1. Introduction

The development of robots is advancing at a rapid pace, and demand is expanding from industry to services and special applications. For instance, quadruped robots are used to explore rough terrain and transport supplies, exoskeleton robots are worn on the body to assist with walking, rescue robots enter disaster-stricken areas for emergency rescue and disaster relief, and humanoid robots perform tasks such as serving tea and pouring water [

1]. In these applications, robots move away from structured and known environments and enter unstructured environments such as unknown mountainous areas, forests, cities, workshops, and households. When robots need to interact physically with humans or the environment, they must ensure the safety of humans, themselves, and objects. Meanwhile, robots also need to avoid self-damage under the impact force generated during physical interactions with humans, the environment, or objects.

Robots’ joints are their most important executive mechanisms, and their characteristics directly determine a robot’s performance, safety, and application scenarios. Traditional robot joints consist of a motor connected in series with a reducer with a large reduction ratio. Through high-stiffness mechanism design and position control algorithms, they provide large driving torque for industrial robots and ensure motion accuracy in production and processing. However, this design significantly reduces robots’ compliance and safety, greatly limiting their applications in unstructured environments such as workshops and households [

2].

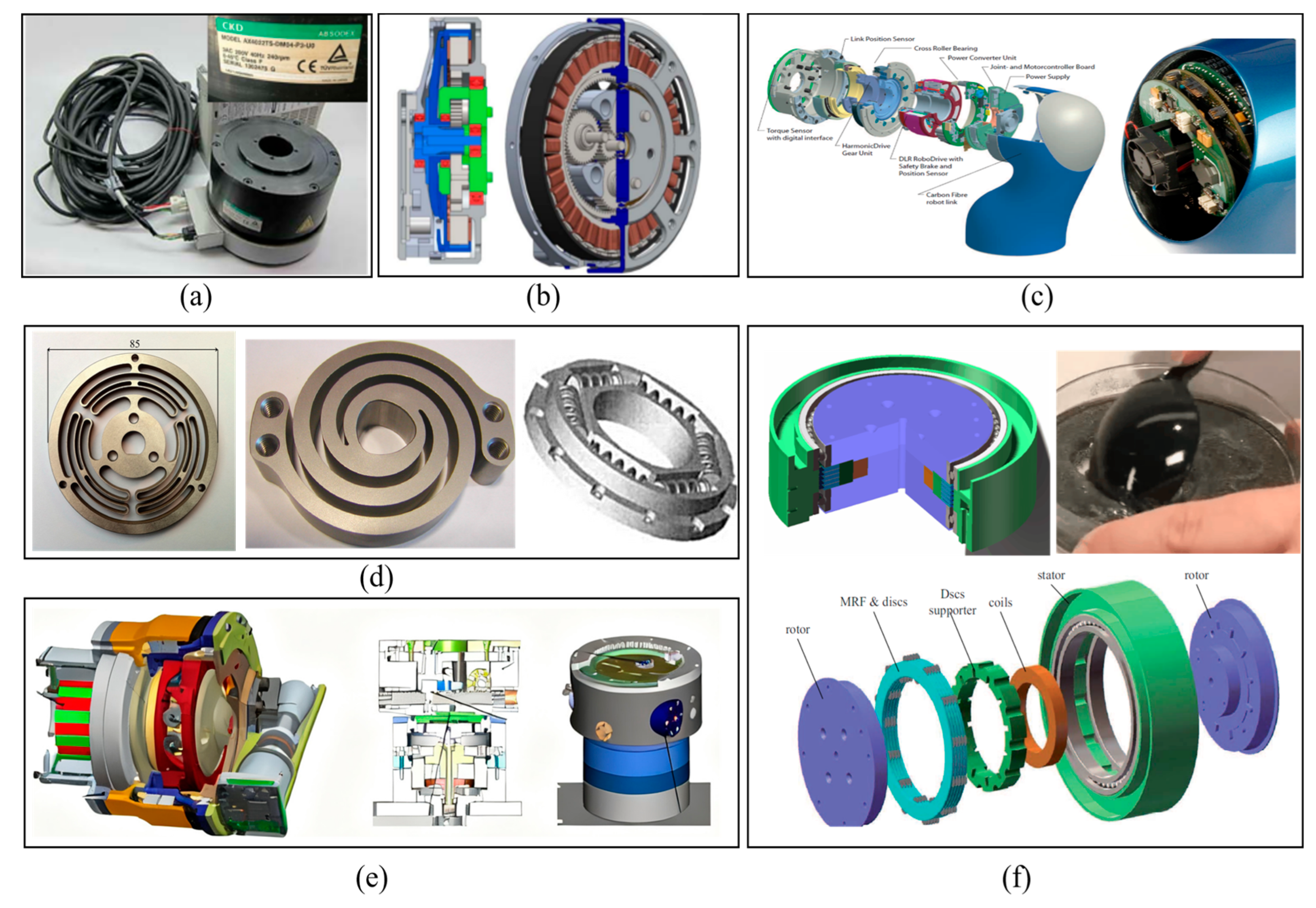

The literature presents several prominent actuator architectures designed to enhance the compliance of robotic joints, as summarized in

Figure 1. Direct-drive actuators (DDA) and quasi-direct-drive actuators (QDA) forgo or minimize reduction gears to achieve high backdrivability, but this often comes at the cost of limited output torque, restricting their use in high-load scenarios [

3,

4]. Robotic integrated joints compactly combine motors, reducers, and drivers, relying on sophisticated sensor feedback for compliance [

5]. A common strategy for introducing passive compliance is the use of series elastic actuators (SEA), which integrate a fixed elastic element in series with the output [

6,

7]. Evolving from SEA, variable-stiffness actuators (VSA) incorporate an additional mechanism to actively modulate the joint stiffness online, though this often leads to increased mechanical complexity [

8,

9].

In

Figure 1f, magneto-rheological actuators (MRAs) incorporate a magneto-rheological fluid clutch (MRC) in series at the end of traditional robot joints [

10,

11,

12]. The stiffness of an MRA is adjusted online by changing the engagement force between the stator and rotor of the MRC. MRAs do not require elastic elements and feature advantages such as simple structure, fast response, excellent compliance, and impact resistance. These characteristics have attracted widespread attention among researchers. Mousavi [

13] designed a T-shaped drum-type MRC and successfully applied it to prosthetic knee joints. In their study, a zoned modeling approach was conducted for the MRC, and the relationship between the MRC’s output torque and its structural parameters was derived. Viau [

14] applied an MRC to a cable-driven robotic arm with two degrees of freedom, endowing the robot with excellent compliance. To ensure safe physical interaction between robots and humans, Ahmed [

15] designed a simple two-degrees-of-freedom robotic arm using two MRCs with a maximum torque of approximately 10 Nm. Fauteux [

16] proposed a dual-differential MRC, which uses a motor–reducer system to drive two MRCs in opposite directions; the engagement forces of the two clutches are coupled and then transmitted to the connecting rod. The dual-differential MRC only requires the motor–reducer system to maintain unidirectional motion at all times and realizes torque output in both positive and negative directions by controlling the current of the two MRCs, thereby eliminating gear backlash. Gudmundsson [

17,

18,

19] used finite element analysis for the multi-objective optimization design of MRC and successfully applied the optimized clutches to prosthetic knee joints. Shafer, Kermani, and Yadmellat conducted a comparative simulation study on the compliance and safety of MRAs, KUKA LWR III robots, SEAs, and DDAs. The results verified that MRAs exhibit better compliance and safety than SEAs in human–robot collaboration [

20]. They also studied modeling and controlling the hysteresis between the current and torque of MRCs using the Preisach model, artificial neural networks, and embedded magnetic sensors [

21,

22] and proposed an active distributed semi-drive transmission method. This method only requires one motor–reducer system to achieve independent control of multiple degrees of freedom through oppositely distributed MRCs, thereby significantly reducing robot costs. Li [

23] introduced an untethered MRF robot that employed an innovative approach by encapsulating the MRF within an elastic membrane. St-Jean [

24] showed that the safety level of collaborative robots can be increased by a factor up to 3 by changing the conventional servo-geared actuator architectures for MR actuators alone. Finally, Li [

25] presented a flexible safety system that used MRF-based joints for the purposes of limb rehabilitation. The joints could control the upper limb rehabilitation system to achieve the desired effect by increasing and changing the patient’s interactive force.

The technical challenges in designing and controlling MRAs lie in the design and control of MRCs. Although MRAs have attracted the attention of scholars worldwide, relevant research remains relatively limited compared to other types of robot joints. The integrated modeling, optimization, and control methods applicable to MRAs still require investigation. This paper focuses on the design and control of a flexible robotic MRA. The innovation of this study lies in conducting multi-physics modeling on the MRC, the core component of the MRA, by combining an equivalent magnetic circuit model and a thermal circuit model. The MRC’s parameters are optimized through a genetic algorithm to meet engineering constraints, and a model reference-based PID feedforward control strategy is designed. Finally, experiments verify that the designed MRA has excellent torque tracking performance, providing an integrated solution with high torque, high compliance, and safety for flexible robotic joints.

The subsequent structure of this article is as follows:

Section 2 primarily addresses the structural design and parameter optimization of the MRA.

Section 3 describes dynamic modeling analysis and torque control research. In

Section 4, through static and dynamic torque output experiments, it is verified that the designed MRA exhibits excellent torque tracking performance.

2. MRA Design and Optimization

In this section, the magnetic field inside the clutch is accurately calculated using an equivalent magnetic circuit model. Then, a thermal circuit model of the clutch is established, and the operating temperature of each component of the clutch is calculated analytically. Finally, based on the magnetic circuit model and thermal circuit model, and considering actual engineering constraints, the structural design and parameter optimization of the MRA are completed, resulting in a safety-oriented design with optimal torque performance.

2.1. Structural Design of MRA

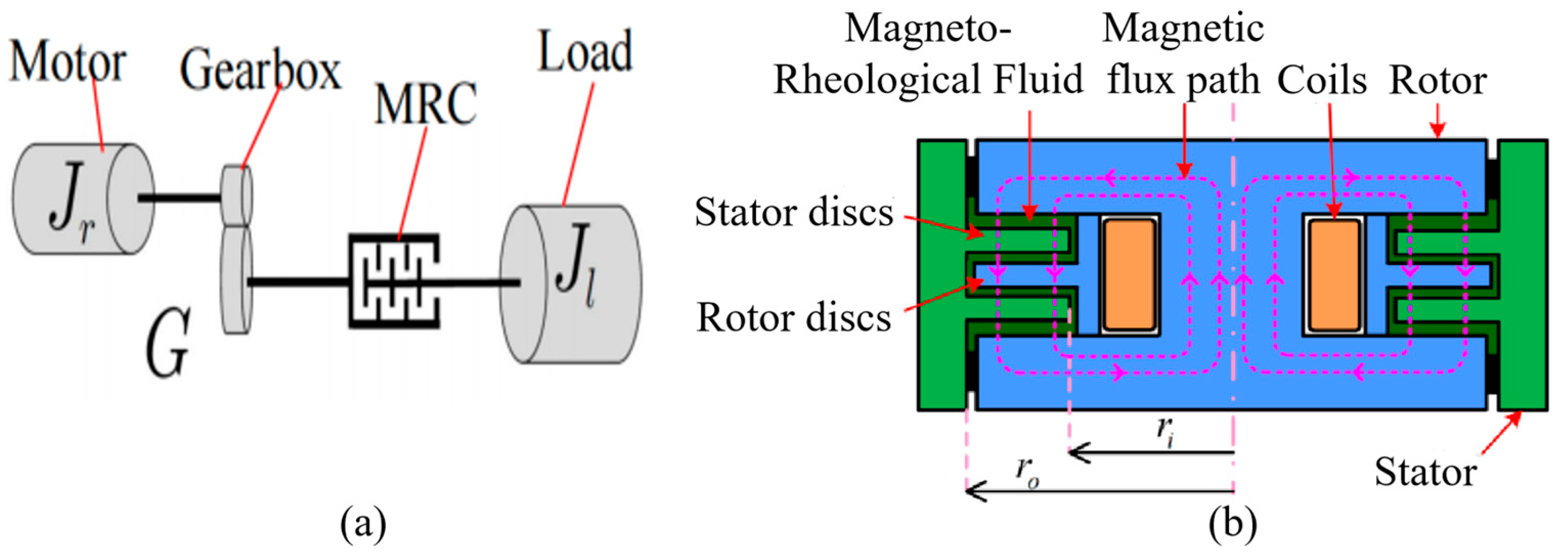

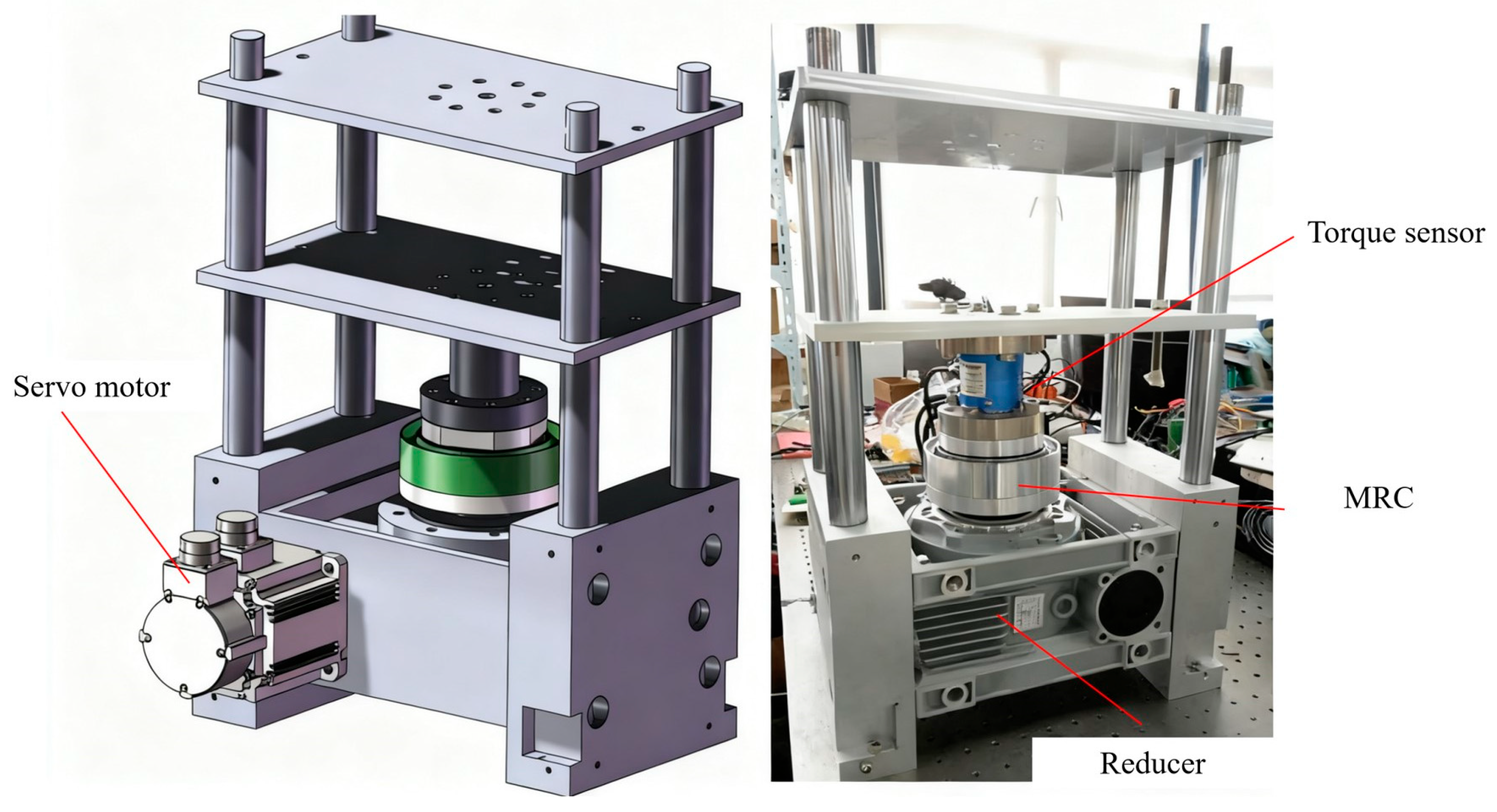

As shown in

Figure 2a, the MRA consists of a traditional robot joint motor and a reducer, with an MRC connected in series. The stator of the MRC is fixedly connected to the output shaft of the reducer and rotates with it, while the rotor of the clutch is connected to the robot load. The working principle of the MRC is illustrated in

Figure 2b. Its main components include a stator, stator disks, a rotor, rotor disks, coils, and magneto-rheological fluid filling the gaps between the stator and rotor disks. The stator disks are fixedly attached to the stator, and the rotor disks are fixedly attached to the rotor. By adjusting the magnitude of the current in the excitation coil, the intensity of the magnetic field acting on the MRC can be regulated, which in turn changes the solidification degree of the MRC. This generates varying engagement forces between the MRC’s stator and rotor disks. Thus, the MRC can transmit different torques to the link according to the current level in the excitation coil. Due to the MRC’s fast response and its ability to undergo continuous and reversible transitions between a liquid state and various semi-solid states, the MRA can achieve rapid and continuous control of torque ranging from very small to very large values while exhibiting excellent compliance and impact resistance.

2.2. Magnetic Circuit Model Analysis of MRC

As shown in

Figure 2b, given the inner radius

and outer radius

of the effective working area of the MRC, the engagement torque

of the MRC can be calculated using the Bingham model [

26,

27] as follows:

where

is the shear stress of magneto-rheological fluid under different magnetic field strengths;

is the nonlinear magnetic induction intensity in magneto-rheological fluid, which is distributed nonlinearly along the radial direction; and

is the number of magneto-rheological fluid gaps. Assuming the number of rotor disks is

, and the number of stator disks is

, then

.

is the inner diameter of the annular stator disks, and

is the outer diameter of the annular rotor disks.

The shear stress of the magneto-rheological fluid can be calculated as

where

is the yield stress of the magneto-rheological fluid under different magnetic field strengths and

is the viscosity coefficient of the magneto-rheological fluid under different magnetic field strengths.

is the shear rate of the magneto-rheological fluid at radius

and can be expressed as

where

is the thickness of the magneto-rheological fluid gap;

is the motor speed of the magneto-rheological fluid joint;

is the rotational speed of the load-connecting rod; and

is the reduction ratio of the reducer.

When the average magnetic induction intensity

in the magneto-rheological fluid is selected to replace the nonlinearly distributed magnetic induction intensity

in Equation (1) for approximate calculation, the clutch torque

of the magneto-rheological fluid clutch can be approximated as

where

is the magneto-rheological torque and

is the viscous torque. Therefore, the output torque of the magneto-rheological fluid joint acting on the load-connecting rod can be expressed as

where

is the sign function. The symbols and descriptions of the magnetic circuit model are shown in

Table 1.

2.3. Thermal Circuit Model Analysis of MRC

When an MRC is used as the power source in a magneto-rheological fluid joint, the relative speed between the rotating disk and the fixed disk of the magneto-rheological fluid clutch can be very low, or even zero. Therefore, the frictional heat generated by the relative friction between the rotor and the stator is extremely small and can be neglected. The heat generation of the magneto-rheological fluid clutch in the magneto-rheological fluid joint is mainly caused by the Joule heat produced when an electric current is applied to the excitation coil. If the magneto-rheological fluid clutch is unreasonably designed and the heat generated by the coil cannot be dissipated in a timely manner, it will lead to an excessively high temperature of the coil, which may result in burnout. Additionally, the magneto-rheological fluid will undergo changes in its properties due to the excessively high temperature, causing the clutch to fail to work normally. Therefore, it is essential to establish a thermal circuit model for the magneto-rheological fluid clutch and take its heat generation into account during the design process so as to ensure that the magneto-rheological fluid clutch can operate safely and reliably for an extended period.

The thermal circuit model is established by dividing the magneto-rheological fluid clutch into regions based on the shape and material properties of the components within the clutch. When constructing the thermal circuit model of the magneto-rheological fluid clutch based on Ohm’s Law for Thermal Circuits, heat is generated in the excitation coil and transferred to the surrounding air through two paths: one is the axial direction, where heat is dissipated to the air via the rotor at the upper and lower ends to the surface of the magnetic yoke; the other is the radial direction, where heat is dissipated to the air from the circumferential surface of the stator.

Let the total amount of heat dissipated along the axial direction be

and the total amount of heat dissipated along the radial direction be

. The total heat generated by the excitation coil is

. Then, according to the law of conservation of energy, the following equation can be obtained:

where

represents the thermal resistance of each part,

is the temperature of the excitation coil,

is the temperature of the magneto-rheological fluid, and

is the surface temperature of the rotor.

There are two ways for the magneto-rheological fluid clutch to dissipate heat to the air: natural convection and radiative heat dissipation. Based on Ohm’s Law for Thermal Circuits, the following closed thermal circuit equation can be derived [

28]:

where

is the convection coefficient,

is the mantle surface area of the stator for radial heat dissipation (m

2),

is the total end-cap surface area of the rotor/yoke for axial heat dissipation (m

2),

is the Boltzmann constant,

is the radiative emissivity coefficient, and

is the ambient air temperature.

Given the limit temperature of the coil and the ambient temperature , the maximum current for the magneto-rheological fluid clutch to operate safely and reliably, the maximum temperature of the magneto-rheological fluid, and the temperature of the rotor yoke can be solved by simultaneously solving Equations (6) and (7). Since the heat conduction areas and , the thermal resistances of each part, and the coil resistance are all calculated based on the structural parameters of the magneto-rheological fluid clutch, the calculated maximum current , maximum temperature of the magneto-rheological fluid, and temperature of the rotor yoke are inevitably closely related to the structural parameters of the magneto-rheological fluid clutch. By using the calculated results to constrain the structural parameters of the magneto-rheological fluid clutch in the optimal design process, a safe and reliable design of the magneto-rheological fluid clutch can be obtained.

The magnetic circuit model and the thermal circuit model are not independent; they form a coupled multi-physics system. Understanding their coupling relationship is essential for accurate modeling and reliable design. The excitation current is the common input to both models. In the magnetic circuit, the excitation current generates the magnetomotive force, which determines the magnetic flux density in the MR fluid and the core, ultimately defining the output torque via Equation (1). Simultaneously, according to the thermal circuit model (Equations (6) and (7)), the same current flowing through the coil resistance produces Joule heating, which is the primary heat source in the system. This heat leads to a rise in the temperatures of the coil, the MR fluid, and other components. The constraints on maximum current and maximum temperature are interdependent. The genetic algorithm finds a set of structural parameters that simultaneously satisfy the torque requirement from the magnetic model without exceeding saturation flux density, while ensuring that the resulting Joule heating, calculated by the thermal model, does not cause temperatures to exceed safe limits for the coil and the MR fluid. This integrated approach ensures that the optimized MRC delivers the required performance reliably under continuous operation.

2.4. Parameter Optimization Design of MRA

The goal of optimizing the design of the magneto-rheological fluid clutch is to select appropriate values for the inner radius

of the annular magneto-rheological fluid, the radius

of the rotor core, the number of turns

of the excitation coil, and the input current

under the constraints of the clutch’s mechanical structure, magnetic saturation, maximum current, and maximum temperature. This selection aims to enable the magneto-rheological fluid clutch to achieve the maximum torque output. The design variables and their parameter design ranges are expressed as follows:

The optimization design problem of the magneto-rheological fluid clutch described above can be mathematically formulated as

The magnetic induction intensity in the magneto-rheological fluid is calculated by the magnetic circuit model (4), while the maximum current

and the operating temperature

of the magneto-rheological fluid are calculated by the thermal circuit model (7) proposed in this chapter. The genetic algorithm is adopted to solve this optimization problem, and the obtained global optimal solution is as follows:

All the results obtained fall within the range of the design variables; therefore, the results can be considered to have converged to the global optimal solution. The thickness of the rotor yoke is = 10.5 mm ≈ 11 mm. It should be noted that these solved optimal parameters have all been rounded to meet the practical requirements of mechanical processing.

The rounded solution obtained is substituted into the equivalent magnetic circuit model, the thermal circuit model, and the Bingham model to calculate the maximum magnetic induction intensity

in the magneto-rheological fluid, the maximum magnetic induction intensity

of the iron core, the maximum magnetic induction intensity

in the rotor-to-yoke at radius

, and the maximum torque

of the designed magneto-rheological fluid clutch. The results are shown in

Table 2.

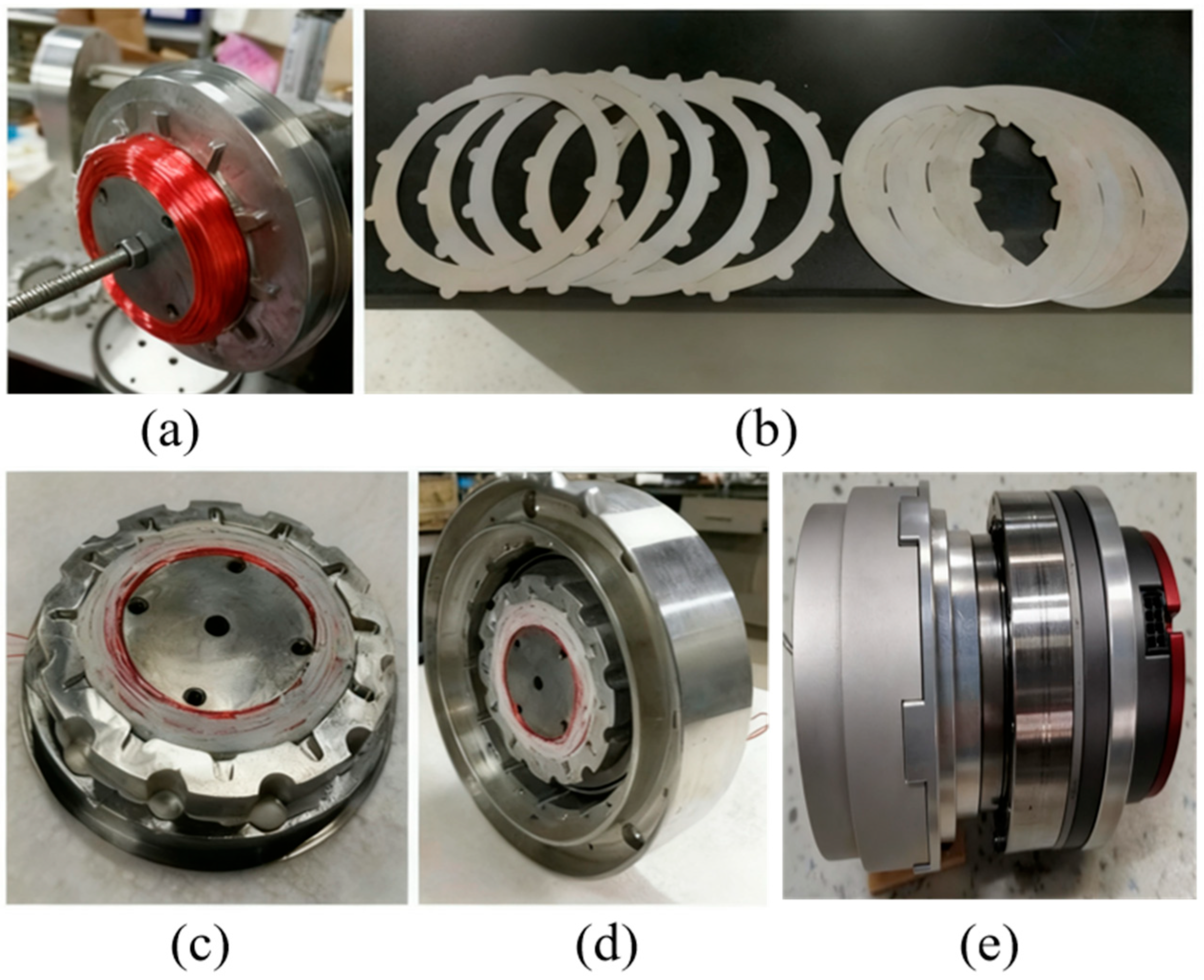

The specific structure of the built-in coil disk-type magneto-rheological fluid clutch designed in this paper is shown in

Figure 3. It consists of a pair of pure iron rotors, an aluminum alloy stator, a set of copper coils, an aluminum alloy disk skeleton, a number of annular rotating disks and stationary disks made of silicon steel sheets, and magneto-rheological fluid filling the gaps between the rotating and stationary disks.

When current is applied to the coil, the coil generates closed magnetic field lines inside the magneto-rheological fluid clutch. These magnetic field lines pass through the iron core of the rotor pair, the yoke of the rotor pair, the magneto-rheological fluid, and the rotating/stationary disks before finally returning to the iron core of the rotor pair to form a closed loop. When an external magnetic field acts on the magneto-rheological fluid, the fluid can transform from a liquid state to a solid-like state in an extremely short time (usually a few milliseconds). The degree of solidification is positively correlated with the strength of the external magnetic field, which creates resistance to the relative motion between the rotating and stationary disks immersed in it. Thus, a current-controllable engagement torque is formed between the rotor and stator of the magneto-rheological fluid clutch. A through-hole is machined in the middle of the rotor pair to facilitate the hollow wiring of the magneto-rheological fluid joint.

5. Conclusions

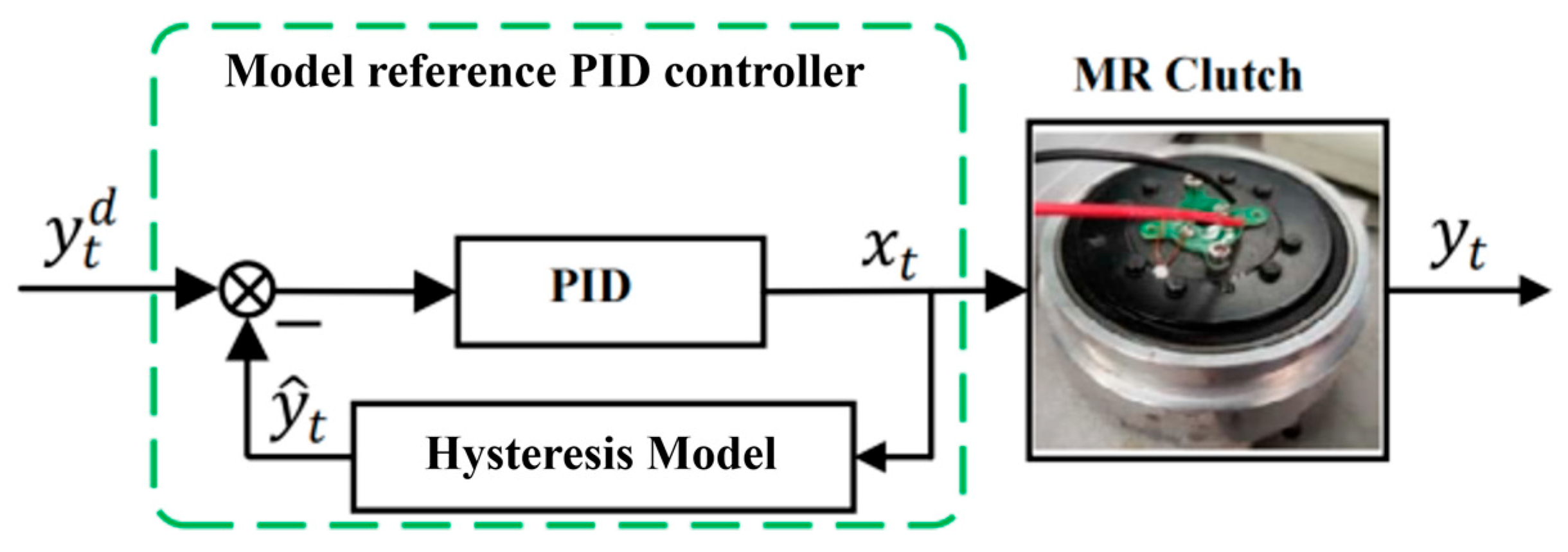

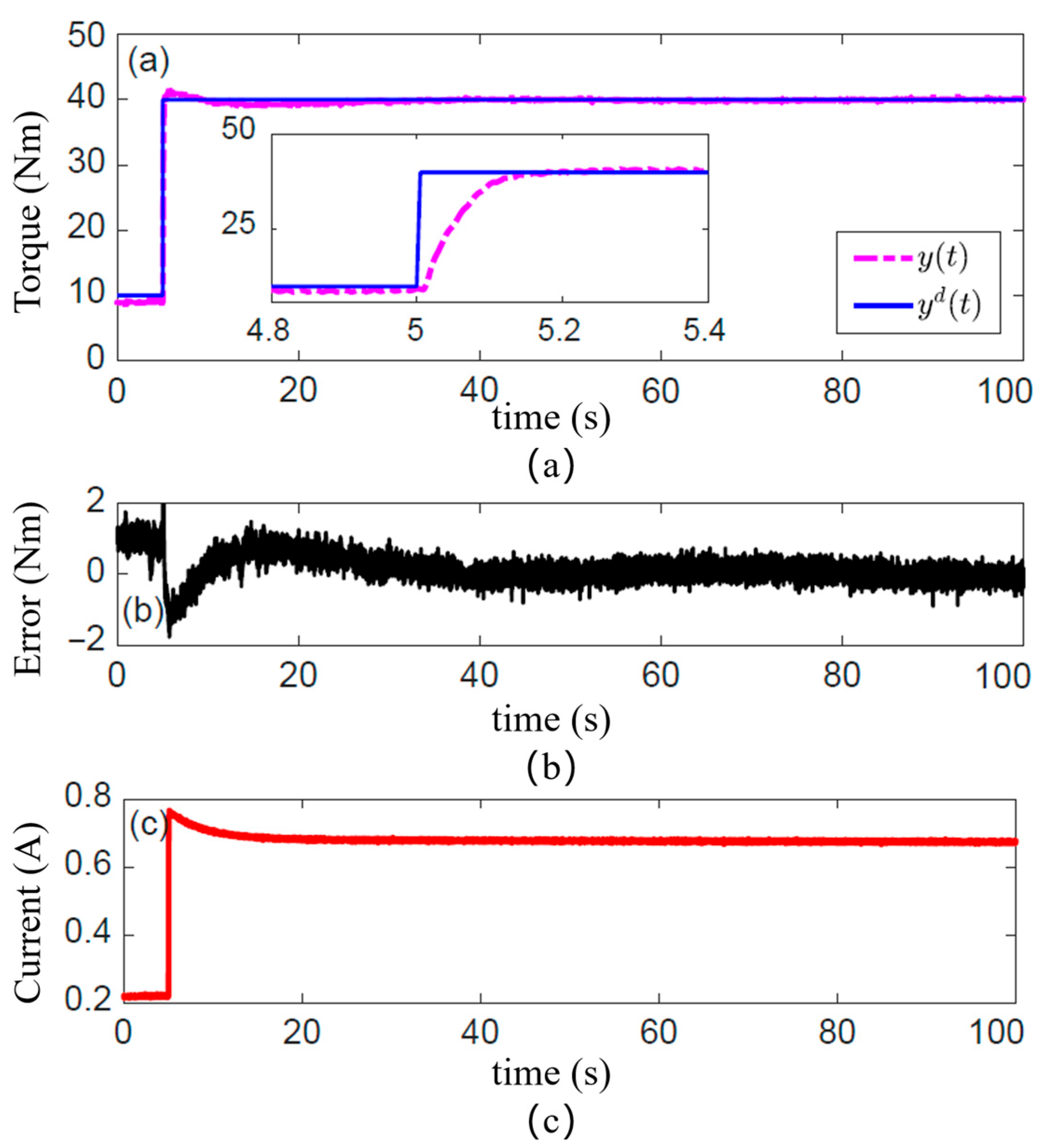

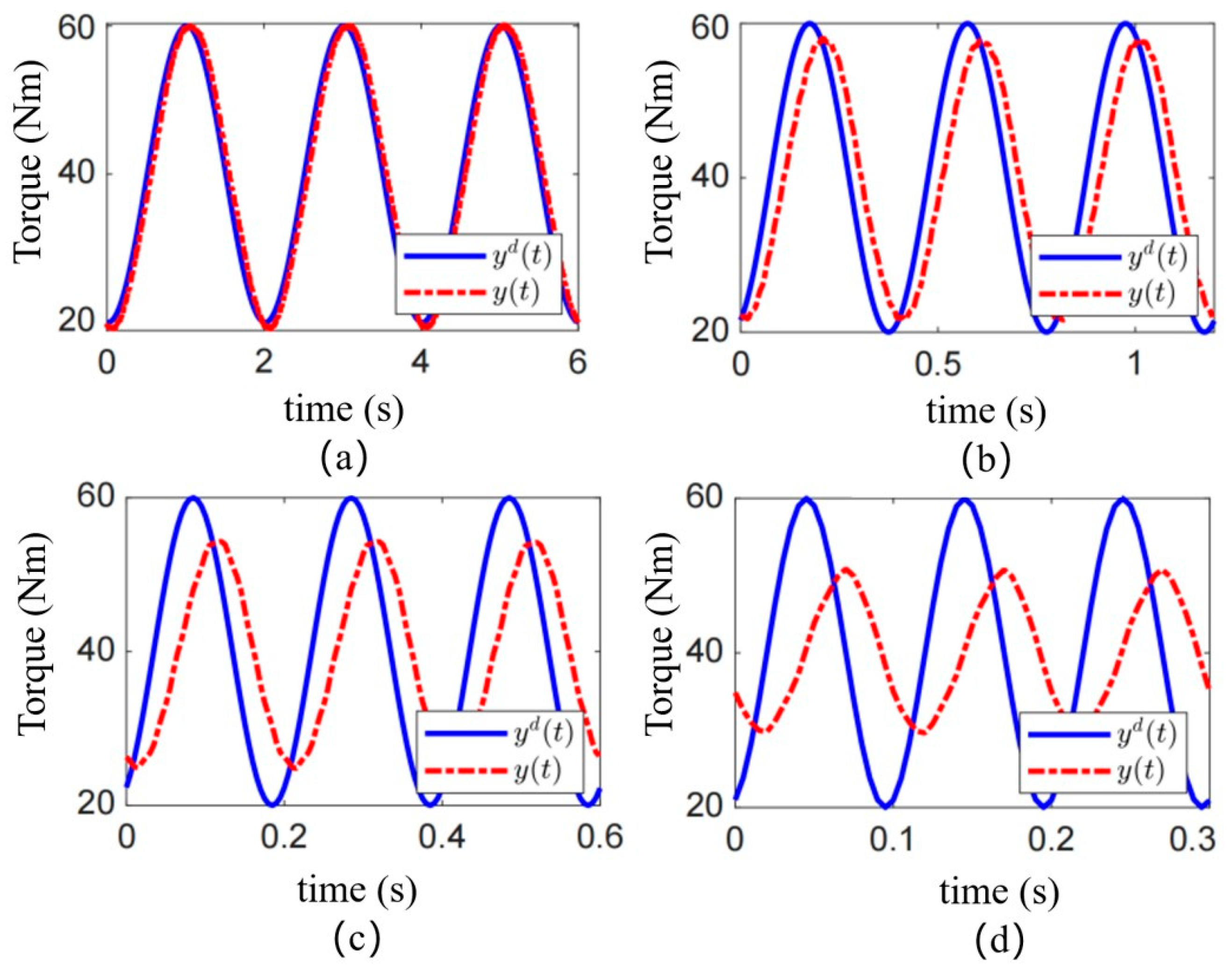

This study presented an integrated solution for the design and control of a Magneto-Rheological Actuator, addressing the combined need for high torque, high compliance, and safety in flexible robotic joints. Through multi-physics modeling of the core MRC component using equivalent magnetic and thermal circuit models and employing a genetic algorithm for parameter optimization under multiple constraints including mechanical structure, magnetic saturation, maximum current, and maximum temperature, a prototype was successfully developed. The optimized MRA achieved a maximum output torque of 153.7 Nm, validating the effectiveness of the design approach. For application scenarios lacking torque sensors, a model-reference PID feedforward control strategy was designed. The experimental results show that it has good torque tracking performance. In static step response, the steady-state tracking error is tightly bounded within ±0.5 Nm (<0.33% of the full-scale range). The RMSE was calculated to be 0.21 Nm. Regarding dynamic tracking performance, the actuator exhibited high-fidelity tracking under a 0.5 Hz sinusoidal command, with an RMSE as low as 0.45 Nm. Effective tracking was maintained at 2.5 Hz (RMSE of 1.8 Nm). However, performance degraded at higher frequencies due to unmodeled rate-dependent hysteresis dynamics, clearly defining the bandwidth limitation (approximately 3.2 Hz) of the current model-based feedforward control. This research shows a complete chain from multi-physics modeling and parameter optimization to sensorless torque control, providing a practical and integrated solution for flexible robotic joints. Future work will focus on two main avenues: first, integrating more advanced dynamic hysteresis models into the control strategy to enhance mid-to-high-frequency dynamic performance; second, applying the designed MRA to quadruped robot or humanoid robot to validate its comprehensive performance in real-world tasks and promote its practical applications.