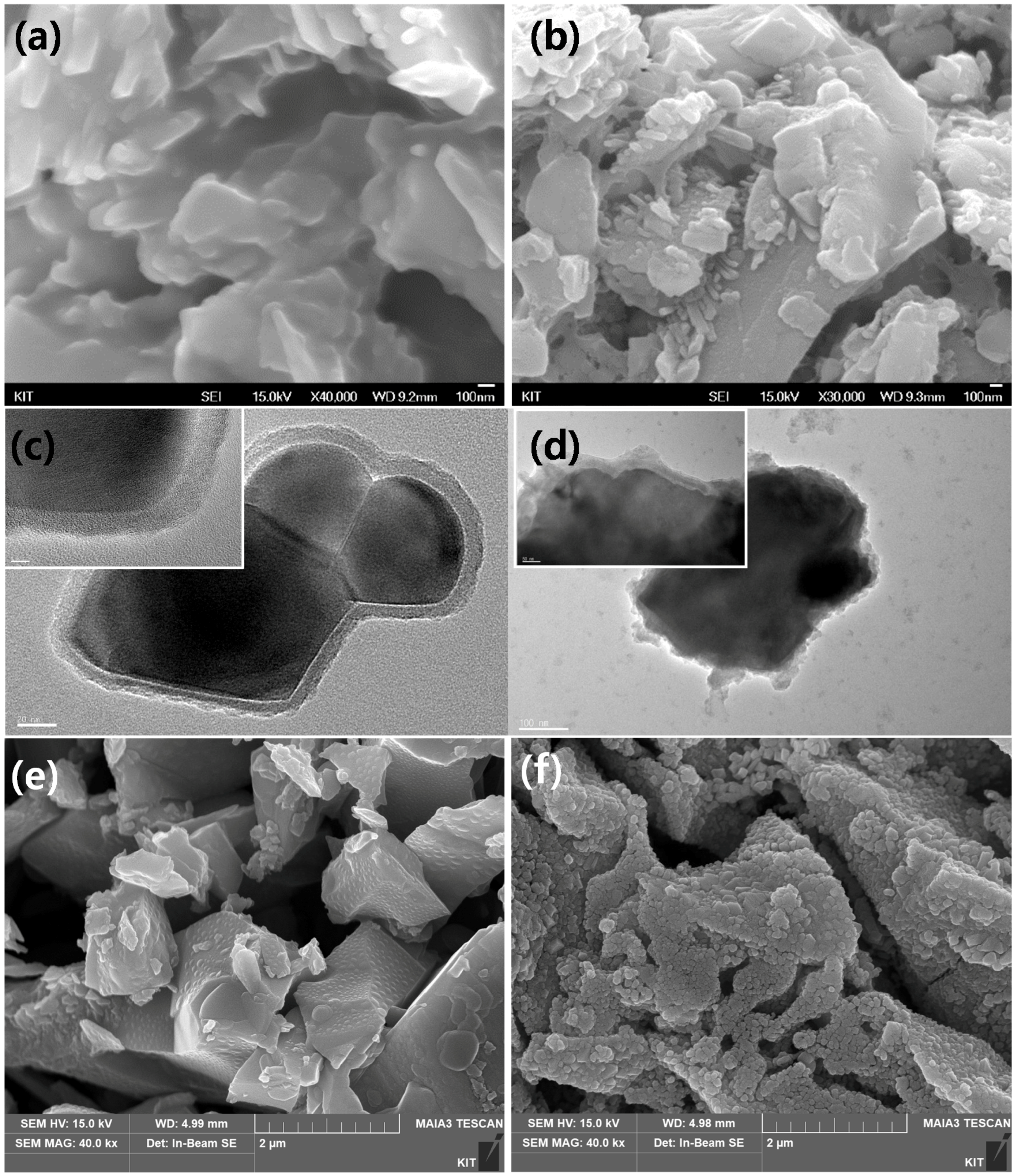

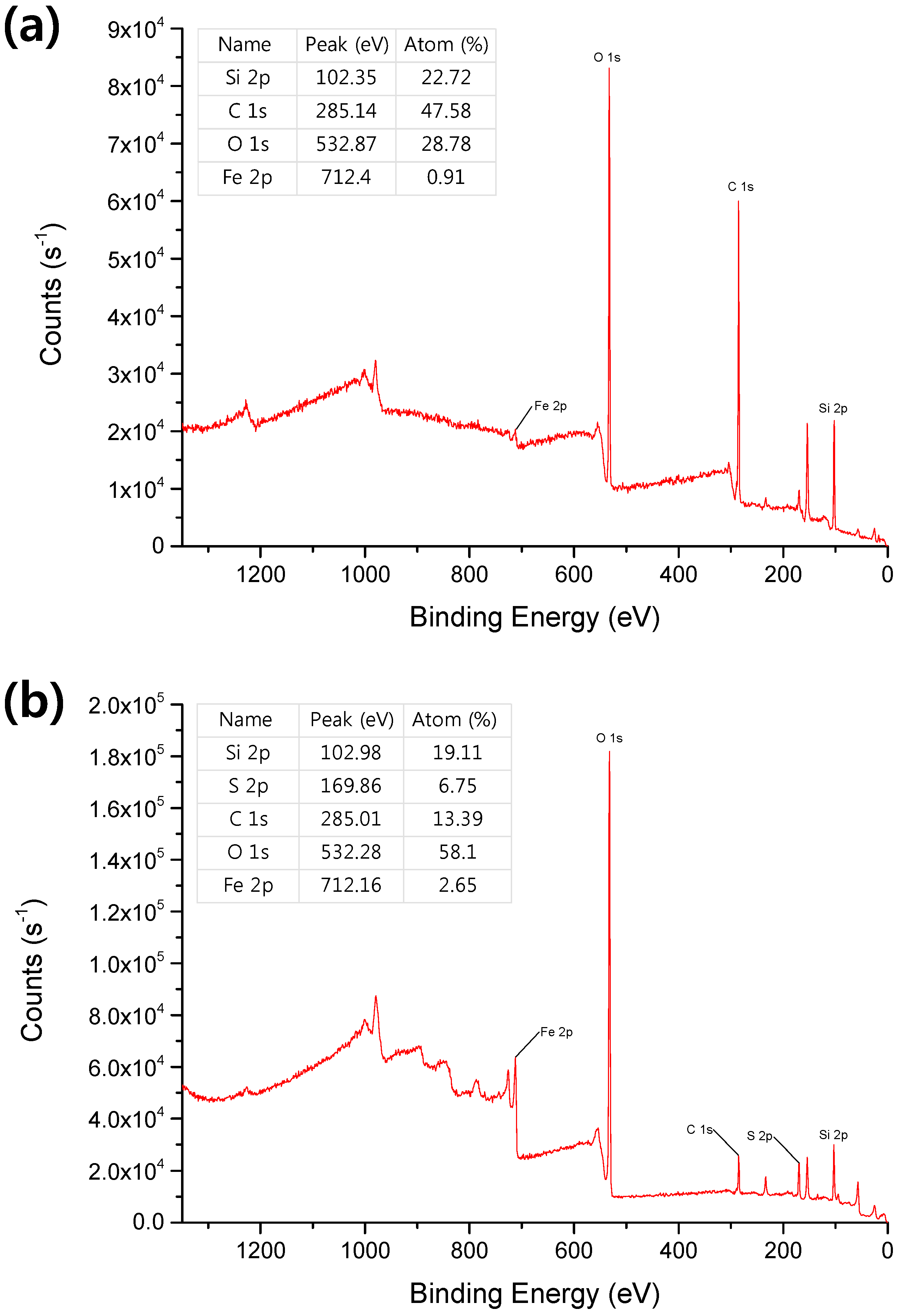

3.2. Formation of the Cathode Thin Layer and Its Thermal Properties

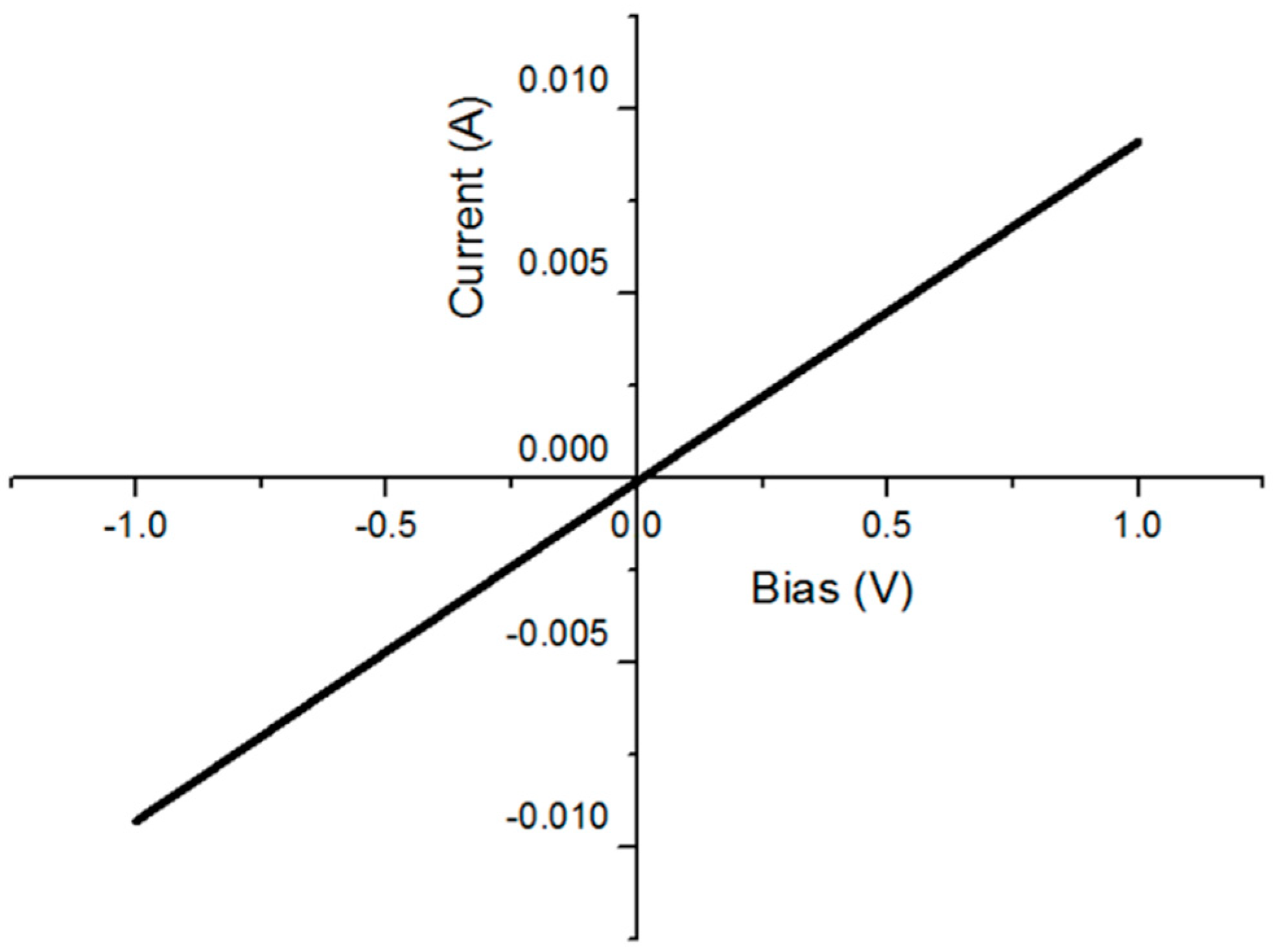

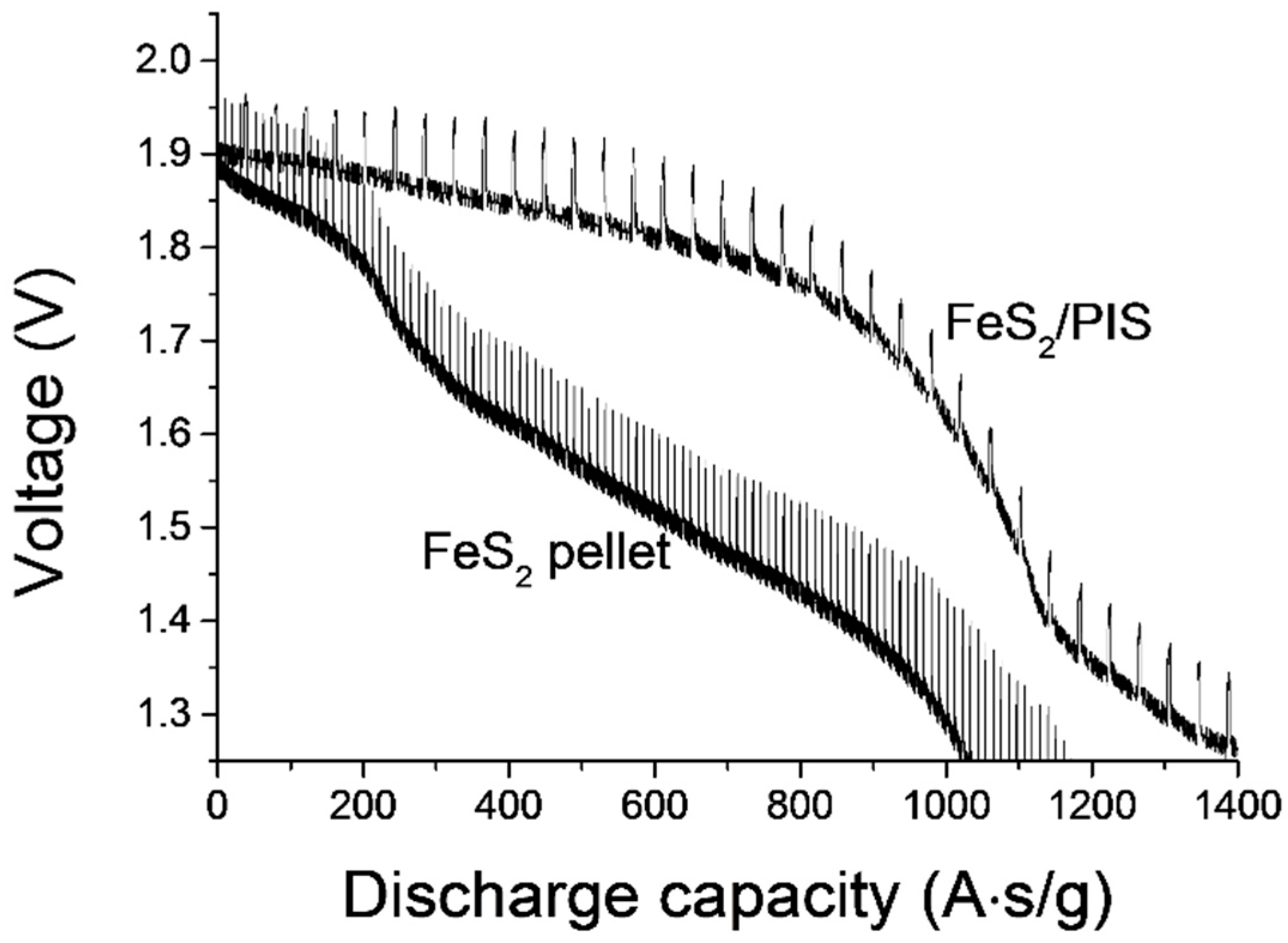

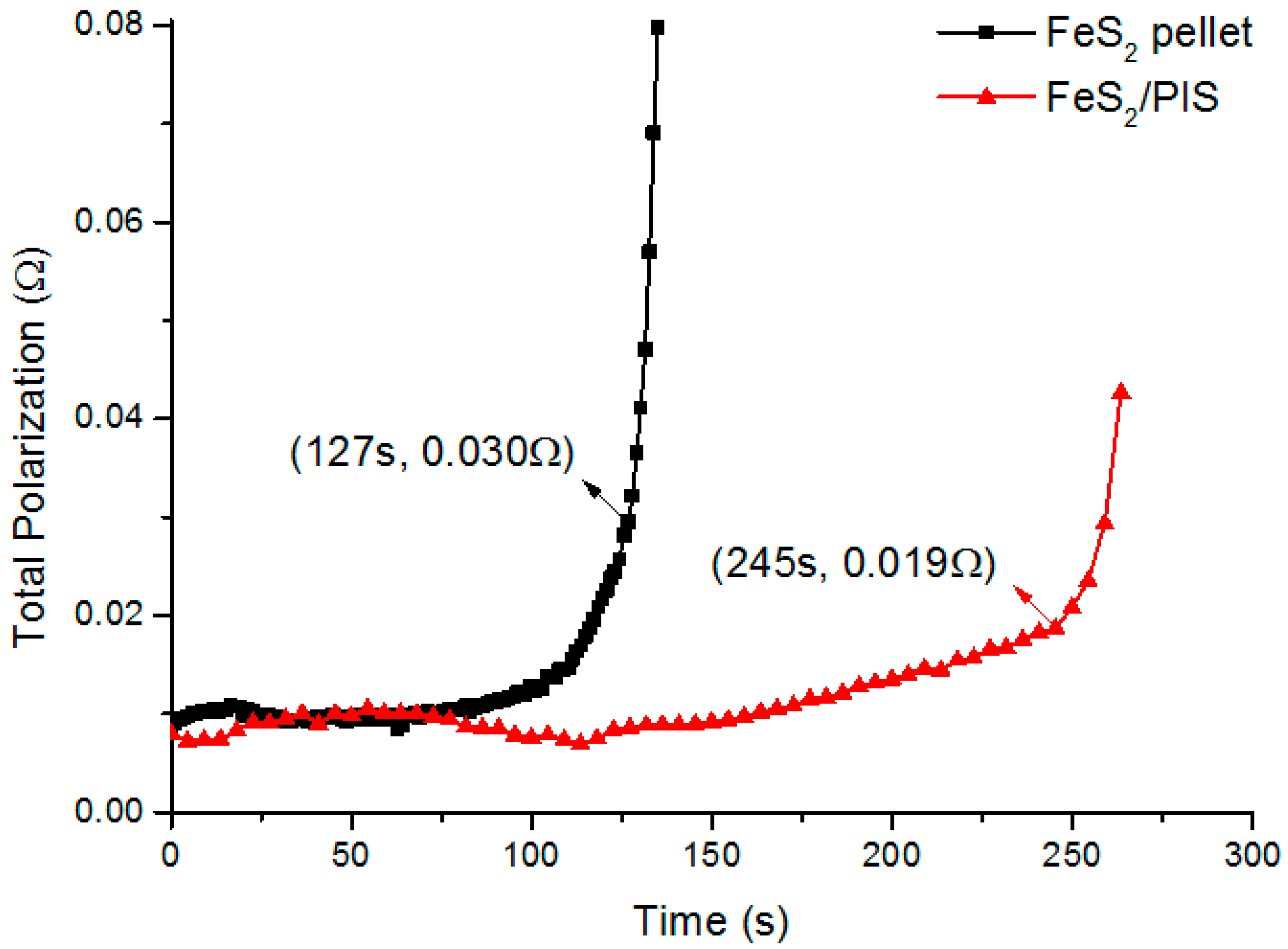

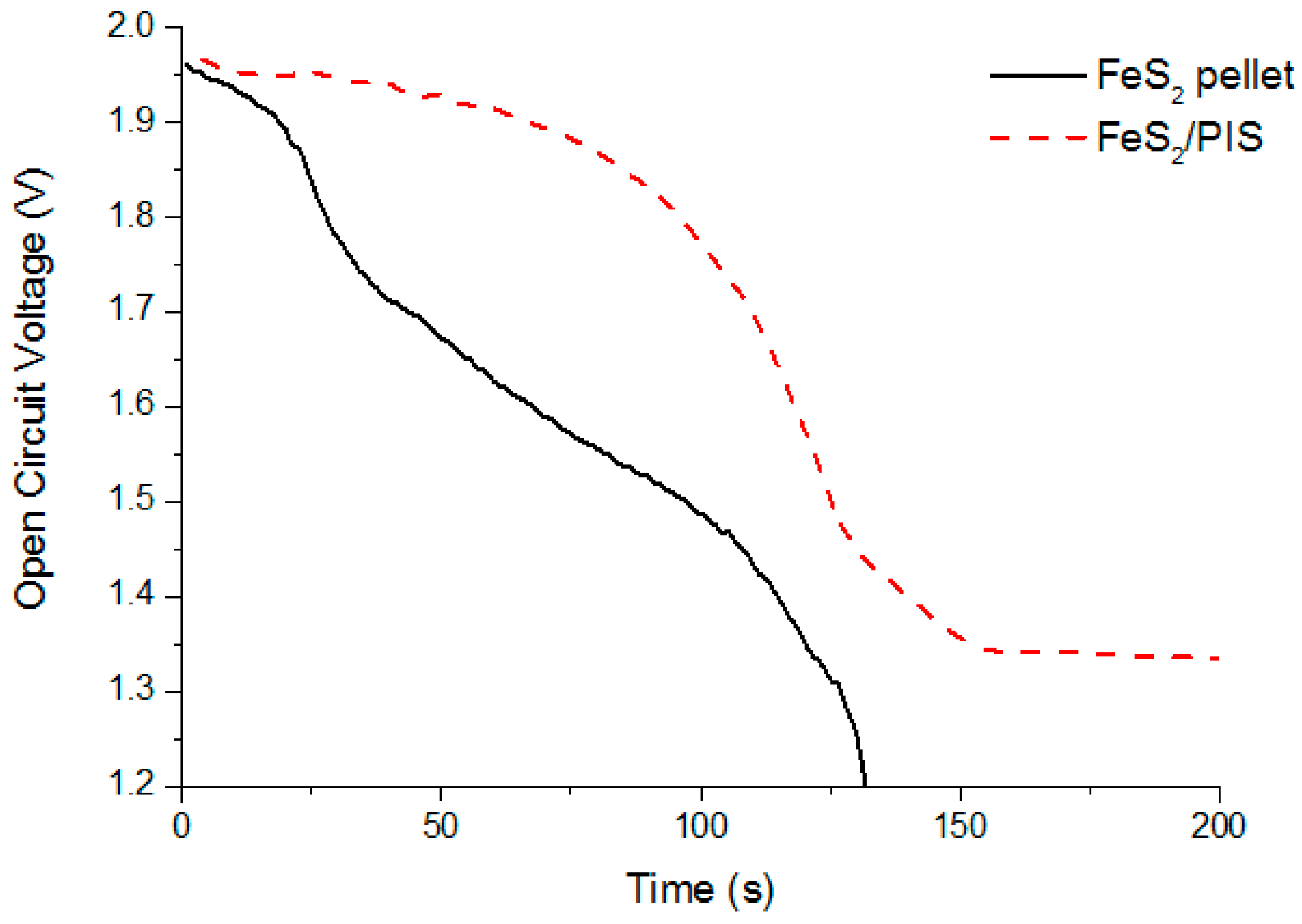

3.3. Electrical Properties of the FeS2/PIS Cathode Layer

- Rt: total polarization (Ω)

- Voc: open circuit voltage (V)

- Vcc: close circuit voltage (V)

- I: discharge current (A)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kim, I.Y.; Shin, S.Y.; Ko, J.H.; Lee, K.S.; Woo, S.P.; Kim, D.K.; Yoon, Y.S. Functional Li-M (Ti, Al, Co, Ni, Mn, Fe)-O Energy Materials. J. Korean Ceram. Soc. 2017, 54, 9–22. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-Y.; Ngo, D.T.; Park, C.-J. Ge–Al Multilayer Thin Film as an Anode for Li-ion Batteries. J. Korean Ceram. Soc. 2017, 54, 249–256. [Google Scholar] [CrossRef]

- Guidotti, R.A.; Masset, P. Thermally activated (“thermal”) battery technology: Part I: An overview. J. Power Sources 2006, 161, 1443–1449. [Google Scholar] [CrossRef]

- Kim, D.; Jung, H.-M.; Um, S. Theoretical Analysis of the Time-Dependent Temperature Evolution for Thermal Runaway Prevention in Multi-Layered LiCl-LiBr-LiF Thermal Batteries. J. Korean Phys. Soc. 2009, 55, 2420–2426. [Google Scholar] [CrossRef]

- Guidotti, R.A.; Masset, P.J. Thermally activated (“thermal”) battery technology: Part IV. Anode materials. J. Power Sources 2008, 183, 388–398. [Google Scholar] [CrossRef]

- Masset, P.; Guidotti, R.A. Thermal activated (“thermal”) battery technology: Part II. Molten salt electrolytes. J. Power Sources 2007, 164, 397–414. [Google Scholar] [CrossRef]

- Masset, P.J.; Guidotti, R.A. Thermal activated (“thermal”) battery technology: Part IIIa: FeS2 cathode material. J. Power Sources 2008, 177, 595–609. [Google Scholar] [CrossRef]

- Masset, P.J.; Guidotti, R.A. Thermal activated (“thermal”) battery technology: Part IIIb. Sulfur and oxide-based cathode materials. J. Power Sources 2008, 178, 456–466. [Google Scholar] [CrossRef]

- Cho, K.-Y.; Riu, D.-H.; Huh, S.-H.; Shin, D.-G.; Kim, H.-E.; Cheong, H.-W.; Cho, S.-B. The Holding Characteristics of the Glass Filter Separators of Molten Salt Electrolyte for Thermal Batteries. J. Korean Ceram. Soc. 2008, 45, 464–471. [Google Scholar] [CrossRef]

- Ko, J.; Kim, I.Y.; Cheong, H.; Yoon, Y.S. Organic binder-free cathode using FeS2-MWCNTs composite for thermal batteries. J. Am. Ceram. Soc. 2017, 100, 4435–4441. [Google Scholar] [CrossRef]

- Ko, J.; Kim, I.Y.; Jung, H.M.; Cheong, H.; Yoon, Y.S. Thin cathode for thermal batteries using a tape-casting process. Ceram. Int. 2017, 43, 5789–5793. [Google Scholar] [CrossRef]

- Zhang, T.; Li, J.T.; Liu, J.; Deng, Y.P.; Wu, Z.G.; Yin, Z.W.; Guo, D.; Huang, L.; Sun, S.G. Suppressing the voltage-fading of layered lithium-rich cathode materials via an aqueous binder for Li-ion batteries. Chem. Commun. 2016, 52, 4683–4686. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Gu, H.; Pan, H.; Yang, S.; Du, W.; Li, X.; Gao, M.; Liu, Y.; Zhu, M.; Ouyang, L.; et al. A Novel Strategy to Suppress Capacity and Voltage Fading of Li- and Mn-Rich Layered Oxide Cathode Material for Lithium-Ion Batteries. Adv. Energy. Mater. 2017, 7, 1601066. [Google Scholar] [CrossRef]

- Kong, J.-Z.; Xu, L.-P.; Wang, C.-L.; Jiang, Y.-X.; Cao, Y.-Q.; Zhou, F. Facile coating of conductive poly(vinylidene fluoride-trifluoroethylene) copolymer on Li1.2Mn0.54Ni0.13Co0.13O2 as a high electrochemical performance cathode for Li-ion battery. J. Alloys Compd. 2017, 719, 401–410. [Google Scholar] [CrossRef]

- Xu, J.; Chou, S.-L.; Gu, Q.; Liu, H.-K.; Dou, S.-X. The effect of different binders on electrochemical properties of LiNi1/3Mn1/3Co1/3O2 cathode material in lithium ion batteries. J. Power Sources 2013, 225, 172–178. [Google Scholar] [CrossRef]

- Morishita, M.; Yamano, A.; Kitaoka, T.; Sakai, H.; Ojima, T.; Sakai, T. Polyamide-Imide Binder with Higher Adhesive Property and Thermal Stability as Positive Electrode of 4V-Class Lithium-Ion Batteries. J. Electrochem. Soc. 2014, 161, A955–A960. [Google Scholar] [CrossRef]

- Wu, F.; Li, W.; Chen, L.; Lu, Y.; Su, Y.; Bao, W.; Wang, J.; Chen, S.; Bao, L. Polyacrylonitrile-polyvinylidene fluoride as high-performance composite binder for layered Li-rich oxides. J. Power Sources 2017, 359, 226–233. [Google Scholar] [CrossRef]

- Pieczonka, N.P.W.; Borgel, V.; Ziv, B.; Leifer, N.; Dargel, V.; Aurbach, D.; Kim, J.H.; Liu, Z.; Huang, X.; Krachkovskiy, S.A.; et al. Lithium Polyacrylate (LiPAA) as an Advanced Binder and a Passivating Agent for High-Voltage Li-Ion Batteries. Adv. Energy Mater. 2015, 5, 1501008. [Google Scholar] [CrossRef]

- Lee, Y.M.; Choi, J.; Ryou, M.H.; Son, B.; Song, J.; Park, J.K.; Cho, K.Y. Improved high-temperature performance of lithium-ion batteries through use of a thermally stable co-polyimide-based cathode binder. J. Power Sources 2014, 252, 138–143. [Google Scholar] [CrossRef]

- Cho, J.-H.; Park, J.-H.; Lee, M.-H.; Song, H.-K.; Lee, S.-Y. A polymer electrolyte-skinned active material strategy toward high-voltage lithium ion batteries: A polyimide-coated LiNi0.5Mn1.5O4 spinel cathode material case. Energy Environ. Sci. 2012, 5, 7124–7131. [Google Scholar] [CrossRef]

- Park, J.-H.; Cho, J.-H.; Kim, S.-B.; Kim, W.-S.; Lee, S.-Y.; Lee, S.-Y. A novel ion-conductive protection skin based on polyimide gel polymer electrolyte: Application to nanoscale coating layer of high voltage LiNi1/3Co1/3Mn1/3O2 cathode materials for lithium-ion batteries. J. Mater. Chem. 2012, 22, 12574–12581. [Google Scholar] [CrossRef]

- Qian, G.; Wang, L.; Shang, Y.; He, X.; Tang, S.; Liu, M.; Li, T.; Zhang, G.; Wang, J. Polyimide Binder: A Facile Way to Improve Safety of Lithium Ion Batteries. Electrochim. Acta 2016, 187, 113–118. [Google Scholar] [CrossRef]

- Pham, H.Q.; Kim, G.; Jung, H.M.; Song, S.-W. Fluorinated Polyimide as a Novel High-Voltage Binder for High-Capacity Cathode of Lithium Ion Batteries. Adv. Funct. Mater. 2017, 28, 1704690. [Google Scholar] [CrossRef]

- Fujiwara, S.; Inaba, M.; Tasaka, A. New molten salt systems for high-temperature molten salt batteries: LiF–LiCl–LiBr-based quaternary systems. J. Power Sources 2010, 195, 7691–7700. [Google Scholar] [CrossRef]

- Zhang, D.; Mai, Y.J.; Xiang, J.Y.; Xia, X.H.; Qiao, Y.Q.; Tu, J.P. FeS2/C composite as an anode for lithium ion batteries with enhanced reversible capacity. J. Power Sources 2012, 217, 229–235. [Google Scholar] [CrossRef]

- Choi, Y.; Yu, H.; Cheong, H.R.; Cho, S.; Lee, Y.S. Effects of Pyrite (FeS2) Particle Sizes on Electrochemical Characteristics of Thermal Batteries. Appl. Chem. Eng. 2014, 25, 161–166. [Google Scholar] [CrossRef]

- Schoeffert, S. Thermal batteries modeling, self-discharge, and self-heating. J. Power Sources 2005, 142, 361–369. [Google Scholar] [CrossRef]

- Masset, P.; Schoeffert, S.; Poinso, J.Y.; Poignet, J.C. LiF-LiCl-LiI vs. LiF-LiBr-KBr as molten salt electrolyte in thermal batteries. J. Electrochem. Soc. 2005, 152, A405–A410. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, I.; Cho, J.; Kim, K.; Ko, J.; Cheong, H.; Yoon, Y.S.; Jung, H.M. Poly(imide-co-siloxane) as a Thermo-Stable Binder for a Thin Layer Cathode of Thermal Batteries. Energies 2018, 11, 3154. https://doi.org/10.3390/en11113154

Oh I, Cho J, Kim K, Ko J, Cheong H, Yoon YS, Jung HM. Poly(imide-co-siloxane) as a Thermo-Stable Binder for a Thin Layer Cathode of Thermal Batteries. Energies. 2018; 11(11):3154. https://doi.org/10.3390/en11113154

Chicago/Turabian StyleOh, Ilwhan, Jaeyoung Cho, Kwansu Kim, Jaehwan Ko, Haewon Cheong, Young Soo Yoon, and Hyun Min Jung. 2018. "Poly(imide-co-siloxane) as a Thermo-Stable Binder for a Thin Layer Cathode of Thermal Batteries" Energies 11, no. 11: 3154. https://doi.org/10.3390/en11113154

APA StyleOh, I., Cho, J., Kim, K., Ko, J., Cheong, H., Yoon, Y. S., & Jung, H. M. (2018). Poly(imide-co-siloxane) as a Thermo-Stable Binder for a Thin Layer Cathode of Thermal Batteries. Energies, 11(11), 3154. https://doi.org/10.3390/en11113154