Simulation of Contamination Deposition on Typical Shed Porcelain Insulators

Abstract

:1. Introduction

2. Mathematical Model and its Control Equation

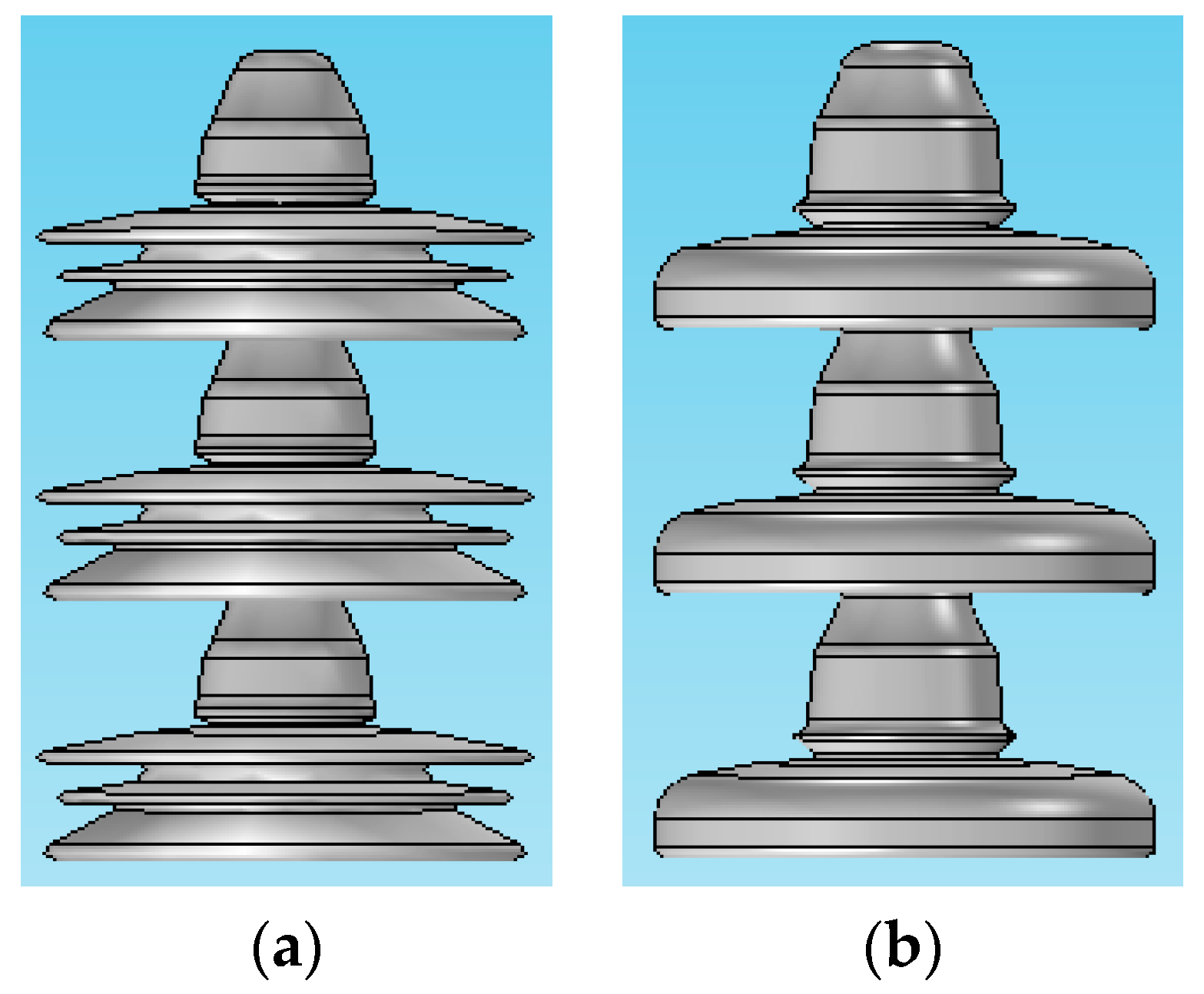

3. Wind Tunnel Test and Its Simulation Results Analysis

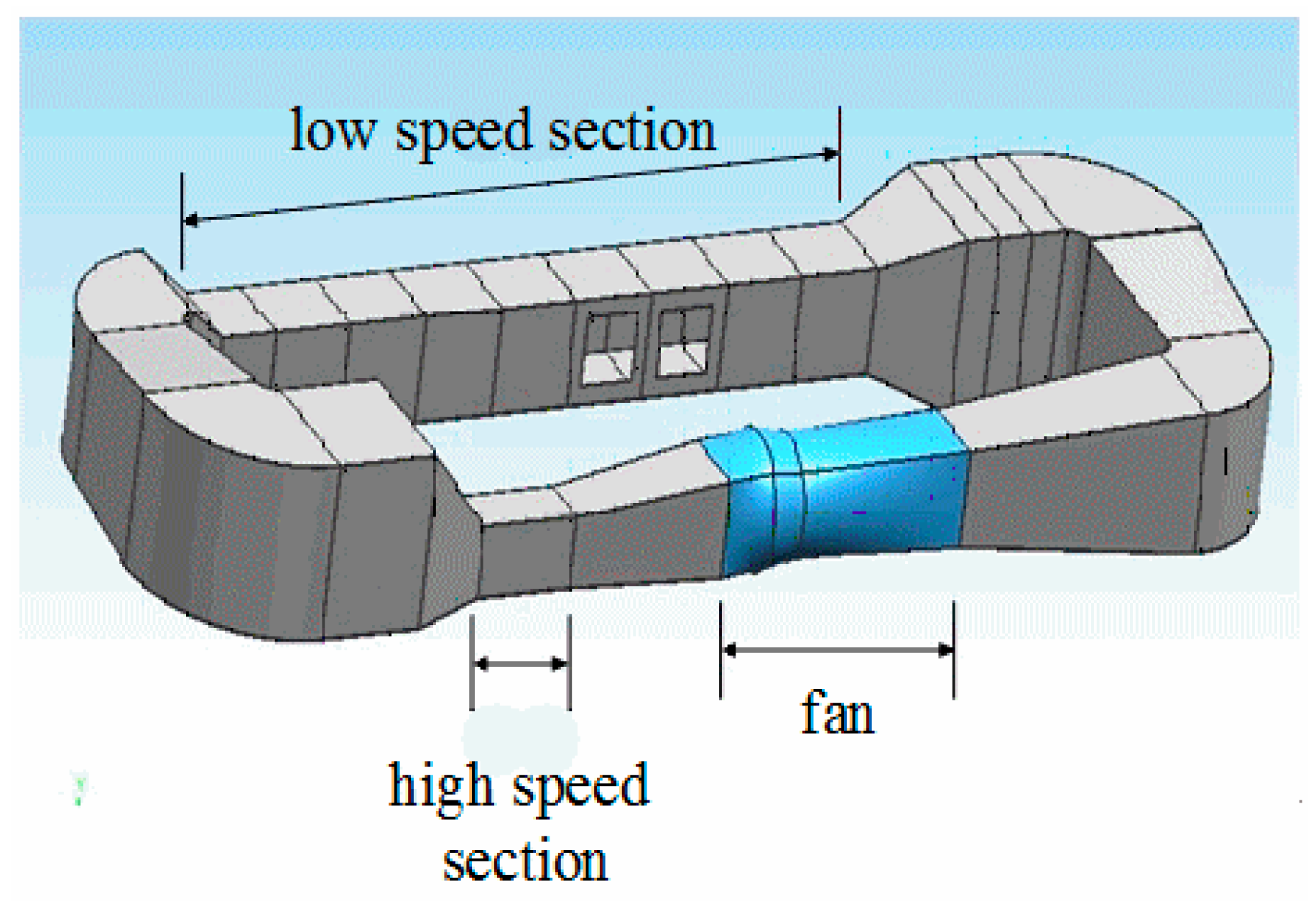

3.1. Wind Tunnel Test Device and its Method

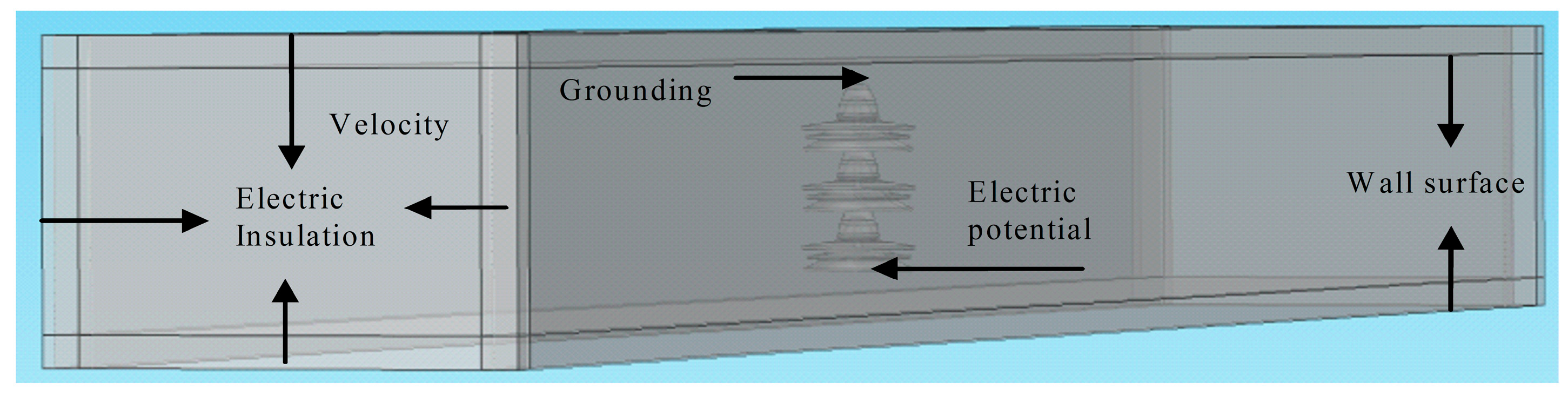

3.2. Wind Tunnel Numerical Simulation

3.3. Comparative Analysis of Test Results and Simulation Results

4. Analysis of Simulation Results with Respect to Natural Pollution Accumulation Characteristics

4.1. Natural Contamination Simulation

4.2. Analysis of the Natural Pollution Accumulation Simulation Results

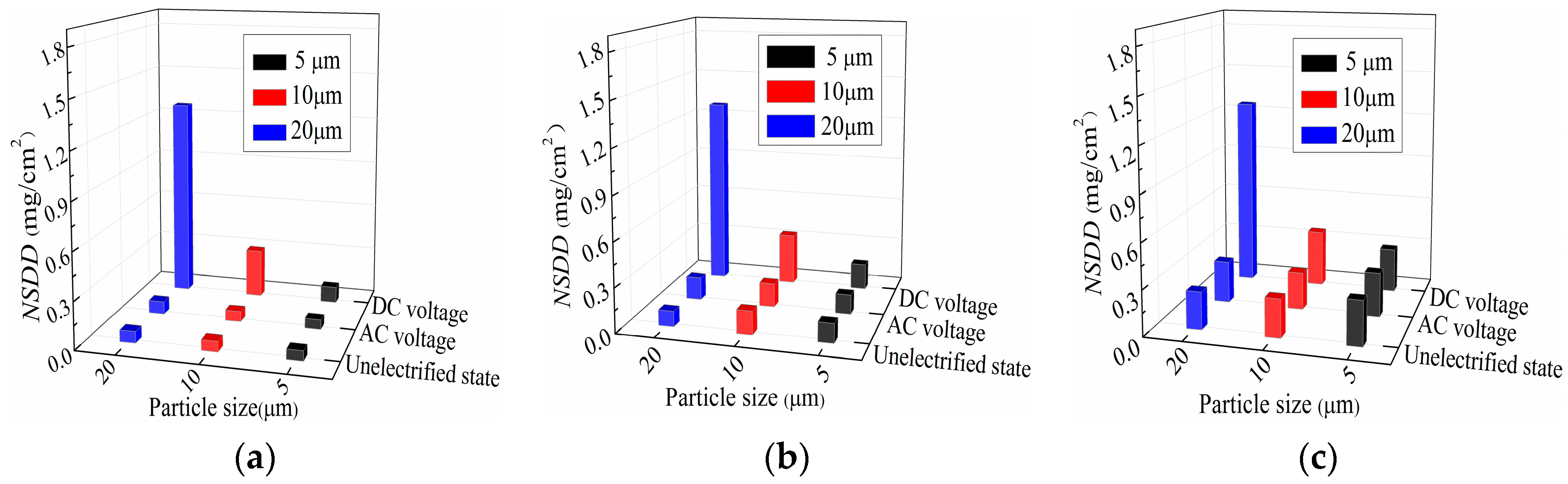

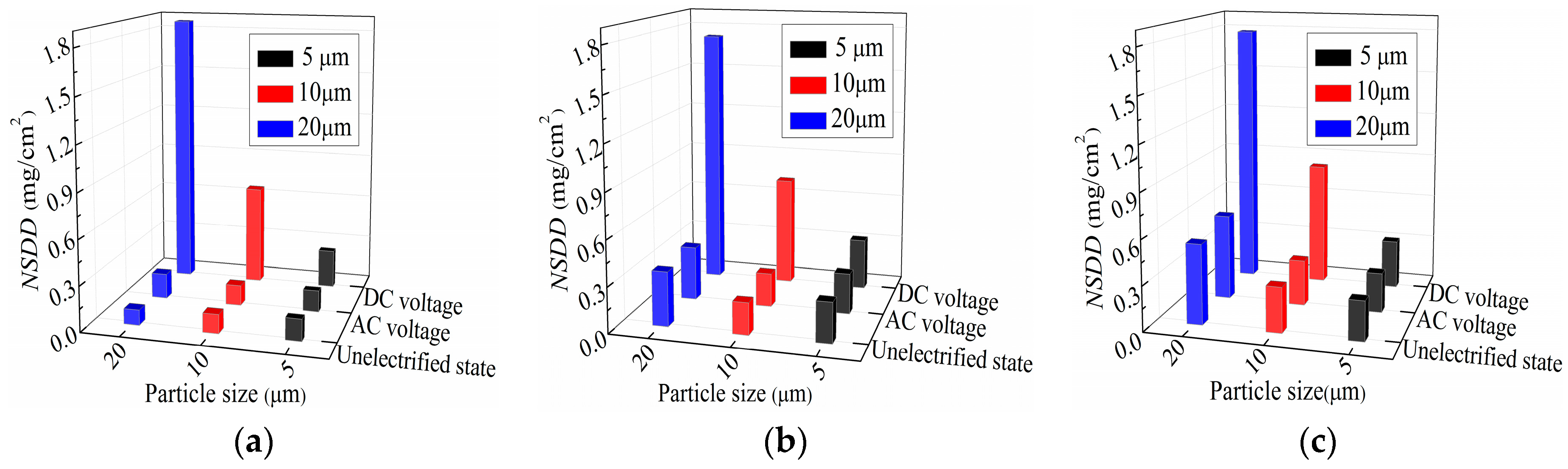

4.2.1. Effects of Multi-Factor Coupling on Contamination Accumulation

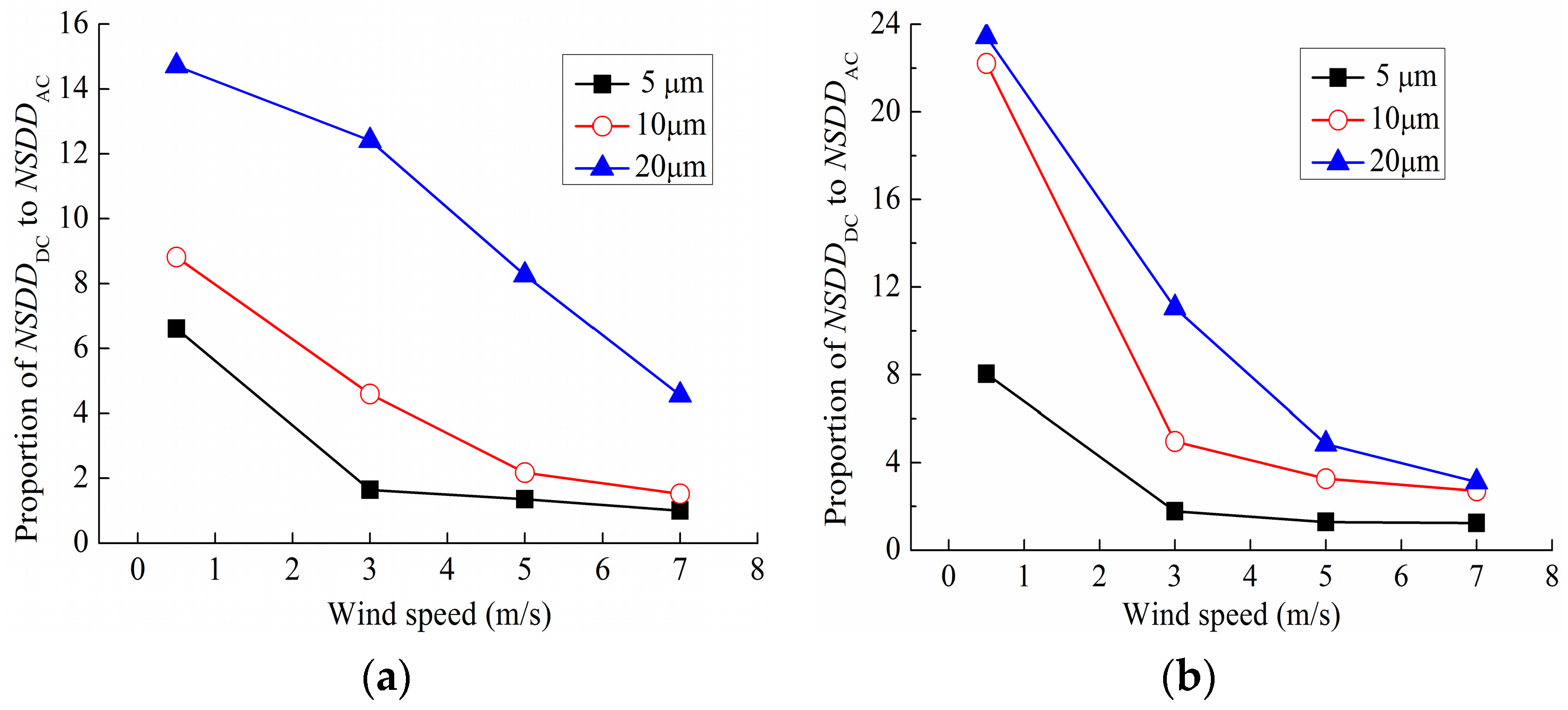

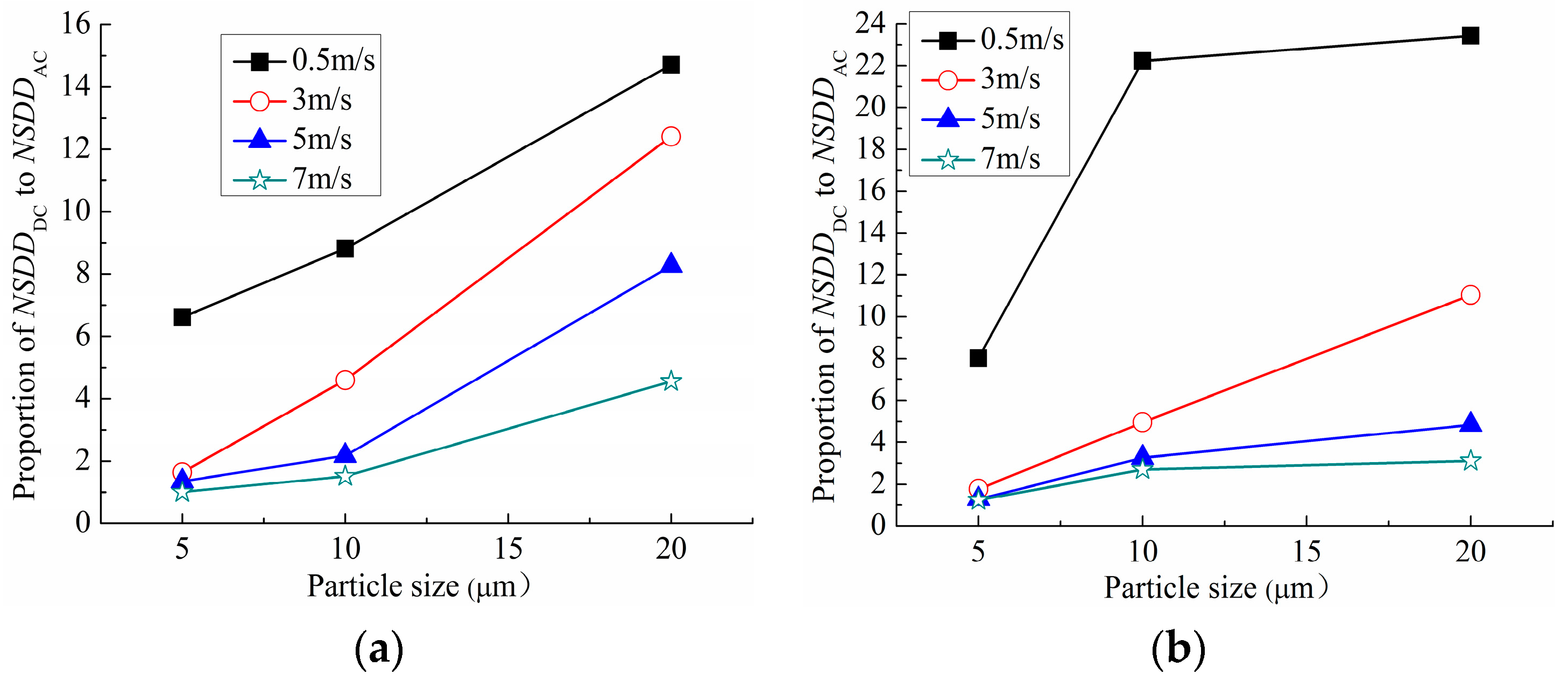

4.2.2. Studies on the Proportion of NSDDDC to NSDDAC

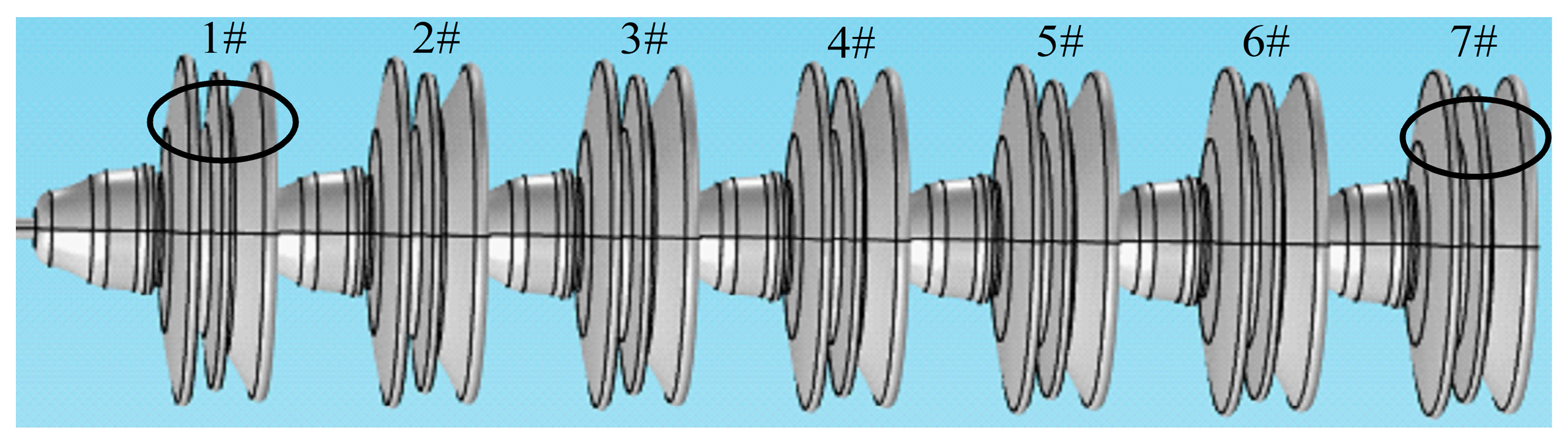

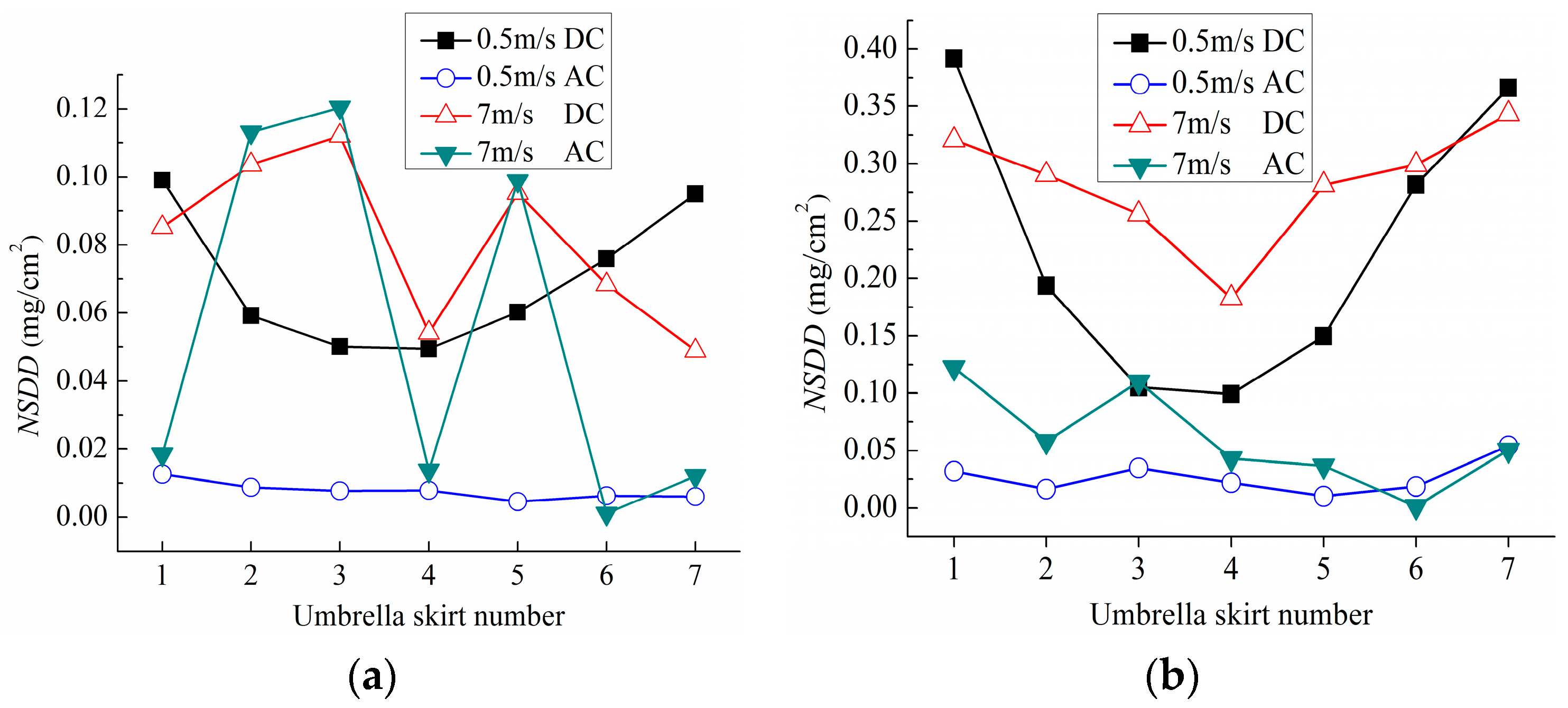

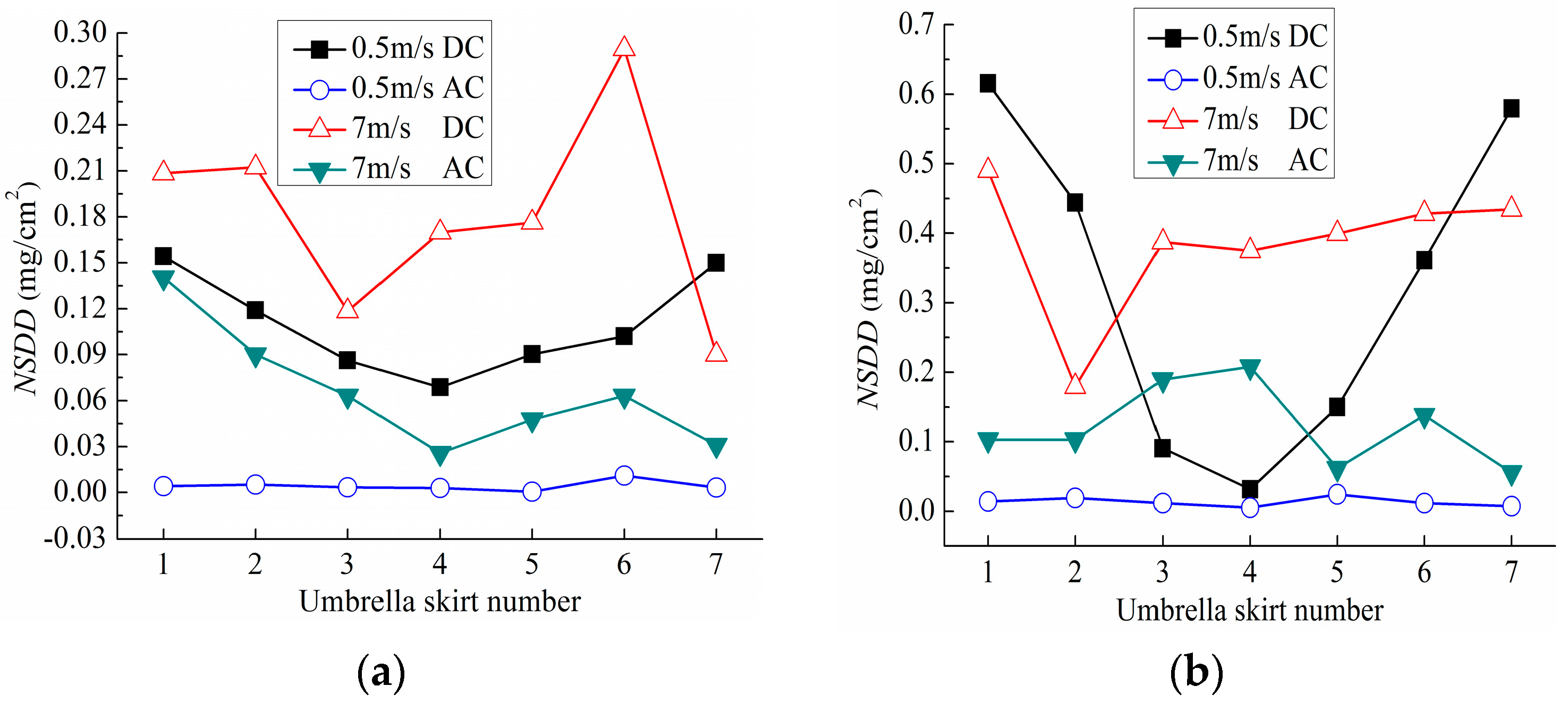

4.2.3. Distribution Law of the Contamination along the Insulator Skirt

5. Conclusions

- At the same wind speed, under DC voltage, the deposit amount on the porcelain bell jar insulator is larger than that of the porcelain three umbrella insulators. Additinoally, the NSDD increases with the increase in particle size, and displays approximately a linear change.

- Under a small wind speed (≤7 m/s) and small particle size (≤20 µm), the deposition effect of electric force on the particles under DC voltage are the main factors. However, the gravity force and drag force mainly lead to particle deposition under AC voltage and unelectrified state.

- The proportion of NSDDDC to NSDDAC of porcelain three-umbrella insulator and porcelain bell jar insulator decreases as the wind speed increases at the same particle diameter, while it increases as the particle diameter increases at the same wind speed.

- When the wind speed is 0.5 m/s, the NSDD on the porcelain three-umbrella insulator and porcelain bell jar insulator along the strings display a U-shaped distribution, while the deposition amount difference on each skirt under AC voltage is quite small. At the wind speed of 7 m/s, U-shaped distribution gradually disappears.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xu, S.; Wu, C.; Li, S. Research on pollution accumulation characteristics of Insulators during fog-haze days. Proc. CSEE 2017, 37, 2142–2151. [Google Scholar]

- Su, Z. Influences of fog-haze on external insulation of transmission and distribution equipments. Power Syst. Technol. 2013, 37, 2284–2290. [Google Scholar]

- Jiang, X.; Shu, L.; Sun, C. Power System Contamination and Ice–Insulation; China Electric Power Press: Beijing, China, 2009. [Google Scholar]

- Jiang, X.; Liu, Y.; Meng, Z.; Long, C.; Jin, X.; Zhang, Z. Effect of Fog-Haze on AC Flashover Performance of Insulator. High Volt. Eng. 2014, 40, 3311–3317. [Google Scholar]

- Armstrong, M.J.; Ross, C.A.H. Implications of distribution voltage configuration on TeDP electrical systems. Aircr. Eng. Aerosp. Technol. 2014, 86, 501–508. [Google Scholar] [CrossRef]

- Hu, C.; Xie, C.; Yuan, C. A review on influence mechanism of haze on external insulation characteristics of transmission and transformation equipment. Power Syst. Prot. Control 2015, 43, 147–154. [Google Scholar]

- Bessedik, S.A.; Hadi, H. Prediction of flashover voltage of insulators using least squares support vector machine with particle swarm optimisation. Electr. Power Syst. Res. 2013, 104, 87–92. [Google Scholar] [CrossRef]

- Li, H.; Liu, G.; Li, L. Natural contamination deposit law of line disc anti-contamination glass insulator in Guangzhou area. Proc. Chin. Soc. Electr. Eng. Chin. Soc. Electr. Eng. 2011, 31, 118–124. [Google Scholar]

- Wang, S.; HU, W.; Gong, J. Natural Pollution Accumulation Characteristics of Overhead Transmission Line Insulator Strings of Zhejiang Electric Power Grid. High Volt. Eng. 2014, 40, 1002–1009. [Google Scholar]

- Su, Z.; Liu, Y. Comparison of natural contaminants accumulated on surface of suspension and post insulators with DC and AC stress in northern China’s inland areas. Power Syst. Technol. 2004, 28, 13–17. [Google Scholar]

- Zhang, B.; He, J.; Zeng, R.; Liang, X. Voltage distribution along a long ceramic insulator string in a high-voltage tower window. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2010, 29, 811–823. [Google Scholar] [CrossRef]

- Wang, B.; Liang, X.; Zhang, Y. Natural pollution test of composite and porcelain insulators under AC and DC stress. High Volt. Eng. 2009, 9, 2322–2328. [Google Scholar]

- Zhang, R.; Huang, D.; Wu, G. Experimental Research on Natural Contamination Rules of 1000 kV Post Porcelain Insulator. High Volt. Eng. 2015, 41, 3679–3686. [Google Scholar]

- Ravelomanantsoa, N.; Farzaneh, M.; Chisholm, W.A. Laboratory investigation of the HV insulator contamination process under winter conditions. In Proceedings of the 2008 International Conference on High Voltage Engineering and Application, Chongqing, China, 9–13 November 2008. [Google Scholar]

- Zhang, Z.; Zhang, D.; Jiang, X.; Liu, X. Study on natural contamination performance of typical types of insulators. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1901–1909. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, H.; Jiang, X. Analysis of ice growth on different type insulators based on fluid dynamics. Trans. China Electrotech. Soc. 2012, 27, 35–43. [Google Scholar]

- Wang, L.; Liu, T.; Mei, H.; Xiang, Y. Research on contamination deposition characteristics of post insulator based on computational fluid dynamics. High Volt. Eng. 2015, 41, 2741–2749. [Google Scholar]

- Li, S.; Marshall, J.S.; Ratner, A.; Yao, Q. Molecular dynamics simulation of particle deposition and agglomeration in two-phase dilute flow. J. Eng. Thermophys. 2007, 28, 1035–1038. [Google Scholar]

- Hughes, M.P.; Pethig, R.; Wang, X.B. Dielectrophoretic forces on particles in travelling electric fields. J. Phys. D Appl. Phys. 1996, 29, 474–482. [Google Scholar] [CrossRef]

- Liu, G. Discrete Element Methods of Fine Particle Dynamics in Presence of van der Waals and Electrostatic Forces. Ph.D. Thesis, Tsinghua University, Beijing, China, 2011. [Google Scholar]

- Wang, J.; Chen, L.H.; Liu, Y.; Liang, X.D. Effect of the electric field on the contamination accumulation characteristic of the insulators. High Volt. Eng. 2011, 37, 585–593. [Google Scholar]

- Olsen, R.G.; Furumasu, B.C.; Hartmann, D.P. Contamination mechanisms for HVDC insulators. In Proceedings of the IEEE Power Apparatus and Systems Winter Conferences, New York, NY, USA, 30 January–4 February 1977. [Google Scholar]

- Babuška, I.; Oh, H.S. The pversion of the finite element method for domains with corners and for infinite domains. Numer. Methods Partial Differ. Equ. 1990, 6, 371–392. [Google Scholar] [CrossRef]

- Lv, Y.; Li, J.; Zhang, X.; Pang, G. Simulation Study on Pollution Accumulation Characteristics of XP13-160 Porcelain Suspension Disc Insulators. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2196–2206. [Google Scholar] [CrossRef]

- Tu, Y.; Sun, Y.; Peng, Q. Particle size distribution characteristics of naturally polluted insulators under the fog-haze environment. High Volt. Eng. 2014, 40, 3318–3326. [Google Scholar]

| Model | Contents | ||

|---|---|---|---|

| Structural Height/mm | Creepage Distance/mm | Shed Diameter/mm | |

| Porcelain three-umbrella insulator XSP-160 | 170 | 545 | 330 |

| Porcelain bell jar insulator XP13-160 | 170 | 340 | 280 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Zhao, W.; Li, J.; Zhang, Y. Simulation of Contamination Deposition on Typical Shed Porcelain Insulators. Energies 2017, 10, 1045. https://doi.org/10.3390/en10071045

Lv Y, Zhao W, Li J, Zhang Y. Simulation of Contamination Deposition on Typical Shed Porcelain Insulators. Energies. 2017; 10(7):1045. https://doi.org/10.3390/en10071045

Chicago/Turabian StyleLv, Yukun, Weiping Zhao, Jingang Li, and Yazhao Zhang. 2017. "Simulation of Contamination Deposition on Typical Shed Porcelain Insulators" Energies 10, no. 7: 1045. https://doi.org/10.3390/en10071045

APA StyleLv, Y., Zhao, W., Li, J., & Zhang, Y. (2017). Simulation of Contamination Deposition on Typical Shed Porcelain Insulators. Energies, 10(7), 1045. https://doi.org/10.3390/en10071045