Maximizing Lubricant Life for Internal Combustion Engines

Abstract

1. Introduction

2. Problem Definition

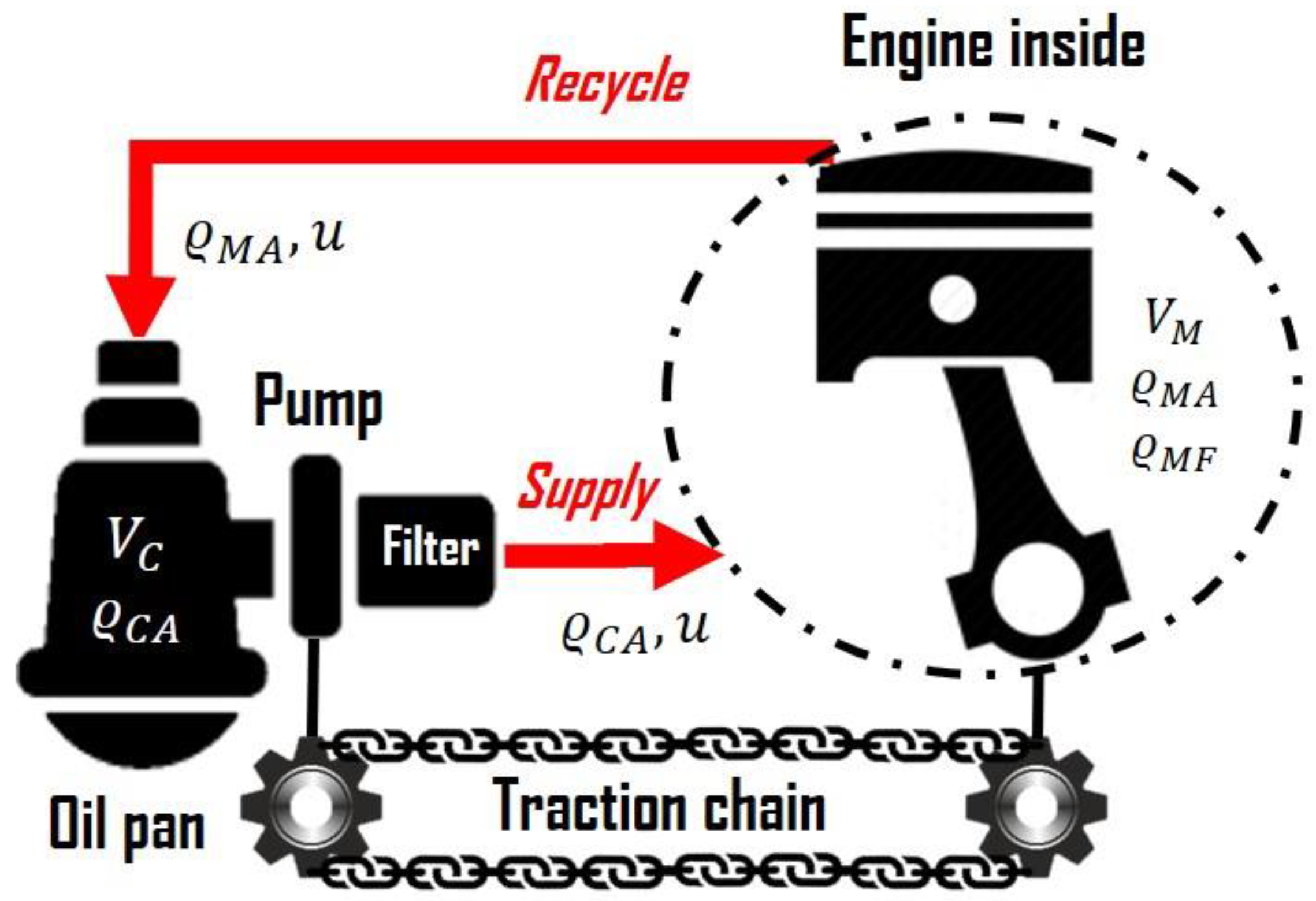

2.1. Lubrication in Internal Combustion Engines

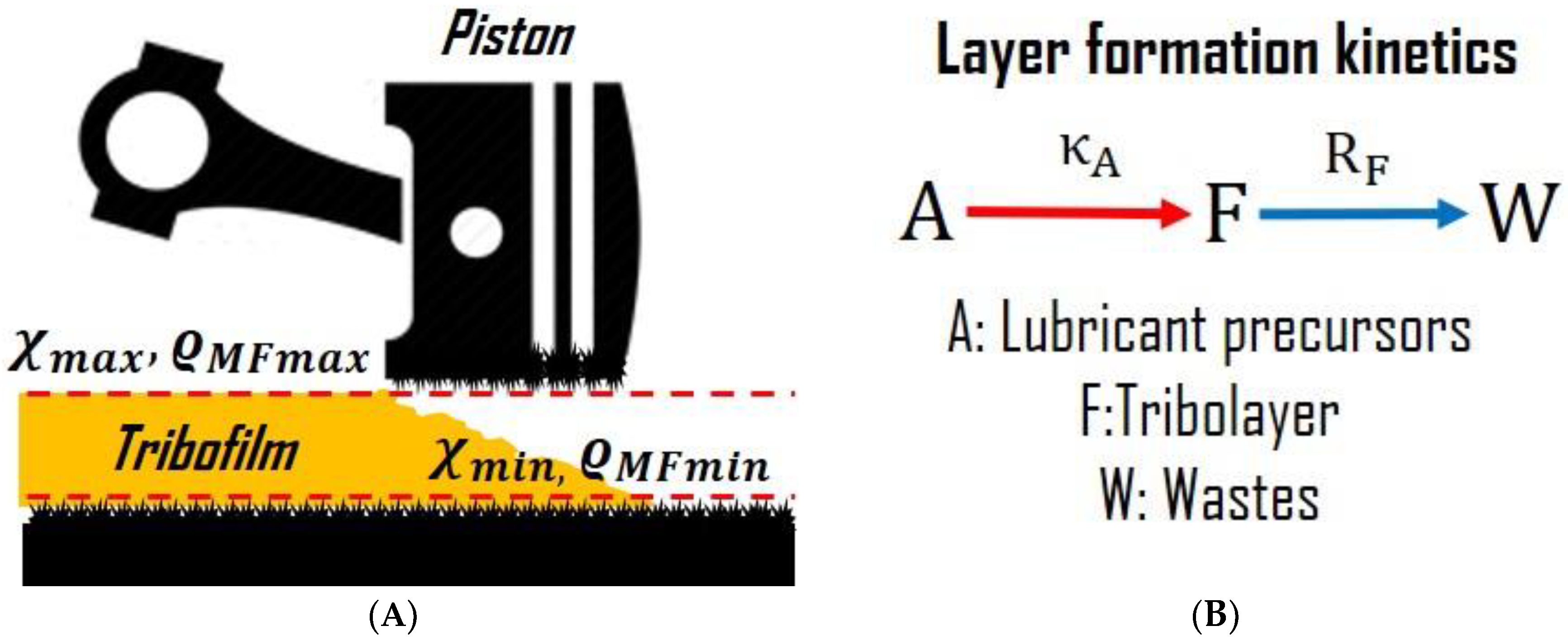

2.2. Mathematical Model for the Lubricating System

2.3. Experimental Estimation of the Model Parameters

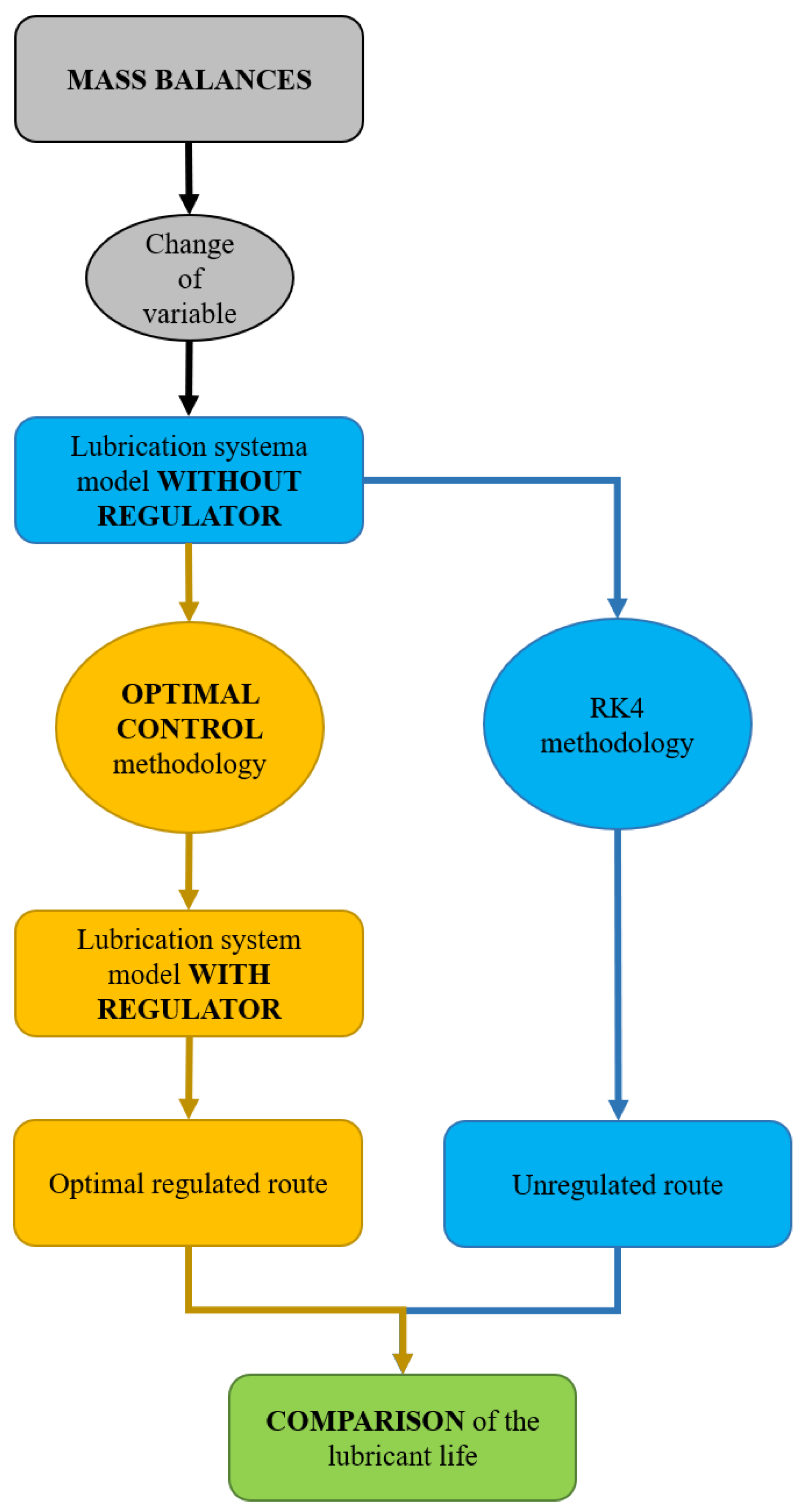

3. Materials and Methods

3.1. Maximization Methodology

3.2. Lubrication System Model without Regulator

3.3. Lubrication System Model with Regulator

3.4. Arrangements to Compare the Lubrication System Performance

4. Results and Discussion

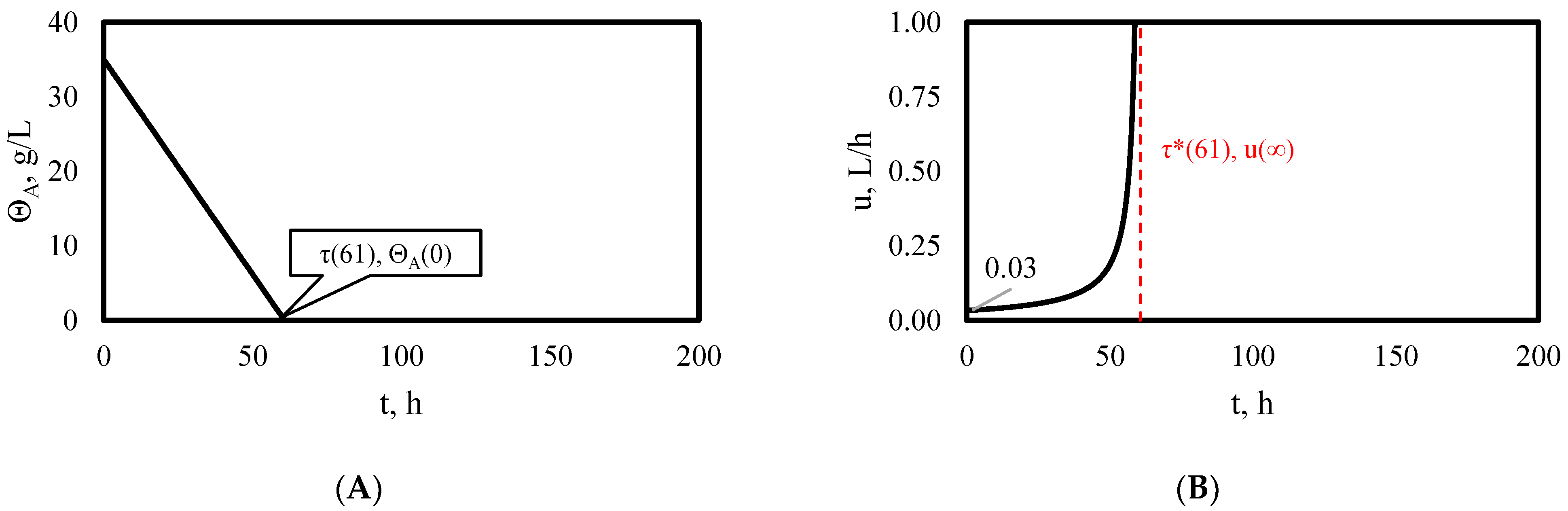

4.1. Analysis of the Behavior of the Lubrication System without Control

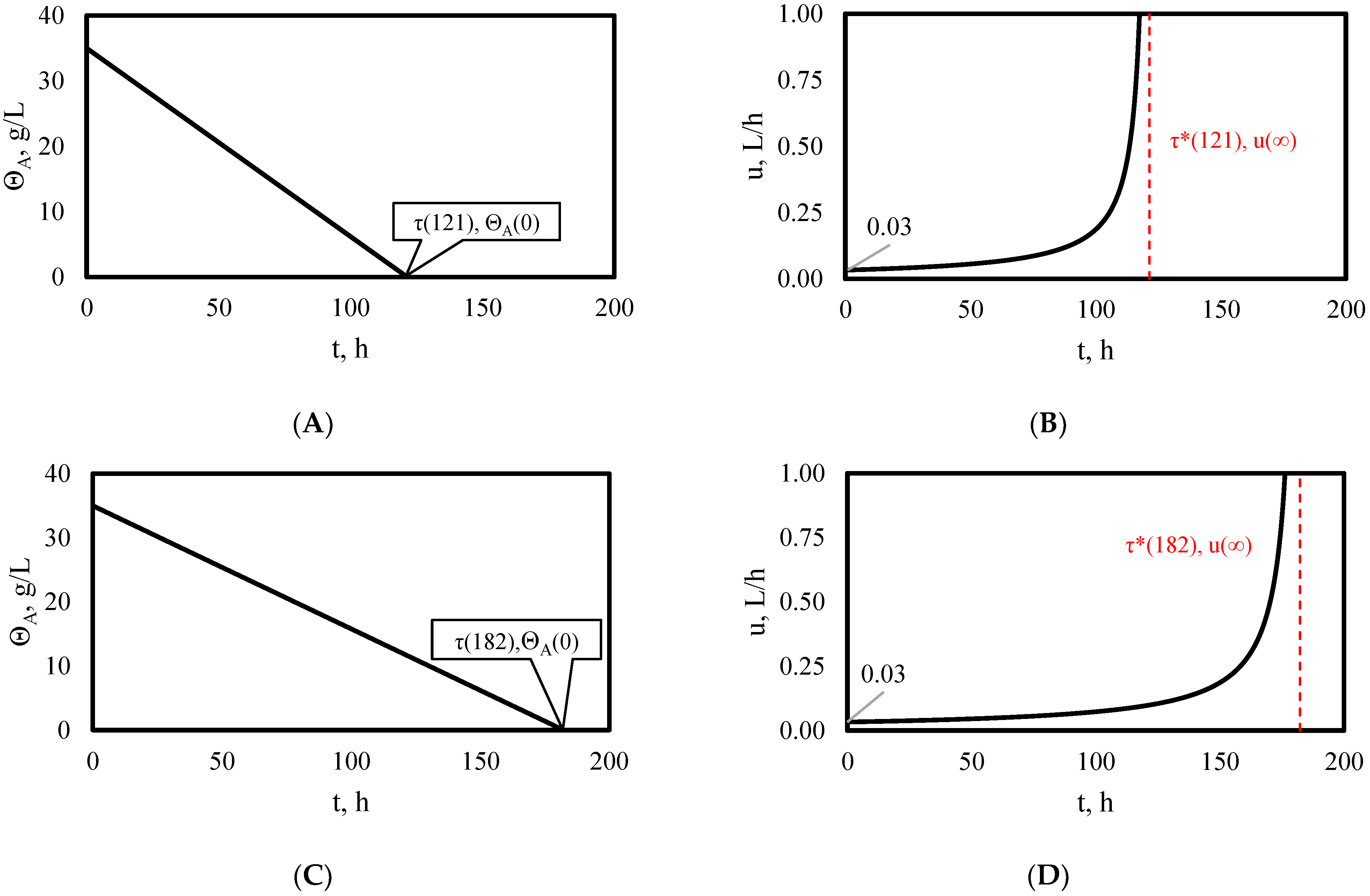

4.2. Analysis of the Behavior of the Lubrication System with Regulator

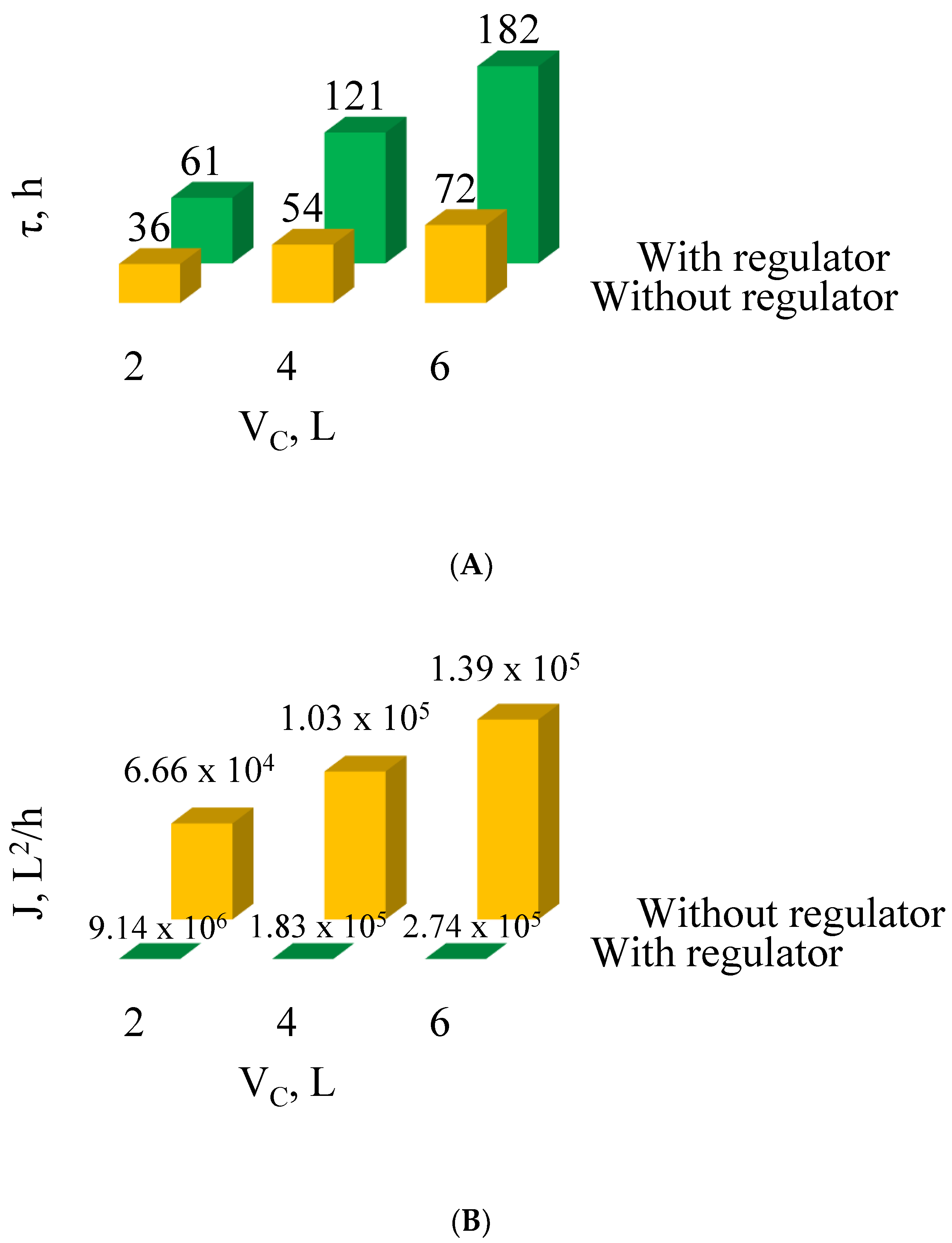

4.3. Comparison of the Behavior of the Lubrication System with and without Regulator

4.4. Results Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pinheiro, C.; Ascensão, V.; Cardoso, C.; Quina, M.; Gando-Ferreira, L. An overview of waste lubricant oil management system: Physicochemical characterization contribution for its improvement. J. Clean. Prod. 2017, 150, 301–308. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G. Life cycle assessment of a waste lubricant oil management system. Int. J. Life Cycle Assess. 2013, 18, 102–112. [Google Scholar] [CrossRef]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel–rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef]

- Zulhanafi, P.; Syahrullail, S. The tribological performances of Super Olein as fluid lubricant using four-ball tribotester. Tribol. Int. 2019, 130, 85–93. [Google Scholar] [CrossRef]

- Panda, J.N.; Bijwe, J.; Pandey, R.K. Particulate PTFE as a super-efficient secondary solid lubricant in PAEK composites for exceptional performance in adhesive wear mode. Compos. Part C Open Access 2021, 4, 100110. [Google Scholar] [CrossRef]

- Chowdary, K.; Kotia, A.; Lakshmanan, V.; Elsheikh, A.H.; Ali, M.K.A. A review of the tribological and thermophysical mechanisms of bio-lubricants based nanomaterials in automotive applications. J. Mol. Liq. 2021, 339, 116717. [Google Scholar] [CrossRef]

- Zhao, B.; Dai, X.-D.; Zhang, Z.-N.; Xie, Y.-B. A new numerical method for piston dynamics and lubrication analysis. Tribol. Int. 2016, 94, 395–408. [Google Scholar] [CrossRef]

- Fang, C.; Meng, X.; Xie, Y. A piston tribodynamic model with deterministic consideration of skirt surface grooves. Tribol. Int. 2017, 110, 232–251. [Google Scholar] [CrossRef]

- Akchurin, A.; Bosman, R.; Lugt, P.M. Generation of wear particles and running-in in mixed lubricated sliding contacts. Tribol. Int. 2017, 110, 201–208. [Google Scholar] [CrossRef]

- Akchurin, A.; Bosman, R.; Lugt, P.M.; van Drogen, M. On a Model for the Prediction of the Friction Coefficient in Mixed Lubrication Based on a Load-Sharing Concept with Measured Surface Roughness. Tribol. Lett. 2015, 59, 19. [Google Scholar] [CrossRef]

- Azam, A.; Dorgham, A.; Morina, A.; Neville, A.; Wilson, M.C. A simple deterministic plastoelastohydrodynamic lubrication (PEHL) model in mixed lubrication. Tribol. Int. 2019, 131, 520–529. [Google Scholar] [CrossRef]

- Ghanbarzadeh, A.; Wilson, M.; Morina, A.; Dowson, D.; Neville, A. Development of a new mechano-chemical model in boundary lubrication. Tribol. Int. 2016, 93, 573–582. [Google Scholar] [CrossRef]

- Azam, A.; Ghanbarzadeh, A.; Neville, A.; Morina, A.; Wilson, M.C. Modelling tribochemistry in the mixed lubrication regime. Tribol. Int. 2019, 132, 265–274. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Maya-Yescas, R.; Béjar-Gómez, L. Reduction of lubricant life in lubrication systems for internal combustion engines due to high lubricant supply rates. Mater. Lett. 2022, 313, 131785. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, Y. Boundary lubrication by adsorption film. Friction 2015, 3, 115–147. [Google Scholar] [CrossRef]

- Zhang, C. Analysis on mechanism of thin film lubrication. Chin. Sci. Bull. 2005, 50, 2645. [Google Scholar] [CrossRef]

- Harris, K.L.; Pitenis, A.A.; Sawyer, W.G.; Krick, B.A.; Blackman, G.S.; Kasprzak, D.J.; Junk, C.P. PTFE Tribology and the Role of Mechanochemistry in the Development of Protective Surface Films. Macromolecules 2015, 48, 3739–3745. [Google Scholar] [CrossRef]

- Cafolla, C.; Foster, W.; Voïtchovsky, K. Lubricated friction around nanodefects. Sci. Adv. 2020, 6, eaaz3673. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Y.; Zhang, L.; Zheng, Y.; Politis, D.J.; Liu, X.; Wang, L.-L. Experimental and modelling study of interaction between friction and galling under contact load change conditions. Friction 2022, 10, 454–472. [Google Scholar] [CrossRef]

- Holmberg, K.; Ronkainen, H.; Laukkanen, A.; Wallin, K. Friction and wear of coated surfaces—Scales, modelling and simulation of tribomechanisms. Surf. Coat. Technol. 2007, 202, 1034–1049. [Google Scholar] [CrossRef]

- Söderfjäll, M.; Herbst, H.M.; Larsson, R.; Almqvist, A. Influence on friction from piston ring design, cylinder liner roughness and lubricant properties. Tribol. Int. 2017, 116, 272–284. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Béjar-Gómez, L.; Huirache-Acuna, R.; Lara-Romero, J.; Maya-Yescas, R. Delumping Strategy to Infer Lubrication Reaction Pathways in Internal Combustion Engines. Int. J. Chem. React. Eng. 2020, 18, 20190043. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Aguilar-Ramírez, C.E.; Béjar-Gómez, L.; Maya-Yescas, R. Mass balance of the tribofilm in lubricated systems. Tribol. Int. 2021, 155, 106757. [Google Scholar] [CrossRef]

- Acharya, B.; Seed, C.M.; Krim, J. Shear activation of ZDDP reaction films in the presence and absence of nanodiamonds. Appl. Surf. Sci. Adv. 2022, 7, 100214. [Google Scholar] [CrossRef]

- Spikes, H. The History and Mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Minfray, C.; Martin, J.M.; de Barros, M.I.; le Mogne, T.; Kersting, R.; Hagenhoff, B. Chemistry of ZDDP tribofilm by ToF-SIMS. Tribol. Lett. 2004, 17, 351–357. [Google Scholar] [CrossRef]

- Ueda, M.; Kadiric, A.; Spikes, H. On the Crystallinity and Durability of ZDDP Tribofilm. Tribol. Lett. 2019, 67, 123. [Google Scholar] [CrossRef]

- Shimizu, Y.; Spikes, H. The Influence of Slide–Roll Ratio on ZDDP Tribofilm Formation. Tribol. Lett. 2016, 64, 19. [Google Scholar] [CrossRef]

- Shimizu, Y.; Spikes, H. The Tribofilm Formation of ZDDP Under Reciprocating Pure Sliding Conditions. Tribol. Lett. 2016, 64, 46. [Google Scholar] [CrossRef]

- Muraki, M.; Yanagi, Y.; Sakaguchi, K. Synergistic effect on frictional characteristics under rolling-sliding conditions due to a combination of molybdenum dialkyldithiocarbamate and zinc dialkyldithiophosphate. Tribol. Int. 1997, 30, 69–75. [Google Scholar] [CrossRef]

- Persson, B. Contact mechanics for randomly rough surfaces. Surf. Sci. Rep. 2006, 61, 201–227. [Google Scholar] [CrossRef]

- Bonaventure, J.; Cayer-Barrioz, J.; Mazuyer, D. Transition Between Mixed Lubrication and Elastohydrodynamic Lubrication with Randomly Rough Surfaces. Tribol. Lett. 2016, 64, 44. [Google Scholar] [CrossRef]

- Petrova, D.; Weber, B.; Allain, C.; Audebert, P.; Venner, C.H.; Brouwer, A.M.; Bonn, D. Fluorescence microscopy visualization of the rough-ness-induced transition between lubrication regimes. Sci. Adv. 2019, 5, eaaw4761. Available online: https://www.science.org (accessed on 1 January 2022). [CrossRef] [PubMed]

- Khaemba, D.N.; Jarnias, F.; Thiebaut, B.; Neville, A.; Morina, A. The role of surface roughness and slide-roll ratio on the decomposition of MoDTC in tribological contacts. J. Phys. D Appl. Phys. 2017, 50, 085302. [Google Scholar] [CrossRef]

- Lewis, F.L.; Vrabie, D.; Syrmos, V.L. Optimal Control; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Domínguez-García, S.; Béjar-Gómez, L.; Nápoles-Rivera, F.; Maya-Yescas, R. Optimal Control of Make-up Lubricating Systems for Internal Combustion Engines. ACAM 2021, 4, 74. [Google Scholar] [CrossRef]

- Göllmann, L.; Kern, D.; Maurer, H. Optimal control problems with delays in state and control variables subject to mixed control-state constraints. Optim. Control Appl. Methods 2009, 30, 341–365. [Google Scholar] [CrossRef]

- Alt, W.; Schneider, C. Linear-quadratic control problems withL1-control cost. Optim. Control Appl. Methods 2015, 36, 512–534. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domínguez-García, S.; Béjar-Gómez, L.; López-Velázquez, A.; Maya-Yescas, R.; Nápoles-Rivera, F. Maximizing Lubricant Life for Internal Combustion Engines. Processes 2022, 10, 2070. https://doi.org/10.3390/pr10102070

Domínguez-García S, Béjar-Gómez L, López-Velázquez A, Maya-Yescas R, Nápoles-Rivera F. Maximizing Lubricant Life for Internal Combustion Engines. Processes. 2022; 10(10):2070. https://doi.org/10.3390/pr10102070

Chicago/Turabian StyleDomínguez-García, Saúl, Luis Béjar-Gómez, Andrés López-Velázquez, Rafael Maya-Yescas, and Fabricio Nápoles-Rivera. 2022. "Maximizing Lubricant Life for Internal Combustion Engines" Processes 10, no. 10: 2070. https://doi.org/10.3390/pr10102070

APA StyleDomínguez-García, S., Béjar-Gómez, L., López-Velázquez, A., Maya-Yescas, R., & Nápoles-Rivera, F. (2022). Maximizing Lubricant Life for Internal Combustion Engines. Processes, 10(10), 2070. https://doi.org/10.3390/pr10102070