Path Planning for Dragon-Fruit-Harvesting Robotic Arm Based on XN-RRT* Algorithm

Abstract

1. Introduction

2. Robotic Arm Path Planning and Collision Detection

2.1. Path Planning Definition

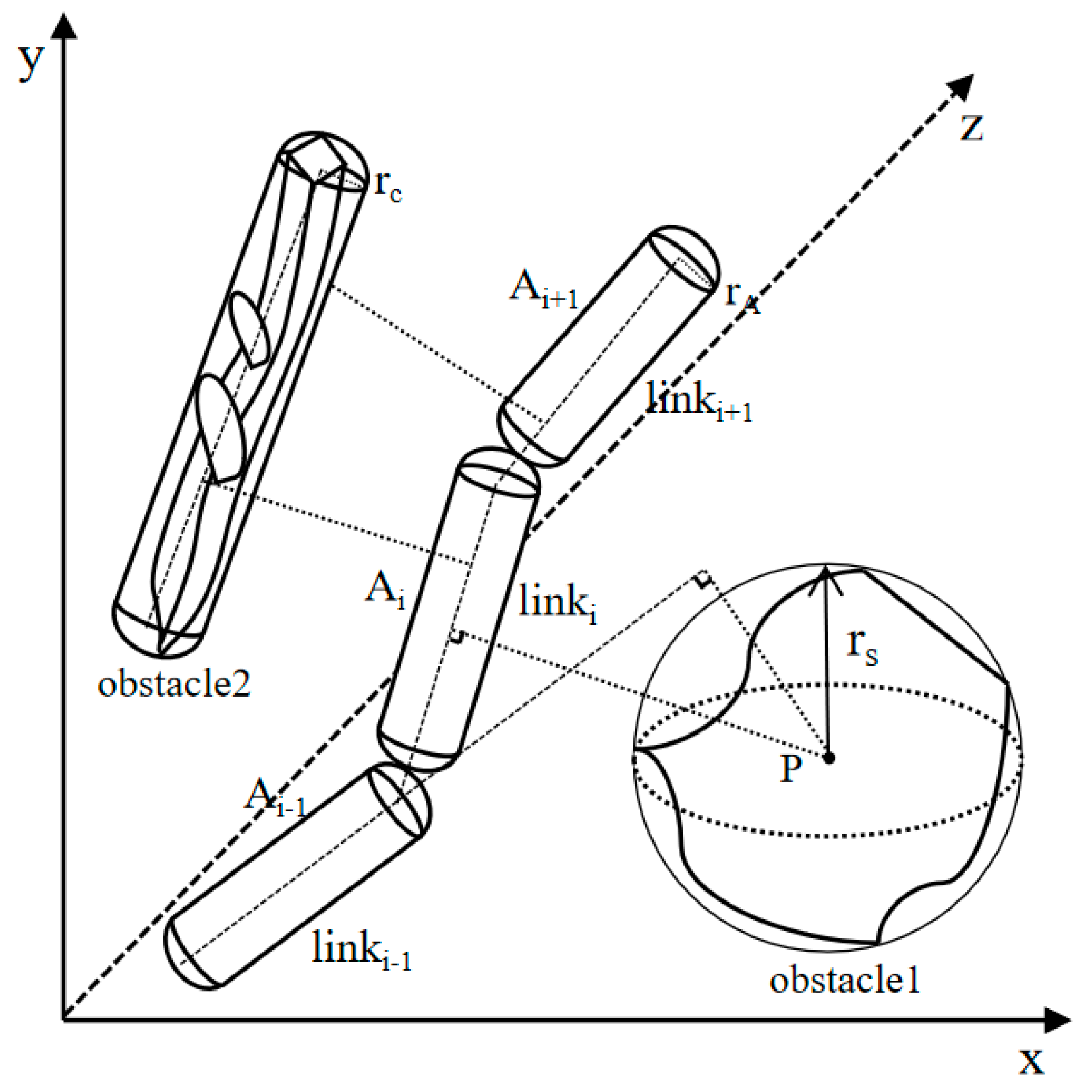

2.2. Collision Detection Description

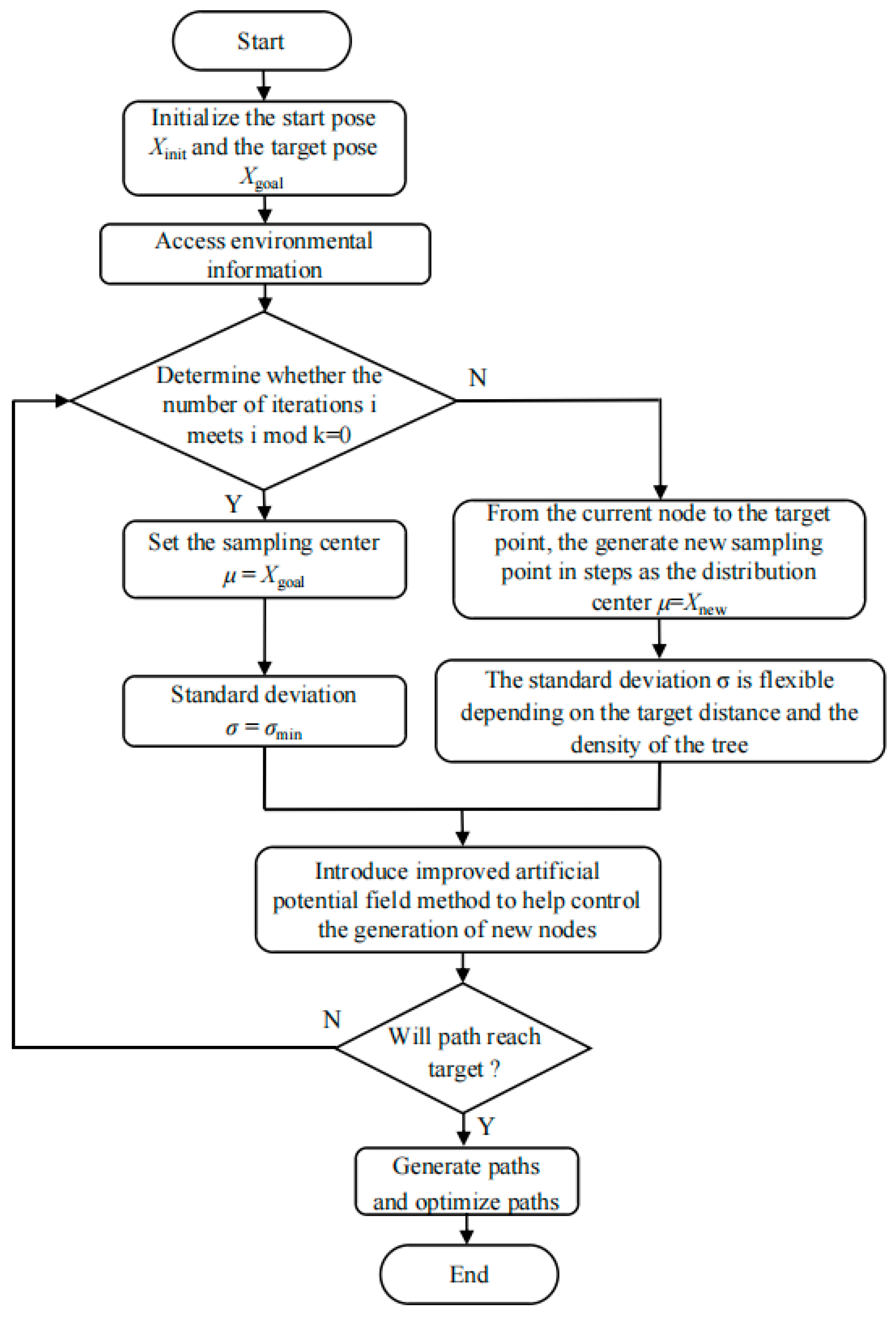

3. XN-RRT* Algorithm

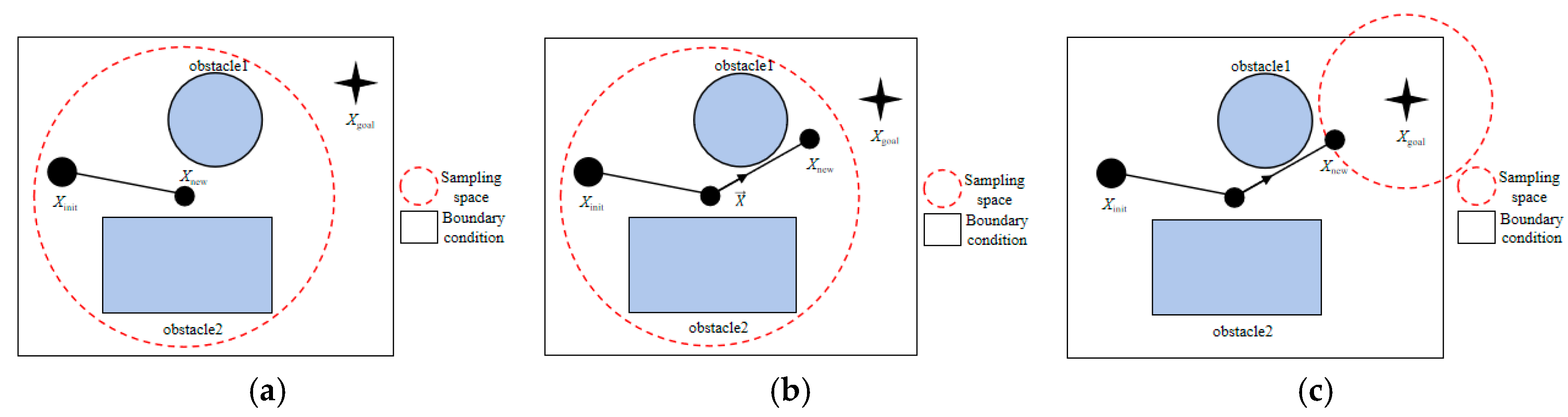

3.1. Based on Normal Distribution Dynamic Sampling Method

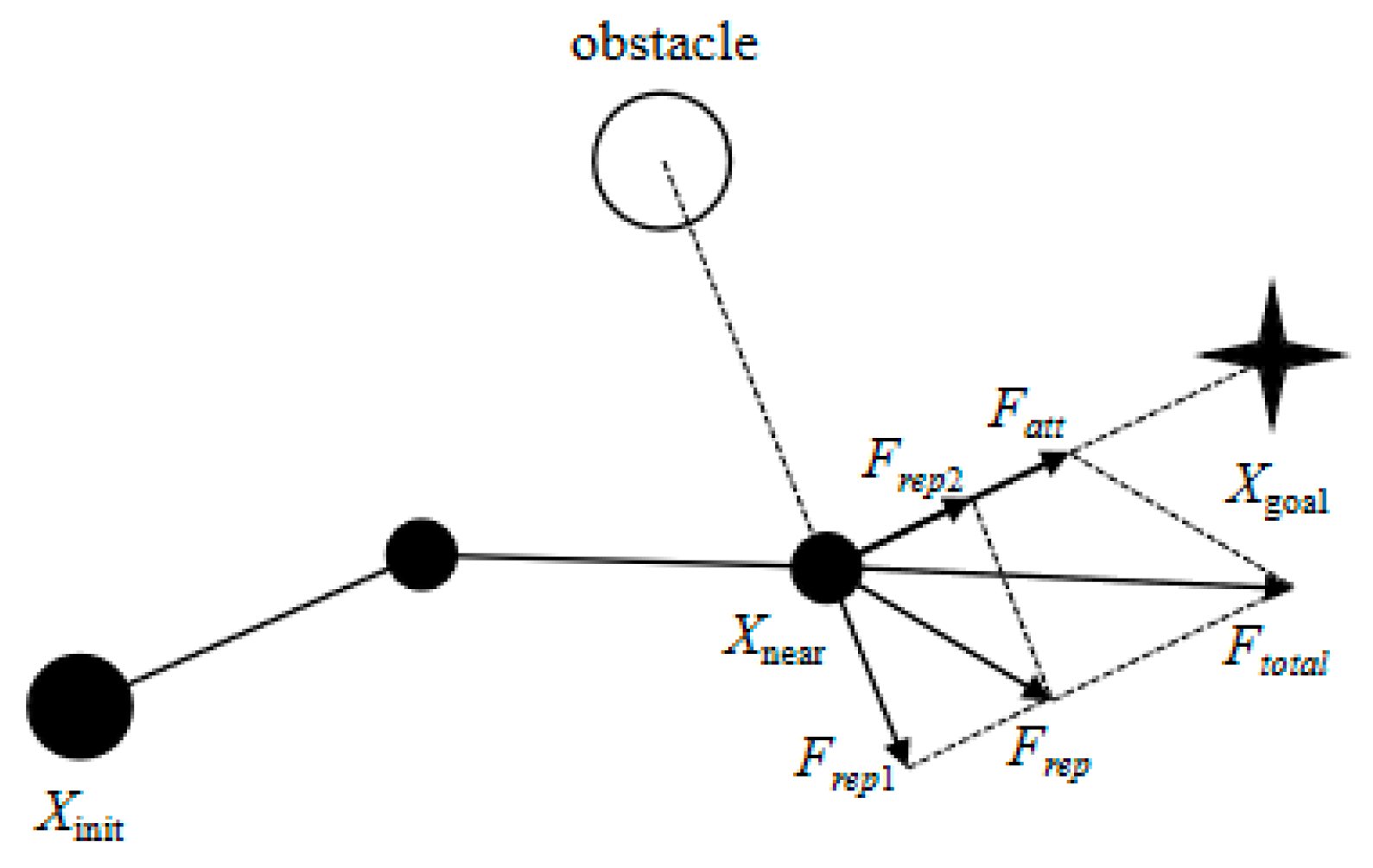

3.2. Improved Artificial Potential Field Method-Assisted Guided Sampling Strategy

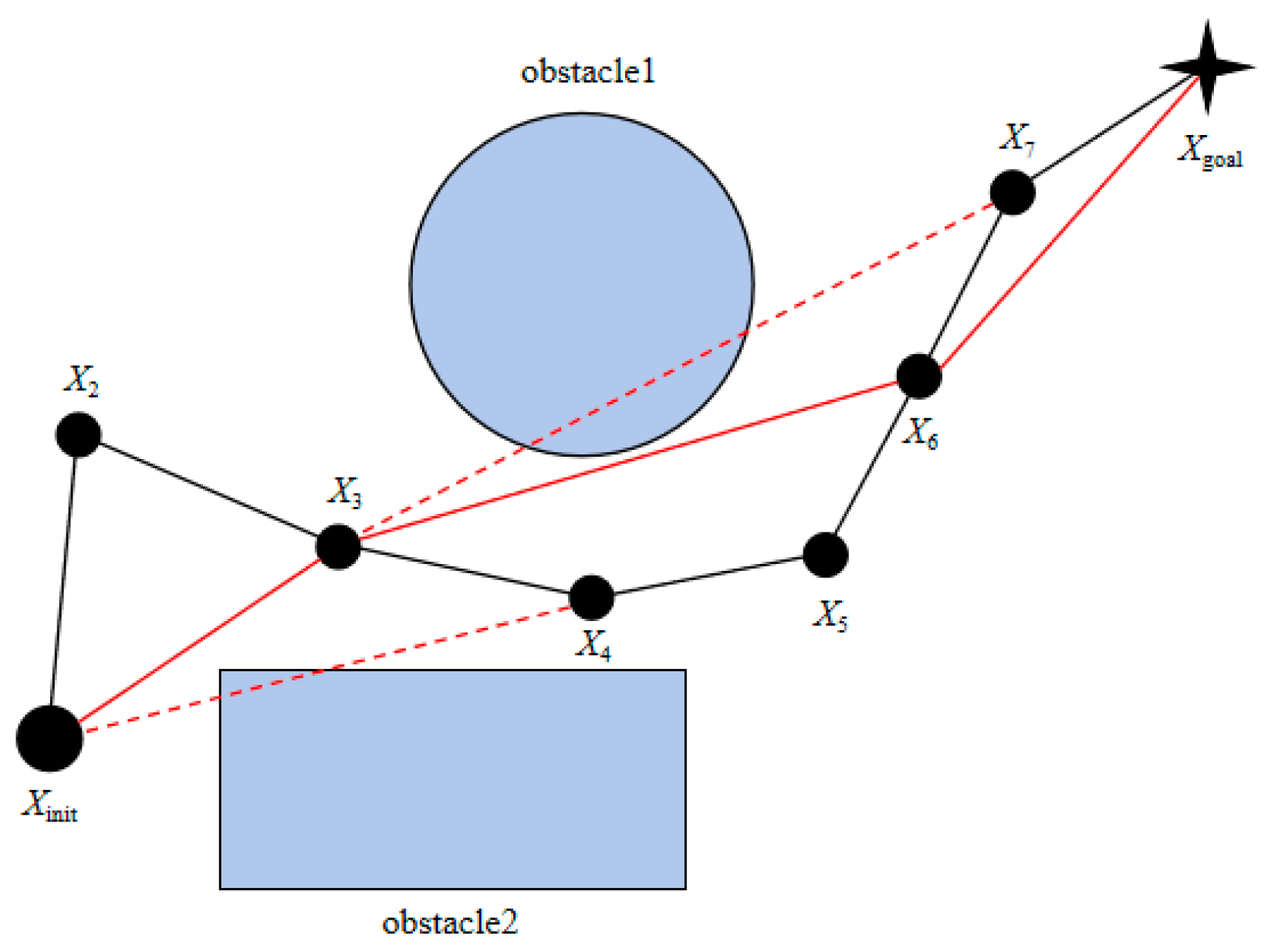

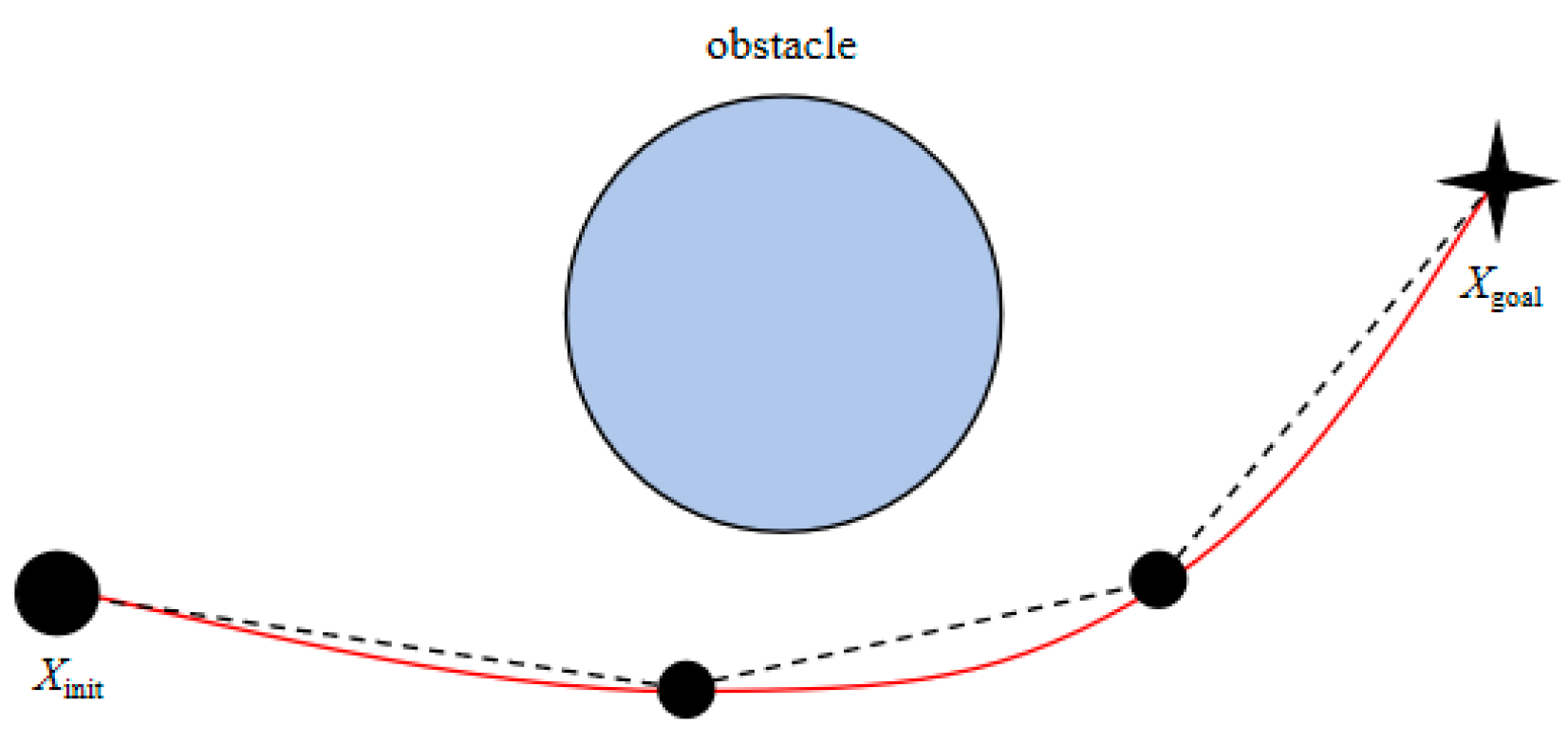

3.3. Path Optimization Method

4. Algorithm Simulation and Analysis

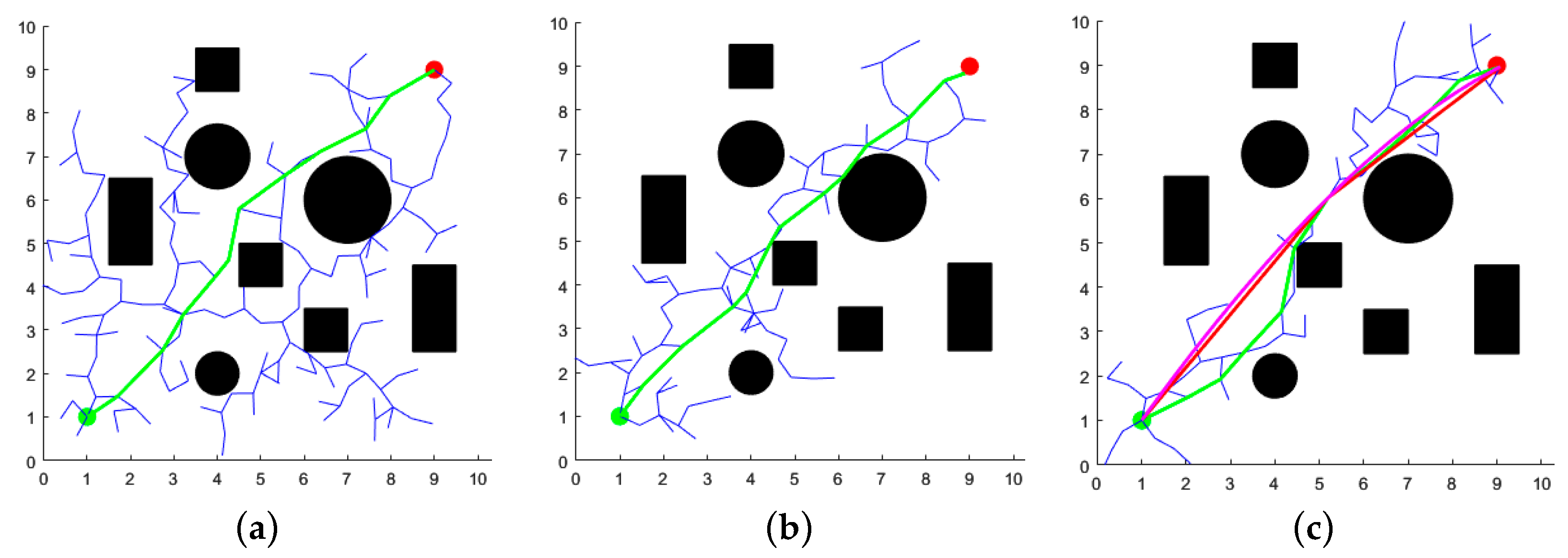

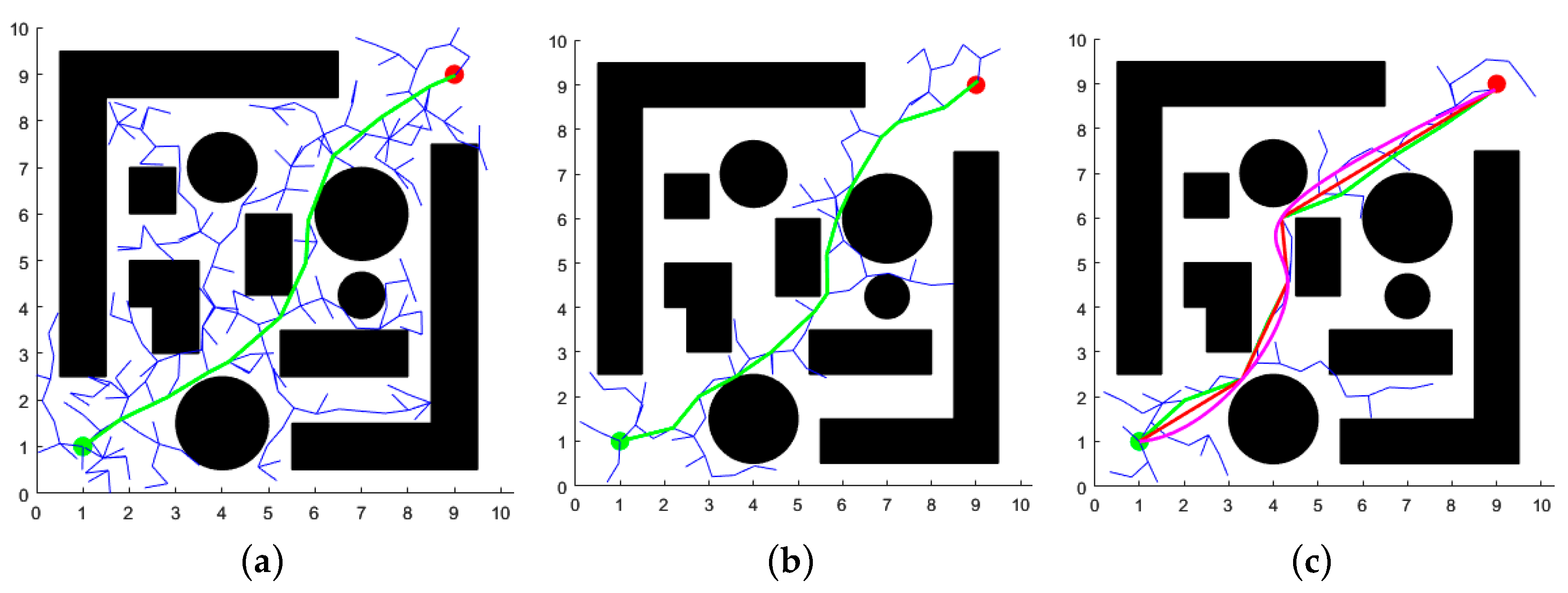

4.1. Two-Dimensional Space Simulation and Analysis

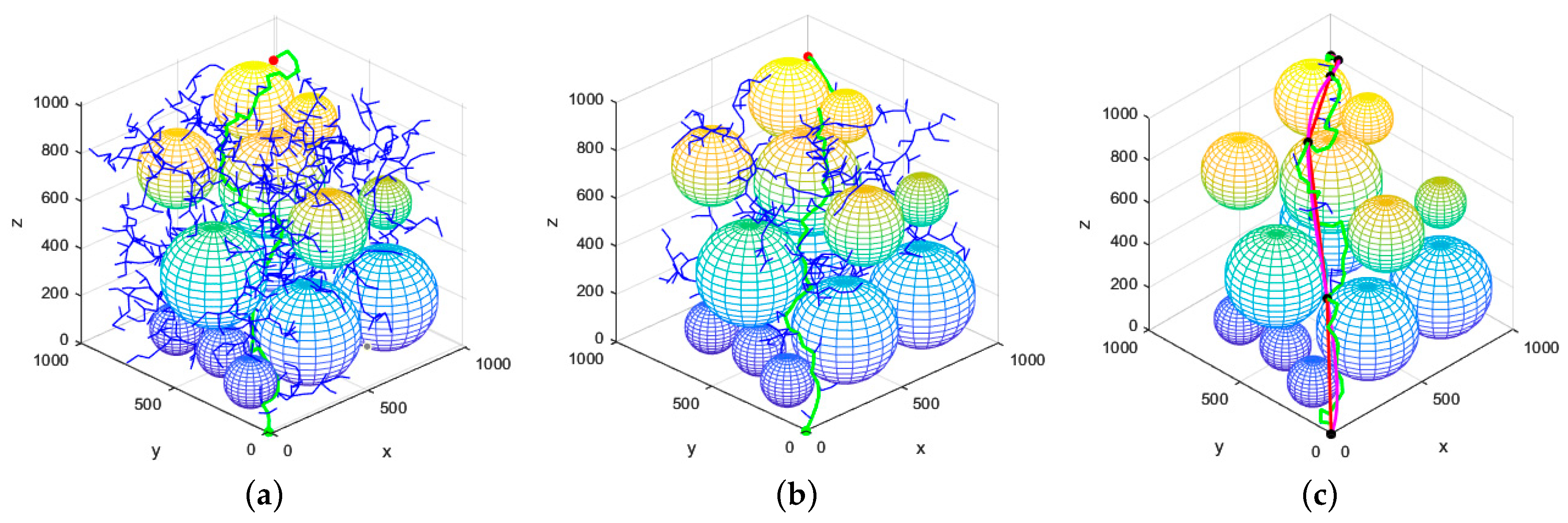

4.2. Three-Dimensional Space Simulation and Analysis

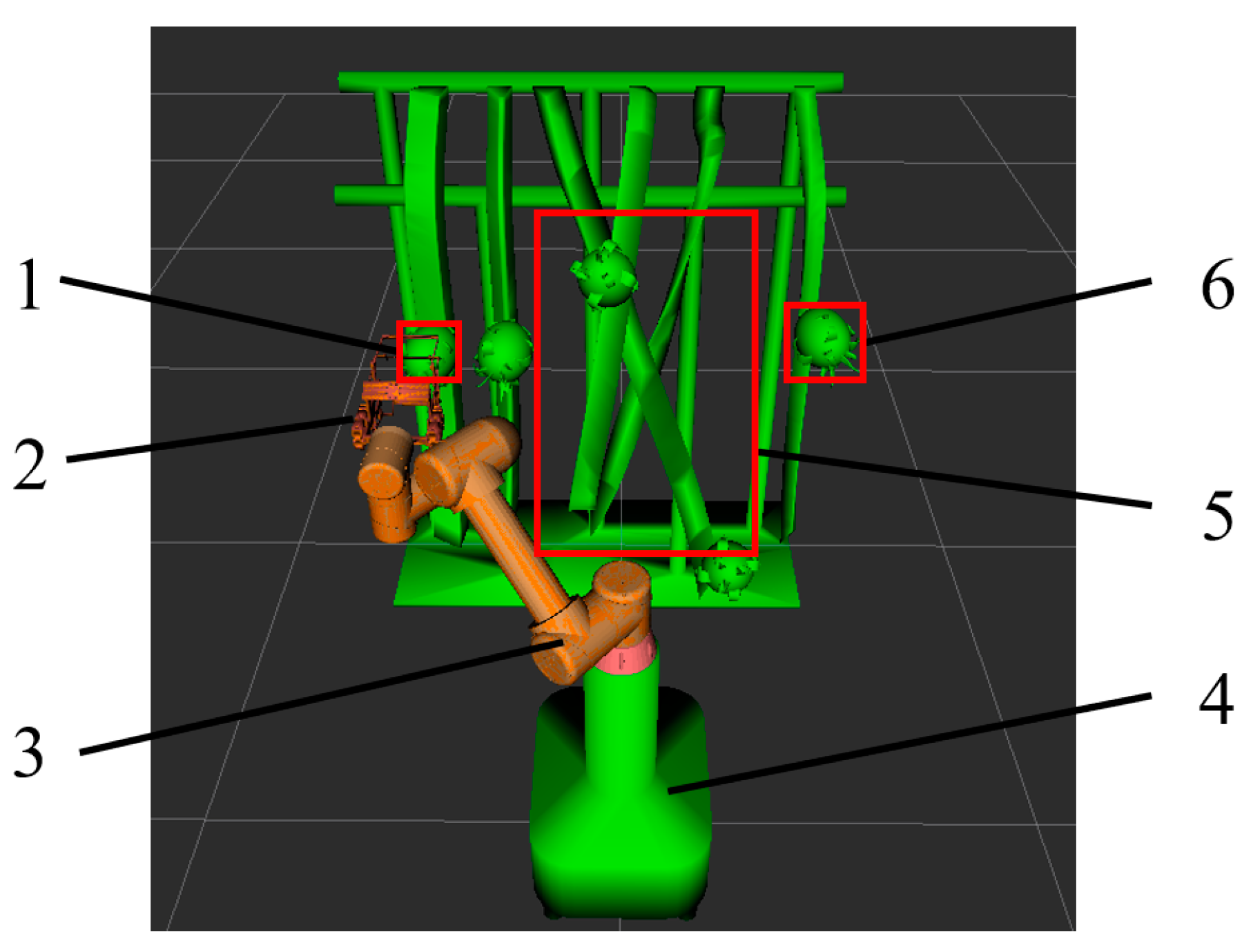

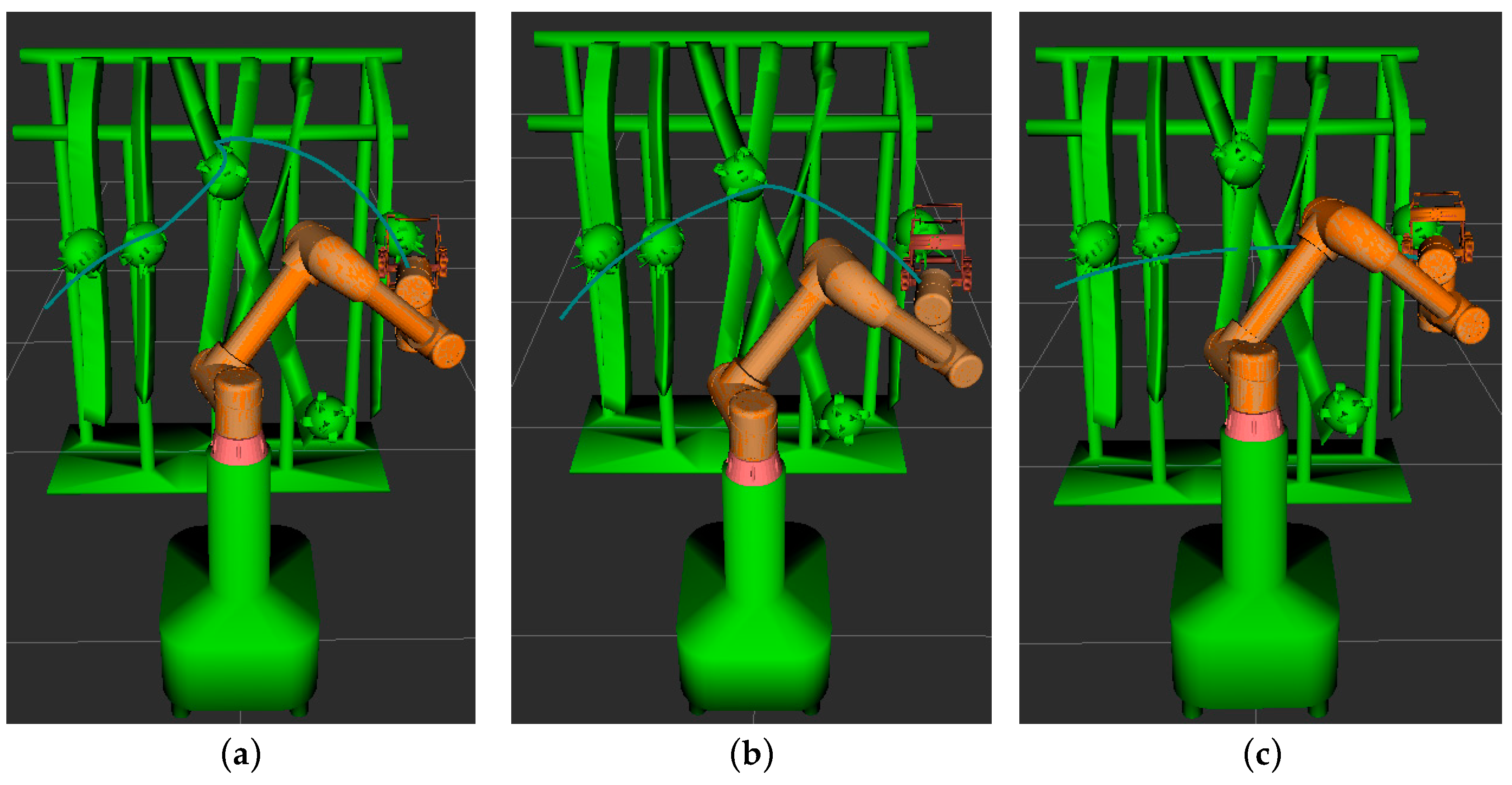

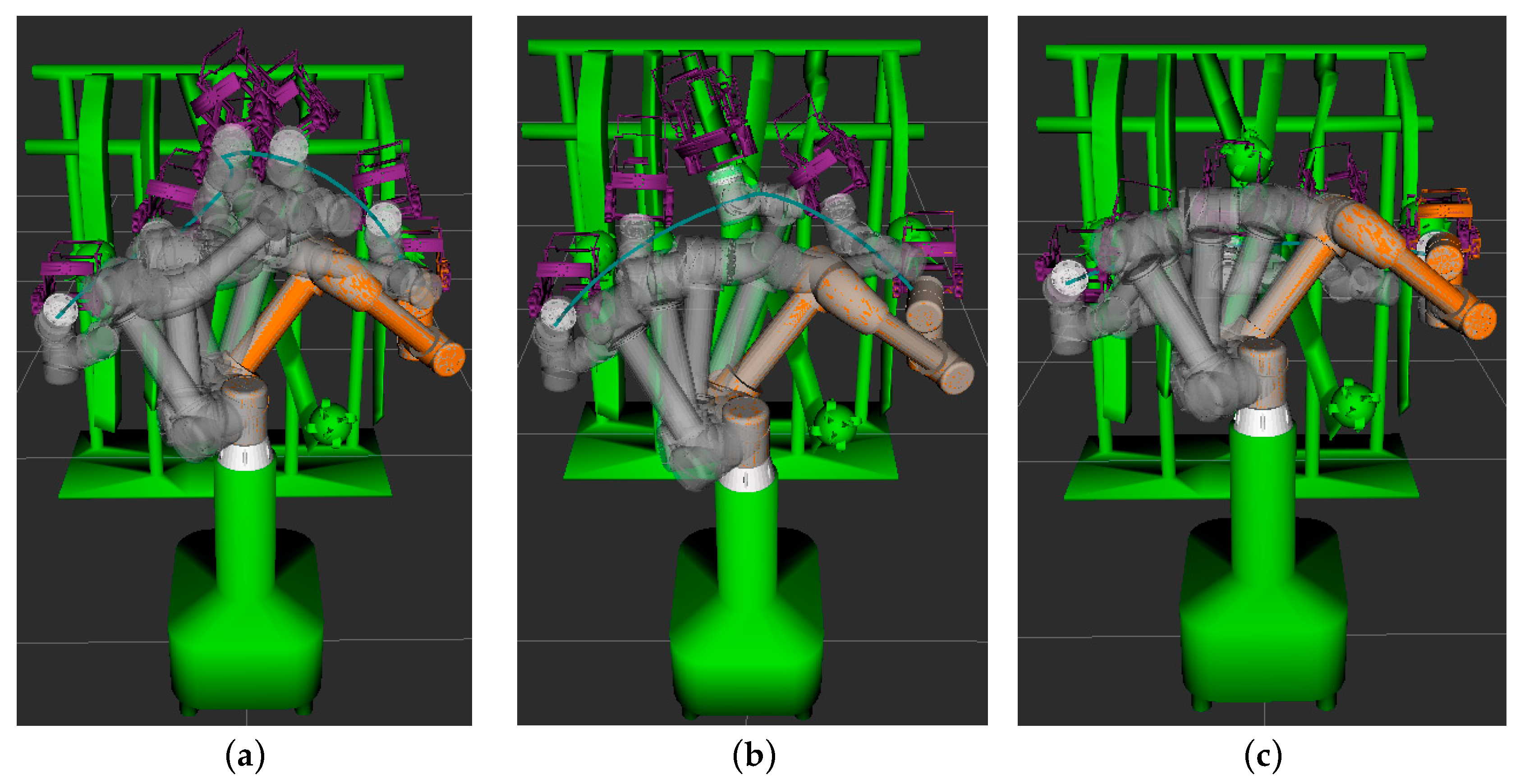

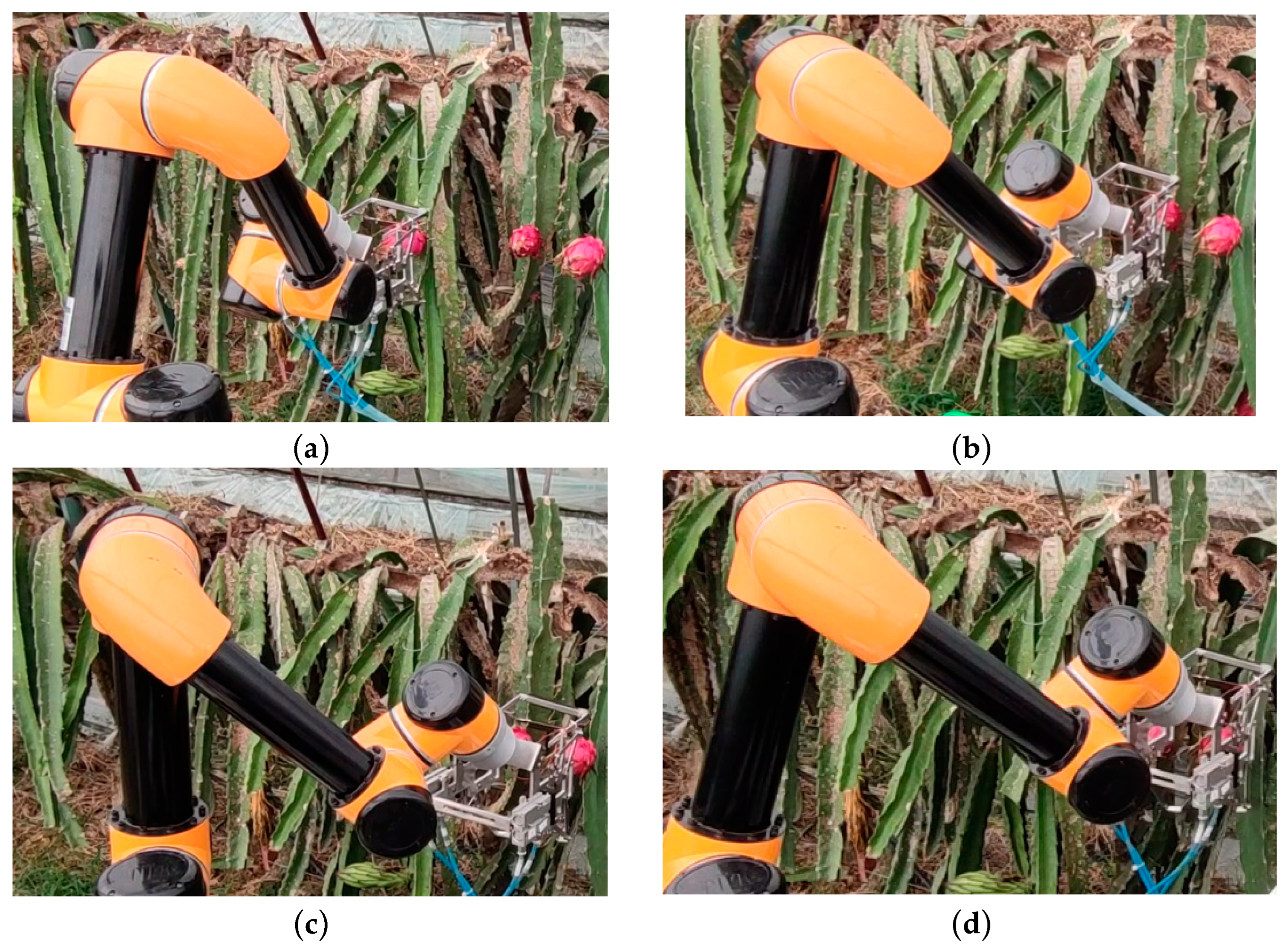

5. Simulation Environment Picking Test and Analysis

6. Conclusions

- (1)

- In addressing the path planning problem for dragon-fruit-picking robotic arms operating in complex environments, the XN-RRT* algorithm is introduced. This approach incorporates a normal-distribution-based sampling strategy and an enhanced artificial potential field (APF) guidance technique to facilitate node generation. Additionally, a greedy algorithm is employed to eliminate redundant nodes, and cubic B-spline curves are applied to optimize the path. These methods effectively mitigate the randomness of sampling points, reduce the overall path length, and enhance path smoothness.

- (2)

- The results of the simulation tests demonstrate that the XN-RRT* algorithm outperforms both the traditional RRT* and APF-RRT* algorithms in terms of path quality and smoothness. Notably, it excels in search time, path length, node utilization efficiency, and path stability, thereby showcasing its superior performance in complex spatial path planning.

- (3)

- The results from the dragon fruit picking experiment indicate that the XN-RRT* algorithm achieves a path planning success rate of 98%. Compared to the RRT* algorithm, the running time is reduced by 90.32%, the path length is shortened by 27.12%, and the planning success rate is improved by 14%. These findings substantiate the effectiveness and practical applicability of the XN-RRT* algorithm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.L.; Gong, L.; Yuan, J. Current status and development trends of agricultural robots. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–22+55. [Google Scholar]

- Hu, H.R.; Zhang, Y.Y.; Zhou, J.L. Research status and analysis of end-effector of fruit and vegetable picking robot. J. Chin. Agric. Mech. 2024, 45, 231–236. [Google Scholar]

- Zhuang, M.; Li, G.; Ding, K. Obstacle avoidance path planning for apple picking robotic arm incorporating artificial potential field and a* algorithm. IEEE Access 2023, 11, 100070–100082. [Google Scholar] [CrossRef]

- Xun, Y.; Li, D.Z.; Wang, Y. Motion Planning of Harvesting Manipulator Based on VS-IRRT Algorithm. Trans. Chin. Soc. Agric. Mach. 2023, 54, 129–138. [Google Scholar]

- Yang, S.H.; Xie, X.B.; Bing, Z.K. Path Planning of Green Walnut Picking Robotic Arm Based on HER-TD3 Algorithm. Trans. Chin. Soc. Agric. Mach. 2024, 55, 113–123. [Google Scholar]

- Yan, B.; Quan, J.; Yan, W. Three-Dimensional Obstacle Avoidance Harvesting Path Planning Method for Apple-Harvesting Robot Based on Improved Ant Colony Algorithm. Agriculture 2024, 14, 1336. [Google Scholar] [CrossRef]

- Shi, W.; Wang, K.; Zhao, C. Obstacle avoidance path planning for the dual-arm robot based on an improved RRT algorithm. Appl. Sci. 2022, 12, 4087. [Google Scholar] [CrossRef]

- Liu, X.S.; Kang, L.; Shan, Z.B. Path planning of robot arm based on APF-informed-RRT* algorithm with bidirectional target bias. J. Electron. Meas. Instrum. 2024, 38, 75–83. [Google Scholar]

- Yin, X.; Chen, Y.; Guo, W.H. Flexible grasping of robot arm based on improved Informed-RRT star. Chin. J. Eng. 2025, 47, 113–120. [Google Scholar]

- Xia, X.; Li, T.; Sang, S. Path planning for obstacle avoidance of robot arm based on improved potential field method. Sensors 2023, 23, 3754. [Google Scholar] [CrossRef]

- Zhou, X.; Yan, J.; Yan, M. Path planning of rail-mounted logistics robots based on the improved dijkstra algorithm. Appl. Sci. 2023, 13, 9955. [Google Scholar] [CrossRef]

- Chatzisavvas, A.; Dossis, M.; Dasygenis, M. Optimizing Mobile Robot Navigation Based on A-Star Algorithm for Obstacle Avoidance in Smart Agriculture. Electronics 2024, 13, 2057. [Google Scholar] [CrossRef]

- Jia, H.D.; Fang, L.J.; Wang, H.Z. Adaptive path planning of manipulators combining Informed-RRT* with artificial potential field. Comput. Integr. Manuf. Syst. 2024, 1–21. Available online: https://kns.cnki.net/kcms/detail//11.5946.TP.20230117.1454.008.html (accessed on 20 April 2025).

- Li, Y.; Zhao, J.; Chen, Z. A robot path planning method based on improved genetic algorithm and improved dynamic window approach. Sustainability 2023, 15, 4656. [Google Scholar] [CrossRef]

- Ma, J.T.; Wang, Y.; He, Y.; Wang, K.; Zhang, Y.T. Motion planning of citrus harvesting manipulator based on informed guidance point of configuration space. Trans. Chin. Soc. Agric. Eng. 2019, 35, 100–108. [Google Scholar]

- Bao, X.L.; Bao, Y.G.; Ma, X.J. Research on Obstacle Avoidance Planning of Citrus Picking Robot in Natural Enyironment. Trans. Chin. Soc. Agric. Mach. 2024, 1–11. [Google Scholar] [CrossRef]

- Cao, M.; Zhou, X.; Ju, Y. Robot motion planning based on improved RRT algorithm and RBF neural network sliding. IEEE Access 2023, 11, 121295–121305. [Google Scholar] [CrossRef]

- Karaman, S.; Frazzoli, E. Sampling-based algorithms for optimal motion planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, L.; Tian, R. Research on obstacle avoidance motion planning method of manipulator in complex multi scene. J. Northwest. Polytech. Univ. 2023, 41, 500–509. [Google Scholar] [CrossRef]

- Li, N.; Gao, X.; Yang, L. Dynamic Path Planning for a Picking Robot Arm Based on lmproved Algorithm Fusion and Switching. Trans. Chin. Soc. Agric. Mach. 2024, 55, 221–230+272. [Google Scholar]

- Xiong, J.T.; Chen, H.R.; Yao, Z.S. Motion Planning for Lychee Picking Manipulator Based on PIB-RRTstar Algorithm. Trans. Chin. Soc. Agric. Mach. 2024, 55, 82–92. [Google Scholar]

- Li, X.; Yang, J.; Wang, X. Adaptive Step RRT*-Based Method for Path Planning of Tea-Picking Robotic Arm. Sensors 2024, 24, 7759. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Yue, X.L.; Li, B. Motion Planning of Picking Manipulator Based on CTB-RRT* Algorithm. Trans. Chin. Soc. Agric. Mach. 2021, 52, 129–136. [Google Scholar]

- Wang, J.; Li, T.; Li, B. GMR-RRT*: Sampling-based path planning using gaussian mixture regression. IEEE Trans. Intell. Veh. 2022, 7, 690–700. [Google Scholar] [CrossRef]

- Wang, H.Z.; Gao, M.; Wang, J.H. Multi-scene Fast Motion Planning of Manipulator Based on Improved RRT*-Connect Algorithm. Trans. Chin. Soc. Agric. Mach. 2022, 53, 432–440. [Google Scholar]

- Zhang, J.H.; Ren, B.Z.; Zhao, Y. Collision Detection and Obstacle Avoidance ofPlanar Redundant Manipulator based on Dichotomous Heuristic. J. Mech. Eng. 2023, 59, 113–122. [Google Scholar]

- Strub, M.P.; Gammell, J.D. Adaptively Informed Trees (AIT*): Fast asymptotically optimal path planning through adaptive heuristics. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 3191–3198. [Google Scholar]

- Behera, L.; Rybak, L.; Malyshev, D.; Gaponenko, E. Determination of workspaces and intersections of robot links in a multi-robotic system for trajectory planning. Appl. Sci. 2021, 11, 4961. [Google Scholar] [CrossRef]

- Ma, B.; Wei, C.; Huang, Q. APF-RRT*: An Efficient Sampling-Based Path Planning Method with the Guidance of Artificial Potential Field. In Proceedings of the IEEE 2023 9th International Conference on Mechatronics and Robotics Engineering (ICMRE), Shenzhen, China, 10–12 February 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 207–213. [Google Scholar]

| Environment | Algorithm | Average Path Length/m | Average Running Time/s | Average Iteration Times |

|---|---|---|---|---|

| Simple discrete environment | RRT* algorithm | 12.064 | 4.401 | 465.3 |

| APF-RRT* algorithm | 11.821 | 1.387 | 224.7 | |

| XN-RRT* algorithm | 11.152 | 0.723 | 89.2 | |

| Complex narrow environment | RRT* algorithm | 12.148 | 5.582 | 561.5 |

| APF-RRT* algorithm | 12.115 | 1.885 | 262.3 | |

| XN-RRT* algorithm | 11.741 | 0.842 | 118.4 |

| Environment | Algorithm | Average Path Length/m | Average Running Time/s | Average Iteration Times |

|---|---|---|---|---|

| 3D environment | RRT* algorithm | 2506.068 | 29.548 | 1698 |

| APF-RRT* algorithm | 2363.286 | 9.764 | 846 | |

| XN-RRT* algorithm | 2215.865 | 1.118 | 114 |

| Algorithm | Path Length/mm | Running Time/s | Success Rate/% |

|---|---|---|---|

| RRT* algorithm | 1343.27 | 5.412 | 84 |

| APF-RRT* algorithm | 1251.64 | 2.746 | 90 |

| XN-RRT* algorithm | 978.91 | 0.524 | 98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, C.; Wang, J.; Yuan, F.; Chen, S.; Zhou, H. Path Planning for Dragon-Fruit-Harvesting Robotic Arm Based on XN-RRT* Algorithm. Sensors 2025, 25, 2773. https://doi.org/10.3390/s25092773

Fang C, Wang J, Yuan F, Chen S, Zhou H. Path Planning for Dragon-Fruit-Harvesting Robotic Arm Based on XN-RRT* Algorithm. Sensors. 2025; 25(9):2773. https://doi.org/10.3390/s25092773

Chicago/Turabian StyleFang, Chenzhe, Jinpeng Wang, Fei Yuan, Sunan Chen, and Hongping Zhou. 2025. "Path Planning for Dragon-Fruit-Harvesting Robotic Arm Based on XN-RRT* Algorithm" Sensors 25, no. 9: 2773. https://doi.org/10.3390/s25092773

APA StyleFang, C., Wang, J., Yuan, F., Chen, S., & Zhou, H. (2025). Path Planning for Dragon-Fruit-Harvesting Robotic Arm Based on XN-RRT* Algorithm. Sensors, 25(9), 2773. https://doi.org/10.3390/s25092773