Determining Division Location for Sectional Wind Turbine Blades

Abstract

:1. Introduction

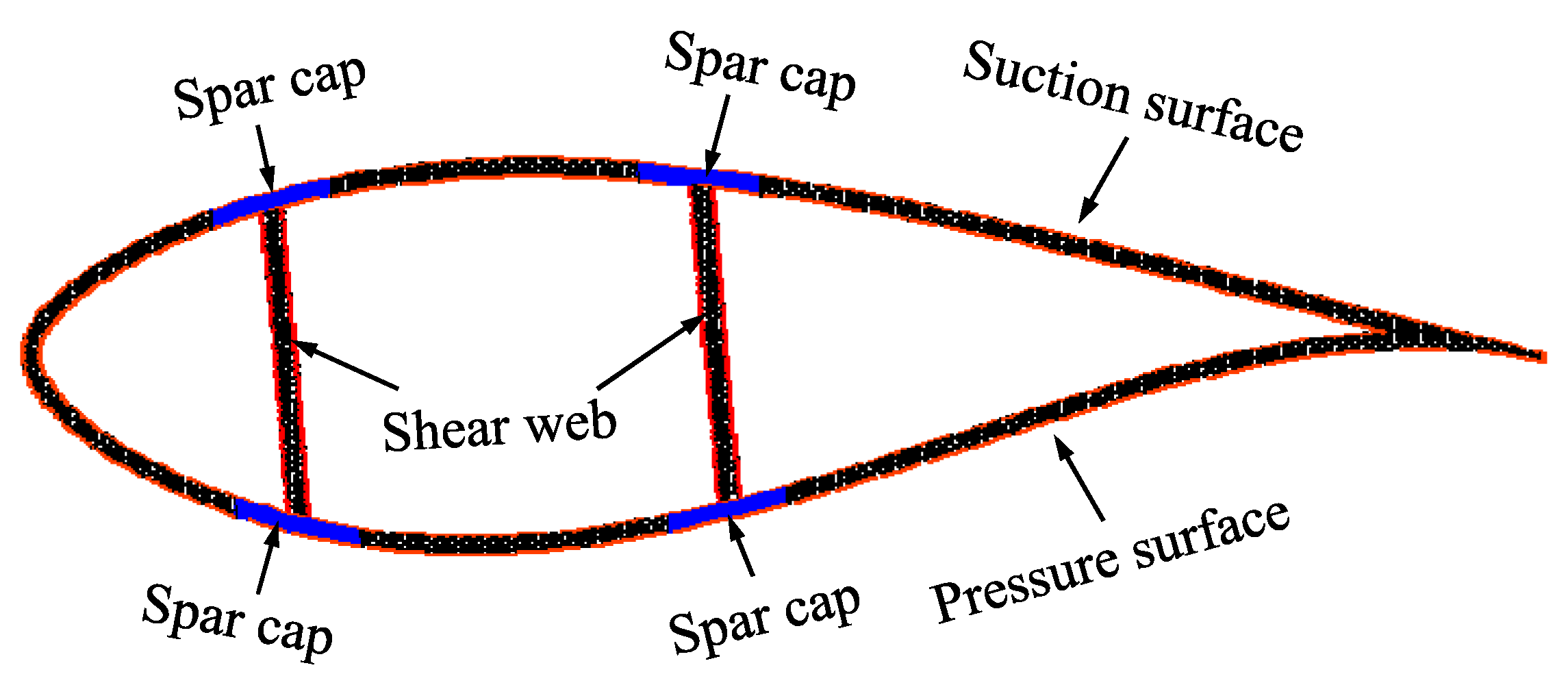

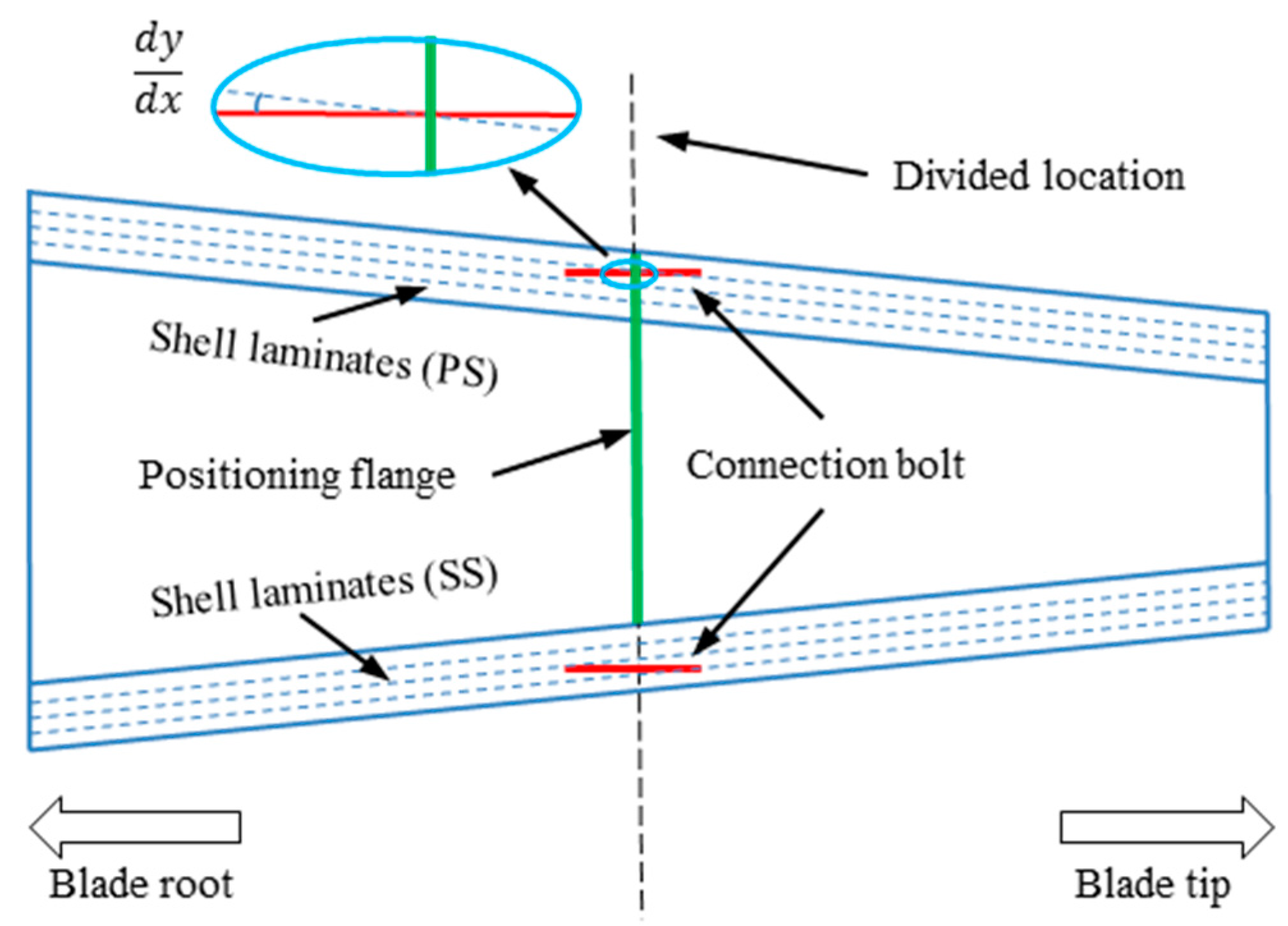

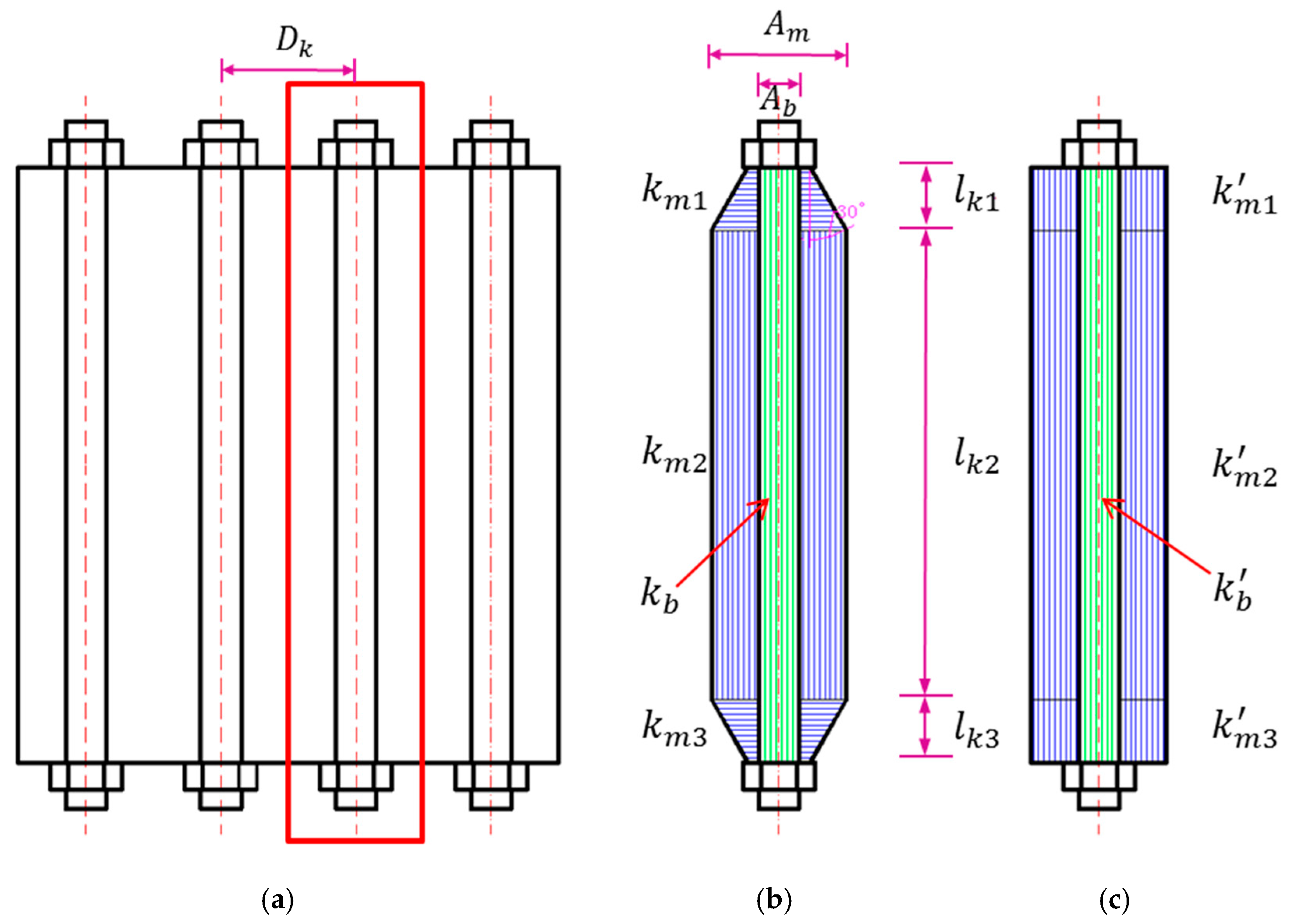

2. Evaluation of Connection Performance of Sectional Blades

2.1. Connection Strength for Sectional Blades

2.2. Manufacturing and Assembling Accessibility for Sectional Blades

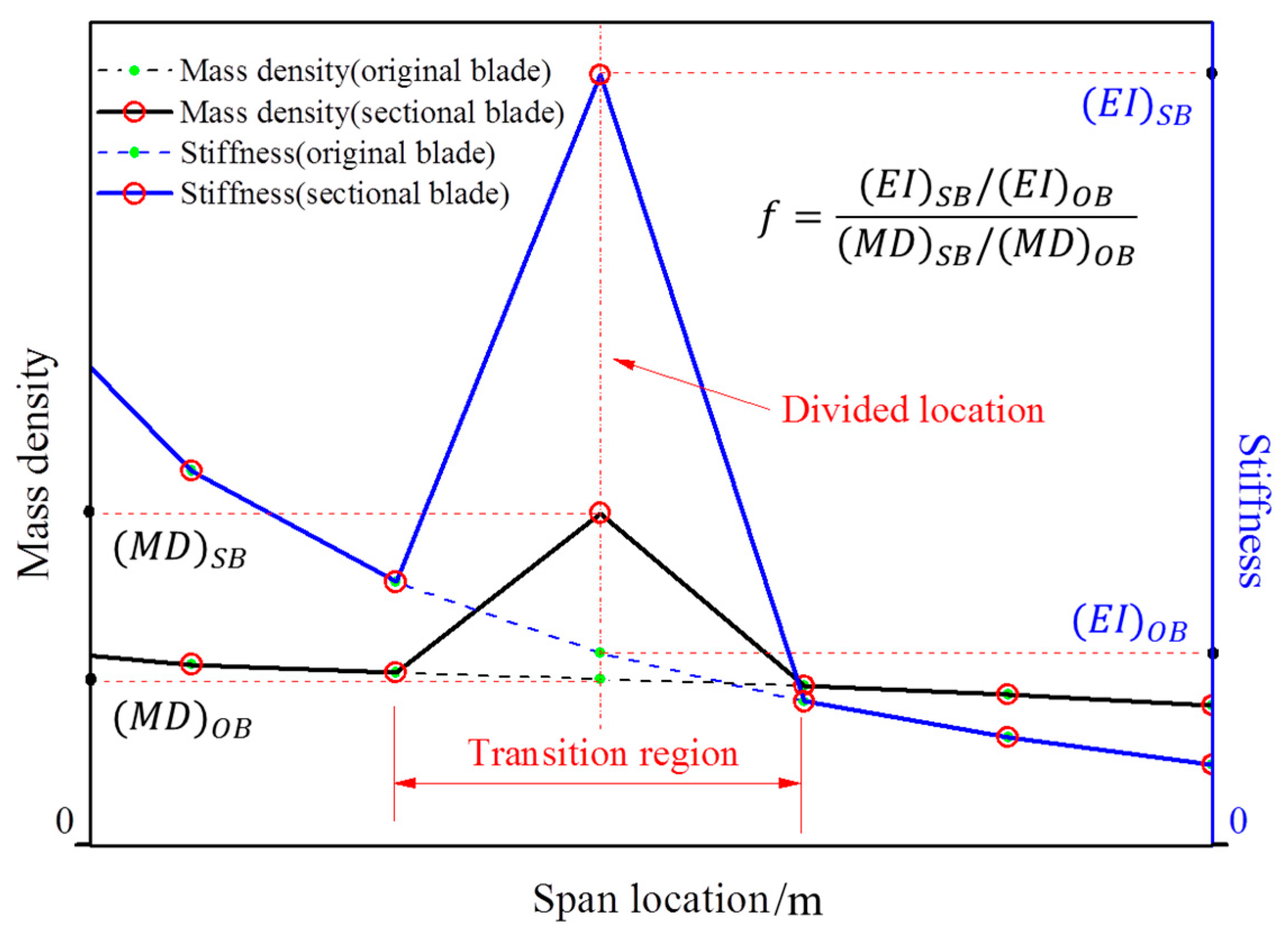

2.3. Division Location Determination by Natural Frequencies of Sectional Blades

2.3.1. Natural Frequencies Calculation

2.3.2. Analysis and Deduction of Parameters and

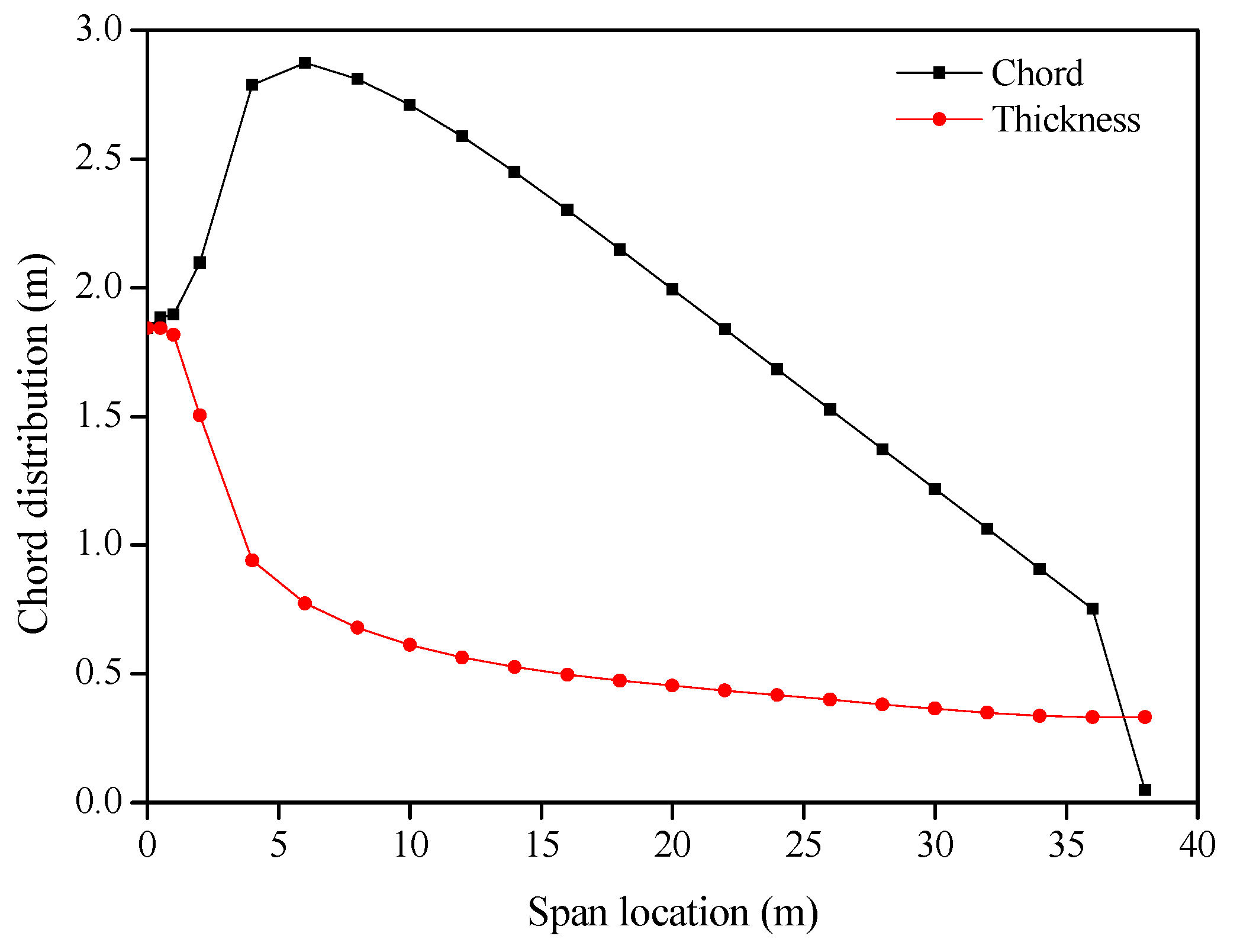

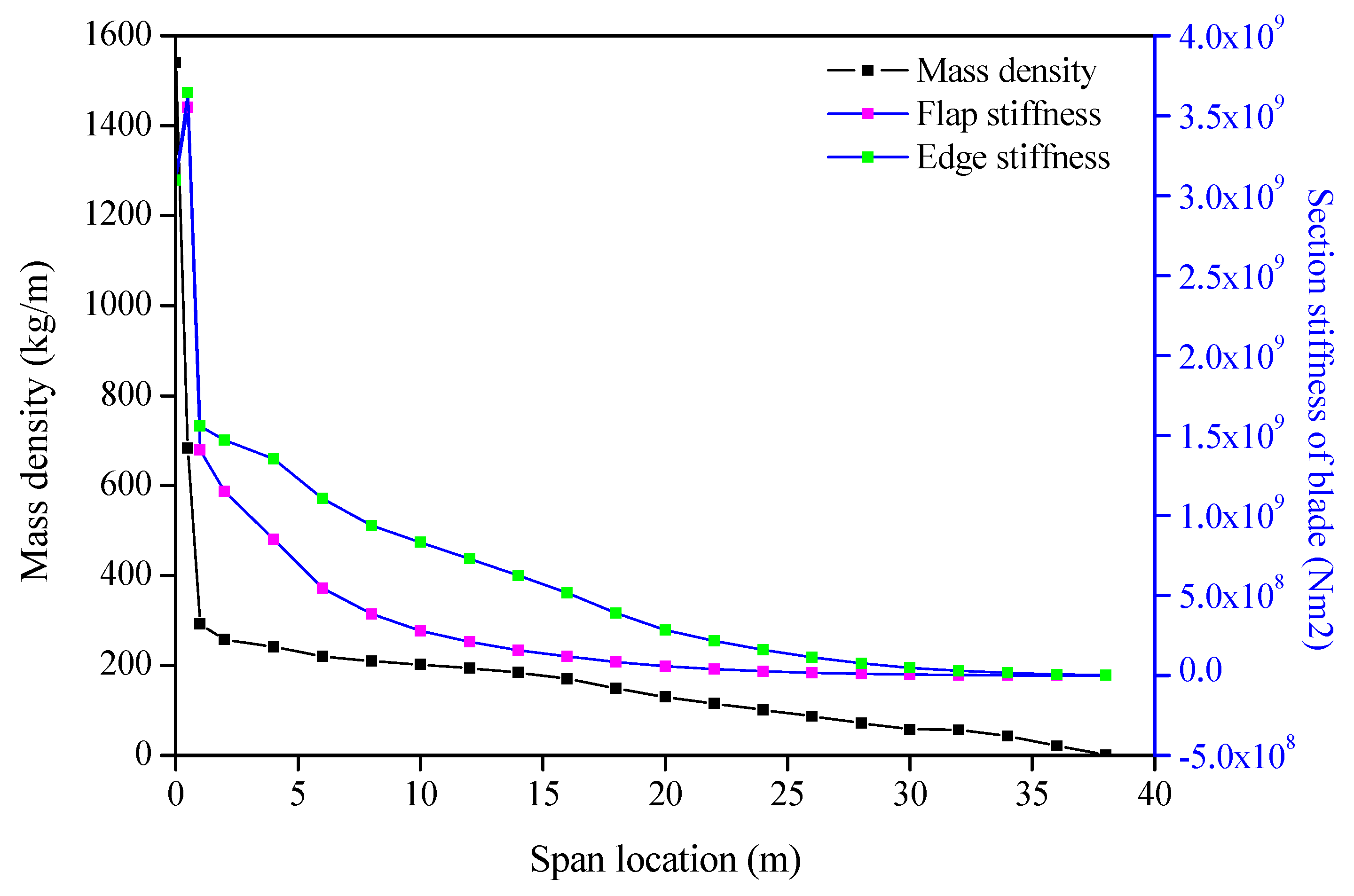

3. Case Study of a Commercial Sectional Blade

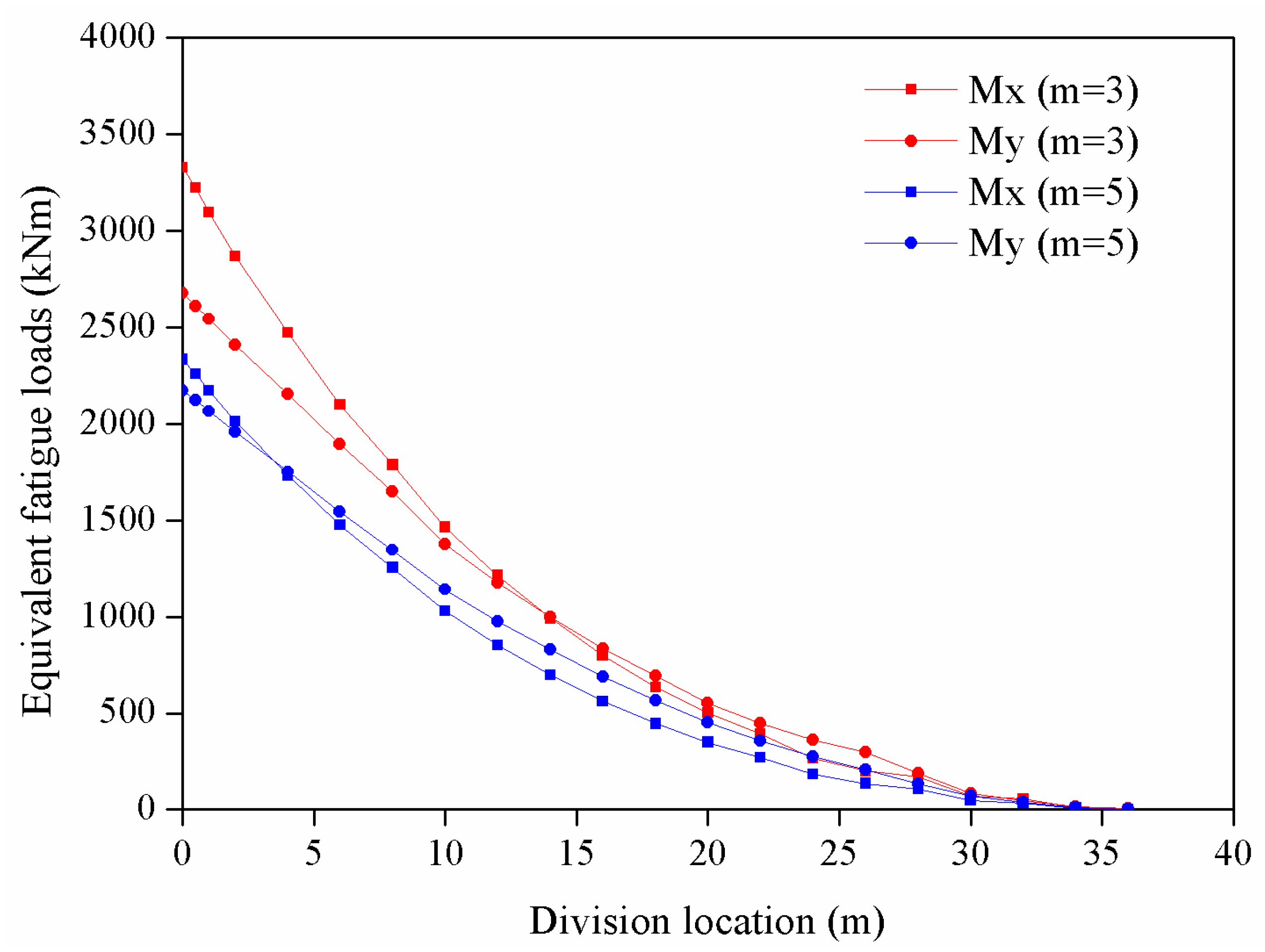

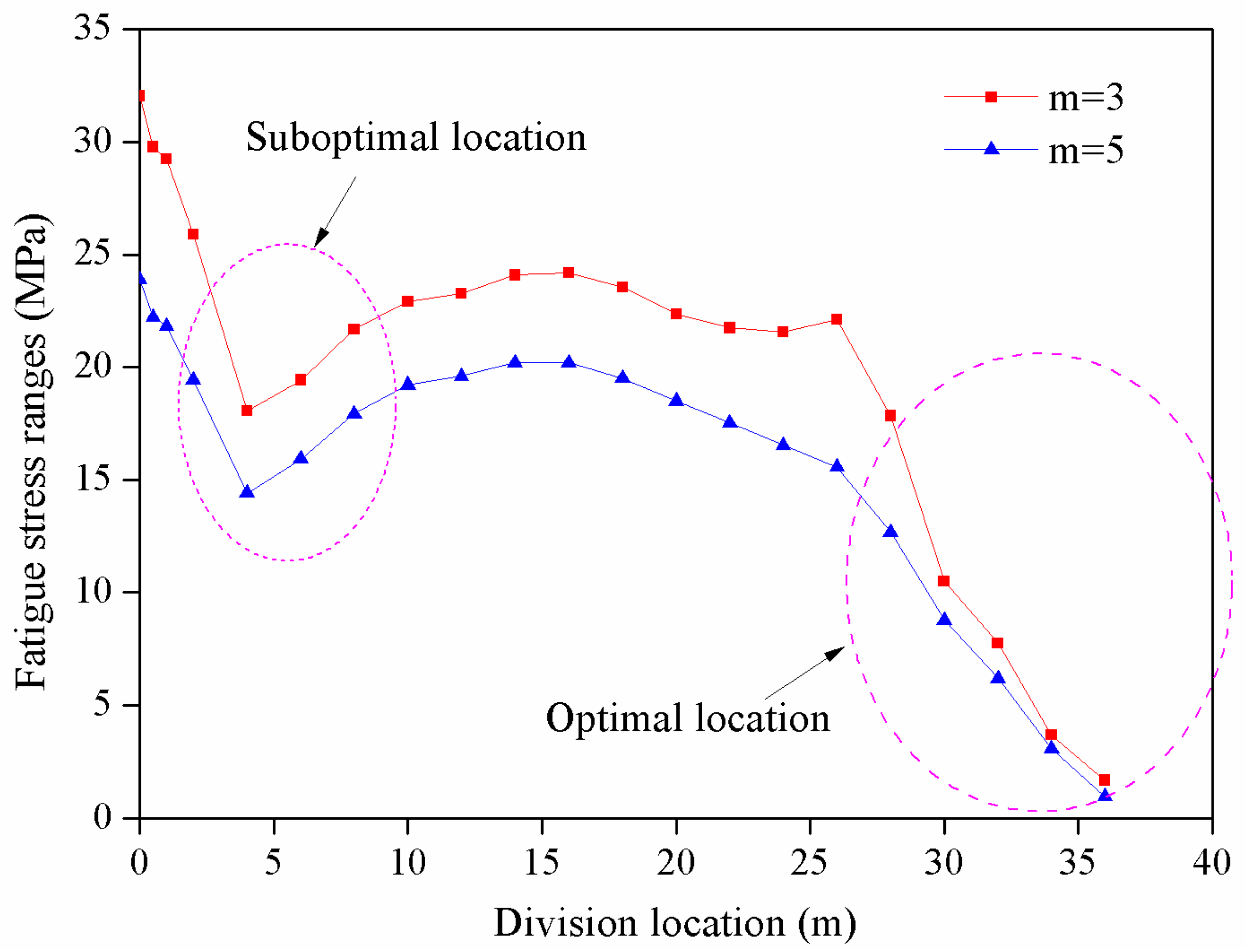

3.1. Calculation of Connection Strength of Sectional Blades

3.2. Manufacturing and Assembling Requirements of Sectional Blades

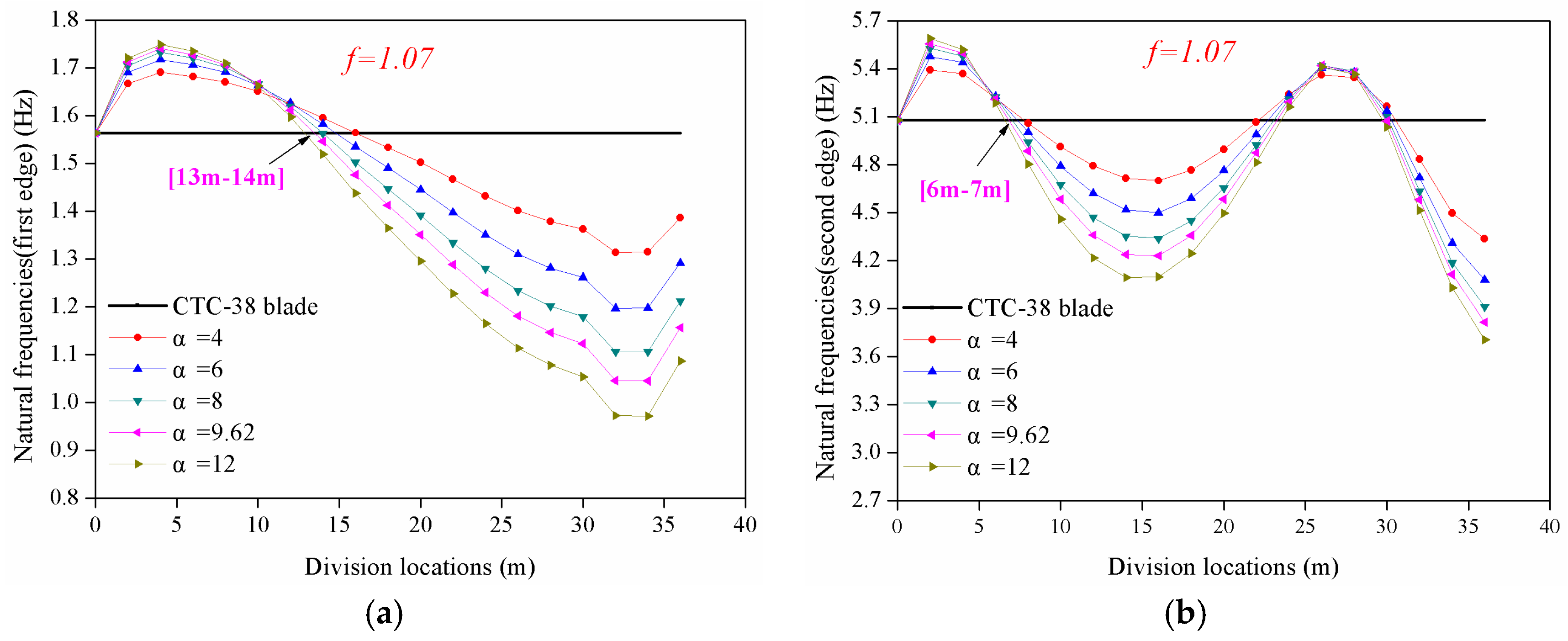

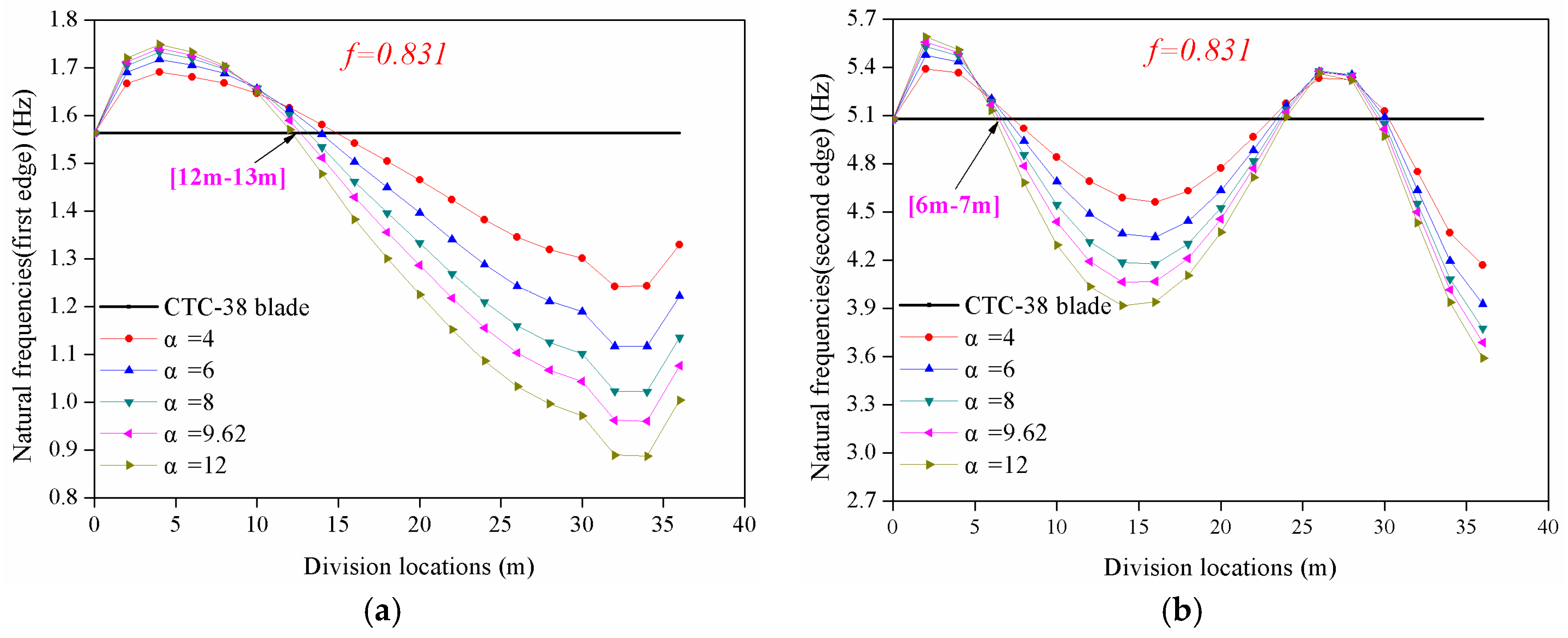

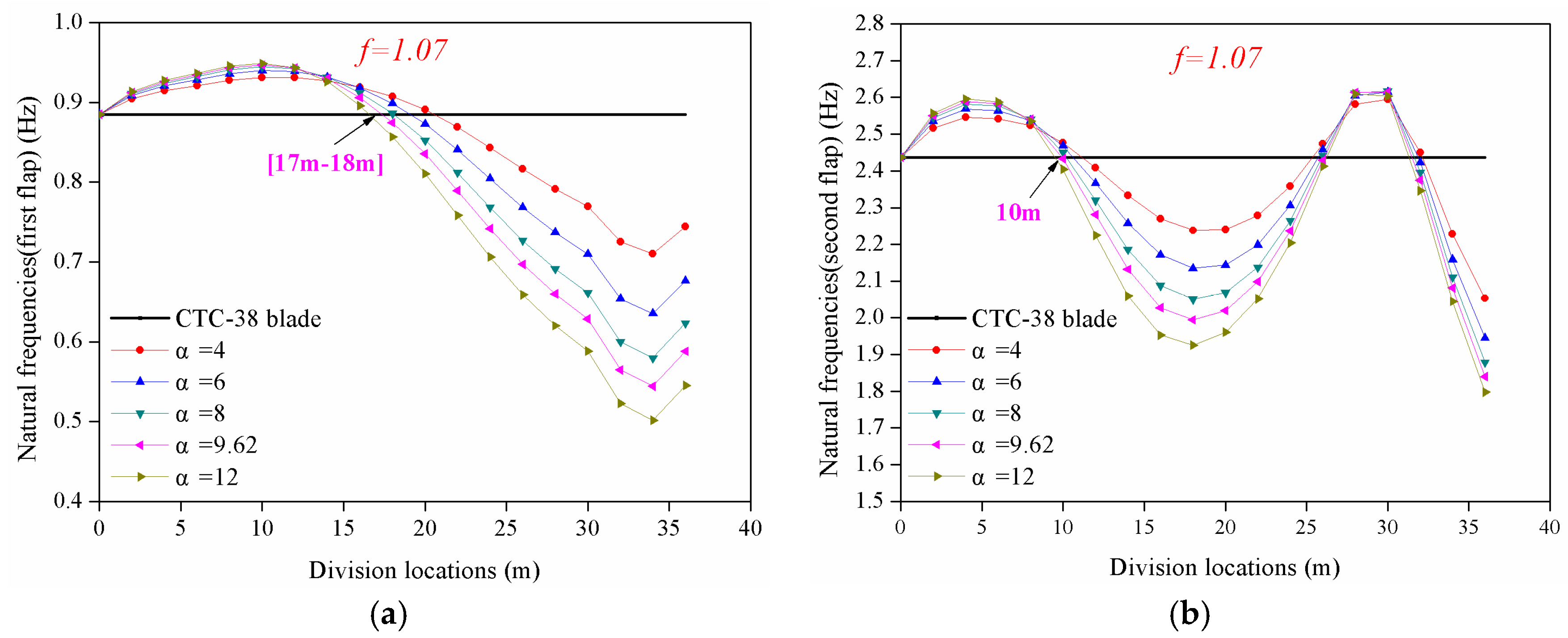

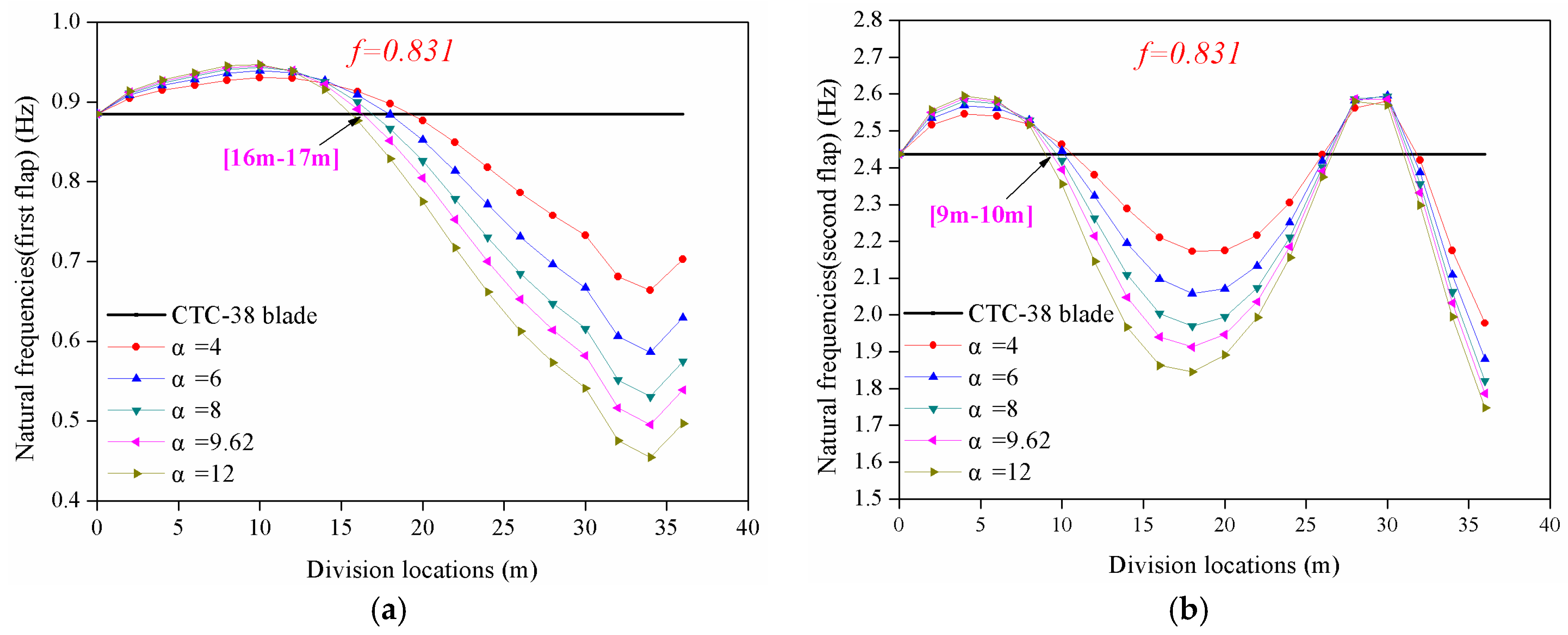

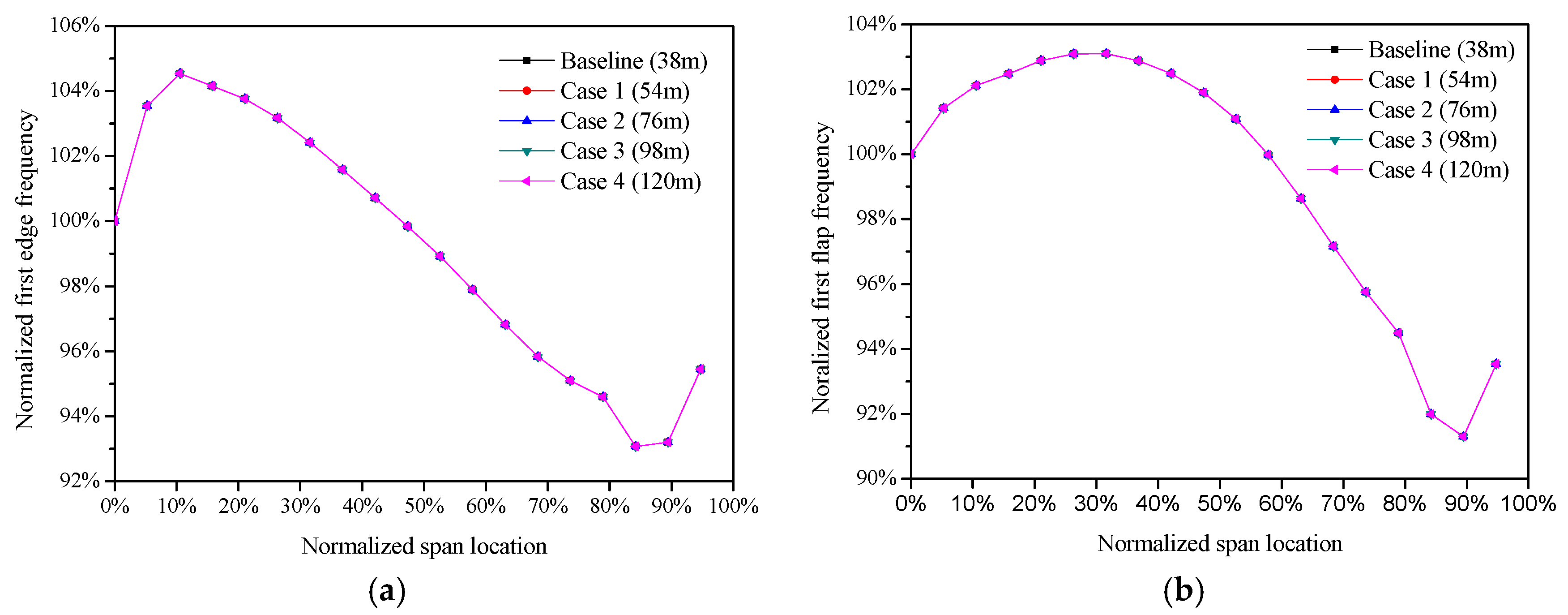

3.3. Natural Frequencies Variation of Sectional Blades

4. Trends of Sectional Blades for Large WTs

4.1. Upscaling Studies of Sectional Blades

4.2. Challenges and Recommendations for Large Sectional Blades

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Symbol | Designation |

| Cross-section area of blade section, general | |

| Cross-section area of bolt, general | |

| Unit cross-section area of assumed bolt | |

| Cross-section area (bolts) of the sectional blade at the division location | |

| Cross-section area (FRC) of the original blade | |

| Cross-section area unit, general | |

| Contact area of clamped members of a bolted joint | |

| Cross-section area of the sectional blade at the division location | |

| Unit cross-section area of assumed blade shell | |

| Constant related to position at the cross-section plane | |

| Constant related to position at the cross-section plane | |

| The chord of the blade section | |

| Constant related to position at the cross-section plane | |

| Distance of adjacent bolts in multi-bolted joints of the sectional blade | |

| Young’s modulus, general | |

| Young’s modulus of the bolt material | |

| Young’s modulus of FRC material | |

| Young’s modulus of the clamped member material | |

| Equivalent young’s modulus of materials of the sectional blade at the division location | |

| Equivalent young’s modulus of materials of the bolted joint based on the ideal stress model | |

| Centrifugal force of blades | |

| Ratio of section bending stiffness to mass density of the sectional to the original blade | |

| A physical dimension, decided by coordinates at given position | |

| Axial stiffness of the bolt | |

| Axial stiffness of the clamped members | |

| Axial stiffness of clamped members based on the ideal stress model, shown in Figure 5c | |

| Axial stiffness of the upper clamped member based on hypothesis stress model, shown in Figure 5b | |

| Axial stiffness of the upper clamped members based on the ideal stress model, shown in Figure 5c | |

| Axial stiffness of the middle clamped member based on hypothesis stress model, shown in Figure 5b | |

| Axial stiffness of the middle clamped member based on the ideal stress model, shown in Figure 5c | |

| Axial stiffness of the bottom clamped member based on hypothesis stress model, shown in Figure 5b | |

| Axial stiffness of the bottom clamped member based on the ideal stress model, shown in Figure 5c | |

| Span–wise length from the rotor center to the center of blade gravity | |

| Axial length of clamped members, shown in Figure 5 | |

| Axial length of upper clamped members, shown in Figure 5 | |

| Axial length of middle clamped members, shown in Figure 5 | |

| Axial length of bottom clamped members, shown in Figure 5 | |

| Bending moments on the x-axis at the cross section | |

| Bending moments on the y-axis at the cross section | |

| Load introduction factor | |

| Permissible load cycle number, defined by Eurocode 3 | |

| Area moment of inertia on the user-defined -axis | |

| Area moment of inertia on the x-axis | |

| Product moment of area | |

| Area moment of inertia on the y-axis | |

| Scale factor for different geometrical blades | |

| First moment of area on the x-axis | |

| First moment of area on the y-axis | |

| Thickness of the blade section | |

| Coordinate value on the x-axis | |

| x coordinate of centroid of the cross-section unit | |

| Coordinate value on the y-axis | |

| y coordinate of centroid of the cross-section unit | |

| Horizontal coordinate axis | |

| Vertical coordinate axis | |

| Bolt load variation of the bolted joint | |

| External load variation of the bolted joint | |

| Fatigue bolt load variation of the bolted joint | |

| External fatigue load variation of the bolted joint | |

| Fluctuating stress limit of bolts for a given fatigue cycles in the sectional blade | |

| Fluctuating stress limit of FRC for a given fatigue cycles in the original blade | |

| Fluctuating stress limit for a given fatigue cycles | |

| Detail category with respect to fatigue cycles, defined in Eurocode 3 | |

| Fluctuating direct stress along the z-axis due to bending moments | |

| Bending stiffness of the original blade | |

| Bending stiffness of the sectional blade | |

| Bending stiffness of the original blade on the x-axis | |

| Bending stiffness of the sectional blade on the x-axis | |

| Bending stiffness of the original blade on the y-axis | |

| Bending stiffness of the sectional blade on the y-axis | |

| Axial stiffness of the original blade | |

| Axial stiffness of the sectional blade | |

| Mass density of the original blade, equal to beam mass of unit length | |

| Mass density of the sectional blade, equal to beam mass of unit length | |

| Load factor of the bolted joint | |

| Load factor of the bolted joint, obtained by the ideal stress model | |

| Axial stiffness ratio of to bolt, calculated by the ideal stress model | |

| Constant related to position at the cross-section plane | |

| Constant related to position at the cross-section plane | |

| Minimum value of | |

| Cross-section area portion of FRC at the division location | |

| Density | |

| Density of connection bolt material for sectional blades | |

| Density of components | |

| Equivalent density of the sectional blade at the division location | |

| Density of FRC material of the original blade | |

| Axial stress due to centrifugal force of blades | |

| Direct stress due to blade weight, | |

| Direct stress due to bending moments, and | |

| Direct stress along the z-axis due to bending moments | |

| Bending stiffness (on the x-axis) ratio of the original blade to the sectional blade at the division location | |

| Bending stiffness (on the y-axis) ratio of the original blade to the sectional blade at the division location | |

| Cross-section mass density ratio of the original blade to the sectional blade at the division location | |

| Variable expressing | |

| Vaing | |

| Variable expressing s | |

| Magnification factors for |

Abbreviations

| WT | Wind turbine |

| FRC | Fiber-reinforced composite |

| GFRC | Glass-fiber-reinforced composite |

Appendix A

References

- Hernández, C.V.; Telsnig, T.; Pradas, A.V. JRC Wind Energy Status Report 2016 Edition. Available online: www.apren.pt/fotos/newsletter/conteudos/wind_energy_status_report-2016_joint_research_centre_2017_1490879640.pdf (accessed on 7 September 2017).

- Barr, A. Blade technology trends and market developments. In Proceedings of the Sandia 2014 Wind Turbine Blade Workshop, Albuquerque, NM, USA, 25–29 August 2014. [Google Scholar]

- IWES Develops Test Field for Offshore Wind Turbines. Available online: http://der-lab.net/iwes-develops-test-field-for-offshore-wind-turbines/ (accessed on 7 September 2017).

- Smith, K. WindPACT Turbine Design Scaling Studies Technical Area 2: Turbine, Rotor, and Blade Logistics. Available online: https://www.nrel.gov/docs/fy01osti/29439.pdf (accessed on 7 September 2017).

- Cotrell, J.; Stehly, T.; Johnson, J.; Roberts, J.; Parker, Z.; Scott, G.; Heimiller, D. Analysis of Transportation and Logistics Challenges Affecting the Deployment of Larger Wind Turbines: Summary of Results. Available online: www.nrel.gov/docs/fy14osti/61063.pdf (accessed on 7 September 2017).

- Griffin, D.A. Blade System Design Studies Volume I: Composite Technologies for Large Wind Turbine Blades. Available online: https://pdfs.semanticscholar.org/7c26/295163ed8dd054f2a6c15127c54ab9003a25.pdf (accessed on 7 September 2017).

- European Wind Energy Association. UpWind: Design Limits and Solutions for Very Large Wind Turbines; European Wind Energy Association: Brussels, Belgium, 2011. [Google Scholar]

- Sieros, G.; Chaviaropoulos, P.; Sørensen, J.D.; Bulder, B.; Jamieson, P. Upscaling wind turbines: Theoretical and practical aspects and their impact on the cost of energy. Wind Energy 2012, 15, 3–17. [Google Scholar] [CrossRef]

- Ashuri, T.; Zaaijer, M.B.; Martins, J.R.; Zhang, J. Multidisciplinary design optimization of large wind turbines—Technical, economic, and design challenges. Energy Conver. Manag. 2016, 123, 56–70. [Google Scholar] [CrossRef]

- Saenz, E.; Nuin, I.; Montejo, R.; Sanz, J. Development and validation of a new joint system for sectional blades. Wind Energy 2014, 18, 419–428. [Google Scholar] [CrossRef]

- MEGAWIND. 30 m Split Rotor Blade. Available online: http://www.cres.gr/megawind/split_rotor_blade.htm (accessed on 7 September 2017).

- Dutton, A.G.; Geiger, T.; Hahn, F.; Olesen, M.; Kenche, C.; Korsgaard, J.; Van Delft, D.R.V. Design concept for sectional wind turbine blades. In Proceedings of the European Wind Energy Conference (EWEC99), Nice, France, 1–5 March 1999. [Google Scholar]

- Dutton, A.G.; Kildegaard, C.; Dobbe, T.; Bensoussan, R.; Kensche, C.; Hahn, F.; Van Delft, D.R.V.; De Winkel, G.D. Design, Structural Testing, and Cost Effectiveness of Sectional Wind Turbine Blades. Available online: http://cordis.europa.eu/project/rcn/37637_en.html (accessed on 7 September 2017).

- Hahn, F.; Kensche, C.W.; Paynter, R.J.H.; Dutton, A.G.; Kildegaard, C.; Korsgaard, J. Design, fatigue test, and NDE of a sectional wind turbine rotor blade. J. Thermoplast. Compos. Mater. 2002, 15, 267–277. [Google Scholar] [CrossRef]

- Vionis, P.; Lekou, D.; Gonzalez, F.; Mieres, J.; Kossivas, T.; Soria, E.; Gutierrez, E.; Galiotis, C.; Philippidis, T.P.; Voutsinas, S.; et al. Development of a MW Scale wind turbine for high wind complex terrain sites: The MEGAWIND project. In Proceedings of the European Wind Energy Conference, Athens, Greece, 27 Feburary–3 March 2006. [Google Scholar]

- GAMESA, G-128 4.5 MW. Available online: http://www.gamesacorp.com (accessed on 7 September 2017).

- ENERCON, E-126 State of the Art. Available online: http://www.enercon.de/en-en/66.htm/ (accessed on 7 September 2017).

- ENERCON, ENERCON Delivers First E-115 Turbines for Export Project. Available online: http://northern-observer.com/enercon-delivers-first-new-turbines-export (accessed on 7 September 2017).

- Qin, Z. The First Sectional Wind Turbine Blade Has Successfully Passed Extreme Static Test in China. Available online: http://www.iet.cn/xwdt/kydt/201511/t20151120_4470609.html (accessed on 7 September 2017). (In Chinese).

- Nanami, N. Structural and Damage Assessment of Multi-Section Modular Hybrid Composite Wind Turbine Blade. Available online: http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/153418/NANAMI-DISSERTATION-2014.pdf?sequence=1&isAllowed=y (accessed on 7 September 2017).

- Bhat, C.; Noronha, D.J.; Saldana, F.A. Structural Performance Evaluation of Segmented Wind Turbine Blade through Finite Element Simulation. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2015, 9, 980–989. [Google Scholar]

- Saldanha, F.A.; Rao, V.V.; Christopher, J.; Adhikari, R. Investigations on concepts for modularizing a horizontal axis wind turbine blade. In Proceedings of the ASME 2013 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Portland, OR, USA, 4–7 August 2013. [Google Scholar]

- Xu, B.; Han, J.L. Numerical simulation on a joint segment of a prestressed prefabricated sectional wind turbine blade model. Eng. Mech. 2016, 33, 209–215. [Google Scholar]

- Kensche, C.W. Fatigue of composites for wind turbines. Int. J. Fatigue 2006, 28, 1363–1374. [Google Scholar] [CrossRef]

- LM. Meet a Record-Breaker: LM 88.4 P. Available online: http://www.lmwindpower.com (accessed on 7 September 2017).

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook, 2nd ed.; John Wiley & Sons: Chichester, UK, 2011. [Google Scholar]

- Lloyd, G. Rules and Guidelines IV Industrial Services: Part I: Guideline for the Certification of Wind Turbines. Available online: https://www.scribd.com/doc/42161563/Guideline-for-the-Certification-of-Win-Turbines-Edition-2010-1 (accessed on 7 September 2017).

- Pilkey, W.D. Formulas for Stress, Strain, and Structural Matrices; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Bickford, J.H. Introduction to the Design and Behavior of Bolted Joints: Non-Gasketed Joints; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- International Electrotechnical Commission. Wind Turbines—Part 3: Design Requirements for Offshore Wind Turbines; International Electrotechnical Commission: Geneva, Switzerland, 2009. [Google Scholar]

- Bickford, J.H. Handbook of Bolts and Bolted Joints; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Verein Deutscher Ingenieure. Systematic Calculation of High Duty Bolt Joints-Joints with One Cylindrical Bolt; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2003. [Google Scholar]

- Lehnhoff, T.F.; Wistehuff, W.E. Nonlinear Effects on the Stresses and Deformations of Bolted Joints. J. Press. Vessel Technol. 1996, 118, 54–58. [Google Scholar] [CrossRef]

- Nassar, S.A.; Yang, X.; Gandham, S.V.T.; Wu, Z. Nonlinear Deformation Behavior of Clamped Bolted Joints under a Separating Service Load. J. Press. Vessel Technol. 2011, 133, 140–144. [Google Scholar] [CrossRef]

- Burguete, R.L.; Patterson, E.A. Effect of mean stress on the fatigue limit of high tensile bolts. ARCHIVE Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1995, 209, 257–262. [Google Scholar] [CrossRef]

- Megson, T.H.G. Structural and Stress Analysis; Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Hosseini-Toudeshky, H.; Jahanmardi, M.; Goodarzi, M.S. Progressive debonding analysis of composite blade root joint of wind turbines under fatigue loading. Compos. Struct. 2014, 120, 417–427. [Google Scholar] [CrossRef]

- Martínez, V.; Güemes, A.; Trias, D.; Blanco, N. Numerical and experimental analysis of stresses and failure in T-bolt joints. Compos. Struct. 2011, 93, 2636–2645. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; Öchsner, A. Modeling of Adhesively Bonded Joints; Springer: Berlin, Germany, 2008. [Google Scholar]

- Hobbs, J.; Burguete, R.; Heyes, P.; Patterson, E. The effect of eccentric loading on the fatigue performance of high-tensile bolts. Int. J. Fatigue 2000, 22, 531–538. [Google Scholar] [CrossRef]

- Eurocode 3: Design of Steel Structures-Part 1–9: Fatigue. Available online: http://www.phd.eng.br/wp-content/uploads/2015/12/en.1993.1.9.2005-1.pdf (accessed on 7 September 2017).

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 9th ed.; McGraw-Hill Series; Mechanical Engineering: New York, NY, USA, 2011. [Google Scholar]

- Griffith, D.T. The SNL100–01 Blade: Carbon Design Studies for the Sandia 100-Meter Blade; SAND2013–1178; Sandia National Laboratories: Albuquerque, NJ, USA, 2013. [Google Scholar]

- Hansen, M.O.L. Aerodynamics of Wind Turbines, 2nd ed.; Routledge: Abingdon, UK, 2008. [Google Scholar]

- Griffith, D.T.; Ashwill, T.D.; Resor, B.R. Large Offshore Rotor Development Design and Analysis of the Sandia 100-meter Wind Turbine Blade. In Proceedings of the 53 AIAA/ASME/ASCE/AHS/ASC Structures, Strutural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

| Sponsor/Supporter | Total Length | Division Location | Connection Type | Status | Date |

|---|---|---|---|---|---|

| DLR | 11.58 m | 5.79 m (50%) | T-bolts | Has run safely for 18 years | 1982 |

| CLRC & LM & DLR & Delft | 13.4 m | 4.5 m (34%) | Tube | Static and fatigue test successfully | 2000 |

| 23.3 m | 7.3 m (31%) | T-bolts | Static and fatigue test successfully | 2000 | |

| CRES | 29.65 m | 12.4 m (42%) | T-bolts | Bolt failure in fatigue test | 2006 |

| Enercon | 59 m | 24 m (40%) | Bolts | A small amount of installation | 2007 |

| Gamesa | 62.5 m | 32 m (51%) | Fitting channel and bolts | Limited installation | 2010 |

| Enercon | 56 m | 12 m (21%) | Bolts | Prototype installation | 2014 |

| IET-wind, CAS | 38 m | 18 m (47%) | Embedded sleeves and bolts | Static test already, preparing for fatigue test | 2015 |

| Variable | Ratio (Scaled/Base) |

|---|---|

| Power () | |

| Mass (m) | |

| Aerodynamic moments () | |

| Centrifugal forces () |

| Stress Cause | Ratio (Scaled/Base) | Features |

|---|---|---|

| Centrifugal forces () | Axial stress | |

| Aerodynamic moments () | Direct stress of bending | |

| Mass () | Direct stress of bending |

| Variable | Baseline | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|---|

| Scale factor | 1 | = 1.414 | 2 | = 2.582 | = 3.162 |

| Blade length (m) | 38 | 54 | 76 | 98 | 120 |

| Rotor power (MW) | 1.5 | 3 | 6 | 10 | 15 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Z.; Zhang, L.; Yang, K.; Wang, J.; Liao, C.; Xu, J. Determining Division Location for Sectional Wind Turbine Blades. Energies 2017, 10, 1404. https://doi.org/10.3390/en10091404

Qin Z, Zhang L, Yang K, Wang J, Liao C, Xu J. Determining Division Location for Sectional Wind Turbine Blades. Energies. 2017; 10(9):1404. https://doi.org/10.3390/en10091404

Chicago/Turabian StyleQin, Zhiwen, Lei Zhang, Ke Yang, Jihui Wang, Caicai Liao, and Jianzhong Xu. 2017. "Determining Division Location for Sectional Wind Turbine Blades" Energies 10, no. 9: 1404. https://doi.org/10.3390/en10091404

APA StyleQin, Z., Zhang, L., Yang, K., Wang, J., Liao, C., & Xu, J. (2017). Determining Division Location for Sectional Wind Turbine Blades. Energies, 10(9), 1404. https://doi.org/10.3390/en10091404