A Capacitive Pressure Sensor with a Hierarchical Microporous Scaffold Prepared by Melt Near-Field Electro-Writing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MWCNTs/PCL Dielectric Layer

2.3. Preparation of MXene Electrode Layer

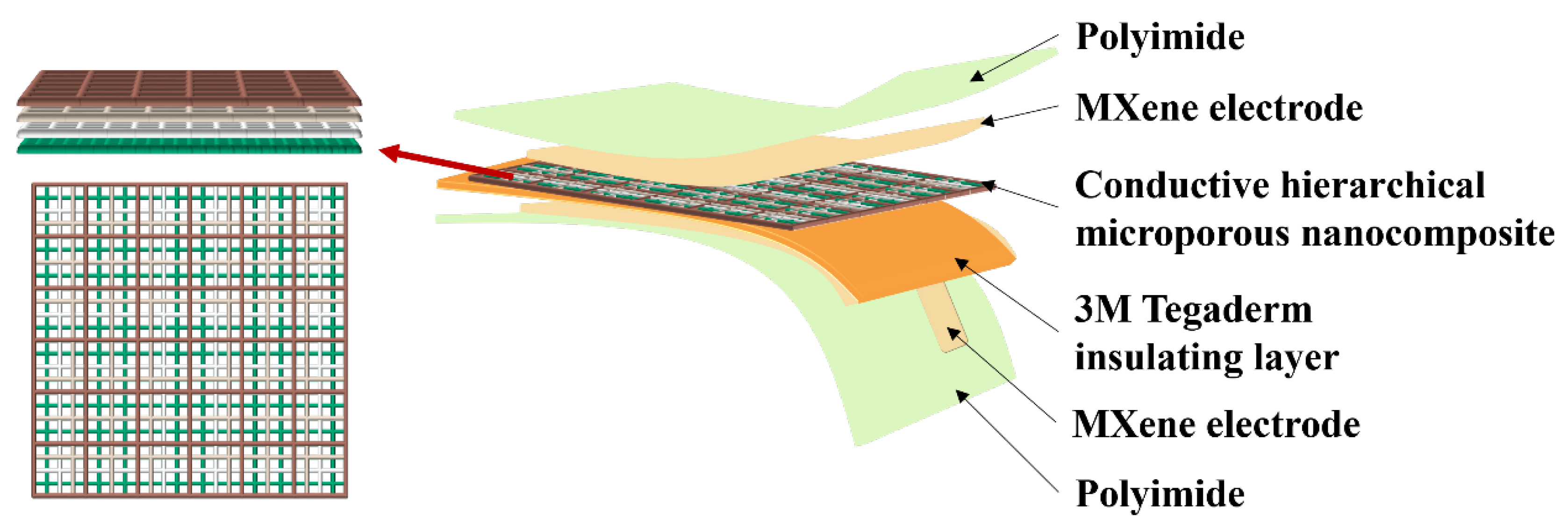

2.4. Assembly of HMCPS

2.5. Characterization and Measurements:

3. Results

3.1. Structure and Morphology

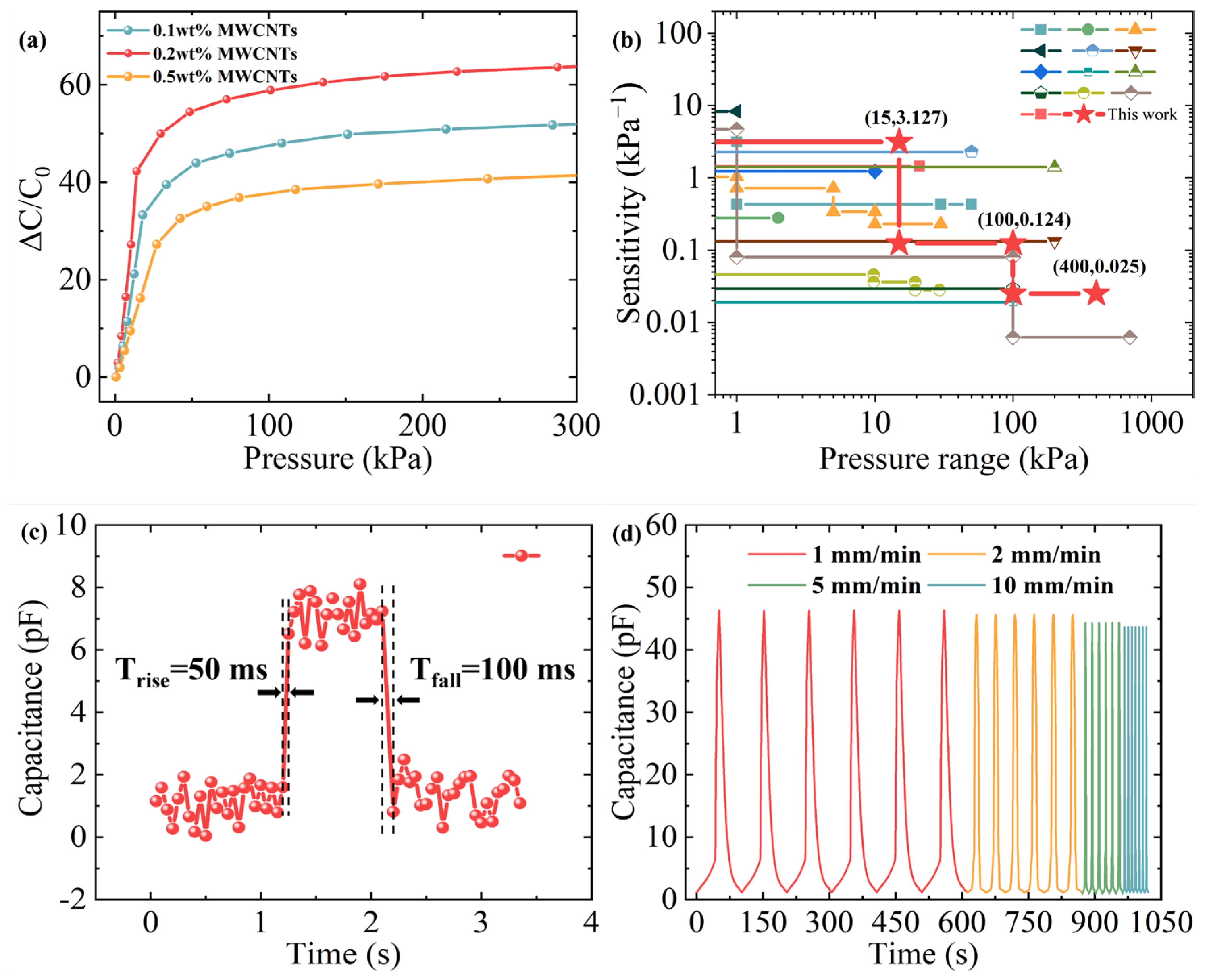

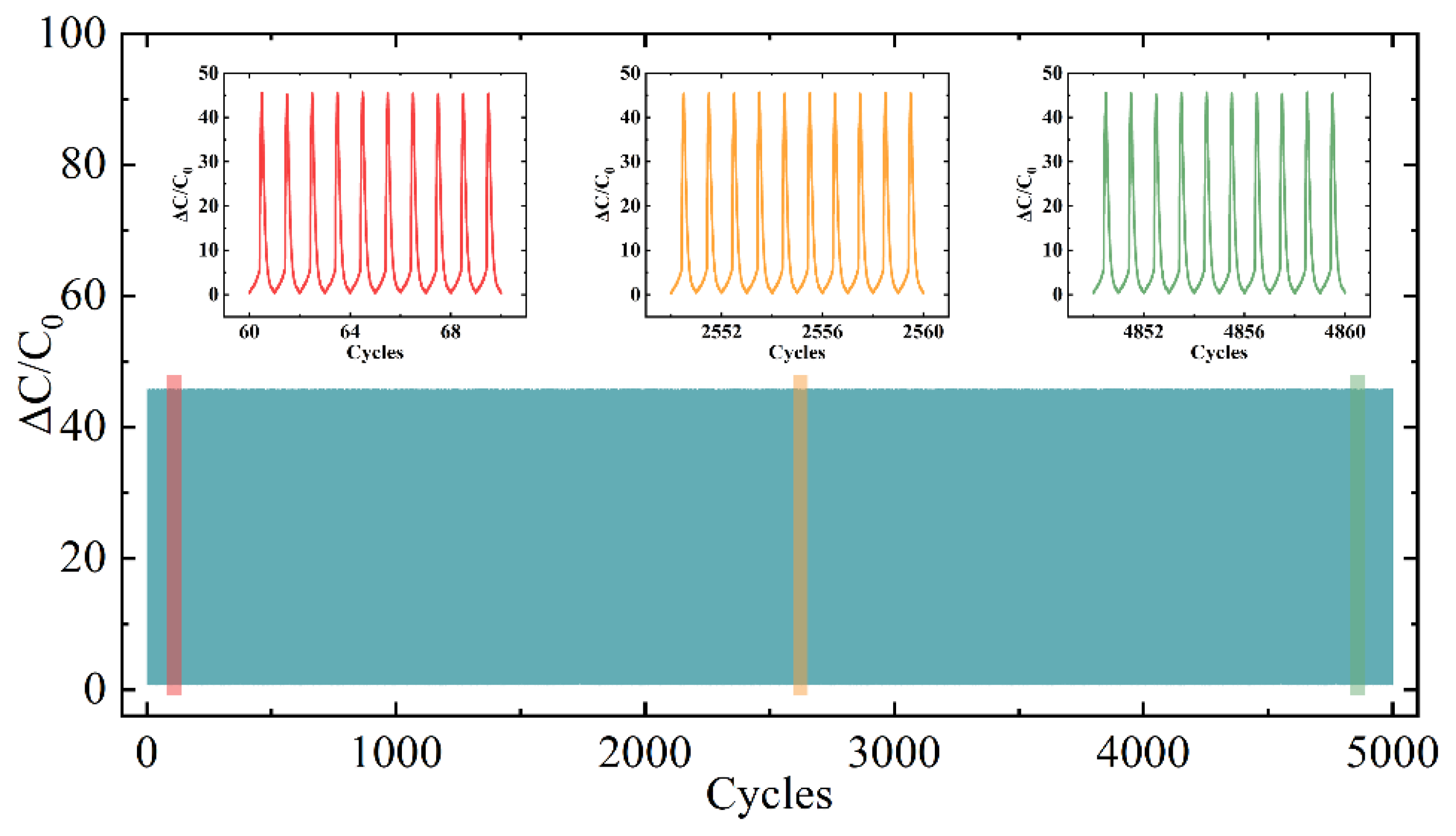

3.2. Electromechanical Performance

3.3. Mechanism Analysis

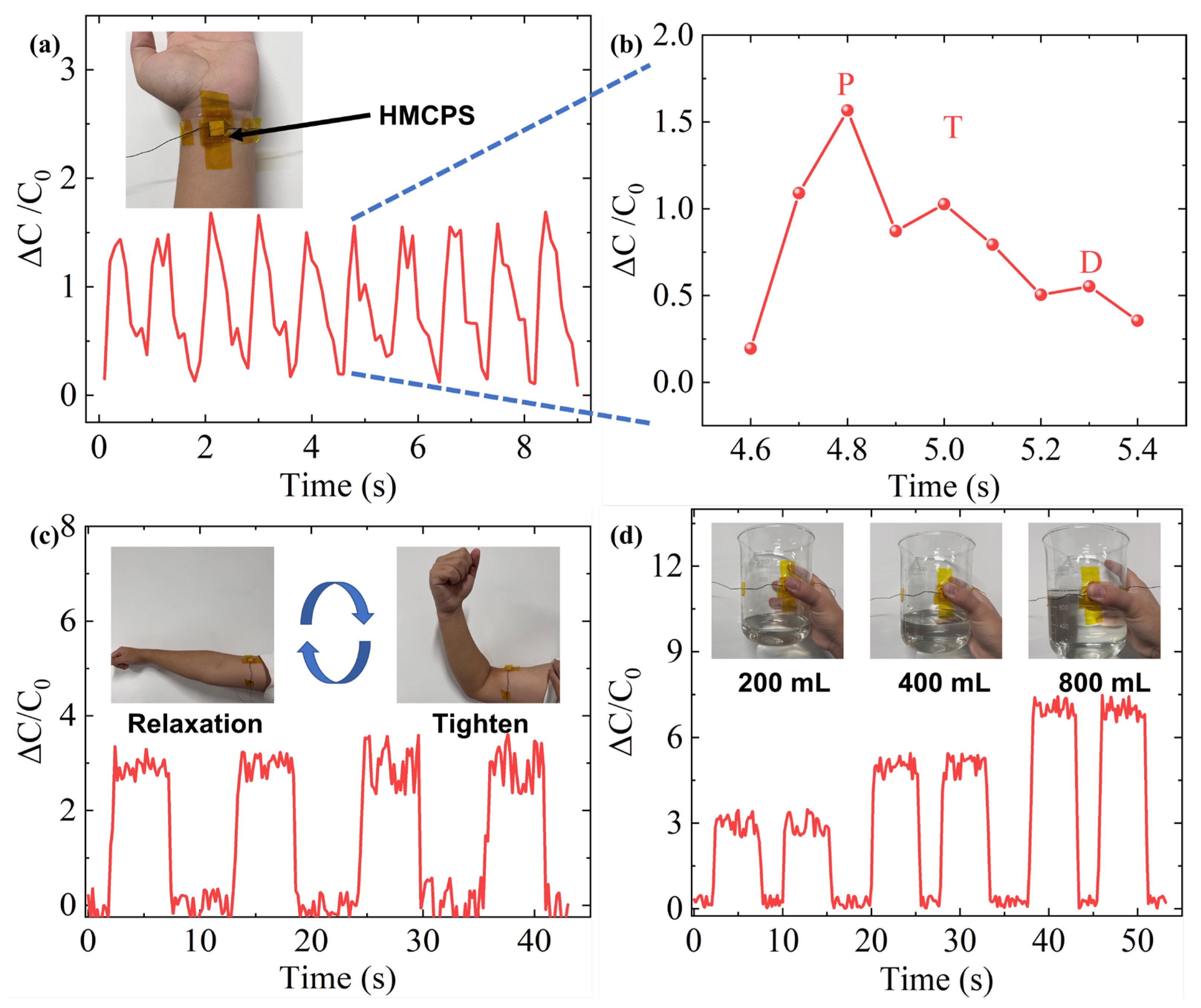

3.4. Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ha, K.H.; Zhang, W.; Jang, H.; Kang, S.; Wang, L.; Tan, P.; Hwang, H.; Lu, N. Highly sensitive capacitive pressure sensors over a wide pressure range enabled by the hybrid responses of a highly porous nanocomposite. Adv. Mater. 2021, 33, 2103320. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Panahi-Sarmad, M.; Chen, T.; Wang, A.; Xu, R.; Xiao, X. Highly sensitive and flexible capacitive pressure sensor based on a dual-structured nanofiber membrane as the dielectric for attachable wearable electronics. ACS Appl. Electron. Mater. 2022, 4, 469–477. [Google Scholar] [CrossRef]

- Zhong, Y.; Gu, F.; Wu, L.; Wang, J.; Dai, S.; Zhu, H.; Cheng, G.; Ding, J. Porous conductive electrode for highly sensitive flexible capacitive pressure sensor over a wide range. J. Alloys Compd. 2023, 934, 167919. [Google Scholar] [CrossRef]

- Yu, P.; Li, X.; Li, H.; Fan, Y.; Cao, J.; Wang, H.; Guo, Z.; Zhao, X.; Wang, Z.; Zhu, G. All-fabric ultrathin capacitive sensor with high pressure sensitivity and broad detection range for electronic skin. ACS Appl. Mater. Interfaces 2021, 13, 24062–24069. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, J.; Duan, A.; Yang, S.; Chen, L.; Wang, Z.; Song, J. A highly sensitive flexible pressure sensor based on nanoarchitectonics with biomimetic petal structure. Appl. Phys. A 2025, 131, 256. [Google Scholar] [CrossRef]

- Xiao, Y.; Guo, D.; Yang, L.; Tong, Y.; Wu, X.; Wang, Y. Fabric-based capacitive pressure sensors for porous four-phase composites with high sensitivity and wide linearity range. Compos. Sci. Technol. 2024, 256, 110794. [Google Scholar] [CrossRef]

- Park, J.; Kim, D.-W.; Lee, J. HT-AggNet: Hierarchical temporal aggregation network with near-zero-cost layer stacking for human activity recognition. Eng. Appl. Artif. Intell. 2025, 149, 110465. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, P.; Huang, L.; Sui, H.; Wang, S.; Ding, C. A flexible capacitive proximity-tactile dual-mode sensor based on the biomimetic petal-like electrode. Sens. Actuators A Phys. 2024, 379, 115975. [Google Scholar] [CrossRef]

- Liang, B.; Huang, B.; He, J.; Yang, R.; Zhao, C.; Yang, B.-R.; Cao, A.; Tang, Z.; Gui, X. Direct stamping multifunctional tactile sensor for pressure and temperature sensing. Nano Res. 2022, 15, 3614–3620. [Google Scholar] [CrossRef]

- Yi, Z.; Liu, Z.; Li, W.; Ruan, T.; Chen, X.; Liu, J.; Yang, B.; Zhang, W. Piezoelectric dynamics of arterial pulse for wearable continuous blood pressure monitoring. Adv. Mater. 2022, 34, 2110291. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, S.; Ma, R.; Chen, Z.; Zhuo, J.; Cao, L.; Yang, J.; Yang, G.; Yi, F. High-performance multimodal smart textile for artificial sensation and health monitoring. Nano Energy 2022, 103, 107778. [Google Scholar] [CrossRef]

- Yan, J.; Yan, Y.; Fang, L.; Sun, Z.; Jiang, C.; Shi, F.; Shi, Z.; Wang, Y. A compact and fast photoelectric sound sensor based on GaN integrated transceiver chip and PDMS/Ag composite film. Sens. Actuators A Phys. 2025, 386, 116342. [Google Scholar] [CrossRef]

- Wu, L.; Li, X.; Choi, J.; Zhao, Z.J.; Qian, L.; Yu, B.; Park, I. Beetle-inspired gradient slant structures for capacitive pressure sensor with a broad linear response range. Adv. Funct. Mater. 2024, 34, 2312370. [Google Scholar] [CrossRef]

- Yang, W.; Liu, Y.; Xu, W.; Nie, H.-Y. Design and fabrication of flexible capacitive sensor with cellular structured dielectric layer via 3D printing. IEEE Sens. J. 2021, 21, 10473–10482. [Google Scholar] [CrossRef]

- Ko, J.-B.; Kim, S.-W.; Kim, H.-B.; Jeong, H.-Y.; Moon, S.-Y.; Yang, Y.-J. 3D-Printed Multi-Axis Alignment Airgap Dielectric Layer for Flexible Capacitive Pressure Sensor. Micromachines 2024, 15, 1347. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, Z.; Liu, Z.; Fu, J.; Shan, T.; Yang, X.; Lei, Q.; Yang, Y.; Li, D. Flexible capacitive pressure sensors for wearable electronics. J. Mater. Chem. C 2022, 10, 1594–1605. [Google Scholar] [CrossRef]

- Mishra, R.B.; El-Atab, N.; Hussain, A.M.; Hussain, M.M. Recent progress on flexible capacitive pressure sensors: From design and materials to applications. Adv. Mater. Technol. 2021, 6, 2001023. [Google Scholar] [CrossRef]

- Cheng, M.; Yuan, Y.; Li, Q.; Chen, C.; Chen, J.; Tian, K.; Zhang, M.; Fu, Q.; Deng, H. Polyimide aerogel-based capacitive pressure sensor with enhanced sensitivity and temperature resistance. J. Mater. Sci. Technol. 2025, 217, 60–69. [Google Scholar] [CrossRef]

- Basarir, F.; Haj, Y.A.; Zou, F.; De, S.; Nguyen, A.; Frey, A.; Haider, I.; Sariola, V.; Vapaavuori, J. Edible and Biodegradable Wearable Capacitive Pressure Sensors: A Paradigm Shift toward Sustainable Electronics with Bio-Based Materials. Adv. Funct. Mater. 2024, 34, 2403268. [Google Scholar] [CrossRef]

- Ha, K.-H.; Huh, H.; Li, Z.; Lu, N. Soft capacitive pressure sensors: Trends, challenges, and perspectives. ACS Nano 2022, 16, 3442–3448. [Google Scholar] [CrossRef]

- Thorali, N.; Kim, D.S.; Lee, H.; Kim, D.R.; Lee, D.-W. Enhancing sensitivity in wireless capacitive pressure sensors via highly flexible LC circuits utilizing porous polydimethylsiloxane dielectric layer. Sens. Actuators A Phys. 2024, 379, 115973. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, Q.; Zhou, T.; Wu, W.; Li, H.; Yin, Z.; Ma, J.; Jiao, T. Progress and challenges in flexible capacitive pressure sensors: Microstructure designs and applications. Chem. Eng. J. 2024, 485, 149926. [Google Scholar] [CrossRef]

- Guan, T.; Li, H.; Liu, J.; Zhang, W.; Wang, S.; Ye, W.; Bian, B.; Yi, X.; Wu, Y.; Liu, Y. Preparation of Ion Composite Photosensitive Resin and Its Application in 3D-Printing Highly Sensitive Pressure Sensor. Sensors 2025, 25, 1348. [Google Scholar] [CrossRef]

- Atalay, O.; Atalay, A.; Gafford, J.; Walsh, C. A highly sensitive capacitive-based soft pressure sensor based on a conductive fabric and a microporous dielectric layer. Adv. Mater. Technol. 2018, 3, 1700237. [Google Scholar] [CrossRef]

- Zhou, Q.; Ji, B.; Hu, B.; Li, S.; Xu, Y.; Gao, Y.; Wen, W.; Zhou, J.; Zhou, B. Tilted magnetic micropillars enabled dual-mode sensor for tactile/touchless perceptions. Nano Energy 2020, 78, 105382. [Google Scholar] [CrossRef]

- Nie, K.; Wang, Z.; Tang, R.; Zheng, L.; Li, C.; Shen, X.; Sun, Q. Anisotropic, flexible wood hydrogels and wrinkled, electrodeposited film electrodes for highly sensitive, wide-range pressure sensing. ACS Appl. Mater. Interfaces 2020, 12, 43024–43031. [Google Scholar] [CrossRef]

- Cicek, M.O.; Doganay, D.; Durukan, M.B.; Gorur, M.C.; Unalan, H.E. Seamless monolithic design for foam based, flexible, parallel plate capacitive sensors. Adv. Mater. Technol. 2021, 6, 2001168. [Google Scholar] [CrossRef]

- Ji, B.; Zhou, Q.; Lei, M.; Ding, S.; Song, Q.; Gao, Y.; Li, S.; Xu, Y.; Zhou, Y.; Zhou, B. Gradient architecture-enabled capacitive tactile sensor with high sensitivity and ultrabroad linearity range. Small 2021, 17, 2103312. [Google Scholar] [CrossRef]

- He, Y.; Zhou, M.; Mahmoud, M.; Lu, X.; He, G.; Zhang, L.; Huang, M.; Elnaggar, A.Y.; Lei, Q.; Liu, H. Multifunctional wearable strain/pressure sensor based on conductive carbon nanotubes/silk nonwoven fabric with high durability and low detection limit. Adv. Compos. Hybrid Mater. 2022, 5, 1939–1950. [Google Scholar] [CrossRef]

- Cui, X.; Zheng, J.; Huang, Y.; Wang, R.; Zhang, H. MXene/MWCNTs-based capacitive pressure sensors combine high sensitivity and wide detection range for human health and motion monitoring. Sens. Actuators A Phys. 2024, 379, 115858. [Google Scholar] [CrossRef]

- Lv, C.; Tian, C.; Jiang, J.; Dang, Y.; Liu, Y.; Duan, X.; Li, Q.; Chen, X.; Xie, M. Ultrasensitive linear capacitive pressure sensor with wrinkled microstructures for tactile perception. Adv. Sci. 2023, 10, 2206807. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Gao, F.; Hu, Y.; Zhang, S.; Shang, H.; Ge, C.; Tan, B.; Zhang, X.; Zhang, J.; Hu, P. Skin-inspired tactile sensor based on gradient pore structure enable broad range response and ultrahigh pressure resolution. Chem. Eng. J. 2022, 443, 136446. [Google Scholar] [CrossRef]

- Jiang, C.-S.; Lv, R.-Y.; Zou, Y.-L.; Peng, H.-L. Flexible pressure sensor with wide pressure range based on 3D microporous PDMS/MWCNTs for human motion detection. Microelectron. Eng. 2024, 283, 112105. [Google Scholar] [CrossRef]

- Ao, Y.; Ao, J.; Yang, X.; Zhao, L.; Hu, L.; Le, G.; Li, J.; Qu, F.; Zhou, Y.; Wang, X. Preparation and characterization of hierarchical nanostructures composed by CuO nanowires within directional microporous Cu. Vacuum 2020, 182, 109774. [Google Scholar] [CrossRef]

- Sattayasamitsathit, S.; O’Mahony, A.M.; Xiao, X.; Brozik, S.M.; Washburn, C.M.; Wheeler, D.R.; Gao, W.; Minteer, S.; Cha, J.; Burckel, D.B. Highly ordered tailored three-dimensional hierarchical nano/microporous gold–carbon architectures. J. Mater. Chem. 2012, 22, 11950–11956. [Google Scholar] [CrossRef]

- Loewner, S.; Heene, S.; Baroth, T.; Heymann, H.; Cholewa, F.; Blume, H.; Blume, C. Recent advances in melt electro writing for tissue engineering for 3D printing of microporous scaffolds for tissue engineering. Front. Bioeng. Biotechnol. 2022, 10, 896719. [Google Scholar] [CrossRef]

- Jin, Y.; Xie, C.; Gao, Q.; Zhou, X.; Li, G.; Du, J.; He, Y. Fabrication of multi-scale and tunable auxetic scaffolds for tissue engineering. Mater. Des. 2021, 197, 109277. [Google Scholar] [CrossRef]

- Pawar, R.; Pathan, A.; Nagaraj, S.; Kapare, H.; Giram, P.; Wavhale, R. Polycaprolactone and its derivatives for drug delivery. Polym. Adv. Technol. 2023, 34, 3296–3316. [Google Scholar] [CrossRef]

- Tu, J.; Chu, C.; Gao, Y.; Wang, Z.; Xu, P.; Ding, Y. Enhanced dielectric and mechanical properties of polylactic acid/polycaprolactone blends by introducing double-layer carbon nanofillers. J. Appl. Polym. Sci. 2024, 141, e54874. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Pan, Y.; Huang, H. A Capacitive Pressure Sensor with a Hierarchical Microporous Scaffold Prepared by Melt Near-Field Electro-Writing. Sensors 2025, 25, 2814. https://doi.org/10.3390/s25092814

Zheng Z, Pan Y, Huang H. A Capacitive Pressure Sensor with a Hierarchical Microporous Scaffold Prepared by Melt Near-Field Electro-Writing. Sensors. 2025; 25(9):2814. https://doi.org/10.3390/s25092814

Chicago/Turabian StyleZheng, Zhong, Yifan Pan, and Hao Huang. 2025. "A Capacitive Pressure Sensor with a Hierarchical Microporous Scaffold Prepared by Melt Near-Field Electro-Writing" Sensors 25, no. 9: 2814. https://doi.org/10.3390/s25092814

APA StyleZheng, Z., Pan, Y., & Huang, H. (2025). A Capacitive Pressure Sensor with a Hierarchical Microporous Scaffold Prepared by Melt Near-Field Electro-Writing. Sensors, 25(9), 2814. https://doi.org/10.3390/s25092814