Chitin and Chitosans: Characteristics, Eco-Friendly Processes, and Applications in Cosmetic Science

Abstract

1. Introduction

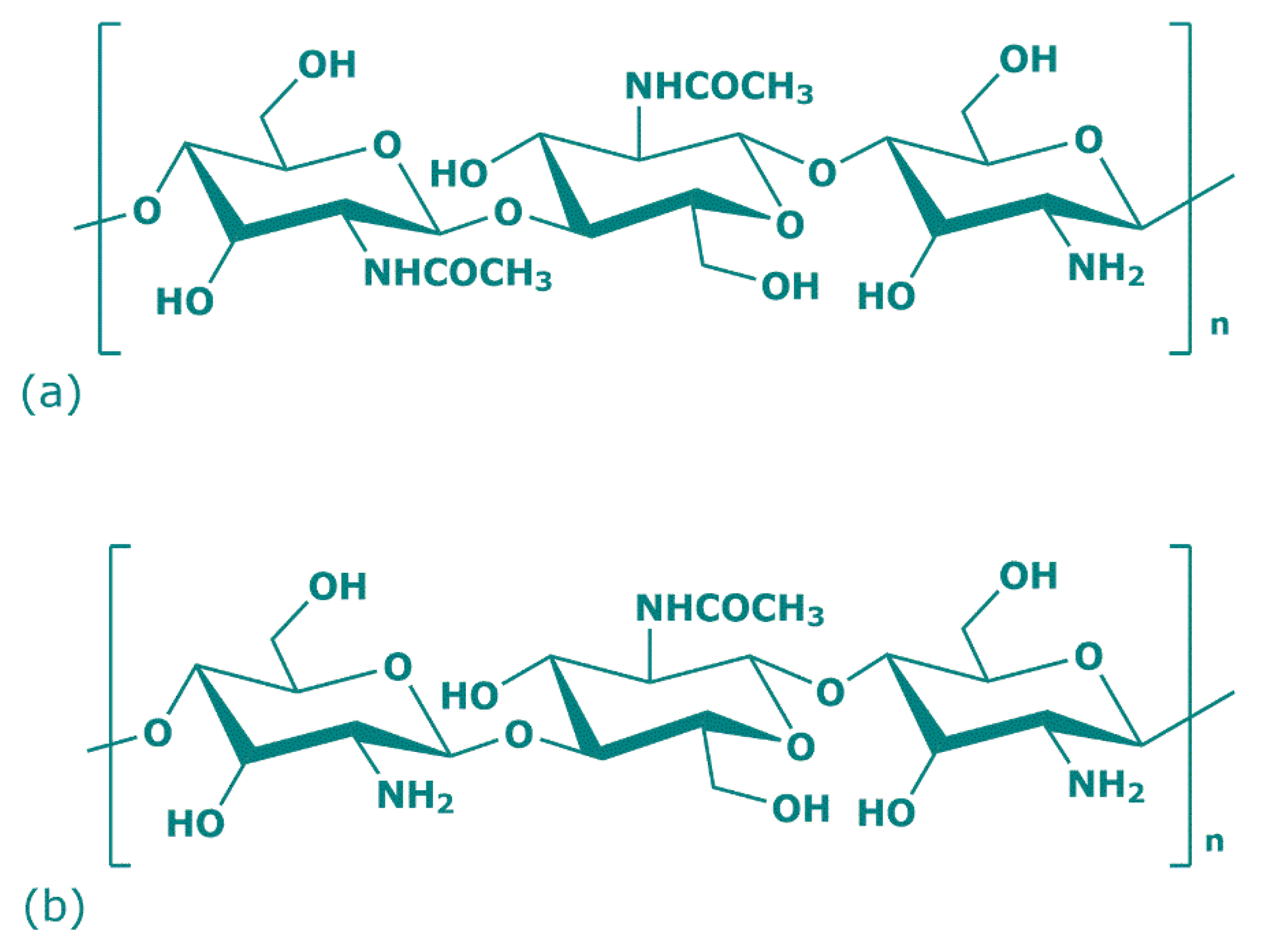

2. Chitin and Chitosans: Structure, Properties, and Applications

2.1. Physical and Chemical Characterization of Chitin and Chitosans

2.1.1. Degree of Deacetylation

(DD) = 97.67 − (26.486 (A1655/A3450))

2.1.2. Molecular Weight

2.1.3. Solubility

2.1.4. Derivatives

2.2. Chitin and Chitosans Biological Properties

2.2.1. Antimicrobial Activity

2.2.2. Antioxidant Activity

2.2.3. Mucoadhesive Properties

2.2.4. Penetration Enhancement Properties

2.3. Chitin and Chitosans General Applications

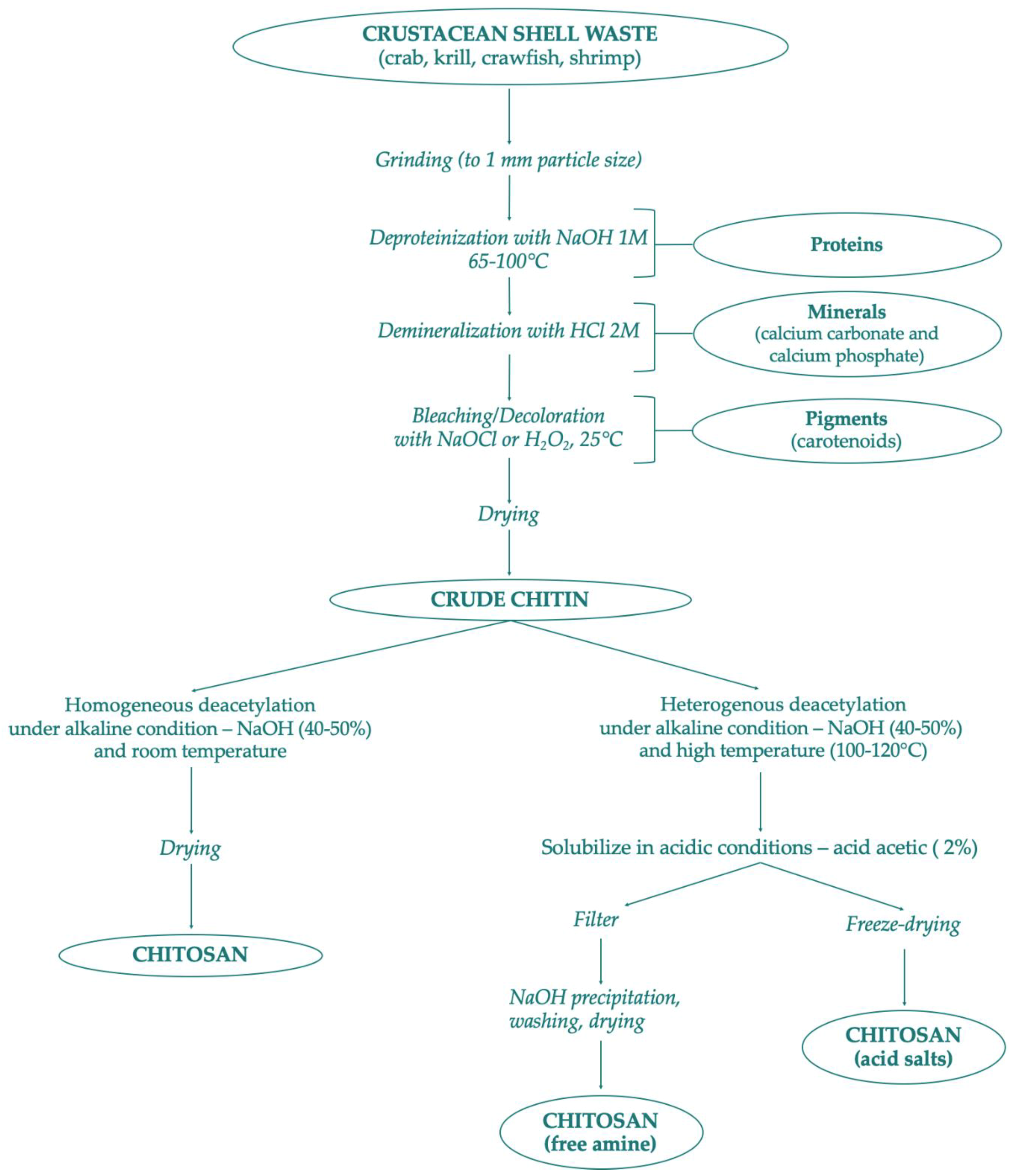

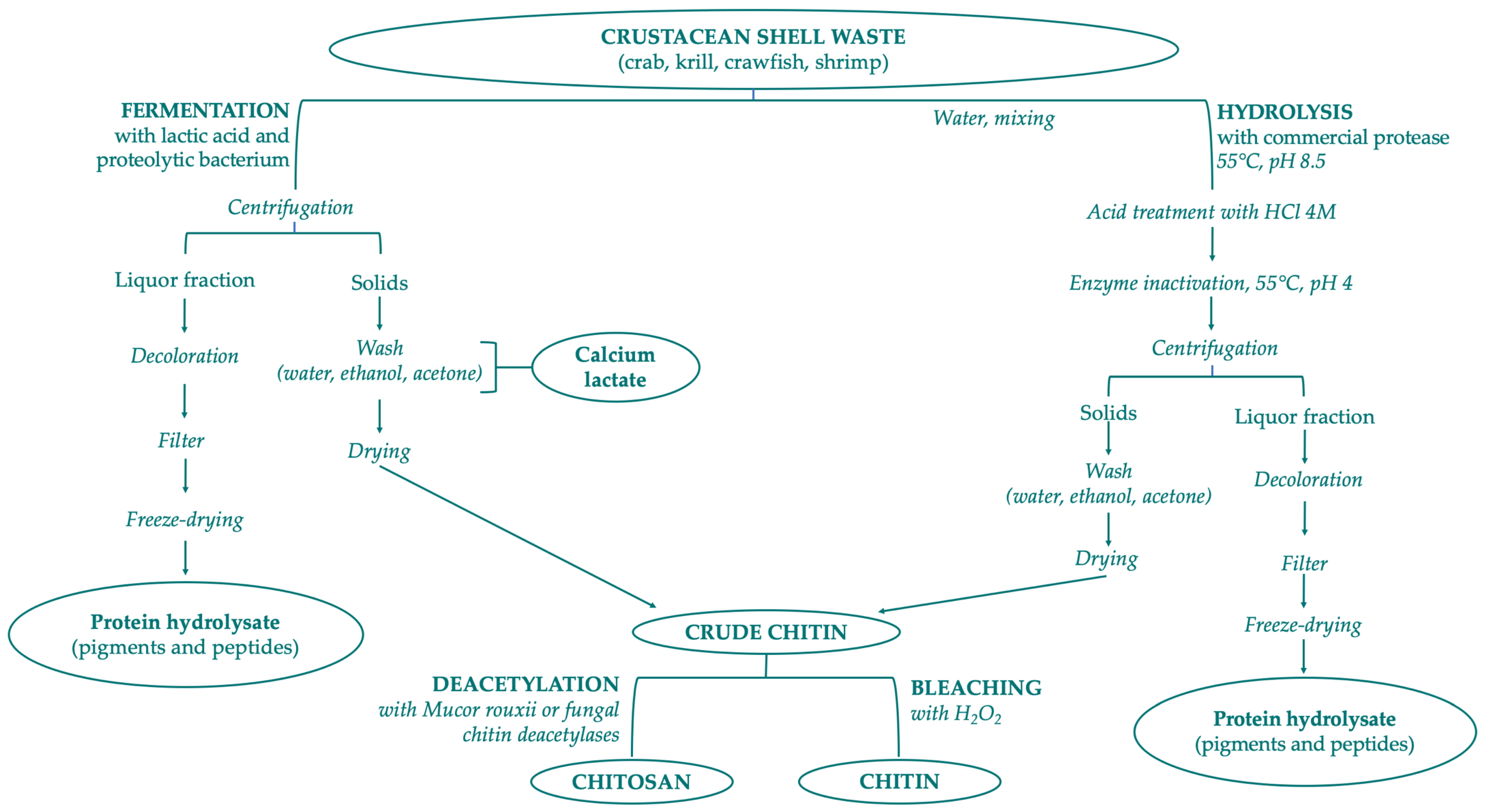

3. Extraction of Chitin and Chitosans from Natural Sources

3.1. Bioextraction of Chitin

3.1.1. Chitin Enzymatic Deproteinization

3.1.2. Chitin Bacteria Fermentation

Lactic Acid Bacteria Fermentation

Non-Lactic Acid Bacteria Fermentation

3.2. Enzymatic Deacetylation of Chitin

4. Applications in Cosmetics

4.1. Skin Care Applications

4.1.1. Antiaging and Moisturizing Agent

4.1.2. Ultraviolet Protective Cosmetics

4.1.3. Skin Cleansing

4.2. Nail Care Applications

4.3. Hair Care Applications

4.4. Oral Care Applications

4.4.1. Caries Treatment

4.4.2. Erosive Tooth Ware Treatment

4.4.3. Gingivitis Treatment

4.4.4. Periodontitis Treatment

5. Conclusions

Funding

Conflicts of Interest

References

- Liobikienė, G.; Mandravickaitė, J.; Bernatonienė, J. Theory of planned behavior approach to understand the green purchasing behavior in the EU: A cross-cultural study. Ecol. Econ. 2016, 125, 38–46. [Google Scholar] [CrossRef]

- Tukker, A.; Cohen, M.J.; Hubacek, K.; Mont, O. Sustainable consumption and production. J. Ind. Ecol. 2010, 14, 1–3. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers: Applications and Trends; William Andrew: Norwich, NY, USA, 2015. [Google Scholar]

- Anastas, P.; Eghbali, N. Green chemistry: Principles and practice. Chem. Soc. Rev. 2010, 39, 301–312. [Google Scholar] [CrossRef] [PubMed]

- Anastas, P.T.; Warner, J.C. Green chemistry. Frontiers 1998, 640. [Google Scholar]

- Cervellon, M.-C.; Rinaldi, M.-J.; Wernerfelt, A.-S. How green is green? Consumers’ understanding of green cosmetics and their certifications’. In Proceedings of the 10th International Marketing Trends Conference, Paris, France, 20–22 January 2011; pp. 20–21. [Google Scholar]

- Elliott, R. The taste for green: The possibilities and dynamics of status differentiation through “green” consumption. Poetics 2013, 41, 294–322. [Google Scholar] [CrossRef]

- Ritter, A.M.; Borchardt, M.; Vaccaro, G.L.; Pereira, G.M.; Almeida, F. Motivations for promoting the consumption of green products in an emerging country: Exploring attitudes of Brazilian consumers. J. Clean. Prod. 2015, 106, 507–520. [Google Scholar] [CrossRef]

- Kim, S.-K. Marine Cosmeceuticals: Trends and Prospects; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Ravenstijn, J. Bioplastics in consumer electronics. Ind. Biotechnol. 2010, 6, 252–263. [Google Scholar] [CrossRef]

- Kalia, S.; Avérous, L. Biopolymers: Biomedical and Environmental Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 70. [Google Scholar]

- Yadav, M.; Goswami, P.; Paritosh, K.; Kumar, M.; Pareek, N.; Vivekanand, V. Seafood waste: A source for preparation of commercially employable chitin/chitosan materials. Bioresources and Bioprocessing 2019, 6, 8. [Google Scholar] [CrossRef]

- Kim, S.; Seock, Y.K. Impacts of health and environmental consciousness on young female consumers’ attitude towards and purchase of natural beauty products. Int. J. Consum. Stud. 2009, 33, 627–638. [Google Scholar] [CrossRef]

- European Commission. Glossary and Acronyms Related to Cosmetics Legislation; Brussels, B., Ed.; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- de Souza, K.V.; Lopes, E.D.O.; Bartiko, D.; Vidal, C.D.S.; de Souza, J.B. Use of biopolymer in pulp and paper industry wastewater treatment by advanced oxidative process. Sci. For. 2017, 45, 363–372. [Google Scholar]

- Casadidio, C.; Butini, M.E.; Trampuz, A.; Di Luca, M.; Censi, R.; Di Martino, P. Daptomycin-loaded biodegradable thermosensitive hydrogels enhance drug stability and foster bactericidal activity against staphylococcus aureus. Eur. J. Pharm. Biopharm. 2018, 130, 260–271. [Google Scholar] [CrossRef] [PubMed]

- Othman, S.H. Bio-nanocomposite materials for food packaging applications: Types of biopolymer and nano-sized filler. Agric. Agric. Sci. Procedia 2014, 2, 296–303. [Google Scholar] [CrossRef]

- Coviello, T.; Matricardi, P.; Marianecci, C.; Alhaique, F. Polysaccharide hydrogels for modified release formulations. J. Control. Release 2007, 119, 5–24. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, A.S. Hydrogels for biomedical applications. Adv. Drug Deliv. Rev. 2012, 64, 18–23. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.; Boudrant, J.; Meyer, D.; Manno, N.; DeMarchis, M.; Paoletti, M.G. Current views on fungal chitin/chitosan, human chitinases, food preservation, glucans, pectins and inulin: A tribute to henri braconnot, precursor of the carbohydrate polymers science, on the chitin bicentennial. Carbohydr. Polym. 2012, 87, 995–1012. [Google Scholar] [CrossRef]

- Dutta, P.K.; Dutta, J.; Tripathi, V. Chitin and Chitosan: Chemistry, Properties and Applications; CSIR: Delhi, India, 2004. [Google Scholar]

- Jang, M.K.; Kong, B.G.; Jeong, Y.I.; Lee, C.H.; Nah, J.W. Physicochemical characterization of α-chitin, β-chitin, and γ-chitin separated from natural resources. J. Polym. Sci. Part A Polym. Chem. 2004, 42, 3423–3432. [Google Scholar] [CrossRef]

- Aranaz, I.; Mengíbar, M.; Harris, R.; Paños, I.; Miralles, B.; Acosta, N.; Galed, G.; Heras, Á. Functional characterization of chitin and chitosan. Curr. Chem. Biol. 2009, 3, 203–230. [Google Scholar]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Structure analysis and degree of substitution of chitin, chitosan and dibutyrylchitin by ft-ir spectroscopy and solid state 13c nmr. Carbohydr. Polym. 2004, 58, 409–416. [Google Scholar] [CrossRef]

- Younes, I.; Rinaudo, M. Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef]

- Rouget, C. Des substances amylacées dans les tissus des animaux, spécialement des articulés (chitine). Comp. Rend 1859, 48, 792–795. [Google Scholar]

- Tharanathan, R.N.; Kittur, F.S. Chitin—the undisputed biomolecule of great potential. Food Sci. Nutr. 2003, 43, 61–87. [Google Scholar] [CrossRef]

- Zargar, V.; Asghari, M.; Dashti, A. A review on chitin and chitosan polymers: Structure, chemistry, solubility, derivatives, and applications. Chembioeng Rev. 2015, 2, 204–226. [Google Scholar] [CrossRef]

- Castro, S.P.M.; Paulín, E.G.L. Is chitosan a new panacea? Areas of application. In The Complex World of Polysaccharides; InTech: Princeton, NJ, USA, 2012. [Google Scholar]

- Lim, S.-H.; Hudson, S.M. Review of chitosan and its derivatives as antimicrobial agents and their uses as textile chemicals. J. Macromol. Sci. Part C Polym. Rev. 2003, 43, 223–269. [Google Scholar] [CrossRef]

- Sabnis, S.; Block, L.H. Improved infrared spectroscopic method for the analysis of degree of n-deacetylation of chitosan. Polym. Bull. 1997, 39, 67–71. [Google Scholar] [CrossRef]

- Heidari, F.; Razavi, M.; Bahrololoom, M.E.; Tahriri, M.; Rasoulianboroujeni, M.; Koturi, H.; Tayebi, L. Preparation of natural chitosan from shrimp shell with different deacetylation degree. Mater. Res. Innov. 2018, 22, 177–181. [Google Scholar] [CrossRef]

- Zając, A.; Hanuza, J.; Wandas, M.; Dymińska, L. Determination of n-acetylation degree in chitosan using raman spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 134, 114–120. [Google Scholar] [CrossRef]

- Dimzon, I.K.D.; Knepper, T.P. Degree of deacetylation of chitosan by infrared spectroscopy and partial least squares. Int. J. Biol. Macromol. 2015, 72, 939–945. [Google Scholar] [CrossRef]

- No, H.K.; Meyers, S.P. Preparation and characterization of chitin and chitosan—A review. J. Aquat. Food Prod. Technol. 1995, 4, 27–52. [Google Scholar] [CrossRef]

- Kumar, M.N.R. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Kang, Y.; Wu, X.; Ji, X.; Bo, S.; Liu, Y. Strategy to improve the characterization of chitosan by size exclusion chromatography coupled with multi angle laser light scattering. Carbohydr. Polym. 2018, 202, 99–105. [Google Scholar] [CrossRef]

- Weinhold, M.X.; Thöming, J. On conformational analysis of chitosan. Carbohydr. Polym. 2011, 84, 1237–1243. [Google Scholar] [CrossRef]

- Prego, C.; Torres, D.; Alonso, M.J. The potential of chitosan for the oral administration of peptides. Expert Opin. Drug Deliv. 2005, 2, 843–854. [Google Scholar] [CrossRef] [PubMed]

- Cheba, B.A. Chitin and chitosan: Marine biopolymers with unique properties and versatile applications. Biotechnol. Biochem 2011, 6, 149–153. [Google Scholar]

- Helander, I.; Nurmiaho-Lassila, E.-L.; Ahvenainen, R.; Rhoades, J.; Roller, S. Chitosan disrupts the barrier properties of the outer membrane of gram-negative bacteria. Int. J. Food Microbiol. 2001, 71, 235–244. [Google Scholar] [CrossRef]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Zheng, T.; Homer, R.J.; Kim, Y.-K.; Chen, N.Y.; Cohn, L.; Hamid, Q.; Elias, J.A. Acidic mammalian chitinase in asthmatic Th2 inflammation and IL-13 pathway activation. Science 2004, 304, 1678–1682. [Google Scholar] [CrossRef]

- Synowiecki, J.; Al-Khateeb, N.A. Production, properties, and some new applications of chitin and its derivatives. Food Sci. Nutr. 2003, 43, 145–171. [Google Scholar] [CrossRef]

- Eaton, P.; Fernandes, J.C.; Pereira, E.; Pintado, M.E.; Malcata, F.X. Atomic force microscopy study of the antibacterial effects of chitosans on Escherichia coli and staphylococcus aureus. Ultramicroscopy 2008, 108, 1128–1134. [Google Scholar] [CrossRef]

- Kurita, K. Chitin and chitosan: Functional biopolymers from marine crustaceans. Mar. Biotechnol. 2006, 8, 203. [Google Scholar] [CrossRef]

- Gomes, L.P.; Andrade, C.T.; Del Aguila, E.M.; Alexander, C.; Paschoalin, V.M. Assessing the antimicrobial activity of chitosan nanoparticles by fluorescence-labeling. Int. J. Biotechnol. Bioeng. 2018, 12, 111–117. [Google Scholar]

- Liu, X.; Jiang, Q.; Xia, W. One-step procedure for enhancing the antibacterial and antioxidant properties of a polysaccharide polymer: Kojic acid grafted onto chitosan. Int. J. Biol. Macromol. 2018, 113, 1125–1133. [Google Scholar] [CrossRef] [PubMed]

- Juliano, C.; Magrini, G. Methylglyoxal, the major antibacterial factor in manuka honey: An alternative to preserve natural cosmetics? Cosmetics 2019, 6, 1. [Google Scholar] [CrossRef]

- Je, J.-Y.; Park, P.-J.; Kim, S.-K. Free radical scavenging properties of hetero-chitooligosaccharides using an esr spectroscopy. Food Chem. Toxicol. 2004, 42, 381–387. [Google Scholar] [CrossRef] [PubMed]

- Park, P.-J.; Je, J.-Y.; Kim, S.-K. Free radical scavenging activity of chitooligosaccharides by electron spin resonance spectrometry. J. Agric. Food Chem. 2003, 51, 4624–4627. [Google Scholar] [CrossRef] [PubMed]

- Demetgül, C.; Beyazit, N. Synthesis, characterization and antioxidant activity of chitosan-chromone derivatives. Carbohydr. Polym. 2018, 181, 812–817. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, W.; Wang, G.; Yin, X.; Li, Q.; Dong, F.; Guo, Z. Synthesis, characterization, and the antioxidant activity of N,N,N-trimethyl chitosan salts. Int. J. Biol. Macromol. 2018, 118, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Hu, C.; Xue, Y. In vitro evaluation of chitosan-coated liposome containing both coenzyme q10 and α-lipoic acid: Cytotoxicity, antioxidant activity, and antimicrobial activity. J. Cosmet. Dermatol. 2018, 17, 258–262. [Google Scholar] [CrossRef]

- M Ways, T.; Lau, W.; Khutoryanskiy, V. Chitosan and its derivatives for application in mucoadhesive drug delivery systems. Polymers 2018, 10, 267. [Google Scholar] [CrossRef]

- Moreno, J.A.S.; Mendes, A.C.; Stephansen, K.; Engwer, C.; Goycoolea, F.M.; Boisen, A.; Nielsen, L.H.; Chronakis, I.S. Development of electrosprayed mucoadhesive chitosan microparticles. Carbohydr. Polym. 2018, 190, 240–247. [Google Scholar] [CrossRef]

- Pereira, G.G.; Santos-Oliveira, R.; Albernaz, M.S.; Canema, D.; Weismüller, G.; Barros, E.B.; Magalhães, L.; Lima-Ribeiro, M.H.M.; Pohlmann, A.R.; Guterres, S.S. Microparticles of aloe vera/vitamin e/chitosan: Microscopic, a nuclear imaging and an in vivo test analysis for burn treatment. Eur. J. Pharm. Biopharm. 2014, 86, 292–300. [Google Scholar] [CrossRef] [PubMed]

- Chaiyasan, W.; Praputbut, S.; Kompella, U.B.; Srinivas, S.P.; Tiyaboonchai, W. Penetration of mucoadhesive chitosan-dextran sulfate nanoparticles into the porcine cornea. Colloids Surf. B Biointerfaces 2017, 149, 288–296. [Google Scholar] [CrossRef]

- Smith, J.; Wood, E.; Dornish, M. Effect of chitosan on epithelial cell tight junctions. Pharm. Res. 2004, 21, 43–49. [Google Scholar] [CrossRef]

- Singla, A.; Chawla, M. Chitosan: Some pharmaceutical and biological aspects-an update. J. Pharm. Pharmacol. 2001, 53, 1047–1067. [Google Scholar] [CrossRef] [PubMed]

- Contri, R.; Fiel, L.; Alnasif, N.; Pohlmann, A.; Guterres, S.; Schäfer-Korting, M. Skin penetration and dermal tolerability of acrylic nanocapsules: Influence of the surface charge and a chitosan gel used as vehicle. Int. J. Pharm. 2016, 507, 12–20. [Google Scholar] [CrossRef] [PubMed]

- Kojima, T.; Kitano, H.; Niwa, M.; Saito, K.; Matsushita, Y.; Fukushima, K. Imaging analysis of cosmetic ingredients interacted with human hair using tof-sims. Surf. Interface Anal. 2011, 43, 562–565. [Google Scholar] [CrossRef]

- Pimenta, B.C.R.; Quintão, T.D.S.C.; Chaker, J.A.; de Oliveira, P.M.; Gelfuso, G.M.; de Oliveira Karnikowski, M.G.; Gris, E.F. Improving stability of antioxidant compounds from Plinia cauliflora (jabuticaba) fruit peel extract by encapsulation in chitosan microparticles. J. Food Eng. 2018, 238, 195–201. [Google Scholar]

- Casanova, F.; Estevinho, B.N.; Santos, L. Preliminary studies of rosmarinic acid microencapsulation with chitosan and modified chitosan for topical delivery. Powder Technol. 2016, 297, 44–49. [Google Scholar]

- Sakulwech, S.; Lourith, N.; Ruktanonchai, U.; Kanlayavattanakul, M. Preparation and characterization of nanoparticles from quaternized cyclodextrin-grafted chitosan associated with hyaluronic acid for cosmetics. Asian J. Pharm. Sci. 2018, 13, 498–504. [Google Scholar] [CrossRef]

- Kong, S.-Z.; Li, D.-D.; Luo, H.; Li, W.-J.; Huang, Y.-M.; Li, J.-C.; Hu, Z.; Huang, N.; Guo, M.-H.; Chen, Y. Anti-photoaging effects of chitosan oligosaccharide in ultraviolet-irradiated hairless mouse skin. Exp. Gerontol. 2018, 103, 27–34. [Google Scholar] [CrossRef]

- Ganguly, A.; Ian, C.K.; Sheshala, R.; Sahu, P.S.; Al-Waeli, H.; Meka, V.S. Application of diverse natural polymers in the design of oral gels for the treatment of periodontal diseases. J. Mater. Sci. Mater. Med. 2017, 28, 39. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.; Escudero, C.; Sediqi, N.; Smistad, G.; Hiorth, M. Fluoride loaded polymeric nanoparticles for dental delivery. Eur. J. Pharm. Sci. 2017, 104, 326–334. [Google Scholar] [CrossRef] [PubMed]

- Morsy, R.; Ali, S.S.; El-Shetehy, M. Development of hydroxyapatite-chitosan gel sunscreen combating clinical multidrug-resistant bacteria. J. Mol. Struct. 2017, 1143, 251–258. [Google Scholar] [CrossRef]

- Azuma, K.; Koizumi, R.; Izawa, H.; Morimoto, M.; Saimoto, H.; Osaki, T.; Ito, N.; Yamashita, M.; Tsuka, T.; Imagawa, T. Hair growth-promoting activities of chitosan and surface-deacetylated chitin nanofibers. Int. J. Biol. Macromol. 2018, 126, 11–17. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, J.L.; Campos, E.V.R.; Pereira, A.E.S.; Nunes, L.E.; da Silva, C.C.; Pasquoto, T.; Lima, R.; Smaniotto, G.; Polanczyk, R.A.; Fraceto, L.F. Geraniol encapsulated in chitosan/gum arabic nanoparticles: A promising system for pest management in sustainable agriculture. J. Agric. Food Chem. 2018, 66, 5325–5334. [Google Scholar] [CrossRef] [PubMed]

- Boonlertnirun, S.; Boonraung, C.; Suvanasara, R. Application of chitosan in rice production. J. Met. Mater. Miner. 2017, 18, 47–52. [Google Scholar]

- Xie, H.; Yue, H.; Zhang, W.; Hu, W.; Zhou, X.; Prinsen, P.; Luque, R. A chitosan modified pt/sio2 catalyst for the synthesis of 3-poly (ethylene glycol) propyl ether-heptamethyltrisiloxane applied as agricultural synergistic agent. Catal. Commun. 2018, 104, 118–122. [Google Scholar] [CrossRef]

- Xing, K.; Xing, Y.; Liu, Y.; Zhang, Y.; Shen, X.; Li, X.; Miao, X.; Feng, Z.; Peng, X.; Qin, S. Fungicidal effect of chitosan via inducing membrane disturbance against ceratocystis fimbriata. Carbohydr. Polym. 2018, 192, 95–103. [Google Scholar] [CrossRef]

- Said, M.; Atassi, Y.; Tally, M.; Khatib, H. Environmentally friendly chitosan-g-poly (acrylic acid-co-acrylamide)/ground basalt superabsorbent composite for agricultural applications. J. Polym. Environ. 2018, 26, 3937–3948. [Google Scholar] [CrossRef]

- de Moraes Crizel, T.; de Oliveira Rios, A.; Alves, V.D.; Bandarra, N.; Moldão-Martins, M.; Flôres, S.H. Active food packaging prepared with chitosan and olive pomace. Food Hydrocoll. 2018, 74, 139–150. [Google Scholar] [CrossRef]

- Khan, I.; Tango, C.N.; Miskeen, S.; Oh, D.-H. Evaluation of nisin-loaded chitosan-monomethyl fumaric acid nanoparticles as a direct food additive. Carbohydr. Polym. 2018, 184, 100–107. [Google Scholar] [CrossRef] [PubMed]

- Patinya, S. Fabrication and characterization of chitosan-titanium dioxide nanocomposite film as ethylene scavenging and antimicrobial active food packaging. Food Hydrocoll. 2018, 84, 125–134. [Google Scholar]

- Sharif, M.A.; Kumer, A.; Ahmed, M.B.; Paul, S. Chitosan is a new target of chemical replacement to formalin in food preservative. IJCS 2018, 6, 757–760. [Google Scholar]

- Hosseini, S.F.; Nahvi, Z.; Zandi, M. Antioxidant peptide-loaded electrospun chitosan/poly (vinyl alcohol) nanofibrous mat intended for food biopackaging purposes. Food Hydrocoll. 2019, 89, 637–648. [Google Scholar] [CrossRef]

- Britto, D.D.; Pinola, F.G.; Mattoso, L.H.; Assis, O.B. Analysis of thermal and aqueous suspension stabilities of chitosan based nanoencapsulated vitamins. Quím. Nova 2016, 39, 1126–1130. [Google Scholar]

- Talón, E.; Trifkovic, K.T.; Nedovic, V.A.; Bugarski, B.M.; Vargas, M.; Chiralt, A.; González-Martínez, C. Antioxidant edible films based on chitosan and starch containing polyphenols from thyme extracts. Carbohydr. Polym. 2017, 157, 1153–1161. [Google Scholar] [CrossRef]

- Li, L.; Luo, C.; Li, X.; Duan, H.; Wang, X. Preparation of magnetic ionic liquid/chitosan/graphene oxide composite and application for water treatment. Int. J. Biol. Macromol. 2014, 66, 172–178. [Google Scholar] [CrossRef] [PubMed]

- Morsi, R.E.; Alsabagh, A.M.; Nasr, S.A.; Zaki, M.M. Multifunctional nanocomposites of chitosan, silver nanoparticles, copper nanoparticles and carbon nanotubes for water treatment: Antimicrobial characteristics. Int. J. Biol. Macromol. 2017, 97, 264–269. [Google Scholar] [CrossRef]

- Li, X.; Sun, J.; Che, Y.; Lv, Y.; Liu, F. Antibacterial properties of chitosan chloride-graphene oxide composites modified quartz sand filter media in water treatment. Int. J. Biol. Macromol. 2019, 121, 760–773. [Google Scholar] [CrossRef]

- Tang, S.; Mei, X.; Chen, W.; Huang, S.-H.; Bai, Z.-W. A high-performance chiral selector derived from chitosan (p-methylbenzylurea) for efficient enantiomer separation. Talanta 2018, 185, 42–52. [Google Scholar] [CrossRef]

- Tang, S.; Liu, J.-D.; Chen, W.; Huang, S.-H.; Zhang, J.; Bai, Z.-W. Performance comparison of chiral separation materials derived from N-cyclohexylcarbonyl and N-hexanoyl chitosans. J. Chromatogr. A 2018, 1532, 112–123. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Bin, Q.; Chen, W.; Bai, Z.-W.; Huang, S.-H. Chiral stationary phases based on chitosan bis (methylphenylcarbamate)-(isobutyrylamide) for high-performance liquid chromatography. J. Chromatogr. A 2016, 1440, 112–122. [Google Scholar] [CrossRef] [PubMed]

- Acet, Ö.; Baran, T.; Erdönmez, D.; Aksoy, N.H.; Alacabey, İ.; Menteş, A.; Odabaşi, M. O-carboxymethyl chitosan schiff base complexes as affinity ligands for immobilized metal-ion affinity chromatography of lysozyme. J. Chromatogr. A 2018, 1550, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Rahmaninia, M.; Rohi, M.; Hubbe, M.A.; Zabihzadeh, S.M.; Ramezani, O. The performance of chitosan with bentonite microparticles as wet-end additive system for paper reinforcement. Carbohydr. Polym. 2018, 179, 328–332. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Hu, X.; Zhang, X.; Guo, D.; Zhang, J.; Kong, F. Chitosan/titanium dioxide nanocomposite coatings: Rheological behavior and surface application to cellulosic paper. Carbohydr. Polym. 2016, 151, 752–759. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; He, Z.; Zhang, L.; Ni, Y. In situ grafting of chitosan onto cellulosic fibers using maleic anhydride for paper wet strength improvement. BioResources 2018, 13, 4018–4028. [Google Scholar] [CrossRef]

- Muryeti, M.; Budimulyani, E. The use of chitosan as antitermite in papermaking. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2018. [Google Scholar]

- Khwaldia, K.; Basta, A.H.; Aloui, H.; El-Saied, H. Chitosan–caseinate bilayer coatings for paper packaging materials. Carbohydr. Polym. 2014, 99, 508–516. [Google Scholar] [CrossRef] [PubMed]

- Naz, F.; Zuber, M.; Zia, K.M.; Salman, M.; Chakraborty, J.; Nath, I.; Verpoort, F. Synthesis and characterization of chitosan-based waterborne polyurethane for textile finishes. Carbohydr. Polym. 2018, 200, 54–62. [Google Scholar] [CrossRef] [PubMed]

- Sumithra, M. Development of medical textile product using chitosan incorporated herbal extract (aristolochia bracteolate). Int. J. Pharm. Life Sci. 2018, 9, 5748–5754. [Google Scholar]

- Arshad, N.; Zia, K.M.; Jabeen, F.; Anjum, M.N.; Akram, N.; Zuber, M. Synthesis, characterization of novel chitosan based water dispersible polyurethanes and their potential deployment as antibacterial textile finish. Int. J. Biol. Macromol. 2018, 111, 485–492. [Google Scholar] [CrossRef] [PubMed]

- Zou, H.; Lin, B.; Xu, C.; Lin, M.; Zhan, W. Preparation and characterization of individual chitin nanofibers with high stability from chitin gels by low-intensity ultrasonication for antibacterial finishing. Cellulose 2018, 25, 999–1010. [Google Scholar] [CrossRef]

- Zhao, X.; Yim, C.-H.; Du, N.; Abu-Lebdeh, Y. Crosslinked chitosan networks as binders for silicon/graphite composite electrodes in li-ion batteries. J. Electrochem. Soc. 2018, 165, A1110–A1121. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, M.; Wang, X.; Wu, Z.; Zeng, P.; Huang, C.; Wang, Y. MoS2-coated N-doped mesoporous carbon spherical composite cathode and cnts/chitosan modified separator for advanced lithium sulfur batteries. ACS Sustain. Chem. Eng. 2018, 6, 16828–16837. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, J.H.; Nam, D.H.; Cho, M.; Kim, J.; Chanthad, C.; Lee, Y. Epoxidized natural rubber/chitosan network binder for silicon anode in lithium-ion battery. ACS Appl. Mater. Interfaces 2018, 10, 16449–16457. [Google Scholar] [CrossRef] [PubMed]

- Meng, T.; Zeng, R.; Sun, Z.; Yi, F.; Shu, D.; Li, K.; Li, S.; Zhang, F.; Cheng, H.; He, C. Chitosan-confined synthesis of n-doped and carbon-coated Li4Ti5O12 nanoparticles with enhanced lithium storage for lithium-ion batteries. J. Electrochem. Soc. 2018, 165, A1046–A1053. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Li, H.; Han, G.-C.; Yun, L.; Zhong, H. Electrochemical performance of lead-carbon battery with chitosan composite carbon/lead negative plate. Int. J. Electrochem. Sci 2018, 13, 136–146. [Google Scholar] [CrossRef]

- Saekhor, K.; Udomsinprasert, W.; Honsawek, S.; Tachaboonyakiat, W. Preparation of an injectable modified chitosan-based hydrogel approaching for bone tissue engineering. Int. J. Biol. Macromol. 2019, 123, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, A.; Moztarzadeh, F.; Mohandesi, J.A. Investigating the effect of chitosan on hydrophilicity and bioactivity of conductive electrospun composite scaffold for neural tissue engineering. Int. J. Biol. Macromol. 2019, 121, 625–632. [Google Scholar] [CrossRef]

- Salehi, M.; Bagher, Z.; Kamrava, S.K.; Ehterami, A.; Alizadeh, R.; Farhadi, M.; Falah, M.; Komeili, A. Alginate/chitosan hydrogel containing olfactory ectomesenchymal stem cells for sciatic nerve tissue engineering. J. Cell. Physiol. 2019, 234, 15357–15368. [Google Scholar] [CrossRef]

- Madni, A.; Khan, R.; Ikram, M.; Naz, S.S.; Khan, T.; Wahid, F. Fabrication and characterization of chitosan–vitamin c–lactic acid composite membrane for potential skin tissue engineering. Int. J. Polym. Sci. 2019, 2019, 4362395. [Google Scholar] [CrossRef]

- Olad, A.; Hagh, H.B.K. Graphene oxide and amin-modified graphene oxide incorporated chitosan-gelatin scaffolds as promising materials for tissue engineering. Compos. Part B: Eng. 2019, 162, 692–702. [Google Scholar] [CrossRef]

- Rijal, N.P.; Adhikari, U.; Khanal, S.; Pai, D.; Sankar, J.; Bhattarai, N. Magnesium oxide-poly (ε-caprolactone)-chitosan-based composite nanofiber for tissue engineering applications. Mater. Sci. Eng. B 2018, 228, 18–27. [Google Scholar] [CrossRef]

- Tithito, T.; Suntornsaratoon, P.; Charoenphandhu, N.; Thongbunchoo, J.; Krishnamra, N.; Tang, I.; Pon-On, W. Fabrication of biocomposite scaffolds made with modified hydroxyapatite inclusion of chitosan-grafted-poly (methyl methacrylate) for bone tissue engineering. Biomed. Mater. (Bristolengland) 2019, 14, 025013. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Han, M.; Sun, Y.; Hua, Y.; Chen, G.; Zhang, L. Oligoarginine mediated collagen/chitosan gel composite for cutaneous wound healing. Int. J. Biol. Macromol. 2019, 122, 1120–1127. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Wang, B.; Li, J.; Jansen, J.A.; Walboomers, X.F.; Yang, F. Antibacterial effect and wound healing ability of silver nanoparticles incorporation into chitosan-based nanofibrous membranes. Mater. Sci. Eng. C 2019, 98, 1053–1063. [Google Scholar] [CrossRef] [PubMed]

- Maged, A.; Abdelkhalek, A.A.; Mahmoud, A.A.; Salah, S.; Ammar, M.M.; Ghorab, M.M. Mesenchymal stem cells associated with chitosan scaffolds loaded with rosuvastatin to improve wound healing. Eur. J. Pharm. Sci. 2019, 127, 185–198. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, A.M.; de Oliveira, E.G.; Coradini, K.; Bruinsmann, F.A.; Aguirre, T.; Lorenzoni, R.; Barcelos, R.C.S.; Roversi, K.; Rossato, D.R.; Pohlmann, A.R. Chitosan hydrogels containing nanoencapsulated phenytoin for cutaneous use: Skin permeation/penetration and efficacy in wound healing. Mater. Sci. Eng. C 2019, 96, 205–217. [Google Scholar] [CrossRef] [PubMed]

- Adeli, H.; Khorasani, M.T.; Parvazinia, M. Wound dressing based on electrospun pva/chitosan/starch nanofibrous mats: Fabrication, antibacterial and cytocompatibility evaluation and in vitro healing assay. Int. J. Biol. Macromol. 2019, 122, 238–254. [Google Scholar] [CrossRef]

- Khorasani, M.T.; Joorabloo, A.; Adeli, H.; Mansoori-Moghadam, Z.; Moghaddam, A. Design and optimization of process parameters of polyvinyl (alcohol)/chitosan/nano zinc oxide hydrogels as wound healing materials. Carbohydr. Polym. 2019, 207, 542–554. [Google Scholar] [CrossRef]

- Nikolskaya, I.; Beznos, O.; Eltsov, A.; Gachok, I.; Chesnokova, N.; Varlamov, V.; Kost, O. The inclusion of timolol and lisinopril in calcium phosphate particles covered by chitosan: Application in ophthalmology. Mosc. Univ. Chem. Bull. 2018, 73, 85–89. [Google Scholar] [CrossRef]

- Fischak, C.; Klaus, R.; Werkmeister, R.M.; Hohenadl, C.; Prinz, M.; Schmetterer, L.; Garhöfer, G. Effect of topically administered chitosan-n-acetylcysteine on corneal wound healing in a rabbit model. J. Ophthalmol. 2017, 2017, 5192924. [Google Scholar] [CrossRef] [PubMed]

- Messina, M.; Dua, H.S. Early results on the use of chitosan-n-acetylcysteine (lacrimera®) in the management of dry eye disease of varied etiology. Int. Ophthalmol. 2018, 39, 693–696. [Google Scholar] [CrossRef] [PubMed]

- Behl, G.; Iqbal, J.; O’Reilly, N.J.; McLoughlin, P.; Fitzhenry, L. Synthesis and characterization of poly (2-hydroxyethylmethacrylate) contact lenses containing chitosan nanoparticles as an ocular delivery system for dexamethasone sodium phosphate. Pharm. Res. 2016, 33, 1638–1648. [Google Scholar] [CrossRef] [PubMed]

- Anirudhan, T.; Nair, A.S.; Parvathy, J. Extended wear therapeutic contact lens fabricated from timolol imprinted carboxymethyl chitosan-g-hydroxy ethyl methacrylate-g-poly acrylamide as a onetime medication for glaucoma. Eur. J. Pharm. Biopharm. 2016, 109, 61–71. [Google Scholar] [CrossRef] [PubMed]

- Shinde, U.A.; Joshi, P.N.; Jain, D.D.; Singh, K. Preparation and evaluation of N-trimethyl chitosan nanoparticles of flurbiprofen for ocular delivery. Curr. Eye Res. 2019, 44, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Silva, D.; Pinto, L.F.; Bozukova, D.; Santos, L.F.; Serro, A.P.; Saramago, B. Chitosan/alginate based multilayers to control drug release from ophthalmic lens. Colloids Surf. B Biointerfaces 2016, 147, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, S.H.; Arafa, A.S.; Mady, W.H.; Fahmy, H.A.; Omer, L.M.; Morsi, R.E. Preparation and immunological evaluation of inactivated avian influenza virus vaccine encapsulated in chitosan nanoparticles. Biologicals 2018, 51, 46–53. [Google Scholar] [CrossRef]

- Li, Z.; Xiong, F.; He, J.; Dai, X.; Wang, G. Surface-functionalized, ph-responsive poly (lactic-co-glycolic acid)-based microparticles for intranasal vaccine delivery: Effect of surface modification with chitosan and mannan. Eur. J. Pharm. Biopharm. 2016, 109, 24–34. [Google Scholar] [CrossRef]

- van der Maaden, K.; Sekerdag, E.; Schipper, P.; Kersten, G.; Jiskoot, W.; Bouwstra, J. Layer-by-layer assembly of inactivated poliovirus and n-trimethyl chitosan on ph-sensitive microneedles for dermal vaccination. Langmuir 2015, 31, 8654–8660. [Google Scholar] [CrossRef]

- Pawar, D.; Jaganathan, K. Mucoadhesive glycol chitosan nanoparticles for intranasal delivery of hepatitis b vaccine: Enhancement of mucosal and systemic immune response. Drug Deliv. 2016, 23, 185–194. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, J.; Zhou, S.; Yang, N.; Duan, S.; Zhang, Z.; Su, J.; He, J.; Zhang, Z.; Lu, X. Mouse ip-10 gene delivered by folate-modified chitosan nanoparticles and dendritic/tumor cells fusion vaccine effectively inhibit the growth of hepatocellular carcinoma in mice. Theranostics 2017, 7, 1942–1952. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Zhao, X.; Ma, P.X.; Guo, B.; Du, Y.; Han, X. Ph-responsive injectable hydrogels with mucosal adhesiveness based on chitosan-grafted-dihydrocaffeic acid and oxidized pullulan for localized drug delivery. J. Colloid Interface Sci. 2019, 536, 224–234. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira Pedro, R.; Goycoolea, F.M.; Pereira, S.; Schmitt, C.C.; Neumann, M.G. Synergistic effect of quercetin and ph-responsive deae-chitosan carriers as drug delivery system for breast cancer treatment. Int. J. Biol. Macromol. 2018, 106, 579–586. [Google Scholar] [CrossRef]

- Li, T.; Yang, J.; Liu, R.; Yi, Y.; Huang, M.; Wu, Y.; Tu, H.; Zhang, L. Efficient fabrication of reversible ph-induced carboxymethyl chitosan nanoparticles for antitumor drug delivery under weakly acidic microenvironment. Int. J. Biol. Macromol. 2019, 126, 68–73. [Google Scholar] [CrossRef] [PubMed]

- Hyun, H.; Park, M.H.; Jo, G.; Kim, S.Y.; Chun, H.J.; Yang, D.H. Photo-cured glycol chitosan hydrogel for ovarian cancer drug delivery. Mar. Drugs 2019, 17, 41. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, S.; Dutta, P.; Kumar, S.; Koh, J.; Pandey, S. Methyl methacrylate modified chitosan: Synthesis, characterization and application in drug and gene delivery. Carbohydr. Polym. 2019, 211, 109–117. [Google Scholar] [CrossRef] [PubMed]

- Peng, N.; Ai, Z.; Fang, Z.; Wang, Y.; Xia, Z.; Zhong, Z.; Fan, X.; Ye, Q. Homogeneous synthesis of quaternized chitin in naoh/urea aqueous solution as a potential gene vector. Carbohydr. Polym. 2016, 150, 180–186. [Google Scholar] [CrossRef] [PubMed]

- Kashkouli, K.I.; Torkzadeh-Mahani, M.; Mosaddegh, E. Synthesis and characterization of a novel organosilane-functionalized chitosan nanocarrier as an efficient gene delivery system: Expression of green fluorescent protein. Int. J. Biol. Macromol. 2019, 125, 143–148. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Y.; Xu, X.; Guo, T.; Xie, D.; Zhu, R.; Chen, S.; Ramakrishna, S.; He, L. Rgd/tat-functionalized chitosan-graft-pei-peg gene nanovector for sustained delivery of nt-3 for potential application in neural regeneration. Acta Biomater. 2018, 72, 266–277. [Google Scholar] [CrossRef]

- Nam, J.-P.; Nah, J.-W. Target gene delivery from targeting ligand conjugated chitosan–pei copolymer for cancer therapy. Carbohydr. Polym. 2016, 135, 153–161. [Google Scholar] [CrossRef]

- Baghdan, E.; Pinnapireddy, S.R.; Strehlow, B.; Engelhardt, K.H.; Schäfer, J.; Bakowsky, U. Lipid coated chitosan-DNA nanoparticles for enhanced gene delivery. Int. J. Pharm. 2018, 535, 473–479. [Google Scholar] [CrossRef] [PubMed]

- Yan, N.; Chen, X. Sustainability: Don’t waste seafood waste. Nat. News 2015, 524, 155. [Google Scholar] [CrossRef] [PubMed]

- Elieh-Ali-Komi, D.; Hamblin, M.R. Chitin and chitosan: Production and application of versatile biomedical nanomaterials. Int. J. Adv. Res. 2016, 4, 411. [Google Scholar]

- Tolaimate, A.; Desbrieres, J.; Rhazi, M.; Alagui, A. Contribution to the preparation of chitins and chitosans with controlled physico-chemical properties. Polymer 2003, 44, 7939–7952. [Google Scholar] [CrossRef]

- Gortari, M.C.; Hours, R.A. Biotechnological processes for chitin recovery out of crustacean waste: A mini-review. Electron. J. Biotechnol. 2013, 16, 14. [Google Scholar]

- Cheong, J.Y.; Azwady, A.N.; Rusea, G.; Noormasshela, U.; Shaziera, A.N.; Azleen, A.; Muskhazli, M. The availability of astaxanthin from shrimp shell wastes through microbial fermentations, aeromonas hydrophila and cell disruptions. Int. J. Agric. Biol. 2014, 16, 277–284. [Google Scholar]

- Manni, L.; Ghorbel-Bellaaj, O.; Jellouli, K.; Younes, I.; Nasri, M. Extraction and characterization of chitin, chitosan, and protein hydrolysates prepared from shrimp waste by treatment with crude protease from bacillus cereus sv1. Appl. Biochem. Biotechnol. 2010, 162, 345–357. [Google Scholar] [CrossRef]

- Hayes, M. Chitin, chitosan and their derivatives from marine rest raw materials: Potential food and pharmaceutical applications. In Marine Bioactive Compounds; Springer: Cham, Switzerland, 2012; pp. 115–128. [Google Scholar]

- Nwe, N.; Furuike, T.; Tamura, H. Isolation and characterization of chitin and chitosan from marine origin. In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2014; Volume 72, pp. 1–15. [Google Scholar]

- Arbia, W.; Arbia, L.; Adour, L.; Amrane, A. Chitin extraction from crustacean shells using biological methods—A review. Food Technol. Biotechnol. 2013, 51, 12–25. [Google Scholar]

- Haddar, A.; Hmidet, N.; Ghorbel-Bellaaj, O.; Fakhfakh-Zouari, N.; Sellami-Kamoun, A.; Nasri, M. Alkaline proteases produced by bacillus licheniformis rp1 grown on shrimp wastes: Application in chitin extraction, chicken feather-degradation and as a dehairing agent. Biotechnol. Bioprocess Eng. 2011, 16, 669. [Google Scholar] [CrossRef]

- Sila, A.; Nasri, R.; Bougatef, A.; Nasri, M. Digestive alkaline proteases from the goby (Zosterisessor ophiocephalus): Characterization and potential application as detergent additive and in the deproteinization of shrimp wastes. J. Aquat. Food Prod. Technol. 2012, 21, 118–133. [Google Scholar] [CrossRef]

- Mhamdi, S.; Ktari, N.; Hajji, S.; Nasri, M.; Kamoun, A.S. Alkaline proteases from a newly isolated micromonospora chaiyaphumensis s103: Characterization and application as a detergent additive and for chitin extraction from shrimp shell waste. Int. J. Biol. Macromol. 2017, 94, 415–422. [Google Scholar] [CrossRef] [PubMed]

- Hamdi, M.; Hammami, A.; Hajji, S.; Jridi, M.; Nasri, M.; Nasri, R. Chitin extraction from blue crab (Portunus segnis) and shrimp (Penaeus kerathurus) shells using digestive alkaline proteases from p. Segnis viscera. Int. J. Biol. Macromol. 2017, 101, 455–463. [Google Scholar] [CrossRef] [PubMed]

- Castro, R.; Guerrero-Legarreta, I.; Bórquez, R. Chitin extraction from allopetrolisthes punctatus crab using lactic fermentation. Biotechnol. Rep. 2018, 20, e00287. [Google Scholar] [CrossRef]

- Ghorbel-Bellaaj, O.; Jellouli, K.; Younes, I.; Manni, L.; Salem, M.O.; Nasri, M. A solvent-stable metalloprotease produced by pseudomonas aeruginosa a2 grown on shrimp shell waste and its application in chitin extraction. Appl. Biochem. Biotechnol. 2011, 164, 410–425. [Google Scholar] [CrossRef] [PubMed]

- Ghorbel-Bellaaj, O.; Hmidet, N.; Jellouli, K.; Younes, I.; Maâlej, H.; Hachicha, R.; Nasri, M. Shrimp waste fermentation with pseudomonas aeruginosa a2: Optimization of chitin extraction conditions through plackett–burman and response surface methodology approaches. Int. J. Biol. Macromol. 2011, 48, 596–602. [Google Scholar] [CrossRef] [PubMed]

- Hajji, S.; Ghorbel-Bellaaj, O.; Younes, I.; Jellouli, K.; Nasri, M. Chitin extraction from crab shells by bacillus bacteria. Biological activities of fermented crab supernatants. Int. J. Biol. Macromol. 2015, 79, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Teng, W.L.; Khor, E.; Tan, T.K.; Lim, L.Y.; Tan, S.C. Concurrent production of chitin from shrimp shells and fungi. Carbohydr. Res. 2001, 332, 305–316. [Google Scholar] [CrossRef]

- Hembach, L.; Cord-Landwehr, S.; Moerschbacher, B.M. Enzymatic production of all fourteen partially acetylated chitosan tetramers using different chitin deacetylases acting in forward or reverse mode. Sci. Rep. 2017, 7, 17692. [Google Scholar] [CrossRef]

- Leonida, M.D.; Kumar, I. Wound healing and skin regeneration. In Bionanomaterials for Skin Regeneration; Springer: Cham, Switzerland, 2016; pp. 17–25. [Google Scholar]

- Jimtaisong, A.; Saewan, N. Utilization of carboxymethyl chitosan in cosmetics. Int. J. Cosmet. Sci. 2014, 36, 12–21. [Google Scholar] [CrossRef]

- Han, J.H.; Floros, J.D. Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. J. Plast. Film Sheeting 1997, 13, 287–298. [Google Scholar] [CrossRef]

- Montenegro, R.; Freier, T. Chitosan Tissue Dressing. European Patent EP2473201B1, 19 June 2019. [Google Scholar]

- Libio, I.C.; Demori, R.; Ferrão, M.F.; Lionzo, M.I.; da Silveira, N.P. Films based on neutralized chitosan citrate as innovative composition for cosmetic application. Mater. Sci. Eng. C 2016, 67, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Morganti, P.; Palombo, M.; Fabrizi, G.; Guarneri, F.; Slovacchia, F.; Cardillo, A.; Del Ciotto, P.; Carezzi, F.; Morganti, G. New insights on anti. Aging activity of chitin nanofibril. Hyaluronan block copolymers entrapping active ingredients: In vitro and in vivo study. J. Appl. Cosmetol. 2013, 31, 1–29. [Google Scholar]

- Morganti, P.; Palombo, P.; Palombo, M.; Fabrizi, G.; Cardillo, A.; Svolacchia, F.; Guevara, L.; Mezzana, P. A phosphatidylcholine hyaluronic acid chitin–nanofibrils complex for a fast skin remodeling and a rejuvenating look. Clin. Cosmet. Investig. Dermatol. 2012, 5, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Morganti, P.; Palombo, M.; Tishchenko, G.; Yudin, V.E.; Guarneri, F.; Cardillo, M.; Del Ciotto, P.; Carezzi, F.; Morganti, G.; Fabrizi, G. Chitin-hyaluronan nanoparticles: A multifunctional carrier to deliver anti-aging active ingredients through the skin. Cosmetics 2014, 1, 140–158. [Google Scholar] [CrossRef]

- Rajashree, S.; Rose, C. Studies on an anti-aging formulation prepared using aloe vera blended collagen and chitosan. Int. J. Pharm. Sci. Res. 2018, 9, 582–588. [Google Scholar]

- Lehr, C.-M.; Bouwstra, J.A.; Schacht, E.H.; Junginger, H.E. In vitro evaluation of mucoadhesive properties of chitosan and some other natural polymers. Int. J. Pharm. 1992, 78, 43–48. [Google Scholar] [CrossRef]

- Cadet, J.; Douki, T.; Ravanat, J.L. Oxidatively generated damage to cellular DNA by uvb and uva radiation. Photochem. Photobiol. 2015, 91, 140–155. [Google Scholar] [CrossRef]

- Ito, I.; Yoneda, T.; Omura, Y.; Osaki, T.; Ifuku, S.; Saimoto, H.; Azuma, K.; Imagawa, T.; Tsuka, T.; Murahata, Y. Protective effect of chitin urocanate nanofibers against ultraviolet radiation. Mar. Drugs 2015, 13, 7463–7475. [Google Scholar] [CrossRef]

- Ntohogian, S.; Gavriliadou, V.; Christodoulou, E.; Nanaki, S.; Lykidou, S.; Naidis, P.; Mischopoulou, L.; Barmpalexis, P.; Nikolaidis, N.; Bikiaris, D. Chitosan nanoparticles with encapsulated natural and uf-purified annatto and saffron for the preparation of uv protective cosmetic emulsions. Molecules 2018, 23, 2107. [Google Scholar] [CrossRef]

- Tunku Mahmud, T.H.; Abdul-Aziz, A.; Muda, R. A review on the potential use of chitosan-based delivery system in mild facial cleansing formulation. Int. J. Polym. Mater. Polym. Biomater. 2015, 64, 432–437. [Google Scholar] [CrossRef]

- Massaro, M.; Goldberg, J.W.; Subramanyan, K.K.; Johnson, A.W.; Slavtcheff, C.S. Liquid Cleansing Composition Having Simultaneous Exfoliating and Moisturizing Properties. U.S. Patent 6,924,256, 8 February 2005. [Google Scholar]

- Cantoresi, F.; Caserini, M.; Bidoli, A.; Maggio, F.; Marino, R.; Carnevale, C.; Sorgi, P.; Palmieri, R. Randomized controlled trial of a water-soluble nail lacquer based on hydroxypropyl-chitosan (hpch), in the management of nail psoriasis. Clin. Cosmet. Investig. Dermatol. 2014, 7, 185–190. [Google Scholar] [PubMed]

- Baran, R.; Kaoukhov, A. Topical antifungal drugs for the treatment of onychomycosis: An overview of current strategies for monotherapy and combination therapy. J. Eur. Acad. Dermatol. Venereol. 2005, 19, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Cantoresi, F.; Sorgi, P.; Arcese, A.; Bidoli, A.; Bruni, F.; Carnevale, C.; Calvieri, S. Improvement of psoriatic onychodystrophy by a water-soluble nail lacquer. J. Eur. Acad. Dermatol. Venereol. 2009, 23, 832–834. [Google Scholar] [CrossRef] [PubMed]

- Ghannoum, M.; Long, L.; Isham, N.; Bulgheroni, A.; Setaro, M.; Caserini, M.; Palmieri, R.; Mailland, F. Ability of hydroxypropyl chitosan nail lacquer to protect against dermatophyte nail infection. Antimicrob. Agents Chemother. 2015, 59, 1844–1848. [Google Scholar] [CrossRef] [PubMed]

- Matos, B.N.; Reis, T.A.; Gratieri, T.; Gelfuso, G.M. Chitosan nanoparticles for targeting and sustaining minoxidil sulphate delivery to hair follicles. Int. J. Biol. Macromol. 2015, 75, 225–229. [Google Scholar] [CrossRef] [PubMed]

- Sionkowska, A.; Kaczmarek, B.; Michalska, M.; Lewandowska, K.; Grabska, S. Preparation and characterization of collagen/chitosan/hyaluronic acid thin films for application in hair care cosmetics. Pure Appl. Chem. 2017, 89, 1829–1839. [Google Scholar] [CrossRef]

- He, J.; Bao, Y.; Li, J.; Qiu, Z.; Liu, Y.; Zhang, X. Nanocomplexes of carboxymethyl chitosan/amorphous calcium phosphate reduce oral bacteria adherence and biofilm formation on human enamel surface. J. Dent. 2019, 80, 15–22. [Google Scholar] [CrossRef] [PubMed]

- Achmad, H.; Ramadhany, Y.F. Effectiveness of chitosan tooth paste from white shrimp (litopenaeusvannamei) to reduce number of streptococcus mutans in the case of early childhood caries. J. Int. Dent. Med Res. 2017, 10, 358–363. [Google Scholar]

- Assunção, C.M.; Lussi, A.; Rodrigues, J.A.; Carvalho, T.S. Efficacy of toothpastes in the prevention of erosive tooth wear in permanent and deciduous teeth. Clin. Oral Investig. 2018, 23, 273–284. [Google Scholar] [CrossRef] [PubMed]

- Beltrame, A.P.C.; Suchyta, D.; Alraheam, I.A.; Mohammed, A.; Schoenfisch, M.; Walter, R.; Almeida, I.C.; Souza, L.C.; Miguez, P.A. Effect of phosphorylated chitosan on dentin erosion: An in vitro study. Caries Res. 2018, 52, 378–386. [Google Scholar] [CrossRef]

- Lam, P.-L.; Lee, K.K.-H.; Wong, R.S.-M.; Cheng, G.Y.M.; Cheng, S.Y.; Yuen, M.C.-W.; Lam, K.-H.; Gambari, R.; Kok, S.H.-L.; Chui, C.-H. Development of hydrocortisone succinic acid/and 5-fluorouracil/chitosan microcapsules for oral and topical drug deliveries. Bioorganic Med. Chem. Lett. 2012, 22, 3213–3218. [Google Scholar] [CrossRef] [PubMed]

- Davoudi, Z.; Rabiee, M.; Houshmand, B.; Eslahi, N.; Khoshroo, K.; Rasoulianboroujeni, M.; Tahriri, M.; Tayebi, L. Development of chitosan/gelatin/keratin composite containing hydrocortisone sodium succinate as a buccal mucoadhesive patch to treat desquamative gingivitis. Drug Dev. Ind. Pharm. 2018, 44, 40–55. [Google Scholar] [CrossRef] [PubMed]

- Goyal, G.; Garg, T.; Rath, G.; Goyal, A.K. Current nanotechnological strategies for an effective delivery of drugs in treatment of periodontal disease. Crit. Rev™ Ther. Drug Carr. Syst. 2014, 31, 89–119. [Google Scholar] [CrossRef]

- Özdoğan, A.I.; Akca, G.; Şenel, S. Development and in vitro evaluation of chitosan based system for local delivery of atorvastatin for treatment of periodontitis. Eur. J. Pharm. Sci. 2018, 124, 208–216. [Google Scholar] [CrossRef] [PubMed]

- Özdoğan, A.I.; İlarslan, Y.D.; Kösemehmetoğlu, K.; Akca, G.; Kutlu, H.B.; Comerdov, E.; Iskit, A.B.; Şenel, S. In vivo evaluation of chitosan based local delivery systems for atorvastatin in treatment of periodontitis. Int. J. Pharm. 2018, 550, 470–476. [Google Scholar] [CrossRef] [PubMed]

- Liobikienė, G.; Bernatonienė, J. Why determinants of green purchase cannot be treated equally? The case of green cosmetics: Literature review. J. Clean. Prod. 2017, 162, 109–120. [Google Scholar] [CrossRef]

| Effect on Biological Activity | Physicochemical Property |

|---|---|

| Antimicrobial activity | ↑ DD and ↓ MW |

| Antioxidant activity | ↑ DD and ↓ MW |

| Mucoadhesive properties | ↑ DD and ↑ MW |

| Penetration enhancement properties | ↑ DD increased activity, MW is not discriminating |

| Field | Examples | Ref. | |

|---|---|---|---|

| Industrial Applications | Cosmetics | Biodegradable, biocompatible and nontoxic chitosan microparticles encapsulating jabuticaba peel extract | [64] |

| Modified chitosan microparticles containing rosmarinic acid for skin delivery formulations | [65] | ||

| Nanoparticles of quaternized cyclodextrin-grafted chitosan associated with hyaluronic acid as promising skin penetration vehicles | [66] | ||

| Preventive effect of chitosan oligosaccharide against UV-caused damage in hairless mouse dorsal skin | [67] | ||

| Periodontal chitosan gels containing moxifloxacin hydrochloride | [68] | ||

| Fluoride loaded chitosan nanoparticles in the prevention of dental caries | [69] | ||

| Hydroxyapatite-chitosan sunscreen antibacterial gel for skin health care | [70] | ||

| Chitosan and surface-deacetylated chitin nanofibrils induced hair growth | [71] | ||

| Agriculture | Gum arabic/chitosan nanoparticles containing geraniol for pest management | [72] | |

| Chitosan natural biopolymer as a growth stimulator of rice yield | [73] | ||

| Chitosan modified Pt/SiO2 as catalyst for an agricultural synergistic agent | [74] | ||

| Antifungal chitosan agent used to control Ceratocystis fimbriata plant pathogenic fungus that attacks sweet potato | [75] | ||

| Eco-friendly chitosan/basalt hydrogel as soil conditioner and booster of plants growth | [76] | ||

| Food and Nutrition | Food packaging made by chitosan-based films with microparticles of olive pomace | [77] | |

| Nisin-loaded chitosan-monomethyl fumaric acid nanoparticles as a direct food additive | [78] | ||

| Chitosan-TiO2 nanocomposite film as antimicrobial active food packaging | [79] | ||

| Chitosan as an alternative food preservative to formalin | [80] | ||

| Fish-purified antioxidant peptide-loaded electrospun chitosan/PVA nanofibrous mat for food biopackaging applications | [81] | ||

| Tripolyphosphate and chitosan nanoparticles for encapsulation of C, B9, and B12 vitamins | [82] | ||

| Starch or chitosan-based matrices carrying thyme extract polyphenols as antioxidant films for food preservation | [83] | ||

| Water Engineering – Waste Treatment | Graphene oxide-ionic liquid and magnetic chitosan in heavy metal ion pollution clean-up | [84] | |

| Multifunctional nanocomposites of chitosan as contaminant water treatment material | [85] | ||

| Antibacterial chitosan chloride-graphene oxide material and/with quartz sand filter media | [86] | ||

| Chromatography | N-methoxycarbonyl chitosan for high-performance chiral separation materials | [87] | |

| N-cyclohexylcarbonyl and N-hexanoyl chitosans as chiral selectors for enantiomeric separation | [88] | ||

| Chitosan bis(methylphenylcarbamate)-(isobutyrylamide) derivatives as chiral stationary phases for HPLC | [89] | ||

| O-carboxymethyl chitosan for convenient use in the purification of lysozyme | [90] | ||

| Paper Industry | Bentonite microparticles/chitosan system for improving the acidic papermaking dry strengths | [91] | |

| Chitosan/titanium dioxide nanocomposite as antibacterial protective coating for paper packaging | [92] | ||

| Paper wet strength improved with chitosan-based additive using a dipping process | [93] | ||

| Chitosan as antitermite in paper making | [94] | ||

| Caseinate/chitosan films favor reduction in paper water vapor permeability | [95] | ||

| Textile Industry | Series of chitosan-based waterborne polyurethane improve tear strength and antimicrobial activity of polyester cotton dyed and printed fabrics | [96] | |

| Chitosan and herbal extract of Aristolochia bracteolate as medical textile product (band aid) | [97] | ||

| Eco-friendly antimicrobial chitosan-based water dispersible polyurethanes finishes | [98] | ||

| Chitin nanofibers for antibacterial finishing application | [99] | ||

| Batteries | Chitosan networks crosslinked with citric acid or polymeric carboxylic acids as binders for silicon/graphite composite electrodes in lithium ion batteries | [100] | |

| Molybdenum disulfide-coated nitrogen-doped mesoporous carbon sphere/sulfur composite cathode and carbon nanotube/chitosan modified separator promoting lithium sulfur batteries | [101] | ||

| Chitosan/epoxidized natural rubber networks by crosslinking as a binder material | [102] | ||

| Highly crystalline lithium titanate nanoparticles with N-doped carbon-coating and chitosan (as carbon and nitrogen source) | [103] | ||

| Chitosan composite carbon material with high specific electrochemical performance of lead-carbon battery | [104] | ||

| Biomedical and Pharmaceutical Applications | Tissue Engineering | Injectable carboxymethyl chitosan conjugated with α-cyclodextrin hydrogel complexed with poly(ethylene glycol) (PEG1000) | [105] |

| Electrospun nanofibrous scaffolds containing poly(ε-caprolactone), chitosan, and polypyrrole for neural tissue engineering | [106] | ||

| Alginate/chitosan hydrogel for transplantation of olfactory ectomesenchymal stem cells for sciatic nerve tissue engineering (rat model) | [107] | ||

| Chitosan–vitamin C–lactic acid composite membrane decorated with glycerol and PEG | [108] | ||

| Graphene oxide and amine-modified graphene oxide incorporated into chitosan-gelatin scaffold by covalent linking | [109] | ||

| Magnesium oxide-poly(ε-caprolactone)-chitosan-based composite nanofiber by the electrospinning technique | [110] | ||

| Scaffolds made with modified hydroxyapatite blended into chitosan-grafted-poly (methyl methacrylate) matrix | [111] | ||

| Wound Healing | Collagen/chitosan gel composite supplemented with a cell-penetrating peptide (oligo-arginine R8) with an antibacterial activity | [112] | |

| Silver nanoparticles encapsulation into chitosan-based membranes without altering the wound-healing ability | [113] | ||

| Rosuvastatin calcium loaded into chitosan hydrochloride scaffolds based with/without mesenchymal stem cells | [114] | ||

| Phenytoin nanocapsules and nanoemulsions formulated as chitosan hydrogels for cutaneous use in rats | [115] | ||

| Electrospun antibacterial PVA/Chitosan/Starch nanofibrous mats | [116] | ||

| Biocompatible and nontoxic PVA/chitosan/nano zinc oxide hydrogels | [117] | ||

| Ophthalmology | Chitosan-covered calcium phosphate nanoparticles loaded with timolol and lisinopril | [118] | |

| Topical chitosan-N-acetylcysteine for corneal damage in a rabbit model | [119] | ||

| Chitosan-N-acetylcysteine (Lacrimera®) in in patients with moderate to severe dry eye disease | [120] | ||

| Contact lenses made of poly(2-hydroxyethylmethacrylate) containing chitosan nanoparticles as dexamethasone sodium phosphate delivery system | [121] | ||

| Timolol maleate imprinted copolymer of carboxymethyl chitosan-g-hydroxy ethyl methacrylate-g-polyacrylamide incorporated on a poly(2-hydroxyethyl methacrylate) p(HEMA) matrix for glaucoma | [122] | ||

| N-Trimethyl Chitosan Nanoparticles loaded with flurbiprofen-hydroxyl propyl-β-cyclodextrin inclusion complex | [123] | ||

| Layer-by-layer deposition of chitosan and alginate was used to control drug release from ophthalmic lens materials | [124] | ||

| Vaccine | Inactivated avian influenza H5N1 virus vaccine encapsulated in chitosan nanoparticles in broiler chickens | [125] | |

| Chitosan-coated poly(lactic-co-glycolic acid) (PLGA) microparticles for intranasal vaccine delivery of hepatitis B surface Antigen | [126] | ||

| pH-sensitive microneedle chemically coated with inactivated polio vaccine and N-trimethyl chitosan chloride via electrostatic interactions for dermal vaccination in rats | [127] | ||

| Glycol chitosan nanoparticles for mucosal intranasal administration of hepatitis B vaccine | [128] | ||

| Folate-chitosan/ interferon-induced protein-10 gene nanoparticles and DC/tumor fusion vaccine enhanced anti-hepatocellular carcinoma effects in mice | [129] | ||

| Drug Delivery | Chitosan-grafted-dihydrocaffeic acid and oxidized pullulan hydrogels via a Schiff base reaction for local doxorubicin delivery | [130] | |

| 2-chloro-N,N-diethylethylamine hydrochloride/chitosan pH-responsive nanoparticles as quercetin delivery system for breast cancer treatment | [131] | ||

| pH-responsive Carboxymethyl chitosan nanoparticles for doxorubicin hydrochloride-controlled release at pH 4.5 | [132] | ||

| Injectable visible light-cured glycol chitosan hydrogel incorporating paclitaxel-/β-cyclodextrin inclusion complex for ovarian cancer therapy | [133] | ||

| Methyl methacrylate modified chitosan conjugate by a green method via Michael addition in curcumin delivery | [134] | ||

| Gene Delivery | Quaternized chitins vector synthesized via eco-friendly process | [135] | |

| Organosilane-functionalized chitosan nanoparticles as plox plasmid delivery system | [136] | ||

| Chitosan-graft-polyethylenimine (PEI)-PEG gene carrier decorated with arginine-glycine-aspartate/twin-arginine translocation for sustained delivery of NT-3 protein growth factor for neural regeneration | [137] | ||

| Targeting ligand conjugated chitosan–PEI copolymer/siRNA polyplexes for cancer therapy | [138] | ||

| Liposome encapsulated chitosan nanoparticles for enhanced plasmid DNA delivery | [139] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casadidio, C.; Peregrina, D.V.; Gigliobianco, M.R.; Deng, S.; Censi, R.; Di Martino, P. Chitin and Chitosans: Characteristics, Eco-Friendly Processes, and Applications in Cosmetic Science. Mar. Drugs 2019, 17, 369. https://doi.org/10.3390/md17060369

Casadidio C, Peregrina DV, Gigliobianco MR, Deng S, Censi R, Di Martino P. Chitin and Chitosans: Characteristics, Eco-Friendly Processes, and Applications in Cosmetic Science. Marine Drugs. 2019; 17(6):369. https://doi.org/10.3390/md17060369

Chicago/Turabian StyleCasadidio, Cristina, Dolores Vargas Peregrina, Maria Rosa Gigliobianco, Siyuan Deng, Roberta Censi, and Piera Di Martino. 2019. "Chitin and Chitosans: Characteristics, Eco-Friendly Processes, and Applications in Cosmetic Science" Marine Drugs 17, no. 6: 369. https://doi.org/10.3390/md17060369

APA StyleCasadidio, C., Peregrina, D. V., Gigliobianco, M. R., Deng, S., Censi, R., & Di Martino, P. (2019). Chitin and Chitosans: Characteristics, Eco-Friendly Processes, and Applications in Cosmetic Science. Marine Drugs, 17(6), 369. https://doi.org/10.3390/md17060369