Identification and Stability Analysis of Mine Goafs in Mineral Engineering Based on Multi-Survey Data

Abstract

Highlights

- Integration of multi-survey data from remote sensing and 3D laser scanning to identify risky mine goafs.

- Construction of detailed 3D models of complex mine goafs using FLAC3D for numerical simulation.

- Verification of numerical simulation results with on-site investigations to assess geological disasters.

- Effective technical means for detailed surveys and stability assessments of mineral engineering in complex mine goafs are provided.

- The integration of remote sensing and 3D laser scanning enables precise location and shape reconstruction of complex mine goafs.

- Numerical simulations reveal the stress distribution, failure mechanisms, and surface deformation responses of mine goafs, highlighting their impact on mine stability.

- On-site investigations confirm the geological hazards predicted by the numerical models, validating the reliability of the proposed methods.

- The research provides a comprehensive technical approach for assessing and mitigating risks associated with complex mine goafs.

- The proposed methods significantly improve our ability to identify and assess risks in mineral engineering with complex goafs, reducing the likelihood of geological disasters.

- The integration of remote sensing, 3D laser scanning, and numerical modeling offers a practical solution for detailed goaf surveys and stability evaluations.

- The findings can inform regulatory frameworks and safety standards for mining operations in regions with unregulated historical mining activities.

- The study advances the use of multi-survey data and numerical simulations in mining engineering, setting a precedent for future research and applications.

Abstract

1. Introduction

2. Data and Methods

2.1. Data

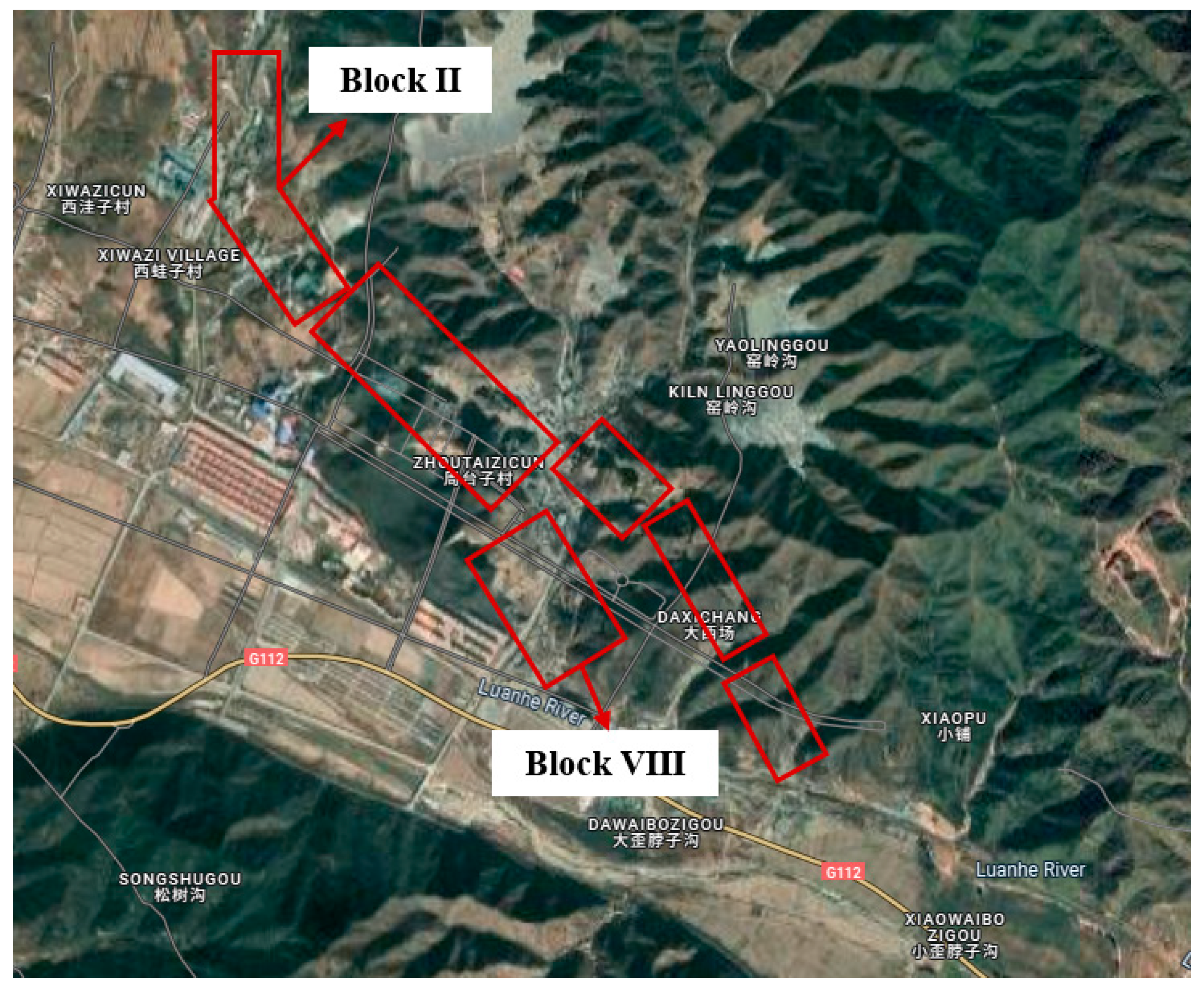

2.1.1. Study Area and Geological Context

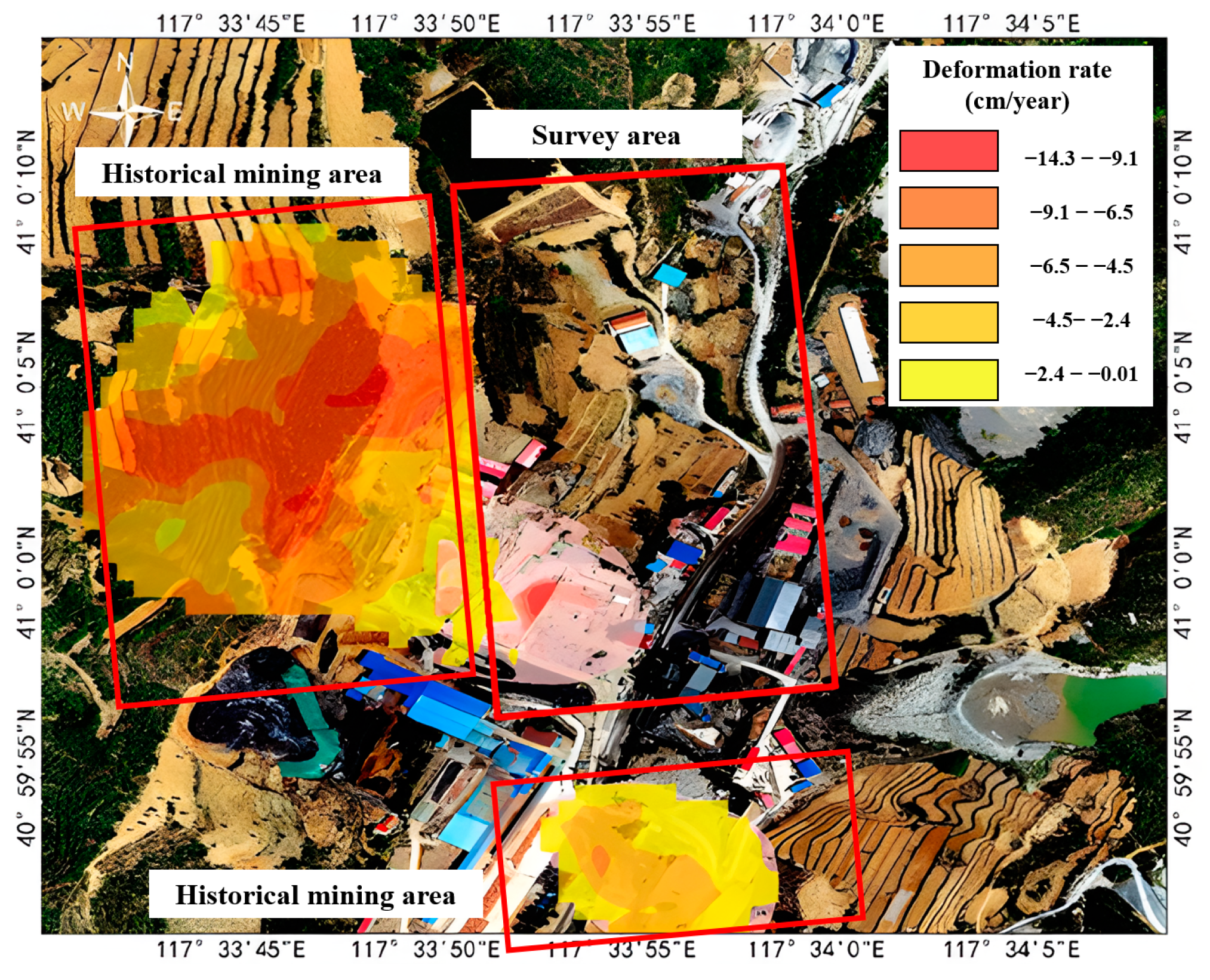

2.1.2. Remote Sensing Data

- (1)

- InSAR time-series data

- (2)

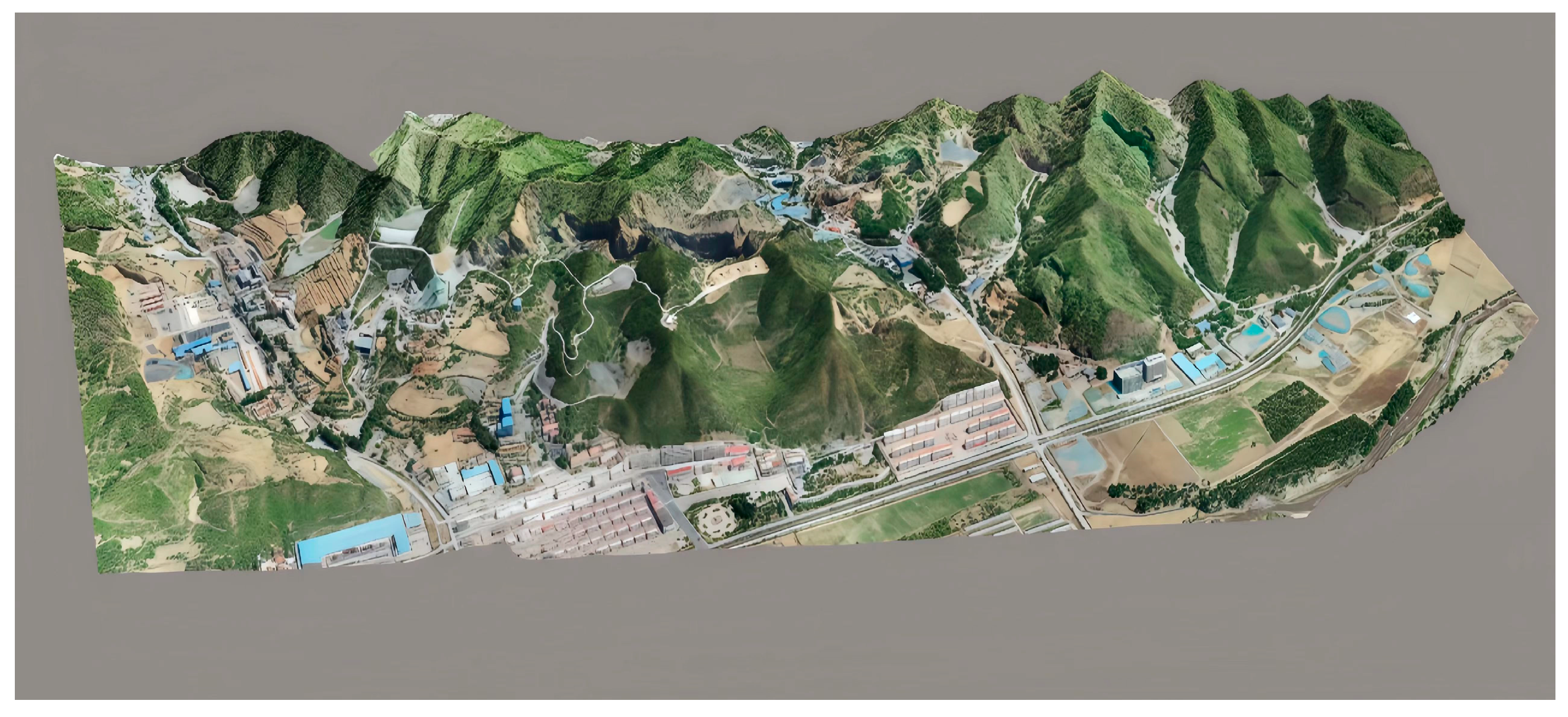

- UAV imagery

- (3)

- Terrestrial LiDAR scans

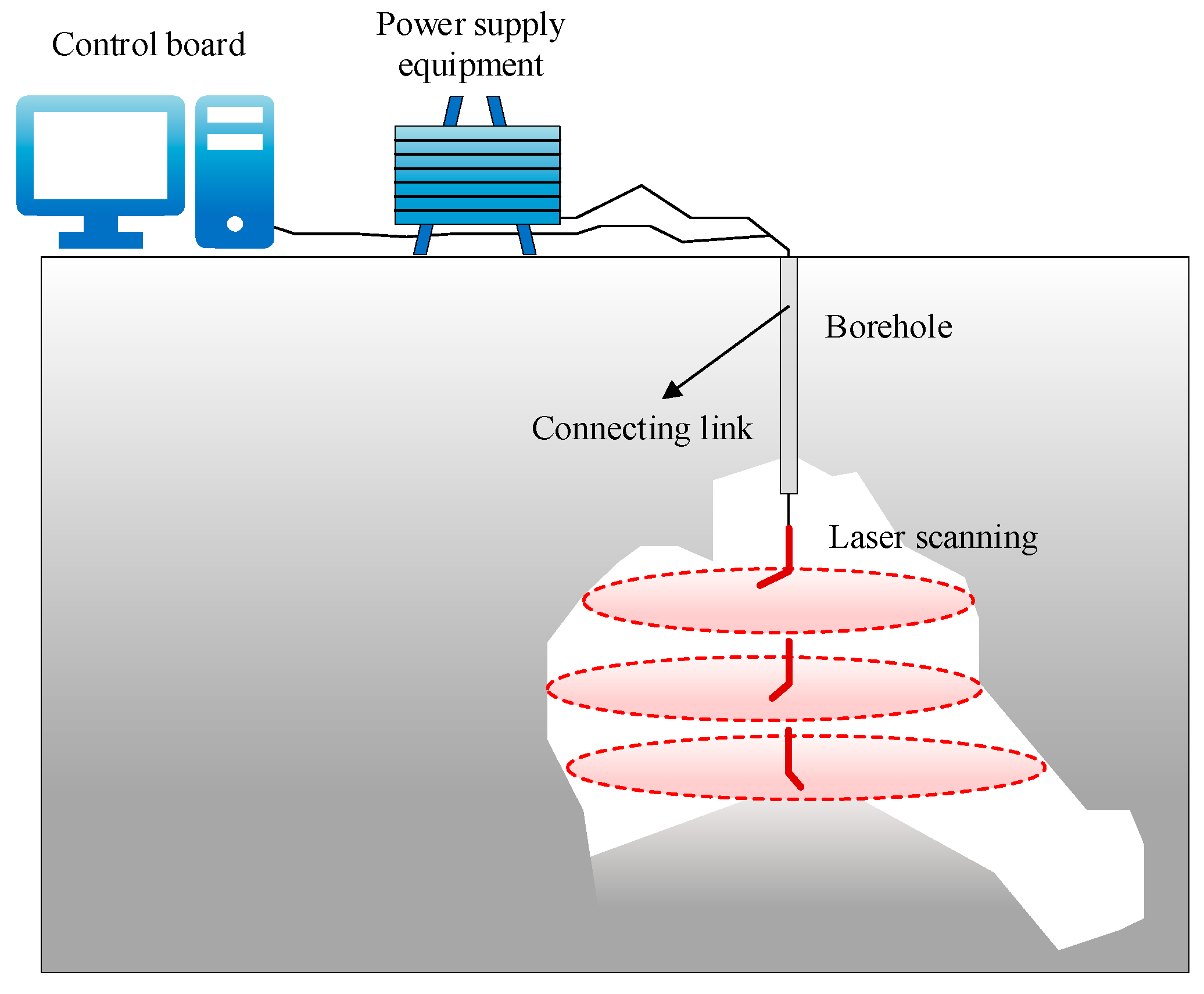

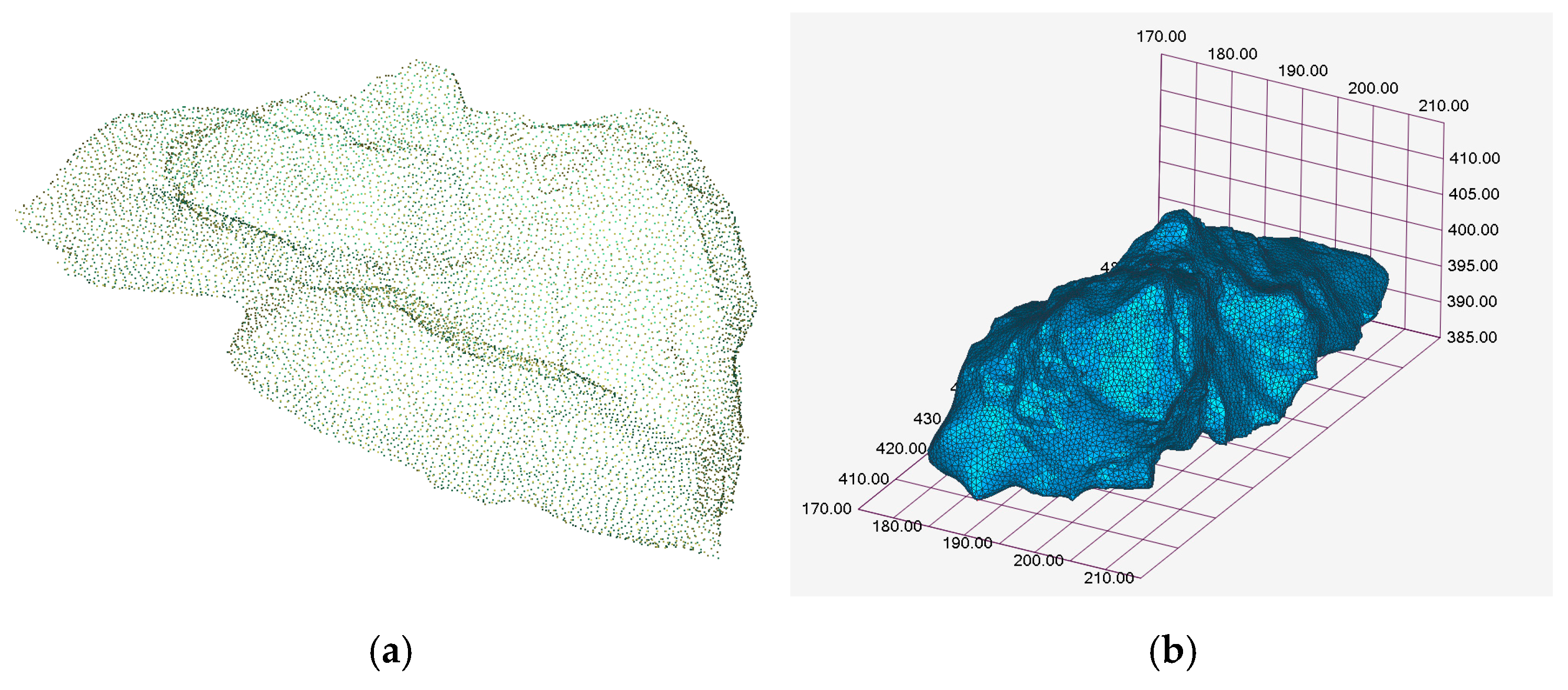

2.1.3. Subsurface Scanning Data

2.2. Methods

2.2.1. Integrated Surface Monitoring Techniques

2.2.2. Subsurface Void Detection and Modeling

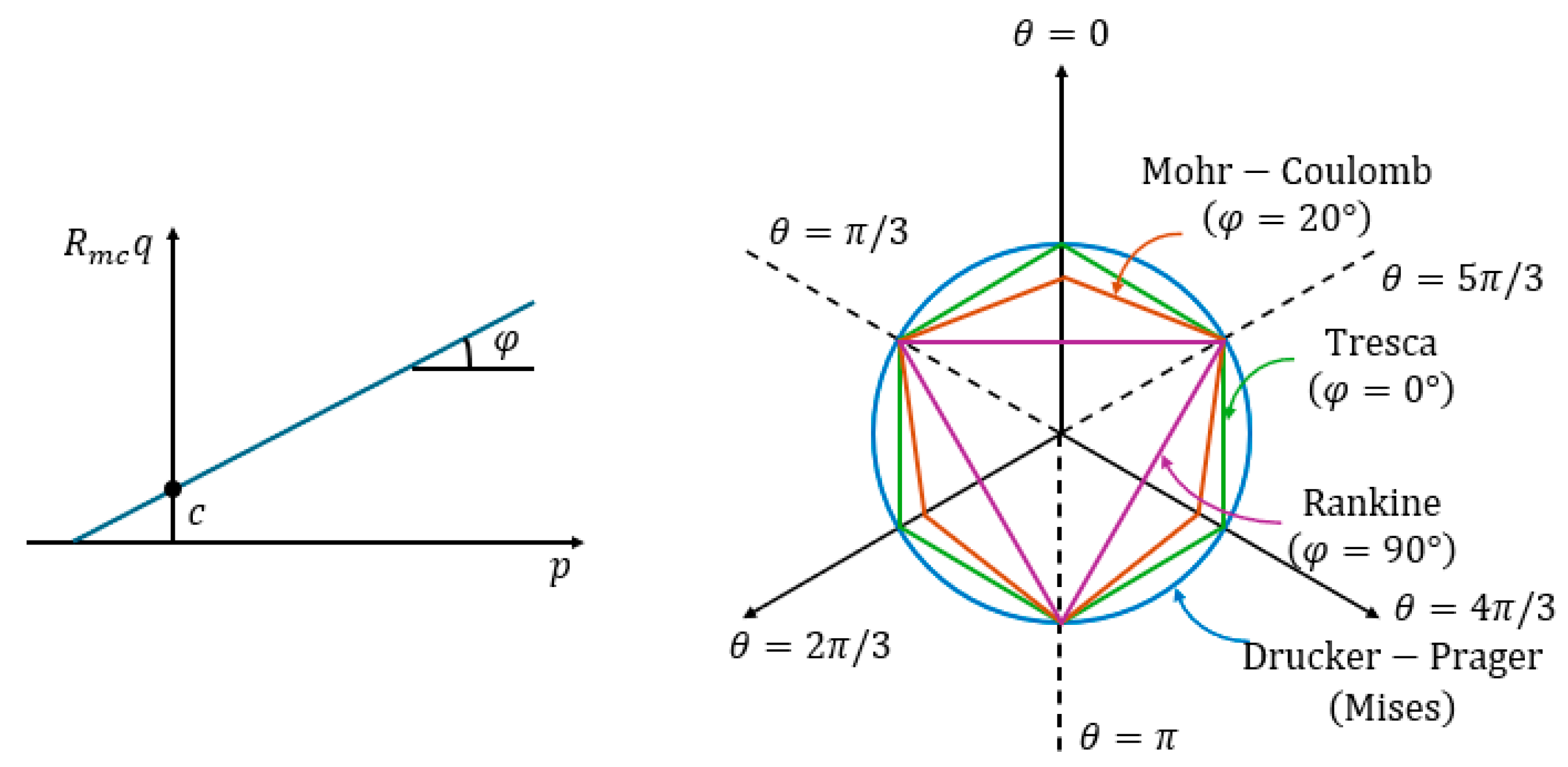

2.2.3. Numerical Modeling of Goaf Stability

3. Results

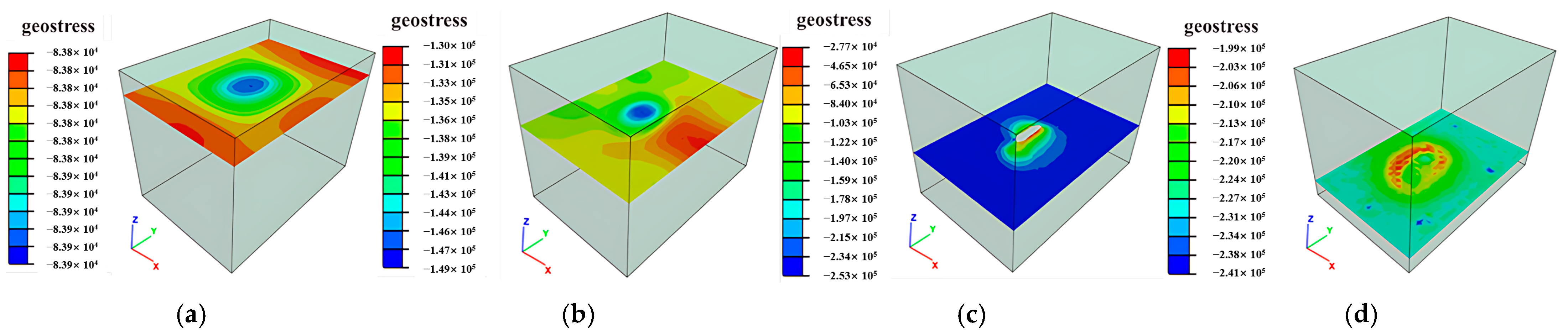

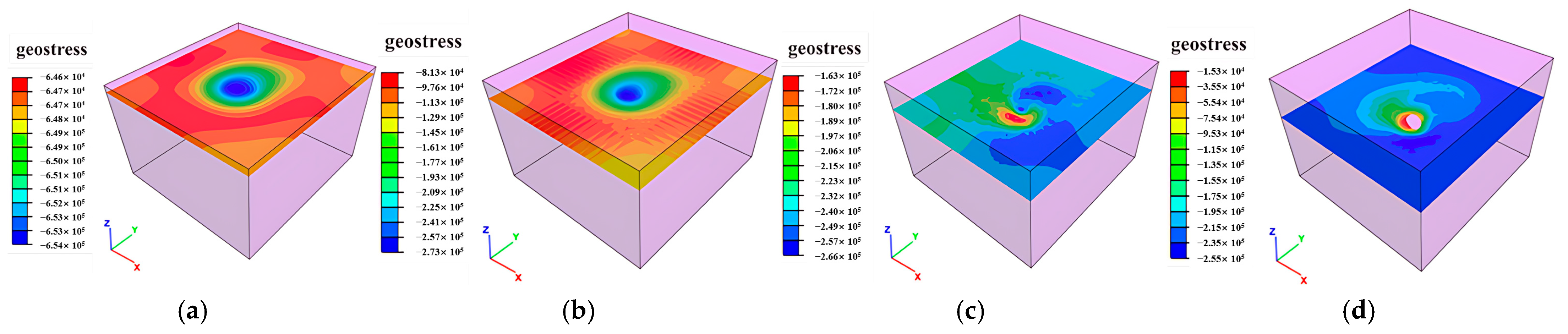

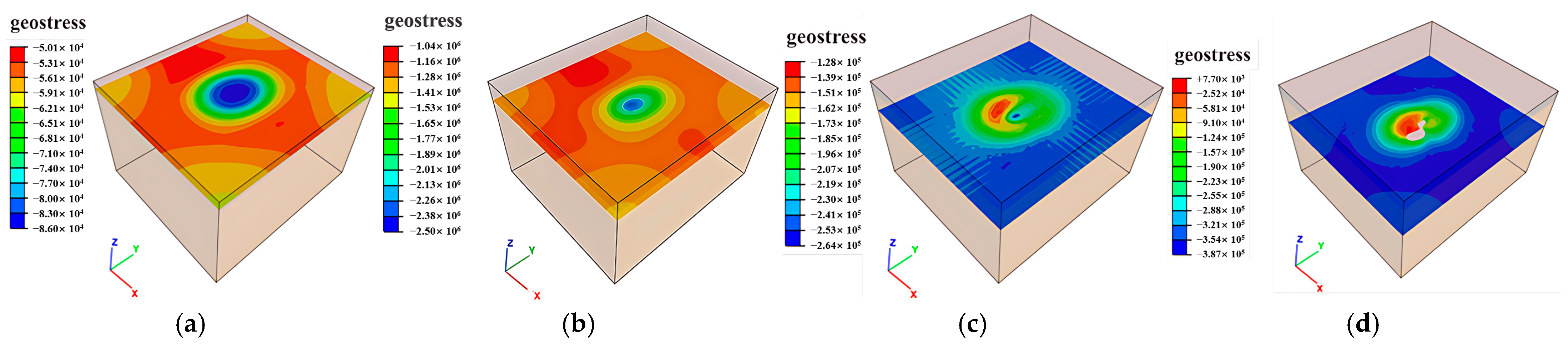

3.1. Ground Pressure Distribution Characteristics

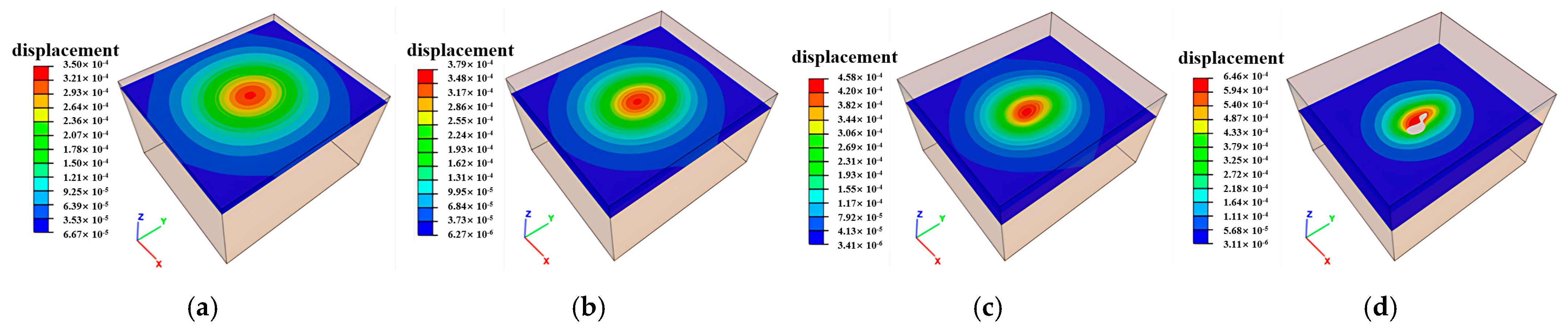

3.2. Deformation Distribution Characteristics

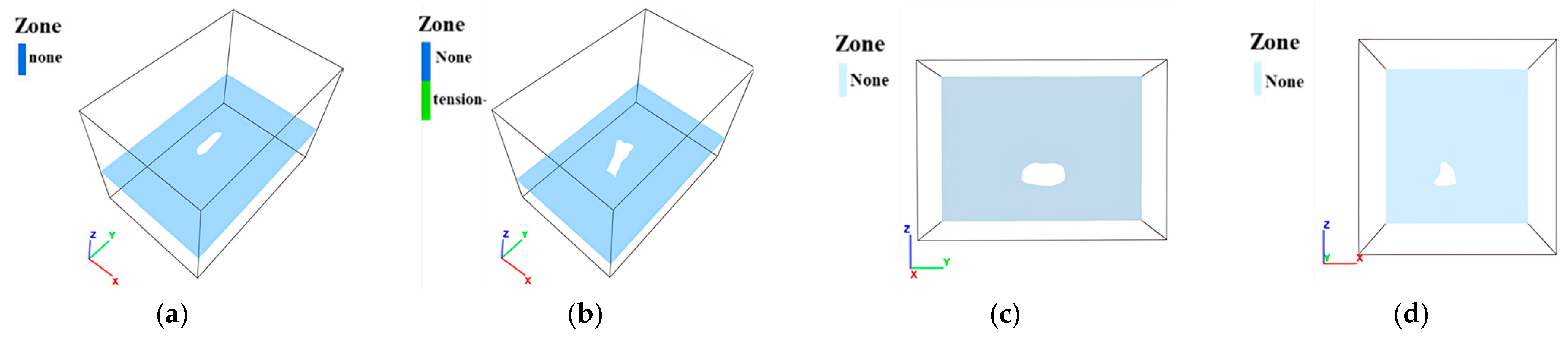

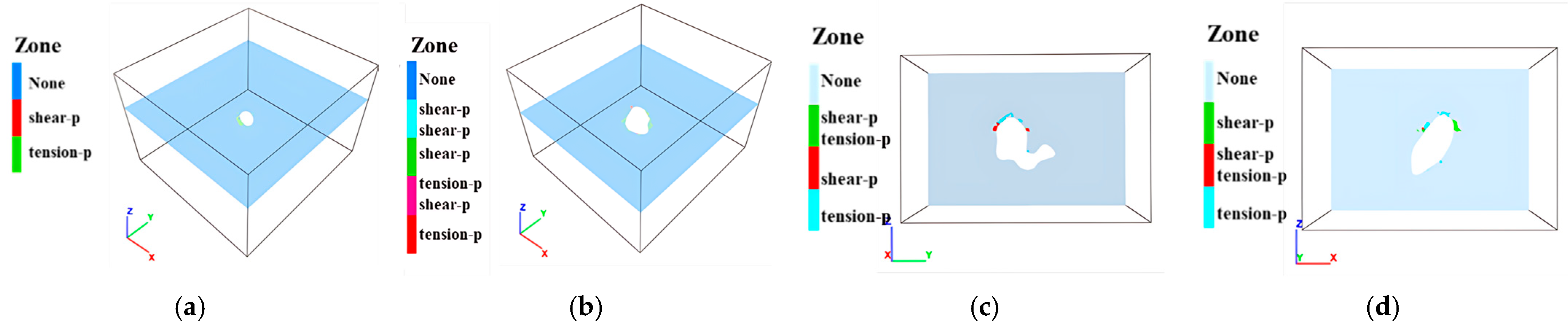

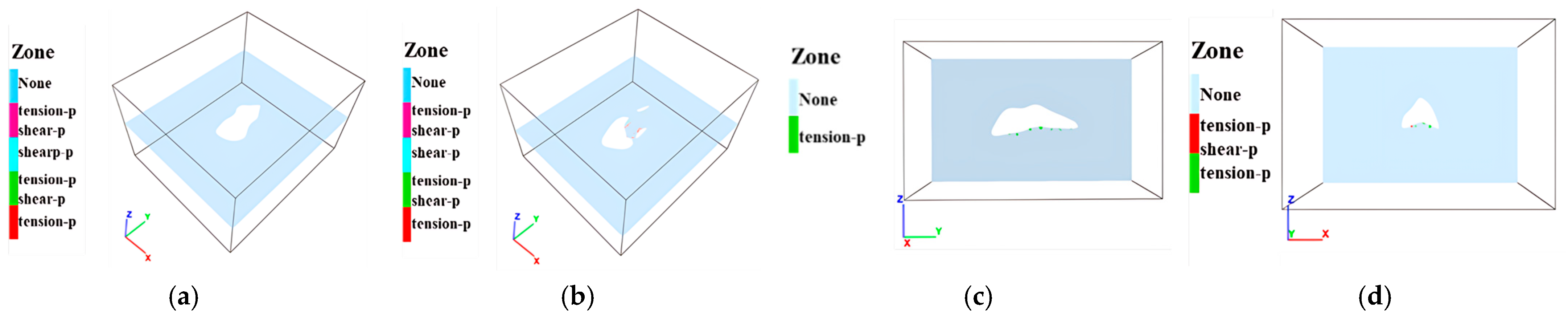

3.3. Destruction of Surrounding Rock

3.4. Surface Subsidence Distribution Characteristics

3.5. Engineering Validation

3.5.1. Ground Subsidence and Surface Fissures in Goaf Regions

3.5.2. Slope Collapse in Mining Pit

4. Conclusions

- (1)

- A novel integration of surface deformation monitoring techniques—incorporating InSAR, UAV photogrammetry, and terrestrial LiDAR (C-ALS)—successfully identified high-risk goafs, with measured surface deformation rates reaching 14 cm/year. The 3D laser scanning system provides groundbreaking capability for characterizing geometrically complex underground voids, offering new technical solutions for mineral engineering applications.

- (2)

- Stability analysis revealed distinct risk stratification: Goafs in ZK4 (Block II) and ZK10 (Block VIII) exhibit unstable conditions, while those in ZK5 and ZK6 (Block II) of maintain marginal stability. Stress concentrations predominantly occur at geometric discontinuities in goaf sidewalls, where tensile stress development in roof strata precipitates localized rockfall hazards due to the inherently low tensile strength of fractured rock masses.

- (3)

- Field verification confirmed that numerical simulation results accurately predict actual geohazards, including ground subsidence craters and slope collapses that critically compromise mine safety. These findings necessitate implementation of high-frequency deformation monitoring coupled with targeted support measures (reinforcement or backfilling) to mitigate geological risks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Yan, Y.; Liu, K.; Zhao, X.; Li, H.; Cao, J.; Zhang, S.; Ma, K. Analysis of Coal Mine Safety Accident Features in China, 2017–2022. Geohazard Mech. 2024, 2, 108–120. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, C.; Jiao, H. Ultimately Exposed Roof Area Prediction of Bauxite Deposit Goaf Based on Macro Joint Damage. Int. J. Min. Sci. Technol. 2020, 30, 699–704. [Google Scholar] [CrossRef]

- Lu, W.; Guo, Z.; Hu, H.; Zhou, Y.; Wang, C.; Zhang, B. Stability Evaluation of Mined-Out Area and Borehole Grouting Treatment—A Case Study in China. Case Stud. Constr. Mater. 2023, 19, e02596. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, X.; Chen, W.; Zhang, F.; Tian, Z. Detection of Water-Enriched Goaf via the Semi-Airborne Transient Electromagnetic Method. J. Appl. Geophys. 2023, 212, 105011. [Google Scholar] [CrossRef]

- Zhu, Y.; Yan, Y.; Dai, A.; Dai, H.; Zhang, Y.; Zhang, W.; Wang, Z.; Li, J. UAV-MSSH: A Novel UAV Photogrammetry-Based Framework for Mining Surface Three-Dimensional Movement Basin Monitoring. Measurement 2025, 242, 115944. [Google Scholar] [CrossRef]

- Can, E. Assessment of Risks Relevant to Underground Measurements for Coal Mining Production and Exploration. Nat. Resour. Res. 2020, 29, 1773–1785. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, S.; Sun, Y.; Yang, X.; Yin, J.; Wang, L.; Du, W. Application of Comprehensive Geophysical Prospecting Method in Fine Detection of Goaf. Chem. Technol. Fuels Oils 2023, 59, 1089–1096. [Google Scholar] [CrossRef]

- Cao, B.; Wang, J.; Du, H.; Tao, Y.; Liu, G. Research on Comprehensive Detection and Visualization of Hidden Cavity Goaf. Sci. Rep. 2022, 12, 22309. [Google Scholar] [CrossRef]

- Cho, H.; Lee, M.; Sun, C.; Kim, H. Evaluation of Engineering Site Conditions in North Gyeongsang Province, South Korea, Using a Large Database of Borehole and Standard Penetration Test Data. Eng. Geol. 2021, 294, 106306. [Google Scholar] [CrossRef]

- Wang, Y.; Si, G.; Belle, B.; Webb, D.; Zhao, L.; Oh, J. Impact of Goaf Gas Drainage from Surface Vertical Boreholes on Goaf Explosive Gas Zones. Int. J. Coal Geol. 2024, 284, 104461. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, G.; Wang, X. Development and Application of a Goaf-Safety Monitoring System Using Multi-Sensor Information Fusion. Tunn. Undergr. Space Technol. 2019, 94, 103112. [Google Scholar] [CrossRef]

- Singh, S.; Banerjee, B.; Raval, S. A Review of Laser Scanning for Geological and Geotechnical Applications in Underground Mining. Int. J. Min. Sci. Technol. 2023, 33, 133–154. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Z.; Zhu, J.; Yi, H.; Feng, G.; Hu, J.; Wu, L.; Preusse, A.; Wang, Y.; Papst, M. Locating and Defining Underground Goaf Caused by Coal Mining from Space-Borne SAR Interferometry. ISPRS J. Photogramm. Remote Sens. 2018, 135, 112–126. [Google Scholar] [CrossRef]

- Liu, P.-H.; Wu, J.-H.; Lee, D.-H.; Lin, Y.-H. Detecting Landslide Vulnerability Using Anisotropic Microtremors and Vulnerability Index. Eng. Geol. 2023, 323, 107240. [Google Scholar] [CrossRef]

- Wei, M.; Song, D.; He, X.; Lou, Q.; Li, Z.; Qiu, L.; He, S. New Approach to Monitoring and Characterizing the Directionality of Electromagnetic Radiation Generated from Rock Fractures. J. Appl. Geophys. 2023, 211, 104925. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, X.; Qiu, Y.; Shi, X.; Du, K. Microseismic Location in Hardrock Metal Mines by Machine Learning Models Based on Hyperparameter Optimization Using Bayesian Optimizer. Rock Mech. Rock Eng. 2023, 56, 8771–8788. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, J. Refined Approaches for Open Stope Stability Analysis in Mining Environments: Hybrid SVM Model with Multi-Optimization Strategies and GP Technique. Rock Mech. Rock Eng. 2024, 57, 9781–9804. [Google Scholar] [CrossRef]

- He, L.; Wu, D.; Ma, L. Numerical Simulation and Verification of Goaf Morphology Evolution and Surface Subsidence in a Mine. Eng. Fail. Anal. 2023, 144, 106918. [Google Scholar] [CrossRef]

- Ke, L.; Wu, M.; Ye, Y.; Hu, N.; Meng, Y. Stability Risk Early Warning for Mine Goaf: Based on D-RES and Asymmetric Fuzzy Connection Cloud Model. J. Comput. Sci. 2024, 78, 102279. [Google Scholar] [CrossRef]

- Li, M.; Li, K.; Liu, Y.; Wu, S.; Qin, Q.; Yue, R. Goaf Risk Prediction Based on IAOA–SVM and Numerical Simulation: A Case Study. Undergr. Space 2024, 15, 153–175. [Google Scholar] [CrossRef]

- Fan, H.; Li, T.; Gao, Y.; Deng, K.; Wu, H. Characteristics inversion of underground goaf based on InSAR techniques and PIM. Int. J. Appl. Earth Obs. Geoinf. 2021, 103, 102526. [Google Scholar] [CrossRef]

- Jia, N. Structural detection of goaf based on three-dimensional ERT technology. Syst. Soft Comput. 2025, 7, 200179. [Google Scholar] [CrossRef]

- Zhou, Y.; Feng, S.; Li, J. Study on the Failure Mechanism of Rock Mass Around a Mined-Out Area Above a Highway Tunnel: Similarity Model Test and Numerical Analysis. Tunn. Undergr. Space Technol. 2021, 118, 104182. [Google Scholar] [CrossRef]

- Feng, D.; Gan, L.; Xiong, M.; Li, W.; Huang, Y. Uncertainty Analysis of 3D Post-Failure Behavior in Landslide and Reinforced Slope Based on the SPH Method and the Random Field Theory. Eng. Geol. 2025, 350, 108017. [Google Scholar] [CrossRef]

- T/SZEMA 0002-2022; Code for InSAR Settlement Monitoring and Early Warning. Shenzhen Environmental Monitoring Association: Shenzhen, China, 2022.

| Warning Level | I (Low Risk) | II (Medium Risk) | III (High Risk) |

|---|---|---|---|

| Surface deformation rate (mm/year) | <10 | 10–20 | >20 |

| Risk description | The surface deformation is controllable and belongs to normal fluctuation. | The surface deformation is obvious, and there are potential safety hazards. | Severe surface deformation may lead to pavement collapse. |

| Counter measure | Routine monitoring | Strengthen monitoring frequency | Start emergency reinforcement |

| Main Parameters | Length (m) | Spatial Volume (m3) | Accurate Model Shape | ||

|---|---|---|---|---|---|

| X-Axis | Y-Axis | Z-Axis | |||

| ZK4 in Block II | 14.59 | 21.07 | 7.35 | 442.90 |  |

| ZK5, ZK6 in Block II | 43.35 | 69.09 | 49.09 | 29,280.60 |  |

| ZK10 in Block VIII | 36.60 | 68.97 | 27.95 | 20,097.60 |  |

| Name | Modulus of Elasticity (GPa) | Cohesion (MPa) | Internal Friction Angle (°) | Poisson’s Ratio | Compressive Strength (MPa) | Tensile Strength (MPa) | Density (kg/m3) |

|---|---|---|---|---|---|---|---|

| Upper surrounding rock | 19.00 | 2.50 | 55 | 0.30 | 62.50 | 3.75 | 2700 |

| Lower surrounding rock | 25.43 | 3.50 | 65 | 0.23 | 96.08 | 3.34 | 2900 |

| Magnetite | 29.27 | 4.20 | 70 | 0.27 | 227.00 | 3.38 | 3270 |

| Location | Subsidence Area (m2) | Damage Characteristics |

|---|---|---|

| Block II | 200 | Surface subsidence with collapse crater formation, accompanied by roadway degradation |

| Block VIII | 2879 | Extensive ground collapse, surface fissure propagation, and localized slope failures |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, H.; Zhang, M.; Min, Q.; Han, S.; Zhang, J.; Li, M. Identification and Stability Analysis of Mine Goafs in Mineral Engineering Based on Multi-Survey Data. Sensors 2025, 25, 2776. https://doi.org/10.3390/s25092776

Jia H, Zhang M, Min Q, Han S, Zhang J, Li M. Identification and Stability Analysis of Mine Goafs in Mineral Engineering Based on Multi-Survey Data. Sensors. 2025; 25(9):2776. https://doi.org/10.3390/s25092776

Chicago/Turabian StyleJia, Huihui, Mengxi Zhang, Qiaoling Min, Shuai Han, Jingyi Zhang, and Mingchao Li. 2025. "Identification and Stability Analysis of Mine Goafs in Mineral Engineering Based on Multi-Survey Data" Sensors 25, no. 9: 2776. https://doi.org/10.3390/s25092776

APA StyleJia, H., Zhang, M., Min, Q., Han, S., Zhang, J., & Li, M. (2025). Identification and Stability Analysis of Mine Goafs in Mineral Engineering Based on Multi-Survey Data. Sensors, 25(9), 2776. https://doi.org/10.3390/s25092776