A DC Microgrid Coordinated Control Strategy Based on Integrator Current-Sharing

Abstract

:1. Introduction

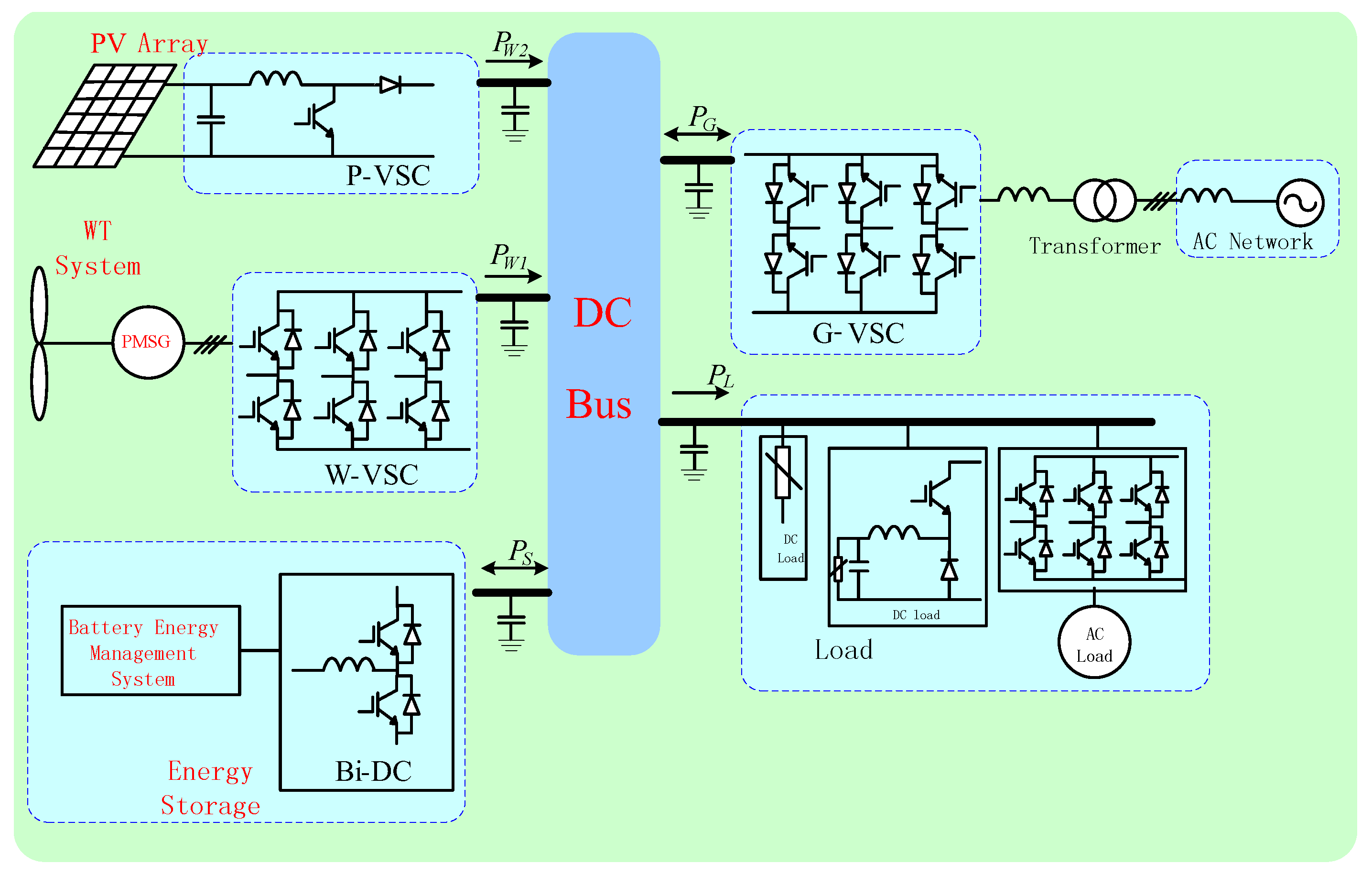

2. DC Microgrid Structure and Composition

2.1. DC Microgrid Structure

2.2. DC Microgrid Composition

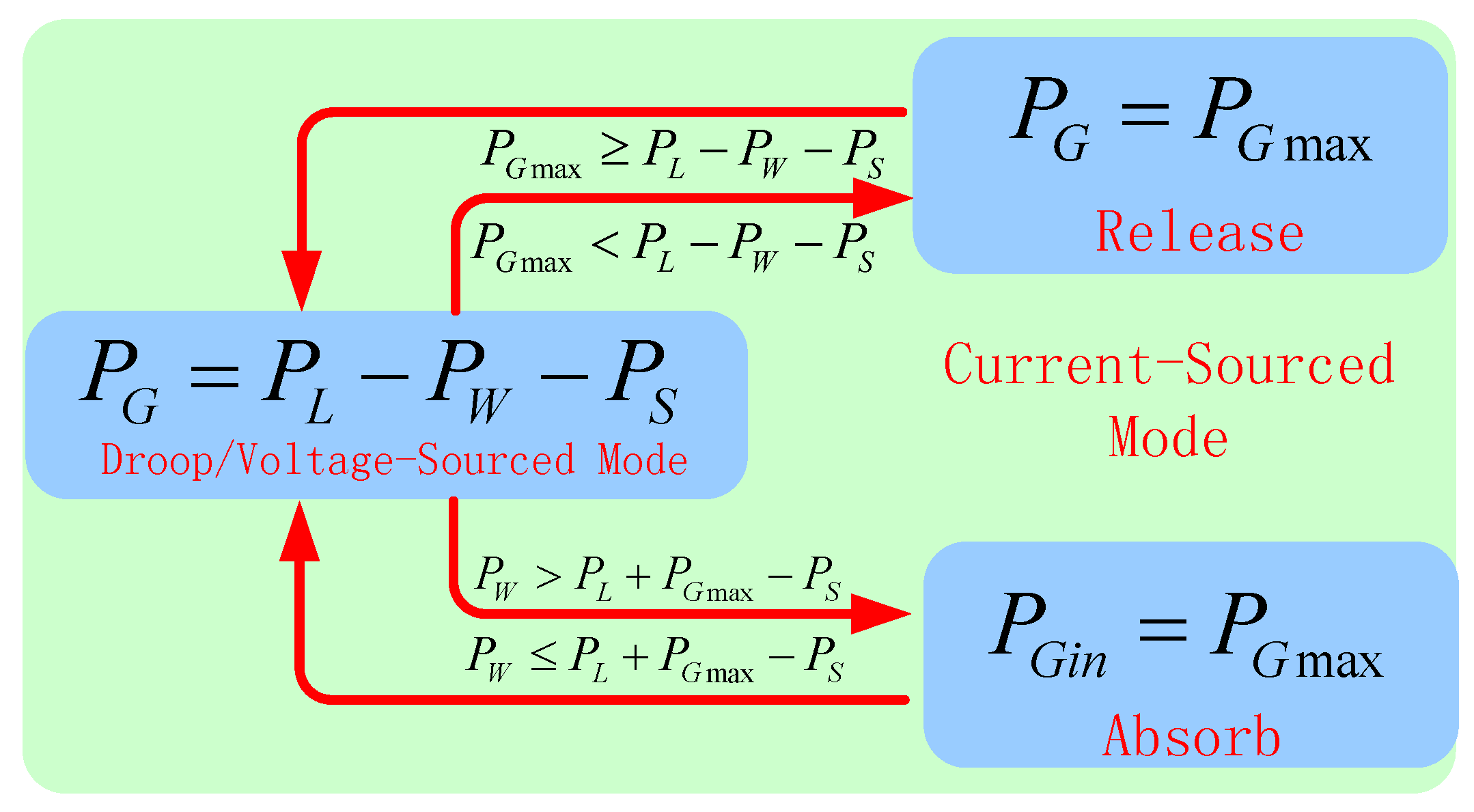

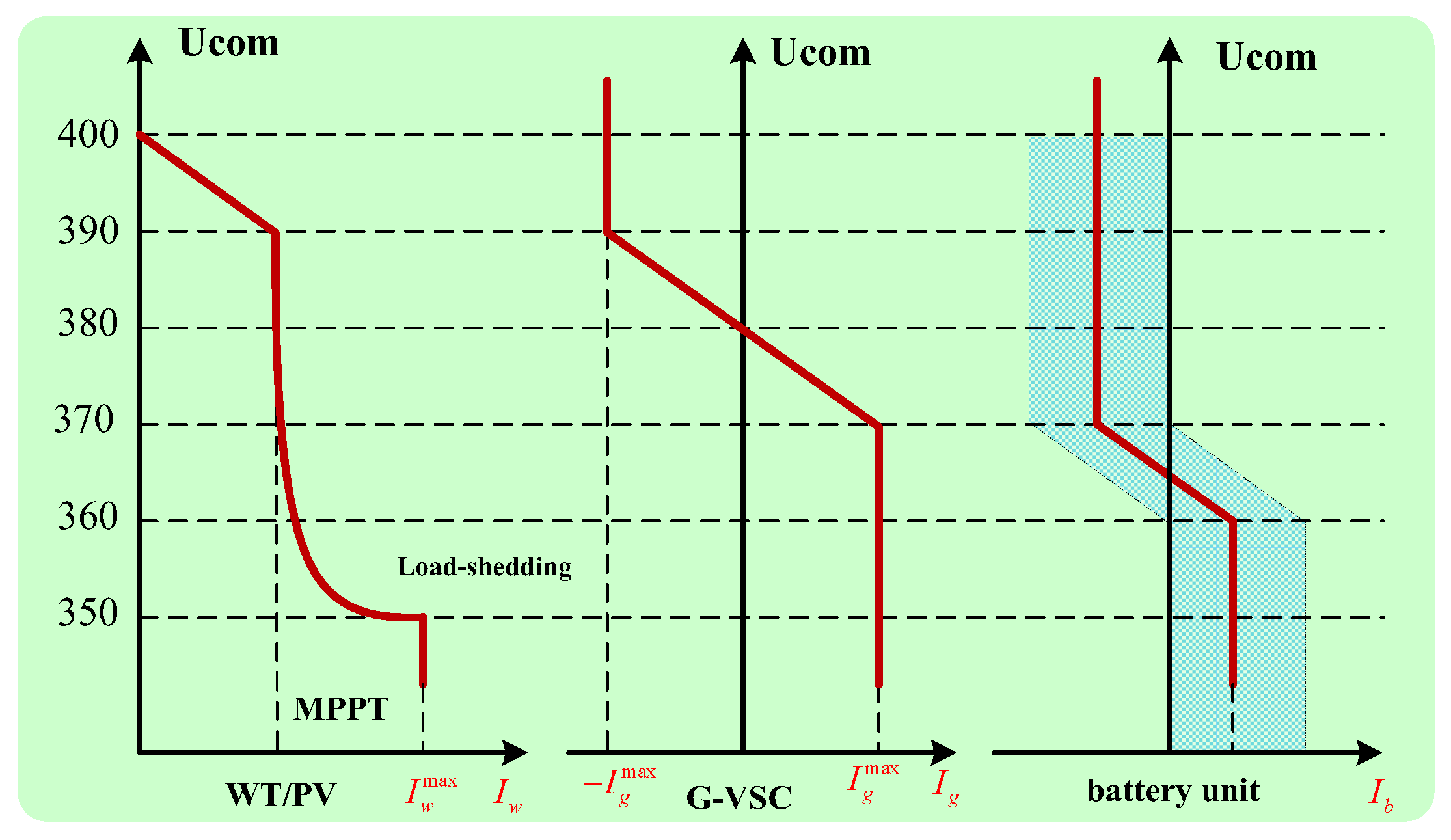

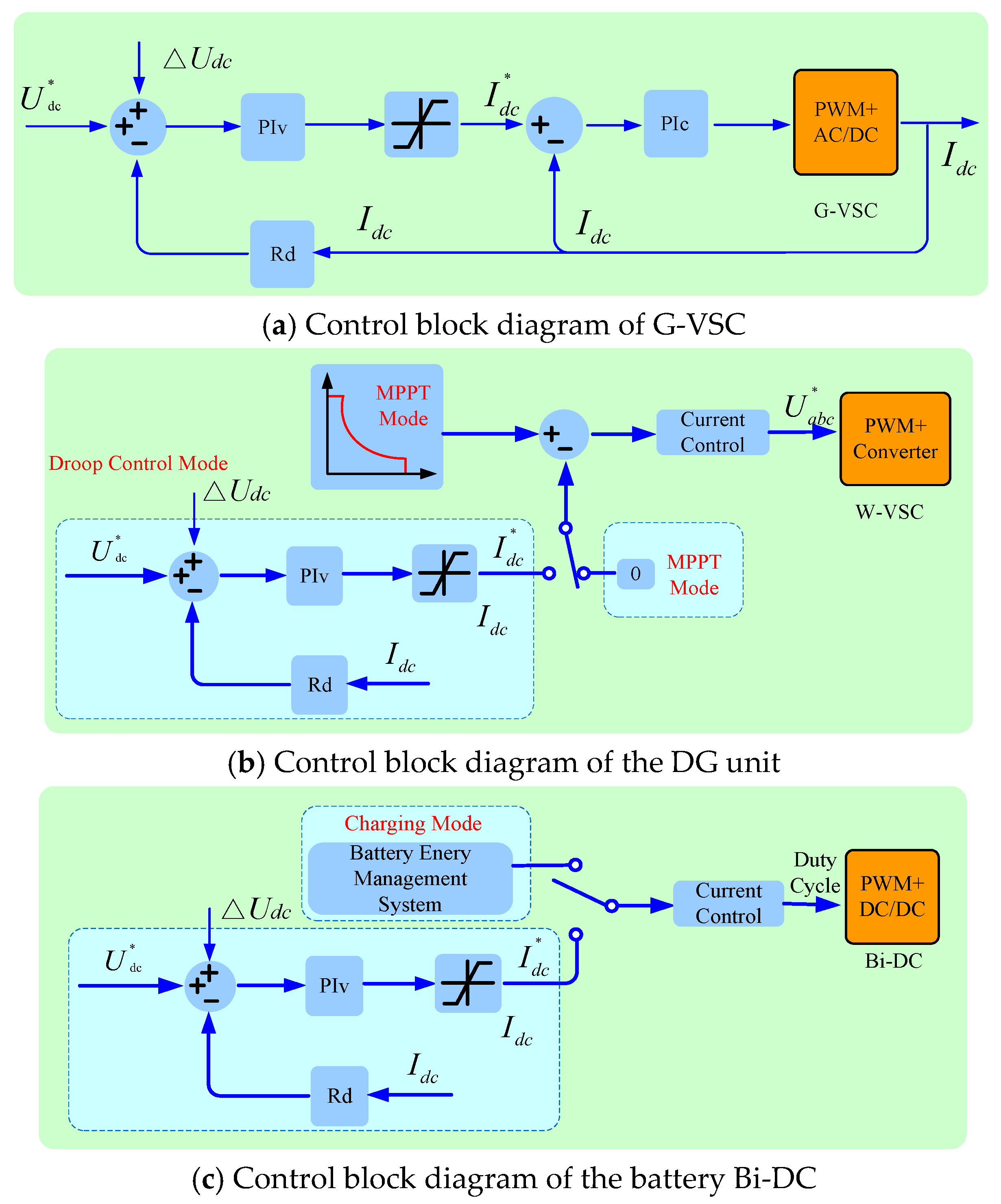

- Grid-connected converter: The DC microgrid is integrated with the AC main network through a voltage-sourced Pulse-Width Modulation (PWM) converter Grid-Voltage Sourced Converter (G-VSC). Figure 2 illustrates how G-VSC switches from different operation modes. The parameters for Figure 2 are shown in Table 1. When the DC microgrid operates in a normal grid-connected mode, the DC bus voltage stability is ensured by G-VSC under droop control. However, the G-VSC will switch to current-limiting mode if the interchanged power between the microgrid and the main network reaches the maximum power of G-VSC. When the output power of PV and WT is sufficient, the microgrid will provide power to the main network through G-VSC.

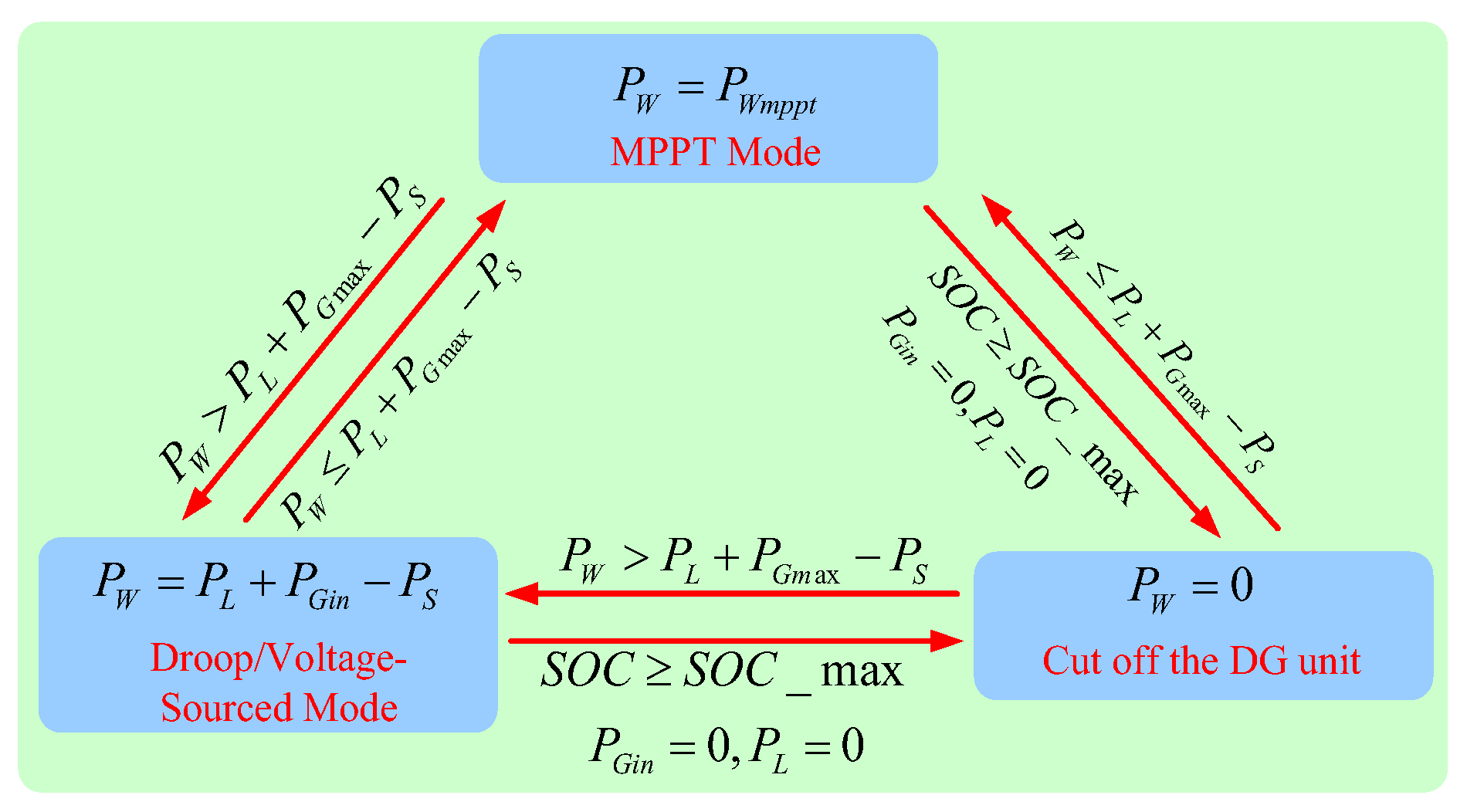

- Distributed generation unit: The DG unit is composed by the wind turbine generator system and photovoltaic generator system, which are tied with the DC microgrid by a DC/DC converter and a voltage-sourced converter Wind-Voltage Sourced Converter (W-VSC), respectively. In Figure 3, the switching process of the DG unit in different modes is illustrated. In order to capture the most wind and solar energy possible, the DG unit works in the MPPT manner normally, enhancing the energy utilization efficiency. When the wind and solar are sufficient and the DG unit output is large, the DC bus voltage rises, and the operation mode will switch to droop control to sustain the voltage stability. The DG unit will shut down if the main network is not connected, all loads are shed and the battery is fully charged.

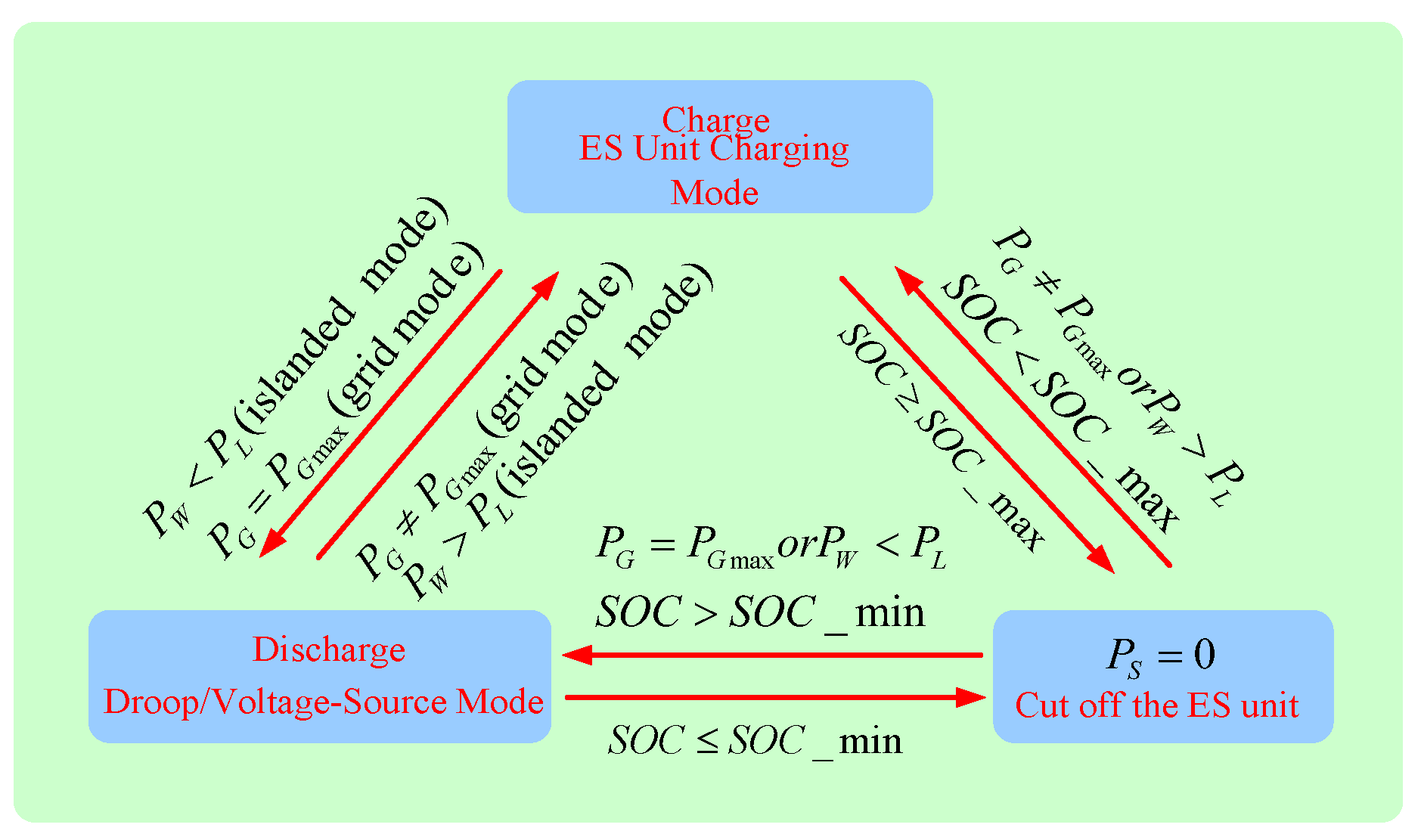

- Energy storage battery: The ES battery is connected with the DC microgrid by a bilateral DC/DC converter and switches its operation modes as in Figure 4. The battery works under the charging mode when the DC microgrid operates normally; when fully charged, the battery would be shed from the microgrid as a standby. However, when the microgrid is islanded due to a main network fault, the ES unit would stabilize the DC bus voltage as a balancing bus, in order to ensure stable system operation.

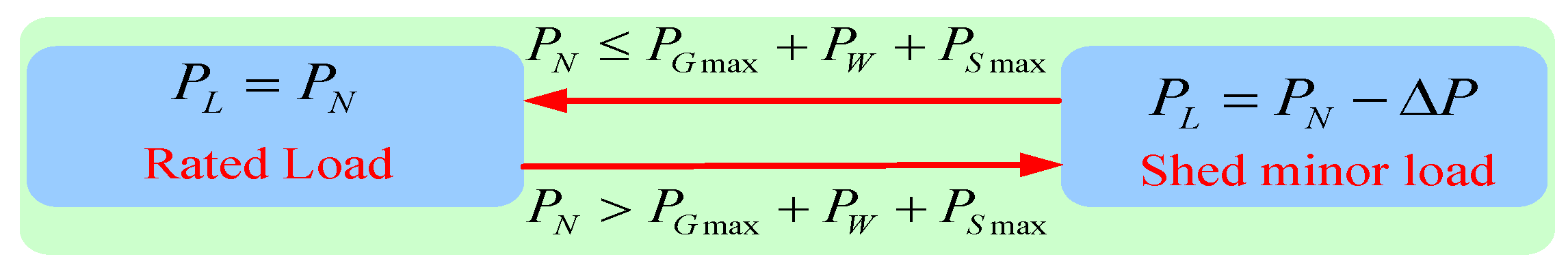

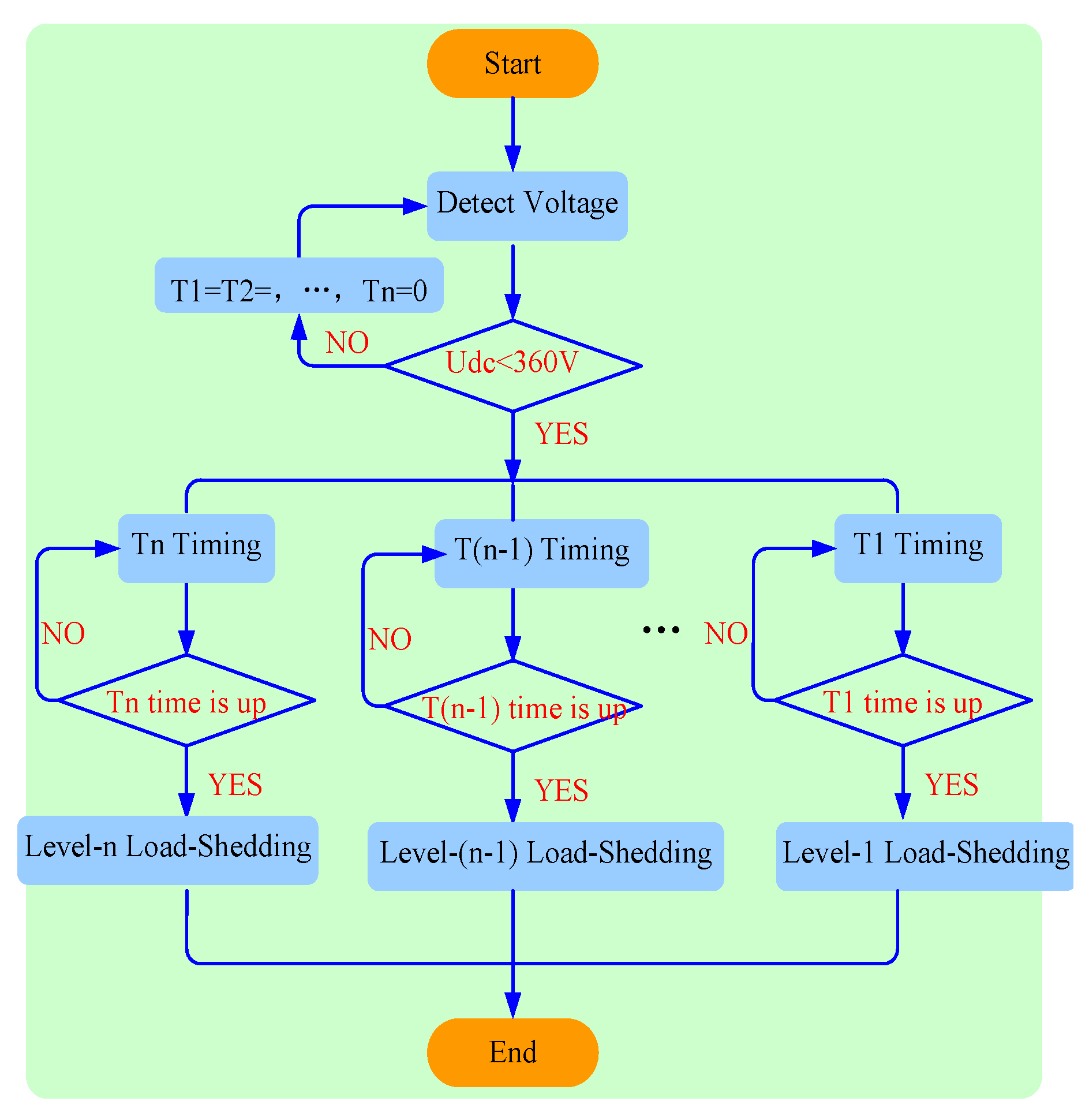

- Load: The DC and AC loads are connected with the DC microgrid through a DC/DC converter and DC/AC converter, respectively. The loads unit switches its operation mode as shown in Figure 5. When power supply is insufficient, load-shedding control in terms of loads priority is needed to ensure power balance of the DC microgrid and power supply quality of the important loads.

3. Research on the Operational Control Strategy of the DC Microgrid

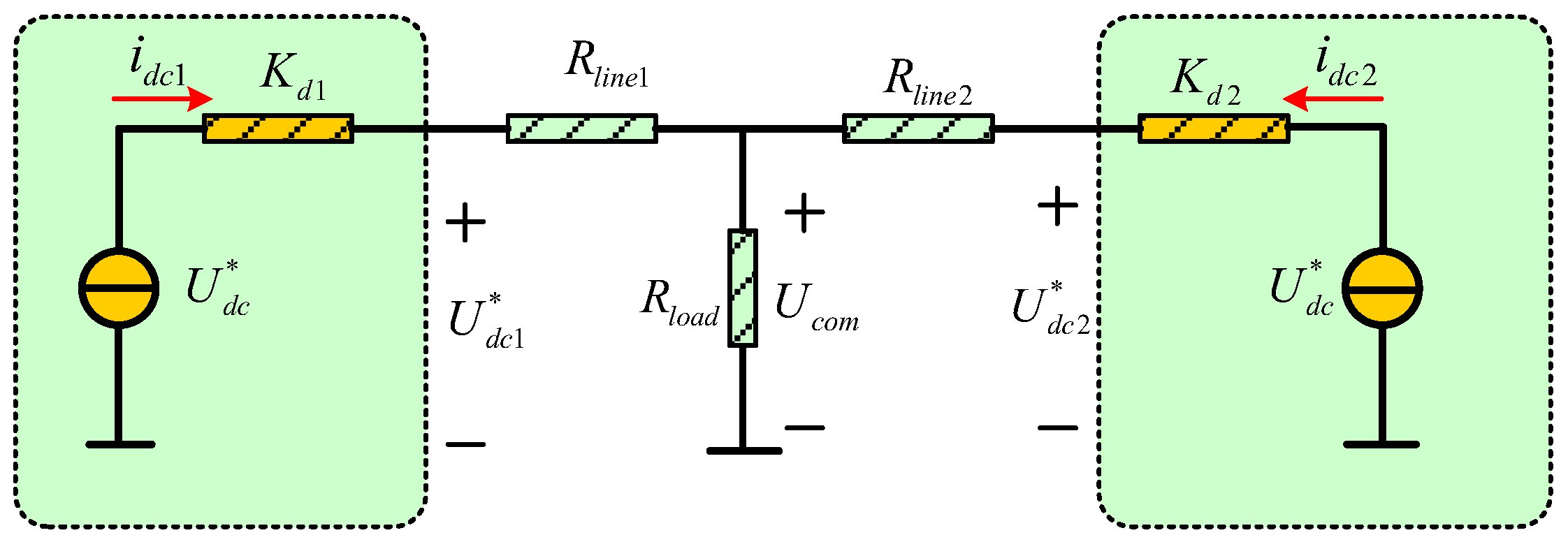

3.1. The DC Droop Control Strategy Based on Integrator Current-Sharing

3.2. The Hierarchical/Droop Voltage Control Strategy

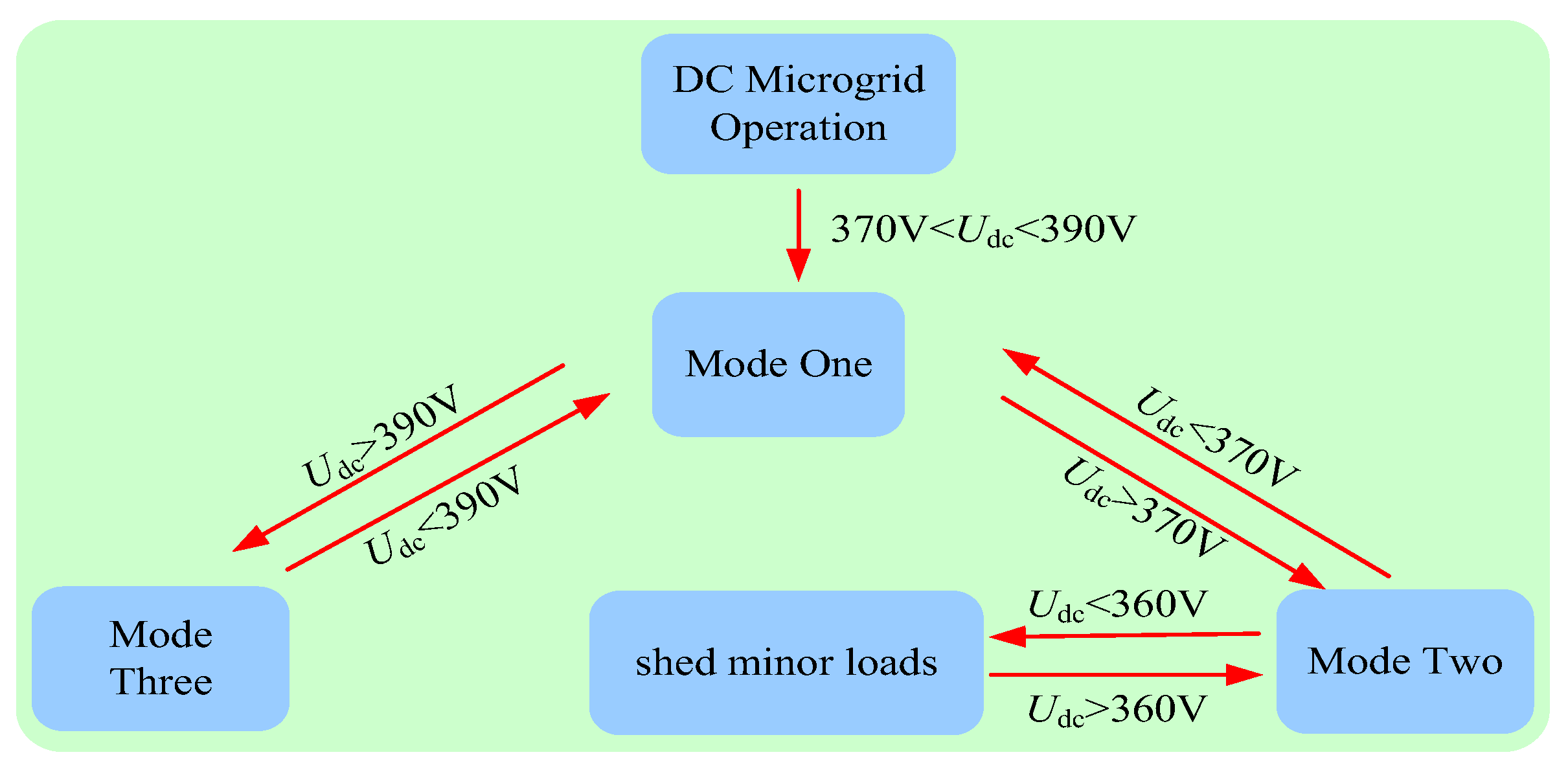

- Operation Mode 1: The G-VSC sustains the stability of DC bus voltage; the DG unit operates under the MPPT mode; the storage battery is in constant-current charge under the control of the battery management system and then shed from the microgrid when fully charged. In this mode, the DC bus voltage is maintained within ±10 V of the rated voltage.

- Operation Mode 2: The storage battery sustains the stability of the DC bus voltage. When the transmitted power of the AC main network to the DC microgrid reaches the G-VSC limitation, or faults like short-circuit occurred, G-VSC will switch to current-limiting mode. The DG unit operates in the MPPT mode. Under this circumstance, the bus voltage is stabilized within 360 V–370 V.

- Operation Mode 3: The DG unit sustains the stability of the DC bus voltage. When the loads are light and the DC bus voltage rises to over 390 V, the battery would charge with the control of the battery management system, and the G-VSC transmits electric power to the AC main network in its maximum power or cut off from the DC microgrid.

3.3. The Converter Control Scheme of Each Unit

4. Simulation Results

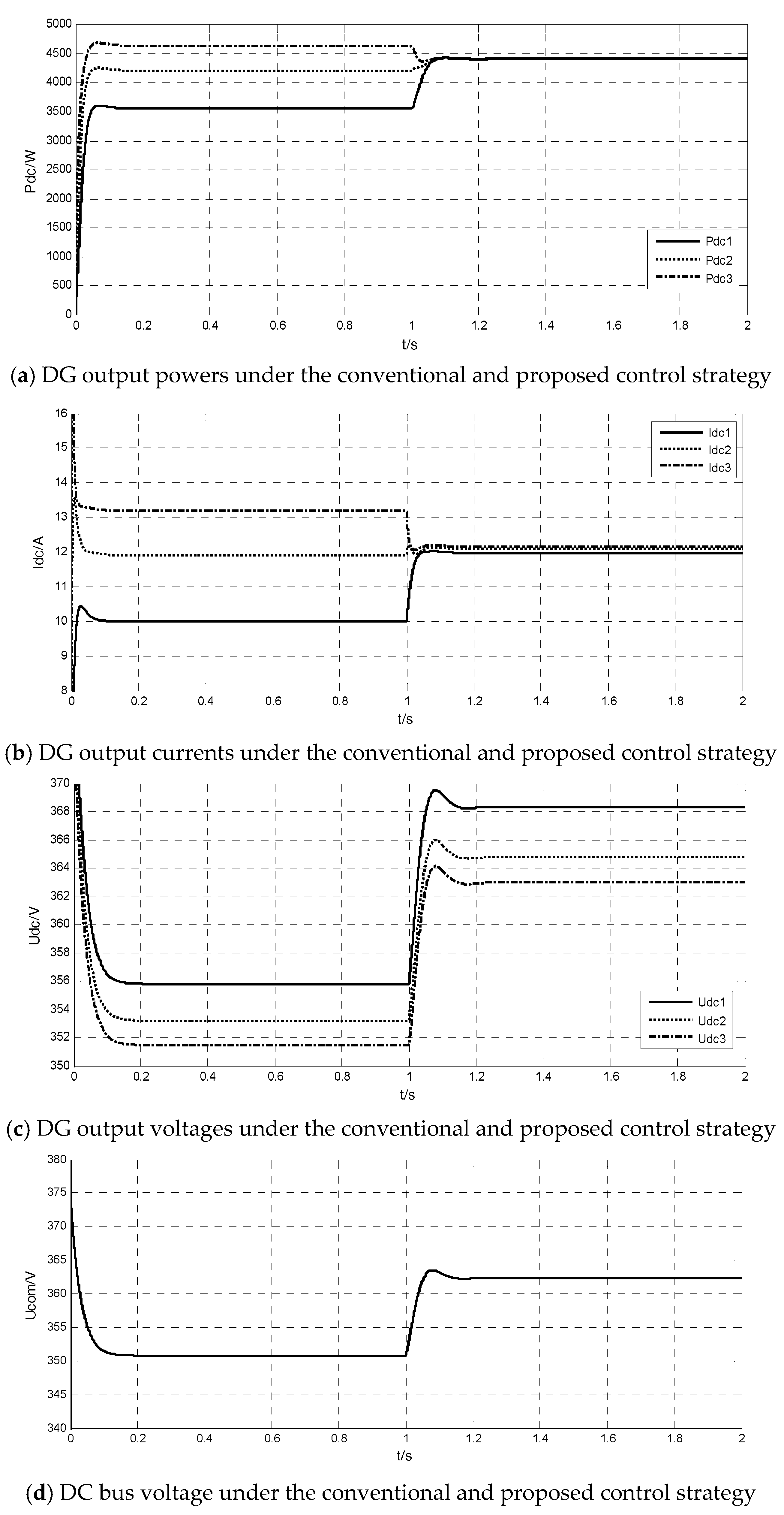

4.1. Verification to the Droop Control Strategy Based on Integrator Current-Sharing

4.2. Verification to System Coordinated Control Strategy

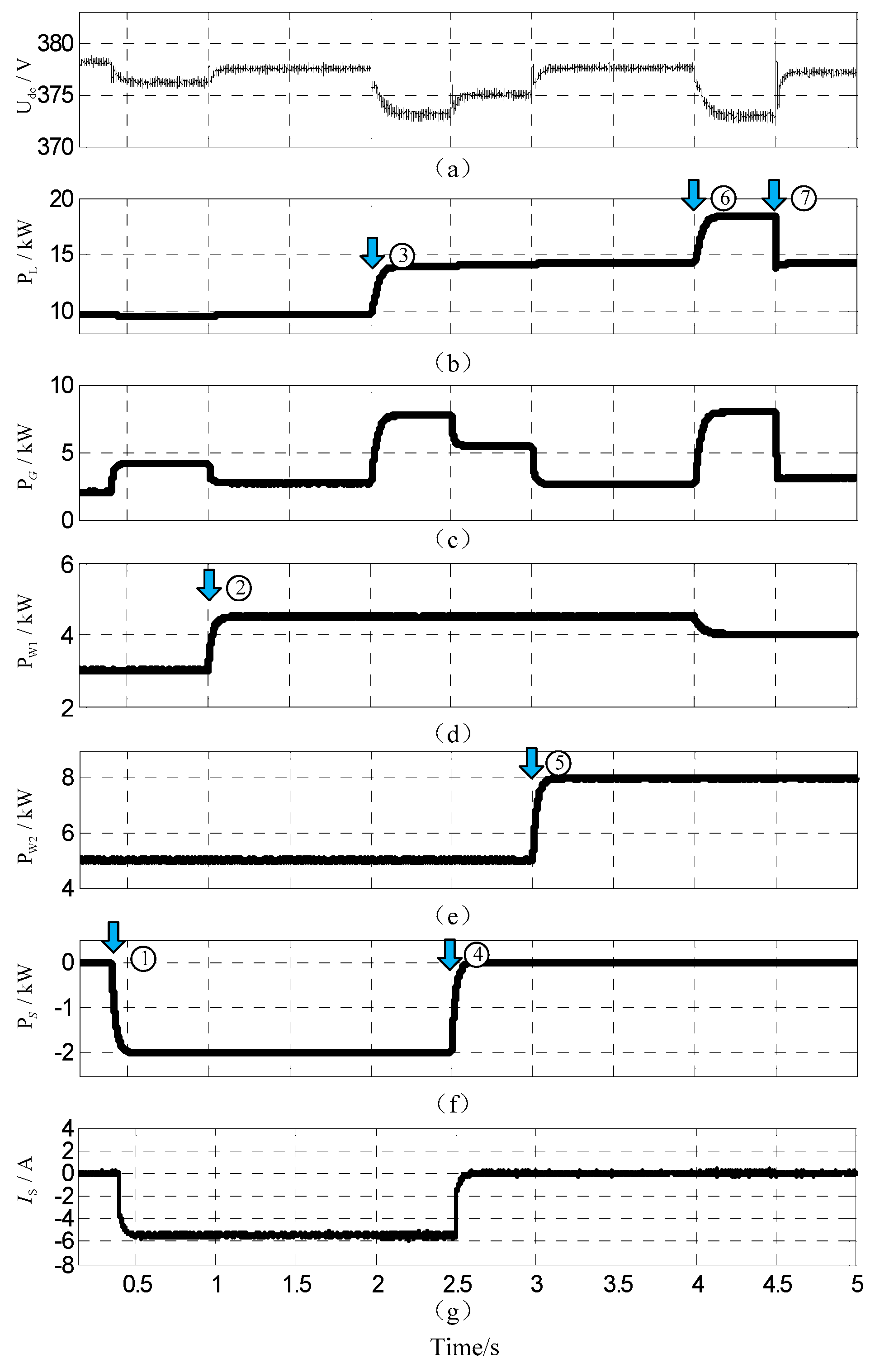

- Simulation 1: The system stably operates in Mode 1, and the AC main network is working to maintain the stability of the DC bus voltage. The result is depicted in Figure 12, and Table 4 shows the major incidents in the first simulation. From Figure 12, when the load and DG unit output power have changed, G-VSC adjusts the exchange power between the DC microgrid and the main network according to the droop characteristic to sustain the bus voltage within 370 V–390 V, while the battery is cut off from the DC bus, becoming a standby.

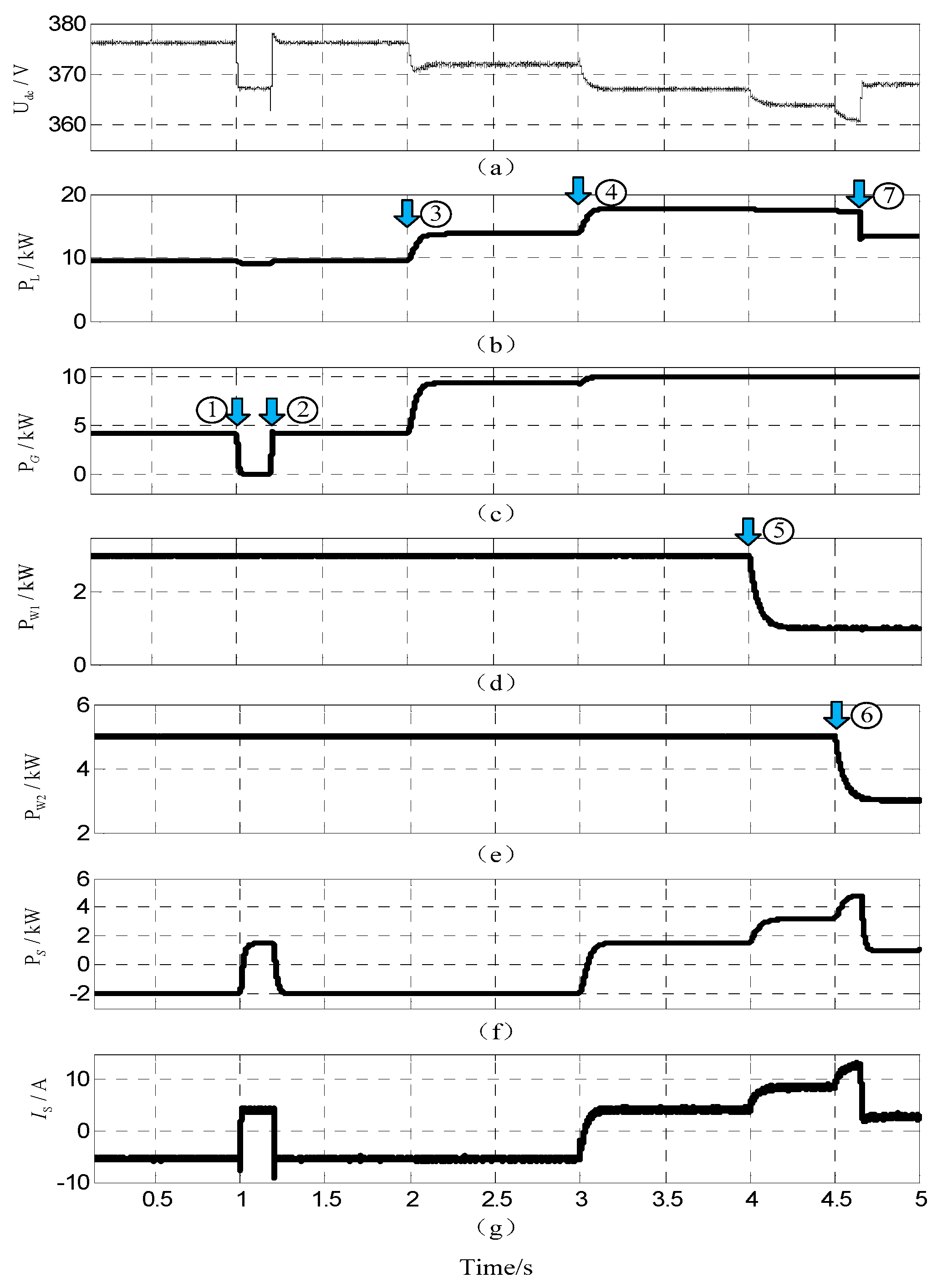

- Simulation 2: When the battery works to maintain the stability of the DC bus voltage, the simulation result is shown as Figure 13, while Table 5 lists the major incidents in the simulation. At first, the system stably runs in Mode 1. At t = 1.0 s, the AC main network malfunctions and is shed from the DC microgrid, after which the system switches to Mode 2 in which the battery works to sustain the stability of the DC bus voltage. At t = 1.2 s, the fault is removed and the system returns to operation Mode 1. Load 3 and Load 2 are tied with the DC bus at t = 2.0 s and t = 3.0 s, respectively. This causes the output power of the AC main network to gradually attain the maximum power allowance of G-VSC and then turn into current-limiting mode, where the system switches back to Mode 2 again. Although the loads and micro-sources’ output still change afterwards, the DC bus voltage is maintained within 360 V–370 V through the droop control of the storage battery. At t = 4.7 s, the output power cannot meet the load demand since the output of the PV generation system has been reduced. According to the load grades, Load 3 is cut off. After cutting, the output power can meet the load requirement, and the system can stably operate in the mode.

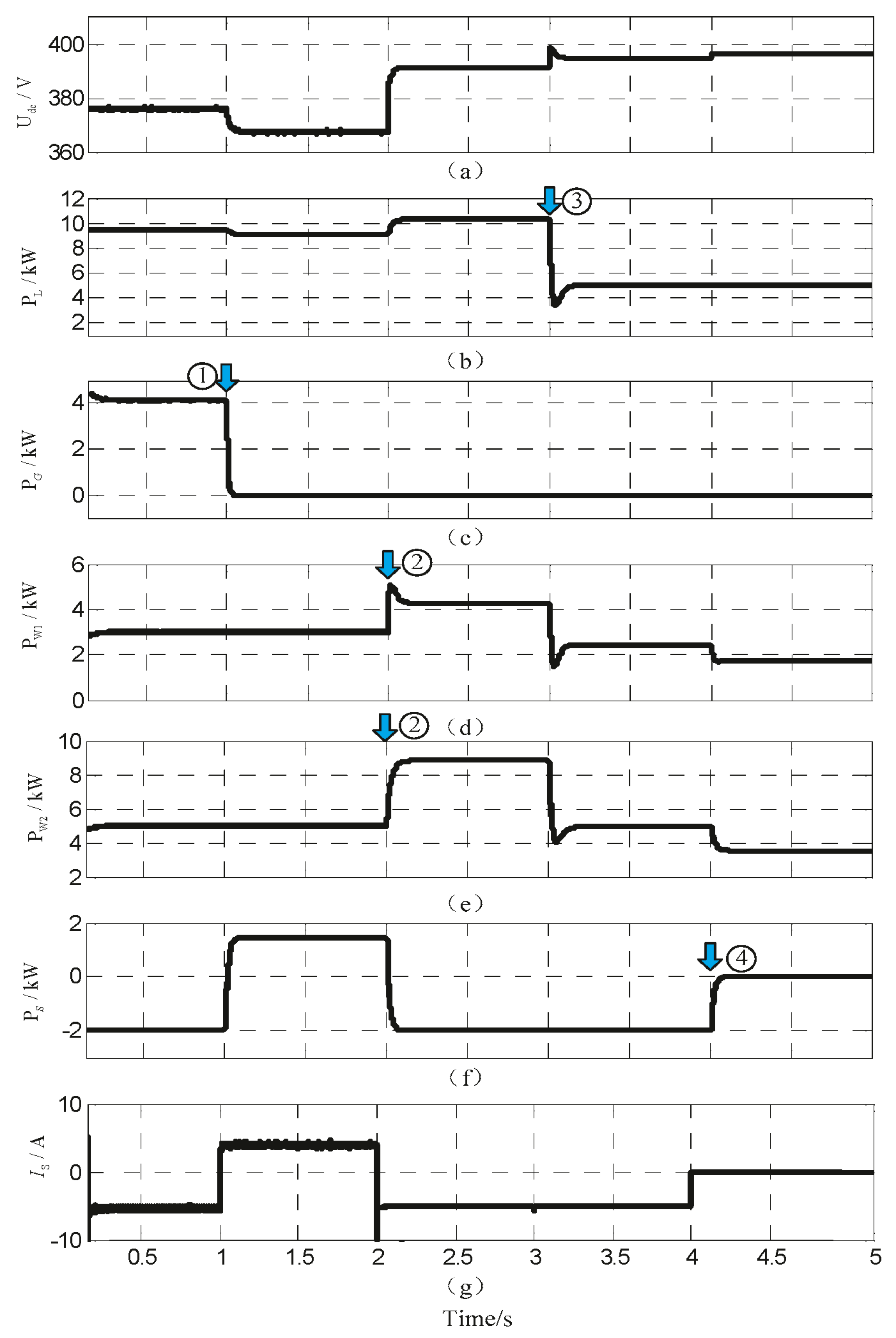

- Simulation 3: When the islanded mode is taken into consideration and the DG unit sustains the stability of the DC bus voltage, the simulation result is shown as Figure 14. Table 6 lists the major incidents in the simulation. At t = 1 s, the DC microgrid in the islanded mode is disconnected from the main network, causing the system to switch to operation Mode 2, in which the battery maintains the stability of the DC bus voltage. At t = 2 s, the output power of the DG unit increases, and the DC bus voltage rises over 390 V, after which the DC microgrid switches to Mode 3. In Mode 3, the DG generation unit is under voltage-sourced control to sustain the stability of the DC bus voltage and the power balance. The output of the PV and WT generation systems is decided in terms of their capacity ratio (2:1). At t = 3 s, the active load changes, the stability of the DC bus voltage and system power balance are achieved through the droop control of the DG unit. At t = 4 s, the battery is fully charged and cut off from the DC microgrid.

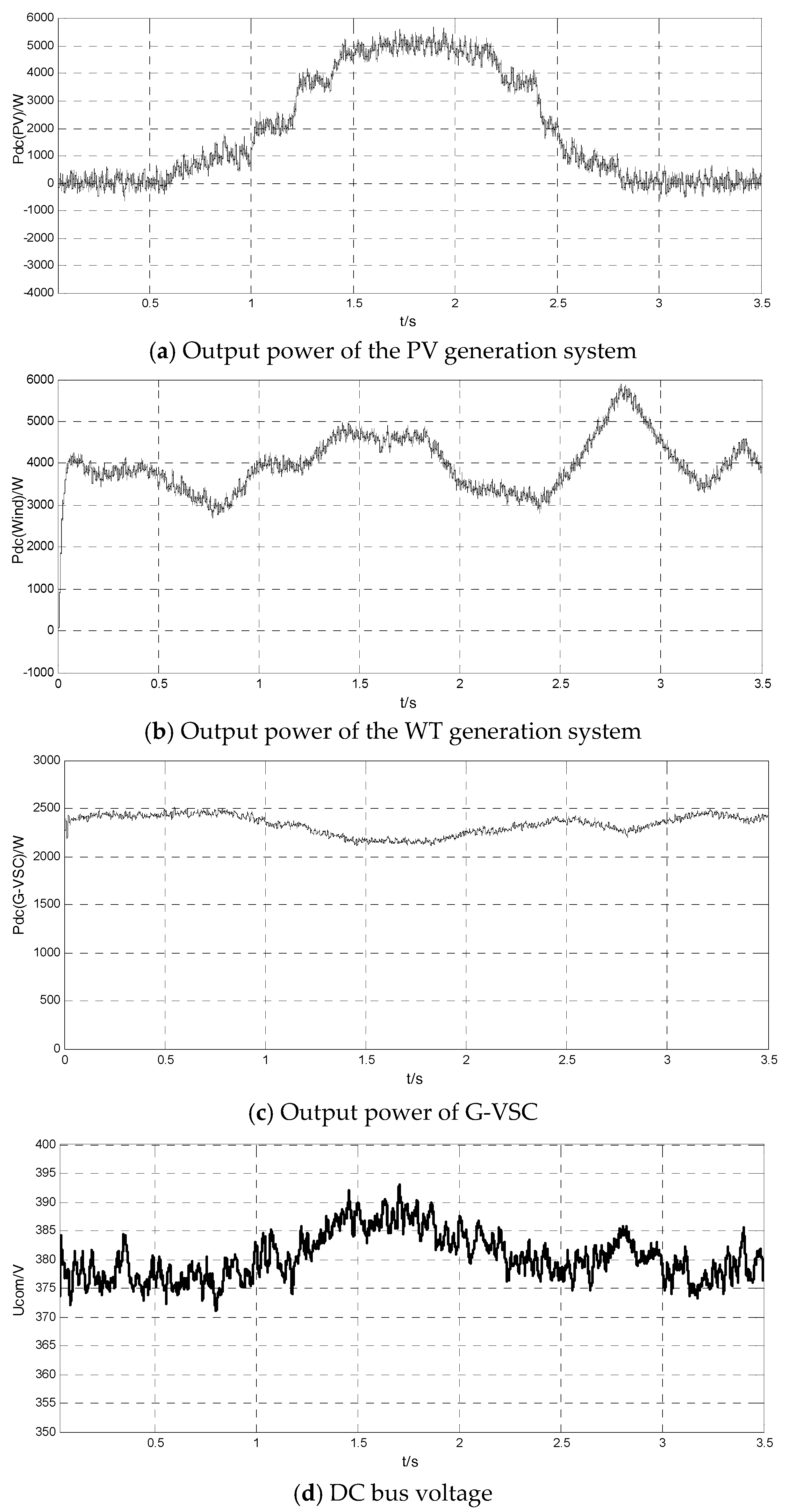

4.3. Verification to the Actual PV and WT Generation System

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Yan, B.; Wang, B.; Zhu, L. A novel, stable, and economic power sharing scheme for an autonomous microgrid in the energy internet. Energies 2015, 8, 12741–12764. [Google Scholar] [CrossRef]

- Lim, Y.; Kim, H.M.; Kinoshita, T. Distributed load-shedding system for agent-based autonomous microgrid operations. Energies 2014, 7, 385–401. [Google Scholar] [CrossRef]

- Lasseter, R.H.; Paigi, P. Microgrid: A conceptual solution. In Proceedings of the IEEE Conference on Power Electronics Specialists, Aachen, Germany, 20–25 June 2004; pp. 4285–4290. [Google Scholar]

- Patterson, M.; Macia, N.F.; Kannan, A.M. Hybrid microgrid model based on solar photovoltaic battery fuel cell system for intermittent load applications. IEEE Trans. Energy Convers. 2015, 30, 359–366. [Google Scholar] [CrossRef]

- Xiao, H.; Luo, A.; Shuai, Z. An Improved control method for multiple bidirectional power converters in hybrid AC/DC microgrid. IEEE Trans. Smart Grid 2016, 7, 340–347. [Google Scholar] [CrossRef]

- Salomonsson, D.; Sannino, A. A low-voltage DC distribution system for commercial power systems with sensitive electronic loads. IEEE Trans. Power Deliv. 2007, 22, 1620–1627. [Google Scholar] [CrossRef]

- Mehrdad, B.; Abolfazl, J.; Mehdi, E. Cooperative energy management of hybrid DC renewable grid using decentralized control strategies. Energies 2016, 9, 859. [Google Scholar]

- Liu, Y.Q.; Wang, J.Z.; Li, N.N.; Fu, Y.; Ji, Y.C. Enhanced load power sharing accuracy in droop-controlled DC microgrids with both mesh and radial configurations. Energies 2015, 8, 3591–3605. [Google Scholar] [CrossRef]

- Gao, F.; Bozhko, S.; Costabeber, A. Comparative stability analysis of droop control approaches in voltage-source-converter-based DC microgrids. IEEE Trans. Power Electron. 2017, 32, 2395–2415. [Google Scholar] [CrossRef]

- Vu, T.V.; Paran, S.; Diaz, F. An alternative distributed control architecture for improvement in the transient response of DC microgrids. IEEE Trans. Ind. Electron. 2016, 64, 574–584. [Google Scholar] [CrossRef]

- Hamzeh, M.; Ghazanfari, A.; Mohamed, Y. Modeling and design of an oscillatory current-sharing control strategy in DC microgrids. IEEE Trans. Ind. Electron. 2015, 62, 6647–6657. [Google Scholar] [CrossRef]

- Bryan, J.; Duke, R.; Round, S. Decentralized generator scheduling in a nanogrid using DC bus signaling. In Proceedings of the IEEE Power Engineering Society General Meeting, Denver, CO, USA, 6–10 June 2004; pp. 977–982. [Google Scholar]

- Khorsandi, A.; Ashourloo, M.; Mokhtari, H. Automatic droop control for a low voltage DC microgrid. IET Gener. Trans. Distrib. 2016, 10, 41–47. [Google Scholar] [CrossRef]

- Lu, X.; Wan, J. Modeling and Control of the Distributed Power Converters in a Standalone DC Microgrid. Energies 2016, 9, 217. [Google Scholar] [CrossRef]

- Dou, C.; Yue, D.; Guerrero, J.M. Multiagent System-Based Distributed Coordinated Control for Radial DC Microgrid Considering Transmission Time Delays. IEEE Trans. Smart Grid 2016, 99, 1–12. [Google Scholar] [CrossRef]

- Hu, R.; Weaver, W.W. DC microgrid droop control based on battery state of charge balancing. In Proceedings of the IEEE Power and Energy Conference, Urbana, IL, USA, 19–20 February 2016; pp. 1–8. [Google Scholar]

- Hwang, C.S.; Kim, E.S.; Kim, Y.S. A Decentralized Control Method for Distributed Generations in an Islanded DC Microgrid Considering Voltage Drop Compensation and Durable State of Charge. Energies 2016, 9, 1070. [Google Scholar] [CrossRef]

- Salomonsson, D.; Soder, L.; Sannino, A. An adaptive control system for a dc microgrid for data centers. IEEE Trans. Ind. Appl. 2008, 44, 1910–1917. [Google Scholar] [CrossRef]

- Xu, L.; Chen, D. Control and operation of a DC microgrid with variable generation and energy storage. IEEE Trans. Power Deliv. 2011, 26, 2513–2522. [Google Scholar] [CrossRef]

- Zhou, T.; Francois, B. Energy management and power control of a hybrid active wind generator for distributed power generation and grid integrator. IEEE Trans. Ind. Electron. 2011, 58, 95–104. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Vasquez, J.C.; Matas, J. Hierarchical control of droop-controlled AC and DC Microgrids—A general approach toward standardization. IEEE Trans. Ind. Electron. 2011, 58, 158–172. [Google Scholar] [CrossRef]

- Chen, D.; Xu, L. Autonomous DC voltage control of a DC microgrid with multiple slack terminals. IEEE Trans. Power Syst. 2012, 27, 1897–1905. [Google Scholar] [CrossRef]

- Han, Y.; Chen, W.R.; Li, Q. Energy management strategy based on multiple operating states for a photovoltaic/fuel cell/energy storage DC microgrid. Energies 2017, 10, 136. [Google Scholar] [CrossRef]

- Teleke, S.; Baran, M.E.; Huang, A.Q.; Bhattacharya, S.; Anderson, L. Control strategies for battery energy storage for wind farm dispatching. IEEE Trans. Energy Convers. 2009, 24, 725–732. [Google Scholar] [CrossRef]

- Dragicevic, T.; Guerrero, J.M.; Vasquez, J.C. Supervisory control of an adaptive-droop regulated DC microgrid with battery management capability. IEEE Trans. Power Electron. 2013, 29, 1–12. [Google Scholar] [CrossRef]

- Lu, X.; Guerrero, J.M.; Sun, K. An improved droop control method for DC microgrids based on low bandwidth communication with DC bus voltage restoration and enhanced current sharing accuracy. IEEE Trans. Power Electron. 2013, 29, 1–12. [Google Scholar] [CrossRef]

- Lee, S.W.; Cho, B.H. Master–slave based hierarchical control for a small power DC-distributed microgrid system with a storage device. Energies 2016, 9, 880. [Google Scholar] [CrossRef]

- Wang, P.B.; Lu, X.N.; Yang, X. An improved distributed secondary control method for DC microgrids with enhanced dynamic current sharing performance. IEEE Trans. Power Electron. 2016, 31, 6658–6673. [Google Scholar] [CrossRef]

- Dragicevic, T.; Lu, X.N.; Vasquez, J.C. DC Microgrids—Part I: A review of control strategies and stabilization techniques. IEEE Trans. Power Electron. 2016, 31, 4876–4891. [Google Scholar] [CrossRef]

- Yu, S.Y.; Kim, H.J.; Kim, J.H. SoC-Based Output Voltage Control for BESS with a Lithium-Ion Battery in a Stand-Alone DC Microgrid. Energies 2016, 9, 924. [Google Scholar] [CrossRef]

- Lu, X.; Sun, K.; Guerrero, J.M. SoC-based droop method for distributed energy storage in DC microgrid applications. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics (ISIE), Hangzhou, China, 28–31 May 2012; pp. 1640–1645. [Google Scholar]

| PG: actual output power of AC main network | SOC: current state of charge |

| PGmax: the maximum output power of G-VSC | SOCmax: maximum state of charge |

| PGin: actual absorbed power by AC main network | SOCmin: minimum state of charge |

| PW: actual output power of DG unit | PL: actual power of loads |

| PWmppt: maximum tracing power of DG unit | PN: rated power of loads |

| PS: release(+)/absorb(−) power of battery | ΔP: power of shedding loads |

| PSmax: maximum output power of battery |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| (V) | 380 | (V) | 380 |

| Kd | 0.2 | Kp1 | 0.004 |

| Rline1 (Ω) | 0.05 | Kp2 | 0.004 |

| Rline2 (Ω | 0.2 | Kp3 | 0.004 |

| Rline3 (Ω) | 0.5 | Ku1 | 50 |

| Ku2 | 50 | Ku3 | 50 |

| Rated DC bus voltage | 380 V |

| Maximum output power of the AC main network | 10 kW |

| Maximum output power of W-VSC in the WT generation system | 5 kW |

| Maximum output power of DC/DC in the PV generation system | 10 kW |

| Maximum output power of Bi-DC in the ES system | 5 kW |

| Load 1 (Level1) | 10 kW |

| Load 2 (Level2) | 5 kW |

| Load 3 (Level3) | 5 kW |

| Incident | Operation Condition | Time (s) |

|---|---|---|

| 1 | Battery charges by linking with the DC bus | 0.4 |

| 2 | The output of WT generation system increases from 3 kW–4.5 kW | 1.0 |

| 3 | Load 2 is connected to the DC bus | 2.0 |

| 4 | Battery is cut off from the DC bus after being fully charged | 2.5 |

| 5 | The output of the PV generation system rises from 5 kW–8 kW | 3.0 |

| 6 | Load 3 is connected to the DC bus | 4.0 |

| 7 | Load 3 is shed from the DC bus | 4.5 |

| Incident | Operation Conditions | Time (s) |

|---|---|---|

| 1 | AC main network fails | 1.0 |

| 2 | AC main network recovers from the failure | 1.2 |

| 3 | Load 3 is connected to the DC bus | 2.0 |

| 4 | Load 2 is connected to the DC bus | 3.0 |

| 5 | The output of the WT generation system decreases from 3 kW–1 kW | 4.0 |

| 6 | The output of the PV generation system reduces from 5 kW–3 kW | 4.5 |

| 7 | Load 3 is shed from the DC bus | 4.7 |

| Incident | Operation conditions | Time(s) |

|---|---|---|

| 1 | DC microgrid disconnected from the main network, in islanded mode | 1.0 |

| 2 | The output of the DG generation system increases dramatically | 2.0 |

| 3 | Load 1 is shed from the DC bus Load 2 is connected to the DC bus | 3.0 |

| 4 | Battery is cut off from the DC bus after being fully charged | 4.0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Liu, Y.; Ren, H.; Guerrero, J.M. A DC Microgrid Coordinated Control Strategy Based on Integrator Current-Sharing. Energies 2017, 10, 1116. https://doi.org/10.3390/en10081116

Gao L, Liu Y, Ren H, Guerrero JM. A DC Microgrid Coordinated Control Strategy Based on Integrator Current-Sharing. Energies. 2017; 10(8):1116. https://doi.org/10.3390/en10081116

Chicago/Turabian StyleGao, Liyuan, Yao Liu, Huisong Ren, and Josep M. Guerrero. 2017. "A DC Microgrid Coordinated Control Strategy Based on Integrator Current-Sharing" Energies 10, no. 8: 1116. https://doi.org/10.3390/en10081116

APA StyleGao, L., Liu, Y., Ren, H., & Guerrero, J. M. (2017). A DC Microgrid Coordinated Control Strategy Based on Integrator Current-Sharing. Energies, 10(8), 1116. https://doi.org/10.3390/en10081116