Comparative Study of Strain Measurement Techniques for Assessing Creep in CFRP Tendons

Abstract

1. Introduction

2. Materials and Methods

2.1. CFRP Tendons

2.2. Strain Sensors

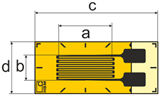

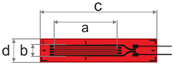

2.2.1. Foil Gauges

- HBK’s methacrylate X60;

- HBK’s cyanoacrylate Z70, and its newer version CA80;

- TML’s EB2, recommended by the manufacturer for long-term measurements [17].

2.2.2. Contact Extensometer

2.2.3. Digital Image Correlation (DIC)

2.2.4. Distributed Fibre Optic Sensing (DFOS)

2.3. Other Sensors

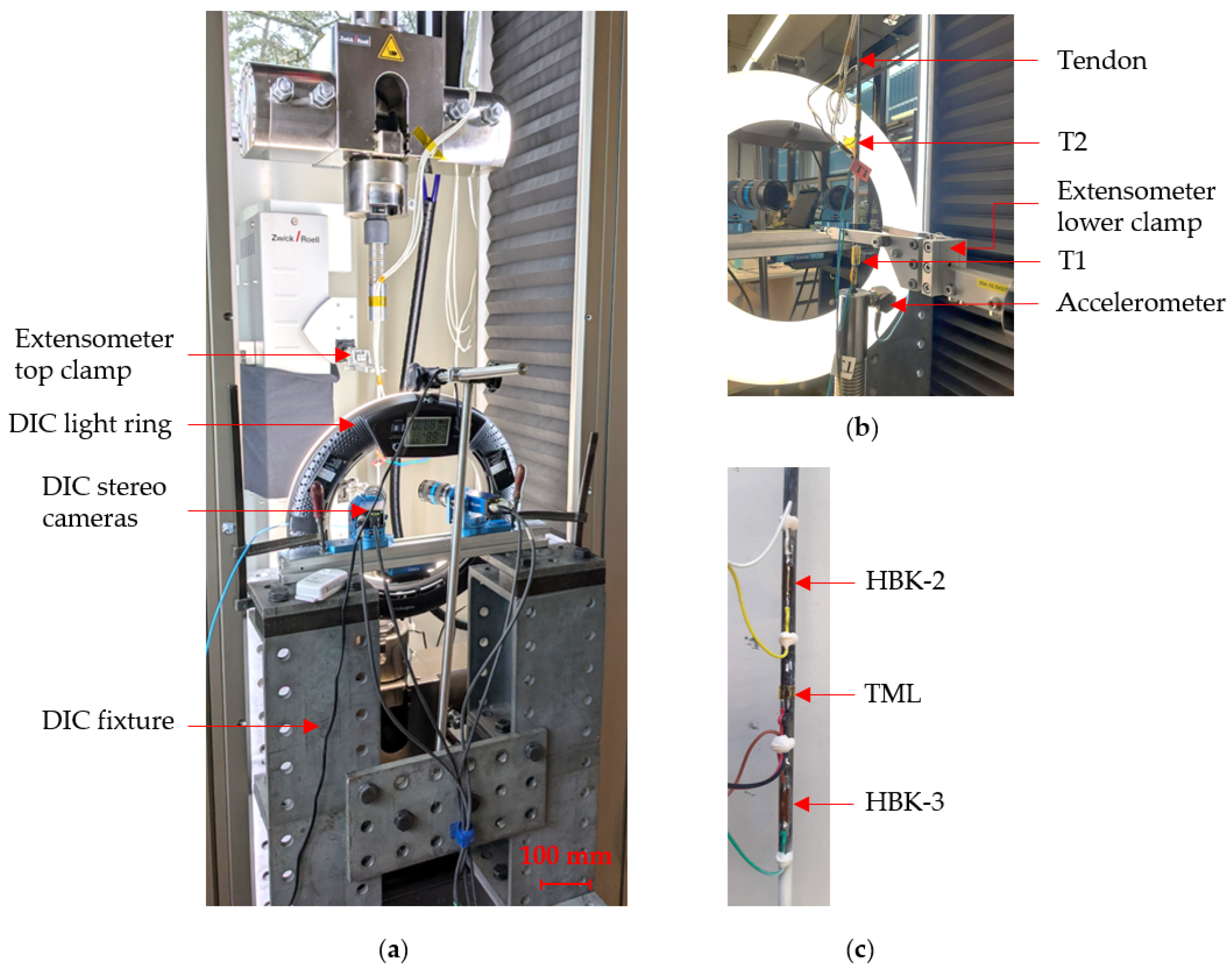

2.4. Test Set-Up

2.4.1. Series A

2.4.2. Series B

3. Results and Observations

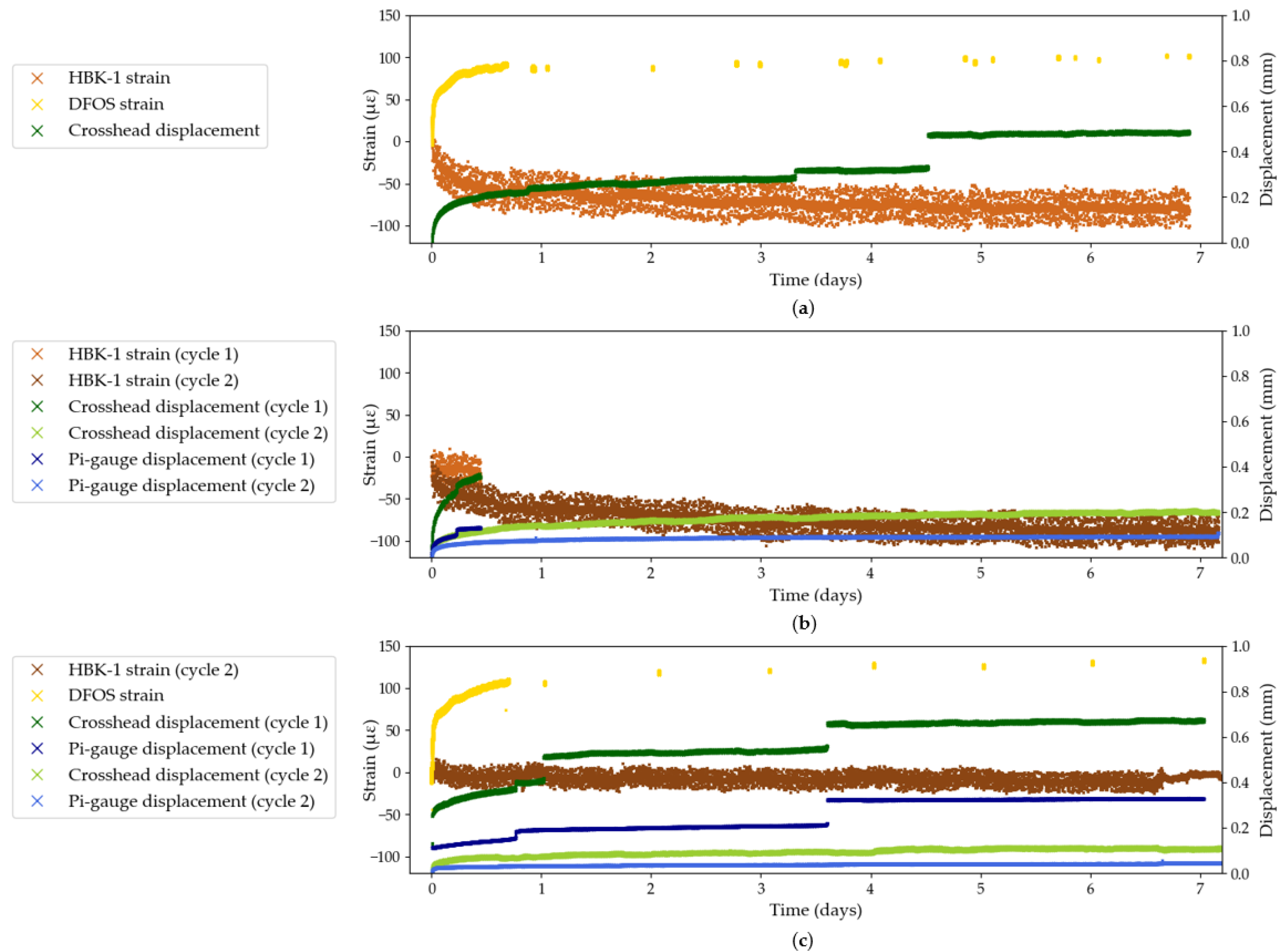

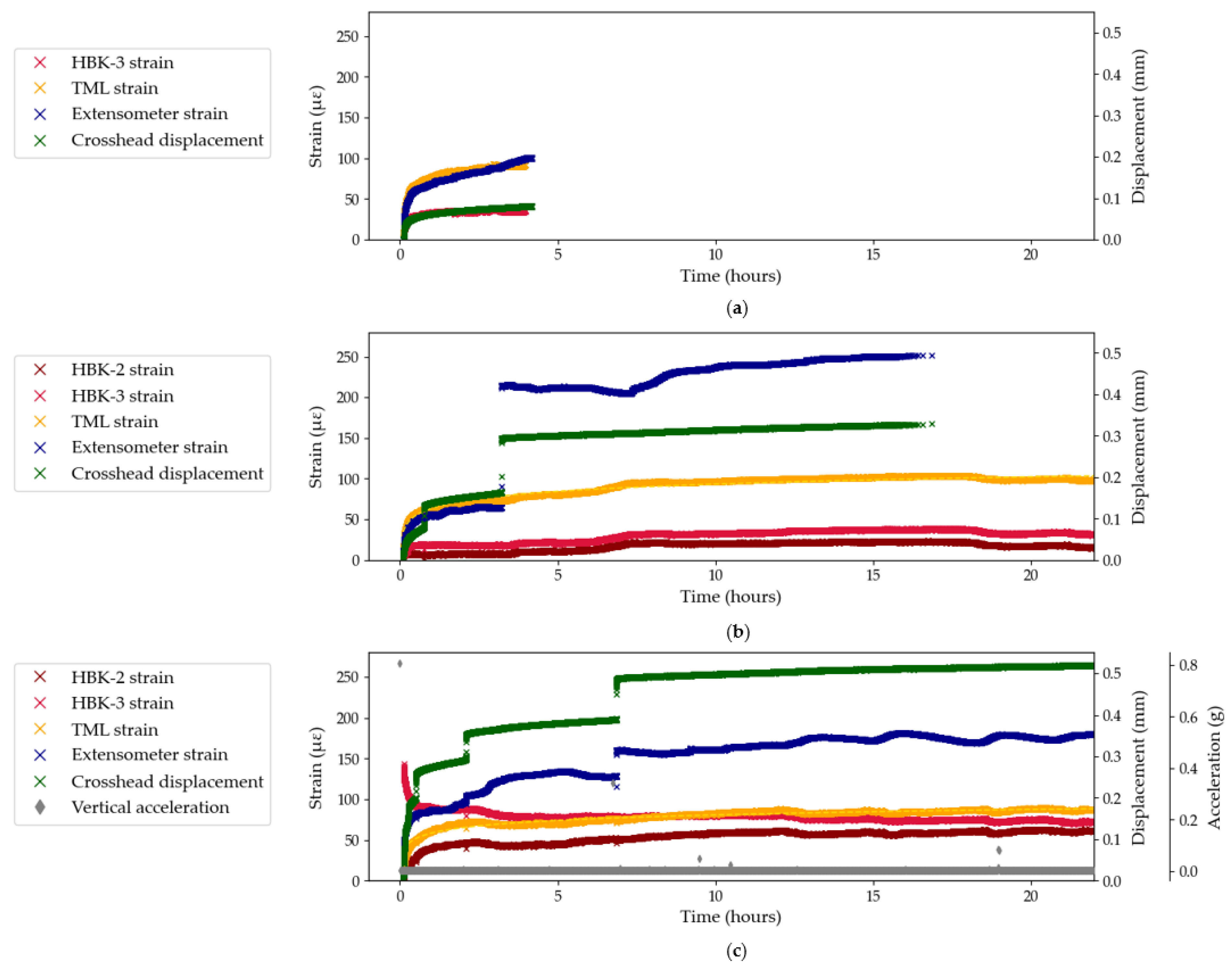

3.1. Mobility and Creep of the Test Set-Up

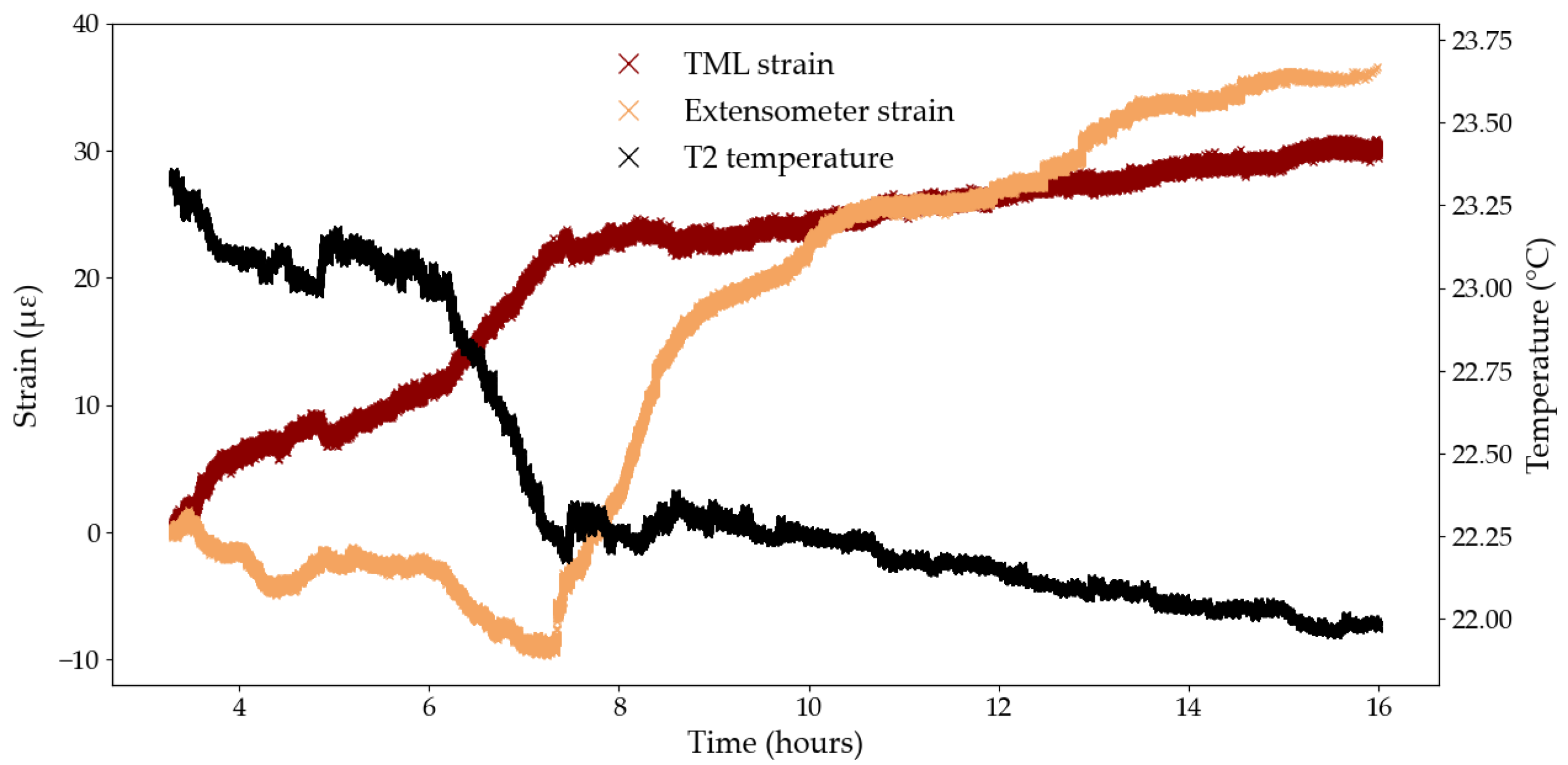

3.1.1. Extensometer Discontinuities

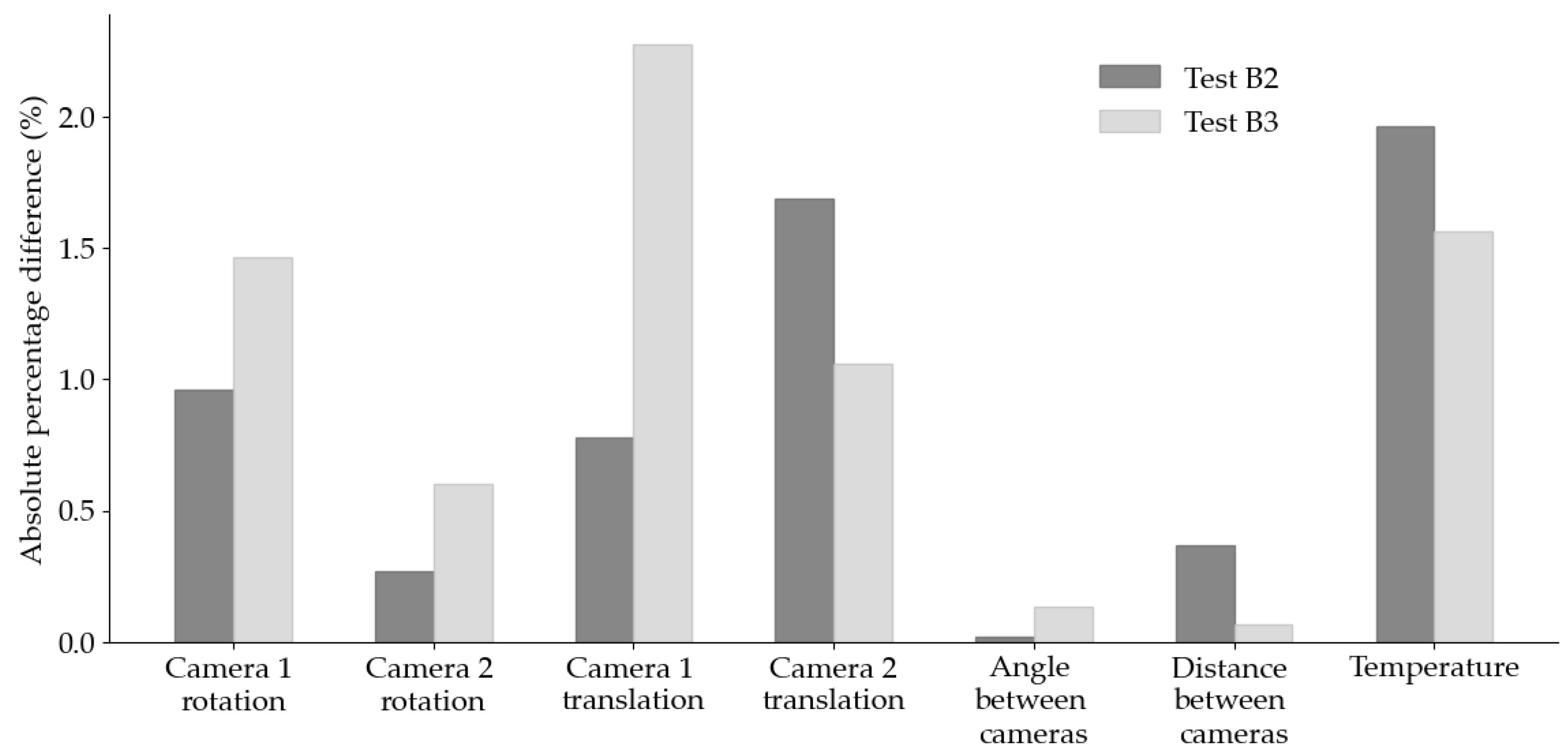

3.1.2. DIC Pre- and Post-Test Calibration

3.2. Limitations of Strain Gauges

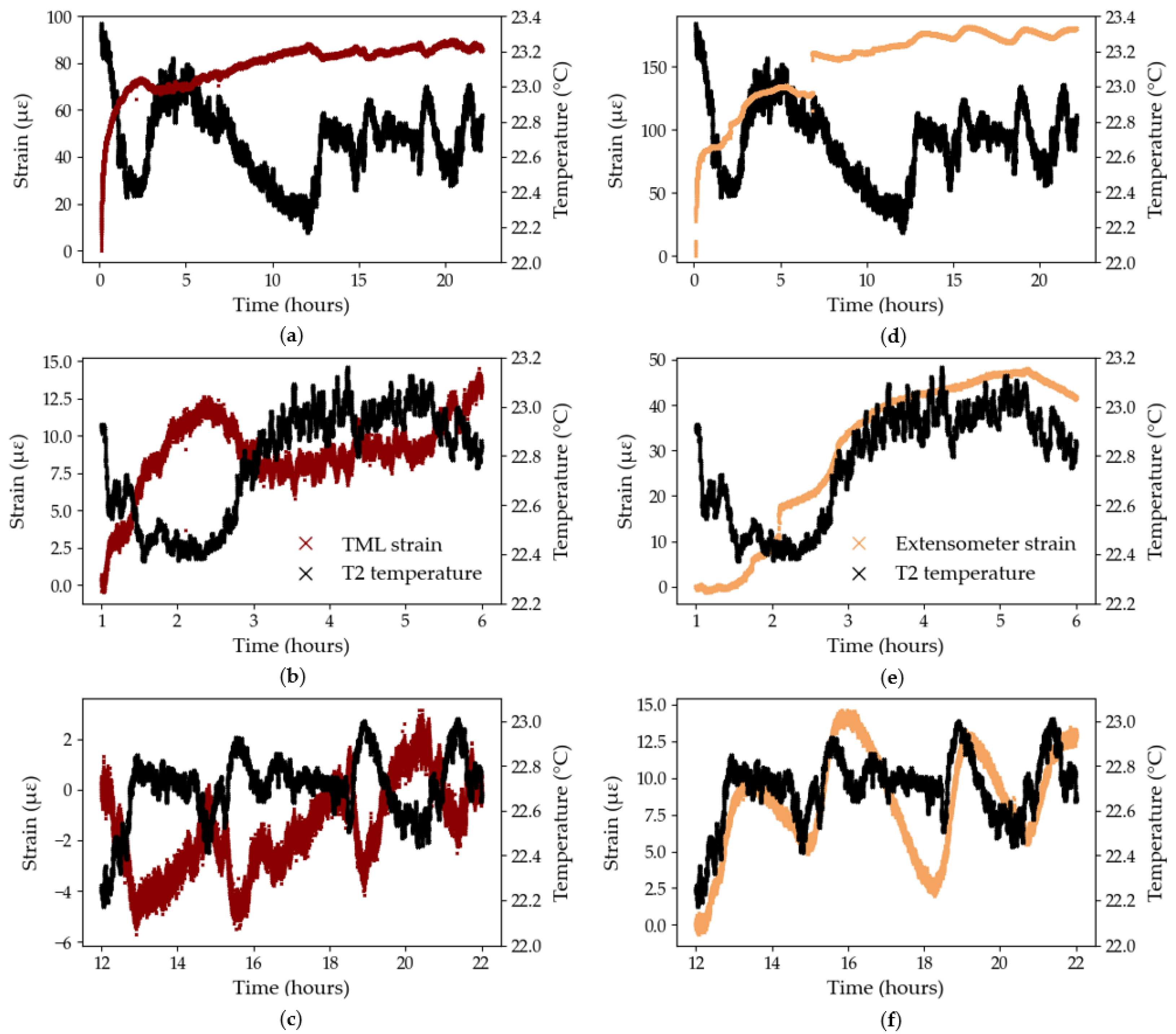

3.3. Temperature Sensitivities

3.4. Material Inhomogeneities

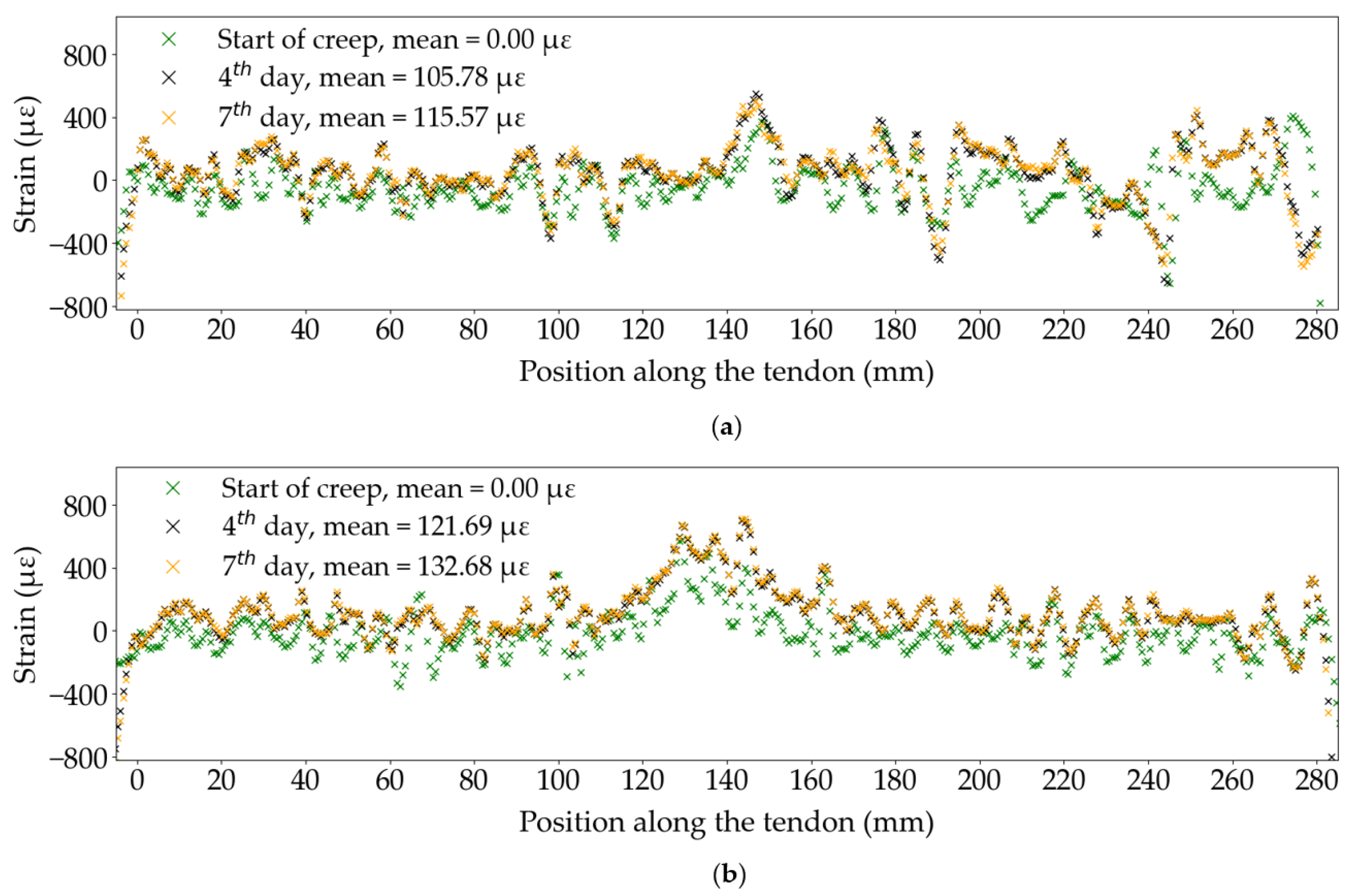

3.4.1. Distributed Fibre Optic

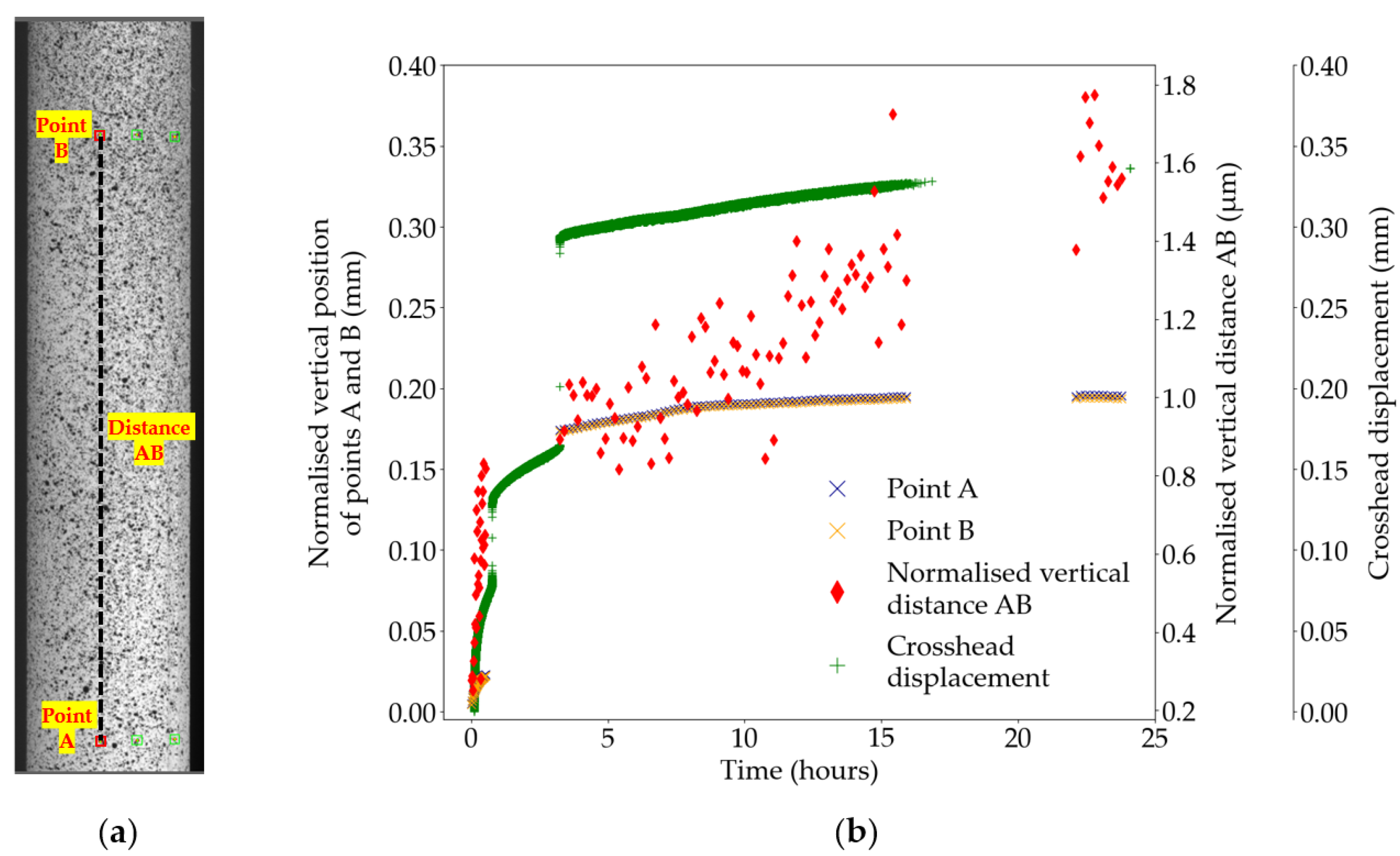

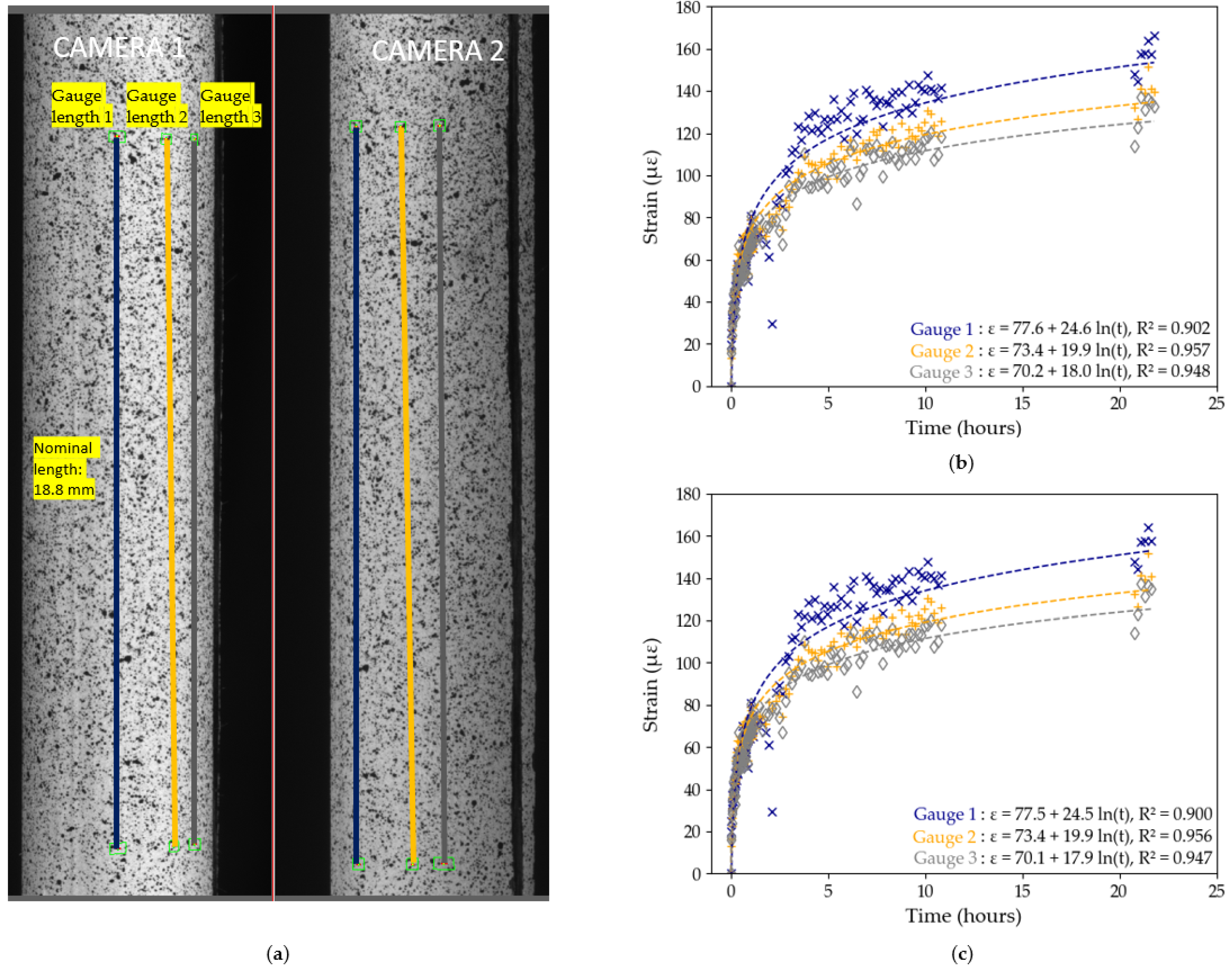

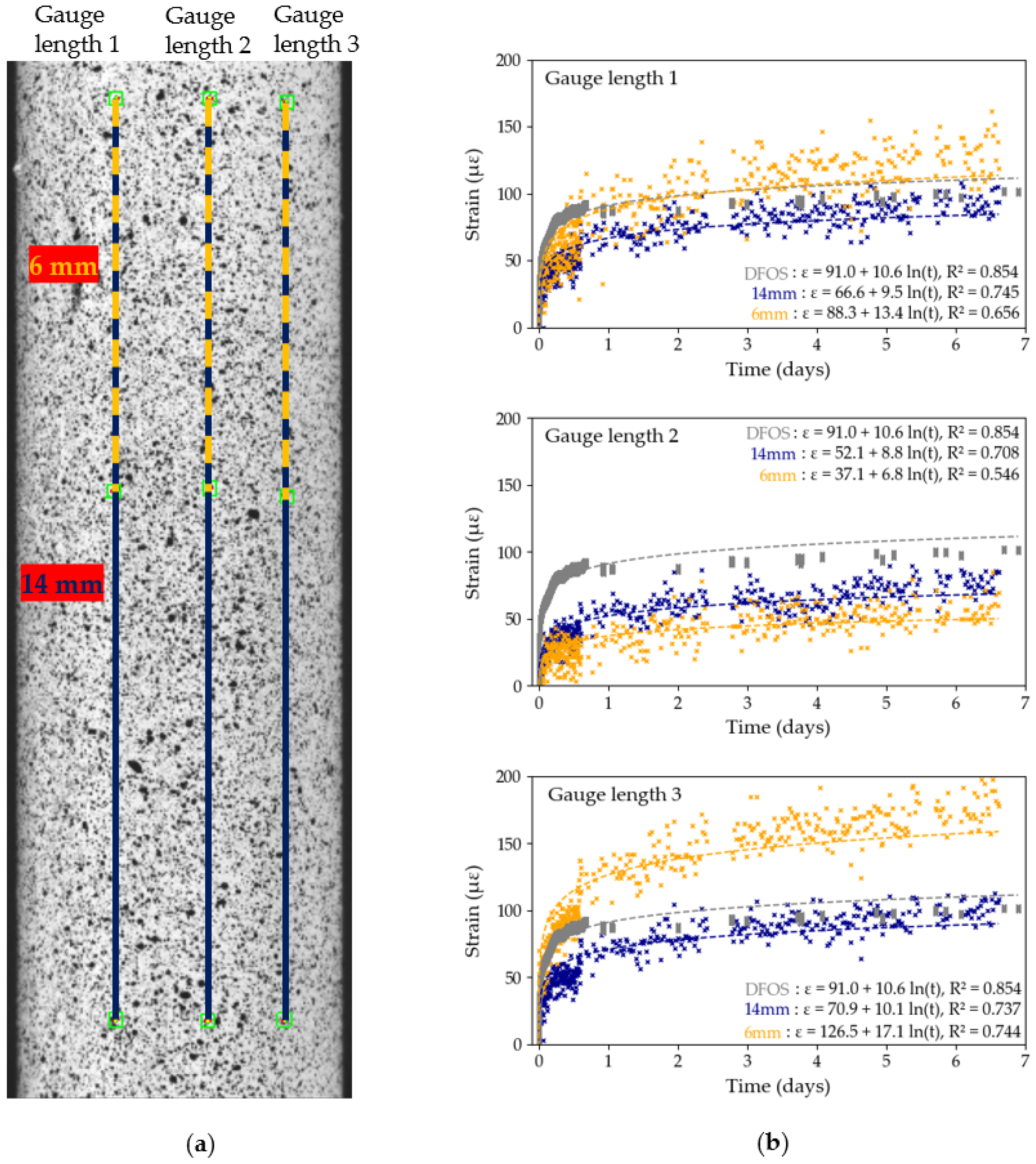

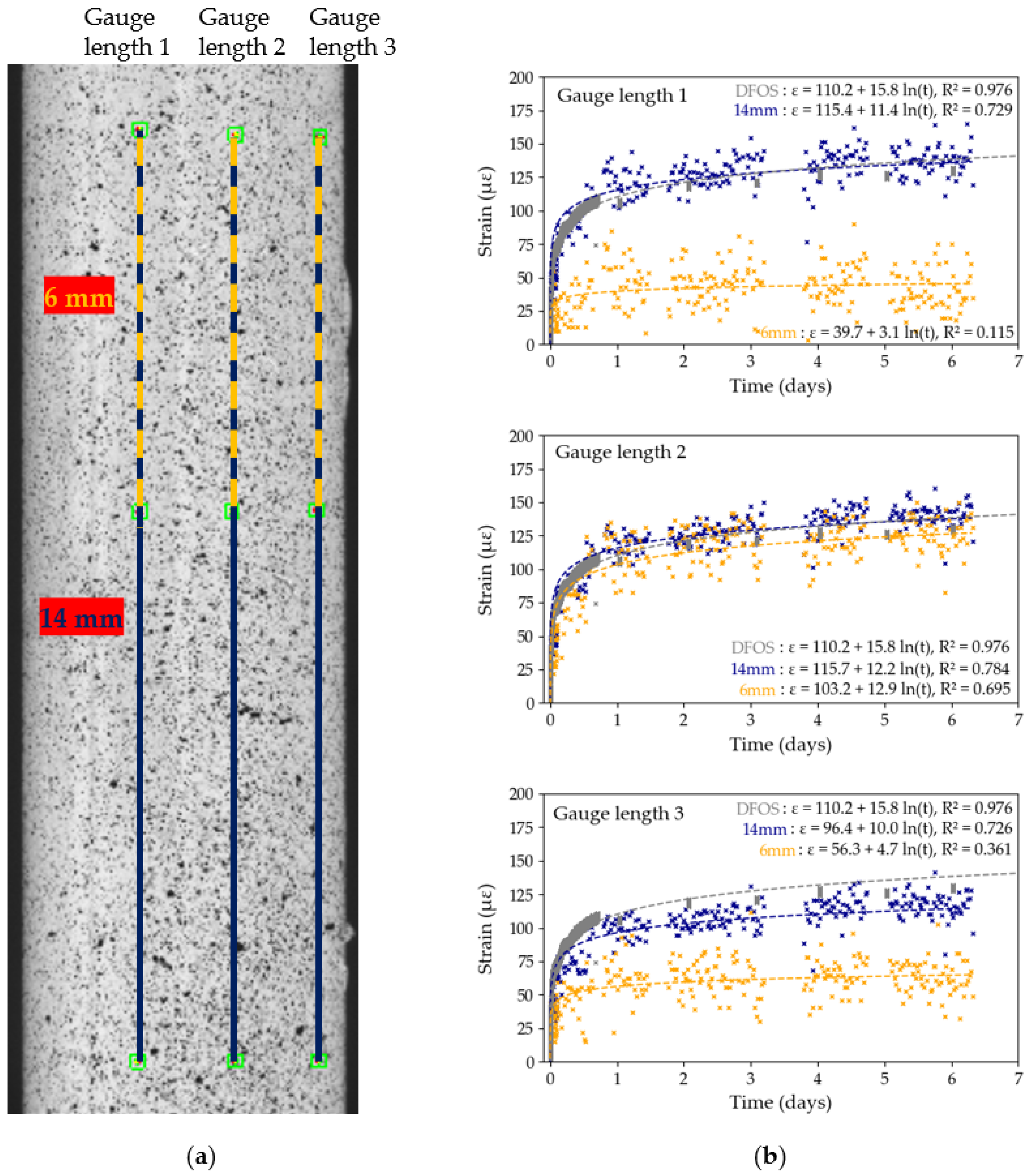

3.4.2. DIC Gauge Length

4. Discussion: Creep of CFRP Tendons

5. Conclusions

- The contact extensometer recorded jumps of up to 250% in measured strain due to sudden movement of the anchored CFRP tendon during sustained loading, while bonded strain sensing techniques were unaffected by movement of the test set-up.

- The bonded TML strain gauge recorded a small and recoverable range of temperature-induced strains, consistently 12 με/°C, while the response of the extensometer to temperature changes varied in phase and magnitude, with a maximum reported CTE of 40 με/°C.

- The stereoscopic DIC set-up was shown to be highly sensitive to curved surfaces and out-of-plane motions with a variability of up to 43% in computed creep strains between different gauge length positions across the tendon’s diameter.

- The DFOS recorded localised peaks of 150% of the averaged measured strain at the tendon’s mid length; however, these localised strain peaks had no significant influence on the overall creep behaviour of the CFRP tendons.

- The HBK foil gauges either recorded a decrease in strain over time, which disagrees with the physical definition of creep, or underestimated the creep strains when compared to the other strain sensing techniques, demonstrating their inadequacy for measuring strain of CFRP tendons under high sustained loading conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFRP | Carbon Fibre-Reinforced Polymer |

| DIC | Digital Image Correlation |

| DFOS | Distributed Fibre Optic System |

| UTS | Ultimate Tensile Strength |

| CTE | Coefficient of Thermal Expansion |

| RTD | Resistance Temperature Detector |

| ROI | Region of Interest |

References

- Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars; Number 440.1R-15; American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Sena-Cruz, J.; Sá, M.; Correia, J.R.; Mottram, J.T.; Keller, T.; Pérez, M.G.; Ascione, L.; Tromp, L.; Russo, S. Design of Fibre-Polymer Composite Structures (CEN/TS 19101): Serviceability Limit States and Creep Rupture. In Proceedings of the 11th International Conference on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), Rio de Janeiro, Brazil, 23–26 July 2023. [Google Scholar]

- Tanks, J.D.; Rader, K.E.; Sharp, S.R. Accelerated Creep Testing of CFRP with the Stepped Isostress Method. In Proceedings of the Mechanics of Composite and Multi-Functional Materials; River Publishers: Gistrup, Denmark, 2016; Volume 7. [Google Scholar] [CrossRef]

- Phoeuk, M.; Choi, D.Y.; Kwon, M. Long-Term Creep Rupture of Carbon Fiber Reinforced Polymer Grids Under High Stress Levels: Experimental Investigation. Materials 2024, 18, 35. [Google Scholar] [CrossRef] [PubMed]

- Ascione, F.; Berardi, V.P.; Feo, L.; Giordano, A. An experimental study on the long-term behavior of CFRP pultruded laminates suitable to concrete structures rehabilitation. Compos. Part B Eng. 2008, 39, 1147–1150. [Google Scholar] [CrossRef]

- Ando, N.; Matsukawa, H.; Kawamura, M.; Fujii, M.; Miyagawa, T.; Inoue, S. Experimental Studies on the Long-Term Tensile Properties of FRP Tendons. In Proceedings of the Fracture Mechanics of Concrete Structures; AEDIFICA TIO Publishers: Freiburg, Germany, 1998; p. 10. [Google Scholar]

- Jiang, Z.; Fang, Z.; Fang, C.; Li, Q.; Wang, Z. Experimental investigation on high-temperature creep behavior of carbon fiber reinforced polymer cable. Compos. Struct. 2022, 291, 115533. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, J.; Song, S.; Zhou, F.; Wang, C. Experimental Investigation on the Creep Property of Carbon Fiber Reinforced Polymer Tendons under High Stress Levels. Materials 2018, 11, 2273. [Google Scholar] [CrossRef] [PubMed]

- Anderegg, P.; Brönnimann, R.; Meier, U. Reliability of long-term monitoring data. J. Civ. Struct. Health Monit. 2014, 4, 69–75. [Google Scholar] [CrossRef][Green Version]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and Application of Resistance Strain Force Sensors. Sensors 2020, 20, 5826. [Google Scholar] [CrossRef] [PubMed]

- Tuttle, M.E.; Brinson, H.F. Prediction of the long-term creep compliance of general composite laminates. Exp. Mech. 1986, 26, 89–102. [Google Scholar] [CrossRef]

- Toray. T700S Commercial Documentation. Data Sheet AQ. 866-6, 2014. Available online: https://www.toraycma.com/products/carbon-fiber/#pattern5_1 (accessed on 4 November 2025).

- Geigy, C. Huntsman, ARALDITE® LY 556 / ARADUR® 917 / ACCELERATOR DY 070. Data sheet. Available online: https://products.huntsman.com/products/araldite-ly-556-dy-070-dwe3a5ao (accessed on 4 November 2025).

- Schapery, R. Thermal Expansion Coefficients of Composite Materials Based on Energy Principles. J. Compos. Mater. 1968, 2, 380–404. [Google Scholar] [CrossRef]

- Boloux, A.; Bisby, L.; Ott, V.; Terrasi, G.P. The Performance of Prestressed Carbon Fibre Reinforced Polymer (CFRP) Bridge Tendons after 18 Years in Service. In Proceedings of the 16th International Symposium on Fiber-Reinforced Polymer (FRP) Reinforcement for Concrete Structures, New Orleans, LA, USA, 23–24 March 2024. [Google Scholar]

- Espion, B.; Halleux, P. Long-Term Measurements of Strain with Strain-Gauges and Stability of Strain-Gauge Transducers; Technical Report; Laboratory for Testing Materials and Structures, University of Brussels: Brussels, Belgium, 2000. [Google Scholar]

- TML Strain Gauge Catalogue 2025–2026; Technical Report; Tokyo Measuring Instruments Laboratory Co., Ltd.: Shinagawa City, Japan, 2025.

- HBM LY Linear Strain Gauges. 2021. Available online: https://www.hbm.com/4561/ly-linear-strain-gauges-with-1-measurement-grid/?product_type_no={LY}%{20Linear}%{20Strain}%{20Gauges}%20with%201%{20Measuring}%{20Grid} (accessed on 18 September 2025).

- ISO 9513; Metallic Materials—Calibration of Extensometer Systems Used in Uniaxial Testing. Internation. International Organization for Standardization: Geneva, Switzerland, 2012.

- Dual Band Bend Insensitive Fiber. Available online: https://fibercore.humaneticsgroup.com/products/single-mode-sm-fiber/dual-band-bend-insensitive-fiber/sm1250b398125 (accessed on 18 September 2025).

- ODiSI 6000 Series|Optical Distributed Sensor Interrogator. Available online: https://lunainc.com/product/odisi-6000-series (accessed on 18 September 2025).

- Züst, G.L.; Ott, V.; Terrasi, G.P. Development of a Pretensioning Anchorage for Sand-Coated CFRP Tendons: Modeling and Validation. Polymers 2022, 14, 5531. [Google Scholar] [CrossRef] [PubMed]

- Martinoni, T.; Ott, V.; Carvelli, V.; Terrasi, G.P. Tensile behavior of unidirectional thick-Ply all-carbon hybrid laminates: A systematic experimental and numerical study. Compos. Part C Open Access 2024, 14, 100462. [Google Scholar] [CrossRef]

| Foil Gauge | Dimensions (mm) † | Resistance () | Gauge Factor | Rated Strain Limit | CTE * (/°C) |

|---|---|---|---|---|---|

| HBK 1-LY5x-6 |  [18] [18], , | 120 | 2.06 ± 1.0% | 5% | 10.8 |

| HBK 1-LY4x-6 |  [18] [18], , | 350 | 2.09 ± 1.0% | 5% | 10.8 |

| TML FLKB-6-11 |  [17] [17], , | 120 | 2.10 ± 1.0% | 5% | 11.8 |

| System Name | Foil Gauge | Adhesive |

|---|---|---|

| HBK-1 | HBK 1-LY4x-6 | Z70 |

| HBK-2 | HBK 1-LY5x-6 | X60 |

| HBK-3 | HBK 1-LY5x-6 | CA80 |

| TML | TML FLKB-6-11 | EP2 |

| Test Name | Load Level | Expected Strain Level | Test Duration | Strain Sensors | Other Sensors |

|---|---|---|---|---|---|

| Test A1 | 80% | 1.42% | 7 days | HBK-1 DFOS DIC | — |

| Test A2 | 80% | 1.42% | 1st cycle: 10 h 2nd cycle: 7 days | HBK-1 DIC | Pi-gauge |

| Test A3 | 80% | 1.42% | 1st cycle: 7 days 2nd cycle: 7 days | HBK-1 DFOS DIC | Pi-gauge |

| Test B1 | 88% | 1.53% | 4.2 h (anchor failure) | HBK-3 TML Extensometer DIC | T1, T2 Sensirion Accelerometer |

| Test B2 | 88% | 1.53% | 22 h | HBK-2, HBK-3 TML Extensometer DIC | T1, T2 Sensirion |

| Test B3 | 88% | 1.53% | 22 h | HBK-2, HBK-3 TML Extensometer DIC | T1, T2 Sensirion Accelerometer |

| Test Name | Strain Device | Creep Coefficient at End of Test (in %) | Creep Equation (t in Hours) | R2 Value | 50-Year Creep Coefficient Prediction (in %) |

|---|---|---|---|---|---|

| A1 | DIC | 0.75 (7 days) | 66.57 + 9.48 ln(t) | 0.745 | 1.36 |

| DFOS | 0.69 (7 days) | 91.04 + 10.56 ln(t) | 0.854 | 1.54 | |

| A3 | DIC | 0.98 (7 days) | 115.70 + 12.17 ln(t) | 0.784 | 1.82 |

| DFOS | 0.90 (7 days) | 110.17 + 15.76 ln(t) | 0.976 | 2.17 | |

| B2 | TML foil gauge | 0.62 (24 h) | 63.49 + 12.92 ln(t) | 0.903 | 1.51 |

| Extensometer | 0.82 (24 h) | 51.60 + 12.40 ln(t) | 0.616 | 1.38 | |

| DIC | 0.75 (24 h) | 65.89 + 15.06 ln(t) | 0.950 | 1.71 | |

| B3 | TML foil gauge | 0.56 (22 h) | 58.42 + 9.73 ln(t) | 0.918 | 1.20 |

| Extensometer | 0.32 (22 h) | 96.38 + 16.82 ln(t) | 0.897 | 2.03 | |

| DIC | 1.05 (22 h) | 73.43 + 19.89 ln(t) | 0.957 | 2.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boloux, A.; Burda, I.; Bisby, L.A.; Terrasi, G.P. Comparative Study of Strain Measurement Techniques for Assessing Creep in CFRP Tendons. Sensors 2025, 25, 6897. https://doi.org/10.3390/s25226897

Boloux A, Burda I, Bisby LA, Terrasi GP. Comparative Study of Strain Measurement Techniques for Assessing Creep in CFRP Tendons. Sensors. 2025; 25(22):6897. https://doi.org/10.3390/s25226897

Chicago/Turabian StyleBoloux, Alexandra, Iurii Burda, Luke A. Bisby, and Giovanni Pietro Terrasi. 2025. "Comparative Study of Strain Measurement Techniques for Assessing Creep in CFRP Tendons" Sensors 25, no. 22: 6897. https://doi.org/10.3390/s25226897

APA StyleBoloux, A., Burda, I., Bisby, L. A., & Terrasi, G. P. (2025). Comparative Study of Strain Measurement Techniques for Assessing Creep in CFRP Tendons. Sensors, 25(22), 6897. https://doi.org/10.3390/s25226897