Saving Energy in the Transportation Sector: An Analysis of Modified Bitumen Application Based on Marshall Test

Abstract

1. Introduction

2. Literature Review

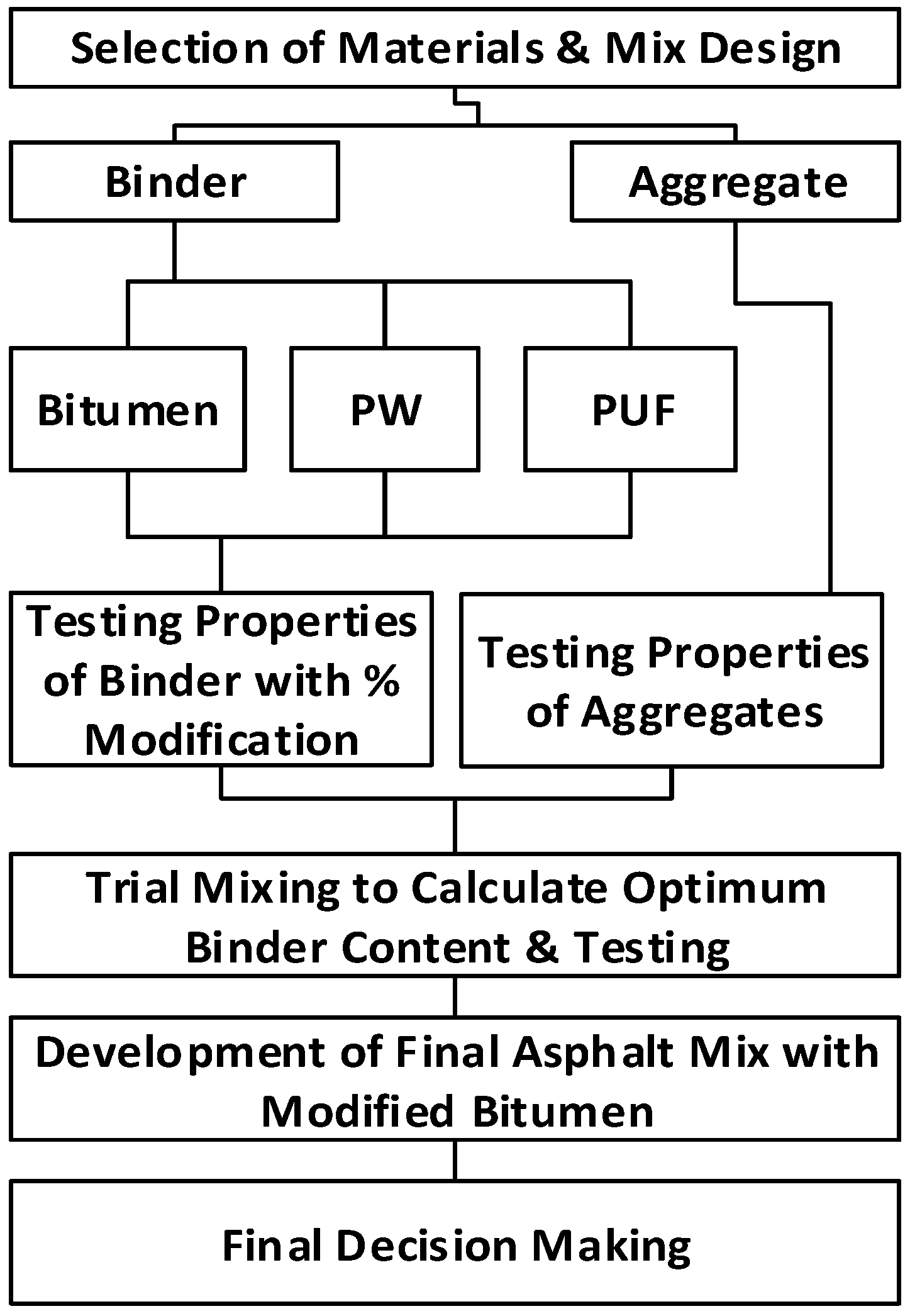

3. Materials and Methods

3.1. Basic Materials

3.2. Modification of Binders

3.3. Properties of Binders

3.4. Properties of Aggregate

3.5. Marshall Test Specimen Preparation and Testing

4. Results and Discussion

4.1. Analysis of Modified Bitumen

4.2. Marshall Stability Analysis

4.3. Fuel Consumption and Saving Analysis

4.4. Statistical Analysis

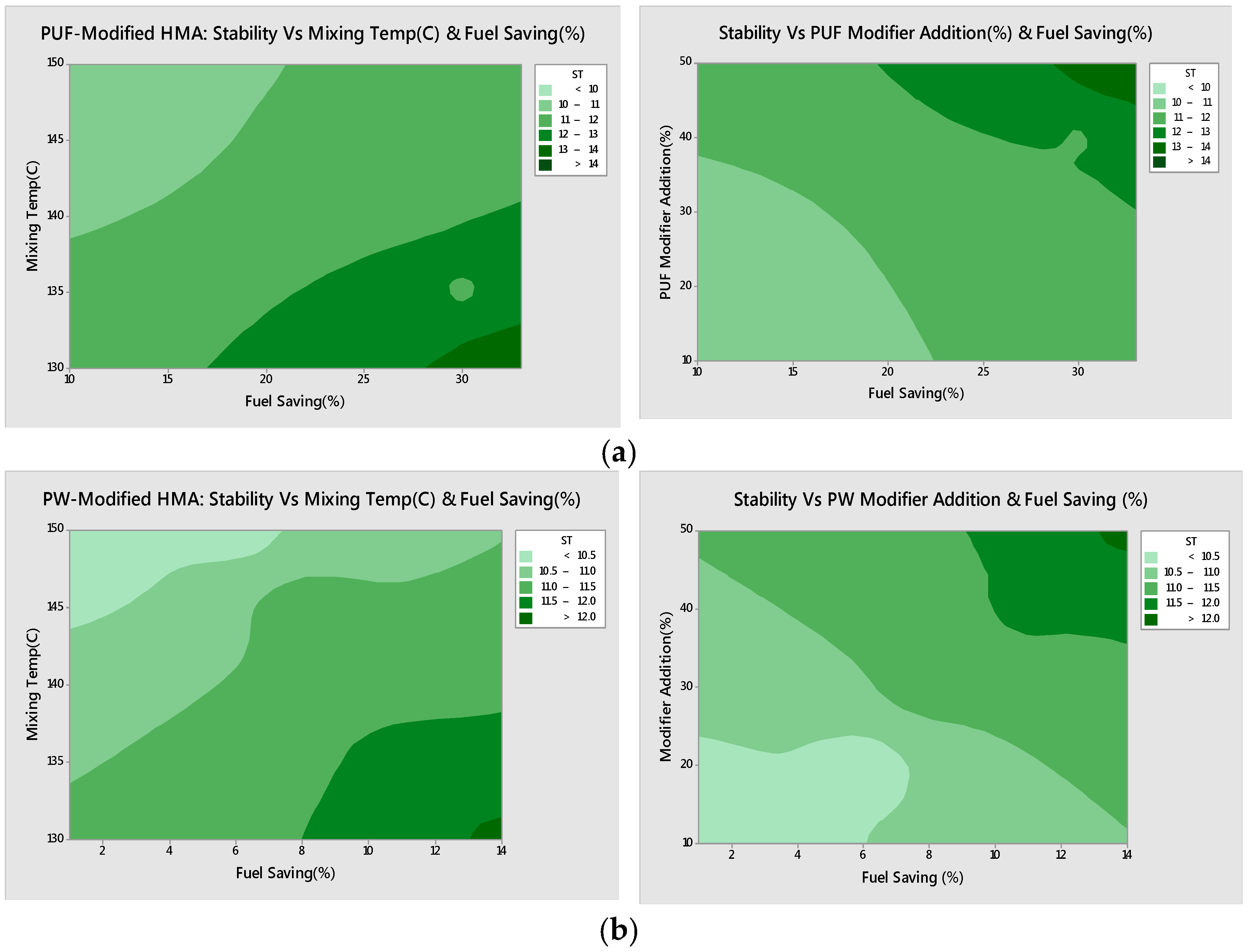

4.4.1. Performance Profiler

4.4.2. Variable Importance

5. Limitations of the Study

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alawi, M.H.; Rajab, M.I. Applications of neural network for optimum asphaltic concrete mixtures. In Proceedings of the 5th WSEAS International Conference on Simulation, Modelling and Optimization, Corfu, Greece, 17–19 August 2005. [Google Scholar]

- ASTM. D6927-15. Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Vaiana, R.; Iuele, T.; Gallelli, V. Warm mix asphalt with synthetic zeolite: A laboratory study on mixes workability. Int. J. Pavement Res. Technol. 2013, 6, 562–569. [Google Scholar]

- Vaiana, R.; Iuele, T.; Gallelli, V.; Tighe, S.L. Warm mix asphalt by water-containing methodology: A laboratory study on workability properties versus micro-foaming time. Can. J. Civ. Eng. 2013, 41, 183–190. [Google Scholar] [CrossRef]

- Boger, Z.; Guterman, H. Knowledge extraction from artificial neural network models. In Proceedings of the 1997 IEEE International Conference on Systems, Man, and Cybernetics, Orlando, FL, USA, 12–15 October 1997. [Google Scholar]

- Brown, E.R.; Kandhal, P.S.; Zhang, J. Performance Testing for Hot Mix Asphalt; National Center for Asphalt Technology Report, 2001(01-05); NCAT: Auburn, AL, USA, 2001. [Google Scholar]

- Cannistraro, G.; Cannistraro, M.; Cannistraro, A.; Galvagno, A.; Engineer, F. Analysis of air pollution in the urban center of four cities Sicilian. Int. J. Heat Technol. 2016, 34, S219–S225. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, A.; Cannistraro, M.; Engineer, F. Evaluation of the sound emissions and climate acoustic in proximity of one railway station. Hospitals 2016, 6, 22.00–26.00. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Mindra, N.; Railean, A.; Rojí, E. Rigid pavement performance models by means of Markov Chains with half-year step time. Int. J. Pavement Eng. 2017, 1–14. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hislop, W.P.; Zhai, H.; Rangel, A. Classification of asphalt binders into simple and complex binders. J. Assoc. Asph. Paving Technol. 1998, 67, 1–41. [Google Scholar]

- Smagulova, N.; Kairbekov, Z.; Ermek, A.; Yermoldina, E. Production of bitumens from coal sources modified by elementary sulfur. In Advanced Materials Research; Trans Tech Publ: Princeton, NJ, USA, 2012. [Google Scholar]

- Masson, J. Brief review of the chemistry of polyphosphoric acid (PPA) and bitumen. Energy Fuels 2008, 22, 2637–2640. [Google Scholar] [CrossRef]

- Senior-Arrieta, V.; Córdoba-Maquilón, J. Mechanical characterization of porous asphalt mixes modified with fatty acid amides-FAA. Ingeniería e Investigación 2017, 37, 43–48. [Google Scholar] [CrossRef]

- Navarro, F.; Partal, P.; Martınez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Bai, M. Investigation of low-temperature properties of recycling of aged SBS modified asphalt binder. Constr. Build. Mater. 2017, 150, 766–773. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Modification of road bitumens with thermoplastic polymers. Polym. Test. 2000, 20, 77–86. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Valtorta, D.; Poulikakos, L.; Partl, M.; Mazza, E. Rheological properties of polymer modified bitumen from long-term field tests. Fuel 2007, 86, 938–948. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Jimenez del Barco, A.; Rubio-Gámez, M. Analysis of the influence of binder properties on the mechanical response of bituminous mixtures. Int. J. Pavement Eng. 2017, 18, 73–82. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, Y.; Han, S.; Yang, Y. Application of FTIR spectroscopy with solvent-cast film and PLS regression for the quantification of SBS content in modified asphalt. Int. J. Pavement Eng. 2017, 1–6. [Google Scholar] [CrossRef]

- Yousefi, A.A. Polyethylene dispersions in bitumen: The effects of the polymer structural parameters. J. Appl. Polym. Sci. 2003, 90, 3183–3190. [Google Scholar] [CrossRef]

- Pérez, I.; Toledano, M.; Gallego, J.; Taibo, J. Mechanical properties of hot mix asphalt made with recycled aggregates from reclaimed construction and demolition debris. Materiales de Construcción 2007, 57, 17–29. [Google Scholar]

- Su, N.; Chen, J. Engineering properties of asphalt concrete made with recycled glass. Resour. Conserv. Recycl. 2002, 35, 259–274. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Chen, M.-Z.; Lin, J.-T.; Wu, S.-P.; Liu, C.-H. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 1532–1536. [Google Scholar] [CrossRef]

- Al-Abdul Wahhab, H.; Dalhat, M.; Habib, M. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2017, 18, 1117–1134. [Google Scholar] [CrossRef]

- García-Travé, G.; Tauste, R.; Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M. Mechanical Performance of SMA Mixtures Manufactured with Reclaimed Geomembrane–Modified Binders. J. Mater. Civ. Eng. 2017, 30, 04017284. [Google Scholar] [CrossRef]

- Vila-Cortavitarte, M.; Lastra-González, P.; Calzada-Pérez, M.Á.; Indacoechea-Vega, I. Analysis of the influence of using recycled polystyrene as a substitute for bitumen in the behaviour of asphalt concrete mixtures. J. Clean. Prod. 2018, 170, 1279–1287. [Google Scholar] [CrossRef]

- Wen, Y.; Wang, Y.; Zhao, K.; Sumalee, A. The use of natural rubber latex as a renewable and sustainable modifier of asphalt binder. Int. J. Pavement Eng. 2017, 18, 547–559. [Google Scholar] [CrossRef]

- Junco, C.; Gadea, J.; Rodríguez, A.; Gutiérrez-González, S.; Calderón, V. Durability of lightweight masonry mortars made with white recycled polyurethane foam. Cem. Concr. Compos. 2012, 34, 1174–1179. [Google Scholar] [CrossRef]

- Gutiérrez-González, S.; Gadea, J.; Rodríguez, A.; Junco, C.; Calderón, V. Lightweight plaster materials with enhanced thermal properties made with polyurethane foam wastes. Constr. Build. Mater. 2012, 28, 653–658. [Google Scholar] [CrossRef]

- Tribout, C.; Husson, B. Use of treated sediments in road building techniques. Eur. J. Environ. Civ. Eng. 2011, 15, 197–213. [Google Scholar] [CrossRef]

- Izquierdo, M.A.; Navarro, F.J.; Martínez-Boza, F.J.; Gallegos, C. Bituminous polyurethane foams for building applications: Influence of bitumen hardness. Constr. Build. Mater. 2012, 30, 706–713. [Google Scholar] [CrossRef]

- Carrera, V.; Cuadri, A.; García-Morales, M.; Partal, P. The development of polyurethane modified bitumen emulsions for cold mix applications. Mater. Struct. 2015, 48, 3407–3414. [Google Scholar] [CrossRef]

- Padhan, R.K.; Gupta, A.A. Preparation and evaluation of waste PET derived polyurethane polymer modified bitumen through in situ polymerization reaction. Constr. Build. Mater. 2018, 158, 337–345. [Google Scholar] [CrossRef]

- Olden, J.D.; Joy, M.K.; Death, R.G. An accurate comparison of methods for quantifying variable importance in artificial neural networks using simulated data. Ecol. Model. 2004, 178, 389–397. [Google Scholar] [CrossRef]

- Alamo-Nole, L.A.; Perales-Perez, O.; Roman-Velazquez, F.R. Sorption study of toluene and xylene in aqueous solutions by recycled tires crumb rubber. J. Hazard. Mater. 2011, 185, 107–111. [Google Scholar] [CrossRef] [PubMed]

- Al-Hadidy, A.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Canavate, J. Composites reinforced with reused tyres: Surface oxidant treatment to improve the interfacial compatibility. Compos. Part A Appl. Sci. Manuf. 2007, 38, 44–50. [Google Scholar] [CrossRef]

- Cuadri, A.; García-Morales, M.; Navarro, F.; Partal, P. Processing of bitumens modified by a bio-oil-derived polyurethane. Fuel 2014, 118, 83–90. [Google Scholar] [CrossRef]

- Copper, K.; Pell, P.S. The Effect of Mix Variables on the Fatigue Strength of Bituminous Materials; Transport and Road Research Laboratory (TRRL): Wokingham, UK, 1974. [Google Scholar]

- Garson, G.D. Interpreting neural-network connection weights. AI Expert 1991, 6, 46–51. [Google Scholar]

- Gibson, N.H. A Viscoelastoplastic Continuum Damage Model for the Compressive Behavior of Asphalt Concrete. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2006. [Google Scholar]

- Goh, A.T. Seismic liquefaction potential assessed by neural networks. J. Geotech. Eng. 1994, 120, 1467–1480. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Kalyoncuoglu, S.F.; Tigdemir, M. An alternative approach for modelling and simulation of traffic data: Artificial neural networks. Simul. Model. Pract. Theory 2004, 12, 351–362. [Google Scholar] [CrossRef]

- Nelder, J.A.; Mead, R. A simplex method for function minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Isacsson, U.; Lu, X. Testing and appraisal of polymer modified road bitumens—State of the art. Mater. Struct. 1995, 28, 139–159. [Google Scholar] [CrossRef]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Gupta, K.; Chopra, T.; Kumar, M. Laboratory Investigations of DBM (Grade 1) Mix Using Different Types of Additives. In Functional Pavement Design; CRC Press: London, UK, 2016; pp. 393–402. [Google Scholar]

- Khanna, S.; Justo, C.; Veeraragavan, A. Highway Materials and Pavement Testing (Laboratory Manual); Nemchand and Bros: Roorkee, India, 2000. [Google Scholar]

- King, G.N.; King, H.W. Polymer Olymer Modified Asphalts: An Overview. In Solutions for Pavement Rehabilitation Problems; American Society of Civil Engineers: Berkeley, CA, USA, 1986. [Google Scholar]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Cannistraro, M.; Lorenzini, E. The applications of the new technologies “e-sensing” in hospitals. Dev. Res. 2016, 1, 11. [Google Scholar] [CrossRef]

- Wulandari, P.S.; Tjandra, D. Use of crumb rubber as an additive in asphalt concrete mixture. Procedia Eng. 2017, 171, 1384–1389. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials. Int. J. Sustain. Built Environ. 2016, 5, 46–82. [Google Scholar] [CrossRef]

- Khan, T.A.; Sharma, D. Effect of waste polymer modifier on the properties of bituminous concrete mixes. Constr. Build. Mater. 2011, 25, 3841–3848. [Google Scholar]

- Nkanga, U.J.; Joseph, J.A.; Adams, F.V.; Uche, O.U. Characterization of bitumen/plastic blends for flexible pavement application. Procedia Manuf. 2017, 7, 490–496. [Google Scholar] [CrossRef]

- Widojoko, L.; Purnamasari, P.E. Study the use of cement and plastic bottle waste as ingredient added to the asphaltic concrete wearing course. Procedia Soc. Behav. Sci. 2012, 43, 832–841. [Google Scholar] [CrossRef]

- Adedeji, A.; Grünfelder, T.; Bates, F.; Macosko, C.; Stroup-Gardiner, M.; Newcomb, D. Asphalt modified by SBS triblock copolymer: Structures and properties. Polym. Eng. Sci. 1996, 36, 1707–1723. [Google Scholar] [CrossRef]

- ISO. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 6: Determination of Bulk Density of Bituminous Specimens; EN-ISO 12697; ISO: Geneva, Switzerland, 2012; Volume 6. [Google Scholar]

- Bansal, S.; Misra, A.K.; Bajpai, P. Evaluation of modified bituminous concrete mix developed using rubber and plastic waste materials. Int. J. Sustain. Built Environ. 2017, 6, 442–448. [Google Scholar] [CrossRef]

- Gawande, A.; Zamare, G.; Renge, V.; Tayde, S.; Bharsakale, G. An overview on waste plastic utilization in asphalting of roads. J. Eng. Res. Stud. 2012, 3, 01–05. [Google Scholar]

- Hendriks, C.F.; Janssen, G. Reuse of construction and demolition waste in the Netherlands for road constructions. Heron 2001, 46, 109–117. [Google Scholar]

- Ling, M.; Luo, X.; Hu, S.; Gu, F.; Lytton, R.L. Numerical modeling and artificial neural network for predicting J-integral of top-down cracking in asphalt pavement. Transp. Res. Rec. J. Transp. Res. Board 2017, 2631, 83–95. [Google Scholar] [CrossRef]

- Siddique, R.; Aggarwal, P.; Aggarwal, Y. Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv. Eng. Softw. 2011, 42, 780–786. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Piccolo, A.; Restivo, R. Potentials and Limits of Oxidative Photocatalysisand Possible Applications in the Field of Cultural Heritage. In Advanced Materials Research; Trans Tech Publ: Princeton, NJ, USA, 2013. [Google Scholar]

| Properties/Tests | Units | Limit | Test Method |

|---|---|---|---|

| Density at 25 °C | Kg/m3 | 1010–1060 | ASTM D70 or D3289 |

| Penetration at 25 °C | Mm/10 | 60–70 | ASTM D5 |

| Softening point | °C | 49–56 | ASTM D36 |

| Ductility at 25 °C | cm | 100 min | ASTM D113 |

| Loss of heating | wt% | 0.2 max | ASTM D6 |

| Drop in penetration after heating | % | 20 max | ASTM D5 |

| Flash point | °C | 232 min | ASTM D92 |

| Solubility in trichloroethylene | wt% | 99.0 min | ASTM D2042 |

| Spot test | - | Negative | AASHTO 102 |

| Viscosity at 60 °C | p | 2000 ± 400 | ASTM D2171 |

| Viscosity at 135 °C | cst | 300 min | ASTM D2170 |

| Test on Residue From Thin Film Oven Test (ASTM D1754) | |||

| Retained penetration (TFOT) | % | 54 min | ASTM D5 |

| Ductility (25 °C), 5 cm/min, cm after TFOT | cm | 50 | ASTM D113 |

| Viscosity at 60 °C | p | 1000 max | ASTM D2171 |

| Type of Test | Test Method | Results | Specifications |

|---|---|---|---|

| Aggregate impact test | BS812: Part 3 | 20.47% | Less than 27% |

| Los Angeles abrasion test | ASTM: C131 | 31% | Less than 35% |

| Aggregate crushing test | BS812: Part 3 | 26.59% | Less than 30% |

| Water absorption test | ASTM: C127 | 1.50% | Less than 2% |

| Specific gravity (aggregate) | ASTM:C127 | 2.37 | 2–3 |

| Passing Sieve Designation | Retained on Sieve Designation | Percent by Weight * |

|---|---|---|

| ¾ in. (19.0 mm) | ½ in. (12.5 mm) | 5 |

| ½ in. (12.5 mm) | 3/8 in. (9.5 mm) | 20 |

| 3/8 in. (9.5 mm) | No. 4 (4.75 mm) | 25 |

| No. 4 (4.75 mm) | No. 10 (2.00 mm) | 15 |

| Total coarse aggregate | - | 65 |

| No. 10 (2.00 mm) | No. 40 (0.475 mm) | 10 |

| No. 40 (0.475 mm) | No. 80 (0.177 mm) | 10 |

| No. 80 (0.177 mm) | No. 200 (0.75 mm) | 8 |

| No. 200 (0.75 mm) | - | 7 |

| Total fine aggregate and filler | - | 35 |

| Total mineral aggregate | - | 100 |

| Bituminous mix | - | - |

| Total mineral aggregate | - | 93 |

| Bitumen content | - | 7 |

| Total mix | - | 100 |

| Sample | Composition | Penetration | Ductility | Flash Point | Softening Point |

|---|---|---|---|---|---|

| (25 °C, 100 g, 5 s) | 25 °C | 1 °C | °C | ||

| Test Method | ASTM: D5-97 | ASTM: D113 | ASTM: D92-16b | ASTM: D36 | |

| Units | 0.1 mm | 1 cm | 1 °C | 1 °C | |

| PUF 1 | 100% B + 0% PUF | 66.0 | 99 | 266 | 55 |

| PUF2 | 90% B + 10% PUF | 65.1 | 98 | 238 | 58 |

| PUF3 | 80% B + 20% PUF | 64.7 | 98 | 230 | 60 |

| PUF4 | 70% B + 30% PUF | 64.0 | 96 | 225 | 63 |

| PUF5 | 60% B + 40% PUF | 63.3 | 94 | 213 | 66 |

| PUF6 | 50% B + 50% PUF | 61.0 | 91 | 203 | 68 |

| PW1 | 100% B +0% PW | 66.0 | 99 | 266 | 55 |

| PW2 | 90% B+ 10% PW | 61.0 | 86 | 231 | 60 |

| PW3 | 80% B + 20% PW | 54.0 | 75 | 219 | 64 |

| PW4 | 70% B + 30% PW | 43.0 | 69 | 208 | 67 |

| PW5 | 60% B + 40% PW | 27.0 | 63 | 200 | 71 |

| PW6 | 50% B + 50% PW | 23.0 | 57 | 187 | 73 |

| Standard | Pure bitumen | 60–70 | >75 | 232 min | 40–55 |

| Remarks | - | >60 are ok | >75 are ok | >232 min are ok | higher than level |

| Sample | Composition | Marshall Stability (60 °C) | Marshall Flow (60 °C) | Mixing Temp (°C) |

|---|---|---|---|---|

| Test Method | ASTM: D1559 | ASTM: D1559 | ||

| Units | KN | mm | ||

| Polyurethane Foam (PUF) | ||||

| PUF 1 | 100% B + 0% PUF | 9.65 | 2.23 | 160 |

| PUF 2 | 90% B + 10% PUF | 10.05 | 2.84 | 150 |

| PUF 3 | 80% B + 20% PUF | 10.34 | 3.01 | 150 |

| PUF 4 | 70% B + 30% PUF | 11.63 | 3.35 | 145 |

| PUF 5 | 60% B + 40% PUF | 11.97 | 3.97 | 135 |

| PUF 6 | 50% B + 50% PUF | 13.92 | 4.16 | 130 |

| Plastic Waste (PW) | ||||

| PW 1 | 100% B + 0% PW | 9.65 | 2.23 | 160 |

| PW 2 | 90% B + 10% PW | 10.09 | 2.79 | 150 |

| PW 3 | 80% B + 20% PW | 10.36 | 3.01 | 150 |

| PW 4 | 70% B + 30% PW | 11.12 | 3.51 | 145 |

| PW 5 | 60% B + 40% PW | 11.54 | 3.78 | 135 |

| PW 6 | 50% B + 50% PW | 12.04 | 4.03 | 130 |

| Standard | With pure bitumen | >9 | 2–4 | 100–170 |

| Remarks | - | ok: criteria fulfilled | ok: within range | ok: within range |

| S.N. | Modifier + Bitumen | Mixing Temp (°C) | Used Fuel Vol. (L) | % Fuel Saving (Gas) |

|---|---|---|---|---|

| 1 | 0% PUF + 100% B | 160 | 0.200 | - |

| 2 | 10% PUF + 90% B | 150 | 0.180 | 10% |

| 3 | 20% PUF + 80% B | 150 | 0.174 | 13% |

| 4 | 30% PUF + 70% B | 145 | 0.148 | 26% |

| 5 | 40% PUF + 60% B | 135 | 0.134 | 33% |

| 6 | 50% PUF + 50% B | 130 | 0.134 | 33% |

| 1 | 0% PW add + 100% B | 160 | 0.200 | - |

| 2 | 10% PW + 90% B | 150 | 0.198 | 1% |

| 3 | 20% PW + 80% B | 150 | 0.187 | 6.5% |

| 4 | 30% PW + 70% B | 145 | 0.184 | 8% |

| 5 | 40% PW + 60% B | 135 | 0.178 | 11% |

| 6 | 50% PW + 50% B | 130 | 0.172 | 14% |

| Parameter | Estimate | Std Error | t Ratio | Prob > |t| |

|---|---|---|---|---|

| Intercept | −74.18191 | 34.68682 | −2.14 | 0.0417 * |

| Modifier (%) | 0.3436028 | 0.127946 | 2.69 | 0.0122 * |

| Modifier type [BIT] | −2.242923 | 1.283906 | −1.75 | 0.0920 |

| Modifier type [PUF] | 7.3048418 | 0.768412 | 9.51 | <0.0001 * |

| Stability (KN) | 3.6878587 | 1.099319 | 3.35 | 0.0024 * |

| Mixing temp (°C) | 0.255308 | 0.198011 | 1.29 | 0.2082 |

| R2 | 0.954754 | Remarks: Near to 1 = V. Good | ||

| RMSE | 2.508468 | Remarks: V. Low = V. Good | ||

| N | 33 | Sample Size | ||

| Parameter | Main Effect | Total Effect | Graphical Description |

|---|---|---|---|

| Modifier type | 0.289 | 0.416 |  |

| Modifier (%) | 0.272 | 0.272 |  |

| Mixing temp (°C) | 0.253 | 0.253 |  |

| Stability (KN) | 0.186 | 0.186 |  |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raheel Shah, S.A.; Arshad, H.; Waqar, A.; Saeed, M.H.; Hafeez, S.; Mansoor, J.; Sadiq, A.N.; Malik, M.A. Saving Energy in the Transportation Sector: An Analysis of Modified Bitumen Application Based on Marshall Test. Energies 2018, 11, 3025. https://doi.org/10.3390/en11113025

Raheel Shah SA, Arshad H, Waqar A, Saeed MH, Hafeez S, Mansoor J, Sadiq AN, Malik MA. Saving Energy in the Transportation Sector: An Analysis of Modified Bitumen Application Based on Marshall Test. Energies. 2018; 11(11):3025. https://doi.org/10.3390/en11113025

Chicago/Turabian StyleRaheel Shah, Syyed Adnan, Hunain Arshad, Ahsan Waqar, Muhammad Hasnain Saeed, Salman Hafeez, Junaid Mansoor, Abdullah Naveed Sadiq, and Muhammad Asad Malik. 2018. "Saving Energy in the Transportation Sector: An Analysis of Modified Bitumen Application Based on Marshall Test" Energies 11, no. 11: 3025. https://doi.org/10.3390/en11113025

APA StyleRaheel Shah, S. A., Arshad, H., Waqar, A., Saeed, M. H., Hafeez, S., Mansoor, J., Sadiq, A. N., & Malik, M. A. (2018). Saving Energy in the Transportation Sector: An Analysis of Modified Bitumen Application Based on Marshall Test. Energies, 11(11), 3025. https://doi.org/10.3390/en11113025