Real-Time Defect Identification in Automotive Brake Calipers Using PCA-Optimized Feature Extraction and Machine Learning

Abstract

1. Introduction

2. Related Work

- Data collection: Collecting total 2200 impact response datasets from normal, internal fault specimens of actual caliper components to establish a learning and validation environment based on practical field data.

- Feature engineering and modeling: Utilizing FFT-PCA-based feature extraction and dimensionality reduction, followed by a comparative evaluation of machine learning classifiers such as SVM, KNN, and DT to derive the optimal combination.

- Real-time solution development: Developing GUI-based real-time software (version 1.0.0) capable of outputting results within an average of 0.05–0.1 s and providing visual feedback for fault detection.

- Validation and proof of concept: Achieving a discrimination accuracy of 97% and a processing time of 117.6 ms through on-site testing witnessed by a certification body, thereby demonstrating its applicability to production line full inspection.

3. Methodology

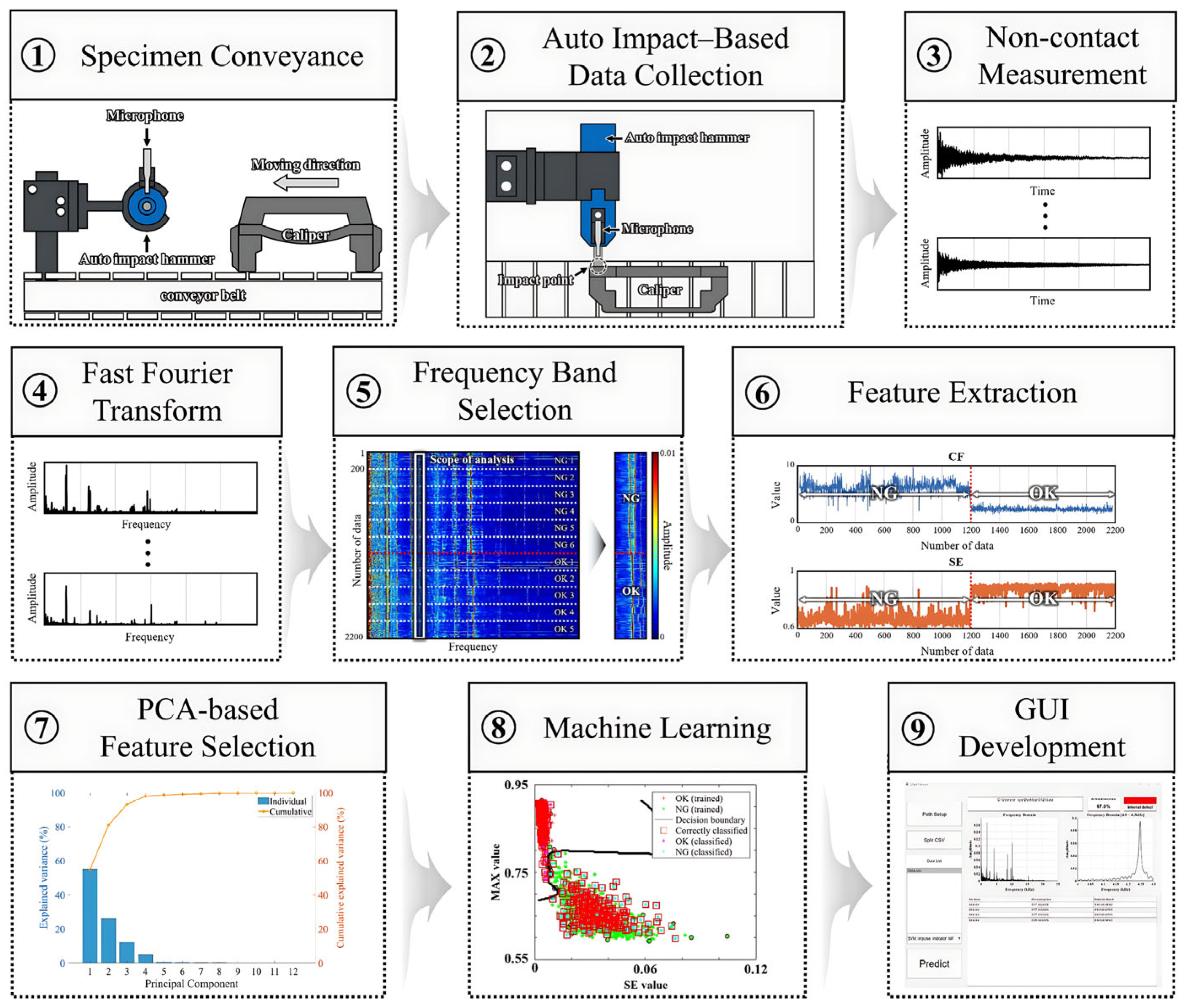

3.1. Suggested System

- Specimen conveyance: In this step, the caliper specimen is automatically conveyed to the measurement position using a conveyor mechanism integrated into the AIAMS. The conveyor operates at a constant speed to maintain consistent alignment and positioning of each specimen while minimizing manual intervention. This enables continuous and uniform measurements under conditions similar to those in an actual production environment.

- Auto-impact based data collection: When the specimen reaches the designated position, an automated impact hammer delivers mechanical impact with a constant force and interval. The hammer is programmed to strike the same location repeatedly to ensure measurement repeatability. This step provides reliable impact-acoustic response signals by exciting the caliper structure under consistent conditions.

- Non-contact measurement: The impact-acoustic response signals of the caliper are measured by a microphone positioned at a fixed distance using a non-contact method. This step minimizes external interference and ensures data stability and repeatability. The acquired acoustic signals contain resonant characteristics and structural information of the caliper.

- Fast Fourier Transform: The recorded time-domain signal is converted into the frequency domain using the Fast Fourier Transform (FFT). This transformation allows extraction of the resonant frequencies and spectral components that reflect the structural integrity and dynamic behavior of the caliper. The frequency-domain data obtained here serve as the foundation for subsequent feature extraction.

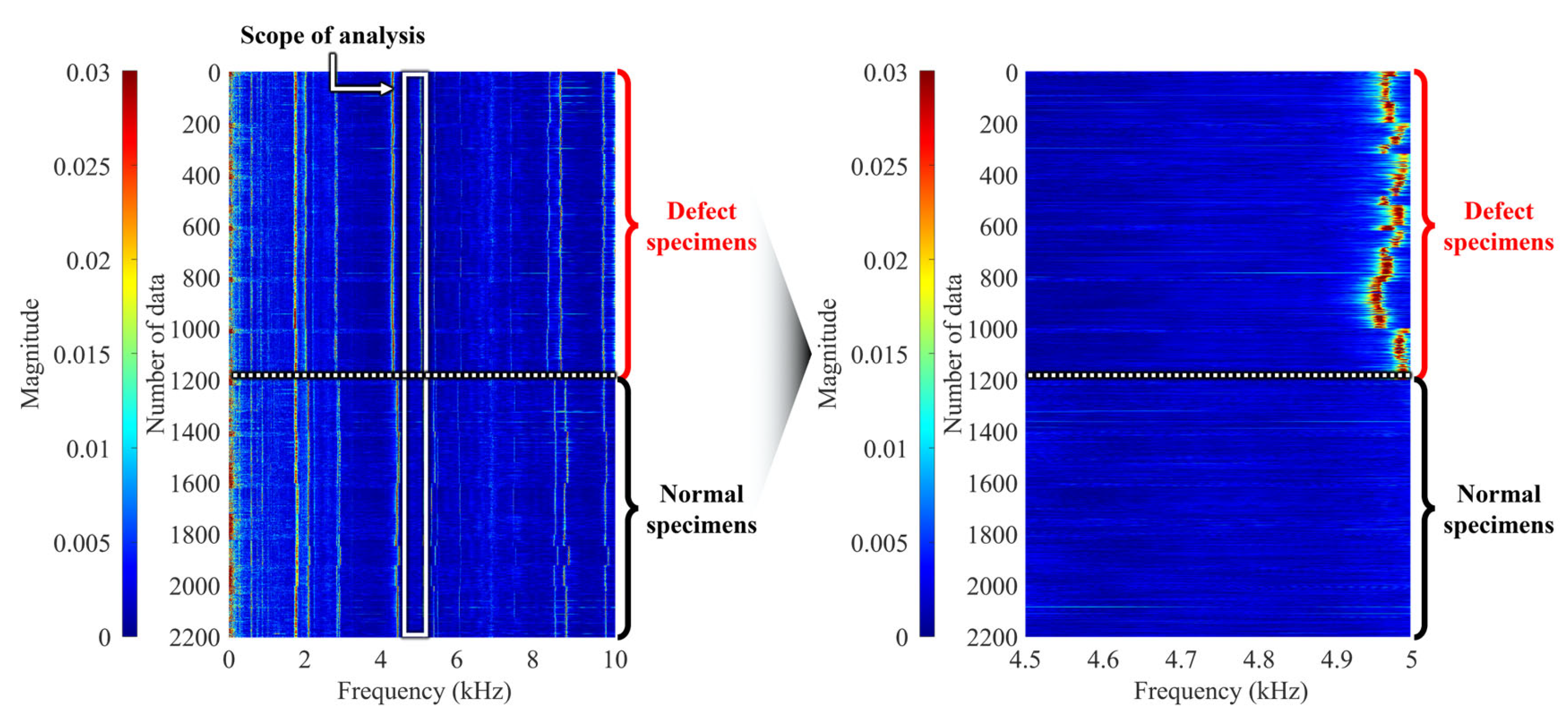

- Frequency band selection: The frequency spectra of normal and faulty specimens are cumulatively analyzed to identify regions exhibiting distinct amplitude differences between the two groups. As a result of this comparative analysis, the 4.5–5.0 kHz range was determined to be the optimal frequency band for discriminating between normal and defective specimens. This selected frequency band is used as the key analysis region for fault identification.

- Feature Extraction: Within the selected frequency range, twelve statistical and spectral features are extracted, including MAX, RMS, CF, STD, K, SE, FM0, M6A, M8A, CLFIPI, and MF. Each feature comprehensively represents the energy distribution, statistical characteristics, and dynamic behavior of the impact-acoustic signal, serving as a critical variable for fault discrimination.

- PCA-based feature selection: PCA is performed on the extracted twelve features to identify the variables that most effectively explain data variability. As a result, SE exhibited the highest contribution to the first principal component (PC1), demonstrating strong discriminative capability. Accordingly, SE was selected as the key feature and combined with the remaining eleven features to construct a total of eleven feature combinations.

- Machine learning: Based on the derived feature combinations, three machine learning models that included SVM, KNN, and DT were trained and validated. The dataset was divided into an 8:2 ratio for training and validation to evaluate model performance. The results confirmed that the proposed approach achieved high accuracy and stability in classifying normal and defective specimens.

- GUI development: Finally, a Graphical User Interface (GUI) was developed for real-time defect identification and visualization. The GUI integrates the trained models, automatically classifying the caliper condition immediately after measurement and displaying the results. This enables users to intuitively monitor defect status, supporting the realization of a fully automated inspection system in industrial environments.

3.2. Automated Impact-Acoustic Measurement System

3.3. Principal Component Analysis

3.4. Machine Learning

3.4.1. Support Vector Machine

3.4.2. K Nearest Neighbor

3.4.3. Decision Tree

4. Experiment Validation

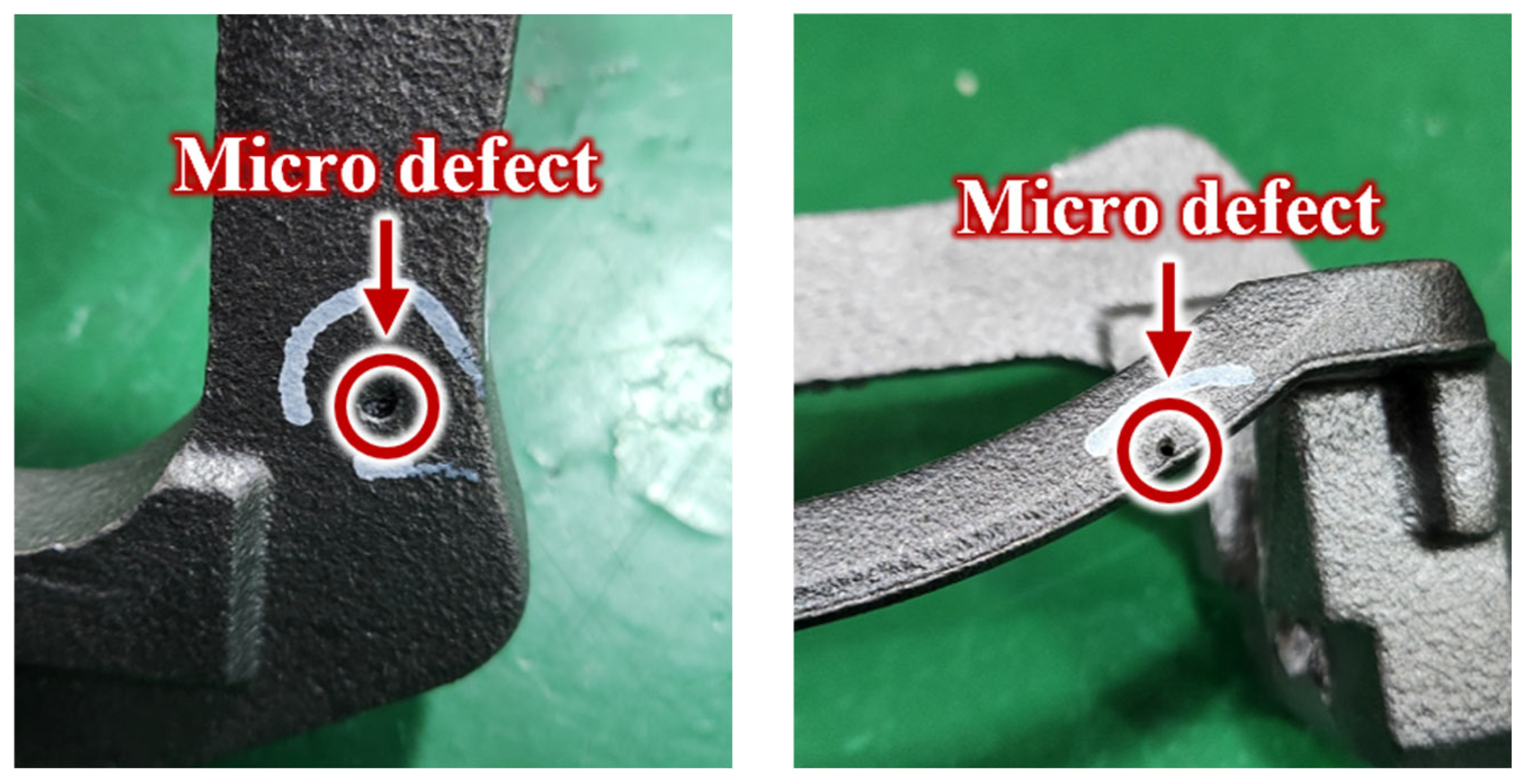

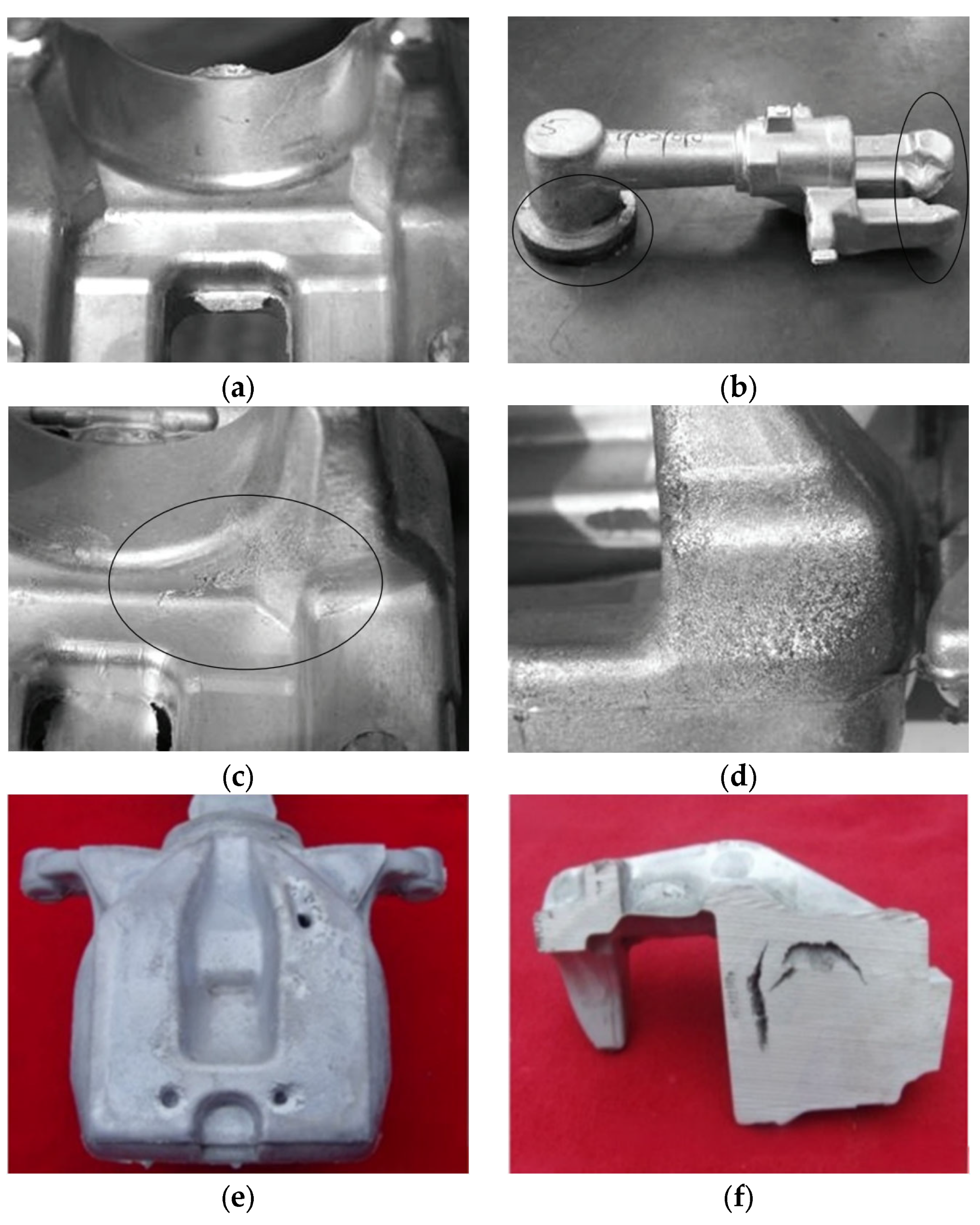

4.1. Experimental Configurations and Specimen

4.2. Experimental Results

4.2.1. Preprocessing

4.2.2. Feature Extraction

4.2.3. Feature Selection and Combination

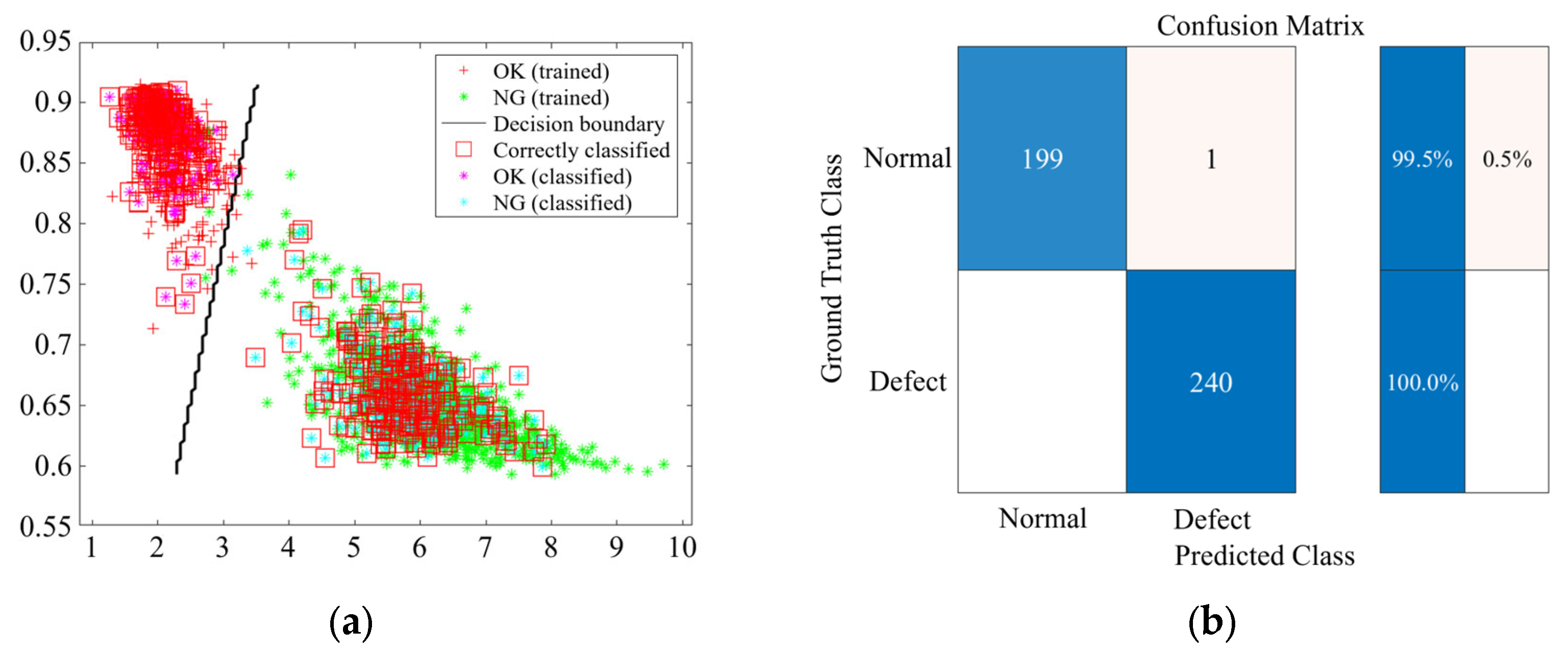

4.2.4. Training and Prediction

4.2.5. Ablation Study

5. Discussion

5.1. Limitations

5.2. Comparative Study

6. Conclusions

- (1)

- The proposed AIAMS integrates an automated impact hammer, a microphone, and a conveyor system to allow for the consistent and repetitive acquisition of impact-acoustic signals in an environment similar to a production site. This system was validated using a total of 11 caliper specimens, consisting of five normal specimens and six faulty specimens.

- (2)

- Each specimen underwent 200 repeated measurements, resulting in a total dataset of 2200 impact response datasets being secured. From this data, 12 statistical and spectral features were extracted in the frequency domain. The PCA results confirmed that SE was the highly discriminative feature that most effectively captured the irregular and energy distribution differences between the normal and faulty specimens.

- (3)

- Feature combinations (FC1-FC11) centered around SE were constructed to train and validate the SVM, KNN, and DT models. As a result, SVM achieved an accuracy of 99.2% or higher for normal specimens and 97.5% or higher for faulty specimens. KNN achieved 98.8% and 98.0% or higher, respectively, and DT achieved 99.2% and 96.5% or higher, respectively. This demonstrates that the proposed method consistently maintains stable and reliable classification performance regardless of the specific feature combination applied.

- (4)

- The research results validate that the proposed AIAMS can detect micro-defects in automotive brake calipers in a highly reliable and automated manner by combining PCA-based feature selection with machine learning techniques. Previous studies have mostly relied on laboratory-scale data, and discussions regarding real-time defect identification; particularly, the processing speed aspect required for applications in mass production processes have been relatively limited. In contrast, the proposed system integrates a conveyor-based non-contact impact-acoustic measurement structure capable of repeated and automated inspections. By applying the Shannon entropy-based high-precision feature extraction technique, the system achieved real-time defect detection with an average processing time within 117.6 ms, demonstrating its suitability for practical implementation in automotive manufacturing environments that demand both high accuracy and rapid inspection speed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baydar, N.; Ball, A.A. Comparative Study of Acoustic and Vibration Signals in Detection of Gear Failures Using Wigner-Ville Distribution. Mech. Syst. Signal Process 2001, 15, 1091–1107. [Google Scholar] [CrossRef]

- Korodi, A.; Anitei, D.; Boitor, A.; Silea, I. Image-processing-based low-cost fault detection solution for end-of-line ECUs in automotive manufacturing. Sensors 2020, 20, 3520. [Google Scholar] [CrossRef]

- Huang, H.; Zhu, K. Automotive parts defect detection based on YOLOv7. Electronics 2024, 13, 1817. [Google Scholar] [CrossRef]

- Hua, S.; Li, B.; Shu, L.; Jiang, P.; Cheng, S. Defect detection method using laser vision with model-based segmentation for laser brazing welds on car body surface. Measurement 2021, 178, 109370. [Google Scholar] [CrossRef]

- Parey, A.; Singh, S. Gearbox Fault Diagnosis Using Acoustic Signals, Continuous Wavelet Transform and Adaptive Neuro-Fuzzy Inference System. Appl. Acoust. 2019, 144, 53–62. [Google Scholar] [CrossRef]

- Bendjama, H.; Bouhouche, S.; Boucherit, M.S. Application of Wavelet Transform for Fault Diagnosis in Rotating Machinery. Int. J. Mach. Learn. Comput. 2012, 2, 82–87. [Google Scholar] [CrossRef]

- Gnanasekaran, S.; Jakkamputi, L.P.; Rakkiyannan, J.; Thangamuthu, M.; Bhalerao, Y. A Comprehensive Approach for Detecting Brake Pad Defects Using Histogram and Wavelet Features with Nested Dichotomy Family Classifiers. Sensors 2023, 23, 9093. [Google Scholar] [CrossRef]

- Hua, X.; Zeng, J.; Li, H.; Huang, J.; Luo, M.; Feng, X.; Xiong, H.; Wu, W. A Review of Automobile Brake-by-Wire Control Technology. Processes 2023, 11, 994. [Google Scholar] [CrossRef]

- Morales Matamoros, O.; Peralta, A.; Sánchez, F.; Rodríguez, R. Artificial Intelligence for Quality Defects in the Automotive Industry: A Comprehensive Review. Sensors 2025, 25, 1288. [Google Scholar] [CrossRef]

- Ding, J.; Xia, T.; Wu, X.; Zheng, S.; Wang, T. Fault Detection and Isolation Strategy for Brake Actuation Units of High-Speed Trains Under Variable Operating Conditions. Mathematics 2025, 13, 1022. [Google Scholar] [CrossRef]

- Kadlec, P.; Gabrys, B.; Strandt, S. Data-Driven Soft Sensors in the Process Industry. Comput. Chem. Eng. 2009, 33, 795–814. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Liu, W.-C. Multiple Time-Series Convolutional Neural Network for Fault Detection and Diagnosis: An Empirical Study in Semiconductor Manufacturing. J. Intell. Manuf. 2021, 32, 823–836. [Google Scholar] [CrossRef]

- Wang, S.; Yu, Z.; Wang, J.; Chen, S. Research on CNN-LSTM Brake Pad Wear Condition Monitoring Based on GTO Multi-Objective Optimization. Actuators 2023, 12, 301. [Google Scholar] [CrossRef]

- Viswanathan, S.; Sridharan, N.V.; Rakkiyannan, J.; Sugumaran, V. Brake Fault Diagnosis Using a Voting Ensemble of Machine Learning Classifiers. Results Eng. 2024, 23, 102857. [Google Scholar] [CrossRef]

- Das, S.S.; Kumar, R.; Prusty, M.R.; Mahanta, T.K.; Patra, S.R. Hydraulic Brake Fault Detection from Acoustic Signals Using Frequency-Domain Filter-Bank Integrated Deep-Learning Framework. Cogent Eng. 2025, 12, 2549368. [Google Scholar] [CrossRef]

- Jensen, K.M.; Santos, I.F.; Corstens, H.J.P. Estimation of Brake Pad Wear and Remaining Useful Life from Fused Sensor System, Statistical Data Processing, and Passenger Car Longitudinal Dynamics. Wear 2024, 538–539, 205220. [Google Scholar] [CrossRef]

- Gurav, K. Digital Twin-Based Fault Localization in Vehicle Braking Systems: A Data-Driven Approach. Int. Res. J. Eng. Technol. 2025, 12, 221–226. [Google Scholar]

- Voloacă, Ş.; Badea-Romero, A.; Badea-Romero, F.; Toma, M.F. Motor Vehicle Brake Pad Wear-A Review. Vehicles 2025, 7, 52. [Google Scholar] [CrossRef]

- Jegadeeshwaran, R.; Sugumaran, V. Fault Diagnosis of Automobile Hydraulic Brake System Using Statistical Features and Support Vector Machines. Mech. Syst. Signal Process. 2015, 52–53, 436–446. [Google Scholar] [CrossRef]

- Yoon, Y.-G.; Woo, J.-H.; Oh, T.-K. A Study on the Application of Machine and Deep Learning Using the Impact Response Test to Detect Defects on the Piston Rod and Steering Rack of Automobiles. Sensors 2022, 22, 9623. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal Component Analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar]

- Metsalu, T.; Vilo, J. ClustVis: A Web Tool for Visualizing Clustering of Multivariate Data Using Principal Component Analysis and Heatmap. Nucleic Acids Res. 2015, 43, W566–W570. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis, 2nd ed.; Springer: New York, NY, USA, 2002. [Google Scholar]

- Huang, S.; Cai, N.; Pacheco, P.P.; Narrandes, S.; Wang, Y.; Xu, W. Applications of Support Vector Machine (SVM) Learning in Cancer Genomics. Cancer Genom. Proteom. 2018, 15, 41–51. [Google Scholar]

- Cervantes, J.; Garcia-Lamont, F.; Rodríguez-Mazahua, L.; Lopez, A. A Comprehensive Survey on Support Vector Machine Classification: Applications, Challenges and Trends. Neurocomputing 2020, 408, 189–215. [Google Scholar] [CrossRef]

- Uddin, S.; Haque, I.; Lu, H.; Moni, M.A.; Goide, E. Comparative Performance Analysis of K-Nearest Neighbour (KNN) Algorithm and Its Different Variants for Disease Prediction. Sci. Rep. 2022, 12, 6256. [Google Scholar] [CrossRef] [PubMed]

- Du, M.; Ding, S.; Jia, H. Study on Density Peaks Clustering Based on K-Nearest Neighbors and Principal Component Analysis. Knowl.-Based Syst. 2016, 99, 135–145. [Google Scholar] [CrossRef]

- Kotsiantis, S.B. Decision Trees: A Recent Overview. Artif. Intell. Rev. 2013, 39, 261–283. [Google Scholar] [CrossRef]

- Costa, V.G.; Pedreira, C.E. Recent Advances in Decision Trees: An Updated Survey. Artif. Intell. Rev. 2023, 56, 4765–4800. [Google Scholar] [CrossRef]

- Sharma, V.; Parey, A. A Review of Gear Fault Diagnosis Using Various Condition Indicators. Procedia Eng. 2016, 144, 253–263. [Google Scholar] [CrossRef]

- Chondronasios, A.; Popov, I.; Jordanov, I. Feature selection for surface defect classification of extruded aluminum profiles. Int. J. Adv. Manuf. Technol. 2016, 83, 33–41. [Google Scholar] [CrossRef]

| Article | Data Type | Processing Speed | Accuracy | Remarks |

|---|---|---|---|---|

| [10] | Contact vibration signal of brake pad | Not specified | 99.45% | CBND classifier with wavelet feature |

| [13] | Contact pressure signal of brake cylinder | Not specified | 99.00% | IRBCP with Mutual Residual and PCA |

| [15] | Contact sensor signal of semiconductor factory equipment | Not specified | 99.48% | MTS-CNN |

| [17] | Contact vibration signal of disc brake and drum brake | Not specified | 98.00% | Ensemble voting classifier with ARMA feature |

| [18] | Non-contact acoustic signal of hydraulic brake system | Not specified | 97.80% | Sequential model-based CNN |

| [21] | Contact vibration signal of hydraulic brake system | Not specified | 98.36% | SVM classification with statistical feature |

| [22] | Vibration signal of piston rod and steering rack | Not specified | 100.00% | PCA-SVM-BiLSTM |

| AIAMS | Non-contact impact-acoustic signal | 117.6 ms | 97.00% | Real-time defect detection machine learning model based on PCA and feature combination |

| Device | Parameter | Specification |

|---|---|---|

| Auto-impact hammer | Durability | 1,000,000 cycles |

| Stroke | 5 mm, 15 mm | |

| Force range | up to 100 N | |

| Size | 137 × 38 × 38 mm | |

| Microphone | Sensitivity | 10 mV/Pa |

| Frequency range | 20~16,000 Hz | |

| Excitation voltage | 18 to 30 VDC | |

| Size | 13.2 × 69.9 mm |

| Feature Combination | Feature 1 | Feature 2 |

|---|---|---|

| FC1 | SE | MAX |

| FC2 | SE | RMS |

| FC3 | SE | CF |

| FC4 | SE | STD |

| FC5 | SE | K |

| FC6 | SE | FM0 |

| FC7 | SE | M6A |

| FC8 | SE | M8A |

| FC9 | SE | CLF |

| FC10 | SE | IPI |

| FC11 | SE | MF |

| Feature Combination | Machine Learning Model | |||||

|---|---|---|---|---|---|---|

| SVM | KNN | DT | ||||

| Normal | Defect | Normal | Defect | Normal | Defect | |

| FC1 (SE-MAX) | 100 | 99.6 | 98.5 | 99.6 | 100 | 99.6 |

| FC2 (SE-RMS) | 97.5 | 99.2 | 98.5 | 98.8 | 97.0 | 99.2 |

| FC3 (SE-CF) | 100 | 100 | 99.5 | 100 | 100 | 99.6 |

| FC4 (SE-STD) | 98.0 | 99.2 | 98.0 | 99.2 | 97.0 | 99.2 |

| FC5 (SE-K) | 100 | 100 | 98.5 | 99.6 | 100 | 99.6 |

| FC6 (SE-FM0) | 99.6 | 100 | 100 | 100 | 96.5 | 100 |

| FC7 (SE-M6A) | 99.6 | 100 | 99.6 | 100 | 100 | 99.6 |

| FC8 (SE-M8A) | 99.6 | 100 | 99.6 | 100 | 100 | 99.6 |

| FC9 (SE-CLF) | 100 | 100 | 100 | 100 | 100 | 100 |

| FC10 (SE-IPI) | 100 | 100 | 100 | 100 | 100 | 100 |

| FC11 (SE-MF) | 98.0 | 99.2 | 98.5 | 98.8 | 97.0 | 99.2 |

| Feature Combination | Machine Learning Model | |||||

|---|---|---|---|---|---|---|

| SVM | KNN | DT | ||||

| Normal | Defect | Normal | Defect | Normal | Defect | |

| FC1 (SE-MAX) | 76.5 | 70.4 | 74.5 | 71.7 | 75.5 | 67.5 |

| FC2 (SE-RMS) | 83.5 | 70.8 | 82.5 | 75.8 | 75.0 | 74.6 |

| FC3 (SE-CF) | 66.5 | 64.6 | 69.5 | 65.4 | 65.5 | 64.6 |

| FC4 (SE-STD) | 83.5 | 69.2 | 80.0 | 77.5 | 83.0 | 78.3 |

| FC5 (SE-K) | 74.5 | 60.8 | 72.0 | 62.5 | 74.5 | 60.4 |

| FC6 (SE-FM0) | 73.5 | 69.2 | 74.5 | 62.5 | 66.5 | 70.4 |

| FC7 (SE-M6A) | 67.0 | 52.1 | 70.5 | 59.2 | 69.5 | 61.3 |

| FC8 (SE-M8A) | 75.5 | 43.8 | 68.0 | 61.3 | 75.0 | 54.6 |

| FC9 (SE-CLF) | 67.5 | 68.8 | 71.0 | 64.6 | 67.5 | 70.0 |

| FC10 (SE-IPI) | 71.5 | 67.1 | 66.5 | 70.4 | 73.5 | 62.5 |

| FC11 (SE-MF) | 83.5 | 67.9 | 88.0 | 63.7 | 87.0 | 67.9 |

| Feature Combination | Machine Learning Model | |||||

|---|---|---|---|---|---|---|

| SVM | KNN | DT | ||||

| Normal | Defect | Normal | Defect | Normal | Defect | |

| FC1 (SE-MAX) | 97.0 | 97.5 | 97.0 | 98.8 | 95.0 | 97.9 |

| FC2 (SE-RMS) | 95.0 | 97.1 | 95.0 | 96.2 | 94.5 | 97.1 |

| FC3 (SE-CF) | 96.5 | 97.1 | 95.0 | 97.1 | 95.0 | 96.7 |

| FC4 (SE-STD) | 95.0 | 96.7 | 94.5 | 97.5 | 95.0 | 96.7 |

| FC5 (SE-K) | 95.5 | 97.1 | 95.5 | 96.7 | 95.0 | 96.2 |

| FC6 (SE-FM0) | 99.0 | 100 | 99.5 | 100 | 98.5 | 99.2 |

| FC7 (SE-M6A) | 97.1 | 95.0 | 95.0 | 97.1 | 94.5 | 97.1 |

| FC8 (SE-M8A) | 95.0 | 96.7 | 95.0 | 97.1 | 95.0 | 96.7 |

| FC9 (SE-CLF) | 99.0 | 99.6 | 99.0 | 99.6 | 99.5 | 98.8 |

| FC10 (SE-IPI) | 98.5 | 99.6 | 98.0 | 99.2 | 97.0 | 100 |

| FC11 (SE-MF) | 95.0 | 96.7 | 95.0 | 96.7 | 94.5 | 97.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Woo, U.; Lee, M.-H.; Kim, J.-Y.; Choi, H.; Oh, T. Real-Time Defect Identification in Automotive Brake Calipers Using PCA-Optimized Feature Extraction and Machine Learning. Sensors 2025, 25, 6753. https://doi.org/10.3390/s25216753

Lee J, Woo U, Lee M-H, Kim J-Y, Choi H, Oh T. Real-Time Defect Identification in Automotive Brake Calipers Using PCA-Optimized Feature Extraction and Machine Learning. Sensors. 2025; 25(21):6753. https://doi.org/10.3390/s25216753

Chicago/Turabian StyleLee, Juwon, Ukyong Woo, Myung-Hun Lee, Jin-Young Kim, Hajin Choi, and Taekeun Oh. 2025. "Real-Time Defect Identification in Automotive Brake Calipers Using PCA-Optimized Feature Extraction and Machine Learning" Sensors 25, no. 21: 6753. https://doi.org/10.3390/s25216753

APA StyleLee, J., Woo, U., Lee, M.-H., Kim, J.-Y., Choi, H., & Oh, T. (2025). Real-Time Defect Identification in Automotive Brake Calipers Using PCA-Optimized Feature Extraction and Machine Learning. Sensors, 25(21), 6753. https://doi.org/10.3390/s25216753