Charge-Domain Type 2.2 µm BSI Global Shutter Pixel with Dual-Depth DTI Produced by Thick-Film Epitaxial Process

Abstract

1. Introduction

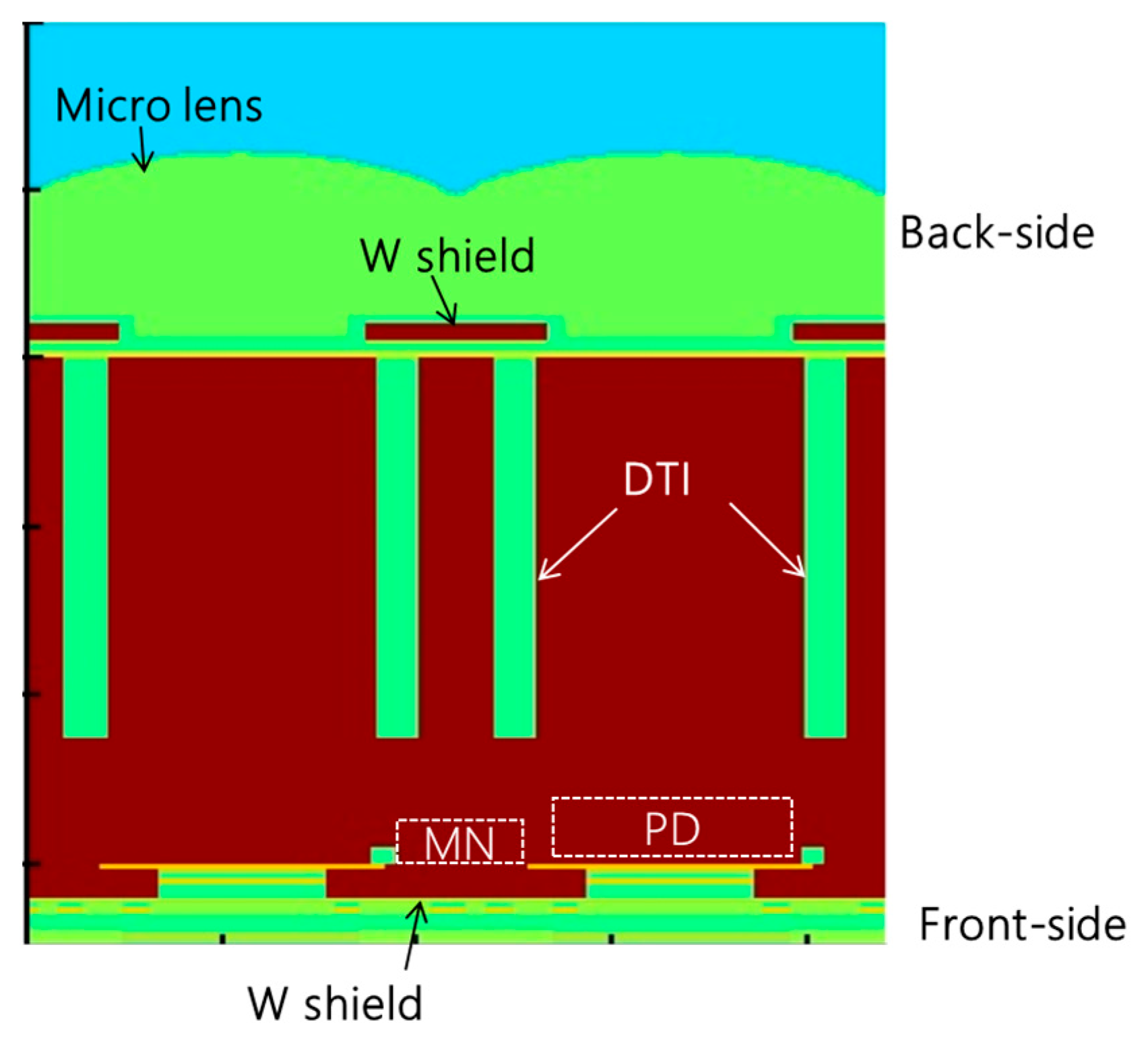

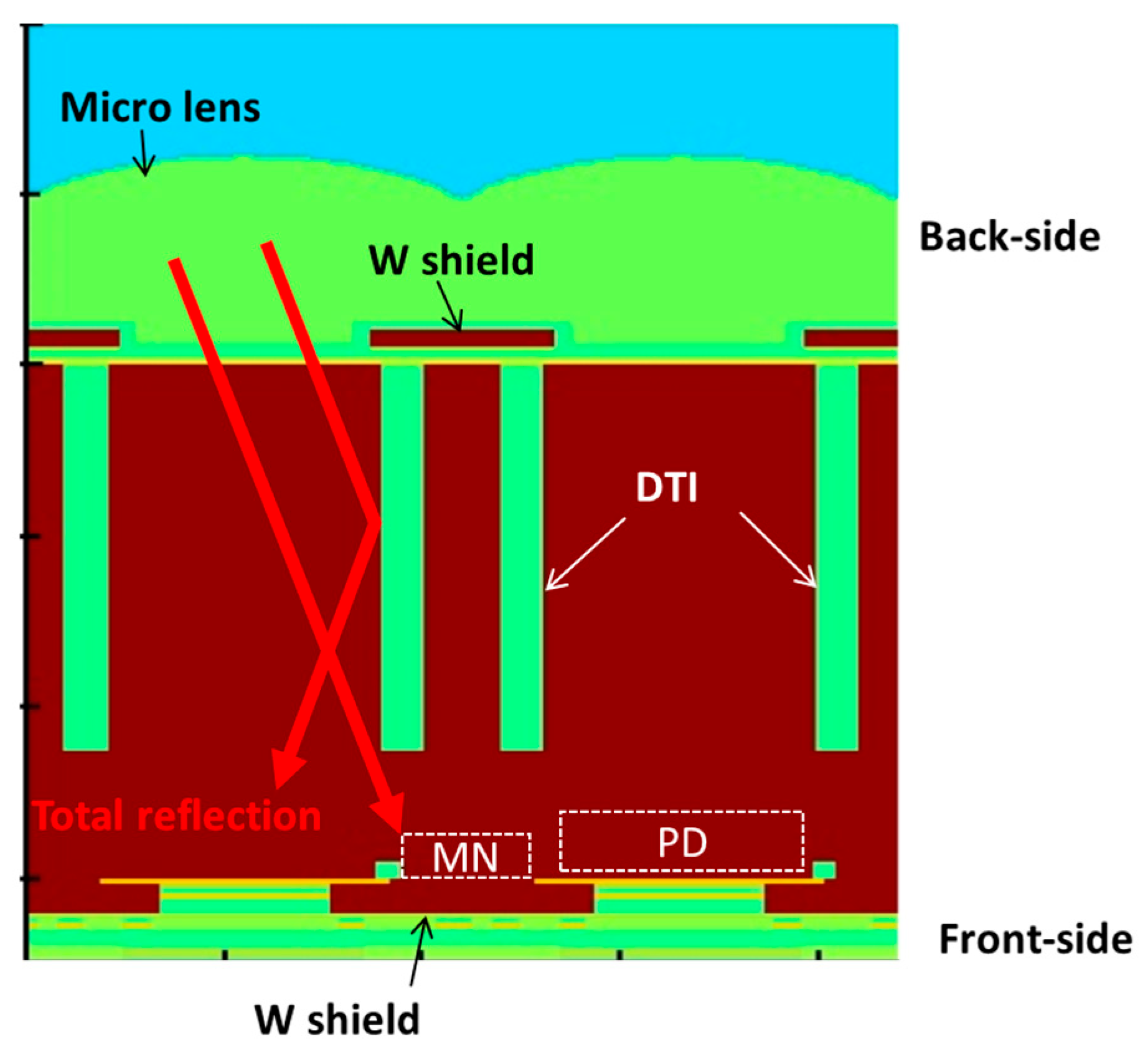

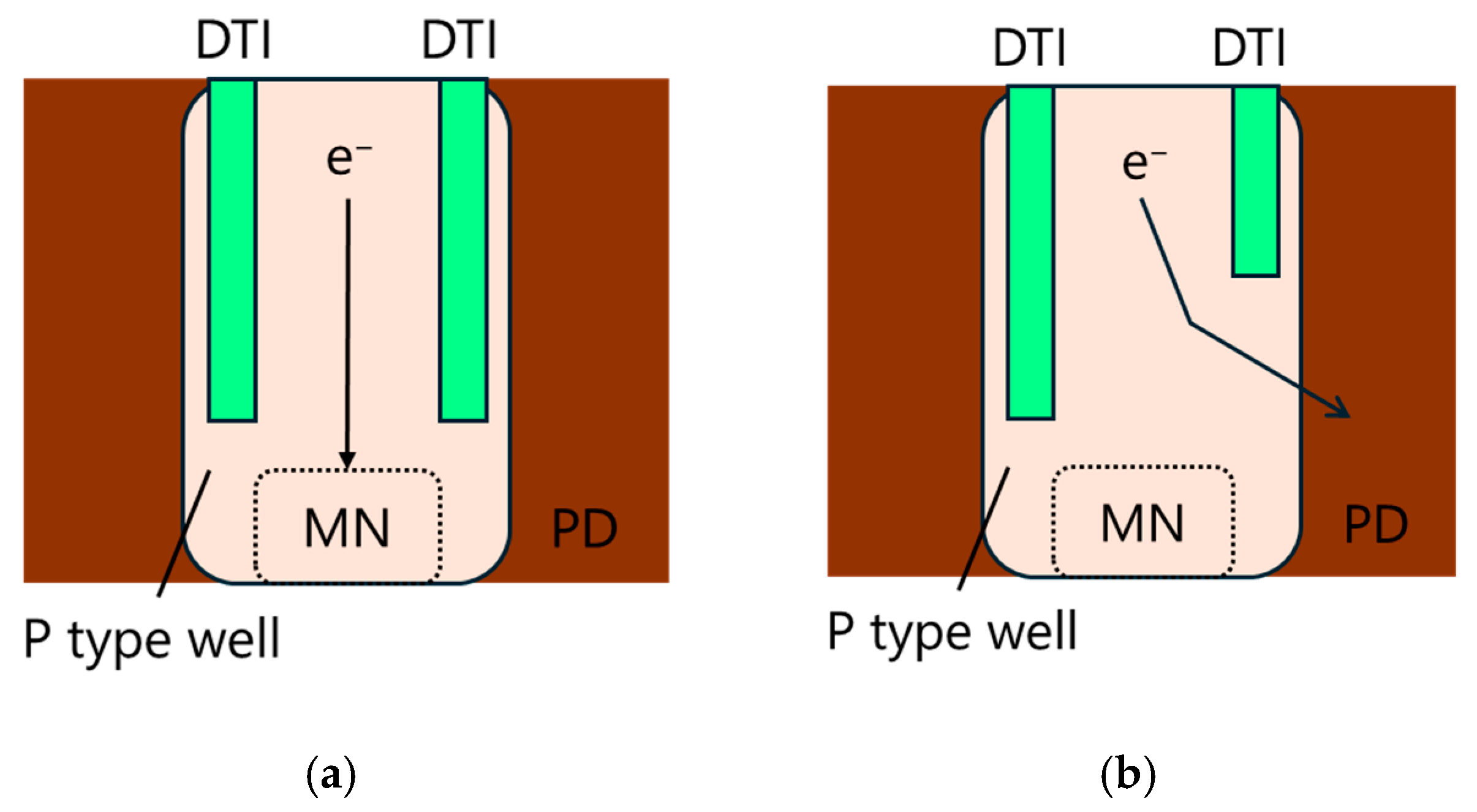

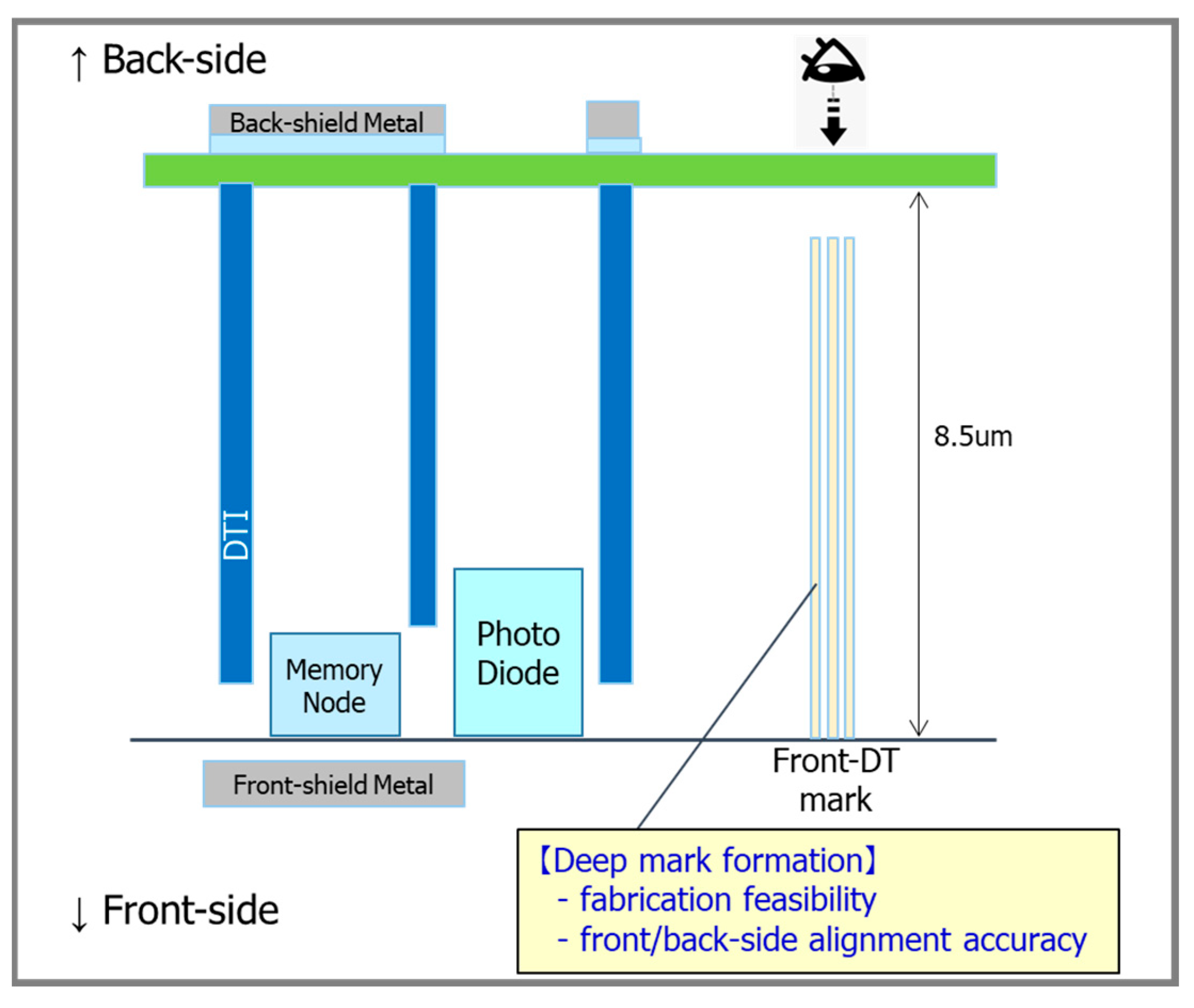

2. Device Structure

3. Development of 2.2 µm BSI Charge-Domain Global Shutter Pixel

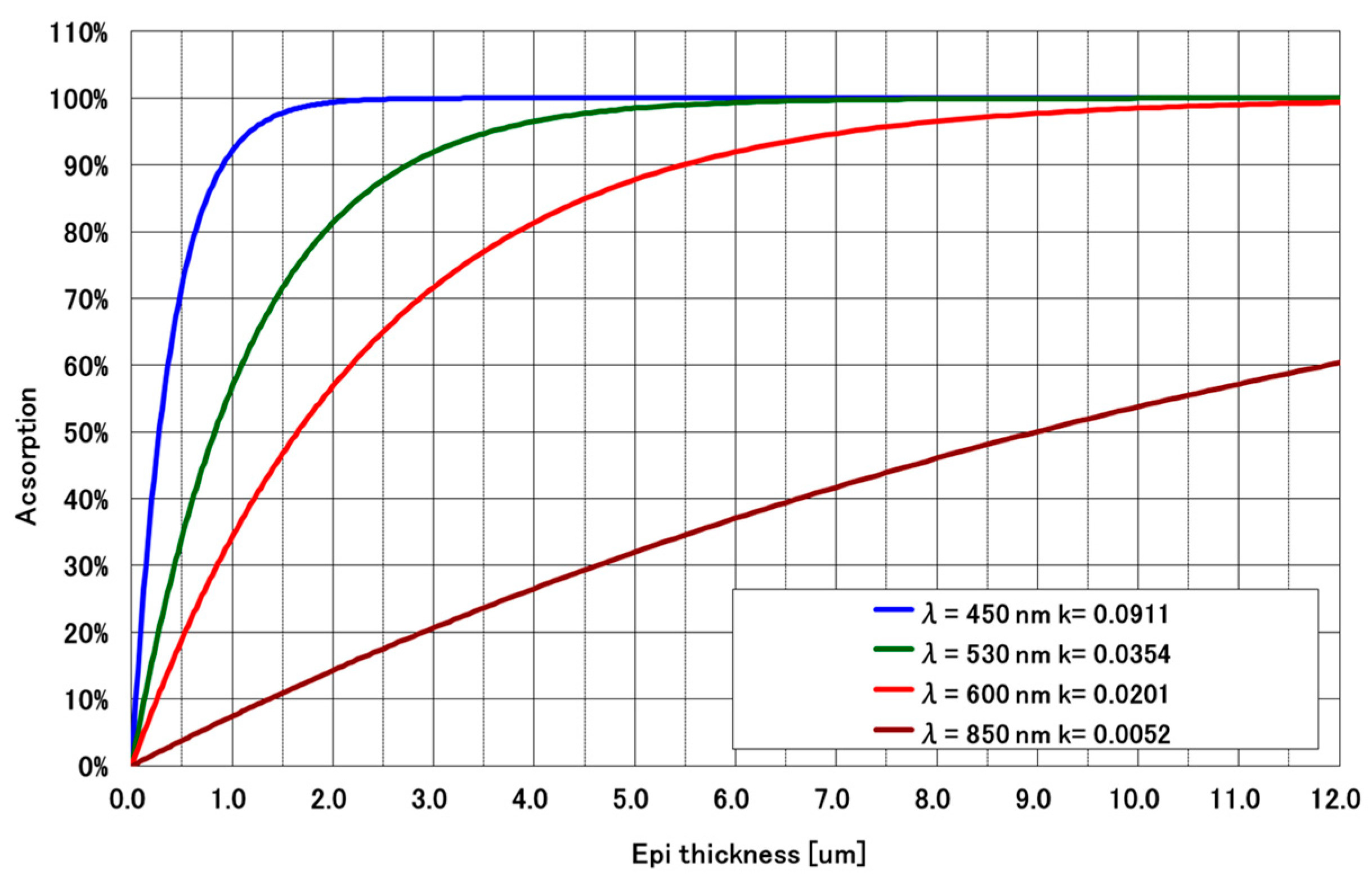

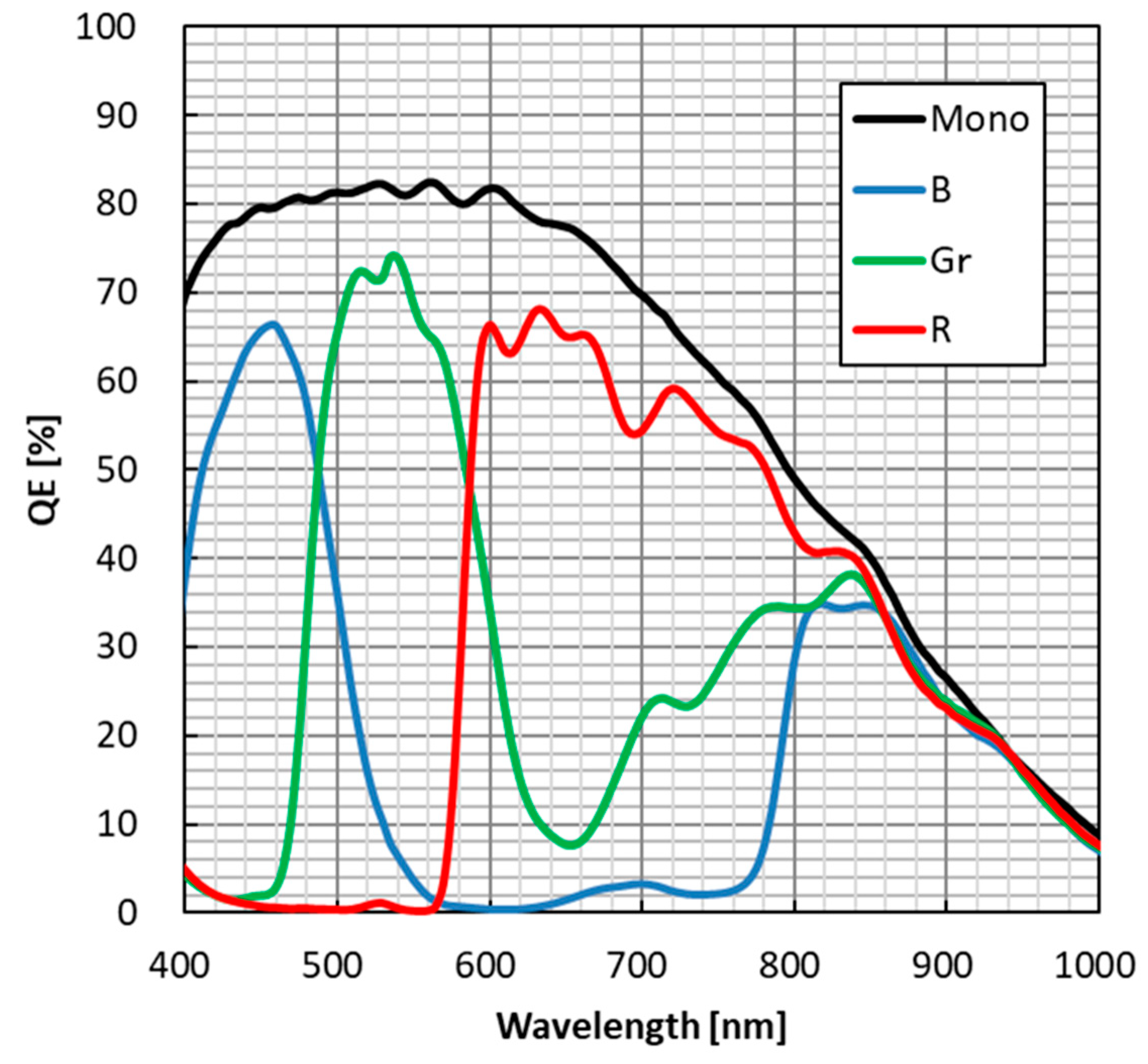

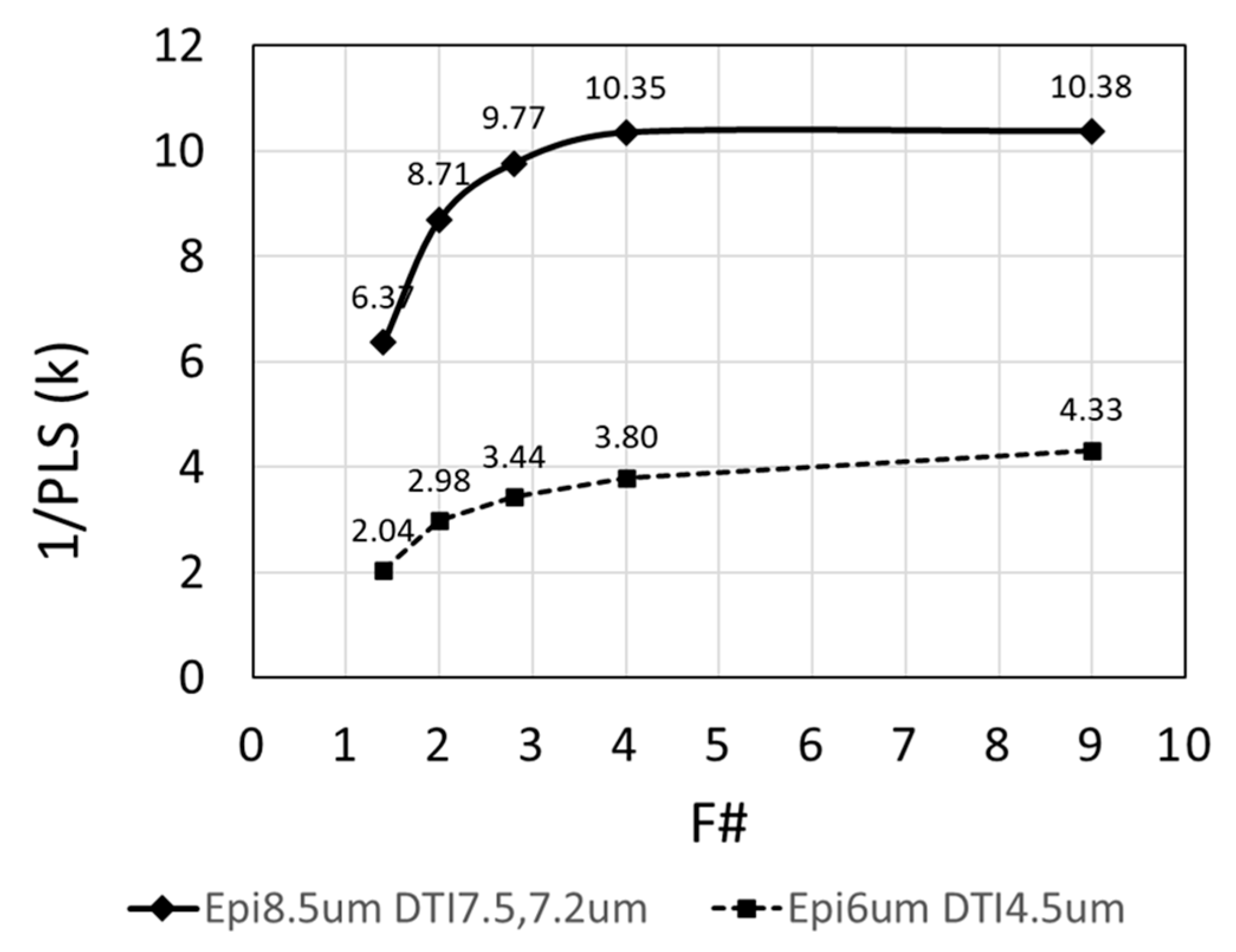

3.1. Optical and Pixel Design

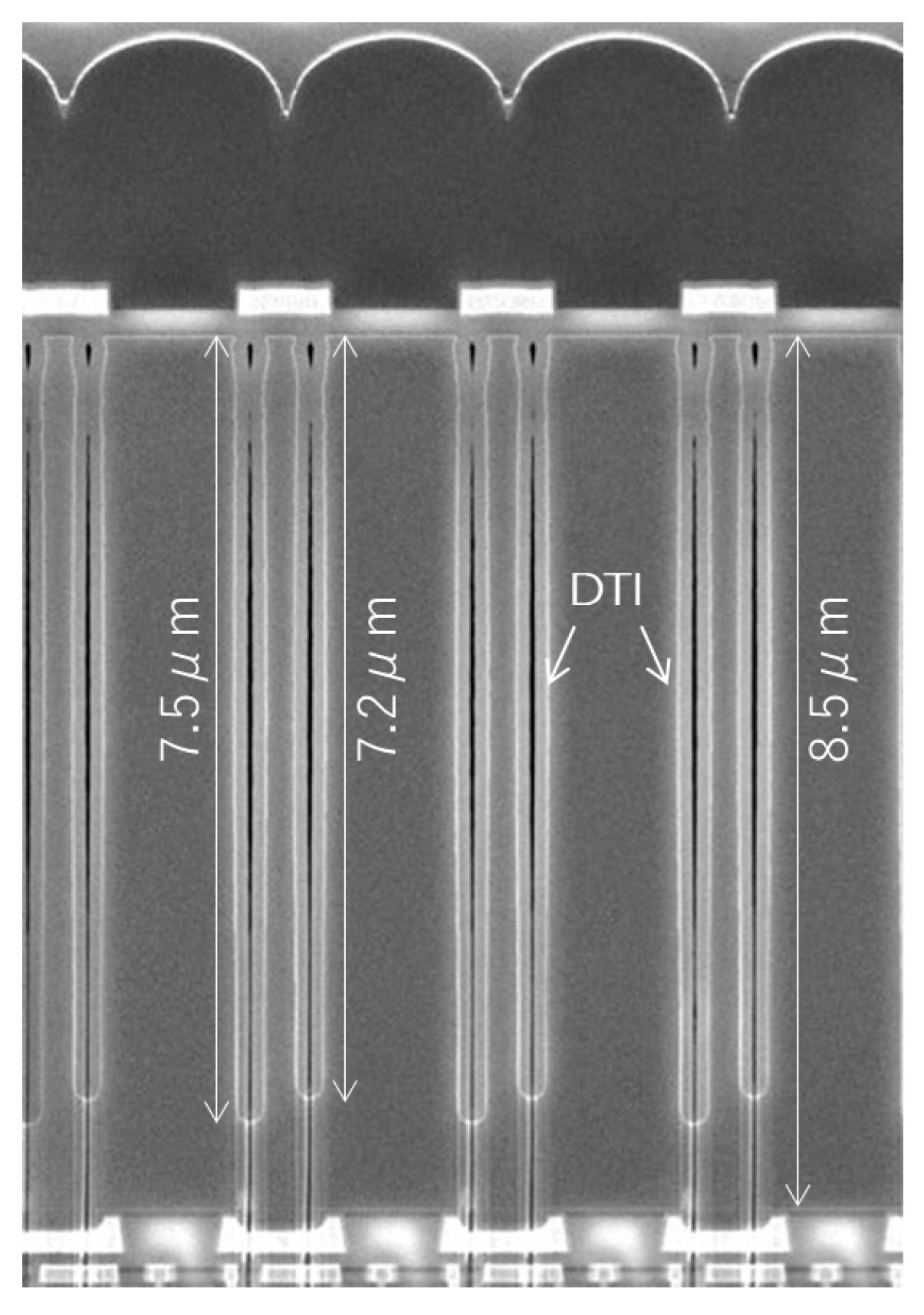

3.2. Process Design

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Yokoyama, T.; Tsutsui, M.; Nishi, Y.; Mizuno, I.; Dmitry, V.; Lahav, A. High Performance 2.5um Global Shutter Pixel with New Designed Light-Pipe Structure. In Proceedings of the IEDM 2018, San Francisco, CA, USA, 1–5 December 2018. [Google Scholar]

- Yoshimichi, K.; Ryoto, Y.; Naoyuki, O.; Harumi, I.; Kazuyoshi, Y.; Takashi, A.; Shigetaka, K.; Junji, Y.; Tooru, I.; Shinichiro, N.; et al. Back-Illuminated 2.74um-Pixel-Pitch Global Shutter CMOS Image Sensor with Charge-Domain Memory Achieving 10k e-saturation Signal. In Proceedings of the IEDM 2018, San Francisco, CA, USA, 1–5 December 2018. [Google Scholar]

- Sakakibara, M. A back-illuminated global-shutter CMOS image sensor with pixel-parallel 14b subthreshold ADC. In Proceedings of the 2018 IEEE International Solid-State Circuits Conference–(ISSCC), San Francisco, CA, USA, 11–15 February 2018; pp. 80–82. [Google Scholar]

- Wang, X.; Bogaerts, J.; Vanhorebeek, G.; Ruythoren, K.; Ceulemans, B.; Lepage, G.; Willems, P.; Meynants, G. A 2.2M CMOS Image Sensor for High Speed Machine Vision Applications. In Proceedings of the IS&T/SPIE Electronic Imaging, San Jose, CA, USA, 26 January 2010; Volume 7536. [Google Scholar]

- Meynants, G. Global shutter pixels with correlated double sampling for CMOS image sensors. Adv. Opt. Technol. 2013, 2, 177–187. [Google Scholar] [CrossRef]

- Roy, F.; Cazaux, Y.; Waltz, P.; Malinge, P.; Billon-Pierron, N. Low Noise Global Shutter Image Sensor Working in the Charge Domain. IEEE Electron Device Lett. 2018, 40, 310–313. [Google Scholar] [CrossRef]

- Yokoyama, T.; Noguchi, Y.; Tsutsui, M.; Nishi, Y.; Takeuchi, M.; Oda, M.; Amos, F. Charge domain type 2.2um BSI Global Shutter pixel with Dual Depth DTI Produced by thick-film epitaxial process. In Proceedings of the 2025 International Image Sensor Workshop, Awaji, Japan, 2–5 June 2025. [Google Scholar]

- Lauxtermann, S.; Lee, A.; Stevens, J.; Joshi, A. Comparison of Global Shutter Pixels for CMOS Image Sensors. In Proceedings of the 2007 International Image Sensor Workshop, Ogunquit, ME, USA, 7–10 June 2007. [Google Scholar]

- Tsutsui, M.; Hirata, T.; Tachikawa, K.; Mizuno, I.; Suzuki, M.; Veinger, D.; Birman, A.; Lahav, A. Development of Low Noise Memory Node in a 2.8um Global Shutter Pixel with Dual Transfer. In Proceedings of the 2017 International Image Sensor Workshop, Hiroshima, Japan, 30 May–2 June 2017; p. 28. [Google Scholar]

- Toyoda, A. A novel tungsten light-shield structure for high-density CCD image sensors. IEEE Trans. Electron Devices 1991, 38, 965–968. [Google Scholar] [CrossRef]

- Velichko, S.; Hynecek, J.J.; Johnson, R.S.; Lenchenkov, V.; Komori, H.; Lee, H.W.; Chen, F.Y. CMOS Global Shutter Charge Storage Pixels with Improved Performance. IEEE Trans. Electron Devices 2015, 63, 106–112. [Google Scholar] [CrossRef]

- Mabuchi, K.; Nakamura, N.; Funatsu, E.; Abe, T.; Umeda, T.; Hoshino, T.; Suzuki, R.; Sumi, H. CMOS Image Sensor Using a Floating Diffusion Driving Buried Photodiode. In Proceedings of the 2004 International Solid-State Circuits Conference, San Francisco, CA, USA, 15–19 February 2004. [Google Scholar]

- Tournier, A.; Leverd, F.; Favennec, L.; Perrot, C.; Pinzelli, L.; Gatefait, M.; Cherault, N.; Jeanjean, D.; Carrere, J.P.; Hirigoyen, F.; et al. Pixel-to-Pixel isolation by Deep Trench technology: Application to CMOS Image Sensor. In Proceedings of the 2011 International Image Sensor Workshop, Hokkaido, Japan, 8–11 June 2011. [Google Scholar]

- Aspnes, D.E.; Theeten, J.B. Spectroscopic Analysis of the Interface Between Si and Its Thermally Grown Oxide. J. Electrochem. Soc. 1980, 127, 1359–1365. [Google Scholar] [CrossRef]

- Ito, K.; Otake, Y.; Kitano, Y.; Matsumoto, A.; Yamamoto, J.; Ogasahara, T.; Hiyama, H.; Naito, R.; Takeuchi, K.; Tada, T.; et al. A Back Illuminated 10um SPAD Pixel Array Comprising Full Trench Isolation and Cu-Cu Bonding with Over 14% PDE at 940 nm. In Proceedings of the IEDM 2020, San Francisco, CA, USA, 12–18 December 2020. [Google Scholar]

| Process Technology | 65 nm CIS BSI |

|---|---|

| Pixel Size | 2.2 μm × 2.2 μm |

| Peak QE (Mono) | 83% (wavelength = 560 nm) |

| 1/PLS (F#9, white halogen light, Mono) | 10,380 |

| Angular response (80%) | >15 degrees |

| MTF @Nyquist frequency | >40% (wavelength = 520 nm) |

| Linear Full Well Capacity | 5400 ele |

| Pixel noise @SF out (25 deg⋅C) | 0.6 ele |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yokoyama, T.; Tsutsui, M.; Nishi, Y.; Noguchi, Y.; Takeuchi, M.; Oda, M.; Amos, F. Charge-Domain Type 2.2 µm BSI Global Shutter Pixel with Dual-Depth DTI Produced by Thick-Film Epitaxial Process. Sensors 2025, 25, 6997. https://doi.org/10.3390/s25226997

Yokoyama T, Tsutsui M, Nishi Y, Noguchi Y, Takeuchi M, Oda M, Amos F. Charge-Domain Type 2.2 µm BSI Global Shutter Pixel with Dual-Depth DTI Produced by Thick-Film Epitaxial Process. Sensors. 2025; 25(22):6997. https://doi.org/10.3390/s25226997

Chicago/Turabian StyleYokoyama, Toshifumi, Masafumi Tsutsui, Yoshiaki Nishi, Yoshihiro Noguchi, Masahiko Takeuchi, Masahiro Oda, and Fenigstein Amos. 2025. "Charge-Domain Type 2.2 µm BSI Global Shutter Pixel with Dual-Depth DTI Produced by Thick-Film Epitaxial Process" Sensors 25, no. 22: 6997. https://doi.org/10.3390/s25226997

APA StyleYokoyama, T., Tsutsui, M., Nishi, Y., Noguchi, Y., Takeuchi, M., Oda, M., & Amos, F. (2025). Charge-Domain Type 2.2 µm BSI Global Shutter Pixel with Dual-Depth DTI Produced by Thick-Film Epitaxial Process. Sensors, 25(22), 6997. https://doi.org/10.3390/s25226997