Application of Artificial Neural Network for Predicting the Drying Kinetics and Chemical Attributes of Linden (Tilia platyphyllos Scop.) during the Infrared Drying Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Drying Experiments

2.3. Kinetics of the Drying Processes

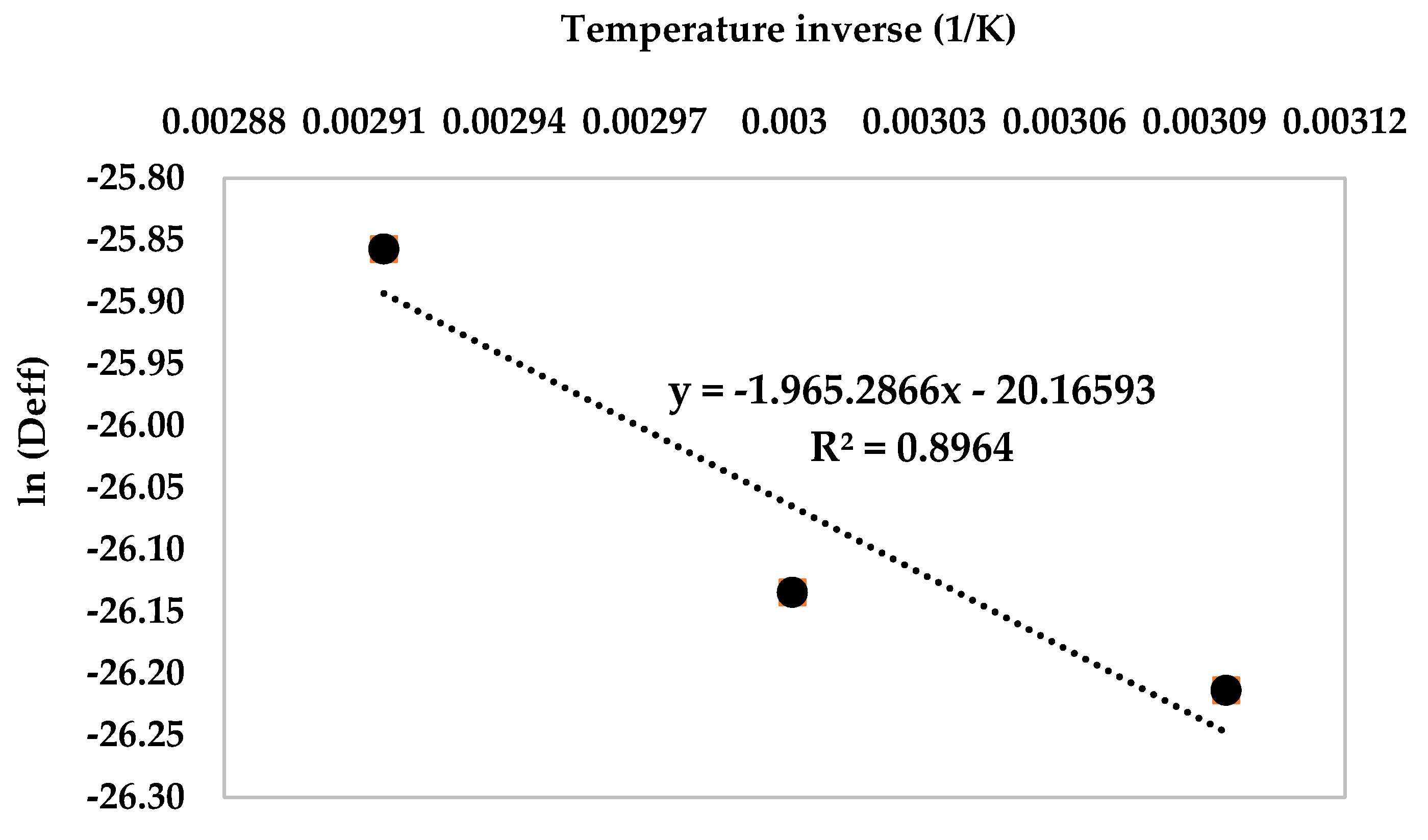

2.4. Effective Moisture Diffusivity and Activation Energy

2.5. Mathematical Thin-Layer Modeling

2.6. Artificial Neural Network

2.7. Determination of Chemical Characteristics

2.8. Model Evaluation

3. Results and Discussion

3.1. Behavior of the Drying Process

3.2. Effective Moisture Diffusivity and Activation Energy

3.3. Comparison of Different Mathematical Models of Thin Layers

3.4. Results of Artificial Neural Network

3.5. Comparison between Mathematical Thin-Layer Models and Artificial Neuron Networks

3.6. Total Phenolic Content (TPC) and Total Flavonoid Content (TFC)

3.7. Results of Artificial Neuron Networks to Predict Chemical Properties of Linden Leaf Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

Abbreviations

| C | degree (°) |

| TPC | total phenolic content (mg/g) |

| TFC | total flavonoid content (mg/g) |

| ANN | artificial neural network |

| RMSE | root mean square error |

| DPPH | radical scavenging activity (2,2-diphenyl-1-picryl-hydrazyl-hydrate) |

| FRAP | ferric reducing antioxidant power |

References

- Weryszko-Chmielewska, E.; Sadowska, D.A. The phenology of flowering and pollen release in four species of linden (Tilia L.). J. Apic. Sci. 2010, 54, 99–108. [Google Scholar]

- Wissam, Z.; Nour, A.A.; Bushra, J.; Zein, N.; Saleh, D. Extracting and studying the antioxidant capacity of polyphenols in dry linden leaves (Tilia cordata). J. Pharmacogn. Phytochem. 2017, 6, 258–262. [Google Scholar]

- Siger, A.; Antkowiak, W.; Dwiecki, K.; Rokosik, E.; Rudzińska, M. Nutlets of Tilia cordata mill. and Tilia platyphyllos scop.–source of bioactive compounds. Food Chem. 2021, 346, 128888. [Google Scholar] [CrossRef]

- Delnavazi, M.R.; Shahabi, M.; Yassa, N. Flavonoids from the leaves of Iranian Linden; Tilia rubra subsp. Caucasica. Res. J. Pharmacogn. 2015, 2, 17–22. [Google Scholar]

- Yayalacı, Y.; Celik, I.; Batı, B. Hepatoprotective and antioxidant activity of linden (Tilia platyphyllos L.) infusion against ethanol-induced oxidative stress in rats. J. Membr. Biol. 2014, 247, 181–188. [Google Scholar] [CrossRef]

- Toker, G.; Küpeli, E.; Memisoğlu, M.; Yesilada, E. Flavonoids with antinociceptive and anti-inflammatory activities from the leaves of Tilia argentea (silver linden). J. Ethnopharmacol. 2004, 95, 393–397. [Google Scholar] [CrossRef]

- Negri, G.; Santi, D.D.; Tabach, R. Flavonol glycosides found in hydroethanolic extracts from Tilia cordata, a species utilized as anxiolytics. Rev. Bras. Plantas Med. 2013, 15, 217–224. [Google Scholar] [CrossRef]

- Tuttu, G.; Ursavaş, S.; Soyler, R. Harvest amounts and ethnobotanical uses of the linden flowers in Turkey. Anatol. J. Forest Res. 2017, 3, 60–66. [Google Scholar]

- Yıldırım, A.; Mavi, A.; Oktay, M.; Kara, A.A.; Algur, Ö.F.; Bilaloǧlu, V. Comparison of antioxidant and antimicrobial activities of Tilia (Tilia argentea Desf ex DC), sage (Salvia triloba L.), and Black tea (Camellia sinensis) extracts. J. Agric. Food Chem. 2000, 48, 5030–5034. [Google Scholar] [CrossRef]

- Buřıčová, L.; Reblova, Z. Czech medicinal plants as possible sources of antioxidants. Czech J. Food Sci. 2008, 26, 132–138. [Google Scholar] [CrossRef]

- Kowalski, R.; Baj, T.; Kalwa, K.; Kowalska, G.; Sujka, M. Essential oil composition of Tilia cordata flowers. J. Essent. Oil Bear. Plants 2017, 20, 1137–1142. [Google Scholar] [CrossRef]

- Kelmendi, N.; Mustafa, B.; Zahiri, F.; Nebija, D.; Hajdari, A. Essential oil composition of tilia platyphyllos scop. collected from different regions of Kosovo. Rec. Nat. Prod. 2020, 14, 371. [Google Scholar] [CrossRef]

- Rodríguez, J.; Clemente, G.; Sanjuan, N.; Bon, J. Modeling drying kinetics of thyme (Thymus vulgaris L.): Theoretical and empirical models, and neural networks. Food Sci. Technol. Int. 2013, 20, 13–22. [Google Scholar] [CrossRef] [PubMed]

- Onwude, D.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. The potential of computer vision, optical backscattering parameters and artificial neural network modeling in monitoring the shrinkage of sweet potato (Ipomoea batatas L.) during drying. J. Sci. Food Agric. 2018, 98, 1310–1324. [Google Scholar] [CrossRef] [PubMed]

- Si, X.; Wu, X.; Yi, J.Y.; Li, Z.; Chen, Q.; Bi, J.; Zhou, L. Comparison of different drying methods on the physical properties, bioactive compounds and antioxidant activity of raspberry powders. J. Sci. Food Agric. 2015, 96, 2055–2062. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Baslar, M. The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J. Therm. Anal. Calorim. 2018, 132, 1131–1143. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.; Abdan, K. Modeling the convective drying process of pumpkin (Cucurbita moschata) using an artificial neural network. Int. Food Res. J. 2016, 23, 237–243. [Google Scholar]

- Liu, Z.; Bai, J.; Yang, W.; Wang, J.; Deng, L. Effect of high-humidity hot air impingement blanching (HHAIB) and drying parameters on drying characteristics and quality of broccoli florets. Dry. Technol. 2019, 37, 1251–1264. [Google Scholar] [CrossRef]

- Riadh, M.H.; Ahmad, S.A.B.; Marhaban, M.H.; Soh, A.C. Infrared heating in food drying: An overview. Dry. Technol. 2015, 33, 322–335. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, J. Feature selection for hyperspectral data based on recursive support vector machines. Int. J. Remote Sens. 2009, 30, 3669–3677. [Google Scholar] [CrossRef]

- Ertekin, C.; Heybeli, N. Thin-layer infrared drying of mint leaves. J. Food Process. Preserv. 2014, 38, 1480–1490. [Google Scholar] [CrossRef]

- Soysal, Y.; Keskin, M.; Arslan, A.; Sekerli, Y.E. Infrared drying characteristics of pepper at different maturity stages. In Proceedings of the International Conference on Energy Research, Alanya, Turkey, 1–2 November 2018; pp. 293–304. [Google Scholar]

- Sharma, G.P.; Verma, R.C.; Pathare, P.B. Thin-layer infrared radiation drying of onion slices. J. Food Eng. 2005, 67, 361–366. [Google Scholar] [CrossRef]

- Adak, N.; Heybeli, N.; Ertekin, C. Infrared drying of strawberry. Food Chem. 2017, 219, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Doymaz, I. Infrared drying of kiwifruit slices. Int. J. Green Energy 2018, 15, 622–628. [Google Scholar] [CrossRef]

- Akoy, E.O.M. Experimental characterization and modeling of thin-layer drying of mango slices. Int. Food Res. J. 2014, 21, 7–11. [Google Scholar]

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, a review of thin layer drying of foods: Theory, modeling, and experimental results. Food Sci. Nutr. 2010, 50, 441–464. [Google Scholar]

- Khaled, A.Y.; Aziz, S.A.; Bejo, S.K.; Nawi, N.M.; Abu Seman, I.A. Spectral features selection and classification of oil palm leaves infected by Basal stem rot (BSR) disease using dielectric spectroscopy. Comput. Electron. Agric. 2018, 144, 297–309. [Google Scholar] [CrossRef]

- Bai, J.; Xiao, H.; Ma, H.; Zhou, C. Artificial neural network modeling of drying kinetics and color changes of ginkgo biloba seeds during microwave drying process. J. Food Qual. 2018, 2018, 3278595. [Google Scholar] [CrossRef]

- Omari, A.; Behroozi-Khazaei, N.; Sharifian, F. Drying kinetic and artificial neural network modeling of mushroom drying process in microwave-hot air dryer. Food Process. Eng. 2018, 41, e12849. [Google Scholar] [CrossRef]

- Bahmani, A.; Jafari, S.M.; Shahidi, S.-A.; Dehnad, D. Mass transfer kinetics of eggplant during osmotic dehydration by neural networks. J. Food Process. Preserv. 2016, 40, 815–827. [Google Scholar] [CrossRef]

- Khaled, A.Y.; Kabutey, A.; Selvi, K.Ç.; Mizera, C.; Hrabe, P.; Herak, D. Application of computational intelligence in describing the drying kinetics of persimmon fruit (Diospyros kaki) during vacuum and hot air drying process. Processes 2020, 8, 544. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Kianmehr, M.H.; Khani, S.; Ghasemi, M. Mathematical modeling of thin-layer drying of carrot. Int. Agrophys. 2009, 23, 313–317. [Google Scholar]

- Crank, J. Mathematics of Diffusion, 2nd ed.; Oxford University Press: London, UK, 1975; p. 414. [Google Scholar]

- Zenoozian, M.S.; Feng, H.; Razavi, S.; Shahidi, F.; Pourreza, H.R. Image analysis and dynamic modeling of thin-layer drying of osmotically dehydrated pumpkin. J. Food Process. Preserv. 2008, 32, 88–102. [Google Scholar] [CrossRef]

- Dash, K.K.; Gope, S.; Sethi, A.; Doloi, M. Study on Thin Layer Drying Characteristics Star Fruit Slices. Int. J. Agric. Food Sci. Technol. 2013, 4, 679–686. [Google Scholar]

- Antonio, V.; Uribe, E.; Lemus, R.; Miranda, M. Hot-air drying characteristics of Aloe vera (Aloe barbadensis Miller) and influence of temperature on kinetic parameters. LWT-Food Sci. Technol. 2007, 40, 1698–1707. [Google Scholar]

- Haykin, S. Neural Networks a Comprehensive Introduction; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Viticult. 1965, 16, 144–153. [Google Scholar]

- Gao, H.; Cheng, N.; Zhou, J.; Wang, B.N.; Deng, J.J.; Cao, W. Antioxidant activities and phenolic compounds of date plum persimmon (Diospyros lotus L.) fruits. J. Food Sci. Technol. 2014, 51, 950–956. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The Ferric Reducing ability of plasma (FRAP) as a measure of Antioxidant power: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Ayadi, M.; Ben Mabrouk, S.; Zouari, I.; Bellagi, A. Kinetic study of the convective drying of spearmint. J. Saudi Soc. Agric. Sci. 2014, 13, 1–7. [Google Scholar] [CrossRef]

- Xiao, H.; Pang, C.; Wang, L.; Bai, J.; Yang, W.; Gao, Z. Drying kinetics and quality of Monukka seedless grapes dried in an air-impingement jet dryer. Biosyst. Eng. 2010, 105, 233–240. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Jahanbakhshi, A.; Kaveh, M. Prediction kinetic, energy and exergy of quince under hot air dryer using ANNs and ANFIS. J. Sci. Food Agric. 2020, 8, 594–611. [Google Scholar] [CrossRef] [PubMed]

- Sacilik, K.; Elicin, A.K. The thin layer drying characteristics of organic apple slices. J. Food Eng. 2006, 73, 281–289. [Google Scholar] [CrossRef]

- Madan, A.; Pare, A.; Nanje Gowda, N.A. Mathematical modeling of thin-layer drying process of bamboo (Bambusa bambos) shoots at varying temperature. Res. Rev. J. Bot. 2014, 3, 1–9. [Google Scholar]

- Younis, M.; Abdelkarim, D.; El-abdein, A.Z. Saudi journal of biological sciences kinetics and mathematical modeling of infrared thin-layer drying of garlic slices. Saudi J. Biol. Sci. 2018, 25, 332–338. [Google Scholar] [CrossRef]

- Ghaderi, A.; Abbasi, S.; Motevali, A.; Minaei, S. Comparison of mathematical models and artificial neural networks for prediction of drying kinetics of mushroom in microwave vacuum dryer. Chem. Ind. Chem. Eng. Q. 2012, 18, 283–293. [Google Scholar] [CrossRef]

- Nadian, M.H.; Rafiee, S.; Aghbashlo, M.; Hosseinpour, S.; Mohtasebi, S.S. Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food Bioprod. Process. 2014, 94, 263–274. [Google Scholar] [CrossRef]

- Turhan, M.; Turhan, K.N.; Sahbaz, F. Drying kinetics of red pepper. J. Food Proc. Preserv. 1997, 21, 209–223. [Google Scholar] [CrossRef]

- Rababah, T.M.; Al-u’datt, M.; Alhamad, M.; Al-Mahasneh, M.; Ereifej, K.; Andrade, J.; Altarifi, B.; Almajwal, A.; Yang, W. Effects of drying process on total phenolics, antioxidant activity and flavonoid contents of common Mediterranean herbs. Int. J. Agric. Biol. Eng. 2015, 8, 145–150. [Google Scholar]

- López, J.; Uribe, E.; Vega-Gálvez, A.; Miranda, M.; Vergara, J.; Gonzalez, E.; Di Scala, K. Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning and firmness of blueberries variety O’Neil. Food Bioproc. Tech. 2010, 3, 772–777. [Google Scholar] [CrossRef]

- Felipe, C.; da Silva, C.; Favaro-Trindade, S.M.; de Alencar, M.T.; Julio, C.B. Physicochemical properties, antioxidant activity and stability of spray-dried propolis. Kinetics, mineral content and colour characteristics of rosemary leave. Energy Convers. Manag. 2010, 49, 1258–1264. [Google Scholar]

- Złotek, U.; Dziki, U.G.; Dziki, D.; Swieca, M.; Nowak, R.; Martinez, E. Influence of drying temperature on phenolic acids composition and antioxidant activity of sprouts and leaves of white and red quinoa. J. Chem. 2019, 2019, 7125169. [Google Scholar] [CrossRef]

- Capecka, E.; Mareczek, A.; Leja, M. Antioxidant activity of fresh and dry herbs of some Lamiaceae species. Food Chem. 2005, 93, 223–226. [Google Scholar] [CrossRef]

- Shan, F.; Tang, H.; Wang, Y.; Guo, M. Study on flavonoids from the Peony leaves by ultrasonic extraction. Adv. Mater. Res. 2011, 236–238, 2250–2254. [Google Scholar] [CrossRef]

- Roshanak, S.; Rahimmalek, M.; Goli, S.A.H. Evaluation of seven different drying treatments in respect to total flavonoid, phenolic, vitamin C content, chlorophyll, antioxidant activity and color of green tea (Camellia sinensis or C. assamica) leaves. J. Food Sci. Technol. 2015, 53, 721–729. [Google Scholar] [CrossRef]

- Azad, M.O.K.; Piao, J.P.; Park, C.H.; Cho, D.H. Far infrared irradiation enhances nutraceutical compounds and antioxidant properties in Angelica gigas nakai powder. Antioxidants 2018, 7, 189. [Google Scholar] [CrossRef]

- Fernandez, N.F.; Casas, M.P.; Munoz, M.J.G.; Gonzalez, H.D. Water Extraction of Bioactive Compounds: From Plants to Drug Development, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 421–439. [Google Scholar]

- Olsson, M.E.; Gustavsson, K.E.; Vagen, I.M. Quercetin and isorhamnetin in sweet and red cultivars of onion (Allium cepa L.) at harvest, after field curing, heat treatment, and storage. J. Agric. Food Chem. 2010, 58, 2323–2330. [Google Scholar] [CrossRef]

| Model No. | Model Name | Model Expression | Reference |

|---|---|---|---|

| 1 | Page model | MR = exp (−ktn) | [26] |

| 2 | Midilli et al. model | MR = a exp (−kt) + bt | [35] |

| 3 | Henderson and Pabis model | MR = a exp (−kt) | [36] |

| 4 | Logarithmic model | MR = a exp (−kt) + c | [37] |

| 5 | Newton model | MR = exp (−kt) | [31] |

| Drying Temperature (°C) | Deff (m2/s) | D0 (m2/s) | Ea (kJ/mol) |

|---|---|---|---|

| 50 | 4.13 × 10−12 | ||

| 60 | 4.47 × 10−12 | 1.746 × 10−9 | 16.339 |

| 70 | 5.89 × 10−12 |

| Drying Temperature (°C) | Model No. | Model Parameters | R2 | RMSE |

|---|---|---|---|---|

| 50 | 1 | k = 0.0472, n = 1.0381 | 0.9992 | 0.0090 |

| 2 | k = 0.0413, n = 1.0933, a = 0.9998, b = 0.0003 | 0.9999 | 0.0025 | |

| 3 | a = 1.0128, k = 0.0538 | 0.9990 | 0.0098 | |

| 4 | a = 1.0096, k = 0.0547, c = 0.0053 | 0.9991 | 0.0099 | |

| 5 | k = 0.0532 | 0.9988 | 0.0104 | |

| 60 | 1 | k = 0.0955, n = 0.9915 | 0.9935 | 0.0257 |

| 2 | k = 0.0716, n = 1.1305, a = 0.9984, b = 0.0009 | 0.9992 | 0.0102 | |

| 3 | a = 1.0032, k = 0.0937 | 0.9935 | 0.0256 | |

| 4 | a = 0.9844, k = 0.1028, c = 0.0286 | 0.9969 | 0.0188 | |

| 5 | k = 0.0934 | 0.9935 | 0.0245 | |

| 70 | 1 | k = 0.2584, n = 0.7815 | 0.9931 | 0.0269 |

| 2 | k = 0.1300, n = 1.1340, a = 0.9914, b = 0.0013 | 0.9984 | 0.0152 | |

| 3 | a = 0.9935, k = 0.1625 | 0.9896 | 0.0330 | |

| 4 | a = 0.9611, k = 0.1866, c = 0.0405 | 0.9998 | 0.0055 | |

| 5 | k = 0.1635 | 0.9896 | 0.0312 |

| No. of Hidden Layers | No. of Neurons | Training | Test | ||

|---|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | ||

| 1 | 3 | 0.9620 | 0.0654 | 0.9978 | 0.0152 |

| 1 | 6 | 0.9602 | 0.0666 | 0.9943 | 0.0194 |

| 1 | 9 | 0.9717 | 0.0566 | 0.9866 | 0.0302 |

| 2 | 3, 3 | 0.9549 | 0.0706 | 0.9974 | 0.0132 |

| 2 | 6, 6 | 0.9769 | 0.0546 | 0.9986 | 0.0210 |

| 2 | 9, 9 | 0.9743 | 0.0568 | 0.9974 | 0.0327 |

| 3 | 3, 3, 3 | 0.9424 | 0.0795 | 0.9962 | 0.0215 |

| 3 | 6, 6, 6 | 0.9672 | 0.0616 | 0.9971 | 0.0163 |

| 3 | 9, 9, 9 | 0.9704 | 0.0587 | 0.9961 | 0.0412 |

| Model | R2 | RMSE | |

|---|---|---|---|

| Computational intelligence | ANN | 0.9986 | 0.0210 |

| Mathematical model | Logarithmic | 0.9998 | 0.0055 |

| Page | 0.9992 | 0.0090 | |

| Midilli et al. | 0.9999 | 0.0025 | |

| Temperature (°C) | TPC (mg/g, DW) | TFC (mg/g, DW) |

|---|---|---|

| Fresh | 127.73 ± 0.76 b | 0.567 ± 0.015 b |

| 50 | 95.184 ± 0.47 a | 2.790 ± 0.150 a |

| 60 | 99.756 ± 0.63 a | 2.631 ± 0.084 a |

| 70 | 99.756 ± 0.63 a | 2.583 ± 0.145 a |

| Significance | <0.001 | <0.001 |

| No. of Hidden Layers | No. of Neurons | Total Phenolics (mg/g, DW) | Total Flavonoids (mg/g, DW) | DPPH, mmol/g, DW | FRAP, mmol/g, DW | ||||

|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | ||

| 1 | 3 | 0.9969 | 2.8914 | 0.9884 | 0.1393 | 0.9977 | 3.1420 | 0.9816 | 1.0760 |

| 1 | 6 | 0.9965 | 3.1026 | 0.9882 | 0.1404 | 0.9977 | 3.1396 | 0.9824 | 1.0485 |

| 1 | 9 | 0.9965 | 3.0855 | 0.9877 | 0.1439 | 0.9975 | 3.3549 | 0.9839 | 1.0017 |

| 2 | 3, 3 | 0.9975 | 2.6100 | 0.9891 | 0.1346 | 0.9978 | 3.0660 | 0.9845 | 0.9808 |

| 2 | 6, 6 | 0.9974 | 2.6835 | 0.9890 | 0.1356 | 0.9978 | 3.0664 | 0.9840 | 0.9986 |

| 2 | 9, 9 | 0.9972 | 2.7533 | 0.9888 | 0.1370 | 0.9978 | 3.0894 | 0.9833 | 1.0197 |

| 3 | 3, 3, 3 | 0.9970 | 2.8433 | 0.9881 | 0.1401 | 0.9979 | 3.0421 | 0.9826 | 1.0402 |

| 3 | 6, 6, 6 | 0.9968 | 2.9741 | 0.9876 | 0.1439 | 0.9980 | 2.9317 | 0.9818 | 1.0690 |

| 3 | 9, 9, 9 | 0.9965 | 3.0873 | 0.9873 | 0.1460 | 0.9979 | 3.0024 | 0.9812 | 1.0906 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selvi, K.Ç.; Alkhaled, A.Y.; Yıldız, T. Application of Artificial Neural Network for Predicting the Drying Kinetics and Chemical Attributes of Linden (Tilia platyphyllos Scop.) during the Infrared Drying Process. Processes 2022, 10, 2069. https://doi.org/10.3390/pr10102069

Selvi KÇ, Alkhaled AY, Yıldız T. Application of Artificial Neural Network for Predicting the Drying Kinetics and Chemical Attributes of Linden (Tilia platyphyllos Scop.) during the Infrared Drying Process. Processes. 2022; 10(10):2069. https://doi.org/10.3390/pr10102069

Chicago/Turabian StyleSelvi, Kemal Çağatay, Alfadhl Yahya Alkhaled, and Taner Yıldız. 2022. "Application of Artificial Neural Network for Predicting the Drying Kinetics and Chemical Attributes of Linden (Tilia platyphyllos Scop.) during the Infrared Drying Process" Processes 10, no. 10: 2069. https://doi.org/10.3390/pr10102069

APA StyleSelvi, K. Ç., Alkhaled, A. Y., & Yıldız, T. (2022). Application of Artificial Neural Network for Predicting the Drying Kinetics and Chemical Attributes of Linden (Tilia platyphyllos Scop.) during the Infrared Drying Process. Processes, 10(10), 2069. https://doi.org/10.3390/pr10102069