1. Introduction

To make an advanced and automated energy management and distribution system, the smart grid incorporates new, smart and intelligent technologies. Smart controllers and relays along with intelligent software tools are used for data management. The best feature of the smart grid is the two-way communication between power companies and consumers. This two-way communication of information enables the utility companies and consumers to control their load, reduce bill and peak-to-average ratio (PAR). The gain of user comfort (UC), implementation of user preferences and integration of renewable energy (RE) is another advantage. The addition of these new and intelligent technologies in the next generation power grid is going to be incorporated across the entire power system. The smart grid incorporates new technologies from generation, transmission and distribution of power consumption at the consumer’s side. These technologies are used for the purpose of enhancing the safety, reliability and efficiency of the power system.

Residential and commercial buildings consume 50% of the global power [

1]. The active collaboration and energy sharing by buildings and homes are not included in the present electricity system. All the energy management efforts carried out are less effective and their efficiency is affected by this. The smart grid enables the next generation energy efficiency and sustainability. In this kind of architecture as discussed above, the aggregation of houses acts as an intelligent collaboration of networked system, whereas, in the conventional system, they act as passive and isolated units [

2].

With the help and cooperation of smart grid technologies, investment in a traditional grid can be changed or reduced by implementing demand side management (DSM) rules. The participants of the DSM or demand response (DR) programs try to reduce their energy utilization at certain instances showing a little flexibility. By offering flexibility, consumers achieve benefits [

3].

Since 1982, the increase in peak electricity demand and electricity usage has increased from the growth in electric appliances and increasing demand of power by industry. The increase is almost 25% by each year according to the USA department of energy [

4]. Moreover, considering the residential sector in the USA, the electricity sales are expected to increase 24% from 2011 to 2040 [

5]. Peak energy demand is expected to be far more than the available transmission, generation and distribution capability of the existing grid. This dilemma can be solved by enhancing the existing transmission capability, decreasing peak load, increasing distributed generation and exploring new methods of energy generation such as renewable energy sources (RESs). Researchers are trying to expand traditional grid infrastructure to meet new challenges; however, it is a very expensive job [

4].

There are also monitory benefits added to the physical system consideration. The peak power stations can be eliminated by reducing the load during peak hours. This ensures decrease in cost of electricity for consumers. As an example, during the California energy crisis of 2000–2001, a 5% peak demand reduction decreased the highest wholesale prices by 50% as stated in [

6]. The authors attempt to decrease peak load demand by intelligent and smart coordination amongst customer’s appliances scheduling. The peak demand is avoided by scheduling the appliances in low peak hours and thus benefiting both the consumers and utility companies [

7].

There is an emerging trend toward scheduling the load of residential homes, reducing electricity cost and balancing the energy consumption across 24 h of a day. The use of microgrid (MG) comprising of RESs are in spotlight. Normally, photovoltaic (PV) source, wind turbines and micro combined heat and power generators are used. The current power generation system is in a transition state to become a large scale distributed power generation system. This transition state to smart grid will be completed with the addition of distributed RESs [

8,

9].

A smart grid also supports changing electricity prices and this change is according to the dynamic status of electric power demand and generation system. The smart grid is now a promising method for the RE generation, resources management, use in the context of increasing energy demand and increasing prices [

10].

The recent smart appliances and smart grid technologies enable residential and commercial sector to use power efficiently using smart grid features. Such electrical appliances have the capability to make their operation according to the changing electricity prices. Peak load management can reduce the cost of electricity consumption. The reliability of electric grid can be improved by using smart appliances and their load management characteristics knowing every minute details of each appliance [

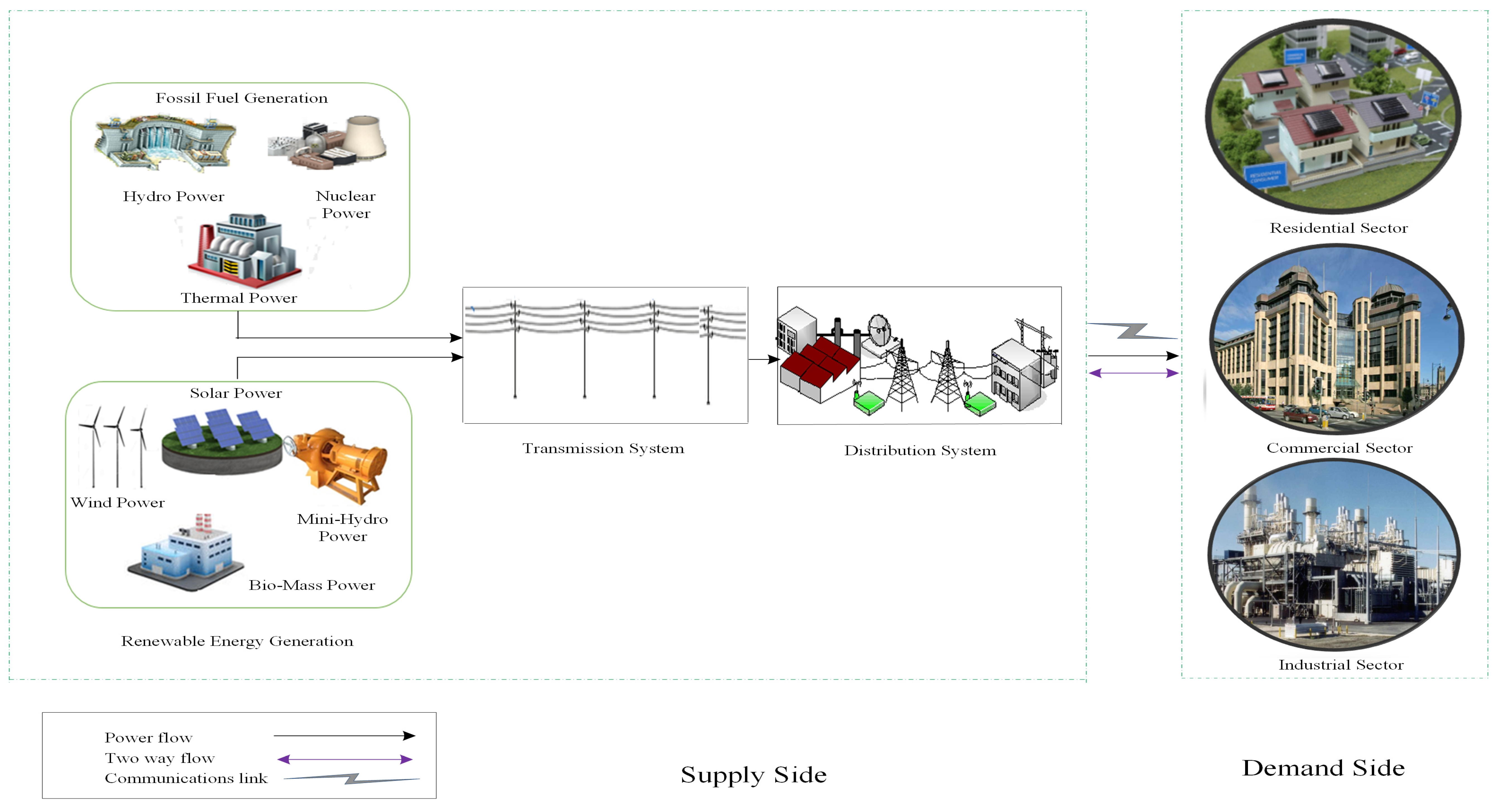

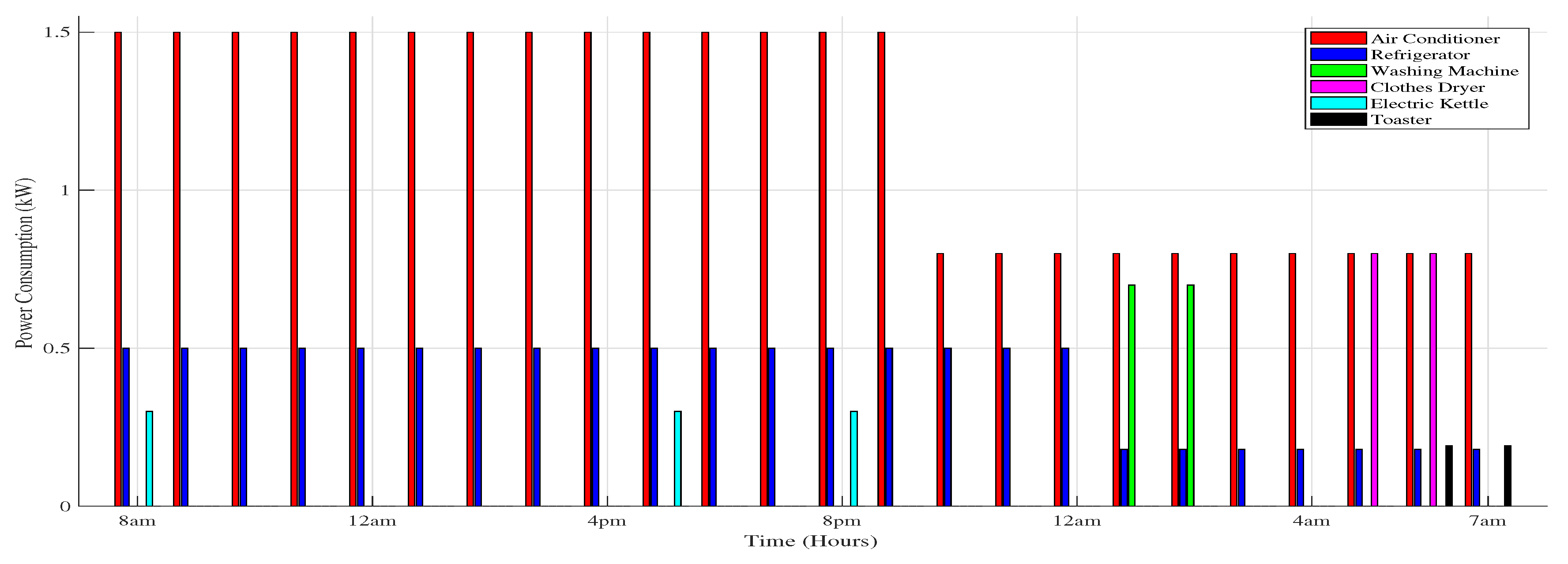

11]. An abstract view of power flow for supply and demand side is presented in

Figure 1.

The researchers are trying to add intelligence for energy management in order to improve the efficiency, comfort, convenience in services and home-based health-care support [

12,

13]. There are many articles, in which especially smart homes energy management systems considering energy efficiency and load management are discussed [

14,

15,

16,

17]. Most of the literature considers reduction of cost via load management by following variations in electricity prices. This paper proposes a novel approach for appliances scheduling in residential buildings which gives a detailed smart home energy management system solution. This approach minimizes the overall daily electricity cost of home appliances.

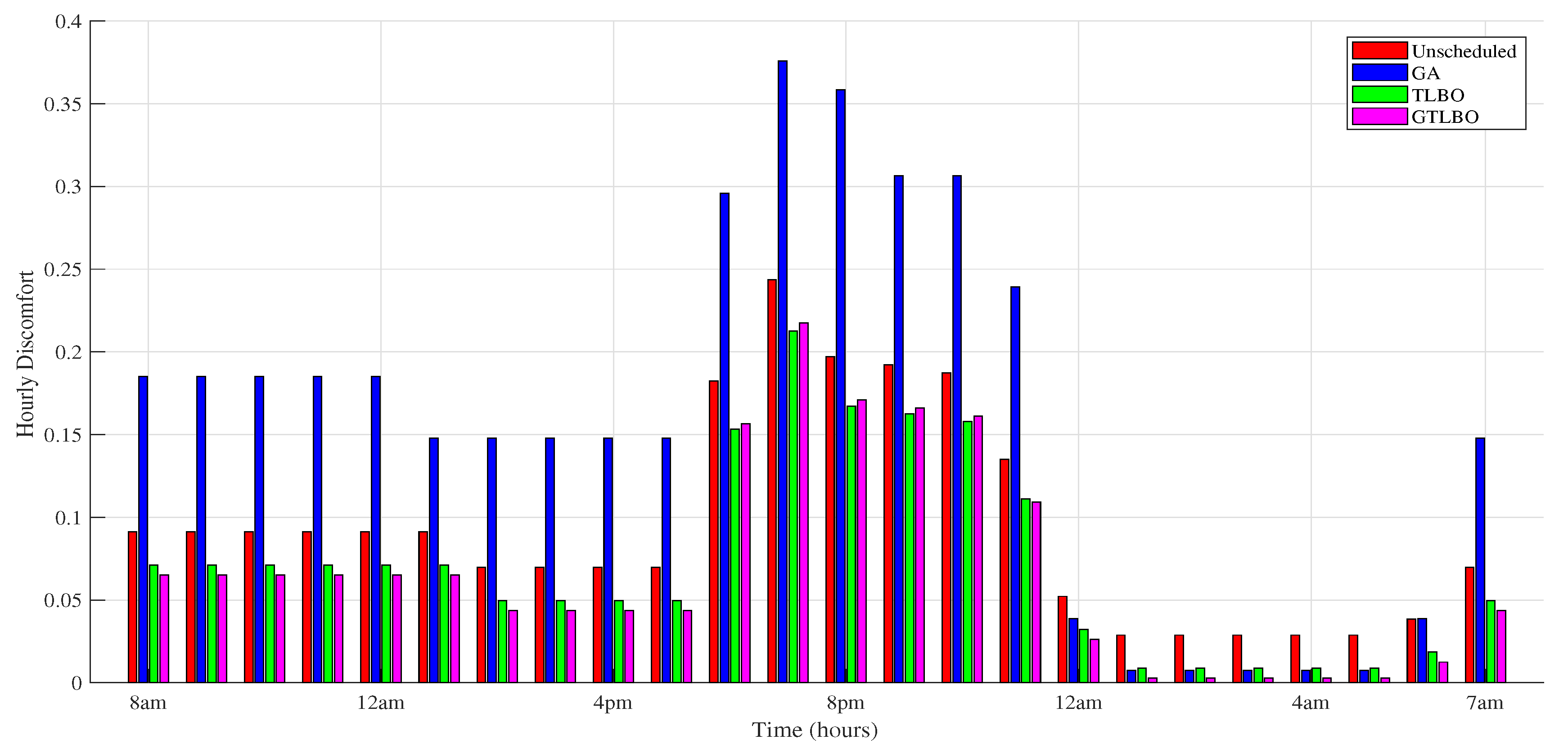

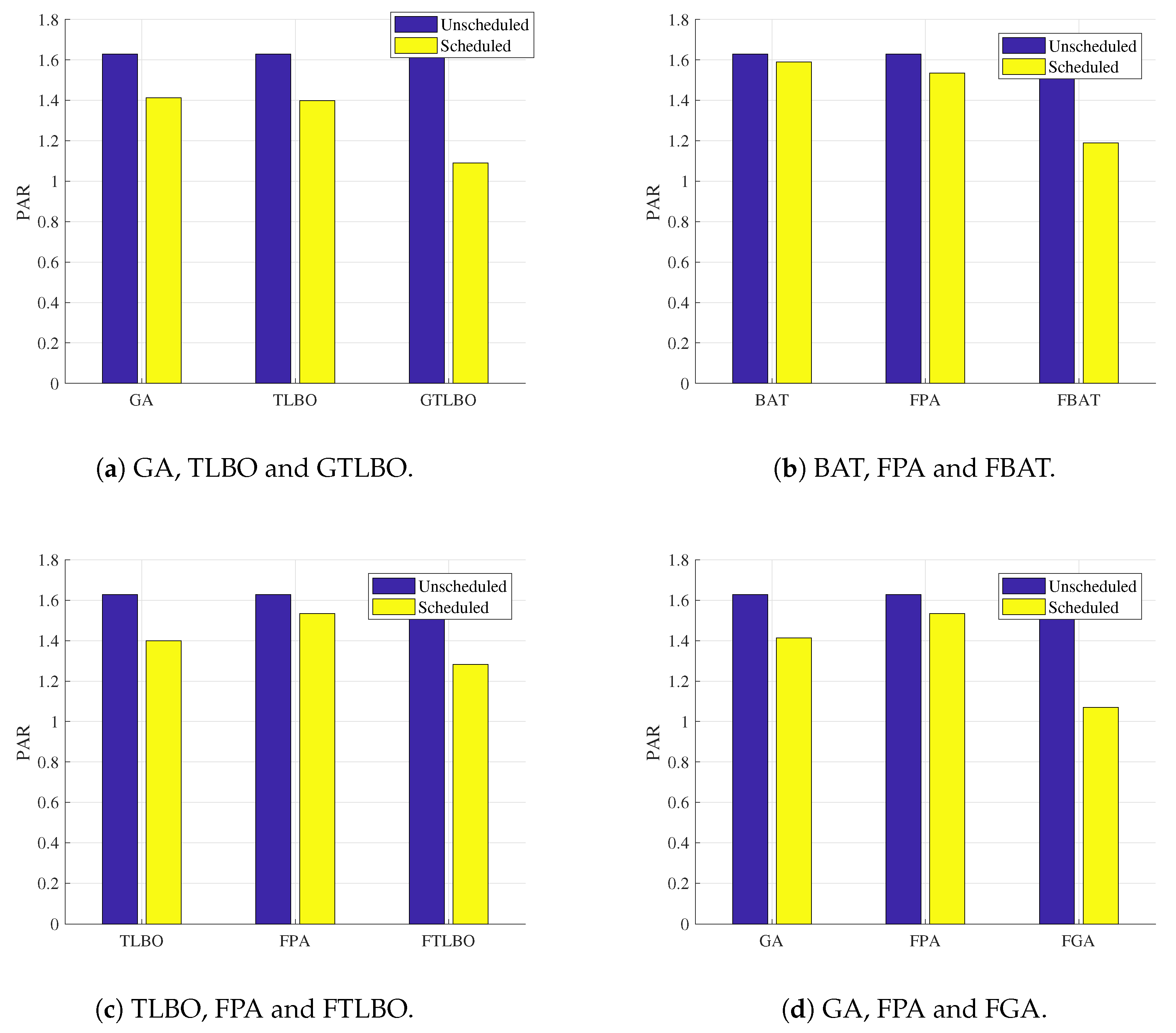

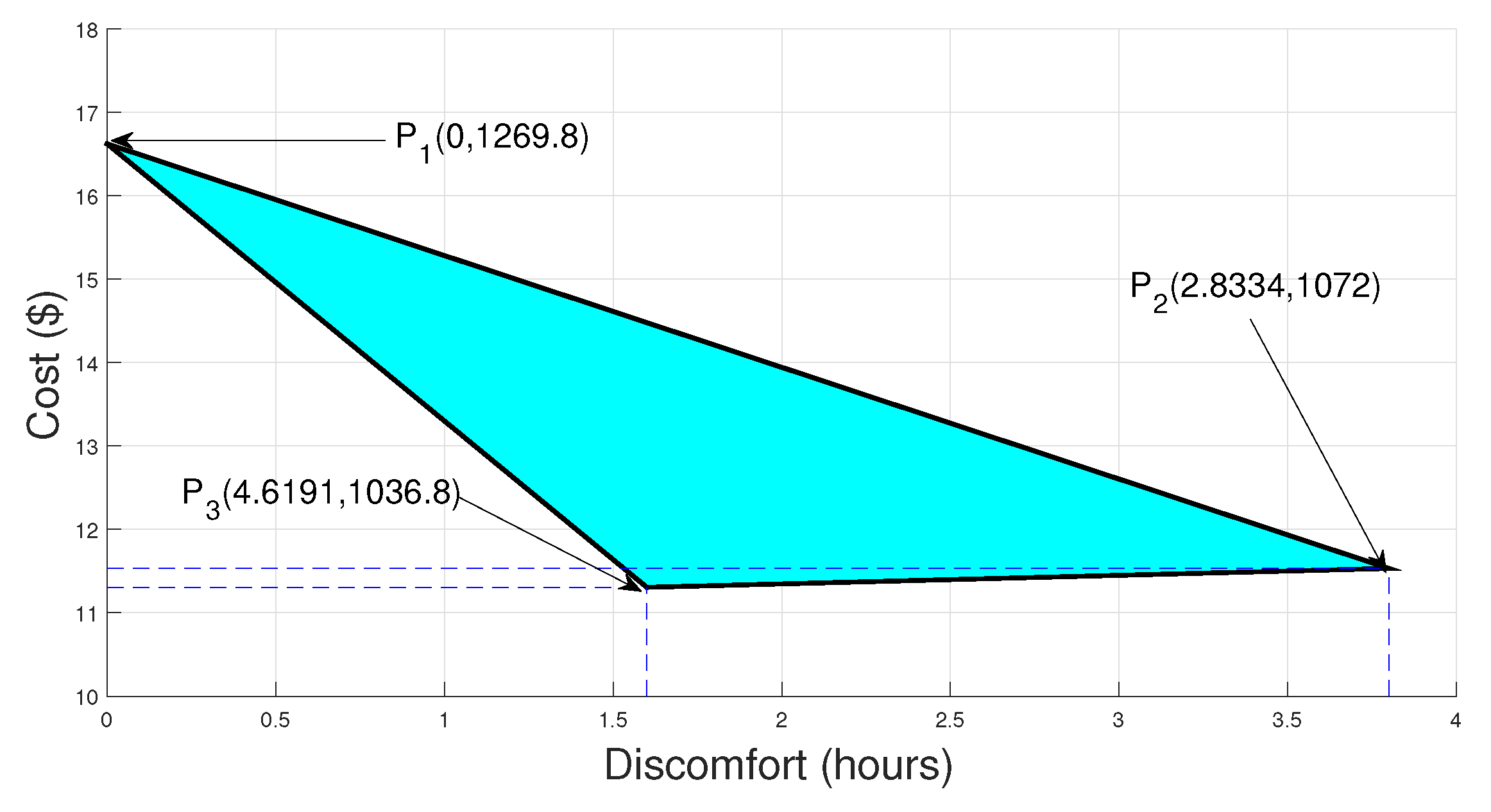

In this work, residential load is scheduled using DSM for smart homes. Considering smart power system for consumers, where a common energy source is used, each consumer uses smart meter and energy consumption scheduling unit (ECSU). The electric grid and smart meter is connected via advanced metering infrastructure (AMI). The AMI communicates between the electric grid and smart meter. Four algorithms are proposed, i.e., genetic teaching learning based optimization (GTLBO), flower pollination teaching learning based optimization (FTLBO), flower pollination BAT (FBAT) and flower pollination genetic algorithm (FGA). These proposed algorithms are used to schedule the load for reducing electricity cost, user discomfort and PAR. Simulation results show that proposed techniques perform better as compared to the existing techniques. However, there is trade-off between cost and user discomfort. The discomfort decreases with the increasing cost and increases with decreasing cost. The list of the acronyms are listed in

Table 1.

The rest of the paper is organized as follows: related work is discussed in

Section 2. Discussion about the proposed system model is provided in

Section 3.

Section 4 explains the problem formulation using a mathematical technique called knapsack. In

Section 5, optimization techniques are explained, In

Section 6, simulation results and discussion have been provided. In

Section 7, conclusions, future work and references are presented.

2. Related Work

A lot of research has been done on residential load scheduling, DSM for smart homes and home energy management (HEM). These are major trends in smart grid research domains.

In [

18], authors discussed HEM controller for the residential load. Moreover, they used four algorithms for the bill and PAR reduction, i.e., the genetic algorithm (GA), binary particle swarm optimization (BPSO), wind driven optimization (WDO), bacterial foraging optimization algorithm (BFOA) and genetic BPSO (GBPSO). The authors achieved 34% PAR and 36% cost reduction. The cost for single, ten and fifty homes are calculated using the above techniques. However, the authors did not consider the UC and user preferences.

A mixed integer programming optimization (MIPO) algorithm is proposed in [

19] for scheduling appliance’s operations. The same proposed algorithm minimizes the peak load and cost using the branch and bound (BAB) algorithm for problem formulation and solution. The use of PV as MG and exporting electricity to grid back are done by this work. However, PAR is not minimized.

In [

20], an optimized energy management system (OEMS) is proposed including RES integration and energy storage system (ESS). The authors also discussed the residential sector. The multiple knapsack problem (MKP) for problem formulation is used to solve the problem of electricity cost and PAR reduction. The authors used BPSO, GA, WDO, BFOA and hybrid of GA and PSO named GA-PSO (HGPO) algorithms to implement the proposed problem. By the integration of RES and ESS, the authors achieved 19.94% and 21.55% cost and PAR reduction, respectively. Moreover, they achieved 25.12% and 24.88%, bill and PAR reduction, respectively, by implementing the HGPO algorithm. This research did not discuss the average waiting time (AWT) for maximizing UC as done by our work.

The authors proposed a generic DSM (G-DSM) model for residential users [

21]. The authors reduced PAR, electricity cost and appliances waiting time. The authors used GA for appliances scheduling and consider 20 users. Moreover, they obtained 39.39% and 45.85% cost reduction for single and 20 users, respectively. The PAR reduction for a single user and 20 users are 17.17% and 45.24%, respectively. The cost reduction on daily basis is 25.62%. Moreover, the authors also discussed the relationship between cost and waiting time of appliances. The UC is compromised; however, their work reduced cost and PAR for single and multiple users.

In [

22], the authors proposed an energy optimization technique. The authors scheduled household appliances for finding the electricity price, weather conditions and dynamic behaviors of users. They considered cost and UC optimization and solved their objective function via MKP. The authors obtained energy savings by 11.77% and 5.91%, with and without people occupancy, respectively. The authors minimized cost; however, user discomfort is increased.

The authors in [

23] proposed an HEMS for cost reduction and load balancing. The performance of HEMS is evaluated by this work using grey wolf optimization (GWO) and BFOA. Reduction in cost and PAR is obtained by dividing the appliances into two classes based on energy consumption pattern as well as peak and off-peak hours that are considered for energy management.

This work obtained 10% cost reduction by GWO as compared to BFOA using critical peak pricing (CPP) scheme. In this work, the cost and PAR are reduced; however, UC is compromised.

In [

24], the authors proposed an HEM architecture and integrated multiple classes of appliances for scheduling the smart home load. They validated the six layers of their model by simulations. The knapsack optimization technique is used for appliances scheduling. Moreover, four cases of appliances for cost reduction are considered. Fault identification and electricity theft control are also considered for efficient use of electricity consumption. In addition, the authors also calculated carbon footprints for user awareness. Simulation results show that peak load reduction of 22.9% for the unscheduled load with person presence controller (PPC), 23.15% for the scheduled load with PPC and 25.56% for the scheduled load with UC index. Similarly, total cost reduction of 23.11%, 24% and 25.7% is obtained, respectively. The authors reduced cost and carbon emissions as already discussed above; however, they did not consider minimizing AWT.

In [

25], the authors proposed a realistic scheduling mechanism (RSM) for reducing electricity cost and enhancing appliances utility. The authors divided a 24 h time horizon into four logical time slots; each of them six hours. BPSO is used for appliances utility, cost reduction, and UC. To create a balance between appliance utility and cost-effectiveness, RSM with a power bank is proposed that gives a UC gain of 0.185 with respect to unscheduled load and 0.149 with respect to BPSO on a scale of 0 to 1. The authors reduced cost and optimized UC; however, PAR is compromised. The RSM model is not good in terms of monitory benefits and expensive to install.

The authors proposed different DSM programs for energy management in [

26]. The authors considered the TLBO, GA, the enhanced differential evolution (EDE) algorithm and the proposed enhanced differential teaching-learning algorithm (EDTLA) to manage energy consumption and UC. The proposed model considered the human preferences and energy consumption pattern. The authors considered the power consumption pattern for shiftable appliances to get monitory benefits. The authors considered cost reduction, UC, reduction of carbon emission and RES integration in this work. The authors also considered PAR reduction and the trade-off between cost and UC. Without integration of RESs, the electricity cost and PAR are reduced up to 36% and 43%, respectively. With integration of RESs, electricity cost, PAR and carbon emissions are reduced up to 67%, 29% and 55%, respectively. The authors considered reduction of cost and carbon emissions; however, AWT is not sufficiently reduced.

In [

27], the authors proposed a hybrid energy generation system (HEGS) and discussed the appliances’ scheduling problem. The proposed model consists of PV, wind turbine, combined heat and power (CHP) energy storage and electric vehicle (EV). The authors reduce cost, which consists of minimum total operational cost, cost of gas consumption, power purchased from the electric grid, storage system cost and charging–discharging costs of EV. The authors proposed an efficient algorithm, i.e., multi-team PSO (MTPSO) which uses different information to update velocity. MTPSO is more stable as compared to PSO. The proposed algorithm reduces cost efficiently; however, there is a trade-off between cost reduction and UC.

The authors proposed a distributed EMS (DEMS) called an incentive-driven distributed energy sharing system (iDES). The authors considered the reduction of communication overhead of appliances and ensured effective load sharing among different homes appliances in [

28]. The authors used a new pricing scheme for different incentives. The load sharing price means the cost of renewable and storage system, changes in power supply for demand and the remaining energy level of the battery storage system. The authors efficiently shared energy and reduced carbon footprints; however, the UC is not considered.

The authors proposed the idea of peer-to-peer power sharing in [

29]. Moreover, the authors discussed two cases, i.e., in the first case, those who can afford renewable and non-renewable power generation resources are included. Such power sources includes: PV panel, diesel generator, a wind turbine—in the second case, those who cannot afford such sources of RE generation. The authors proposed a concept of a marketplace for the power generation and self-sufficiency in the power market. A small-scale power generation system is introduced using an energy management unit (EMU). The authors presented the concept of energy sharing due to which cost is reduced; however, the PAR is increased.

In [

30], the authors proposed an HEM model. To solve the optimization problem, the Time-of-Use (ToU) pricing scheme with RESs and without RESs is considered. The authors used evolutionary algorithms: BPSO, GA and cuckoo search algorithm (CSA) for DSM model and for scheduling the appliances. The authors used a ToU pricing scheme and consider traditional homes and smart homes with RESs. The cost saving achieved by CSA is 6.93% and 43.10% with and without RESs in comparison to GA and BPSO, respectively. The authors reduced cost using HEMS; however, they did not consider UC.

The authors proposed HEMC by using heuristic algorithms such as BPSO, GA and ant colony optimization (ACO) in [

31]. A generic architecture is proposed for a DSM model and formulated the problem using MKP. They used a combined model of ToU and incline block rates (IBR) as a pricing scheme. The authors introduced a GA based energy management controller (EMC), which is more efficient than BPSO and ACO in terms of cost saving, PAR reduction and UC maximization. The cost and PAR are reduced in this work; however, AWT is not considered.

The authors proposed a multi-agent power distribution hub (PDH) in [

32] for energy management. The proposed hub optimize energy consumption and management of ESS. The power is shared among neighbors with no profit and loss, and considered on-peak, off-peak and mid-peak prices. Three scenarios are considered for proposed model, i.e., without BESS, with BESS and with sharing the power of BESS. Power savings of 21% and 6% are achieved for baseline load and without sharing BESS consumption from the utility, respectively. Compared with baseline cost, 36% of electricity cost is reduced and 9% is used for sharing of BESS. The authors reduced cost using ESS and multi-agent; however, in this model, appliances are not scheduled and UC is reduced. Energy is provided for the appliances when needed.

The authors in [

33] discussed an opportunistic scheduling algorithm. The authors used real time pricing (RTP) scheme and optimal stopping rule (OSR). Priority is assigned to consumers based on energy consumption pattern. First come first serve (FCFS) algorithm is used to reduce cost and waiting time for appliances. Priority enabled early deadline first (PEEDF) is also used to maximize the UC. FCFS saved 65.95% cost while MFCFS saved 42.58% cost, which is 23.34% less than FCFS. Moreover, PEEDF saved costs of up to 48.28% which is 5.7% more than FCFS. The authors also used RE during peak hours and sell it back to the grid, when the energy is in a surplus. The authors used the above algorithm to reduce cost; however, UC is compromised.

In [

34], the authors discussed real-time information based energy management to reduce cost and PAR while keeping the UC. Appliances are classified into different categories based on their energy consumption profiles. The authors considered customer preferences, cost saving and UC. Air conditioner and refrigerator are modeled using intelligent programming communication thermostat (IPCT). GA is used to add intelligence to conventional programming communication thermostat (CPCT). Electricity cost, PAR reduction and maximization of UC are considered. Proposed algorithms effectively managed the energy utilization by scheduling home appliances. The proposed model reduces the energy cost and PAR up to 22.63% and 22.77%, respectively. The authors reduced cost and PAR using GA; however, AWT is not reduced, which is causing user discomfort.

The authors used cooperative PSO (CPSO) to optimize scheduling and operation of appliances in [

35]. The authors considered two types of appliances; time-shiftable and power shiftable. They achieved electricity cost reduction, UC and balanced the total load on the main grid. This work reduces cost efficiently; however, PAR is increased.

The authors proposed a smart energy hub (SEH) and modern energy management technique considering electricity and natural gas consumption. SEH is formulated as a non-cooperative game (NCG) [

36] and proved the nash equilibrium (NE). Cost and PAR are reduced by the proposed SEH. The authors used NCG to reduce cost and PAR; however, UC is compromised.

In [

37], the authors proposed a mathematical optimization model to control residential energy load and customer preferences. The customer comfort is modeled considering appliance classes, customer preferences and weather conditions. For UC and electricity cost, WDO is used, while, for the electricity bill and PAR reduction, min-max regret-based knapsack problem is considered. Simulation results show that the optimized results of electricity cost, PAR and UC are achieved. The authors controlled residential load and minimized cost and PAR using WDO; however, they ignore UC.

4. Proposed System Model

The proposed system considers one electrical power system that is comprised of both supply and demand side with several consumers as shown in

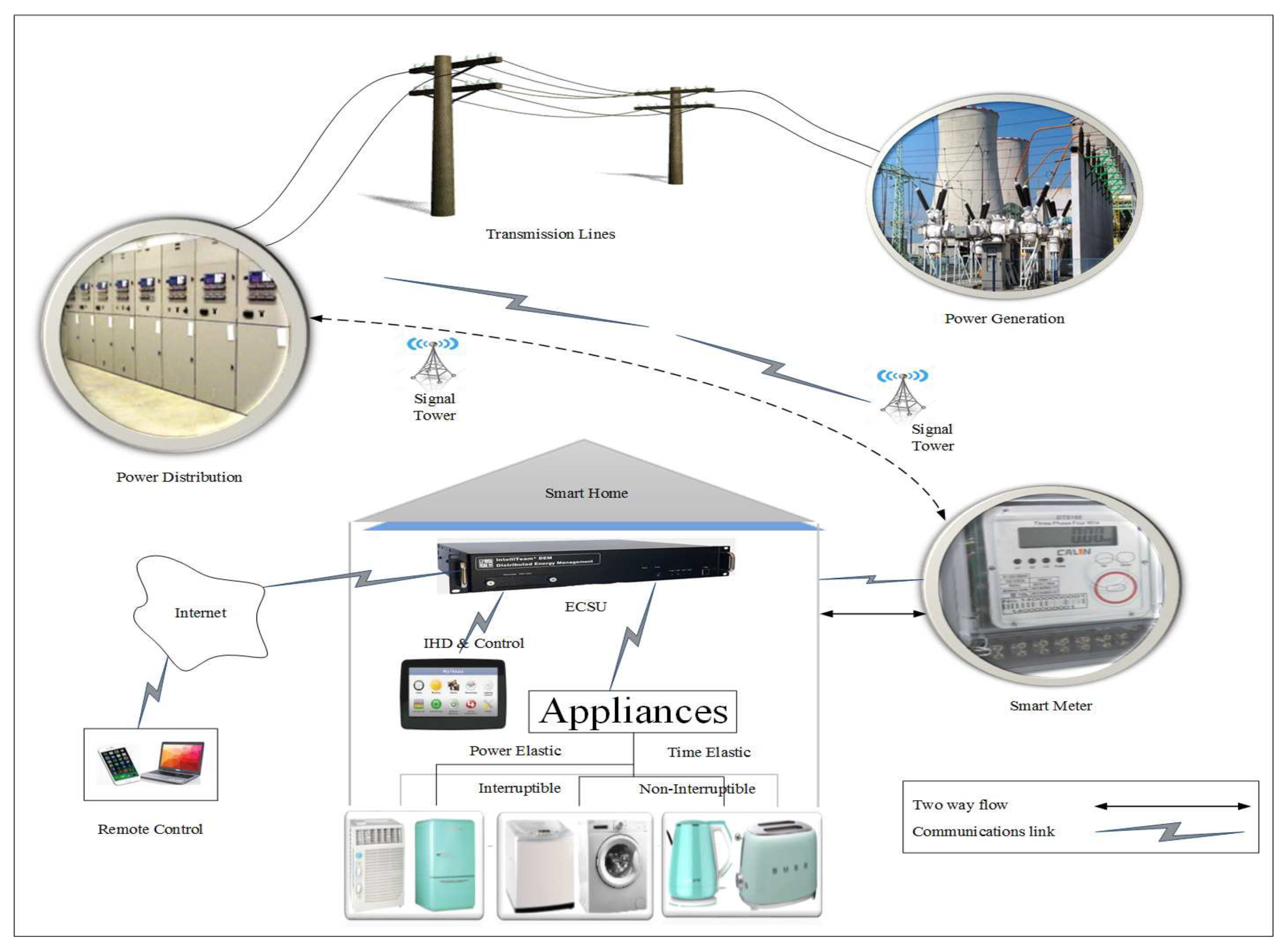

Figure 1. Each consumer is equipped with ECSU, smart meter, remote control, in-home display (IHD) and control. The ECSU is the key factor in HEM to control the consumer energy consumption and to coordinate each consumer with the utility company. The ECSU is connected to the utility company through the network interface such as local area network as shown in

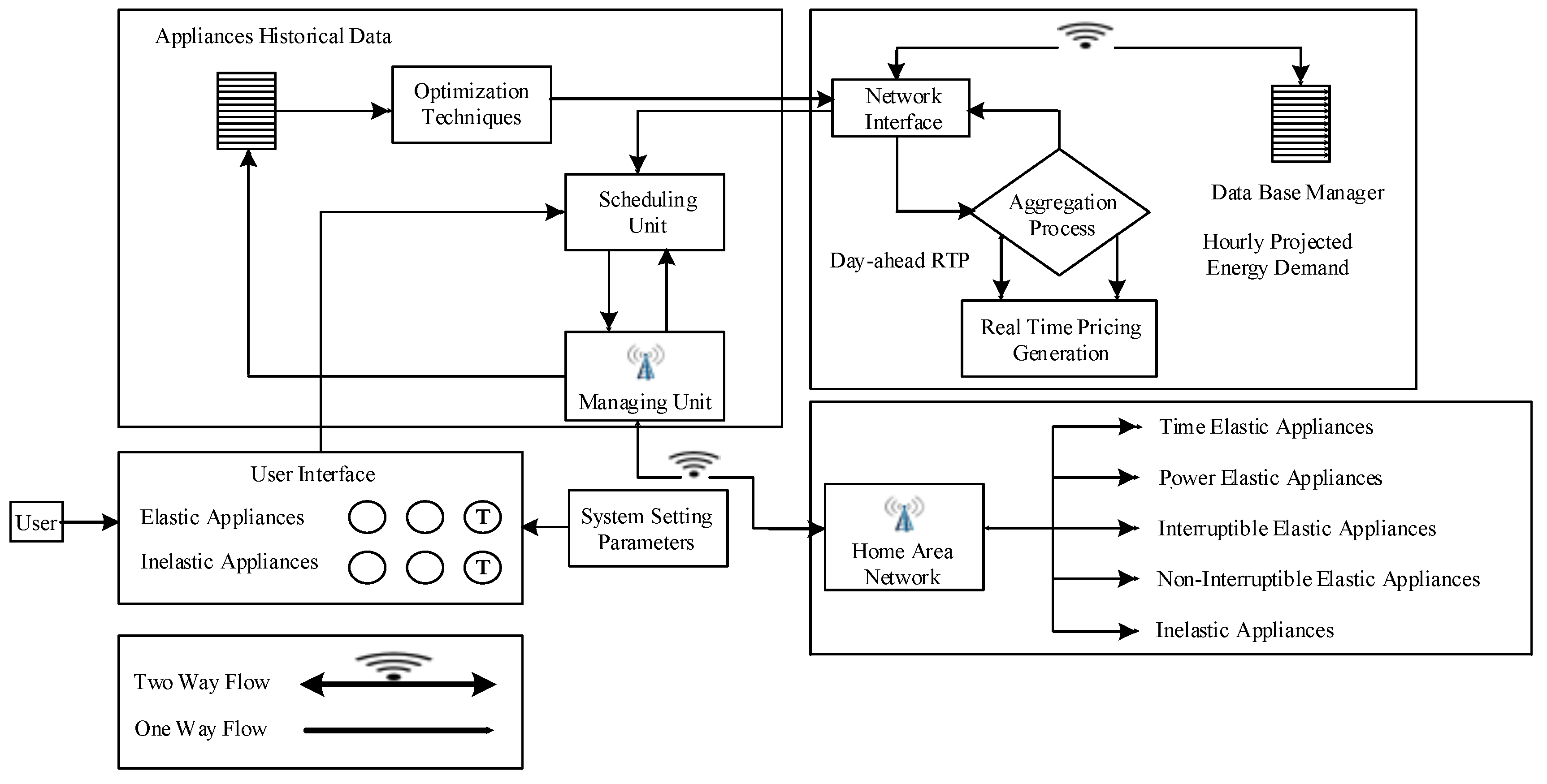

Figure 2. The ECSU receives control parameters setting from users through the user interface and pricing information from the utility to schedule the household appliance’s consumption behaviour.

Each user inputs control parameters such as starting time, ending time and length of operation time, etc., through the user interface to the scheduling unit. The scheduling unit receives price information from utility, and forwards control parameters and price information to managing units. Using historical data and data received from scheduling unit; the managing unit schedules appliances consumption behavior using optimization techniques. Finally, ECSU exchanges the schedule with the utility to optimally control the consumer’s consumption behavior as shown in

Figure 3.

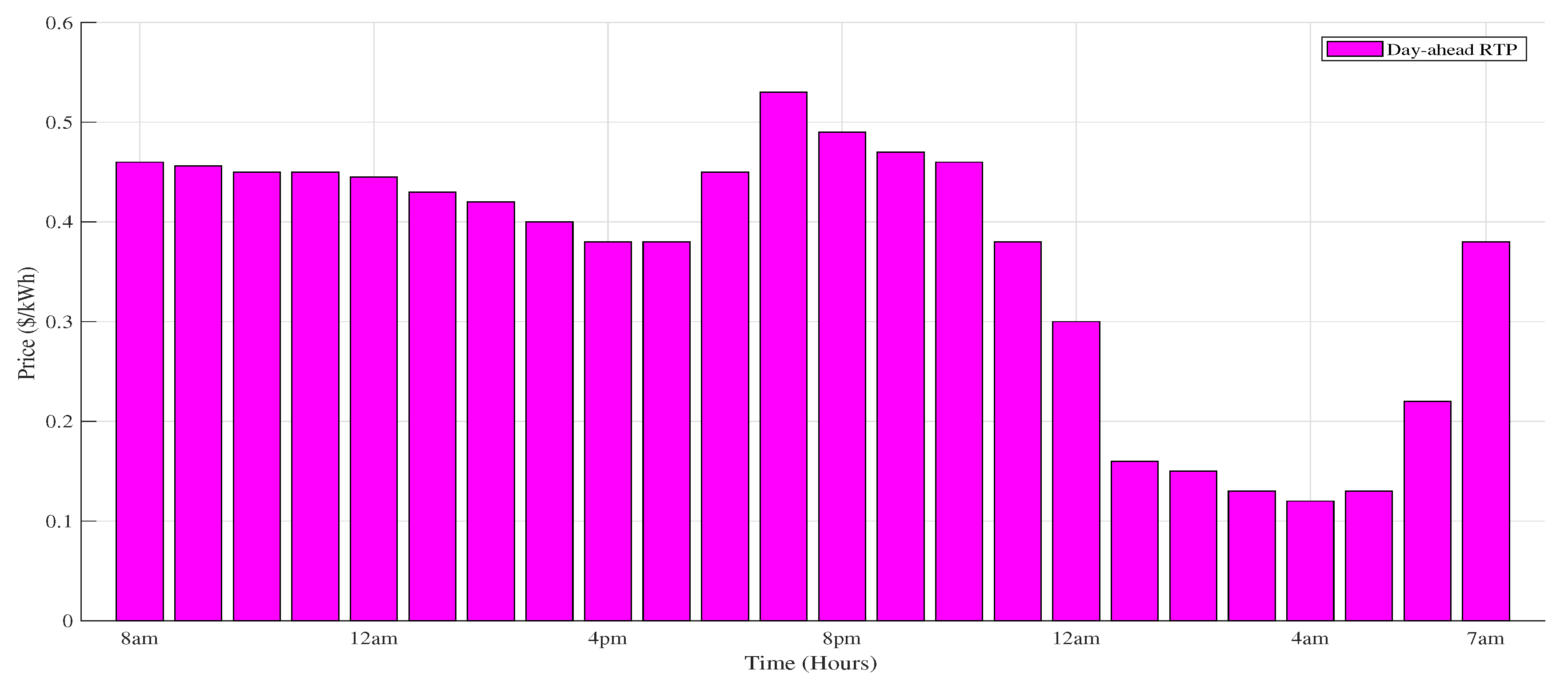

The scheduling time horizon is divided into T time slots, where . The utility generates day-ahead RTP signal. This division and day-ahead RTP is based on the behavior of consumers and their demand patterns, such as on-peak time slots, off-peak time slots, and mid-peak time slots.

The load demand is classified into two types: elastic load and inelastic load. Moreover, the elastic loads is further classified into two categories: time elastic appliances and power elastic appliances. Each time elastic appliance can either be interruptible or non-interruptible. The operation of interruptible appliances can be delayed, interrupted and adjusted or shifted to the time slots other than on-peak time slots, while, for non-interruptible appliances, it is only possible to delay its operation, when needed. On the other hand, there is the inelastic load, having an inflexible price nature. The detailed description of appliances is as follows.

Let the set of appliances are denoted by:

, such that,

.

is the set of time elastic appliances and

is the set of power elastic appliances. For each appliance

i, the current position,

and the position at the next time slot,

is defined. In the time elastic appliances, the operation of interruptible appliances can be adjusted and interrupted, if necessary. The initial position and the position at next time slot for interruptible appliances can be modeled as shown below in Equations (15) and (16):

In time elastic appliances, the non-interruptible appliances can only be delayed on the user requirement, as discussed above. The initial position and position at next time slot for non-interruptible appliances are modeled as in Equations (17) and (18):

The power elastic appliances have elasticity in their power rating, and tolerate flexibility in their operation time. The position of power elastic appliances at the next time slot is modeled as in Equation (19):

The inelastic appliances start operation immediately and need to be power-on at all times during the day. The initial position and the position at next time slots are given as in Equations (20) and (21):

Among the various pricing schemes discussed below, the RTP scheme is chosen because it has more flexibility for appliances scheduling as compared to the ToU tariff, CPP and CPR. To avoid the building of peaks during off-peak hours, the combined RTP and inclined block rate (IBR) pricing scheme are considered. We assume that the utility has no control over the consumer’s consumption and it may only influence the load by providing price flexibility. Load synchronization and building of peaks during off-peak hours can be avoided by adopting combined RTP with IBRs, where the marginal price has a direct relationship with the load. This combined pricing scheme encourages the consumer to shift the load from on-peak to off-peak hours in order to reduce cost and PAR. Using this combined pricing scheme, electricity price depends on time and also on total load. Let

indicate the electricity price at time slot

t, as a function of consumer’s consumption at that time slot as shown using Equation (22):

where

is the electricity price, when the total consumption is less than the threshold of IBRs at time slot

t, and

is the electricity price at time slot

t, when the total consumption exceeds the threshold of IBRs.

7. Conclusions and Future Work

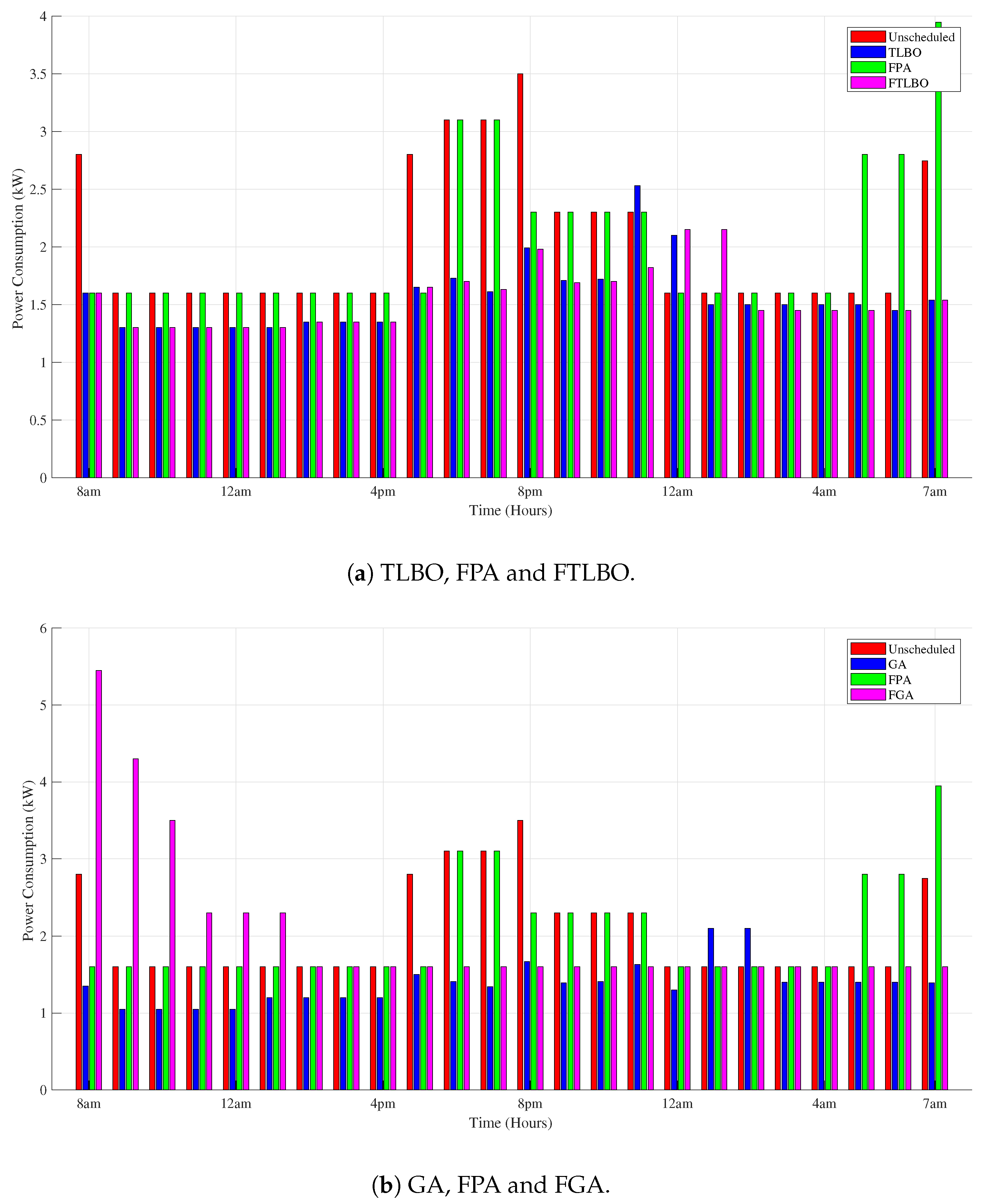

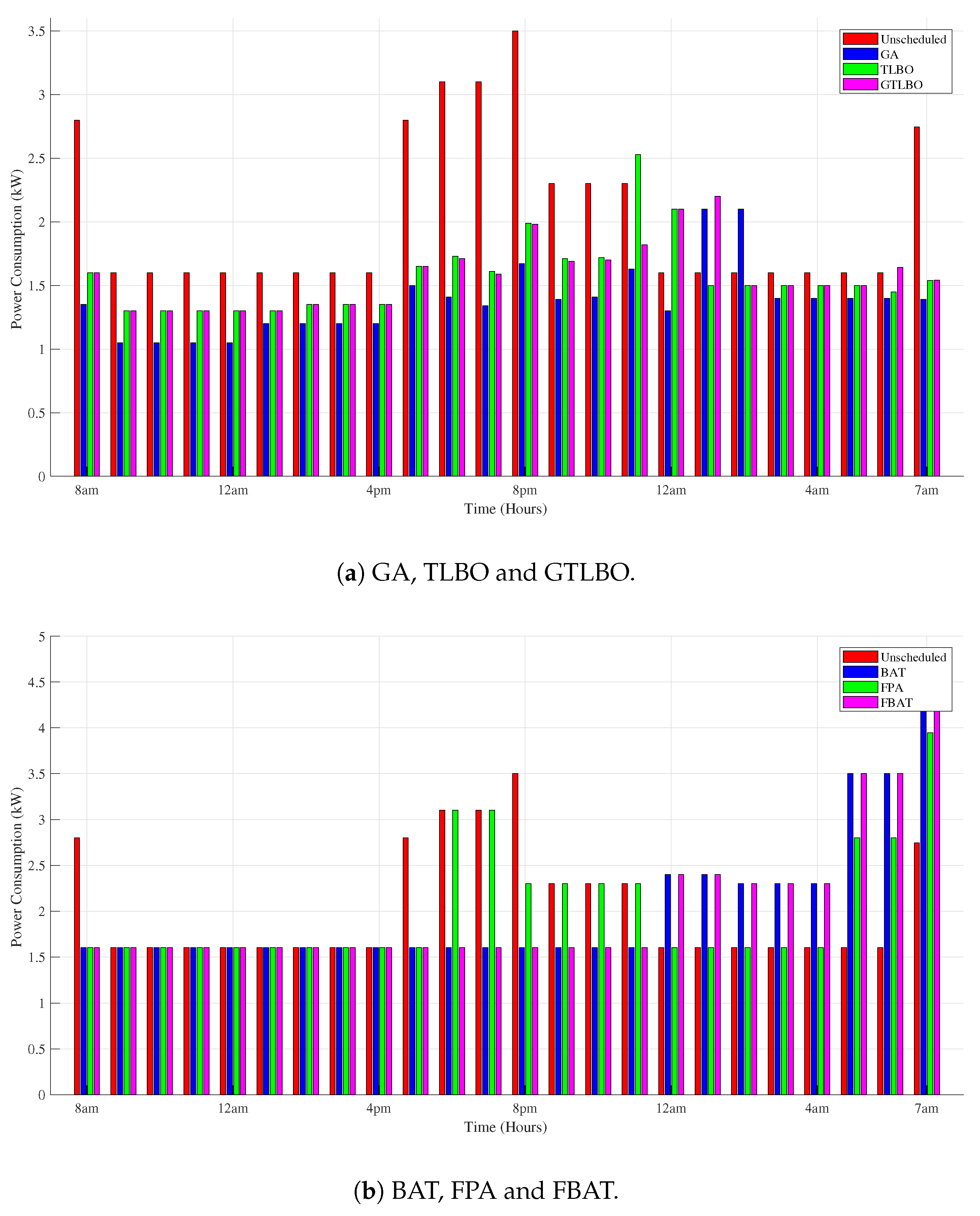

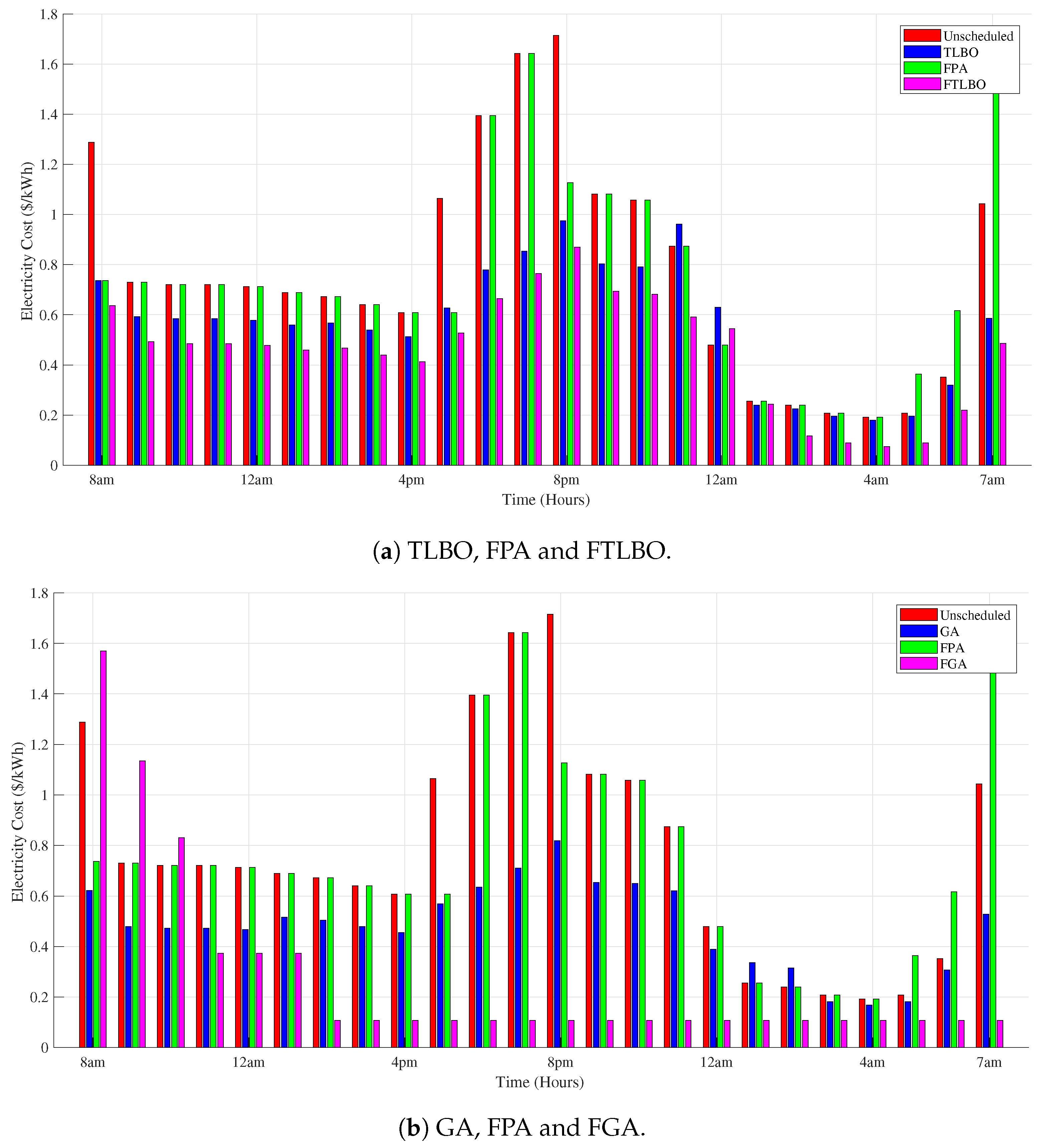

Residential load scheduling is a common method in DSM for smart homes. The electricity cost, PAR and user discomfort are minimized using ECSU. Power elastic and time elastic appliances are considered for the proposed scheme. Combined RTP and IBR pricing schemes are used to avoid the buildings of peaks during off-peak hours. In this work, the heuristic algorithms: GA, TLBO, BAT and FPA are implemented via Matlab to reduce cost, PAR and user discomfort. The daily cost, PAR and user discomfort are reduced up to 37.95%, 9.87%, 7.56% by GA, 26.74%, 12.96%, 3.33% by TLBO, 3.87%, 5.55%, 30.91% by FPA, 12.32%, 2.46%, 48.36% by BAT, respectively. In addition, four hybrid heuristic algorithms: GTLBO, FTLBO, FBAT and FGA are proposed by combining the best features of GA and TLBO, FPA and TLBO, FPA and FBAT, FPA and GA. The daily cost, PAR and user discomfort are reduced by proposed techniques: up to 39.17%, 32.09%, 44.45% by GTLBO, 40.75%, 45.06%, 33.38% by FTLBO, 25.23%, 27.16%, 22.18% by FBAT, 64.49%, 33.95%, 12.72% by FGA, respectively. The simulation results show that the performance of the hybrid techniques are better than their parent’s techniques in term of reducing electricity cost, PAR and user discomfort. Moreover, a trade-off exists between electricity cost and user discomfort, while reducing cost, PAR and user discomfort is compromised by the proposed techniques. The user discomfort is decreasing with the increasing electricity cost. FGA cost is the highest, i.e., $17.86 and user discomfort is the lowest, i.e., 1.76 among the parent techniques. In addition, FBAT electricity cost is the highest, i.e., $13.89 and user discomfort is the lowest, i.e., 1.06 among the proposed techniques.

In the future, the three parameters—electricity cost, PAR and user discomfort will be considered for further optimization using heuristic algorithms. Furthermore, the fog computing concept will be used to implement the above scenario for appliances’ scheduling and optimizing results. In addition, the above scenario was implemented for a single home, and, in the future, it will further be simulated for multiple homes using RES integration.