Multiphysics Optical–Thermal and Mechanical Modeling of a CMOS-SOI-MEMS Infrared Sensor with Metasurface Absorber †

Abstract

1. Introduction

2. Sensor Design and Architecture

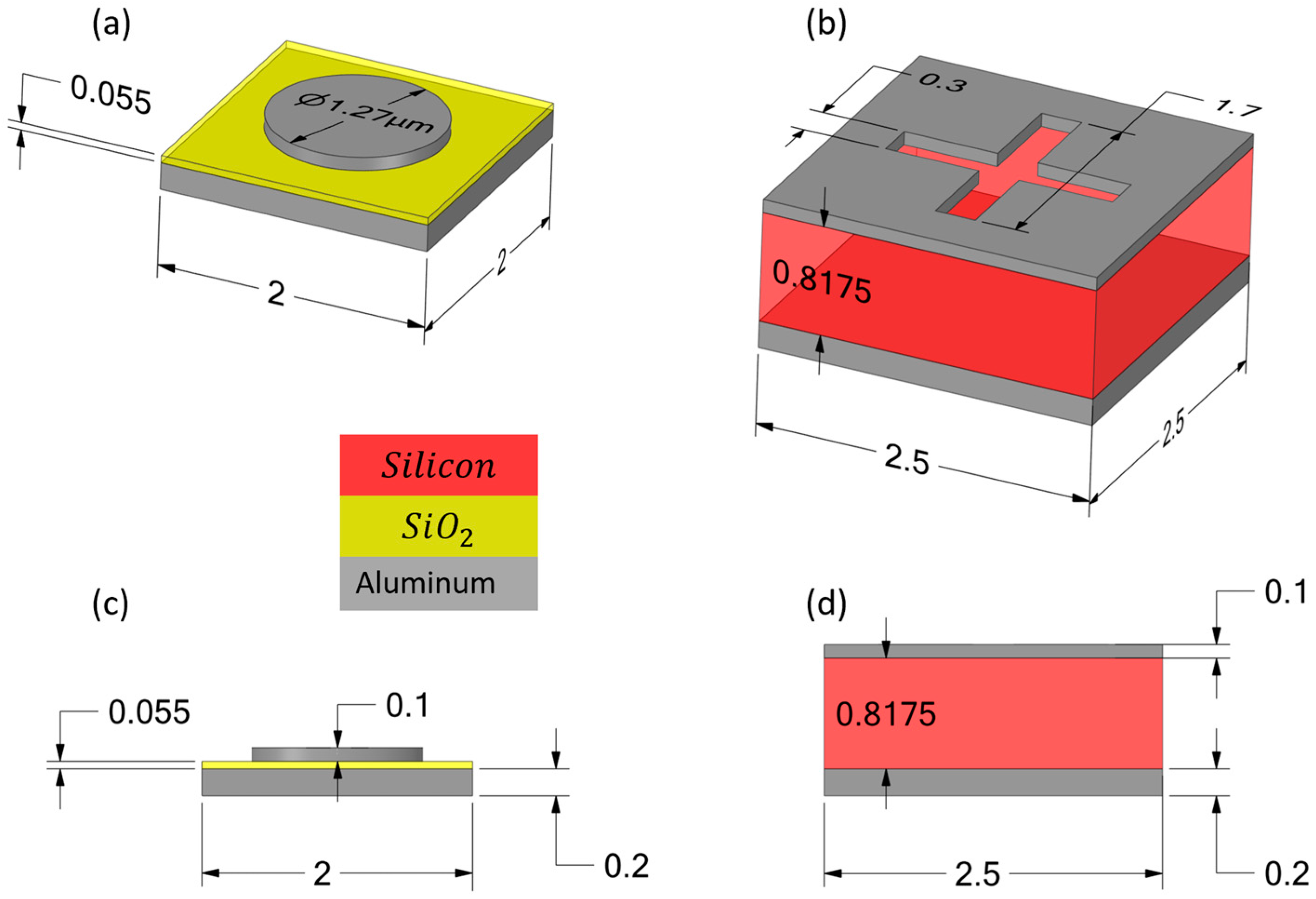

2.1. TMOS Sensor Architecture

2.2. Metamaterial Integration

- Configuration 1: Optimized for peak absorption at 4.26 µm, targeting the CO2 absorption band for non-dispersive infrared (NDIR) gas sensing.

- Configuration 2: Designed for narrowband absorption near 10 µm, suitable for biomedical sensing (e.g., protein vibrational fingerprints) and thermal imaging.

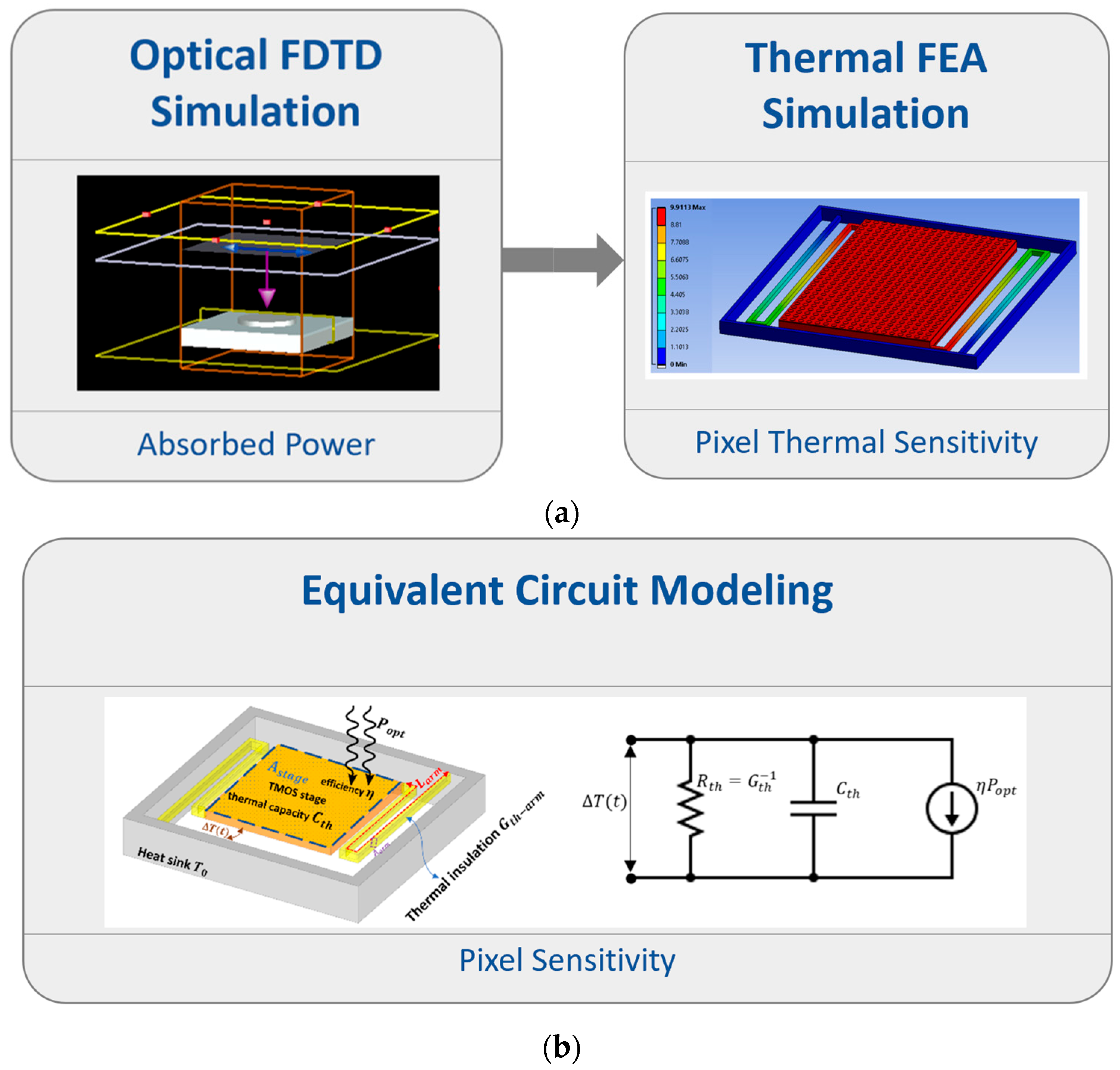

3. Optical Analysis

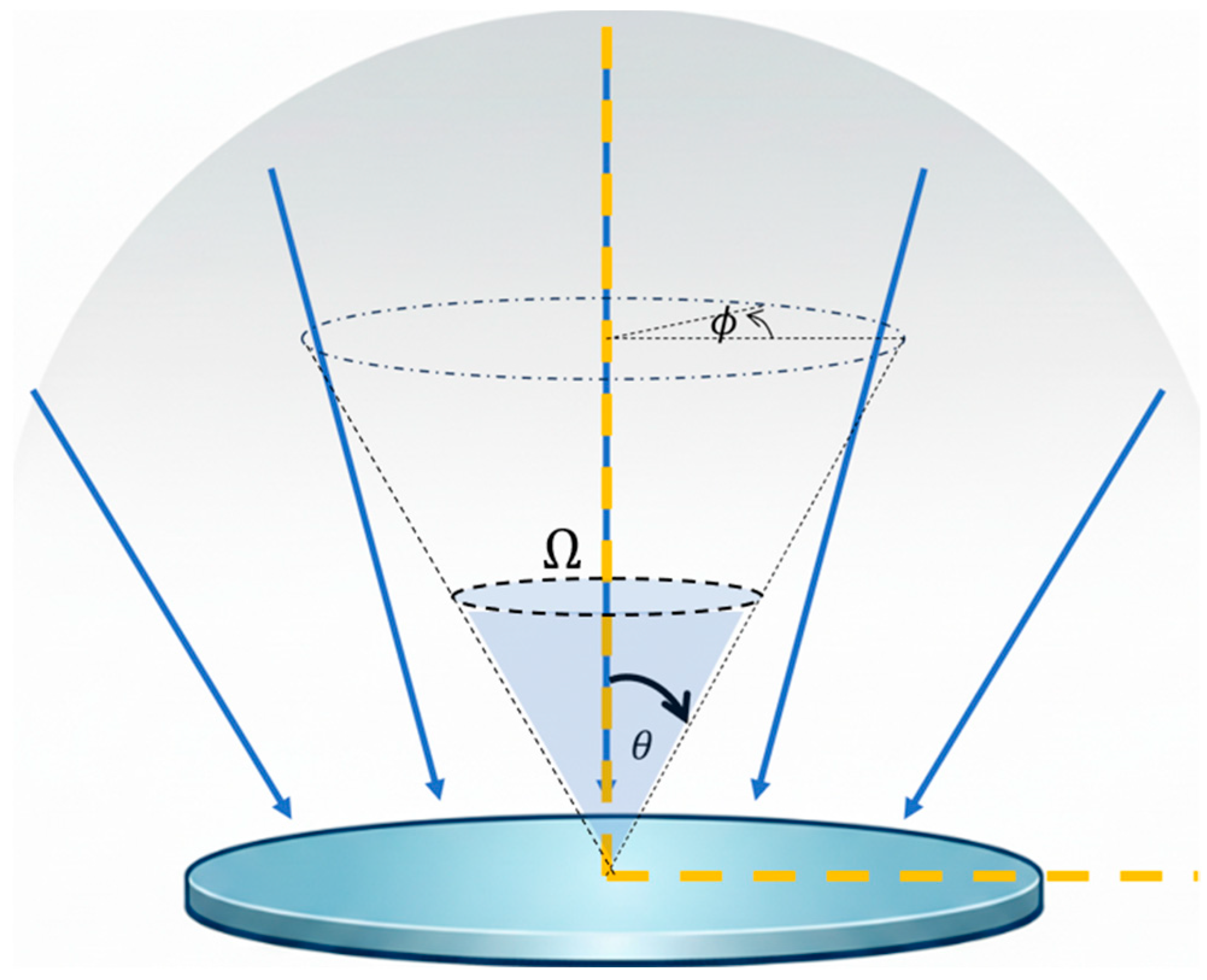

3.1. Incident Irradiance and Radiometric Quantities

3.2. Power Absorbed in a Dispersive and Absorptive Material

3.3. Optical Efficiency Analysis

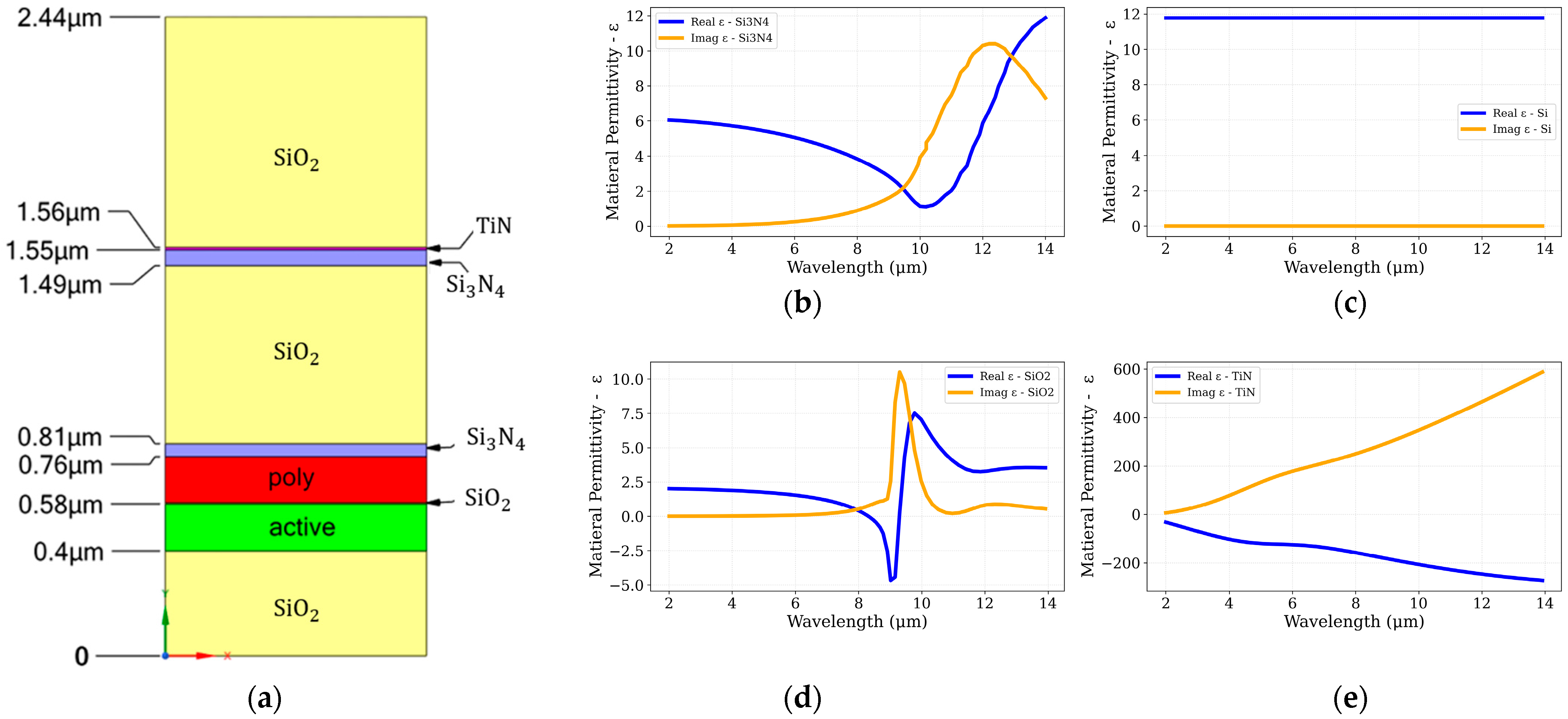

3.3.1. CMOS Layers Absorption and TiN-Embedded Layer

3.3.2. Metamaterial Absorber Layers

4. Thermal Analysis

4.1. Governing Principles of Heat Transfer

4.2. Lumped-Circuit Equivalent Model

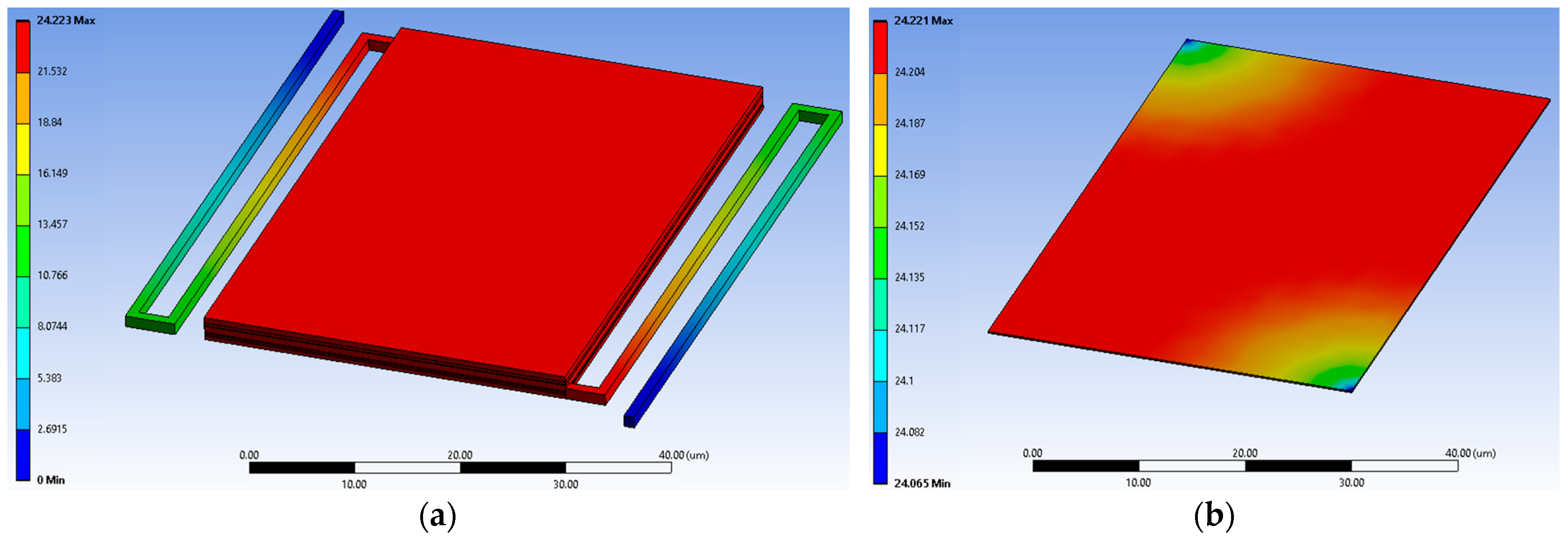

4.3. Simulation Setup and Results

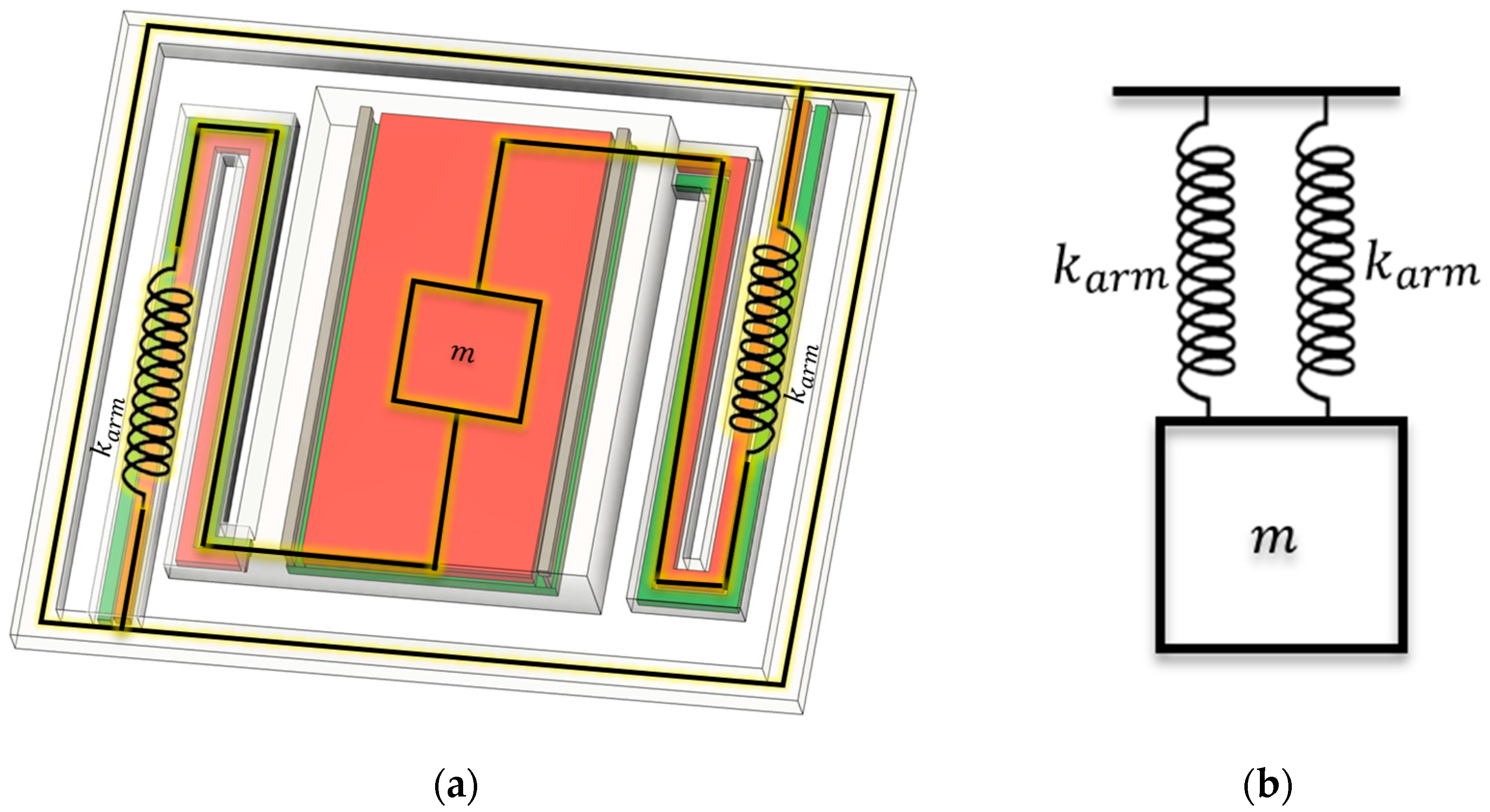

5. Mechanical Analysis

5.1. Modal and Harmonic Analysis

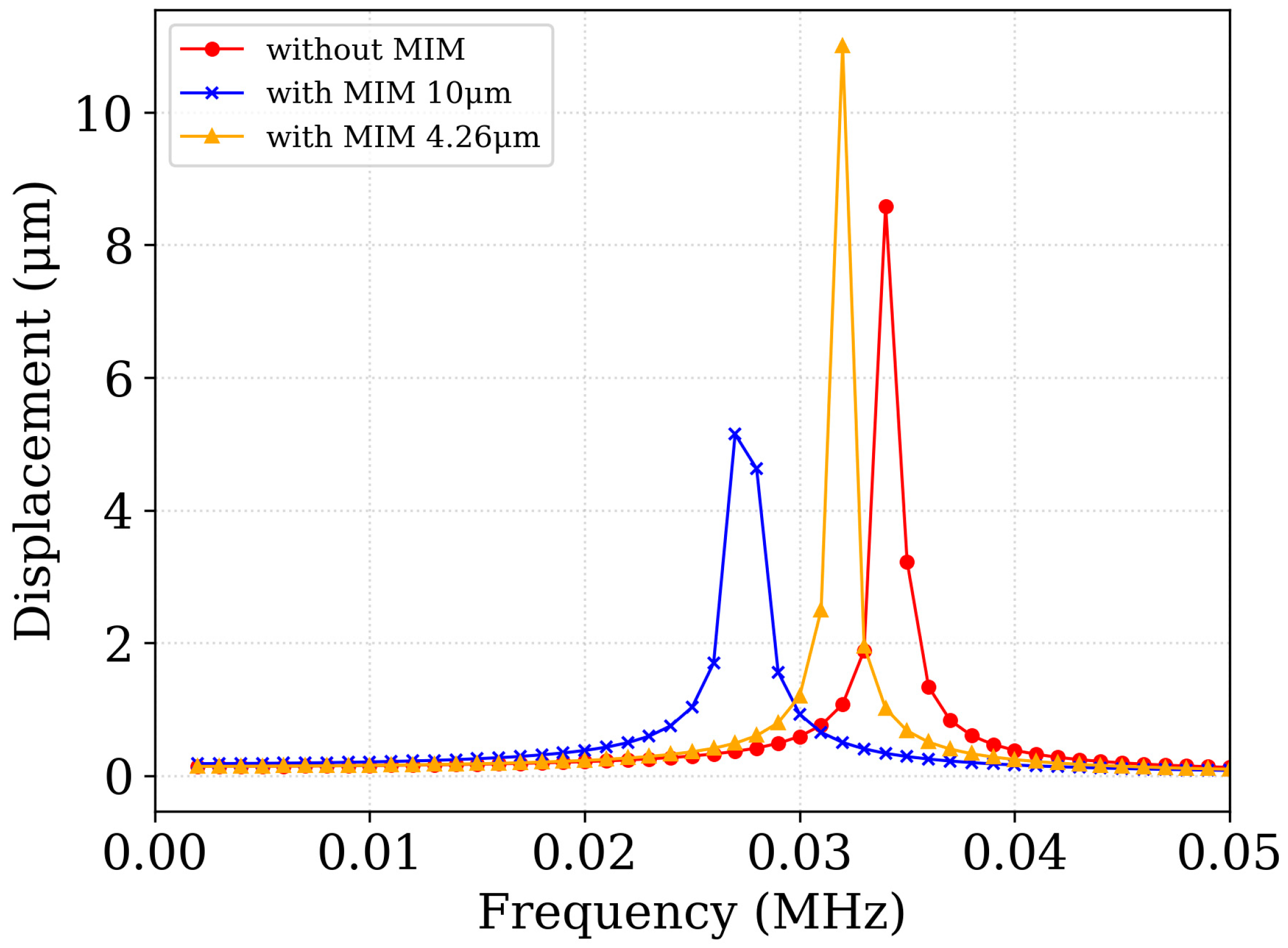

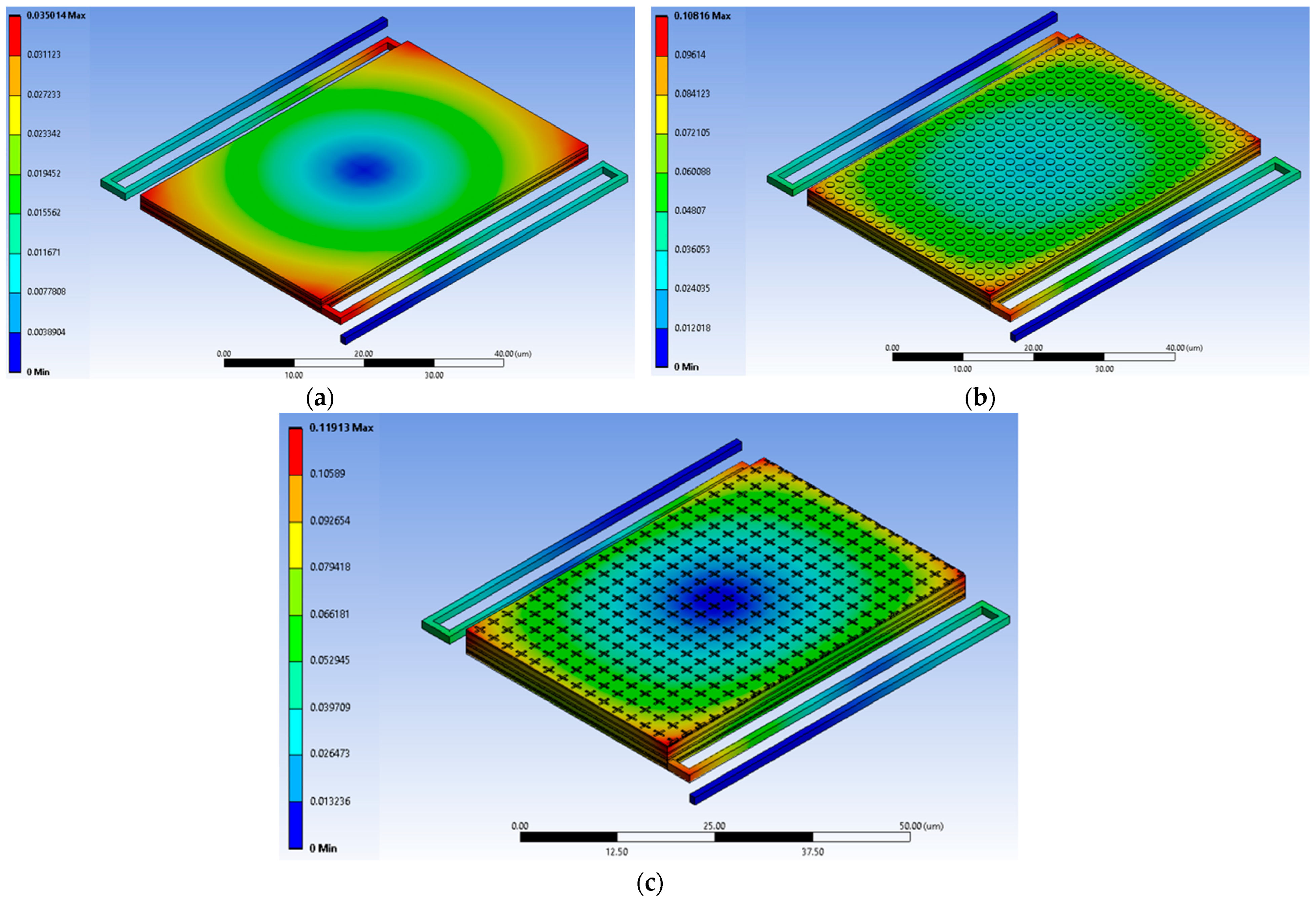

5.2. Mechanical Simulation Results and Physical Interpretation

- Low-Order Modes ( to ): Stage-Dominated Motion. These modes exhibit out-of-plane translation, torsional rotation, and combined deformation of the suspended platform itself (Figure 15a–d). The substantial frequency reduction (e.g., dropping from 31.03 kHz to 24.88 kHz with MIM 2) is a direct consequence of the MIM’s mass being concentrated on the suspended stage.

- High-Order Modes ( and ): Arm-Dominated Motion. These modes, occurring at significantly higher frequencies (), primarily involve the bending and twisting of the support arms (Figure 15e,f). Crucially, their frequencies are negligibly affected by the MIM layers. This confirms that the MIM integration selectively affects the stage’s inertial properties while preserving the high stiffness and mechanical integrity of the support structure. The high arm frequencies (the fundamental frequency) are essential for ensuring thermal isolation compliance without introducing low-frequency structural vulnerabilities.

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CMOS | Complementary Metal-Oxide-Semiconductor |

| CO2 | Carbon Dioxide |

| DRIE | Deep Reactive Ion Etching |

| FEA | Finite Element Analysis |

| FDTD | Finite-Difference Time-Domain |

| IR | Infrared |

| MEMS | Micro-Electro-Mechanical Systems |

| MIM | Metal–Insulator–Metal |

| MOSFET | Metal-Oxide-Semiconductor Field-Effect Transistor |

| PDK | Process-Development-Kit |

| NDIR | Non-Dispersive Infrared |

| SOI | Silicon-On-Insulator |

| WLP | Wafer-Level Vacuum Packaging |

References

- Wilson, A.N.; Gupta, K.A.; Koduru, B.H.; Kumar, A.; Jha, A.; Cenkeramaddi, L.R. Recent Advances in Thermal Imaging and Its Applications Using Machine Learning: A Review. IEEE Sens. J. 2023, 23, 3395–3407. [Google Scholar] [CrossRef]

- Gade, R.; Moeslund, T.B. Thermal Cameras and Applications: A Survey. Mach. Vis. Appl. 2014, 25, 245–262. [Google Scholar] [CrossRef]

- Argirusis, N.; Achilleos, A.; Alizadeh, N.; Argirusis, C.; Sourkouni, G. IR Sensors, Related Materials, and Applications. Sensors 2025, 25, 673. [Google Scholar] [CrossRef] [PubMed]

- Vollmer, M. Infrared Thermal Imaging. In Computer Vision; Ikeuchi, K., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 666–670. ISBN 978-3-030-63415-5. [Google Scholar]

- Mansoor, M.; Haneef, I.; Akhtar, S.; Rafiq, M.; De Luca, A.; Ali, S.; Udrea, F. An SOI CMOS-Based Multi-Sensor MEMS Chip for Fluidic Applications. Sensors 2016, 16, 1608. [Google Scholar] [CrossRef]

- Qu, H. CMOS MEMS Fabrication Technologies and Devices. Micromachines 2016, 7, 14. [Google Scholar] [CrossRef]

- Roy, A.; Ta, B.Q.; Azadmehr, M.; Aasmundtveit, K.E. Post-CMOS Processing Challenges and Design Developments of CMOS-MEMS Microheaters for Local CNT Synthesis. Microsyst. Nanoeng. 2023, 9, 136. [Google Scholar] [CrossRef]

- Zviagintsev, A.; Blank, T.; Brouk, I.; Bar-Lev, S.; Stolyarova, S.; Svetlitza, A.; Bloom, I.; Nemirovsky, A.; Nemirovsky, Y. Micro-Machined CMOS-SOI Transistor (TMOS) Thermal Sensor Operating in Air. In Proceedings of the 2017 IEEE International Conference on Microwaves, Antennas, Communications and Electronic Systems (COMCAS), Tel-Aviv, Israel, 13–15 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–4. [Google Scholar]

- STMicroelectronics. TMOS–STHS34PF80–STM; Datasheet. Available online: https://www.st.com/en/mems-and-sensors/sths34pf80.html (accessed on 1 November 2025).

- Zviagintsev, A.; Blank, T.; Brouk, I.; Bloom, I.; Nemirovsky, Y. Modeling the Performance of Nano Machined CMOS Transistors for Uncooled IR Sensing. IEEE Trans. Electron. Devices 2017, 64, 4657–4663. [Google Scholar] [CrossRef]

- Blank, T.; Brouk, I.; Bar-Lev, S.; Amar, G.; Meimoun, E.; Bouscher, S.; Meltsin, M.; Vaiana, M.; Maierna, A.; Castagna, M.E.; et al. Non-Imaging Digital CMOS-SOI-MEMS Uncooled Passive Infra-Red Sensing Systems. IEEE Sens. J. 2021, 21, 3660–3668. [Google Scholar] [CrossRef]

- Dorodnyy, A.; Koepfli, S.M.; Lochbaum, A.; Leuthold, J. Design of CMOS-Compatible Metal–Insulator–Metal Metasurfaces via Extended Equivalent-Circuit Analysis. Sci. Rep. 2020, 10, 17941. [Google Scholar] [CrossRef]

- Jung, J.-Y.; Lee, J.; Choi, D.-G.; Choi, J.-H.; Jeong, J.-H.; Lee, E.-S.; Neikirk, D.P. Wavelength-Selective Infrared Metasurface Absorber for Multispectral Thermal Detection. IEEE Photonics J. 2015, 7, 6804210. [Google Scholar] [CrossRef]

- Kang, S.; Qian, Z.; Rajaram, V.; Calisgan, S.D.; Alù, A.; Rinaldi, M. Ultra-Narrowband Metamaterial Absorbers for High Spectral Resolution Infrared Spectroscopy. Adv. Opt. Mater. 2019, 7, 1801236. [Google Scholar] [CrossRef]

- Lochbaum, A.; Dorodnyy, A.; Koch, U.; Koepfli, S.M.; Volk, S.; Fedoryshyn, Y.; Wood, V.; Leuthold, J. Compact Mid-Infrared Gas Sensing Enabled by an All-Metamaterial Design. Nano Lett. 2020, 20, 4169–4176. [Google Scholar] [CrossRef]

- Avraham, M.; Klinov, M.; Nemirovsky, Y. The Influence of MIM Metamaterial Absorbers on the Thermal and Electro-Optical Characteristics of Uncooled CMOS-SOI-MEMS Infrared Sensors. Eng. Proc. 2024, 82, 11. [Google Scholar] [CrossRef]

- Anwar, R.; Mao, L.; Ning, H. Frequency Selective Surfaces: A Review. Appl. Sci. 2018, 8, 1689. [Google Scholar] [CrossRef]

- Ogawa, S.; Kimata, M. Metal-Insulator-Metal-Based Plasmonic Metamaterial Absorbers at Visible and Infrared Wavelengths: A Review. Materials 2018, 11, 458. [Google Scholar] [CrossRef]

- Ansys Lumerical, FDTD. Ansys Inc.: Canonsburg PA, USA. Available online: https://www.ansys.com/products/optics/fdtd (accessed on 5 November 2025).

- Ansys, Mechanical. ANSYS, Inc.: Canonsburg PA, USA. Available online: https://www.ansys.com/products/structures/ansys-mechanical (accessed on 30 October 2025).

- Urquia, M.A.; Allegato, G.; Paleari, S.; Tripodi, F.; Oggioni, L.; Garavaglia, M.; Nemirovsky, Y.; Blank, T. High Vacuum Wafer Level Packaging for Uncooled Infrared Sensor. In Proceedings of the 2020 Symposium on Design, Test, Integration & Packaging of MEMS and MOEMS (DTIP), Lyon, France, 15–26 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- Glybovski, S.B.; Tretyakov, S.A.; Belov, P.A.; Kivshar, Y.S.; Simovski, C.R. Metasurfaces: From Microwaves to Visible. Physics Reports 2016, 634, 1–72. [Google Scholar] [CrossRef]

- Zhu, A.Y.; Kuznetsov, A.I.; Luk’yanchuk, B.; Engheta, N.; Genevet, P. Traditional and Emerging Materials for Optical Metasurfaces. Nanophotonics 2017, 6, 452–471. [Google Scholar] [CrossRef]

- Zhuomin, Z.; Benjamin, T.; Graham, M. Radiometric Temperature Measurements. 1: Fundamentals; Experimental methods in the physical sciences; Elsevier AP: Amsterdam, The Netherlands; Heidelgerg, Germany, 2010; ISBN 978-0-12-374021-2. [Google Scholar]

- Avraham, M.; Golan, G.; Nemirovsky, Y. Novel Grey Body for Accurate Radiometric Measurements. Micromachines 2023, 14, 974. [Google Scholar] [CrossRef] [PubMed]

- Pozar, D.M. Microwave Engineering, 4th ed.; Wiley: Hoboken, NJ, USA, 2012; ISBN 978-0-470-63155-3. [Google Scholar]

- Jackson, J.D. Classical Electrodynamics, 3rd ed.; Wiley: Hoboken, NY, USA, 2009; ISBN 978-0-471-30932-1. [Google Scholar]

- Novotny, L.; Hecht, B. Principles of Nano-Optics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2012; ISBN 978-1-107-00546-4. [Google Scholar]

- Palik, E.D.; Ghosh, G. Handbook of Optical Constants of Solids; Academic Press: San Diego, CA, USA, 1998; ISBN 978-0-12-544415-6. [Google Scholar]

- CRC. CRC Handbook of Chemistry and Physics, 97th ed.; Haynes, W.M., Lide, D.R., Bruno, T.J., Eds.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-315-38047-6. [Google Scholar]

- Cherniak, G.; Avraham, M.; Bar-Lev, S.; Golan, G.; Nemirovsky, Y. Study of the Absorption of Electromagnetic Radiation by 3D, Vacuum-Packaged, Nano-Machined CMOS Transistors for Uncooled IR Sensing. Micromachines 2021, 12, 563. [Google Scholar] [CrossRef] [PubMed]

- Landy, N.I.; Sajuyigbe, S.; Mock, J.J.; Smith, D.R.; Padilla, W.J. Perfect Metamaterial Absorber. Phys. Rev. Lett. 2008, 100, 207402. [Google Scholar] [CrossRef]

- Ding, F.; Jin, Y.; Li, B.; Cheng, H.; Mo, L.; He, S. Ultrabroadband Strong Light Absorption Based on Thin Multilayered Metamaterials. Laser Amp; Photonics Rev. 2014, 8, 946–953. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 6th ed.; Incropera, F.P., Incropera, F.P., Eds.; John Wiley: Hoboken, NJ, USA, 2007; ISBN 978-0-471-45728-2. [Google Scholar]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill Higher Education: Boston, MA, USA, 2010; ISBN 978-0-07-352936-3. [Google Scholar]

- Avraham, M.; Golan, G.; Vaiana, M.; Bruno, G.; Castagna, M.E.; Stolyarova, S.; Blank, T.; Nemirovsky, Y. Wafer-Level Packaged CMOS-SOI-MEMS Thermal Sensor at Wide Pressure Range for IoT Applications. In Proceedings of the 7th International Electronic Conference on Sensors and Applications, Virtual, 15–30 November 2020; MDPI: Basel, Switzerland, 2020; p. 30. [Google Scholar]

- Golan, G.; Axelevitch, A.; Sigalov, B.; Gorenstein, B. Integrated Thin Film Heater-Thermocouple Systems. Microelectron. Reliab. 2003, 43, 509–512. [Google Scholar] [CrossRef]

- Senturia, S.D. Microsystem Design; Kluwer: Boston, MA, USA, 2001; ISBN 978-0-7923-7246-2. [Google Scholar]

- Eliahou-Niv, S.; Dahan, R.; Golan, G. Design and Analysis of a Novel Tunable Optical Filter. Microelectron. J. 2006, 37, 302–307. [Google Scholar] [CrossRef]

- Kaajakari, V. Practical MEMS; Small Gear Publishing: Las Vegas, NV, USA, 2009; ISBN 978-0-9822991-0-4. [Google Scholar]

- Ozdemir, S.; Akhtar, S.; Gunal, O.; Khater, M.; Saritas, R.; Abdel-Rahman, E.; Yavuz, M. Measuring the Quality Factor in MEMS Devices. Micromachines 2015, 6, 1935–1945. [Google Scholar] [CrossRef]

- Guo, T.; Wang, Q.; Pu, X.; Yan, Z.; Du, W.; Huang, Z. Bi-Controlled Toroidal Dipole Induced Dual qBICs on Flexible Substrate for Ultrahigh Sensitive Optical Switch and Gas Sensor. J. Appl. Phys. 2025, 137, 203102. [Google Scholar] [CrossRef]

| Silicon | Silicon Nitride | Silicon Dioxide | Aluminum | Thin Silicon Layers and Polysilicon | Titanium Nitride | |

|---|---|---|---|---|---|---|

| 2320 | 3200 | 2200 | 2689 | 2320 | 5210 | |

| 140 | 25 | 1.4 | 237.5 | 40 | 29.1 | |

| 700 | 700 | 730 | 951 | 678 | 586 |

| Silicon | Silicon Nitride | Silicon Dioxide | Aluminum | Titanium Nitride | |

|---|---|---|---|---|---|

| 160 | 250 | 70 | 70 | 250 | |

| ν | 0.22 | 0.27 | 0.17 | 0.33 | 0.22 |

| α (10−6K−1) | 2.6 | 2.8 | 0.5 | 23 | 9 |

| (kHz) | (kHz) | (kHz) | (kHz) | (kHz) | (kHz) | |

|---|---|---|---|---|---|---|

| Without MIM | 31.029 | 34.276 | 191.61 | 220.22 | 305.33 | 306.52 |

| With MIM 1 | 28.87 | 31.89 | 183.79 | 213.17 | 305.35 | 306.38 |

| With MIM 2 | 24.878 | 27.478 | 167.05 | 197.21 | 305.38 | 306.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avraham, M.; Nemirovsky, Y. Multiphysics Optical–Thermal and Mechanical Modeling of a CMOS-SOI-MEMS Infrared Sensor with Metasurface Absorber. Sensors 2025, 25, 6819. https://doi.org/10.3390/s25226819

Avraham M, Nemirovsky Y. Multiphysics Optical–Thermal and Mechanical Modeling of a CMOS-SOI-MEMS Infrared Sensor with Metasurface Absorber. Sensors. 2025; 25(22):6819. https://doi.org/10.3390/s25226819

Chicago/Turabian StyleAvraham, Moshe, and Yael Nemirovsky. 2025. "Multiphysics Optical–Thermal and Mechanical Modeling of a CMOS-SOI-MEMS Infrared Sensor with Metasurface Absorber" Sensors 25, no. 22: 6819. https://doi.org/10.3390/s25226819

APA StyleAvraham, M., & Nemirovsky, Y. (2025). Multiphysics Optical–Thermal and Mechanical Modeling of a CMOS-SOI-MEMS Infrared Sensor with Metasurface Absorber. Sensors, 25(22), 6819. https://doi.org/10.3390/s25226819