Up/Down-Scaling Photoluminescent Micromarks Written in Diamond by Ultrashort Laser Pulses: Optical Photoluminescent and Structural Raman Imaging

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

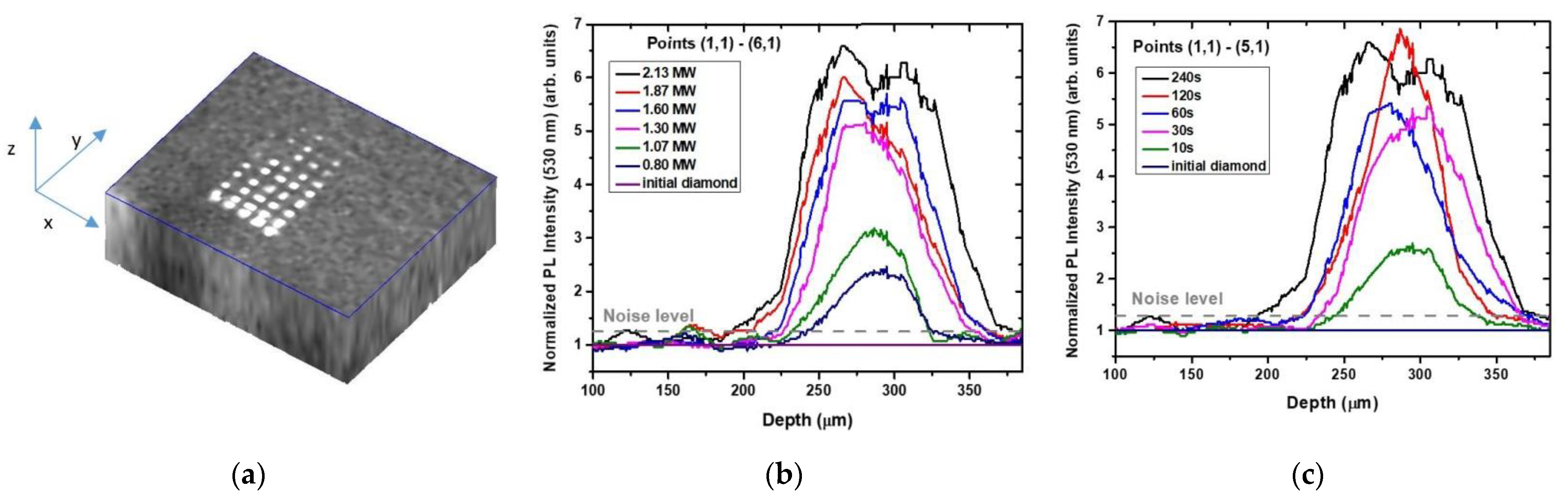

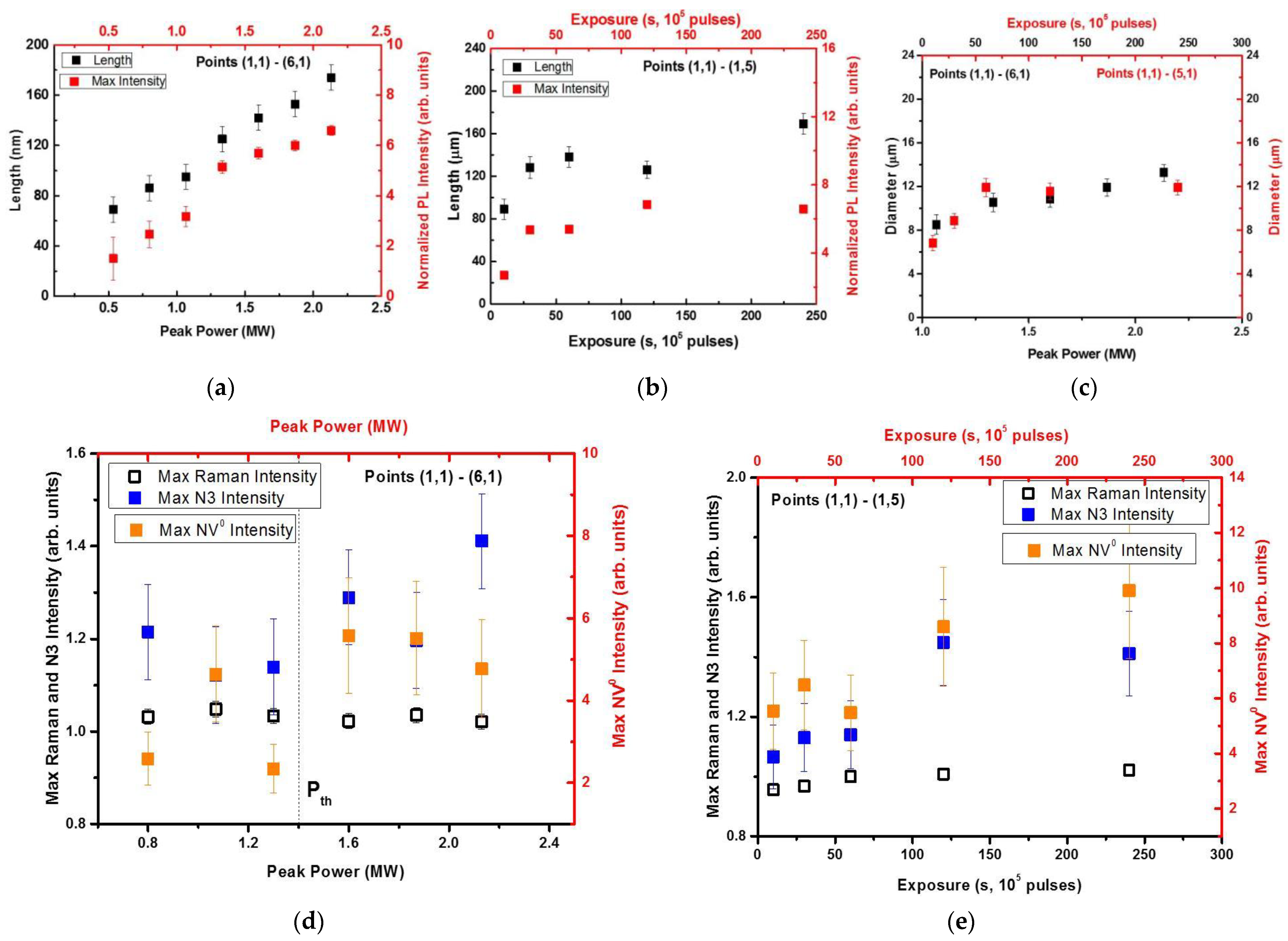

3.1. Power- and Exposure-Dependent Characteristics of Micromarks Visualized by Raman and Photoluminescence Microspectroscopy

3.2. Power- and Exposure-Dependent Structural Modification of Color Centers in Micromarks

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ALROSA. Identification of Diamonds Using Laser Nanomarks. Available online: https://www.youtube.com/watch?v=X3Z_jcWowks (accessed on 7 October 2022).

- Ionin, A.A.; Kudryashov, S.I.; Smirnov, N.A.; Danilov, P.A.; Levchenko, A.O. Optically Transparent for Marking Gemstones. U.S. Patent Application US20210319722A1, 14 October 2021. [Google Scholar]

- Ionin, A.A.; Kudryashov, S.I.; Smirnov, N.A.; Danilov, P.A.; Levchenko, A.O. Method for Creating and Detecting an Optically Permeable Image inside a Diamond. U.S. Patent Application US20210316401A1, 14 October 2021. [Google Scholar]

- Chen, Y.C.; Salter, P.S.; Knauer, S.; Weng, L.; Frangeskou, A.C.; Stephen, C.J.; Ishmael, S.N.; Dolan, P.R.; Johnson, S.; Green, B.L.; et al. Laser writing of coherent colour centres in diamond. Nat. Photonics 2017, 11, 77–80. [Google Scholar] [CrossRef]

- Sotillo, B.; Bharadwaj, V.; Hadden, J.P.; Rampini, S.; Chiappini, A.; Fernandez, T.T.; Armellini, C.; Serpengüzel, A.; Ferrari, M.; Barclay, P.E.; et al. Visible to infrared diamond photonics enabled by focused femtosecond laser pulses. Micromachines 2017, 8, 60. [Google Scholar] [CrossRef]

- Lühmann, T.; Raatz, N.; John, R.; Lesik, M.; Rödiger, J.; Portail, M.; Wildanger, D.; Kleibler, F.; Nordlund, K.; Zaitsev, A.; et al. Screening and engineering of colour centres in diamond. J. Phys. D: Appl. Phys. 2018, 51, 483002. [Google Scholar] [CrossRef]

- Chen, Y.C.; Griffiths, B.; Weng, L.; Nicley, S.S.; Ishmael, S.N.; Lekhai, Y.; Johnson, S.; Stephen, C.J.; Green, B.L.; Morley, G.W.; et al. Laser writing of individual nitrogen-vacancy defects in diamond with near-unity yield. Optica 2019, 6, 662–667. [Google Scholar] [CrossRef]

- Yurgens, V.; Zuber, J.A.; Flågan, S.; De Luca, M.; Shields, B.J.; Zardo, I.; Maletinsky, P.; Warburton, R.J.; Jakubczyk, T. Low-charge-noise nitrogen-vacancy centers in diamond created using laser writing with a solid-immersion lens. ACS Photonics 2021, 8, 1726–1734. [Google Scholar] [CrossRef]

- Kurita, T.; Shimotsuma, Y.; Fujiwara, M.; Fujie, M.; Mizuochi, N.; Shimizu, M.; Miura, K. Direct writing of high-density nitrogen-vacancy centers inside diamond by femtosecond laser irradiation. Appl. Phys. Lett. 2021, 118, 214001. [Google Scholar] [CrossRef]

- Zaitsev, A.M. Optical Properties of Diamond: A Data Handbook; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Kempkes, M.; Zier, T.; Singer, K.; Garcia, M.E. Ultrafast nonthermal NV center formation in diamond. Carbon 2021, 174, 524–530. [Google Scholar] [CrossRef]

- Griffiths, B.; Kirkpatrick, A.; Nicley, S.S.; Patel, R.L.; Zajac, J.M.; Morley, G.W.; Booth, M.J.; Salter, P.S.; Smith, J.M. Microscopic processes during ultrafast laser generation of Frenkel defects in diamond. Phys. Rev. B 2021, 104, 174303. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Danilov, P.A.; Smirnov, N.A.; Stsepuro, N.G.; Rupasov, A.E.; Khmelnitskii, R.A.; Oleynichuk, E.A.; Kuzmin, E.V.; Levchenko, A.O.; Gulina, Y.S.; et al. Signatures of ultrafast electronic and atomistic dynamics in bulk photoluminescence of CVD and natural diamonds excited by ultrashort laser pulses of variable pulsewidth. Appl. Surf. Sci. 2022, 575, 151736. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Vins, V.G.; Danilov, P.A.; Kuzmin, E.V.; Muratov, A.V.; Kriulina, G.Y.; Chen, J.; Kirichenko, A.N.; Gulina, Y.S.; Ostrikov, S.A.; et al. Permanent optical bleaching in HPHT-diamond via aggregation of C-and NV-centers excited by visible-range femtosecond laser pulses. Carbon 2023, 201, 399–407. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Levchenko, A.O.; Danilov, P.A.; Smirnov, N.A.; Ionin, A.A. IR femtosecond laser micro-filaments in diamond visualized by inter-band UV photoluminescence. Opt. Lett. 2020, 45, 2026–2029. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Danilov, P.A.; Kuzmin, E.V.; Gulina, Y.S.; Rupasov, A.E.; Krasin, G.K.; Zubarev, I.G.; Levchenko, A.O.; Kovalev, M.S.; Pakholchuk, P.P.; et al. Pulse-width-dependent critical power for self-focusing of ultrashort laser pulses in bulk dielectrics. Opt. Lett. 2022, 47, 3487–3490. [Google Scholar] [CrossRef] [PubMed]

- Couairon, A.; Mysyrowicz, A. Femtosecond filamentation in transparent media. Phys. Rep. 2007, 441, 47–189. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Khmelnitskii, R.A.; Danilov, P.A.; Smirnov, N.A.; Levchenko, A.O.; Kovalchuk, O.E.; Uspenskaya, M.V.; Oleynichuk, E.A.; Kovalev, M.S. Broadband and fine-structured luminescence in diamond facilitated by femtosecond laser driven electron impact and injection of “vacancy-interstitial” pairs. Opt. Lett. 2021, 46, 1438–1441. [Google Scholar] [CrossRef] [PubMed]

- Kudryashov, S.I.; Danilov, P.A.; Sdvizhenskii, P.A.; Lednev, V.N.; Chen, J.; Ostrikov, S.A.; Kuzmin, E.V.; Kovalev, M.S.; Levchenko, A.O. Transformations of the Spectrum of an Optical Phonon Excited in Raman Scattering in the Bulk of Diamond by Ultrashort Laser Pulses with a Variable Duration. JETP Lett. 2022, 115, 251–255. [Google Scholar] [CrossRef]

- Collins, A.T. The characterisation of point defects in diamond by luminescence spectroscopy. Diam. Relat. Mater. 1992, 1, 457–469. [Google Scholar] [CrossRef]

- Dobrinets, I.A.; Vins, V.G.; Zaitsev, A.M. HPHT-Treated Diamonds; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Lanigan, P.M.; McGuinness, C.D. Diamonds: Natural, Treated and Laboratory-Grown. J. Gemmol. 2022, 38, 201–202. [Google Scholar] [CrossRef]

- Collins, A.T. Vacancy enhanced aggregation of nitrogen in diamond. J. Phys. C: Solid State Phys. 1980, 13, 2641–2650. [Google Scholar] [CrossRef]

- Jackson, W.E.; Webb, S.W. Synthetic diamond strength enhancement through high pressure/high temperature annealing. MRS Online Proc. 1995, 383, 267–272. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Danilov, P.; Kuzmin, E.; Rimskaya, E.; Chen, J.; Khmelnitskii, R.; Kirichenko, A.; Rodionov, N.; Kudryashov, S. Up/Down-Scaling Photoluminescent Micromarks Written in Diamond by Ultrashort Laser Pulses: Optical Photoluminescent and Structural Raman Imaging. Micromachines 2022, 13, 1883. https://doi.org/10.3390/mi13111883

Danilov P, Kuzmin E, Rimskaya E, Chen J, Khmelnitskii R, Kirichenko A, Rodionov N, Kudryashov S. Up/Down-Scaling Photoluminescent Micromarks Written in Diamond by Ultrashort Laser Pulses: Optical Photoluminescent and Structural Raman Imaging. Micromachines. 2022; 13(11):1883. https://doi.org/10.3390/mi13111883

Chicago/Turabian StyleDanilov, Pavel, Evgeny Kuzmin, Elena Rimskaya, Jiajun Chen, Roman Khmelnitskii, Alexey Kirichenko, Nikolay Rodionov, and Sergey Kudryashov. 2022. "Up/Down-Scaling Photoluminescent Micromarks Written in Diamond by Ultrashort Laser Pulses: Optical Photoluminescent and Structural Raman Imaging" Micromachines 13, no. 11: 1883. https://doi.org/10.3390/mi13111883

APA StyleDanilov, P., Kuzmin, E., Rimskaya, E., Chen, J., Khmelnitskii, R., Kirichenko, A., Rodionov, N., & Kudryashov, S. (2022). Up/Down-Scaling Photoluminescent Micromarks Written in Diamond by Ultrashort Laser Pulses: Optical Photoluminescent and Structural Raman Imaging. Micromachines, 13(11), 1883. https://doi.org/10.3390/mi13111883