Configuration Synthesis of Novel Series-Parallel Hybrid Transmission Systems with Eight-Bar Mechanisms

Abstract

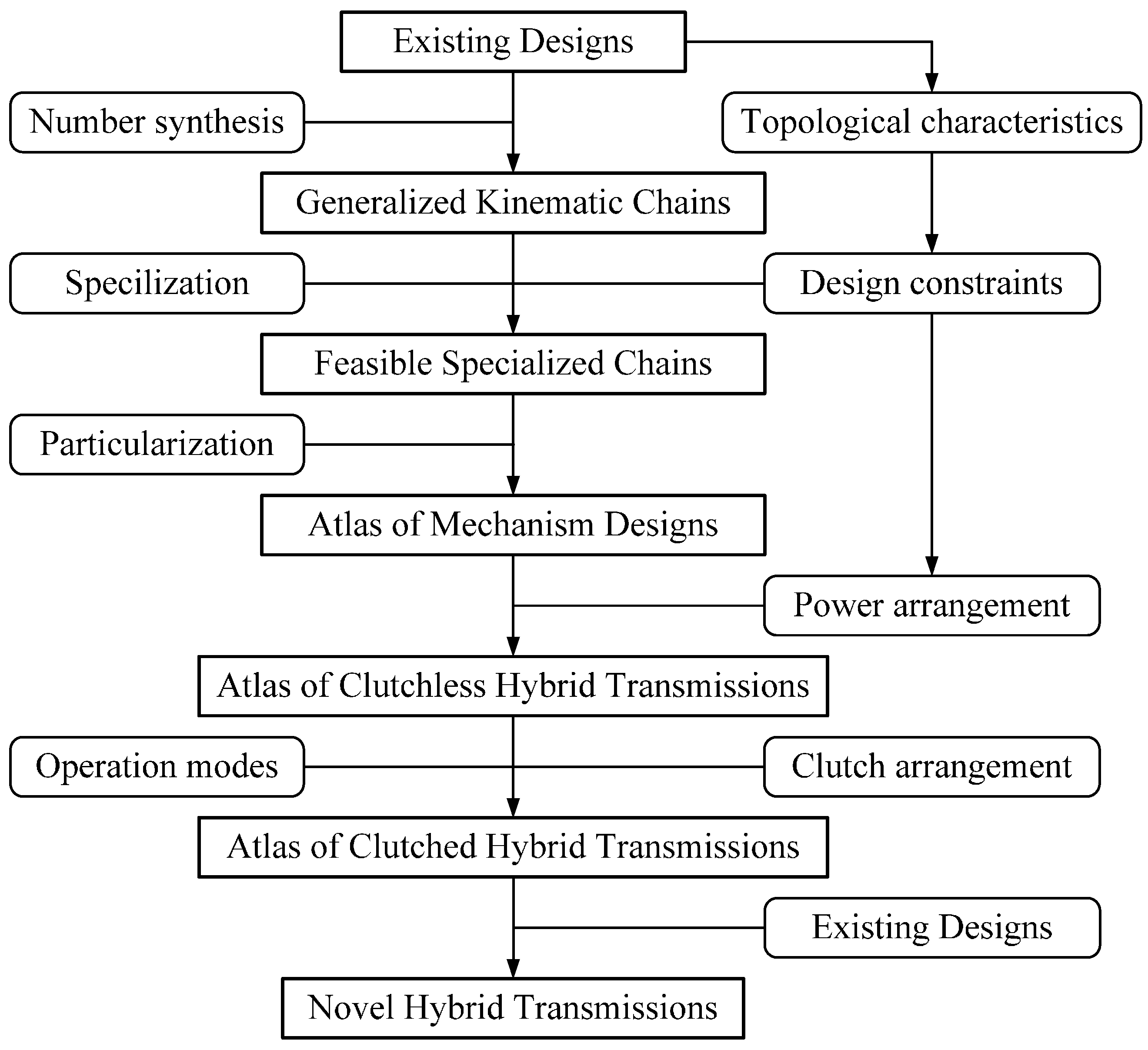

:1. Introduction

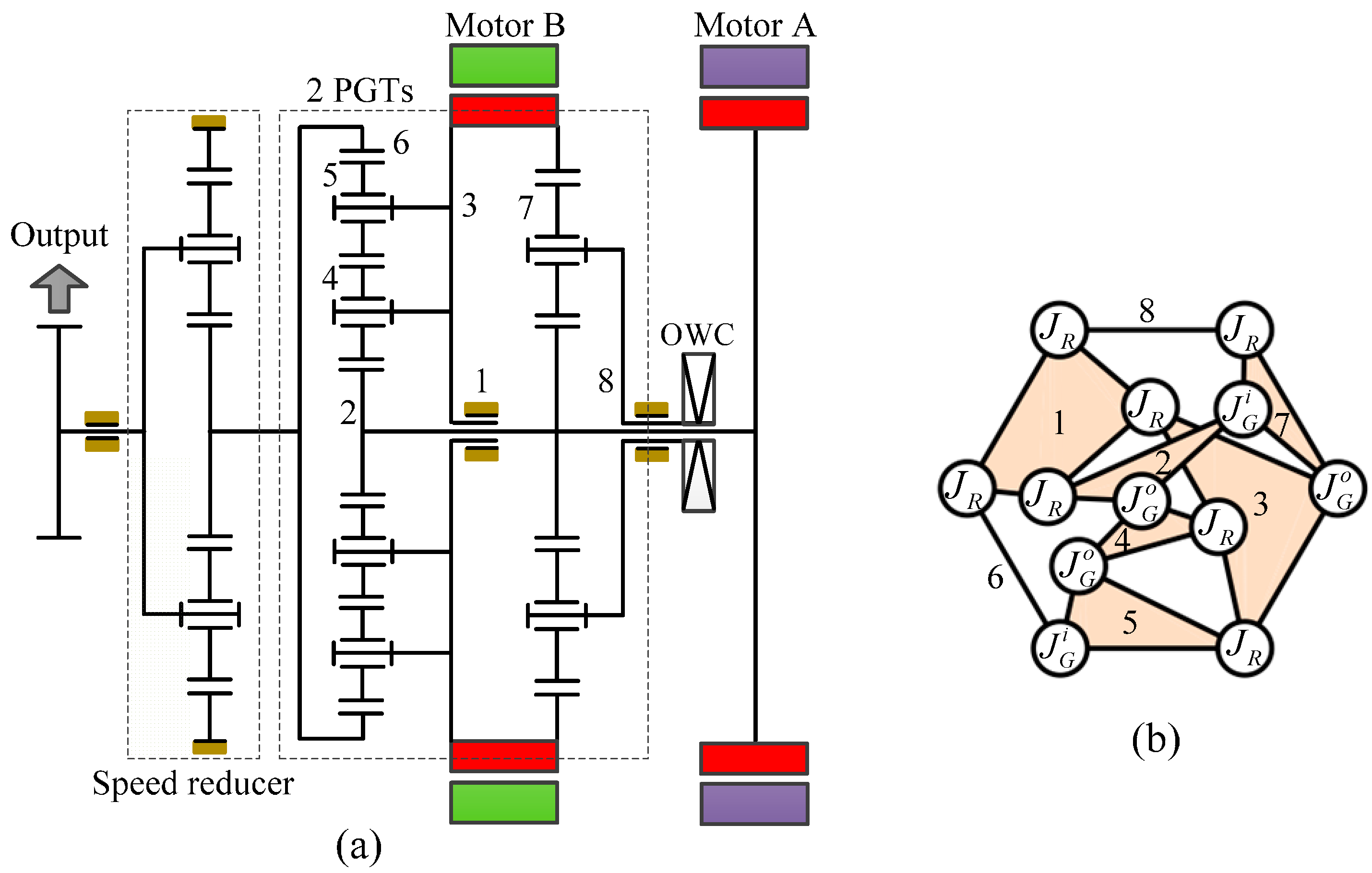

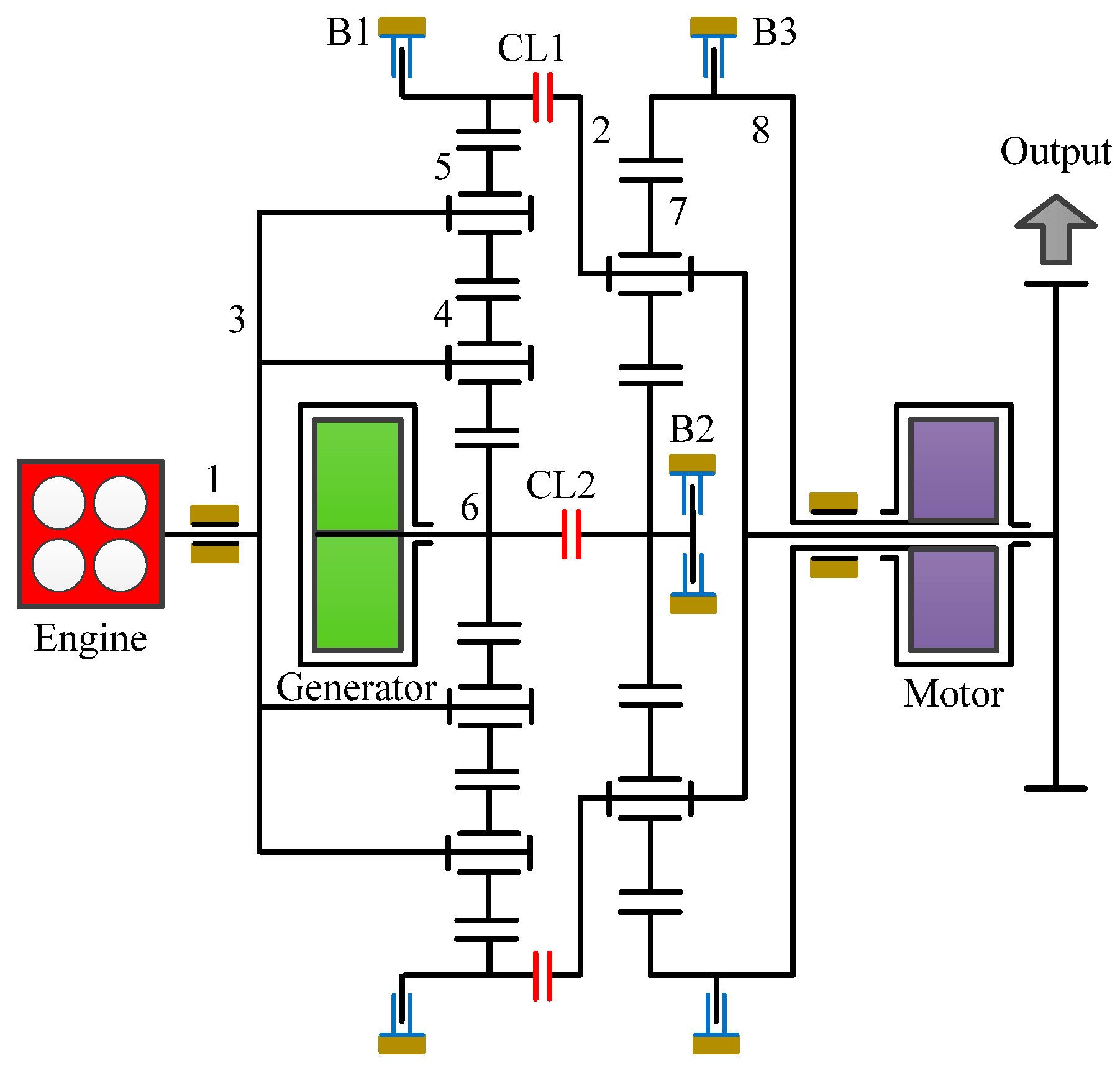

2. Existing Hybrid Transmissions

2.1. Topological Characteristics

- It is a compound PGT mechanism with 2-DoF, which is a combination of a simple PGT and a double planet PGT.

- It has eight members including one ground link (member 1), one sun gear (member 2), two carriers (members 3 and 8), three planetary gears (members 4, 5 and 7) and one ring gear (member 6).

- It has twelve joints, consisting of seven revolute joints (JR) and five gear joints (JG) in which three external gear joints () and two of the gear joints are internal gear joints ().

- It has four separated links adjacent to the ground link.

2.2. Operation Modes

- Motor alone mode: the motor alone drives the vehicle in the forward or backward direction using energy provided by the battery when the battery is at the high level.

- Engine alone mode: when the power demand is moderately high (e.g., during highway cruise control), the transmission shifts to the engine alone mode to further improve fuel efficiency.

- Combined power mode: when the power demand or required for heavy load or high-speed acceleration, the transmission shifts into power mode in which the engine is turned on together with the motor to provide additional power to drive the vehicle.

- Power split mode: when the power demand is low but the engine still must turn on, part of engine power is converted into electricity by the motor or generator to charge the battery and the remaining engine power drives the vehicle.

- Regenerative braking mode: the electric motor is operated as a generator to convert kinetic energy from the vehicle’s braking process into electrical energy, which is stored in the battery.

- Stationary charging mode: the engine drives the generator to charge the battery when the vehicle is at a standstill, and the battery is low.

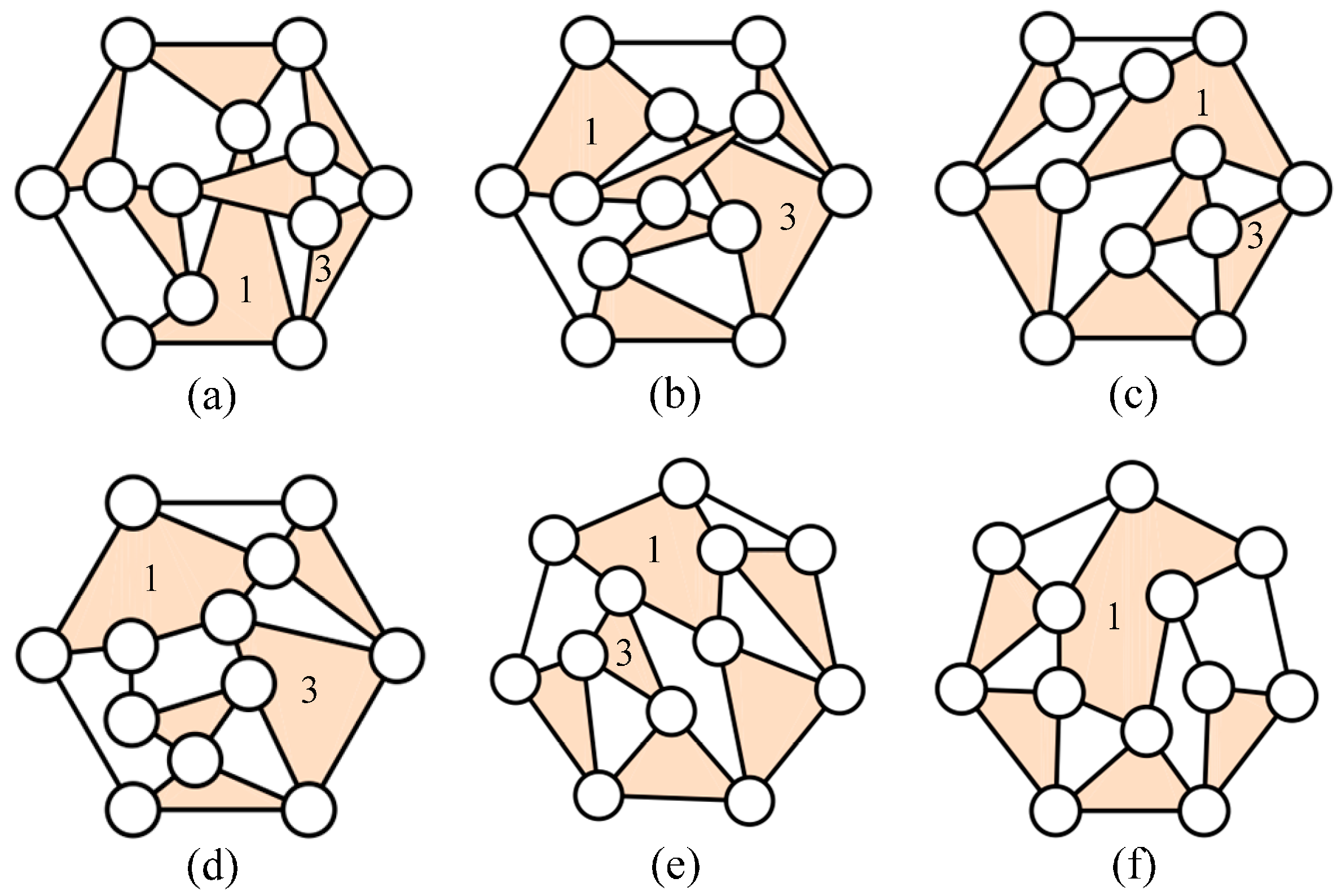

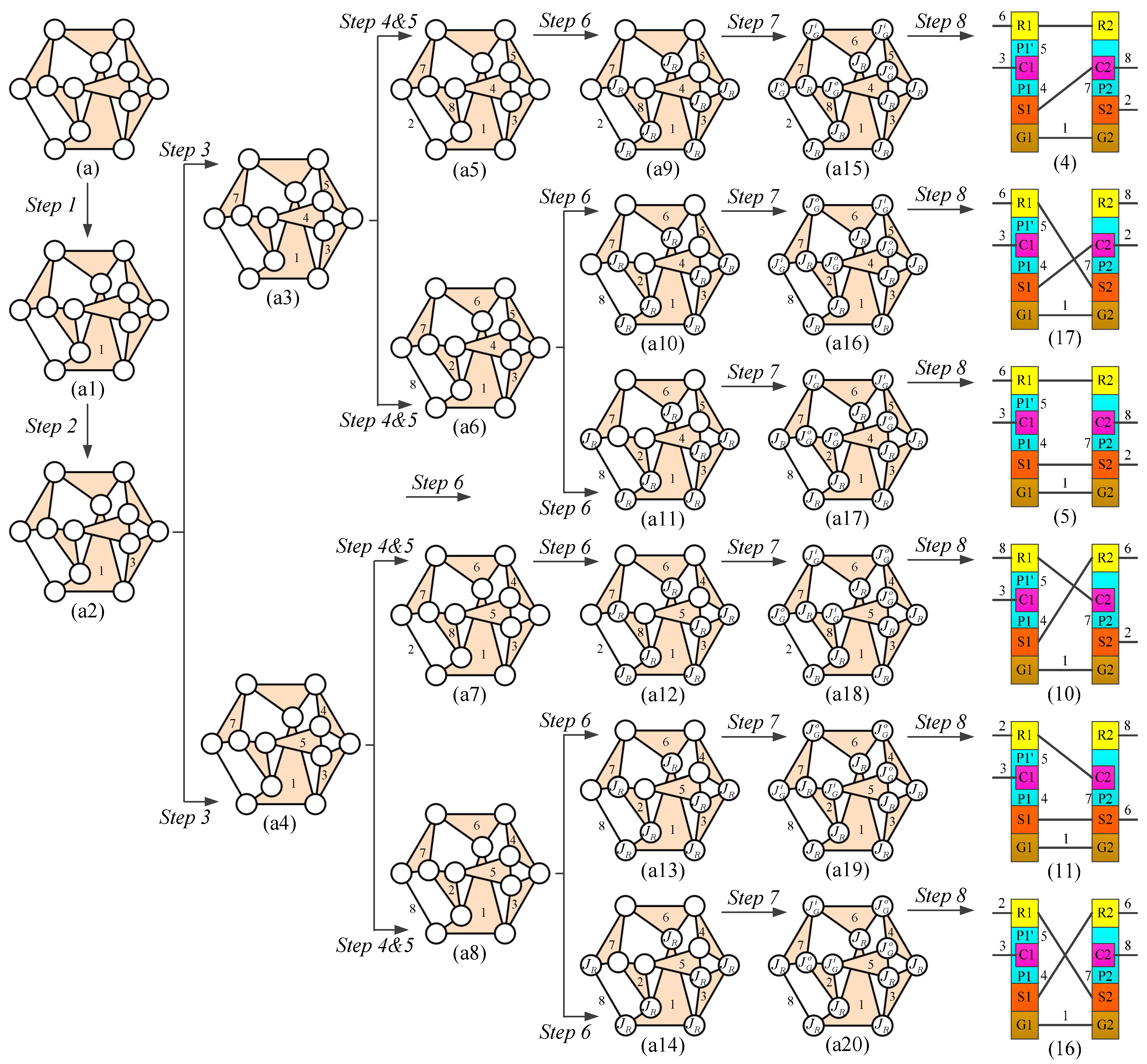

3. Generalized Kinematic Chains

- Since the fixed ground link (member 1) is adjacent to four members (members 2, 3, 6, and 8) by four revolute joints, and it is released and generalized into quaternary link 1 (a link with four joints).

- Since the sun gear (member 2) is adjacent to two planetary gears (members 4 and 7) and the ground link, and it is generalized into ternary link 2 (a link with three joints).

- Since carrier (member 3) is adjacent to three planetary gears (members 4, 5 and 7) and the ground link (member 1), and it is generalized into quaternary link 3.

- Since the planet gear (member 4) is adjacent to two gears (members 2 and 5) and the carrier (member 3), and it is generalized into ternary link 4.

- Since the planet gear (member 5) is adjacent to two gears (members 4 and 6) and the carrier (member 3), and it is generalized into ternary link 5.

- Since the ring gear (member 6) is adjacent to a planet gear (member 5) and the ground link (member 1), and it is generalized into binary link 6 (a link with two joints).

- Since the planet gear (member 7) is adjacent to two gears (members 2 and 3) and the carrier (member 8), and it is generalized into ternary link 7.

- Since the carrier (member 8) is adjacent to a planetary gear (member 7) and the ground link (member 1), and it is generalized into binary link 8.

4. Specialized Chains

4.1. Mechanism Constraints

4.1.1. Ground Link (Member 1):

- There must be one fixed link as the ground link.

- The ground link must be at least a quaternary link adjacent to binary links.

4.1.2. Planet Gear (Members 4, 5 and 7):

- A planet gear must not be adjacent to the ground link.

- There is no three-bar loop formed by any link adjacent to a planet gear, a binary link, and the ground link.

- Each planet gear must have just one carrier.

- Two planet gears (members 4 and 5) always adjacent to each other.

4.1.3. Carrier (Members 3 and 8):

- Carrier of the double planet PGT (member 3) always adjacent to member 4 and 5 and the ground link (member 1).

- In order to maintain the center distance between two or more planet gears in series, they must share a common carrier.

4.1.4. Sun and Ring Gears (Members 2 and 6):

- There must be at least one sun (ring) gear in a simple or double planet PGT.

- The sun (ring) gear must be adjacent to both the ground link and a planet gear.

4.1.5. Revolute Joint (JR):

- There must be seven revolute joints.

- The joints between a planet gear and its carrier, the ground link and a binary link must be revolute joints.

4.1.6. Gear Pair (JG):

- There must be five gear joints, namely three external gear joints () and two internal gear joints ().

- The joint between a planet gear and a ring (sun) gear must be a gear joint.

4.2. Inputs/Output Constraints

4.2.1. Output (O)

- One member of compound PGT must be connected to the output shaft.

- The output must be connected to a ring gear or planetary carrier of a PGT in order to achieve high torque transfer when the motor drives the vehicle alone.

- The output and the motor must be on the same PGT set.

- In the PGT set, the motor speed must be faster than the speed of the output shaft if the third link is fixed.

4.2.2. Motor (M)

- One member of compound PGT must be connected to the motor shaft.

- The motor must be connected to a ring gear or a sun gear in order to achieve speed reduction and obtain higher torque at the output shaft.

- The motor must not be connected to a carrier in order to avoid excessive output speed.

4.2.3. Engine (E)

- One member of compound PGT must be connected to the engine shaft.

- The engine must be at least connected to a ring gear or planetary carrier in order to have high efficiency when the vehicle is at high speed.

- The engine and the generator must be on the same PGT set.

- In the PGT set, the generator speed must be faster than the speed of the engine when the third link is fixed.

4.2.4. Generator (G)

- One member of compound PGT must be connected to the generator shaft.

- The generator must be at least connected to a sun gear or a ring gear in order to achieve high speed during braking and regeneration.

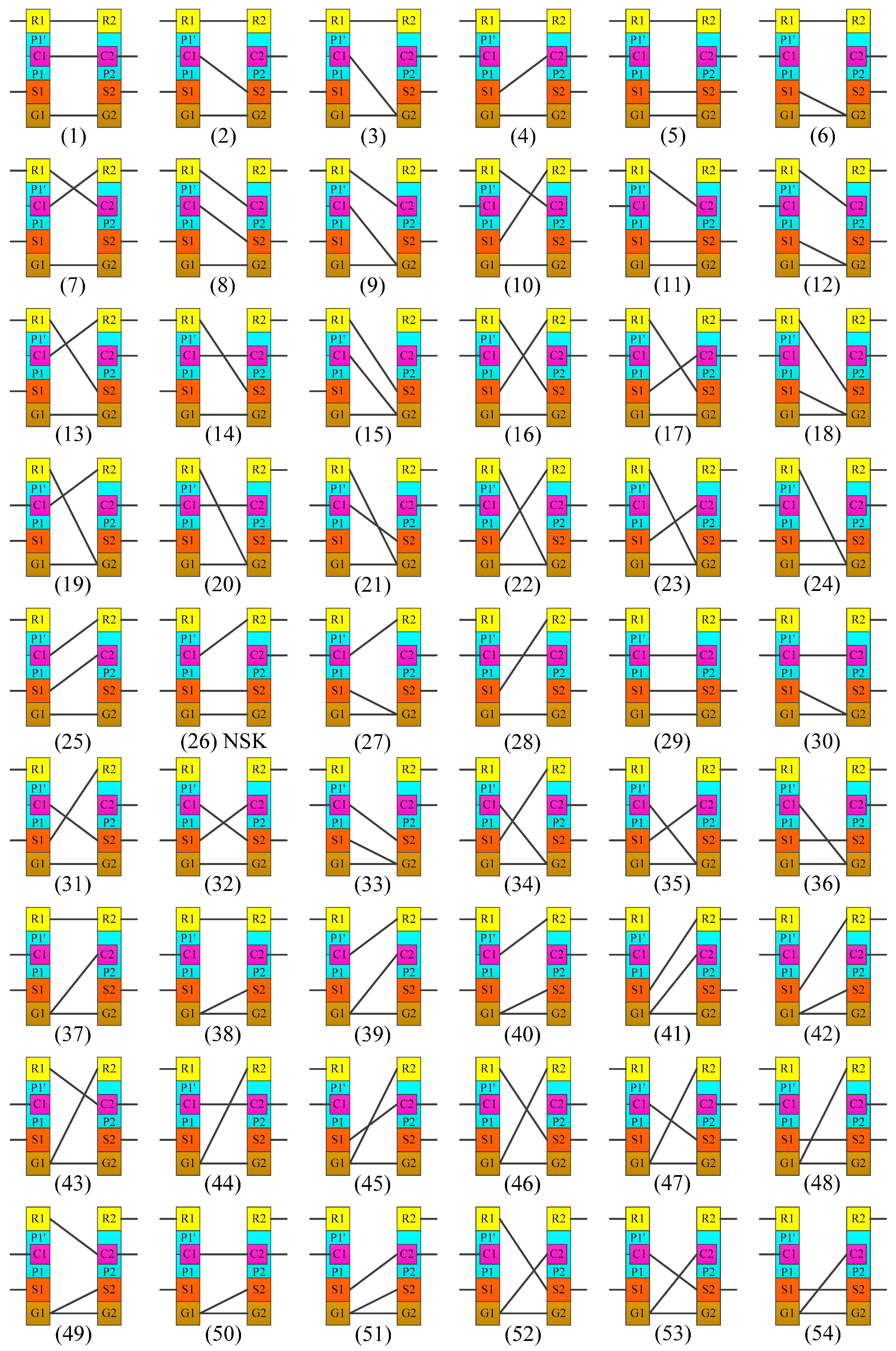

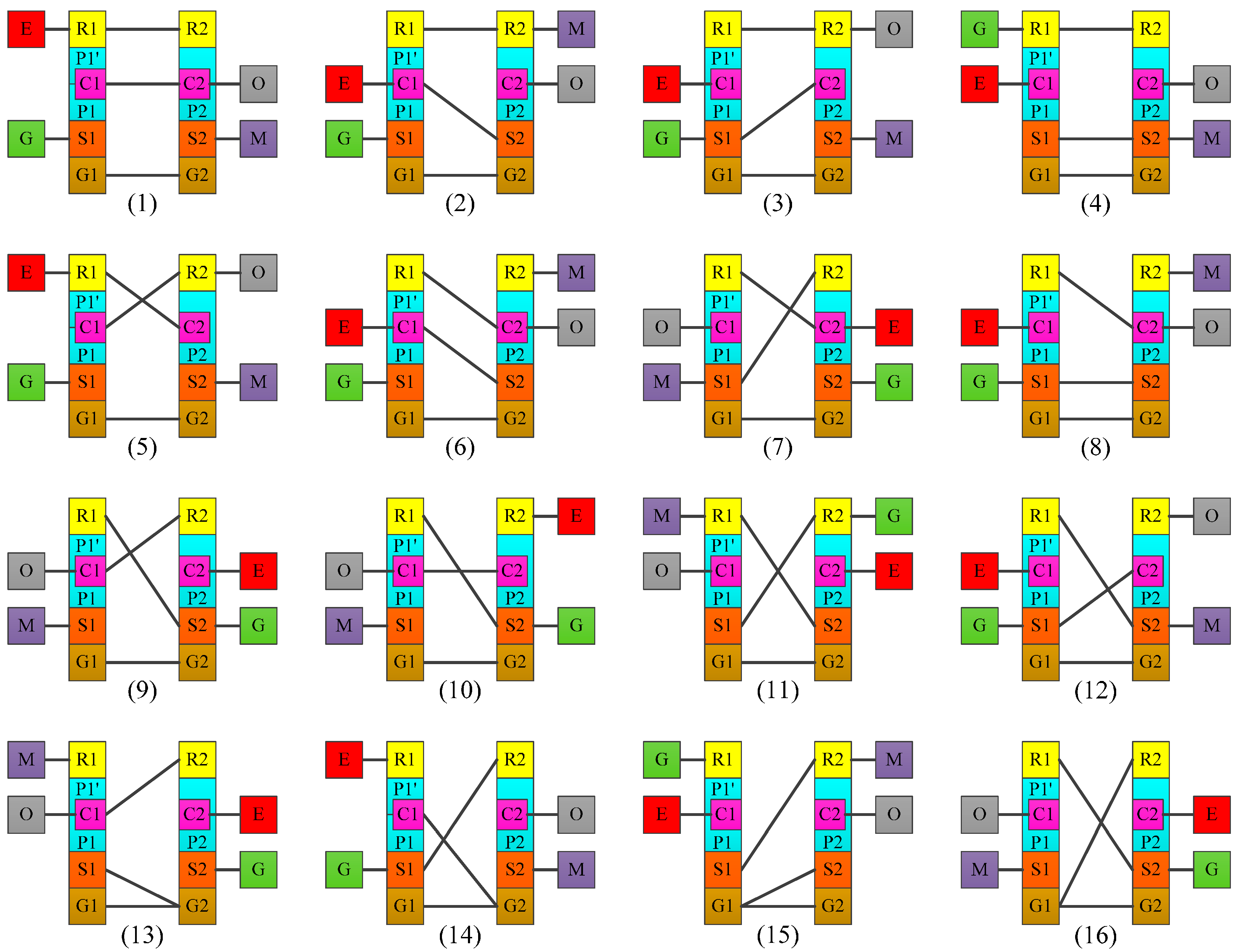

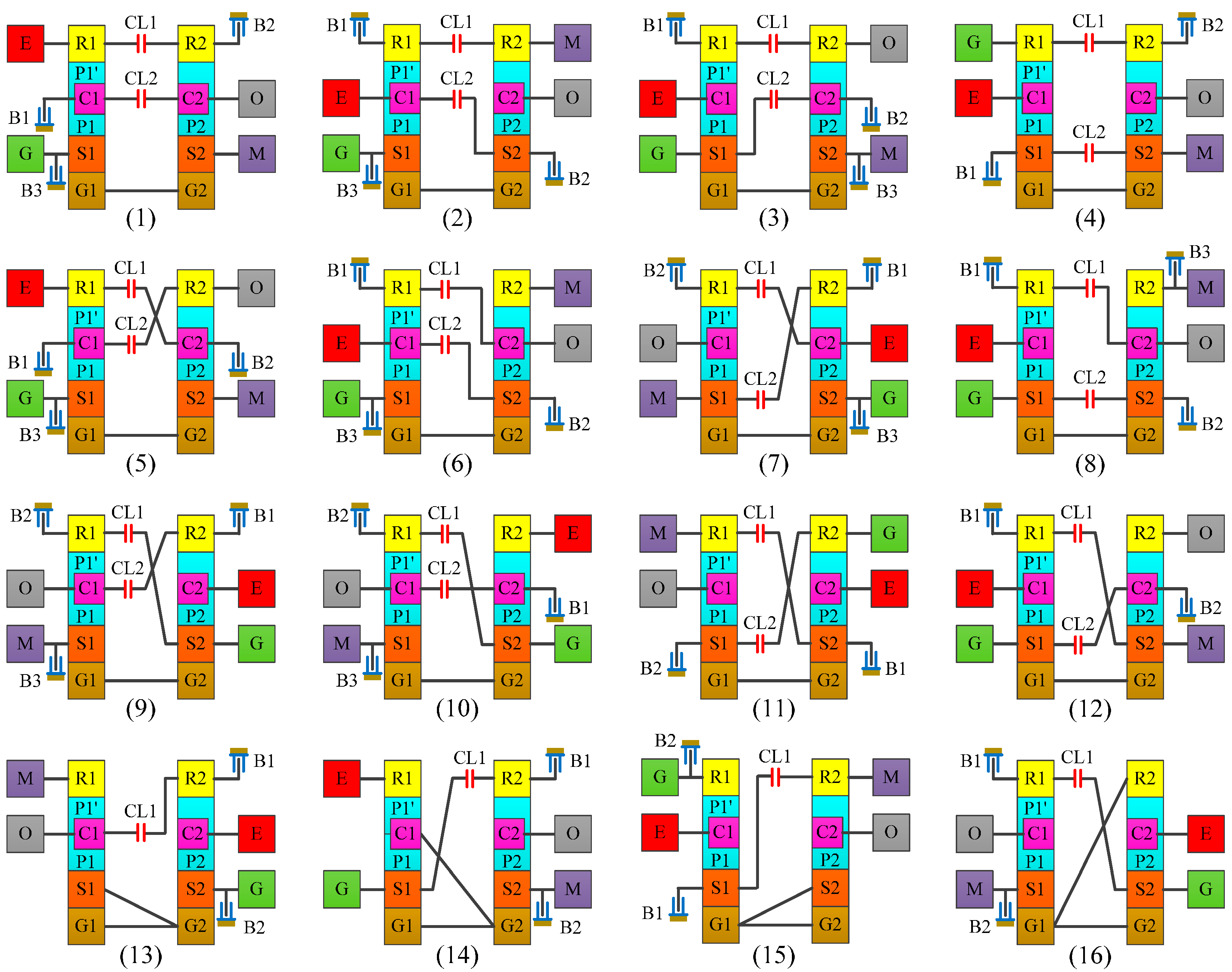

4.3. Feasible Specialized Chains

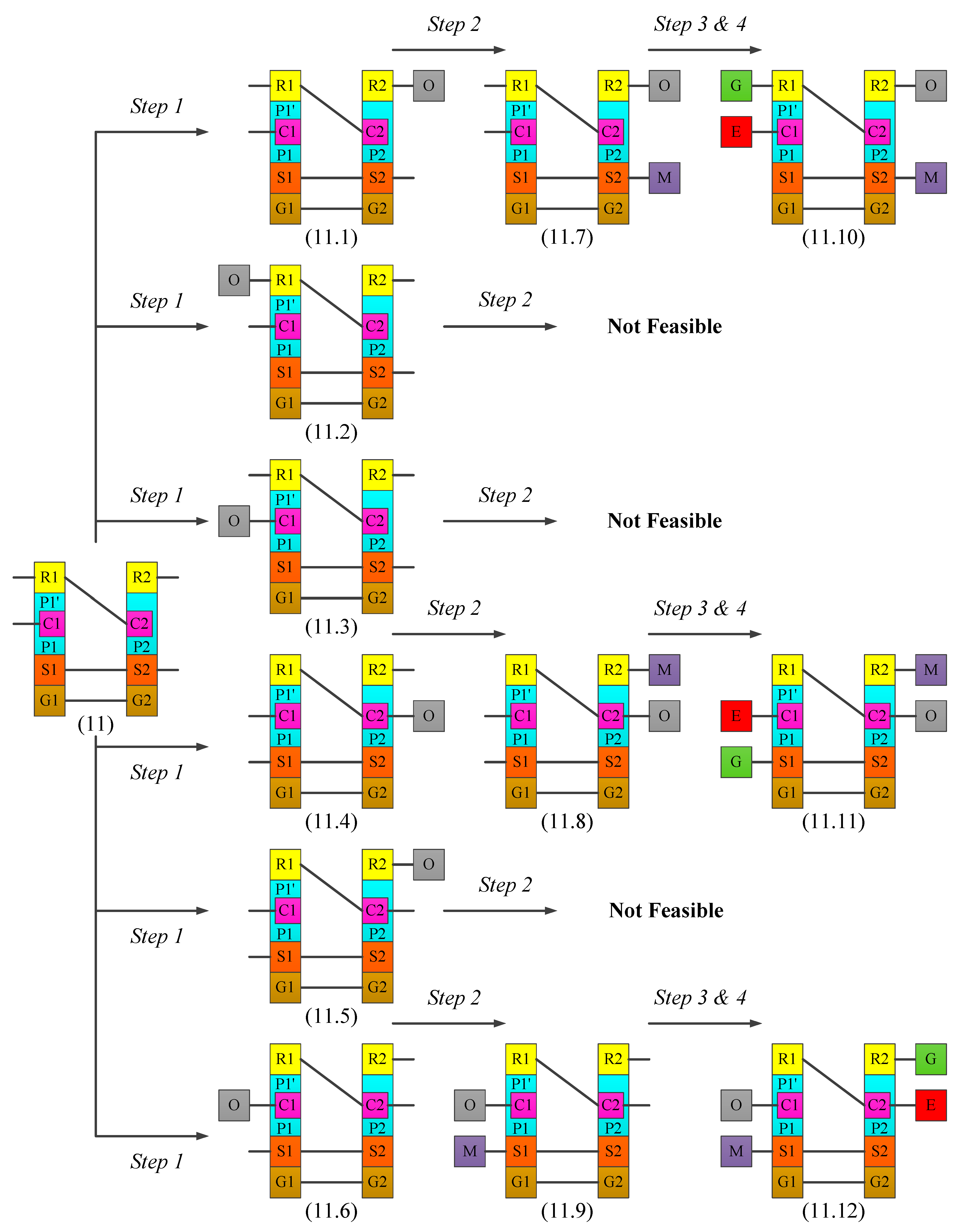

5. Atlas of Mechanism Designs

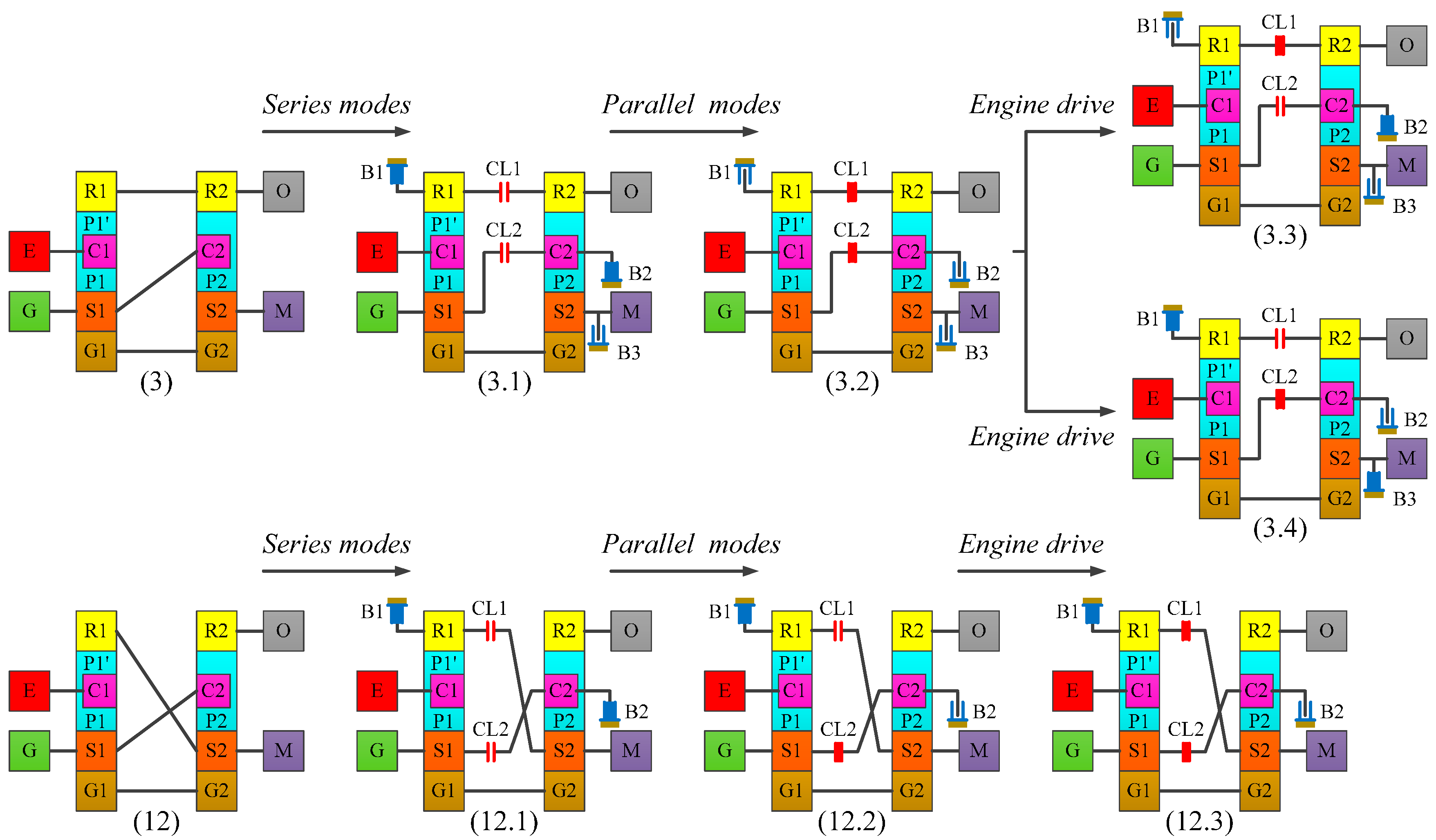

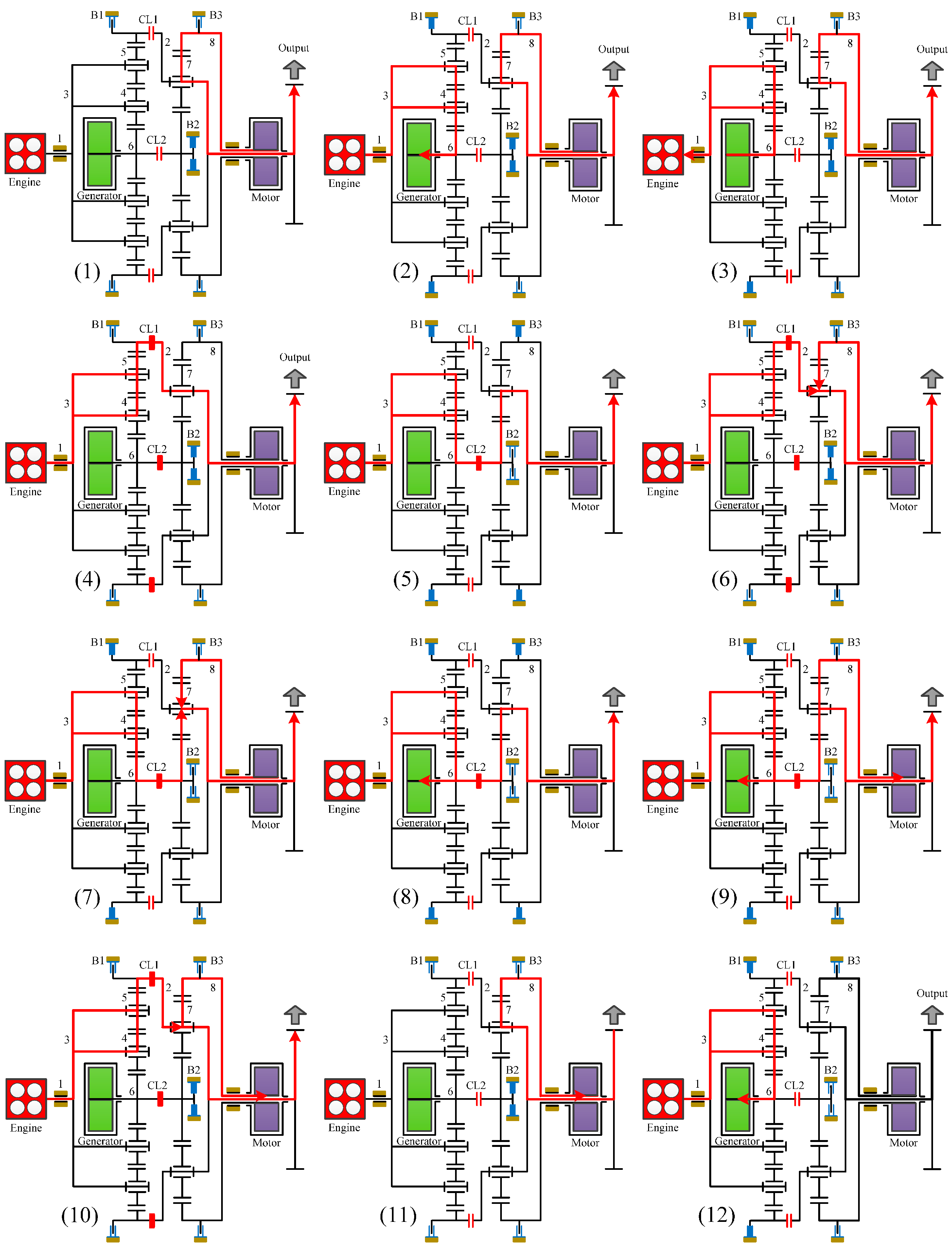

6. Atlas of Clutchless and Clutched Hybrid Transmissions

6.1. Power Arrangement

6.2. Clutch Arrangement

6.2.1. Required Operation Modes

6.2.2. Clutch Arrangement

7. Analysis of a New Series-Parallel Hybrid Transmission

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Berman, B.; Gelb, G.H.; Richardson, N.A.; Wang, T.C. Power Train Using Multiple Power Sources. U.S. Patent 3,566,717, 2 March 1971. [Google Scholar]

- Wong, Y.S.; Chau, K.T. Overview of power management in hybrid electric vehicles. Energy Conv. Manag. 2002, 43, 1953–1968. [Google Scholar]

- Ehsani, M.; Gao, Y.; Miller, J.M. Hybrid electric vehicle: Architecture and motor drives. Proc. IEEE 2007, 95, 719–728. [Google Scholar] [CrossRef]

- Tsai, L.W.; Schultz, G.; Higuchi, N. A novel parallel hybrid transmission. ASME J. Mech. Des. 2001, 123, 161–168. [Google Scholar] [CrossRef]

- Schulz, M. Circulating mechanical power in a power-split hybrid electric vehicle transmission. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 1419–1425. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, H. Performance modeling and optimization of a novel multi-mode hybrid powertrain. ASME J. Mech. Des. 2006, 128, 79–89. [Google Scholar] [CrossRef]

- Mi, C.; Masrur, M.; Gao, W.Z. Hybrid Electric Vehicle: Principles and Applications with Practical Perspectives; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Chen, L.; Zhu, F.; Zhang, M.; Huo, Y.; Yin, C.; Peng, H. Design and analysis of an electrical variable transmission for a series-parallel hybrid electric vehicle. IEEE Trans. Veh. Technol. 2011, 60, 2354–2363. [Google Scholar] [CrossRef]

- Zhu, F.; Chen, L.; Yin, C. Design and analysis of a novel multimode transmission for a HEV using a single electric machine. IEEE Trans. Veh. Technol. 2013, 62, 1097–1110. [Google Scholar] [CrossRef]

- Esmail, E.L. Hybrid transmission for mobile robot. ASME J. Mech. Des. 2012, 134, 021001. [Google Scholar] [CrossRef]

- Yamaguchi, J. Toyota readies gasoline/electric hybrid system. Automot. Eng. 1997, 105, 55–57. [Google Scholar]

- Nagasaka, A.; Nada, M.; Hamada, H.; Hiramatsu, S.; Kikuchi, Y.; Kato, H. Development of the hybrid/battery ECU for the Toyota hybrid system. In Proceedings of the SAE 1998 International Congress & Exposition, Detroit, MI, USA, 23–26 February 1998. [Google Scholar]

- Takasaki, A.; Mizutani, T.; Kitagawa, K.; Yamahana, T.; Odaka, K.; Kuzuya, T.; Mizuno, Y.; Nishikawa, Y. Development of new hybrid transmission for 2009 Prius. In Proceedings of the EVS24 International Battery, Hybrid Fuel Cell Electric Vehicle Symposium, Stavanger, Norway, 13–16 May 2009. [Google Scholar]

- Hata, H.; Kojima, M.; Adachi, M.; Shimizu, T. Power Transmission System. U.S. Patent 7,081,060, 20 September 2006. [Google Scholar]

- Nagamatsu, S. Power Transmission Apparatus of Hybrid Vehicle. U.S. Patent 8,142,317, 27 March 2012. [Google Scholar]

- Zhang, D.; Chen, J.; Hsieh, J.; Rancourt, J.; Schmidt, M.R. Dynamic modeling and simulation of two-mode electric variable transmission. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2001, 215, 1217–1223. [Google Scholar] [CrossRef]

- Grewe, T.; Conlon, B.; Holmes, A. Defining the General Motors 2-mode Hybrid Transmission. Available online: http://documents.epfl.ch/users/f/fr/froulet/www/Hybrid/HybridVehiclessession5-1.pdf (accessed on 19 July 2017).

- Ahn, K.; Cho, S.; Lim, W.; Park, Y.I.; Lee, J.M. Performance analysis and parametric design of the dual-mode planetary gear hybrid powertrain. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 1601–1614. [Google Scholar] [CrossRef]

- Higuchi, N.; Sunaga, Y.; Tanaka, M.; Shimada, H. Development of a new two-motor plug-in hybrid system. SAE Int. J. Alt. Powertr. 2013, 2, 135–145. [Google Scholar] [CrossRef]

- Lehongre, C. Hybrid Engine Transmission Unit Comprising a Double Planetary Gear Train. U.S. Patent 6,468,175, 22 October 2002. [Google Scholar]

- Ai, X.; Mohr, T.W.; Anderson, S. An electromechanical infinitely variable speed transmission. In Proceedings of the SAE 2004 World Congress & Exhibition, Detroit, MI, USA, 8–11 March 2004. [Google Scholar]

- Liu, J. Analysis of Vehicle Transmission System; National Defense Industry Press: Beijing, China, 1998. [Google Scholar]

- Liu, J.; Peng, H. A systematic design approach for two planetary gear split hybrid vehicles. IEEE Veh. Syst. Dyn. 2010, 48, 1395–1412. [Google Scholar] [CrossRef]

- Ngo, H.T.; Yan, H.S. Configuration synthesis of series-parallel hybrid transmission. Inst. Mech. Eng. 2015, 230, 664–678. [Google Scholar] [CrossRef]

- Yan, H.S. Creative Design of Mechanical Devices; Springer: Berlin, Germany, 1998. [Google Scholar]

- Lin, J.L.; Yan, H.S. Reconstruction designs of the lost structures of the Antikythera mechanism with two degrees of freedom. ASME J. Mech. Rob. 2014, 6, 031016. [Google Scholar] [CrossRef]

- Gunji, D.; Matsuda, Y.; Kimura, G. Wheel Hub Motor. U.S. Patent 8,758,178 B2, 24 June 2014. [Google Scholar]

| No. | Operation Mode | System DoF | Power Sources | Remark |

|---|---|---|---|---|

| 1 | Motor alone | 1 | M | M drives the vehicle |

| 2 | Series | 1 | M, E, G | M drives the vehicle, while E drives G |

| 3 | Engine start | 1 | M, G | M drives the vehicle, while G starts E |

| 4 | Engine alone | 1 | E | E alone drives the vehicle with M (and G) idling |

| 5 | Combined power | 1 or 2 | E, M | E and M (and G) drive the vehicle |

| 6 | Split power (CVT) | 1 or 2 | E | E power is split with one part driving the vehicle and the other driving M (and G) |

| 7 | Regenerative braking | 1 | Output | M works as a generator |

| No. | Operation Mode | Clutch and Brake Engagement | Remark | ||||

|---|---|---|---|---|---|---|---|

| CL1 | CL2 | B1 | B2 | B3 | |||

| 1 | Motor alone | x | M alone drives the vehicle, while E idles | ||||

| 2 | Series | x | x | M drives the vehicle, while E drives G | |||

| 3 | Engine start | x | x | M drives the vehicle, while G starts E | |||

| 4 | Engine alone 1 | x | x | x | E alone drives the vehicle with M (and G) idling | ||

| 5 | Engine alone 2 | x | x | x | |||

| 6 | Combined power 1 | x | x | x | E and M (and G) drive the vehicle | ||

| 7 | Combined power 2 | x | x | ||||

| 8 | Split power 1 | x | x | x | E power is split with one part driving the vehicle and the other driving M (and G) | ||

| 9 | Split power 2 | x | x | ||||

| 10 | Split power 3 | x | x | x | |||

| 11 | Regenerative braking | x | M work as a generator | ||||

| 12 | Stationary charging | x | E drives G | ||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoang, N.-T.; Yan, H.-S. Configuration Synthesis of Novel Series-Parallel Hybrid Transmission Systems with Eight-Bar Mechanisms. Energies 2017, 10, 1044. https://doi.org/10.3390/en10071044

Hoang N-T, Yan H-S. Configuration Synthesis of Novel Series-Parallel Hybrid Transmission Systems with Eight-Bar Mechanisms. Energies. 2017; 10(7):1044. https://doi.org/10.3390/en10071044

Chicago/Turabian StyleHoang, Ngoc-Tan, and Hong-Sen Yan. 2017. "Configuration Synthesis of Novel Series-Parallel Hybrid Transmission Systems with Eight-Bar Mechanisms" Energies 10, no. 7: 1044. https://doi.org/10.3390/en10071044

APA StyleHoang, N.-T., & Yan, H.-S. (2017). Configuration Synthesis of Novel Series-Parallel Hybrid Transmission Systems with Eight-Bar Mechanisms. Energies, 10(7), 1044. https://doi.org/10.3390/en10071044