Effects of the Replacement of Pork Backfat with High Oleic Sunflower Oil on the Quality of the “Chorizo Zamorano” Dry Fermented Sausage

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and the Production Process

2.2. Instrumental Color and Texture

2.3. Physicochemical Analysis

2.4. Fatty Acid Composition

2.5. Sensory Analysis

2.6. Statistical Analysis

3. Results and Discussion

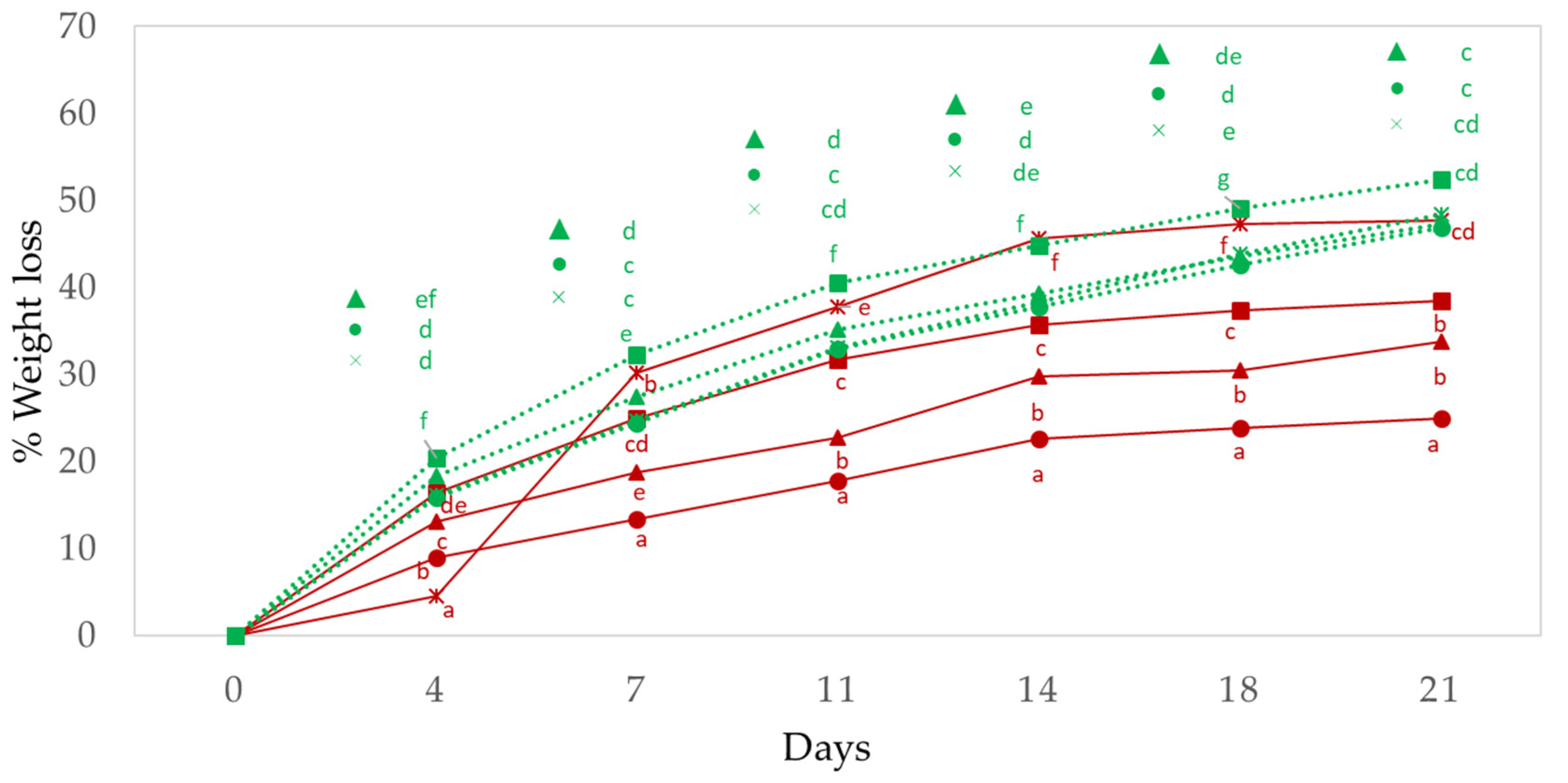

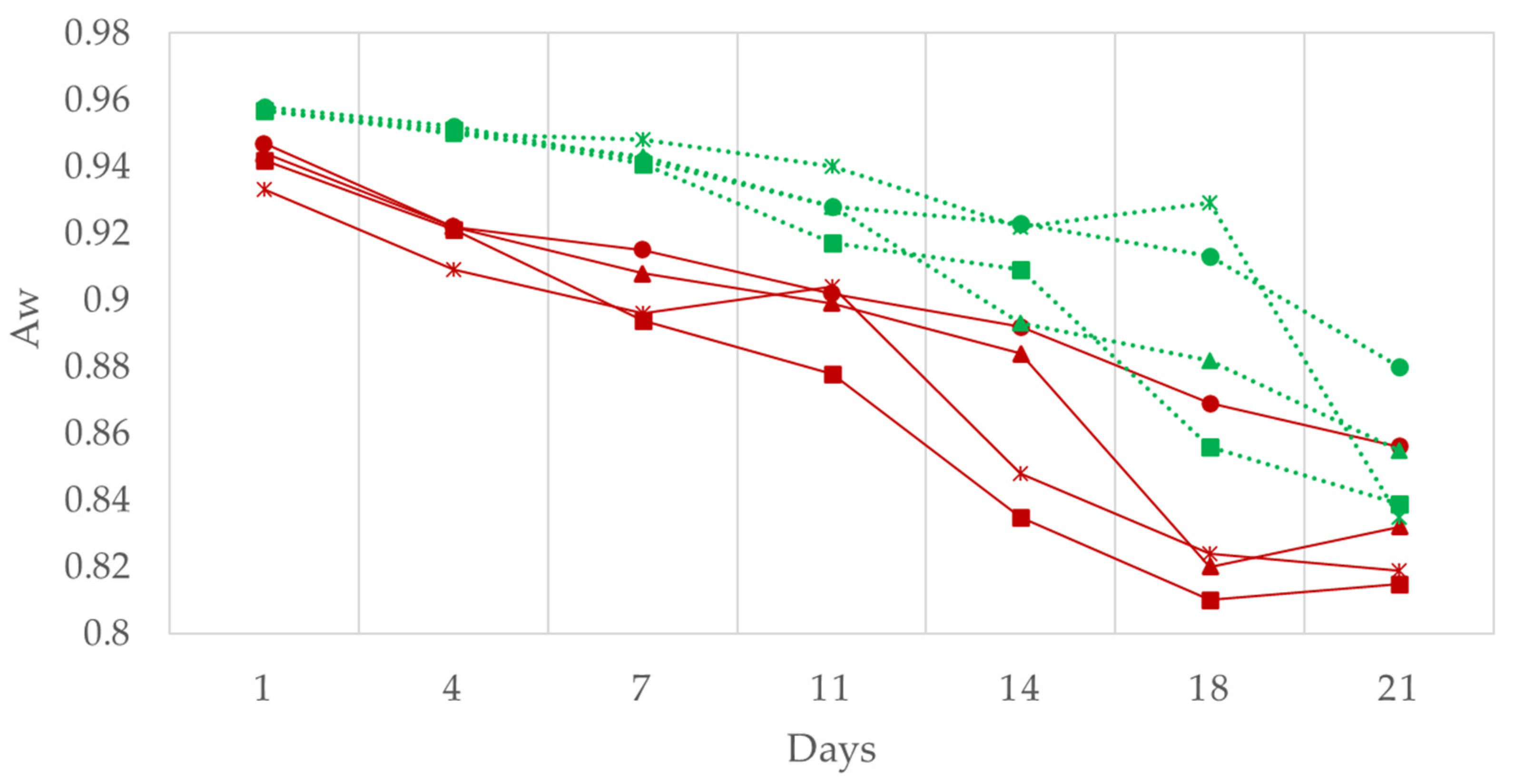

3.1. Physico-Chemical Parameters

3.2. Color and Instrumental Texture

3.3. Fatty Acid Composition

3.4. Sensory Profile

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muguerza, E.; Gimeno, O.; Ansorena, D.; Bloukas, J.G.; Astiasarán, I. Effect of Replacing Pork Backfat with Pre-Emulsified Olive Oil on Lipid Fraction and Sensory Quality of Chorizo de Pamplona—A Traditional Spanish Fermented Sausage. Meat Sci. 2001, 59, 251–258. [Google Scholar] [CrossRef]

- Revilla, I.; Vivar Quintana, A.M. The Effect of Different Paprika Types on the Ripening Process and Quality of Dry Sausages. Int. J. Food Sci. Technol. 2005, 40, 411–417. [Google Scholar] [CrossRef]

- Mendoza, E.; García, M.L.; Casas, C.; Selgas, M.D. Inulin as Fat Substitute in Low Fat, Dry Fermented Sausages. Meat Sci. 2001, 57, 387–393. [Google Scholar] [CrossRef]

- Wirth, F. Technologies for Making Fat-Reduced Meat Products. Fleischwirtschaft 1988, 68, 1153. [Google Scholar]

- Byrne, D.V.; Bredie, W.L.P.; Bak, L.S.; Bertelsen, G.; Martens, H.; Martens, M. Sensory and Chemical Analysis of Cooked Porcine Meat Patties in Relation to Warmed-over Flavour and Pre-Slaughter Stress. Meat Sci. 2001, 59, 229–249. [Google Scholar] [CrossRef]

- Rodríguez-Carpena, J.G.; Morcuende, D.; Estévez, M. Avocado, Sunflower and Olive Oils as Replacers of Pork Back-Fat in Burger Patties: Effect on Lipid Composition, Oxidative Stability and Quality Traits. Meat Sci. 2012, 90, 106–115. [Google Scholar] [CrossRef]

- Utrilla, M.C.; García Ruiz, A.; Soriano, A. Effect of Partial Reduction of Pork Meat on the Physicochemical and Sensory Quality of Dry Ripened Sausages: Development of a Healthy Venison Salchichon. Meat Sci. 2014, 98, 785–791. [Google Scholar] [CrossRef]

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasaran, I.; Bloukas, J.G. Effect of Fat Level and Partial Replacement of Pork Backfat with Olive Oil on Processing and Quality Characteristics of Fermented Sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Beiloune, F.; Bolumar, T.; Toepfl, S.; Heinz, V. Fat Reduction and Replacement by Olive Oil in Bologna Type Cooked Sausage. Quality and Nutritional Aspects. Food Nutr. Sci. 2014, 5, 44062. [Google Scholar] [CrossRef][Green Version]

- Revilla, I.; Santos, S.; Hernández-Jiménez, M.; Vivar-Quintana, A.M. The Effects of the Progressive Replacement of Meat with Texturized Pea Protein in Low-Fat Frankfurters Made with Olive Oil. Foods 2022, 11, 923. [Google Scholar] [CrossRef]

- Wang, X.; Xie, Y.; Li, X.; Liu, Y.; Yan, W. Effects of Partial Replacement of Pork Back Fat by a Camellia Oil Gel on Certain Quality Characteristics of a Cooked Style Harbin Sausage. Meat Sci. 2018, 146, 154–159. [Google Scholar] [CrossRef]

- Kılıç, B.; Özer, C.O. Effects of Replacement of Beef Fat with Interesterified Palm Kernel Oil on the Quality Characteristics of Turkish Dry-Fermented Sausage. Meat Sci. 2017, 131, 18–24. [Google Scholar] [CrossRef]

- Baek, K.H.; Utama, D.T.; Lee, S.G.; An, B.K.; Lee, S.K. Effects of Replacing Pork Back Fat with Canola and Flaxseed Oils on Physicochemical Properties of Emulsion Sausages from Spent Layer Meat. Asian-Australas. J. Anim. Sci. 2016, 29, 865–871. [Google Scholar] [CrossRef] [PubMed]

- Câmara, A.K.F.I.; Pollonio, M.A.R. Reducing Animal Fat in Bologna Sausage Using Pre-Emulsified Linseed Oil: Technological and Sensory Properties. J. Food Qual. 2015, 38, 201–212. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Cerqueira, M.A.; Purriños, L.; Pastrana, L.M.; Vicente, A.A.; Zapata, C.; Lorenzo, J.M. Evaluation of Linseed Oil Oleogels to Partially Replace Pork Backfat in Fermented Sausages. J. Sci. Food Agric. 2020, 100, 218–224. [Google Scholar] [CrossRef]

- Pires, M.A.; Rodrigues, I.; Barros, J.C.; Carnauba, G.; de Carvalho, F.A.; Trindade, M.A. Partial Replacement of Pork Fat by Echium Oil in Reduced Sodium Bologna Sausages: Technological, Nutritional and Stability Implications. J. Sci. Food Agric. 2020, 100, 410–420. [Google Scholar] [CrossRef] [PubMed]

- Panagiotopoulou, E.; Moschakis, T.; Katsanidis, E. Sunflower Oil Organogels and Organogel-in-Water Emulsions (Part II): Implementation in Frankfurter Sausages. LWT 2016, 73, 351–356. [Google Scholar] [CrossRef]

- Kouzounis, D.; Lazaridou, A.; Katsanidis, E. Partial Replacement of Animal Fat by Oleogels Structured with Monoglycerides and Phytosterols in Frankfurter Sausages. Meat Sci. 2017, 130, 38–46. [Google Scholar] [CrossRef] [PubMed]

- da Silva, S.L.; Amaral, J.T.; Ribeiro, M.; Sebastião, E.E.; Vargas, C.; de Lima Franzen, F.; Schneider, G.; Lorenzo, J.M.; Fries, L.L.M.; Cichoski, A.J.; et al. Fat Replacement by Oleogel Rich in Oleic Acid and Its Impact on the Technological, Nutritional, Oxidative, and Sensory Properties of Bologna-Type Sausages. Meat Sci. 2019, 149, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Mora-Gallego, H.; Serra, X.; Guàrdia, M.D.; Arnau, J. Effect of Reducing and Replacing Pork Fat on the Physicochemical, Instrumental and Sensory Characteristics throughout Storage Time of Small Caliber Non-Acid Fermented Sausages with Reduced Sodium Content. Meat Sci. 2014, 97, 62–68. [Google Scholar] [CrossRef] [PubMed]

- Kılıç, B.; Özer, C.O. Potential Use of Interesterified Palm Kernel Oil to Replace Animal Fat in Frankfurters. Meat Sci. 2019, 148, 206–212. [Google Scholar] [CrossRef]

- Alejandre, M.; Astiasarán, I.; Ansorena, D.; Barbut, S. Using Canola Oil Hydrogels and Organogels to Reduce Saturated Animal Fat in Meat Batters. Food Res. Int. 2019, 122, 129–136. [Google Scholar] [CrossRef] [PubMed]

- López-Pedrouso, M.; Lorenzo, J.M.; Gullón, B.; Campagnol, P.C.B.; Franco, D. Novel Strategy for Developing Healthy Meat Products Replacing Saturated Fat with Oleogels. Curr. Opin. Food Sci. 2021, 40, 40–45. [Google Scholar] [CrossRef]

- Smith, S.A.; King, R.E.; Min, D.B. Oxidative and Thermal Stabilities of Genetically Modified High Oleic Sunflower Oil. Food Chem. 2007, 102, 1208–1213. [Google Scholar] [CrossRef]

- Aranda, F.; Gómez-Alonso, S.; Rivera del Álamo, R.M.; Salvador, M.D.; Fregapane, G. Triglyceride, Total and 2-Position Fatty Acid Composition of Cornicabra Virgin Olive Oil: Comparison with Other Spanish Cultivars. Food Chem. 2004, 86, 485–492. [Google Scholar] [CrossRef]

- González Fernández, M.C.; Santos, E.M.; Jaime, I.; Rovira, J. Utilización de cultivos iniciadores en la elaboración de chorizo y su influencia en las propiedades sensoriales. Food Sci. Technol. Int. 1997, 3, 31–42. [Google Scholar] [CrossRef]

- Determination of PH, ISO 2917-1974; International Standard Meat and Meat Products. Determination of the PH. International Organization for Standardisation (ISO): Geneva, Switzerland, 1974.

- Determination of Moisture Content, ISO 1442-1973; International Standard Meat and Meat Products. Determination of Moisture Content. International Organization for Standardisation (ISO): Geneva, Switzerland, 1973.

- Determination of Nitrate Content, ISO 2918-1975; International Standard Meat and Meat Products. Determination of Nitrite Content. International Organization for Standardisation (ISO): Geneva, Switzerland, 1975.

- Determination of Total Fat Content, ISO 1443-1973; International Standards Meat and Meat Products. International Organisatin for Standardisation (ISO): Geneva, Switzerland, 1973.

- Buege, J.A.; Aust, S.D. Microsomal Lipid Peroxidation. In Methods in Enzymology; Biomembranes—Part C: Biological Oxidations; Fleischer, S., Packer, L., Eds.; Academic Press: Cambridge, MA, USA, 1978; Volume 52, pp. 302–310. [Google Scholar]

- Lurueña-Martínez, M.A.; Palacios, C.; Vivar-Quintana, A.M.; Revilla, I. Effect of the Addition of Calcium Soap to Ewes’ Diet on Fatty Acid Composition of Ewe Milk and Subcutaneous Fat of Suckling Lambs Reared on Ewe Milk. Meat Sci. 2010, 84, 677–683. [Google Scholar] [CrossRef]

- Folch, J.; Lees, M.; Sloane Stanley, G.H. A Simple Method for the Isolation and Purification of Total Lipids from Animal Tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Sensory Analysis, ISO 8586-1; General Guidance for the Selection, Training and Monitoring of Assessors—Part 1: Selected Assessors. International Organisatin for Standardisation (ISO): Geneva, Switzerland, 1993.

- Bloukas, J.G.; Paneras, E.D.; Fournitzis, G.C. Effect of Replacing Pork Backfat with Olive Oil on Processing and Quality Characteristics of Fermented Sausages. Meat Sci. 1997, 45, 133–144. [Google Scholar] [CrossRef]

- Serra, X.; Arnau Arboix, J.; Mora, H. Sustitutos de la grasa en productos cárnicos crudos curados. Eurocarne Rev. Int. Sect. Cárnico 2009, 180, 79–90. [Google Scholar]

- Gimeno, O.; Ansorena, D.; Astiasarán, I.; Bello, J. Characterization of Chorizo de Pamplona: Instrumental Measurements of Colour and Texture. Food Chem. 2000, 69, 195–200. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Serra, X.; Guàrdia, M.D.; Miklos, R.; Lametsch, R.; Arnau, J. Effect of the Type of Fat on the Physicochemical, Instrumental and Sensory Characteristics of Reduced Fat Non-Acid Fermented Sausages. Meat Sci. 2013, 93, 668–674. [Google Scholar] [CrossRef] [PubMed]

- Roseiro, L.C.; Santos, C.; Sol, M.; Borges, M.J.; Anjos, M.; Gonçalves, H.; Carvalho, A.S. Proteolysis in Painho de Portalegre Dry Fermented Sausage in Relation to Ripening Time and Salt Content. Meat Sci. 2008, 79, 784–794. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Alvarez, J.A.; Sayas-Barberá, M.E.; Fernández-López, J.; Aranda-Catalá, V. Physicochemical Characteristics of Spanish-Type Dry-Cured Sausage. Food Res. Int. 1999, 32, 599–607. [Google Scholar] [CrossRef]

- Dainty, R.; Blom, H. Flavour Chemistry of Fermented Sausages. In Fermented Meats; Campbell-Platt, G., Cook, P.E., Eds.; Springer: Boston, MA, USA, 1995; pp. 176–193. ISBN 978-1-4615-2163-1. [Google Scholar]

- Muguerza, E.; Ansorena, D.; Astiasarán, I. Improvement of Nutritional Properties of Chorizo de Pamplona by Replacement of Pork Backfat with Soy Oil. Meat Sci. 2003, 65, 1361–1367. [Google Scholar] [CrossRef]

- Fernández-López, J.; Zhi, N.; Aleson-Carbonell, L.; Pérez-Alvarez, J.A.; Kuri, V. Antioxidant and Antibacterial Activities of Natural Extracts: Application in Beef Meatballs. Meat Sci. 2005, 69, 371–380. [Google Scholar] [CrossRef]

- Gómez, R.; Alvarez-Orti, M.; Pardo, J.E. Influence of the Paprika Type on Redness Loss in Red Line Meat Products. Meat Sci. 2008, 80, 823–828. [Google Scholar] [CrossRef]

- Fernández-López, J.; Pérez-Alvarez, J.A.; Sayas-Barberá, E.; López-Santoveña, F. Effect of Paprika (Capsicum annum) on Color of Spanish-Type Sausages during the Resting Stage. J. Food Sci. 2002, 67, 2410–2414. [Google Scholar] [CrossRef]

- Soto, E.; Hoz, L.; Ordóñez, J.A.; Hierro, E.; Herranz, B.; López-Bote, C.; Cambero, M.I. Impact of Feeding and Rearing Systems of Iberian Pigs on Volatile Profile and Sensory Characteristics of Dry-Cured Loin. Meat Sci. 2008, 79, 666–676. [Google Scholar] [CrossRef]

- Klettner, P.; Rodel, W. Bedeutung Der Temperatur Bei Der Rohwurstreifung. Fleischerei 1979, 30, 907–908. [Google Scholar]

- Flagella, Z.; Rotunno, T.; Tarantino, E.; Di Caterina, R.; De Caro, A. Changes in Seed Yield and Oil Fatty Acid Composition of High Oleic Sunflower (Helianthus annuus L.) Hybrids in Relation to the Sowing Date and the Water Regime. Eur. J. Agron. 2002, 17, 221–230. [Google Scholar] [CrossRef]

| Traditional | Reduced Fat | |||||||

|---|---|---|---|---|---|---|---|---|

| Ingredients | Control | 12.5% | 20% | 50% | Control | 12.5% | 20% | 50% |

| Lean pork | 50 | 50 | 50 | 50 | 70 | 70 | 70 | 70 |

| Pork backfat | 50 | 43.75 | 40 | 25 | 30 | 26.25 | 24 | 15 |

| High oleic sunflower oil | 0 | 6.25 | 10 | 25 | 0 | 3.75 | 6 | 15 |

| Traditional | Reduced Fat | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 12.5% | 20% | 50% | SEM | Control | 12.5% | 20% | 50% | SEM | |

| Weight losses (%) | 38.41 ± 0.49 b | 33.82 ± 0.18 c | 24.94 ± 0.32 d | 47.75 ± 0.97 a | 0.62 | 52.4 ± 0.62 | 47.2 ± 3.34 | 46.9 ± 0.21 | 48.3 ± 0.13 | 0.94 |

| pH | 5.28 ± 0.02 | 5.28 ± 0.05 | 5.28 ± 0.03 | 5.18 ± 0.02 | 0.03 | 5.28 ± 0.02 b | 5.15 ± 0.04 a | 5.20 ± 0.03 a | 5.20 ± 0.06 a | 0.01 |

| aw | 0.821 ± 0.009 a | 0.832 ± 0.005 a,b | 0.863 ± 0.001 b | 0.820 ± 0.006 a | 0.01 | 0.839 ± 0.002 a | 0.855 ± 0.001 b | 0.880 ± 0.002 c | 0.835 ± 0.001 a | 0.01 |

| Moisture (%) | 30.23 ± 0.28 | 29.84 ± 1.23 | 29.34 ± 0.12 | 28.98 ± 0.51 | 0.35 | 29.01 ± 1.13 a | 29.8 ± 0.05 a,b | 32.4 ± 0.14 b | 31.0 ± 0.64 a,b | 0.49 |

| Total fat (%) | 31.38 ± 0.94 b | 30.45 ± 0.14 b | 28.82 ± 0.34 a,b | 25.45 ± 0.18 a | 0.04 | 21.82 ± 1.01 b,c | 19.7 ± 0.08 b | 22.75 ± 0.22 c | 16.19 ± 0.51 a | 0.96 |

| TBARS (mg MD/kg) | 0.0014 ± 0.0002 b | 0.0003 ± 0.0000 a,b | 0.0003 ± 0.0001 a,b | 0.0000 ± 0.0000 a | 0.00 | 0.05 ± 0.001 a | 0.06 ± 0.001 b | 0.05 ± 0.001 c | 0.06 ± 0.001 d | 0.0001 |

| Traditional | Reduced Fat | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 12.5% | 20% | 50% | SEM | Control | 12.5% | 20% | 50% | SEM | |

| Lightness (L*) | 37.99 ± 1.23 | 38.43 ± 0.27 | 38.54 ± 0.15 | 37.17 ± 1.21 | 0.46 | 31.73 ± 0.61 | 33.33 ± 0.37 | 35.27 ± 1.50 | 33.01 ± 0.44 | 0.53 |

| Redness (a*) | 26.29 ± 0.11 | 27.21 ± 0.71 | 27.79 ± 0.95 | 26.19 ± 0.34 | 0.54 | 21.04 ± 0.88 a,b | 22.98 ± 0.41 b | 22.6 ± 1.44 a,b | 19.13 ± 0.00 a | 0.62 |

| Yellowness (b*) | 26.26 ± 0.21 a | 27.73 ± 0.86 a,b | 28.26 ± 0.54 b | 27.83 ± 0.11 a,b | 0.39 | 18.27 ± 2.06 | 21.62 ± 0.11 | 22.16 ± 2.04 | 17.44 ± 0.53 | 0.87 |

| Control | 12.5% | 20% | 50% | SEM | Control | 12.5% | 20% | 50% | SEM | |

| Hardness (g) | 4894.86 ± 0.03 c | 4513.09 ± 0.03 b | 4353.36 ± 0.03 b | 3289.74 ± 0.03 a | 425.39 | 8838.19 ± 1832.03 | 8053.21 ± 1628.92 | 6275.67 ± 2390.35 | 5191.86 ± 1539.25 | 657.32 |

| Adhesiveness (g s) | 18.05 ± 10.73 a | 15.08 ± 703 a | 13.09 ± 5.14 a | 5.40 ± 6.24 b | 3.58 | 20.66 ± 12.93 | 27.81 ± 10.78 | 29.73 ± 24.63 | 20.21 ± 18.27 | 5.04 |

| Springiness (mm) | 0.61 ± 0.03 | 0.53 ± 0.00 | 0.56 ± 0.01 | 0.66 ± 0.05 | 0.02 | 0.62 ± 0.05 | 0.56 ± 0.04 | 0.52 ± 0.03 | 0.57 ± 0.05 | 0.01 |

| Gumminess (g) | 2335.81 ± 984.52 c | 2286.48 ± 498.57 c | 2114.61 ± 1205.30 b | 1368.04 ± 745.03 a | 242.48 | 3955.83 ± 1232.08 | 4286.39 ± 1145.62 | 3276.68 ± 1510.75 | 5820.70 ± 694.26 | 381.44 |

| Chewiness (g mm) | 1660.76 ± 269.33 c | 1588.24 ± 689.15 c | 1476.12 ± 575.23 b | 1308.21 ± 328.32 a | 174.25 | 2441.50 ± 568.29 | 2435.39 ± 777.04 | 1717.52 ± 872.84 | 1694.89 ± 218.47 | 234.49 |

| Cohesiveness (g) | 0.51 ± 0.03 | 0.56 ± 0.01 | 0.60 ± 0.02 | 0.56 ± 0.04 | 0.01 | 0.40 ± 0.02 | 0.48 ± 0.03 | 0.45 ± 0.04 | 0.42 ± 0.03 | 0.01 |

| Traditional | Reduced Fat | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 12.5% | 20% | 50% | SEM | Control | 12.5% | 20% | 50% | SEM | |

| C11:0 | 9.17 ± 0.08 | 0.15 ± 0.15 | 0.13 ± 0.04 | 0.11 ± 0.00 | 0.02 | 0.40 ± 0.17 | 0.32 ± 0.05 | 0.45 ± 0.12 | 0.17 ± 0.04 | 0.05 |

| C12:0 | 0.10 ± 0.18 b | 0.06 ± 0.30 a,b | 0.03 ± 0.04 a,b | 0.00 ± 0.00 a | 0.01 | 0.21 ± 0.04 | 0.24 ± 006 | 0.06 ± 0.01 | 0.16 ± 0.05 | 0.03 |

| C14:0 | 1.97 ± 0.36 | 1.86 ± 0.27 | 1.63 ± 0.19 | 1.34 ± 0.01 | 0.41 | 3.07 ± 1.06 | 2.66 ± 0.58 | 3.48 ± 0.77 | 1.72 ± 0.40 | 0.32 |

| C14:1 | 0.15 ± 0.25 | 0.82 ± 0.00 | 0.12 ± 0.07 | 0.06 ± 0.00 | 0.02 | 0.25 ± 0.09 b | 0.22 ± 0.02 a,b | 0.06 ± 0.01 a | 0.20 ± 0.00 a,b | 0.03 |

| C:15:0 | 0.13 ± 0.12 | 0.10 ±0.10 | 0.07 ± 0.07 | 0.11 ± 0.02 | 0.04 | 0.16 ± 0.05 | 0.22 ± 0.09 | 0.10 ± 0.01 | 0.00 ± 0.00 | 0.03 |

| C16:0 | 28.91 ± 2.29 c | 27.19 ± 2.78 c | 23.42 ± 2.08 b | 20.1 ± 0.18 a | 0.82 | 26.46 ± 0.72 b | 27.01 ± 0.47 b | 25.52 ± 0.62 b | 22.08 ± 0.78 a | 0.75 |

| C16:1 | 2.33 ± 1.75 | 1.58 ± 1.62 | 0.35 ± 0.04 | 0.31 ± 0.00 | 0.28 | 3.81 ± 0.77 | 3.09 ± 0.71 | 4.08 ± 0.74 | 2.32 ± 0.33 | 0.31 |

| C17:0 | 0.35 ± 0.02 | 0.34 ± 0.01 | 0.46 ± 0.09 | 0.39 ± 0.00 | 0.05 | 0.41 ± 0.01 | 0.35 ± 0.18 | 0.31 ± 0.06 | 0.25 ± 0.11 | 0.04 |

| C17:1 | 0.24 ± 0.01 | 0.26 ± 0.02 | 0.25 ± 0.06 | 0.26 ± 0.00 | 0.02 | 0.42 ± 0.18 | 0.24 ± 0.06 | 0.34 ± 0.06 | 0.25 ± 0.11 | 0.04 |

| C18:0 | 11.45 ± 0.32 | 11.54 ± 0.19 | 12.54 ± 0.73 | 10.78 ± 0.31 | 0.84 | 10.10 ± 2.84 | 12.92 ± 1.44 | 7.47 ± 2.50 | 11.51 ± 0.18 | 0.93 |

| C18:1t | 0.39 ± 0.15 b | 0.05 ±0.06 a | 0.48 ± 0.04 b | 0.40 ± 0.00 b | 0.52 | 1.29 ± 1.41 | 0.20 ± 0.00 | 0.12 ± 0.00 | 0.11 ± 0.00 | 0.40 |

| C18:1 | 36.87 ± 2.69 a | 40.46 ± 5.54 a,b | 43.46 ± 1.56 b | 48.74 ± 0.37c | 1.49 | 37.25 ± 3.27 a | 38.76 ± 1.95 a,b | 40.05 ± 2.68 a,b | 47.77 ± 1.22 b | 1.66 |

| C18:2 (ω6) | 11.56 ± 1.04 | 11.19 ± 0.22 | 10.11 ± 0.80 | 11.19 ± 0.29 | 0.82 | 13.37 ± 1.79 | 10.95 ± 0.03 | 15.29 ± 2.11 | 11.87 ± 0.40 | 0.72 |

| C18:3 (ω3) | 0.50 ± 0.15 b | 0.57 ± 0.03 b | 0.56 ± 0.06 b | 0.48 ± 0.00 a | 0.12 | 1.11 ± 0.29 | 0.30 ± 0.11 | 1.25 ± 0.33 | 0.74 ± 0.16 | 0.15 |

| C20:3 (ω6) | 0.10 ± 0.02 | 0.07 ± 0.00 | 0.13 ± 0.10 | 0.07 ± 0.00 | 0.01 | 0.36 ± 0.05 | 0.29 ± 0.09 | 0.21 ± 0.08 | 0.23 ± 0.13 | 0.03 |

| C23:0 | 0.00 ± 0.00 a | 0.00 ± 0.00 a | 0.05 ±0.03 b | 0.03 ± 0.00 b | 0.06 | 0.16 ± 0.04 a,b | 0.21ab ± 0.04 | 0.42b ± 0.07 | 0.08 ± 0.00 a | 0.05 |

| ΣSFA | 43.55 ± 1.56 c | 41.79 ± 0.54 b,c | 37.42 ± 0.36 b | 33.49 ± 1.14 a | 1.12 | 41.59 ± 1.98 b | 44.99c ± 0.23 c | 38.60 ± 0.32 a,b | 36.58 ± 0.66 a | 1.23 |

| ΣMUFA | 42.88 ± 0.73 a | 45.18 ± 1.24 b | 50.40 ± 0.66 c | 53.27 ± 2.01 c,d | 1.32 | 43.03 ± 0.83 a | 42.50 ± 1.59 a | 44.65 ± 2.05 a,b | 50.59 ± 1.09 b | 1.28 |

| ΣPUFA | 13.32 ± 2.31 | 12.86 ± 1.63 | 11.92 ± 0.57 | 12.88 ± 1.89 | 0.93 | 15.34 ± 2.74 | 12.52 ± 1.36 | 16.76 ± 2.36 | 12.84 ± 0.44 | 0.84 |

| Traditional | Reduced Fat | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 12.5% | 20% | 50% | SEM | Control | 12.5% | 20% | 50% | SEM | |

| Easy to remove the casing | 3.75 ± 2.84 a | 7.60 ± 0.89 b | 8.30 ± 0.67 b | 9.00 ± 0.00 b | 0.25 | 6.00 ± 2.71 | 6.33 ± 1.51 | 7.71 ± 1.11 | 7.86 ± 1.46 | 0.37 |

| External defects | 1.60 ± 2.27 | 3.40 ± 2.79 | 2.40 ± 3.33 | 0.00 ± 0.00 | 0.48 | 4.33 ± 3.30 | 3.60 ± 1.82 | 3.50 ± 2.65 | 3.50 ± 2.54 | 0.53 |

| Color intensity | 7.00 ± 0.94 | 6.00 ± 1.22 | 5.70 ± 1.25 | 6.60 ± 1.95 | 0.23 | 7.00 ± 2.89 | 8.29 ± 0.49 | 7.00 ± 2.58 | 7.71 ± 0.79 | 0.37 |

| Meat mass binding | 6.20 ± 1.68 | 5.20 ± 1.64 | 4.90 ± 2.64 | 4.20 ± 2.16 | 0.41 | 5.43 ± 1.39 | 5.14 ± 2.12 | 4.57 ± 2.44 | 4.71 ± 1.78 | 0.36 |

| Clean cutting | 5.20 ± 2.48 | 4.60 ± 1.81 | 4.10 ± 1.96 | 3.40 ± 1.81 | 0.25 | 6.43 ± 1.14 | 6.43 ± 1.39 | 5.86 ± 1.57 | 5.86 ± 0.98 | 0.23 |

| Odor intensity | 5.80 ± 1.47 | 5.80 ± 0.83 | 5.90 ± 1.59 | 5.40 ± 1.81 | 0.39 | 7.14 ± 1.21 | 6.57 ± 1.72 | 5.64 ± 1.75 | 5.64 ± 1.59 | 0.31 |

| Rancid odor | 0.70 ± 1.56 | 1.40 ± 1.67 | 0.40 ± 0.96 | 0.20 ± 0.44 | 0.52 | 2.43 ± 3.86 | 0.71 ± 0.95 | 2.14 ± 3.33 | 0.57 ± 1.13 | 0.50 |

| Off-odor | 0.10 ± 0.31 | 0.80 ± 0.83 | 0.30 ± 0.67 | 0.20 ± 0.44 | 0.32 | 1.43 ± 2.94 | 1.50 ± 2.59 | 1.29 ± 2.98 | 1.21 ± 2.07 | 0.48 |

| Flavor intensity | 6.80 ± 0.78 | 6.20 ± 1.09 | 6.00 ± 1.33 | 7.20 ± 0.44 | 0.56 | 6.71 ± 2.16 | 6.57 ± 2.22 | 6.71 ± 1.88 | 5.86 ± 2.38 | 0.39 |

| Saltiness | 4.20 ± 2.14 | 4.80 ± 2.68 | 4.50 ± 2.54 | 5.60 ± 1.34 | 0.23 | 4.86 ± 2.73 | 2.00 ± 2.08 | 3.71 ± 2.69 | 1.79 ± 1.07 | 0.47 |

| Pungent | 5.30 ± 1.49 | 4.40 ± 2.88 | 4.80 ± 1.98 | 5.80 ± 1.78 | 0.33 | 8.29 ± 0.75 | 7.14 ± 1.57 | 6.57 ± 2.37 | 6.57 ± 1.88 | 0.33 |

| Rancidity | 0.70 ± 0.94 | 0.60 ± 0.89 | 0.80 ± 1.54 | 0.40 ± 0.54 | 0.28 | 1.86 ± 3.33 | 1.43 ± 2.50 | 1.14 ± 2.26 | 1.29 ± 3.40 | 0.52 |

| Off-flavor | 0.20 ± 0.42 | 2.00 ± 3.39 | 1.20 ± 2.48 | 0.80 ± 0.83 | 0.62 | 2.57 ± 3.65 | 1.43 ± 2.57 | 1.71 ± 3.40 | 1.29 ± 3.40 | 0.59 |

| Hardness | 4.00 ± 1.63 b | 2.60 ± 1.14 a,b | 1.50 ± 1.26 a | 2.20 ± 0.83 a,b | 0.29 | 6.86 ± 1.46 | 6.57 ± 0.98 | 6.29 ± 1.11 | 5.17 ± 1.21 | 0.25 |

| Chewiness | 3.80 ± 2.04 | 2.00 ± 1.41 | 2.40 ± 2.27 | 3.20 ± 3.27 | 0.21 | 5.71 ± 1.97 | 5.71 ± 1.38 | 6.14 ± 1.67 | 6.43 ± 1.57 | 0.30 |

| Juiciness | 4.40 ± 1.64 | 5.80 ± 1.64 | 5.00 ± 1.24 | 4.80 ± 1.78 | 0.34 | 3.86 ± 2.11 | 3.71 ± 1.70 | 4.71 ± 1.38 | 3.00 ± 2.38 | 0.36 |

| Fatness | 3.80 ± 1.31 | 4.00 ± 0.70 | 4.50 ± 1.58 | 4.00 ± 1.58 | 0.32 | 3.57 ± 0.97 | 3.36 ± 2.13 | 3.43 ± 0.97 | 3.14 ± 2.19 | 0.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Jiménez, M.; Martínez-Martín, I.; Vivar-Quintana, A.M.; Revilla, I. Effects of the Replacement of Pork Backfat with High Oleic Sunflower Oil on the Quality of the “Chorizo Zamorano” Dry Fermented Sausage. Foods 2022, 11, 2313. https://doi.org/10.3390/foods11152313

Hernández-Jiménez M, Martínez-Martín I, Vivar-Quintana AM, Revilla I. Effects of the Replacement of Pork Backfat with High Oleic Sunflower Oil on the Quality of the “Chorizo Zamorano” Dry Fermented Sausage. Foods. 2022; 11(15):2313. https://doi.org/10.3390/foods11152313

Chicago/Turabian StyleHernández-Jiménez, Miriam, Iván Martínez-Martín, Ana M. Vivar-Quintana, and Isabel Revilla. 2022. "Effects of the Replacement of Pork Backfat with High Oleic Sunflower Oil on the Quality of the “Chorizo Zamorano” Dry Fermented Sausage" Foods 11, no. 15: 2313. https://doi.org/10.3390/foods11152313

APA StyleHernández-Jiménez, M., Martínez-Martín, I., Vivar-Quintana, A. M., & Revilla, I. (2022). Effects of the Replacement of Pork Backfat with High Oleic Sunflower Oil on the Quality of the “Chorizo Zamorano” Dry Fermented Sausage. Foods, 11(15), 2313. https://doi.org/10.3390/foods11152313