Natural Contamination and Surface Flashover on Silicone Rubber Surface under Haze–Fog Environment

Abstract

:1. Introduction

2. Onsite Measurements and Experimental Setup

2.1. Atmospheric Sample Collection

2.2. Natural Contamination Test

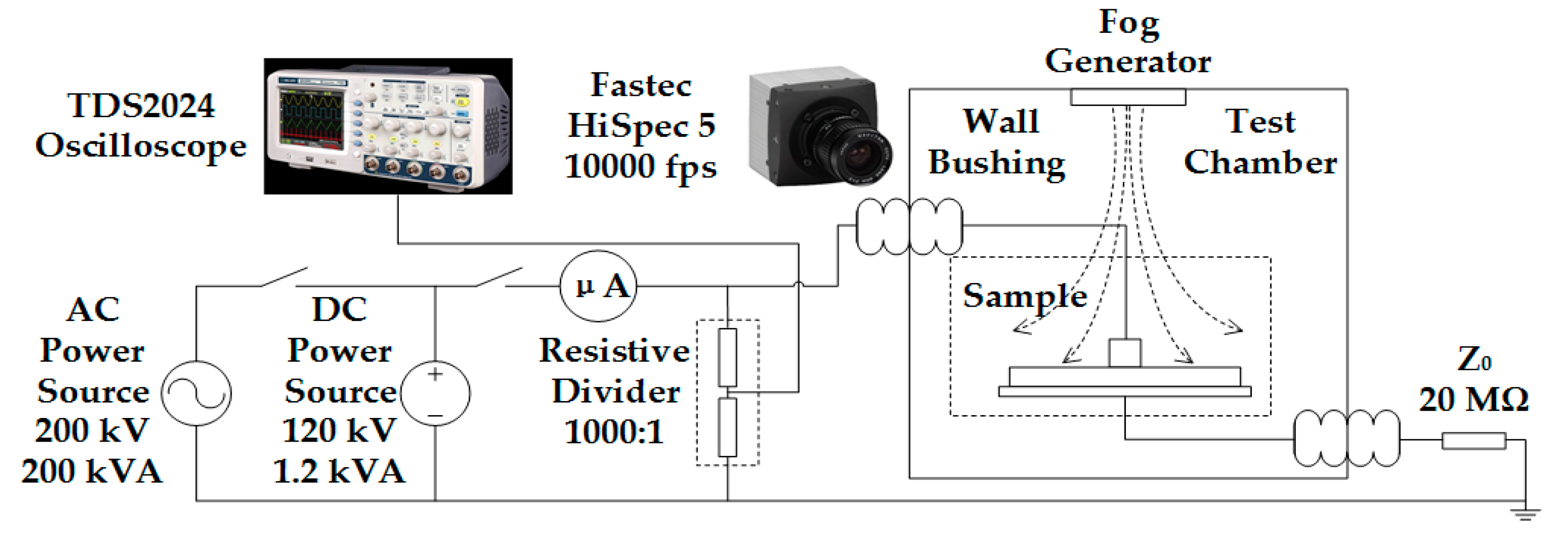

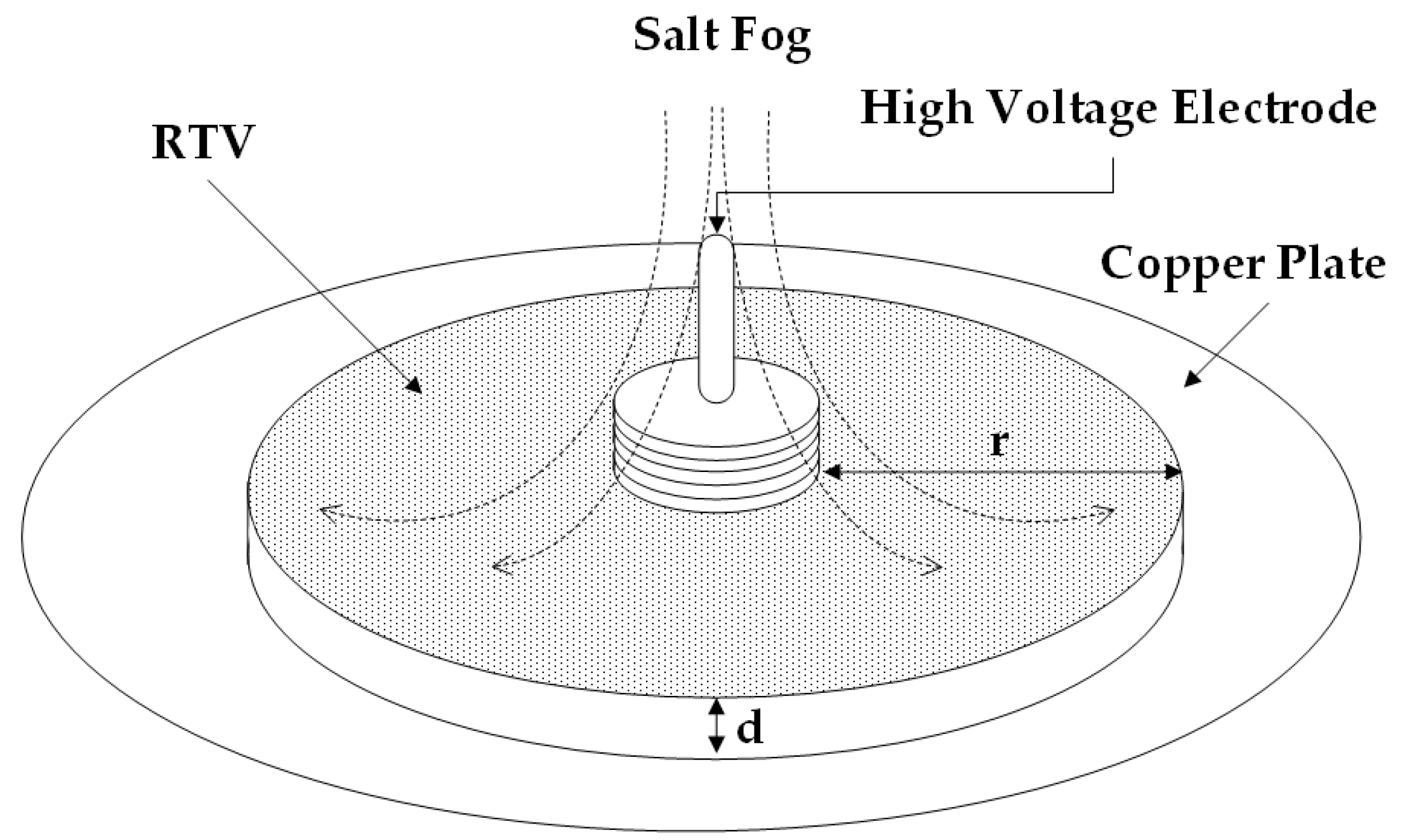

2.3. Experiment Facilities and Procedure

3. Natural Contamination Results

3.1. Inorganic Ion Data

3.2. Particle Size of Contamination

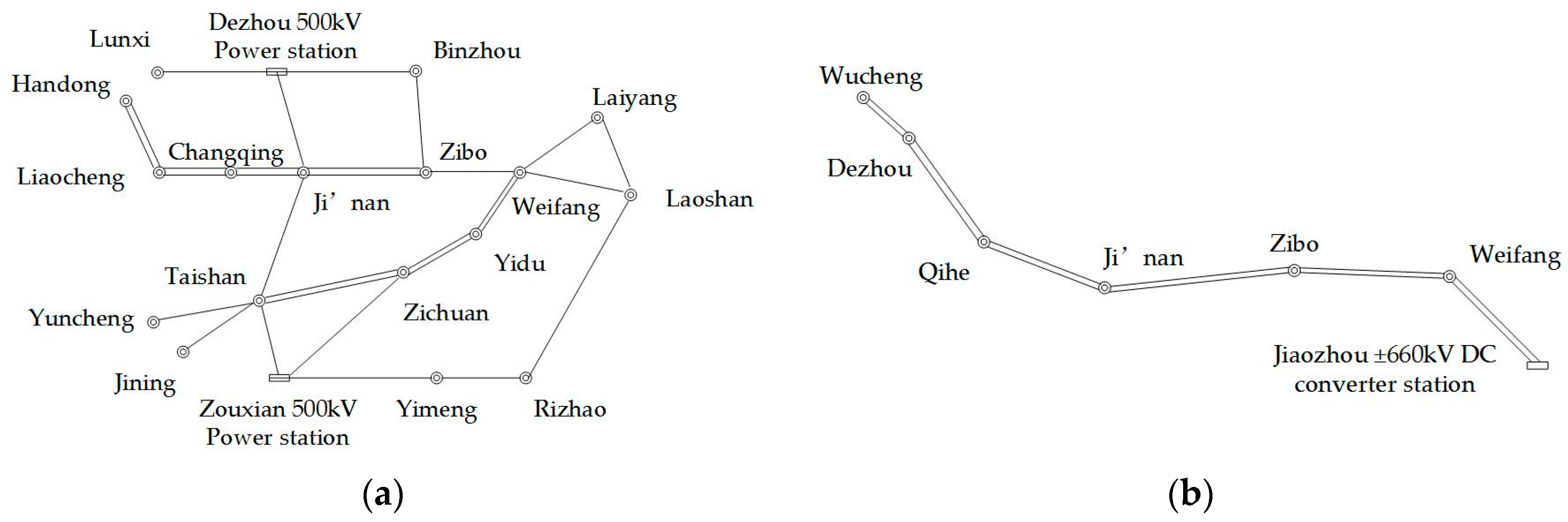

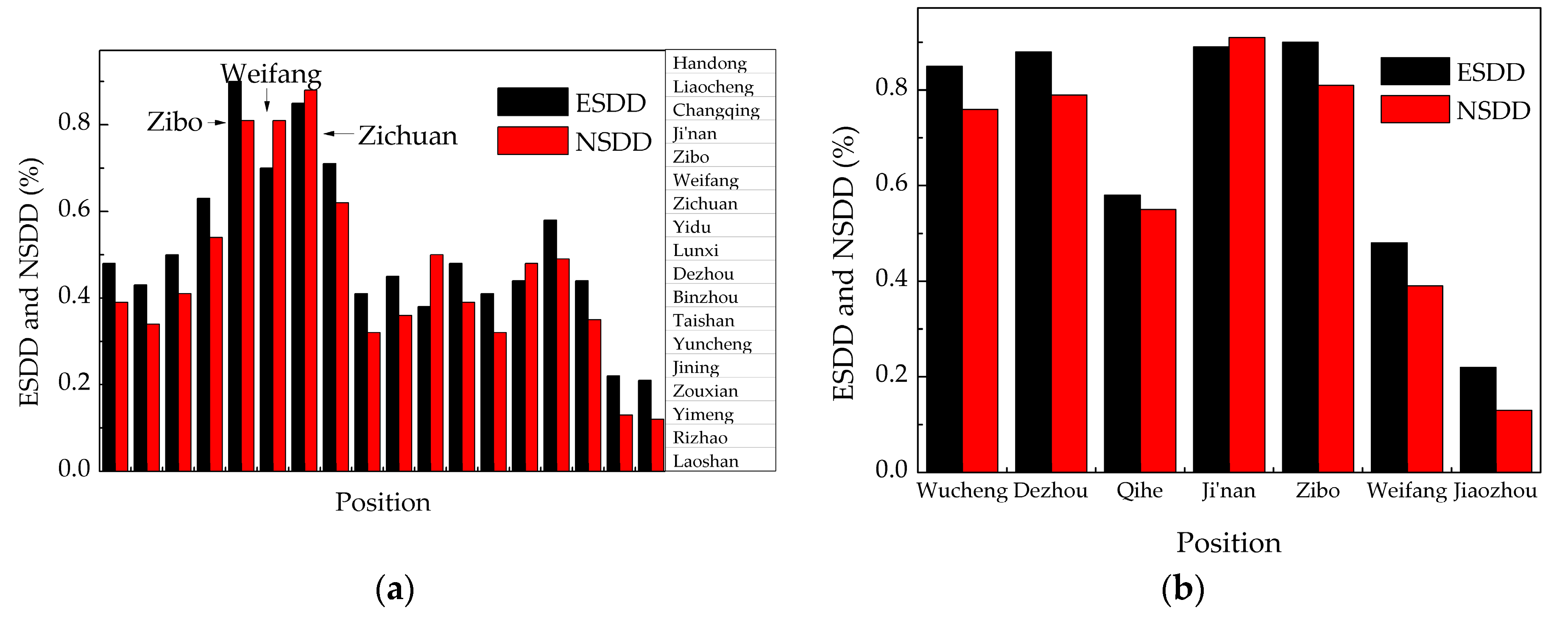

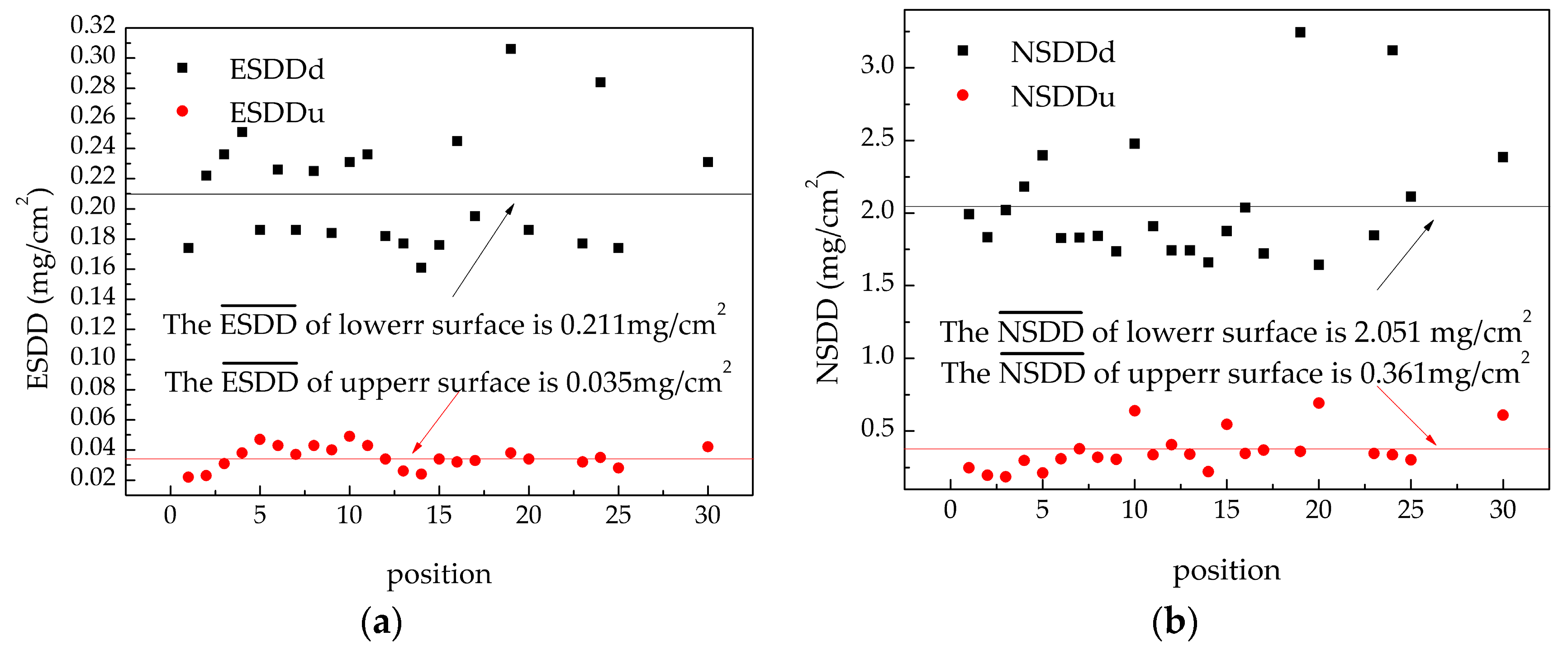

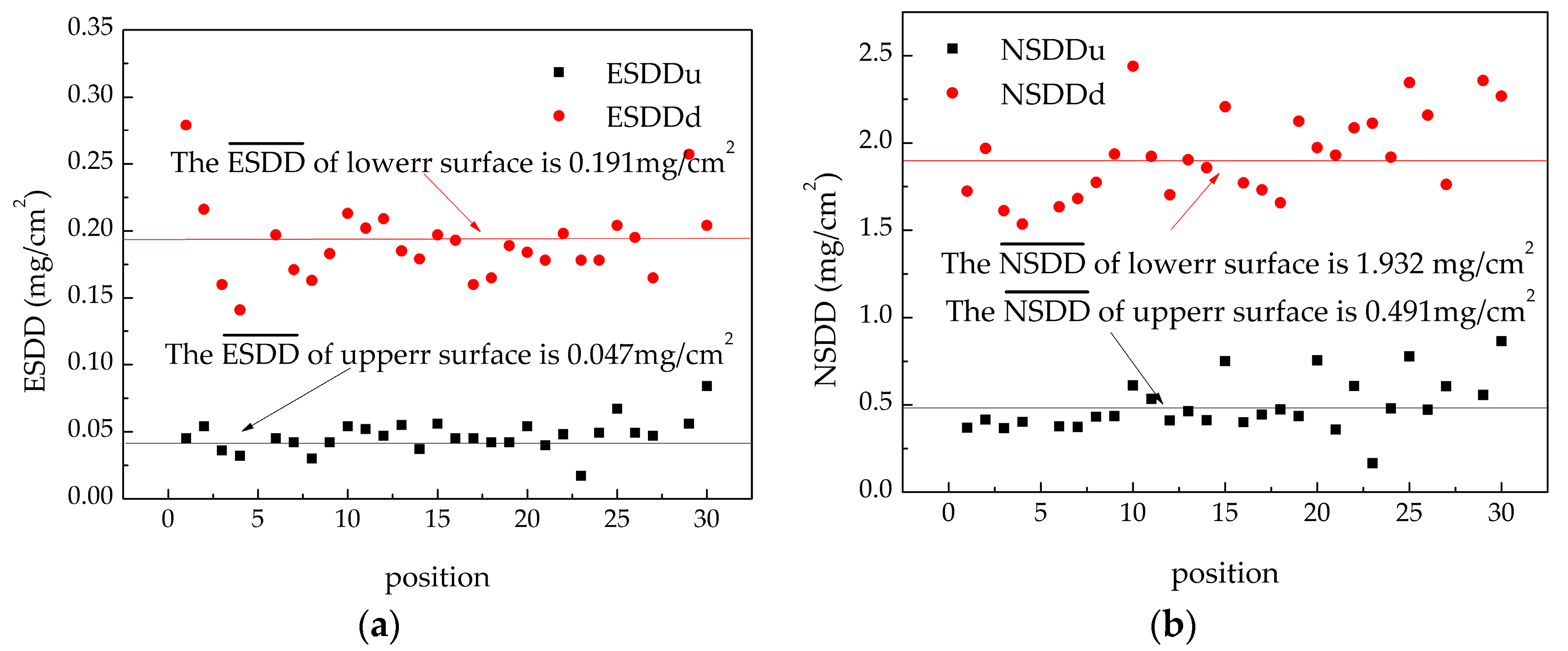

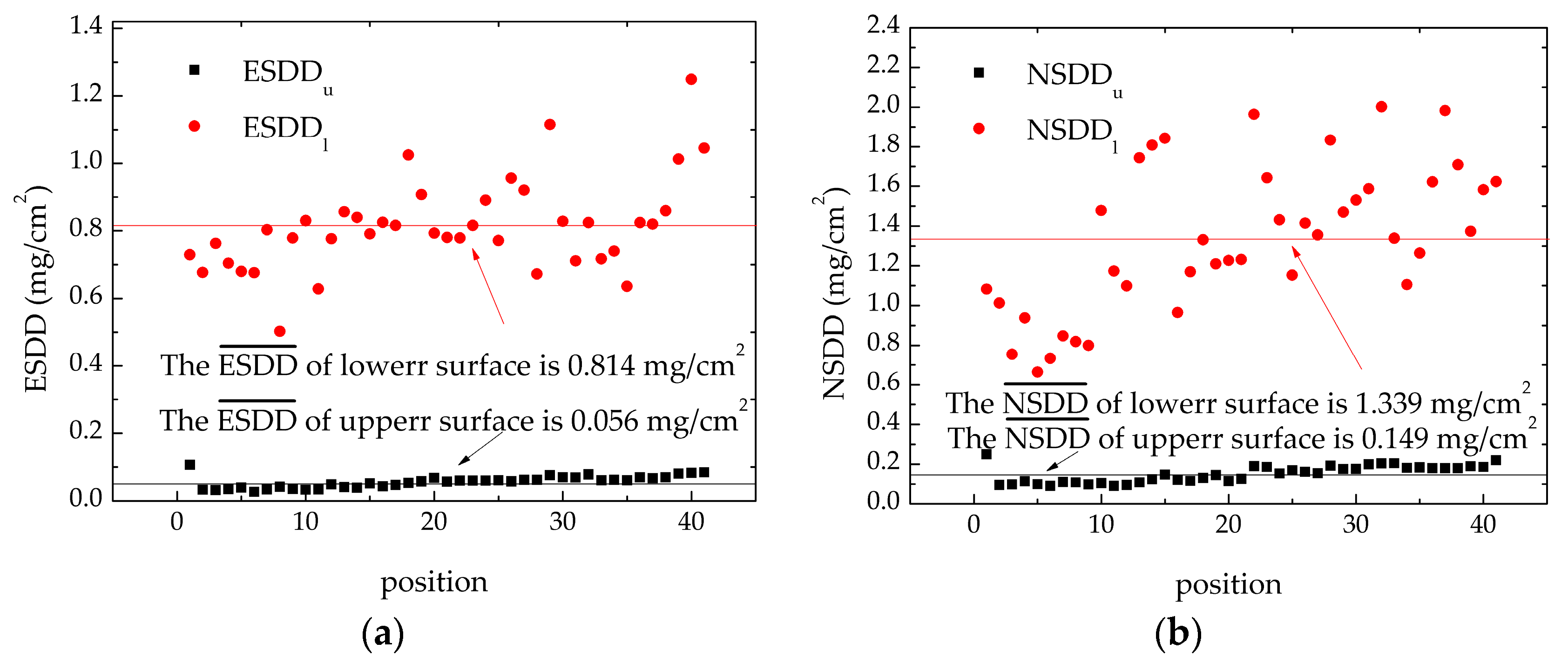

3.3. ESDD and NSDD

3.4. The Simulation of Haze-Fog

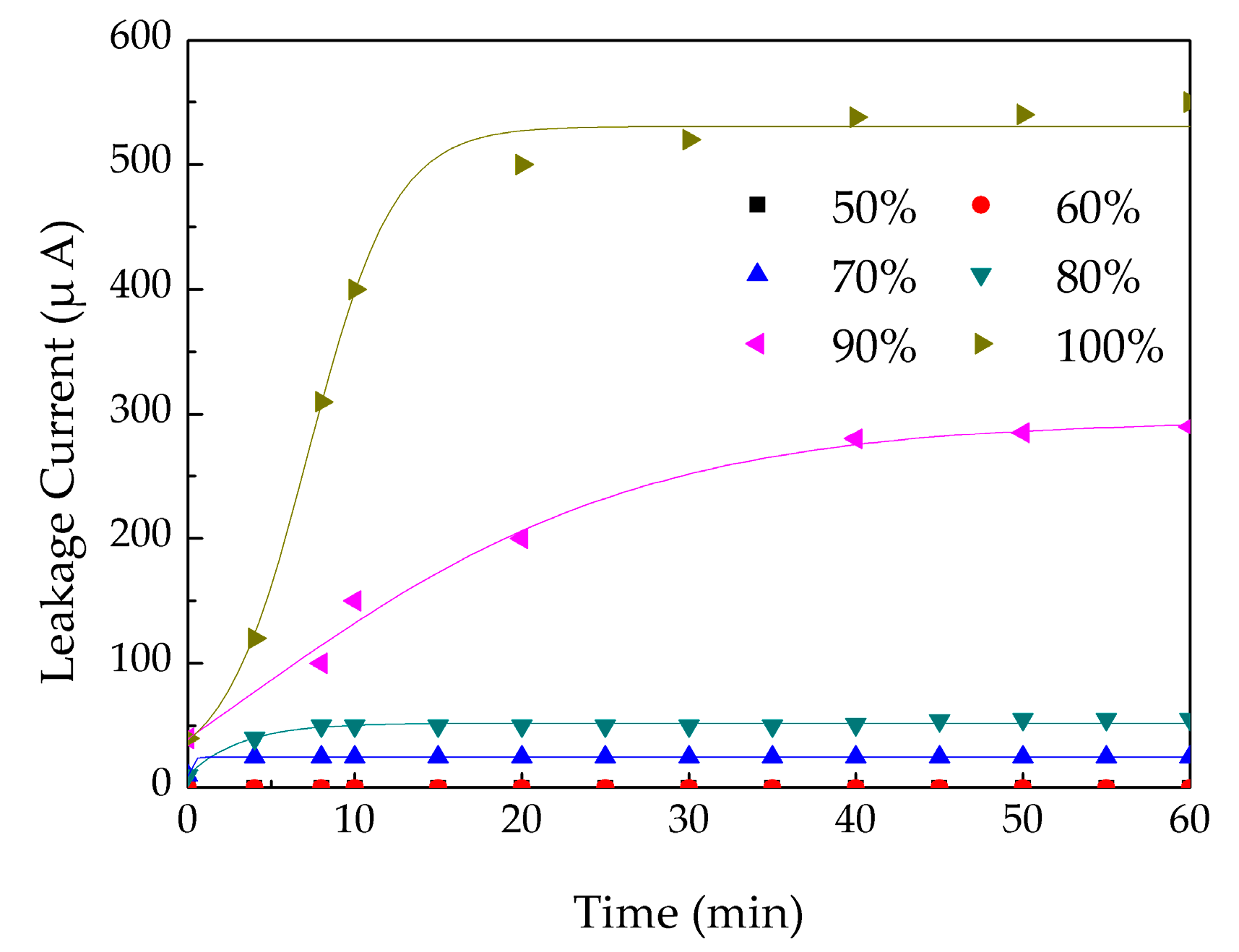

4. Surface Flashover Analysis

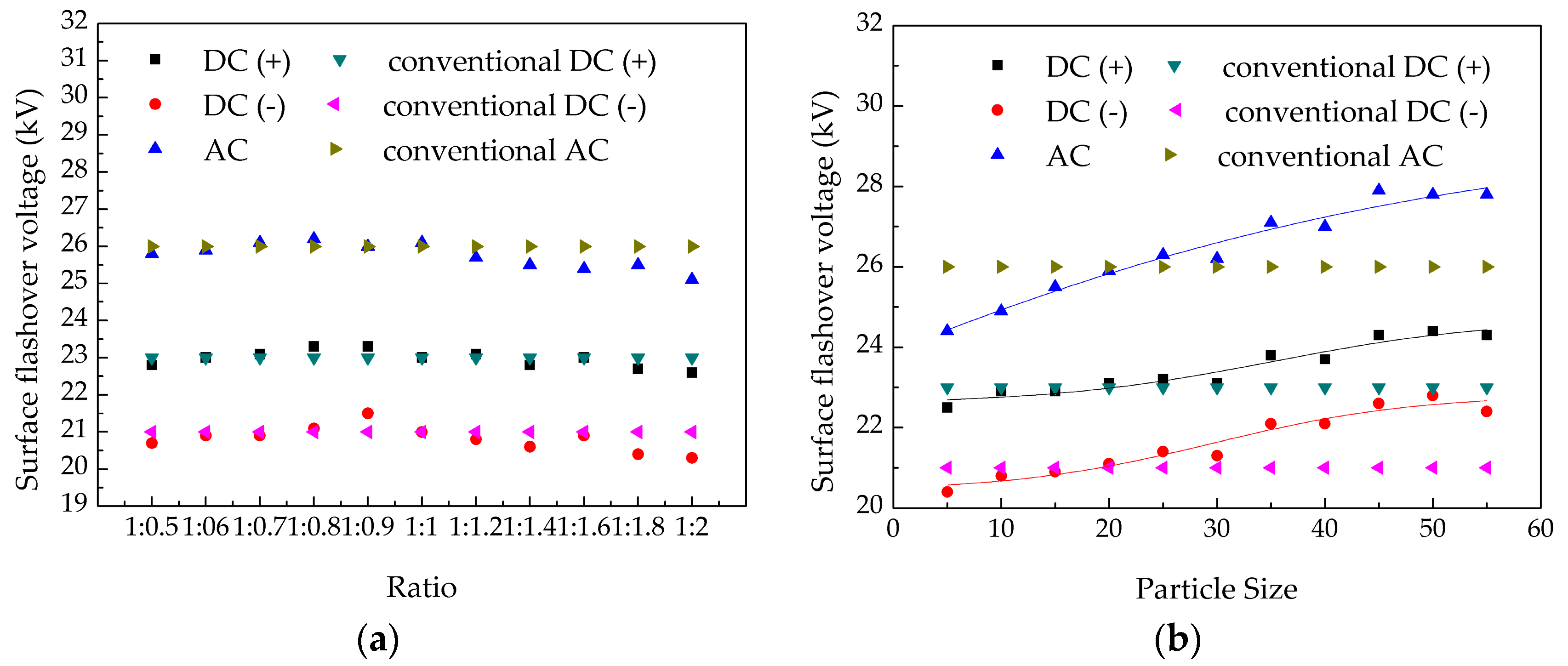

4.1. Comparison with Conventional Pollution Flashover Test

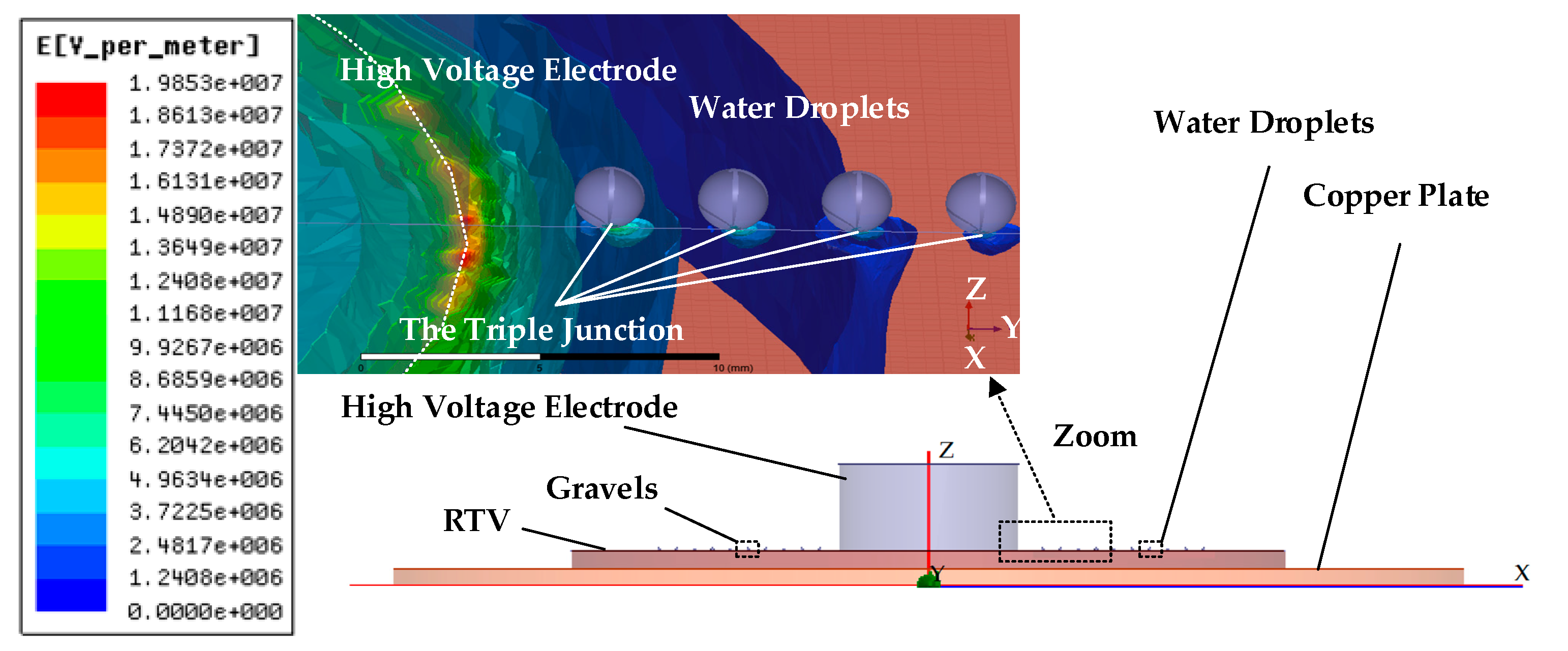

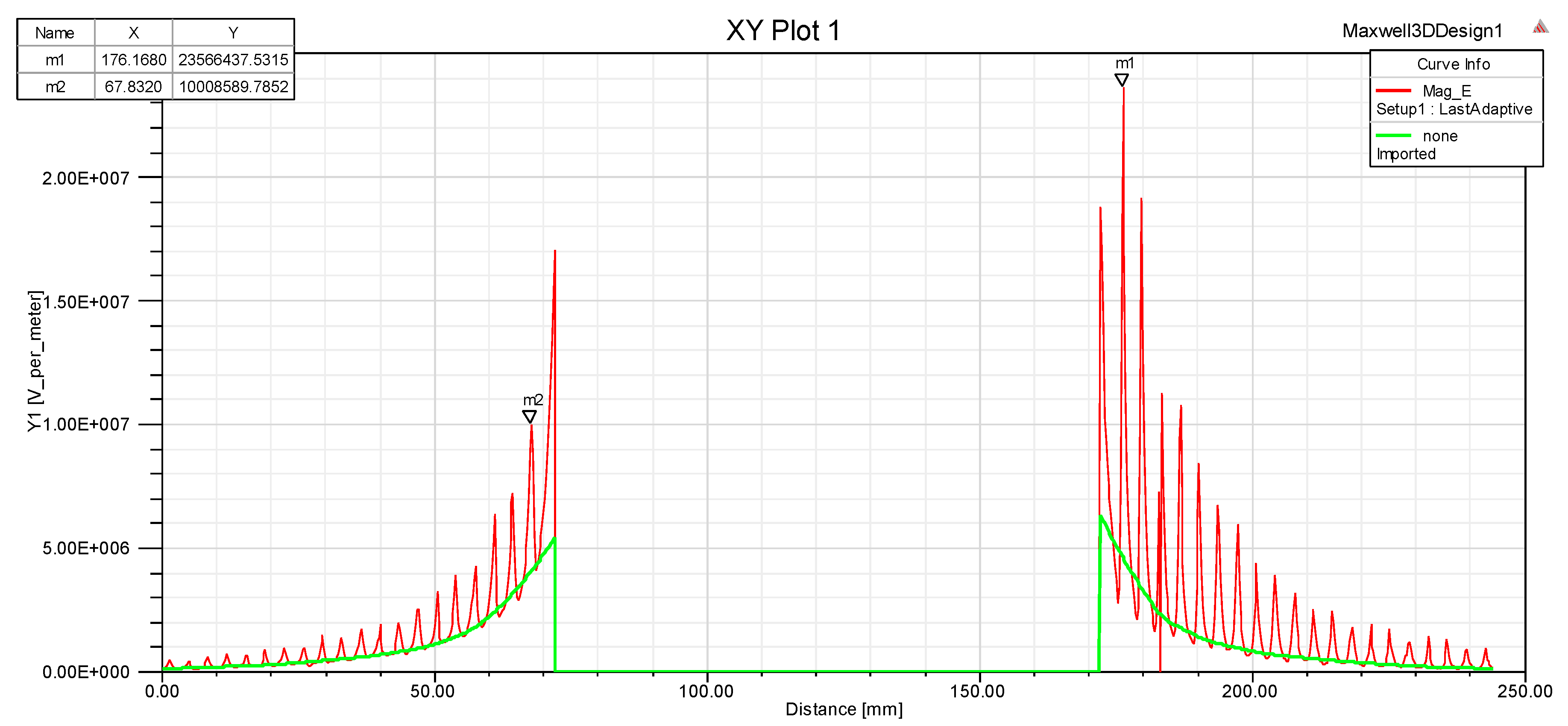

4.2. Electric Field Distribution and Distortion

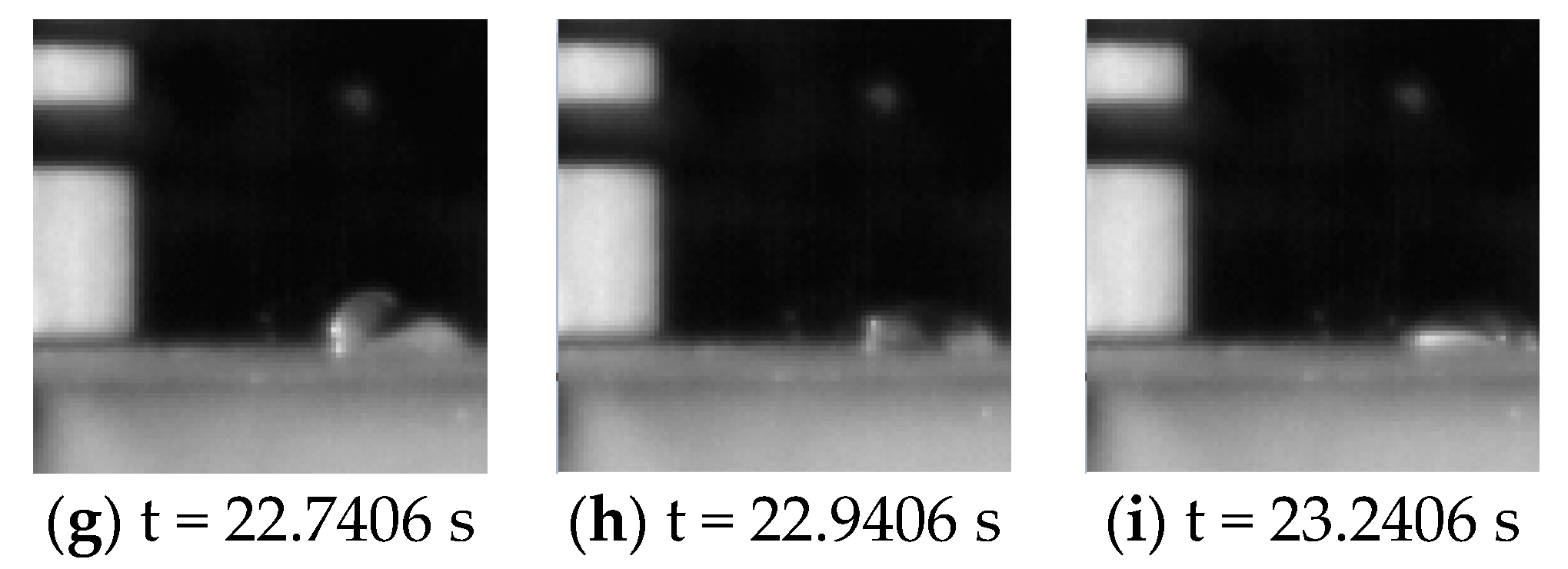

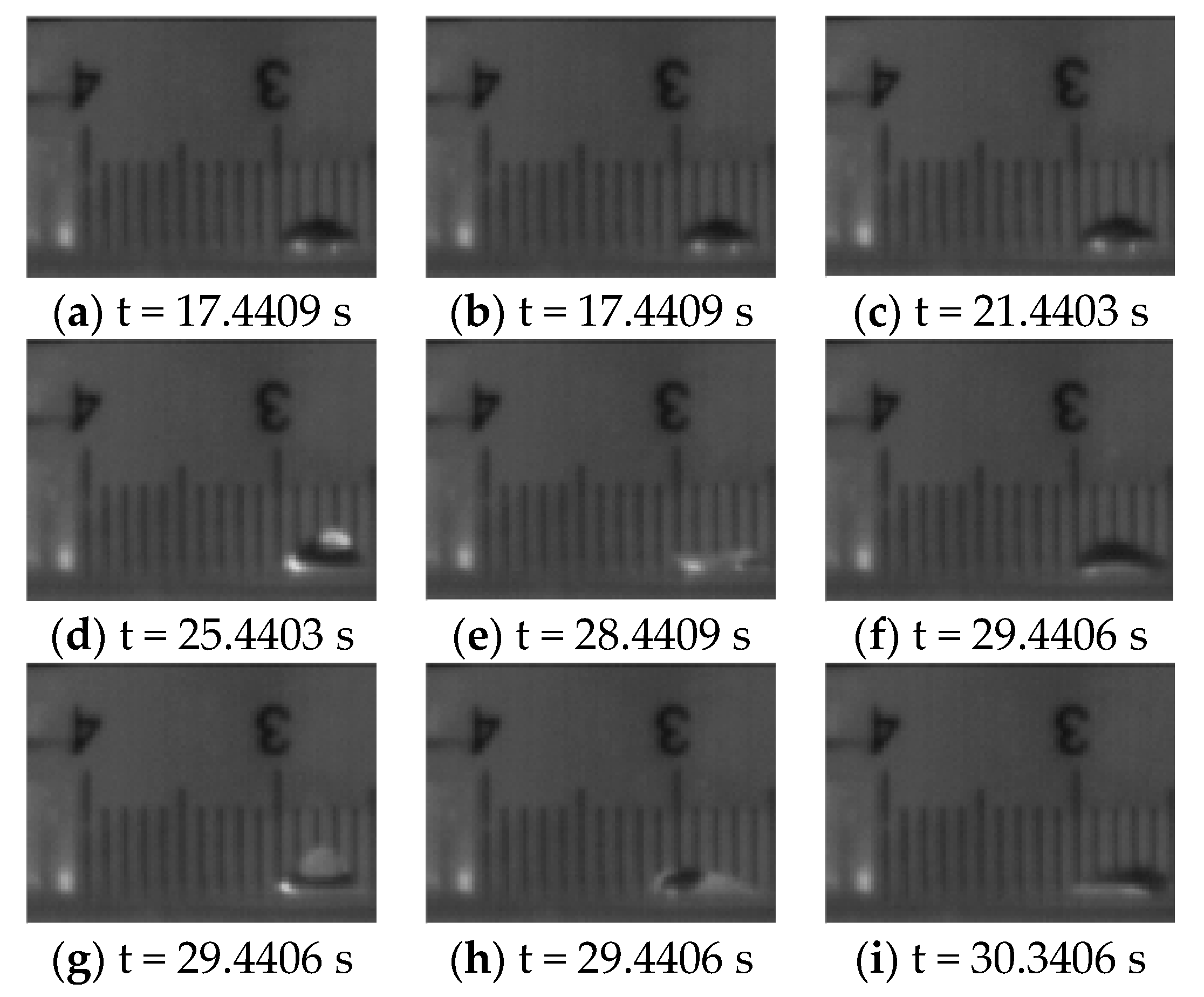

4.3. Dynamic Behavior of Droplets

4.3.1. Positive DC Source

4.3.2. Negative DC Source

4.3.3. AC Source

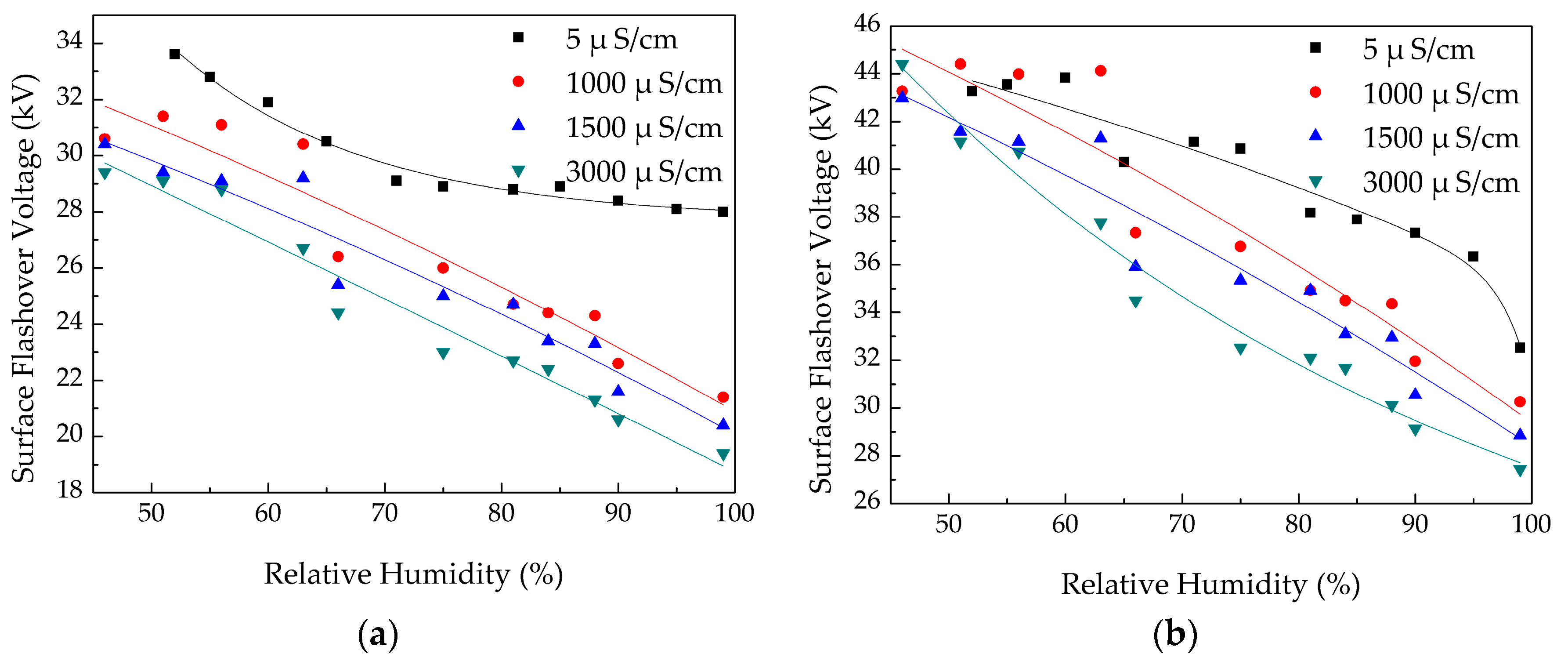

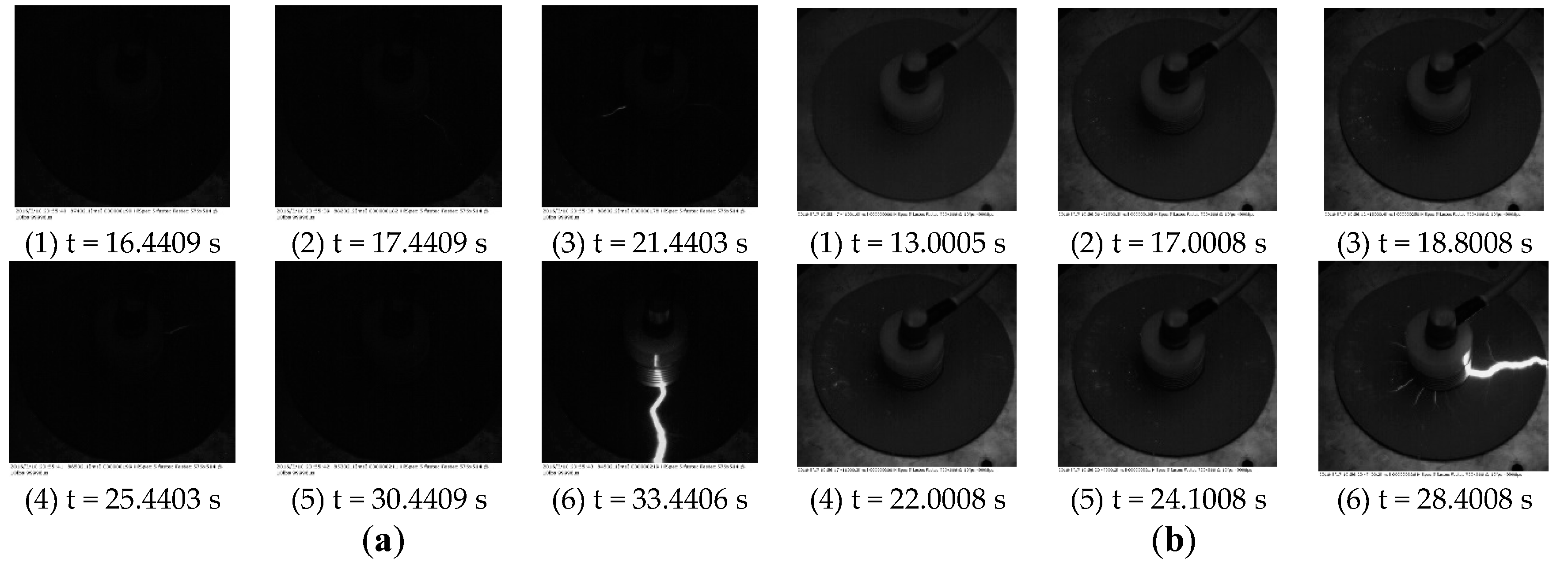

4.4. Surface Pollution Flashover

4.4.1. The Influence of Conductivity

4.4.2. Surface Pollution Flashover

5. Conclusions

- (1)

- The main ion components from haze-fog atmospheric particles are NO3−, SO42−, NH4+, and Ca2+. More than 90% of the contamination particle sizes are within 50 μm. The amount of large particles on the AC line is greater than that of the DC line. The influence of DC polarity power source on the distribution of contamination particle size is not significant.

- (2)

- In haze-fog environment, the maximum ESDD and NSDD under DC positive polar power source are 0.306 mg/cm2 and 3.244 mg/cm2, respectively, the maximum ESDD and NSDD under DC negative polar power source are 0.279 mg/cm2 and 2.439 mg/cm2, respectively, the maximum ESDD and NSDD under AC power source are 0.249 mg/cm2 and 2.002 mg/cm2, respectively. The of DC(+), DC(−) and AC are 0.141 mg/cm2, 0.133 mg/cm2 and 0.111 mg/cm2, respectively. The of DC(+), DC(−) and AC are 1.376 mg/cm2, 1.356 mg/cm2 and 1.124 mg/cm2, respectively.

- (3)

- Under Haze-fog environment, the insulators are easily to accumulate droplets, causing a distortion of the electric field. The droplets on the RTV-coated surface would be deformed or moved due to the electric field, motion direction of which is from the strong electrical field to the weak electrical field. After the deformation or movement, a new triple junction point would be formed.

- (4)

- After the deposition of haze-fog, the local conductivity of the RTV-coated surface increased and reduced the flashover voltage, illustrating that the insulating property of the RTV coating was affected by the haze-fog environment.

- (5)

- Under haze-fog environment, it is essential to strengthen the line patrol and clean the contamination accumulated on insulator surface timely, especially the lower surface. The surface of insulators should be designed to be convenient for droplets to move from the area with strong electric field intensity to the area with weak electric field intensity, so as to break away from the RTV coating surface. Besides, the RTV coating with stronger hydrophobicity could be designed to flush the contamination on RTV coating surface by the own gravity of droplets.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jose, S.; Gharai, B.; Kumar, Y.B.; Rao, P.V.N. Radiative implication of a haze event over Eastern India. Atmos. Pollut. Res. 2015, 6, 138–146. [Google Scholar] [CrossRef]

- Guo, Y.J.; Jiang, X.L.; Liu, Y.; Meng, Z.G.; Li, Z.Y. AC flashover characteristics of insulators under haze–fog environment. IET Gener. Transm. Distrib. 2016, 10, 3563–3569. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, W.J.; Zhou, S.Z.; Yang, L.X.; Chi, J.W.; Sui, X.; Wang, W.X. Integrated evaluation of aerosols during haze–fog episodes at on regional background in North China Plain. Atmos. Res. 2015, 156, 102–110. [Google Scholar] [CrossRef]

- Zhang, Z.J.; You, J.W.; Wei, D.H.; Jiang, X.L.; Zhang, D.D.; Bi, M.Q. Investigations on AC pollution flashover performance of insulator string under different non-uniform pollution conditions. IET Gener. Transm. Distrib. 2016, 10, 437–443. [Google Scholar] [CrossRef]

- Zhang, D.D.; Zhang, Z.J.; Jiang, X.L.; Li, Y.F. Study on Insulator Flashover Voltage Gradient Correction Considering Soluble Pollution Constituents. Energies 2016, 9, 954. [Google Scholar] [CrossRef]

- Jiang, X.L.; Dong, B.B.; Hu, Q.; Yin, F.H.; Xiang, Z.; Shu, L.C. Effect of ultrasonic fog on AC flashover voltage of polluted porcelain and glass insulators. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 429–434. [Google Scholar] [CrossRef]

- Jiang, X.L.; Zhao, S.H.; Xie, Y.B.; Zhang, Z.J.; Shu, L.C. Study on fog flashover performance and fog-water conductivity correction coefficient for polluted insulators. IET Gener. Transm. Distrib. 2013, 7, 143–153. [Google Scholar]

- Jiang, X.L.; Xiang, Z.; Zhang, Z.J.; Hu, J.L.; Hu, Q.; Shu, L.C. AC pollution flashover performance and flashover process of glass insulators at high altitude site. IET Gener. Transm. Dis. 2014, 8, 495–502. [Google Scholar] [CrossRef]

- Arshad; Nekahi, A.; Mcmeekin, S.G.; Farzaneh, M. Flashover Characteristics of Silicone Rubber Sheets under Various Environmental Conditions. Energies 2016, 9, 683. [Google Scholar] [CrossRef]

- Joneidi, I.A.; Kamarposhti, M.A.; Akmal, A.A.S.; Mohseni, H. Leakage current analysis, FFT calculation and electric field distribution under water droplet on polluted silicon rubber insulator. Electr. Eng. 2013, 95, 315–323. [Google Scholar] [CrossRef]

- Souza, A.L.; Lopes, I.J.S. Experimental investigation of corona onset in contaminated polymer surfaces. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1321–1331. [Google Scholar] [CrossRef]

- Xie, G.; He, F.; Liu, X.; Guo, D. Sessile multidroplets and salt droplets under high tangential electric fields. Sci. Rep. 2016, 6, 25002. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wei, Y.; Huang, Z.Y.; Wang, F.P.; Yan, X.Z.; Wu, Z.L. Electrohydrodynamic behavior of water droplets on a horizontal super hydrophobic surface and its self-cleaning application. Appl. Surf. Sci. 2017, 403, 133–140. [Google Scholar] [CrossRef]

- Clayton, C.A.; Perritt, R.L.; Pellizzari, E.D.; Thomas, K.W.; Whitmore, R.W.; Wallace, L.A.; Ozkaynak, H.; Spengler, J.D. Particle Total Exposure Assessment Methodology (PTEAM) study: Distributions of aerosol and elemental concentrations in personal, indoor, and outdoor air samples in a southern California community. J. Exp. Anal. Environ. Epidemiol. 1993, 3, 227–250. [Google Scholar]

- Aaron, V.D.; Martin, R.V.; Michael, B.; Ralph, K.; Robert, L.; Carolyn, V.; Paul, J.V. Global Estimates of Ambient Fine Particulate Matter Concentrations from Satellite-Based Aerosol Optical Depth: Development and Application. Environ. Health Pers. 2010, 118, 847. [Google Scholar]

- Yan, W.; Yang, L.; Chen, J.; Wang, X.F.; Wen, L.; Zhao, T.; Wang, W.X. Aerosol Optical Properties at Urban and Coastal Sites in Northern China. Atmos. Res. 2017, 188, 39–47. [Google Scholar] [CrossRef]

- Lv, Y.; Li, J.; Zhang, X.; Pang, G.; Liu, Q. Simulation study on pollution accumulation characteristics of XP13-160 porcelain suspension disc insulators. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2196–2206. [Google Scholar] [CrossRef]

- Ren, A.; Li, Q.Q.; Xiao, H.S. Influence Analysis and Prediction of ESDD and NSDD Based on Random Forests. Energies 2017, 10, 878. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Selection and Dimensioning of High–Voltage Insulators Intended for Use in Polluted Conditions; IEC/TS 60815; IEC: Geneva, Switzerland, 2008. [Google Scholar]

- Inamuddin; Luqman, M. Ion Exchange Technology II; Springer: Dordrecht, The Netherlands, 2012; pp. 97–107. [Google Scholar]

- International Electrotechnical Commission. Artificial Pollution Tests on High-Voltage Ceramic and Glass Insulators to be Used on a.c. Systems; IEC 60507; IEC: Geneva, Switzerland, 2013. [Google Scholar]

- International Electrotechnical Commission. International Standard: Artificial Pollution Tests on High-Voltage Ceramic and Glass Insulators to be Used on d.c. Systems; IEC: Geneva, Switzerland, 2015. [Google Scholar]

- Vlastos, A.E.; Sherif, E. Experience from insulators with RTV silicon rubber sheds and shed coatings. IEEE Trans. Power Deliv. 1990, 5, 2030–2038. [Google Scholar] [CrossRef]

- Dimitropoulou, M.; Pylarinos, D.; Siderakis, K.; Thalassinakis, E.; Danikas, M. Comparative Investigation of Pollution Accumulation and Natural Cleaning for Different HV Insulators. Eng. Technol. Appl. Sci. Res. 2015, 5, 764–774. [Google Scholar]

| Insulator Type | Voltage Level (kV) | Leakage Distance (mm) | Upper Surface Areas (cm2) | Lower Surface Areas (cm2) |

|---|---|---|---|---|

| XWP2–160 | 500 | 450 (a piece) | 1551 | 1208 |

| FC160P | 500 | 550 (a piece) | 1198 | 2541 |

| FC160P/C170DC | ±660 | 550 (a piece) | 1800 | 2700 |

| Ions | PM2.5 | PM10 | ||||

|---|---|---|---|---|---|---|

| Maximum | Minimum | Average | Maximum | Minimum | Average | |

| NH4+ | 39.47 | 2.78 | 19.64 | 67.35 | 3.10 | 10.84 |

| Na+ | 2.35 | 0.37 | 1.59 | 3.40 | 0.35 | 1.95 |

| K+ | 5.24 | 0.24 | 1.92 | 4.98 | 0.36 | 2.59 |

| Ca2+ | 16.94 | 0.63 | 5.90 | 21.23 | 1.57 | 10.32 |

| Mg+ | 0.81 | 0.15 | 0.38 | 1.10 | 0.38 | 0.65 |

| NO3− | 48.26 | 2.16 | 18.98 | 80.88 | 6.08 | 33.05 |

| SO42− | 59.1 | 5.61 | 15.62 | 92.86 | 5.66 | 31.67 |

| Cl− | 20 | 0.82 | 3.32 | 18.40 | 1.10 | 6.07 |

| Voltage Type | D10 (μm) | D50 (μm) | D90 (μm) | P<3 (%) | P<20 (%) | P<40 (%) |

|---|---|---|---|---|---|---|

| DC(+) | 5.66 | 14.63 | 34.41 | 2.56 | 66.32 | 93.90 |

| DC(−) | 5.27 | 13.59 | 33.37 | 2.88 | 70.09 | 94.25 |

| AC | 6.11 | 34.32 | 57.88 | 2.25 | 42.44 | 84.35 |

| Voltage Type | Mean (mg/cm2) | Standard Deviation | Max (mg/cm2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Upper Surface | Lower Surface | ESDD | NSDD | Upper Surface | Lower Surface | ESDD | NSDD | |||||

| ESDD | NSDD | ESDD | NSDD | ESDD | NSDD | ESDD | NSDD | |||||

| DC(+) | 0.035 | 0.361 | 0.211 | 2.052 | 0.141 | 1.376 | 0.007 | 0.138 | 0.038 | 0.426 | 0.306 | 3.244 |

| DC(−) | 0.047 | 0.491 | 0.191 | 1.932 | 0.133 | 1.356 | 0.012 | 0.153 | 0.028 | 0.248 | 0.279 | 2.439 |

| AC | 0.056 | 0.814 | 0.149 | 1.339 | 0.111 | 1.124 | 0.013 | 0.159 | 0.045 | 0.466 | 0.249 | 2.002 |

| Voltage Type | (μS/cm) | ESDD (mg/cm2) | NSDD (mg/cm2) |

|---|---|---|---|

| DC(+) | 1380 | 0.141 | 1.376 |

| DC(−) | 1250 | 0.133 | 1.356 |

| AC | 950 | 0.111 | 1.124 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, A.; Liu, H.; Wei, J.; Li, Q. Natural Contamination and Surface Flashover on Silicone Rubber Surface under Haze–Fog Environment. Energies 2017, 10, 1580. https://doi.org/10.3390/en10101580

Ren A, Liu H, Wei J, Li Q. Natural Contamination and Surface Flashover on Silicone Rubber Surface under Haze–Fog Environment. Energies. 2017; 10(10):1580. https://doi.org/10.3390/en10101580

Chicago/Turabian StyleRen, Ang, Hongshun Liu, Jianchun Wei, and Qingquan Li. 2017. "Natural Contamination and Surface Flashover on Silicone Rubber Surface under Haze–Fog Environment" Energies 10, no. 10: 1580. https://doi.org/10.3390/en10101580

APA StyleRen, A., Liu, H., Wei, J., & Li, Q. (2017). Natural Contamination and Surface Flashover on Silicone Rubber Surface under Haze–Fog Environment. Energies, 10(10), 1580. https://doi.org/10.3390/en10101580