Regularities of Microstructure Evolution in a Cu-Cr-Zr Alloy during Severe Plastic Deformation

Abstract

:1. Introduction

2. Materials and Methods

3. Results

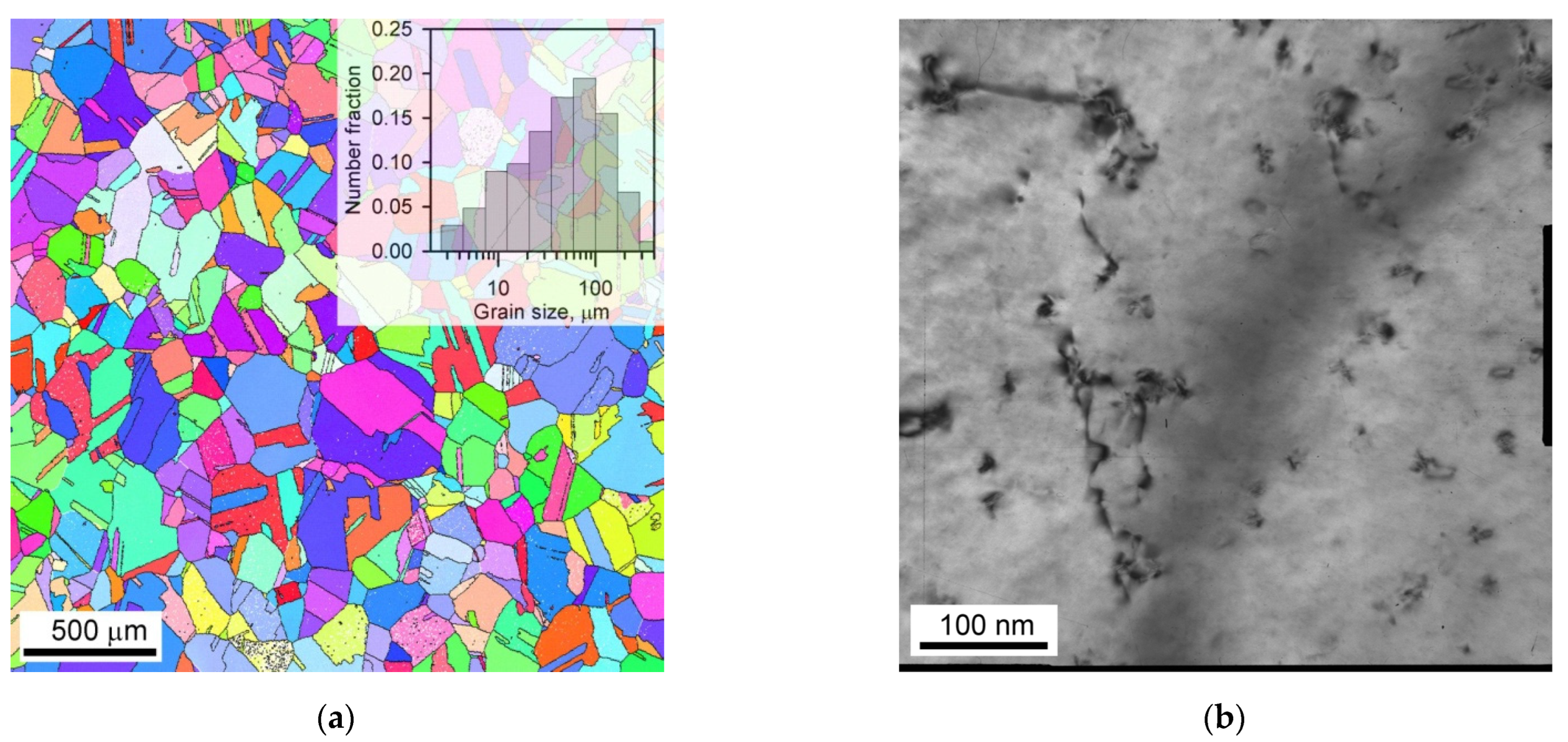

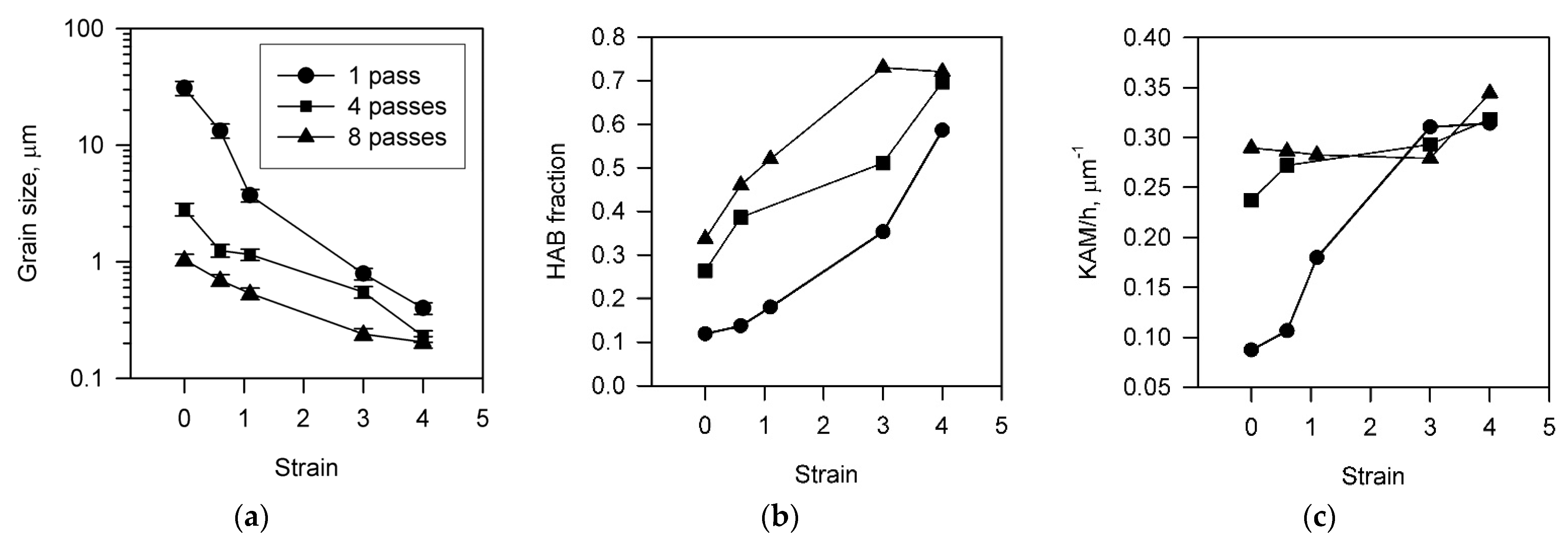

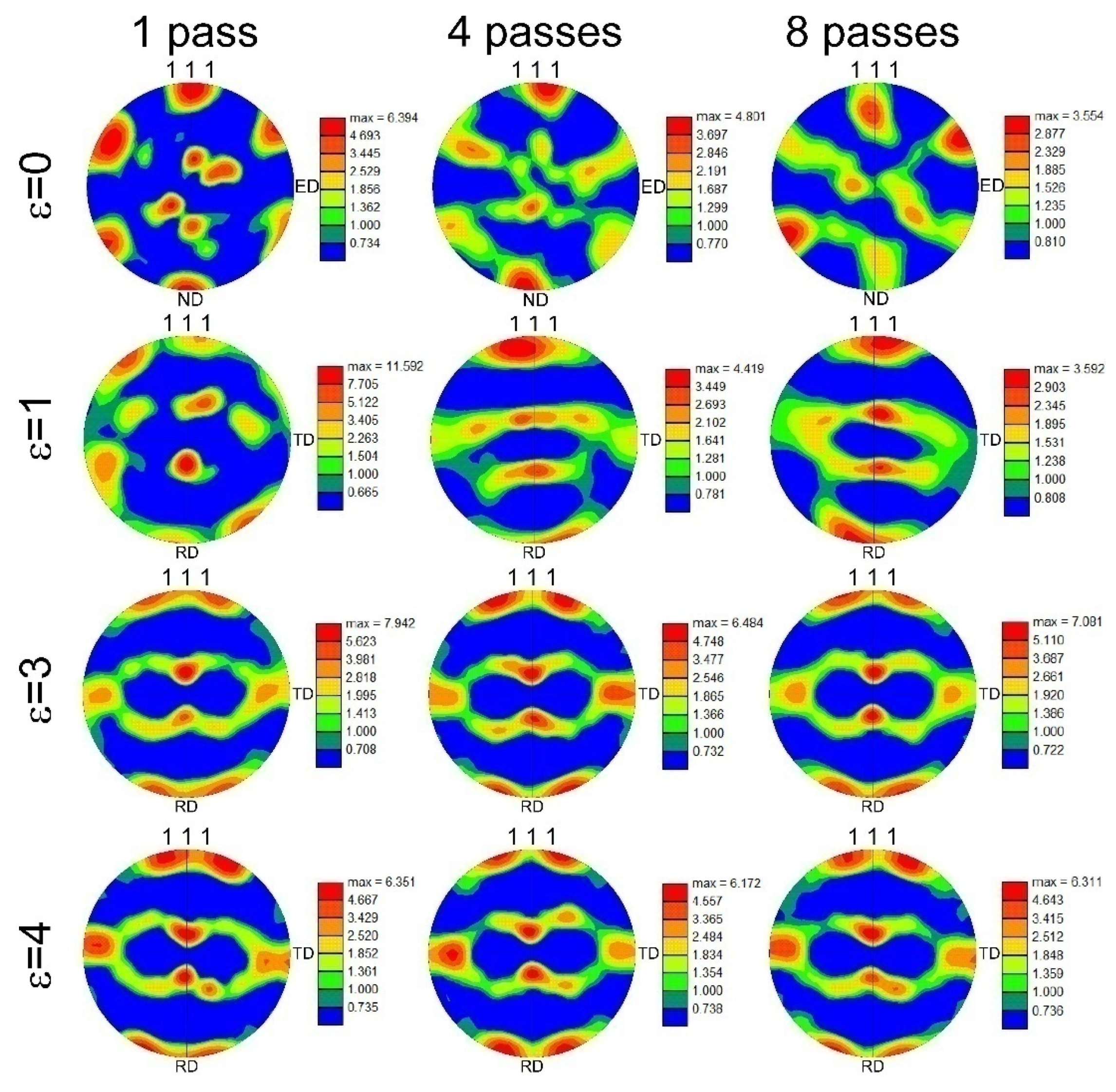

3.1. Deformation Microstructures

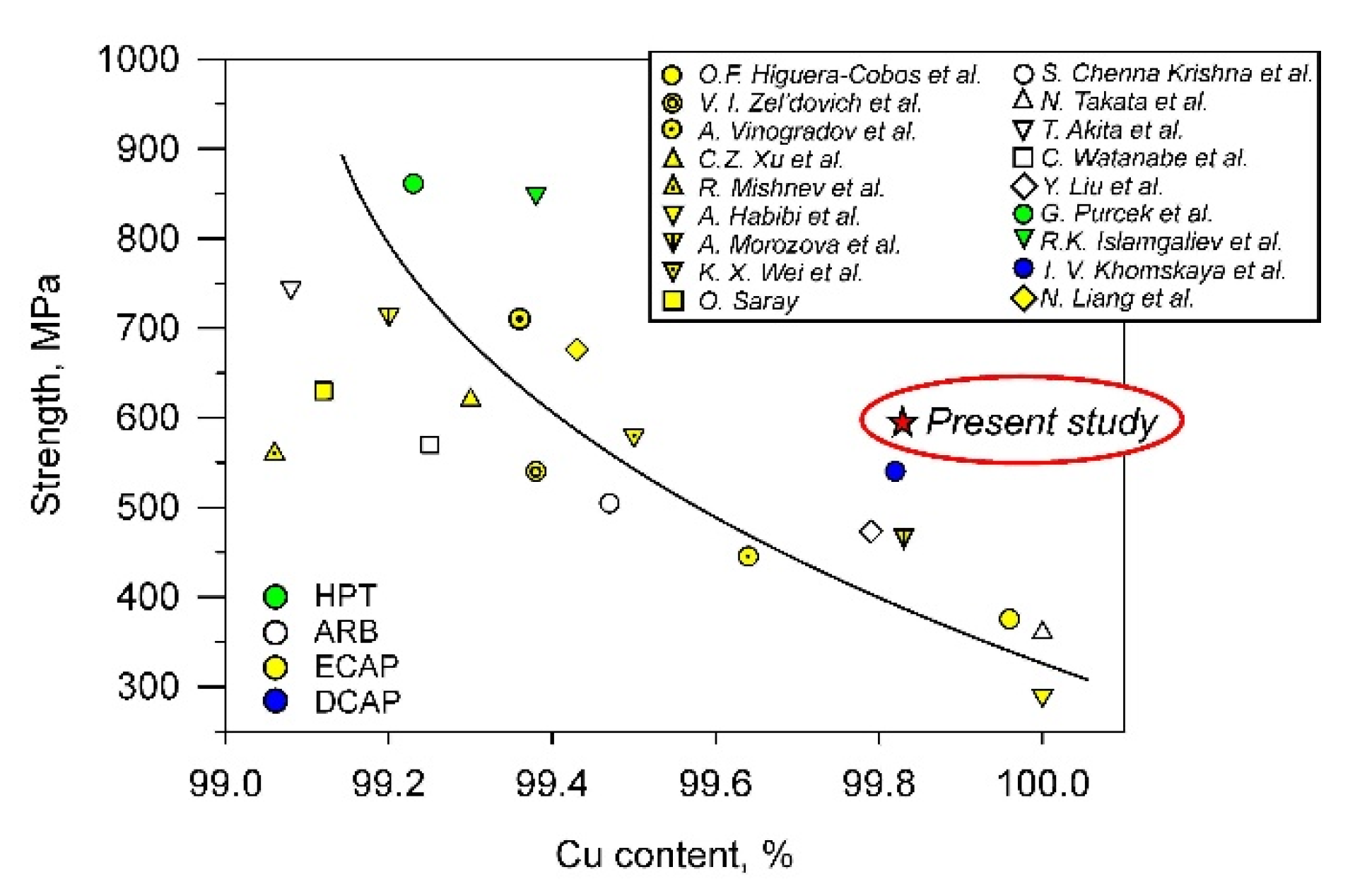

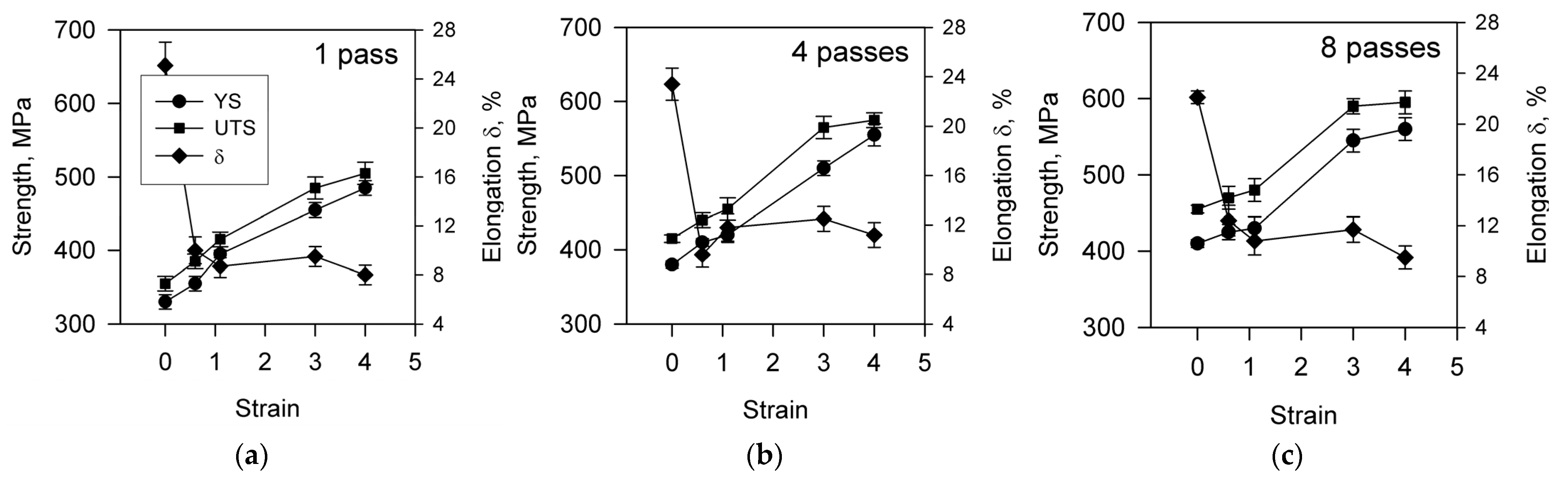

3.2. Mechanical Properties

4. Discussion

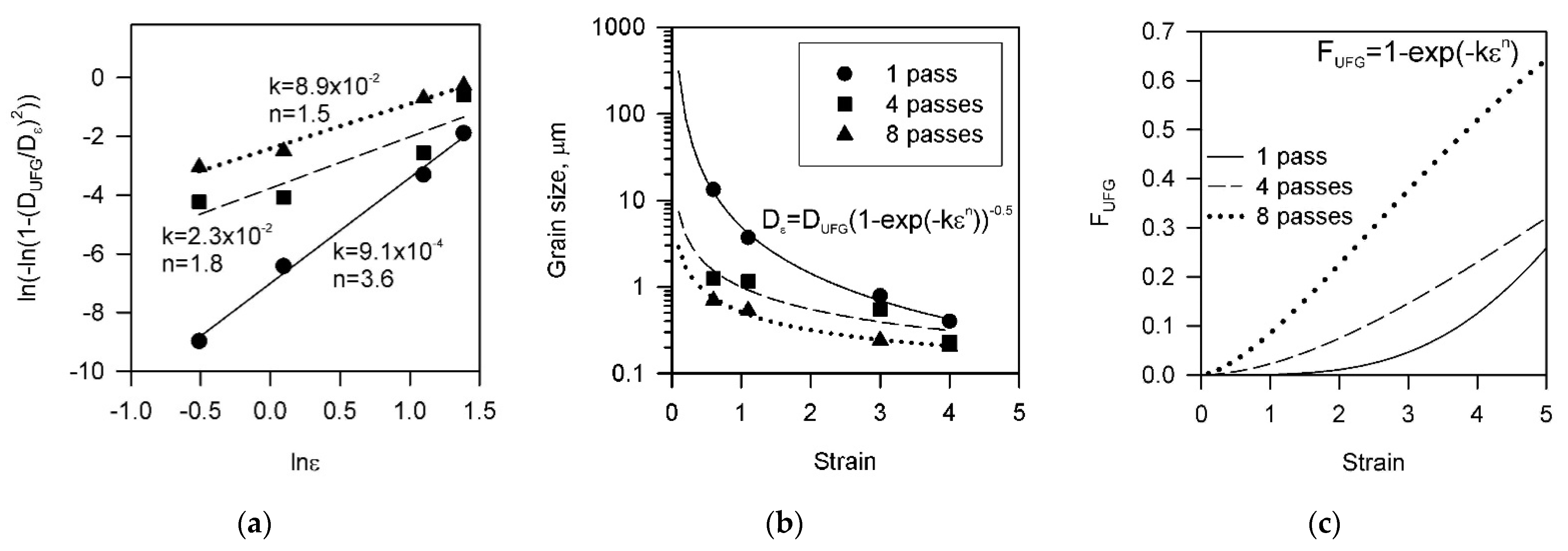

4.1. Grain Refinement

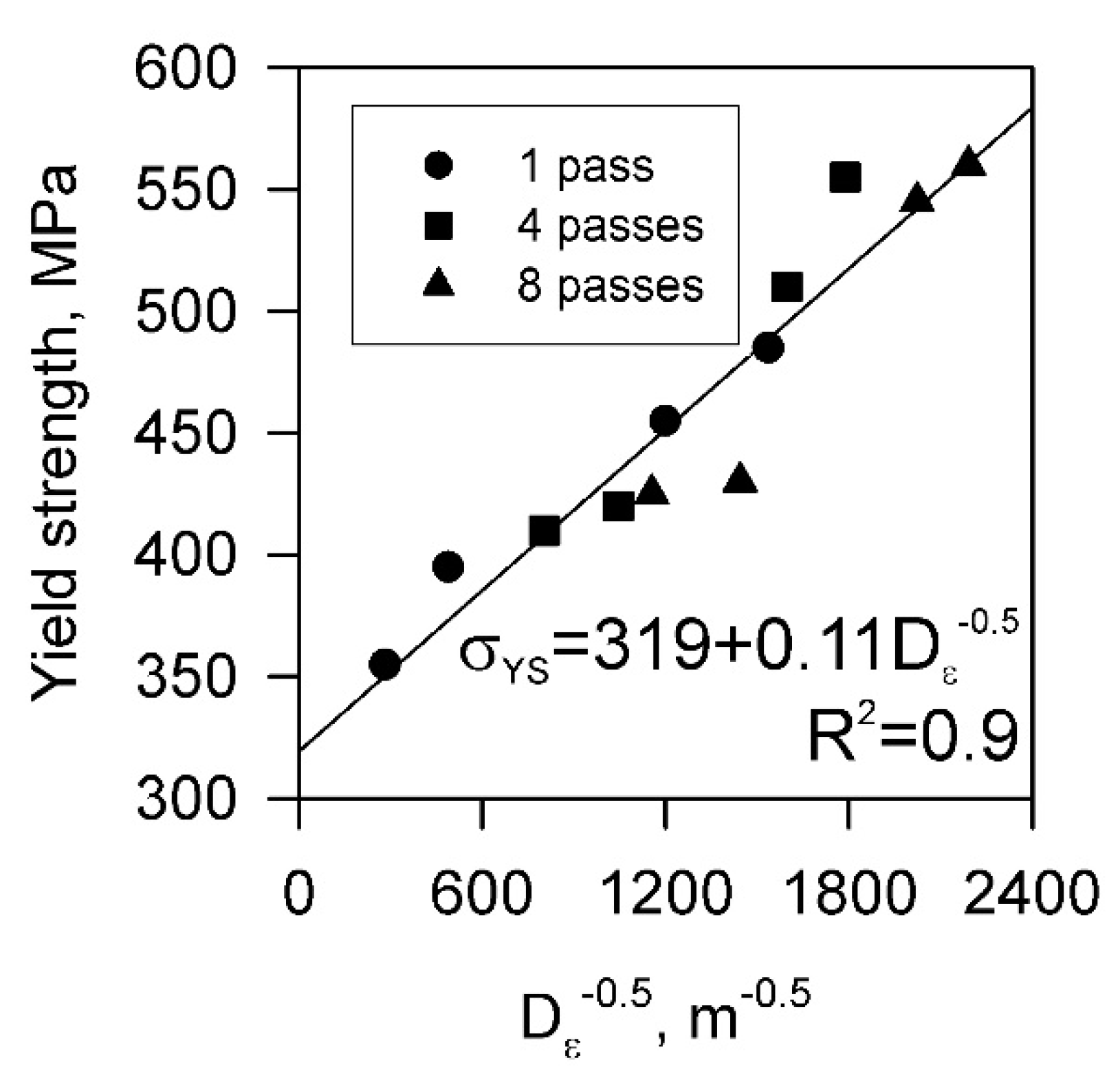

4.2. Strengthening by Severe Plastic Deformation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons: New Jersey, NB, Canada, 2013; pp. 387–413. [Google Scholar] [CrossRef]

- Sabirov, I.; Enikeev, N.A.; Murashkin, M.Y.; Valiev, R.Z. Bulk Nanostructured Materials with Multifunctional Properties; Springer International Publishing: Berlin, Germany, 2015. [Google Scholar] [CrossRef]

- Murashkin, M.Y.; Sabirov, I.; Sauvage, X.; Valiev, R.Z. Nanostructured Al and Cu alloys with superior strength and electrical conductivity. J. Mater. Sci. 2016, 51, 33–49. [Google Scholar] [CrossRef]

- Morozova, A.; Mishnev, R.; Belyakov, A.; Kaibyshev, R. Microstructure and properties of fine grained Cu-Cr-Zr alloys after termo-mechanical treatments. Rev. Adv. Mater. Sci. 2018, 54, 56–92. [Google Scholar] [CrossRef]

- Liang, N.; Liu, J.; Lin, S.; Wang, Y.; Wang, J.T.; Zhao, Y.; Zhu, Y. A multiscale architecture CuCrZr alloy with high strength, electrical conductivity and thermal stability. J. Alloys Compd. 2018, 735, 1389–1394. [Google Scholar] [CrossRef]

- Kulczyk, M.; Pachla, W.; Godek, J.; Smalc-Koziorowska, J.; Skiba, J.; Przybysz, S.; Przybysz, M. Improved compromise between the electrical conductivity and hardness of the thermo-mechanically treated CuCrZr alloy. Mater. Sci. Eng. A 2018, 724, 45–52. [Google Scholar] [CrossRef]

- Wang, Y.; Xing, P.; Wang, P.; Liu, J. A novel method to improve the hardness and electrical conductivity of Cu–Cr–Al alloy. J. Alloys Compd. 2016, 656, 581–584. [Google Scholar] [CrossRef]

- Vinogradov, A.; Suzuki, Y.; Ishida, T.; Kitagawa, K.; Kopylov, V.I. Effect of chemical composition on structure and properties of ultrafine grained Cu-Cr-Zr alloys produced by equal-channel angular pressing. Mater. Trans. 2004, 45, 2187–2191. [Google Scholar] [CrossRef] [Green Version]

- Shangina, D.V.; Gubicza, J.; Dodony, E.; Bochvar, N.R.; Straumal, P.B.; Tabachkova, N.Y.; Dobatkin, S.V. Improvement of strength and conductivity in Cu-alloys with the application of high pressure torsion and subsequent heat-treatments. J. Mater. Sci. 2014, 49, 6674–6681. [Google Scholar] [CrossRef]

- Hernández-Pérez, A.; Eddahbi, M.; Monge, M.A.; Muñoz, A.; Savoini, B. Microstructure and mechanical properties of an ITER-grade Cu–Cr–Zr alloy processed by equal channel angular pressing. Fusion Eng. Des. 2015, 98, 1978–1981. [Google Scholar] [CrossRef]

- Harrison, W.A. Resistivity due to dislocations in copper. J. Phys. Chem. Solids 1958, 5, 44–46. [Google Scholar] [CrossRef]

- Manohar, P.A.; Ferry, M.; Chandra, T. Five decades of the Zener equation. ISIJ Int. 1998, 38, 913–924. [Google Scholar] [CrossRef] [Green Version]

- Bodyakova, A.; Mishnev, R.; Belyakov, A.; Kaibyshev, R. Effect of chromium content on precipitation in Cu–Cr–Zr alloys. J. Mater. Sci. 2022, 57, 13043–13059. [Google Scholar] [CrossRef]

- Shangina, D.V.; Bochvar, N.R.; Morozova, A.I.; Belyakov, A.N.; Kaibyshev, R.O.; Dobatkin, S.V. Effect of chromium and zirconium content on structure, strength and electrical conductivity of Cu-Cr-Zr alloys after high pressure torsion. Mater. Let. 2017, 199, 46–49. [Google Scholar] [CrossRef]

- Bodyakova, A.; Pilipenko, A.; Lugovskaya, A.; Belyakov, A.; Kaibyshev, R. Thermal stability of gradient microstructure in a low-alloyed Cu-Cr-Zr alloy. Mater. Let. 2021, 304, 130531. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, F.; Jiang, J.; Xu, P.; Tong, M.; Tang, Z. Precipitation, recrystallization, and evolution of annealing twins in a Cu-Cr-Zr alloy. Metals 2018, 8, 227. [Google Scholar] [CrossRef] [Green Version]

- Matthiessen, A.; Vogt, A.C.C., IV. On the influence of temperature on the electric conducting-power of alloys. Philos. Trans. R. Soc. Lond. 1864, 154, 167–200. [Google Scholar]

- Chembarisova, R.G.; Galaktionova, A.V.; Yamileva, A.M. Evolution of Secondary Phase Particles in Cu–Cr–Zr Alloys with an Extremely Low Concentration of Solid Solution during Thermomechanical Treatment. Phys. Metal Metallog. 2021, 122, 40–46. [Google Scholar] [CrossRef]

- Zeng, K.; Hämäläinen, M. Thermodynamic analysis of stable and metastable equilibria in the Cu-Cr system. Calphad 1995, 19, 93–104. [Google Scholar] [CrossRef]

- Wang, N.; Li, C.; Du, Z.; Wang, F.; Zhang, W. The thermodynamic re-assessment of the Cu–Zr system. Calphad 2006, 30, 461–469. [Google Scholar] [CrossRef]

- Bochvar, N. Chromium–Copper–Zirconium. In Non-Ferrous Metal Systems. Part 2, 1st ed.; Effenberg, G., Ilyenko, S., Eds.; Springer International Publishing: Berlin, Germany, 2007; pp. 228–242. [Google Scholar] [CrossRef]

- Bochvar, N.R.; Rybalchenko, O.V.; Shangina, D.V.; Dobatkin, S.V. Effect of equal-channel angular pressing on the precipitation kinetics in Cu-Cr-Hf alloys. Mater. Sci. Eng. A 2019, 757, 84–87. [Google Scholar] [CrossRef]

- Murray, J.L. The Cu−Ti (copper-titanium) system. Bull. Alloy Phase Diagr. 1983, 4, 81–95. [Google Scholar] [CrossRef]

- Sakai, Y.; Schneider-Muntau, H.J. Ultra-high strength, high conductivity Cu-Ag alloy wires. Acta Mater. 1997, 45, 1017–1023. [Google Scholar] [CrossRef]

- Shakhova, I.; Sakai, Y.; Belyakov, A.; Kaibyshev, R. Microstructure evolution in a Cu-Ag alloy during large strain deformation and annealing. Mater. Sci. Forum 2011, 667, 493–498. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, G.; Feng, X.; Peng, L.; Huang, G.; Xie, H.; Liu, X. Effect of Ag on Properties, Microstructure, and Thermostability of Cu–Cr Alloy. Materials 2020, 13, 5386. [Google Scholar] [CrossRef] [PubMed]

- Smirnova, N.A.; Levit, V.I.; Pilyugin, V.I.; Kuznetsov, R.I.; Degtyarov, M.V. Structure evolution of fcc single crystals during large plastic deformations. Fiz. Met. Metalloved. 1986, 62, 566. [Google Scholar]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Nesterov, K.M.; Bourgon, J.; Champion, Y.; Valiev, R.Z. Nanostructured Cu-Cr alloy with high strength and electrical conductivity. J. Appl. Phys. 2014, 115, 194301. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Langdon, T.G. Factors influencing microstructural development in equal-channel angular pressing. Metals Mater. Int. 2003, 9, 141–149. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Horita, Z.; Fujinami, T.; Langdon, T.G. The potential for scaling ECAP: Effect of sample size on grain refinement and mechanical properties. Mater. Sci. Eng. A 2001, 318, 34–41. [Google Scholar] [CrossRef]

- Borodin, E.N.; Morozova, A.; Bratov, V.; Belyakov, A.; Jivkov, A.P. Experimental and numerical analyses of microstructure evolution of Cu-Cr-Zr alloys during severe plastic deformation. Mater. Charact. 2019, 156, 109849. [Google Scholar] [CrossRef]

- Raab, G.J.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Continuous processing of ultrafine grained Al by ECAP–Conform. Mater. Sci. Eng. A 2004, 382, 30–34. [Google Scholar] [CrossRef]

- Semenova, I.P.; Polyakov, A.V.; Raab, G.I.; Lowe, T.C.; Valiev, R.Z. Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-Conform. J. Mater. Sci. 2012, 47, 7777–7781. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Tsuzaki, K. Grain refinement in copper under large strain deformation. Philos. Mag. A 2001, 81, 2629–2643. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Mishnev, R.; Shakhova, I.; Belyakov, A.; Kaibyshev, R. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu–Cr–Zr alloy. Mater. Sci. Eng. A 2015, 629, 29–40. [Google Scholar] [CrossRef]

- Morozova, A.I.; Belyakov, A.N.; Kaibyshev, R.O. Effect of Deformation Temperature on Formation of Ultrafine-Grained Structure in the Age-Hardenable Cu–Cr–Zr. Alloy. Phys. Metals Metallog. 2021, 122, 60–66. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proc. R. Soc. Lond. Ser. A 1934, 145, 362–387. [Google Scholar]

- Yang, H.; Ma, Z.; Lei, C.; Meng, L.; Fang, Y.; Liu, J.; Wang, H. High strength and high conductivity Cu alloys: A review. Sci. China Technol. Sci. 2020, 63, 2505–2517. [Google Scholar] [CrossRef]

- Xia, C.; Jia, Y.; Zhang, W.; Zhang, K.; Dong, Q.; Xu, G.; Wang, M. Study of deformation and aging behaviors of a hot rolled–quenched Cu–Cr–Zr–Mg–Si alloy during thermomechanical treatments. Mater. Des. 2012, 39, 404–409. [Google Scholar] [CrossRef]

- Fu, H.; Xu, S.; Li, W.; Xie, J.; Zhao, H.; Pan, Z. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2017, 700, 107–115. [Google Scholar] [CrossRef]

- Sun, L.X.; Tao, N.R.; Lu, K. A high strength and high electrical conductivity bulk CuCrZr alloy with nanotwins. Scr. Mater 2015, 99, 73–76. [Google Scholar] [CrossRef]

- Li, R.; Kang, H.; Chen, Z.; Fan, G.; Zou, C.; Wang, W.; Wang, T. A promising structure for fabricating high strength and high electrical conductivity copper alloys. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Liu, Z.Y.; He, G.Y.; Ou, L.N. Dislocation ordering and texture strengthening of naturally aged Al-Cu-Mg alloy. J. Mater. Sci. Technol. 2022, 118, 1–14. [Google Scholar] [CrossRef]

- Kapoor, G.; Kvackaj, T.; Heczel, A.; Bidulská, J.; Kočiško, R.; Fogarassy, Z.; Gubicza, J. The Influence of Severe Plastic Deformation and Subsequent Annealing on the Microstructure and Hardness of a Cu–Cr–Zr Alloy. Materials 2020, 13, 2241. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, Z.; Xiao, Z.; Zhao, Z.; Yang, Z. Microstructure evolution and properties of Cu-Cr alloy during continuous extrusion process. J. Alloys Compd. 2017, 703, 454–460. [Google Scholar] [CrossRef]

- Song, L.; Yuan, Y.; Yin, Z. Microstructural evolution in Cu-Mg alloy processed by conform. Int. J. Nonferrous Metall. 2013, 3, 33897. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Dai, C.; Li, Z.; Yang, G.; Liu, Y.; Xiao, Z. Microstructure evolution of Cu–0.2 Mg alloy during continuous extrusion process. J. Mater. Res. 2015, 30, 2783–2791. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, Z.; Xiao, Z.; Zhao, Z. Investigations on voids formation in Cu–Mg alloy during continuous extrusion. JOM 2017, 69, 1696–1700. [Google Scholar] [CrossRef]

- Asfandiyarov, R.N.; Raab, G.I.; Aksenov, D.A. Study of the Combined Severe Plastic Deformation Techniques Applied to Produce Contact Wire for High-Speed Railway Lines. Metals 2020, 10, 1476. [Google Scholar] [CrossRef]

- Rusz, S.; Malaník, K.; Donic, T.; Kedron, J.; Tylsar, S.; Salajka, M. Development of Structure at Extrusion of a Strip of Made of Cu through the DRECE Machinery. J. Mater. Sci. Eng. 2011, 1, 94–98. [Google Scholar]

- Belyakov, A.; Gao, W.; Miura, H.; Sakai, T. Strain induced grain evolution in polycrystalline copper during warm deformation. Metall. Mater. Trans. A 1998, 29A, 2957–2965. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Kimura, Y. Regularities of deformation microstructures in ferritic stainless steels during large strain cold working. ISIJ Int. 2008, 48, 1071–1079. [Google Scholar] [CrossRef] [Green Version]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef] [Green Version]

- Mecking, H.; Kocks, U.F. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Tóth, L.S. Texture evolution in equal-channel angular extrusion. Prog. Mater. Sci. 2009, 54, 427–510. [Google Scholar] [CrossRef]

- Hirsch, J.; Lucke, K. Mechanism of deformation and development of rolling textures in polycrystalline f.c.c. metals – I. De-scription of rolling texture development in homogeneous CuZn alloys. Acta Metall. Mater. 1988, 36, 2863–2882. [Google Scholar] [CrossRef]

- Belyakov, A.; Murayama, M.; Sakai, Y.; Tsuzaki, K.; Okubo, M.; Eto, M.; Kimura, T. Development of a high-strength high-conductivity Cu-Ni-P alloy, Part II: Processing by severe deformation. J. Electron. Mater. 2006, 35, 2000–2008. [Google Scholar] [CrossRef]

- Belyakov, A.; Zherebtsov, S.; Tikhonova, M.; Salishchev, G. Kinetics of grain refinement in metallic materials during large strain deformation. Mater. Phys. Mech. 2015, 24, 224–231. [Google Scholar]

- Morozova, A.; Kaibyshev, R. Grain refinement and strengthening of a Cu–0.1Cr–0.06Zr alloy subjected to equal channel angular pressing. Philos. Mag. 2017, 97, 2053–2076. [Google Scholar] [CrossRef]

- Dalla Torre, F.; Lapovok, R.; Sandlin, J.; Thomson, P.F.; Davies, C.H.J.; Pereloma, E.V. Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Schneibel, J.H.; Heilmaier, M. Hall Petch Breakdown at Elevated Temperatures. Mater. Trans. 2014, 55, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Queyreau, S.; Monnet, G.; Devincre, B. Orowan strengthening and forest hardening superposition examined by dislocation dynamics simulations. Acta Mater. 2010, 58, 5586–5595. [Google Scholar] [CrossRef]

- Xu, C.Z.; Wang, Q.J.; Zheng, M.S.; Zhu, J.W.; Li, J.D.; Huang, M.Q.; Du, Z.Z. Microstructure and properties of ultra-fine grain Cu–Cr alloy prepared by equal-channel angular pressing. Mater. Sci. Eng. A 2007, 459, 303–308. [Google Scholar] [CrossRef]

- Watanabe, C.; Monzen, R.; Tazaki, K. Mechanical properties of Cu–Cr system alloys with and without Zr and Ag. J. Mater. Sci. 2008, 43, 813–819. [Google Scholar] [CrossRef] [Green Version]

- Takata, N.; Lee, S.H.; Tsuji, N. Ultrafine grained copper alloy sheets having both high strength and high electric conductivity. Mater. Let. 2009, 63, 1757–1760. [Google Scholar] [CrossRef]

- Akita, T.; Kitagawa, K.; Kita, K.; Gotoh, M.; Hirose, Y.; Tsuji, N. High performance of mechanical and electrical properties of Cu-Cr-Zr alloy sheets produced by ARB process and additional thermo-mechanical treatment. J. Phys. Conf. Ser. 2010, 240, 012119. [Google Scholar] [CrossRef]

- Habibi, A.; Ketabchi, M.; Eskandarzadeh, M. Nanograined pure copper with high-strength and high-conductivity produced via equal channel angular rolling process. J. Mater. Processing Technol. 2011, 211, 1085–1090. [Google Scholar] [CrossRef]

- Wei, K.X.; Wei, W.; Wang, F.; Du, Q.B.; Alexandrov, I.V.; Hu, J. Microstructure, mechanical properties and electrical conductivity of industrial Cu–0.5% Cr alloy processed by severe plastic deformation. Mater. Sci. Eng. A 2011, 528, 1478–1484. [Google Scholar] [CrossRef]

- Higuera-Cobos, O.F.; Cabrera, J.M. Mechanical, microstructural and electrical evolution of commercially pure copper processed by equal channel angular extrusion. Mater. Sci. Eng. A 2013, 571, 103–114. [Google Scholar] [CrossRef]

- Zel’dovich, V.I.; Dobatkin, S.V.; Frolova, N.Y.; Khomskaya, I.V.; Kheifets, A.E.; Shorokhov, E.V.; Nasonov, P.A. Mechanical properties and the structure of chromium–zirconium bronze after dynamic channel-angular pressing and subsequent aging. Phys. Met. Metallogr. 2016, 117, 74–82. [Google Scholar] [CrossRef]

- Saray, O. Biaxial deformation behavior and formability of precipitation hardened ultra-fine grained (UFG) Cu–Cr–Zr alloy. Mater. Sci. Eng. A 2016, 656, 120–129. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Jiang, Y.; Zhang, Y.; Zhou, Z.; Lei, Q. The microstructure evolution and properties of a Cu–Cr–Ag alloy during thermal-mechanical treatment. J. Mater. Res. 2017, 32, 1324–1332. [Google Scholar] [CrossRef]

- Khomskaya, I.V.; Zel’Dovich, V.I.; Shorokhov, E.V.; Frolova, N.Y.; Kheifets, A.E.; Dyakina, V.P. Effect of high-rate deformation on the structure, the properties, and the thermal stability of copper alloyed with chromium and zirconium. Russ. Metall. 2017, 2017, 851–857. [Google Scholar] [CrossRef]

- Chenna Krishna, S.; Karthick, N.K.; Sudarshan Rao, G.; Jha, A.K.; Pant, B.; Cherian, R.M. High strength, utilizable ductility and electrical conductivity in cold rolled sheets of Cu-Cr-Zr-Ti alloy. J. Mater. Eng. Perform. 2018, 27, 787–793. [Google Scholar] [CrossRef]

- Purcek, G.; Yanar, H.A.R.U.N.; Shangina, D.V.; Demirtas, M.; Bochvar, N.R.; Dobatkin, S.V. Influence of high pressure torsion-induced grain refinement and subsequent aging on tribological properties of Cu-Cr-Zr alloy. J. Alloys Compd. 2018, 742, 325–333. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bodyakova, A.; Tkachev, M.; Raab, G.I.; Kaibyshev, R.; Belyakov, A.N. Regularities of Microstructure Evolution in a Cu-Cr-Zr Alloy during Severe Plastic Deformation. Materials 2022, 15, 5745. https://doi.org/10.3390/ma15165745

Bodyakova A, Tkachev M, Raab GI, Kaibyshev R, Belyakov AN. Regularities of Microstructure Evolution in a Cu-Cr-Zr Alloy during Severe Plastic Deformation. Materials. 2022; 15(16):5745. https://doi.org/10.3390/ma15165745

Chicago/Turabian StyleBodyakova, Anna, Maksim Tkachev, Georgy I. Raab, Rustam Kaibyshev, and Andrey N. Belyakov. 2022. "Regularities of Microstructure Evolution in a Cu-Cr-Zr Alloy during Severe Plastic Deformation" Materials 15, no. 16: 5745. https://doi.org/10.3390/ma15165745

APA StyleBodyakova, A., Tkachev, M., Raab, G. I., Kaibyshev, R., & Belyakov, A. N. (2022). Regularities of Microstructure Evolution in a Cu-Cr-Zr Alloy during Severe Plastic Deformation. Materials, 15(16), 5745. https://doi.org/10.3390/ma15165745