A Review of Artificial Intelligence Techniques in Fault Diagnosis of Electric Machines

Abstract

Highlights

- A comprehensive review of AI techniques for fault diagnosis in rotating electrical machines, including supervised, unsupervised, deep learning, and hybrid methods.

- A comparative analysis of diagnostic performance, scalability, and implementation challenges across AI models.

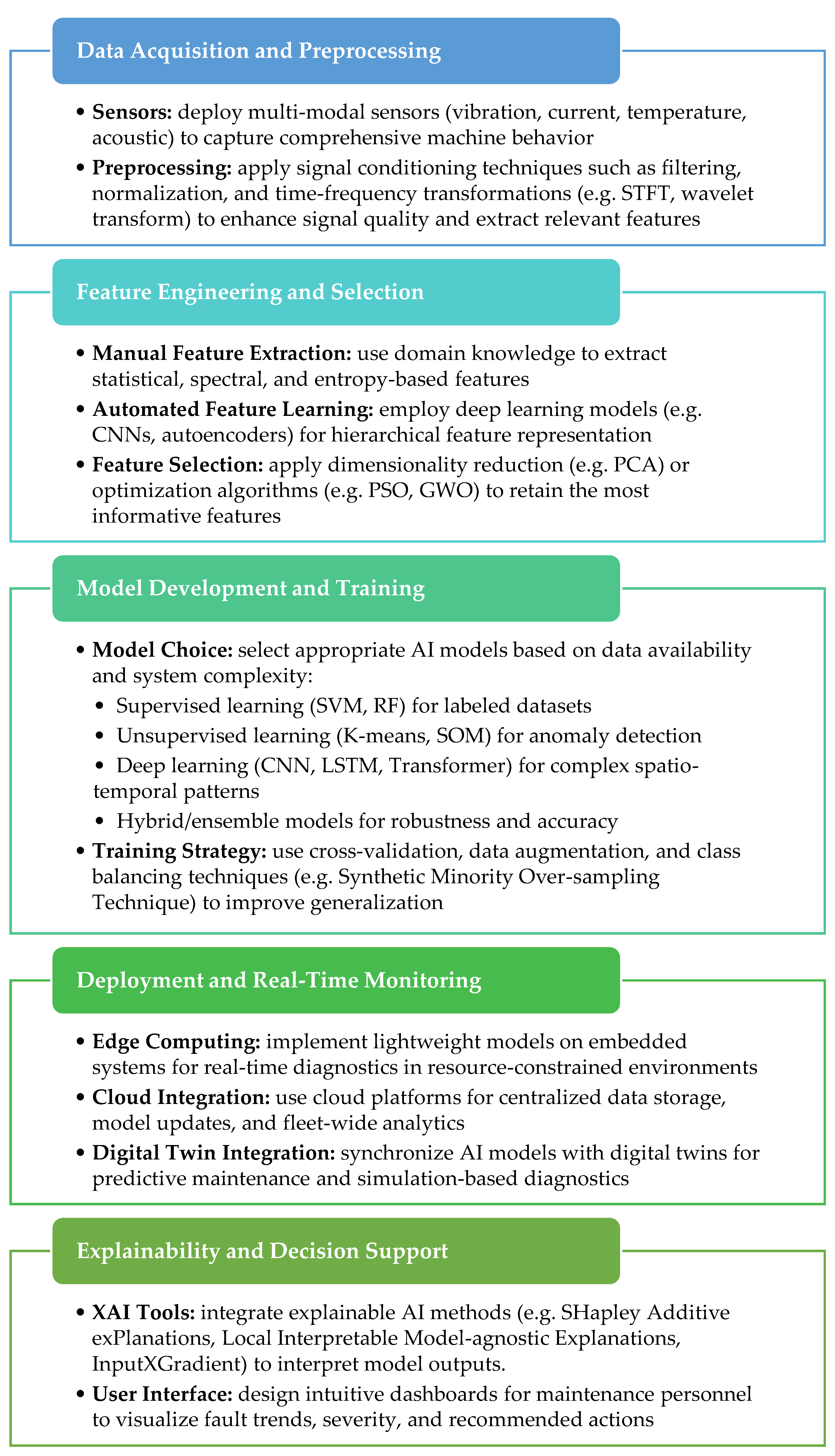

- A modular framework is proposed for implementing intelligent condition monitoring systems in industrial environments.

- AI-based diagnostic systems can significantly improve the reliability, safety, and efficiency of electric machines through early fault detection and predictive maintenance.

- The proposed framework and recommendations provide a practical roadmap for deploying scalable and interpretable AI solutions in real-world industrial settings.

Abstract

1. Introduction

2. Methodological Approach and Source Selection

3. Common Faults in Electric Machines

3.1. Stator Faults

3.2. Rotor Faults

3.3. Bearing Faults

3.4. Other Faults

4. Fault Detection, Data Acquisition and Feature Selection

4.1. Sensor Technologies

4.2. Signal Processing Techniques

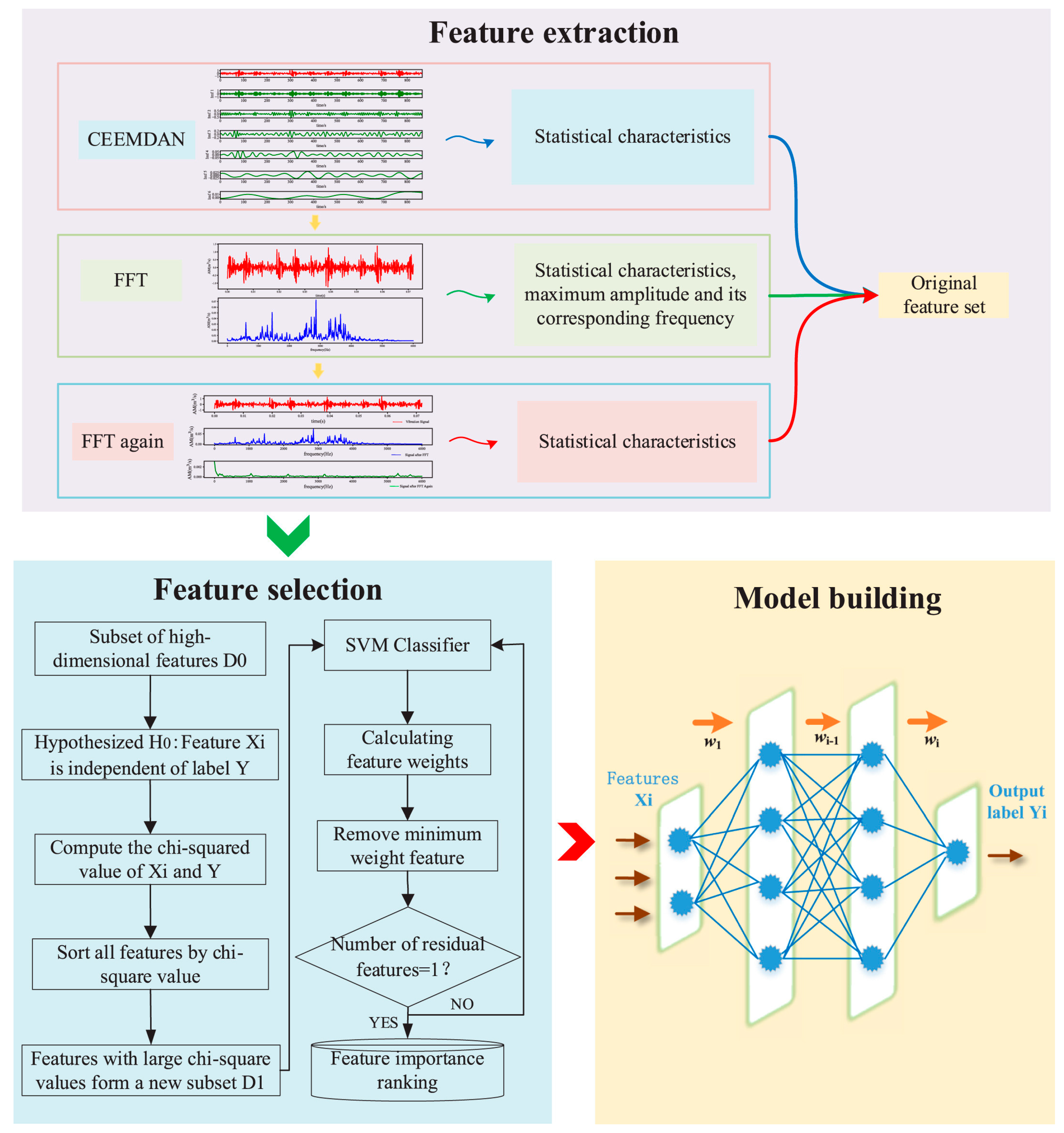

4.3. Feature Types and Selection Strategies in Fault Diagnosis

5. Traditional Machine Learning Approaches

5.1. Supervised Learning Methods

5.2. Unsupervised Learning Methods

6. Deep Learning Approaches

6.1. Convolutional Neural Networks (CNNs)

- 1D-CNNs, which are used for analyzing time-series data such as vibration or current signals. They can automatically extract temporal features that indicate fault patterns, offering high accuracy and fast inference.

- 2D-CNNs, which are applied to image-like representations of signals, such as spectrograms or wavelet scalograms. By converting time-series data into 2D formats, 2D-CNNs can leverage spatial feature extraction to detect subtle fault signatures [42].

6.2. Recurrent Neural Networks (RNNs)

6.3. Autoencoders

6.4. Deep Reinforcement Learning

6.5. Transfer Learning and Domain Adaptation

- Correlation alignment (CORAL) aligns the second-order statistics (covariance) of source and target feature distributions, offering a lightweight and effective solution for reducing domain discrepancy [58].

- Maximum mean discrepancy (MMD) minimizes the distance between source and target distributions in a reproducing kernel Hilbert space, often used in deep domain adaptation networks [59].

- Domain-adversarial neural network (DANN) introduces a domain classifier and a gradient reversal layer to encourage the learning of domain-invariant features through adversarial training [60].

6.6. Emerging Architectures

7. Hybrid and Ensemble Methods

7.1. Neuro-Fuzzy Systems

7.2. Evolutionary and Nature-Inspired Algorithms

- GA has been used to select the most relevant features from vibration or current signals, improving classifier performance and reducing computational cost [66].

- PSO has been applied to optimize the weights of neural networks or the parameters of fuzzy systems [67].

- ACO has been explored for rule extraction and path optimization in diagnostic decision trees.

7.3. Ensemble Learning Approaches

8. Comparative Analysis

9. Challenges and Future Directions

- Begin with modular, scalable AI pipelines that can evolve from anomaly detection to full fault classification as more data becomes available.

- Invest in high-fidelity sensor systems and ensure consistent data labeling and storage practices to support model training and validation.

- Combine domain knowledge (e.g., fuzzy rules) with data-driven models (e.g., CNNs, LSTMs) to improve interpretability and performance.

- Use edge devices for real-time fault detection and cloud platforms for model retraining, historical analysis, and fleet-level insights.

- Ensure that AI decisions are transparent and traceable, especially in safety-critical applications, to build trust among operators and engineers.

- Implement mechanisms for online learning or periodic retraining to adapt to evolving machine conditions and new fault types.

- Link diagnostic outputs with maintenance management systems to automate alerts, scheduling, and inventory planning.

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACO | Ant Colony Optimization |

| AI | Artificial Intelligence |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| CLAHE | Contrast Limited Adaptive Histogram Equalization |

| CNN | Convolutional Neural Network |

| DNN | Deep Neural Network |

| DRL | Deep Reinforcement Learning |

| EMD | Empirical Mode Decomposition |

| FFT | Fast Fourier Transform |

| GA | Genetic Algorithm |

| GNN | Graph Neural Network |

| GRU | Gated Recurrent Unit |

| GWO | Grey Wolf Optimization |

| LSTM | Long Short-Term Memory |

| MCSA | Motor Current Signature Analysis |

| PCA | Principal Component Analysis |

| PMSM | Permanent Magnet Synchronous Motor |

| PSO | Particle Swarm Optimization |

| RNN | Recurrent Neural Network |

| SOM | Self-Organizing Map |

| STFT | Short-Time Fourier Transform |

| SVM | Support Vector Machine |

| VAE | Variational Autoencoder |

| WPEDL | Weighted Probability Ensemble Deep Learning |

| XAI | Explainable Artificial Intelligence |

| XGBoost | Extreme Gradient Boosting |

References

- Waide, P.; Brunner, C.U. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems; International Energy Agency (IEA): Paris, France, 2011. [Google Scholar]

- ABB. Value of Reliability: ABB Survey Report 2023—Industry’s Perspective on Maintenance and Reliability; ABB: Zurich, Switzerland, 2023. [Google Scholar]

- Andrew, A.M. Fault Diagnosis: Models, Artificial Intelligence, Applications. Kybernetes 2005, 34, 742–743. [Google Scholar] [CrossRef]

- Yang, R.; Zhong, M. Machine Learning-Based Fault Diagnosis for Industrial Engineering Systems, 1st ed.; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Wilhelm, Y.; Reimann, P.; Gauchel, W.; Mitschang, B. Overview on hybrid approaches to fault detection and diagnosis: Combining data-driven, physics-based and knowledge-based models. Procedia CIRP 2021, 99, 278–283. [Google Scholar] [CrossRef]

- Stone, G.; Boulter, E.A.; Gilbert, I.; Dhirani, H. Electrical Insulation for Rotating Machines; Wiley/IEEE Press: New York, NY, USA, 2004. [Google Scholar]

- Alwodai, A.; Gu, F.; Ball, A.D. A Comparison of Different Techniques for Induction Motor Rotor Fault Diagnosis. J. Phys. Conf. Ser. 2012, 364, 012066. [Google Scholar] [CrossRef]

- Yassa, N.; Rachek, M.; Houassine, H. Motor Current Signature Analysis for the Air Gap Eccentricity Detection In the Squirrel Cage Induction Machines. Energy Procedia 2019, 162, 251–262. [Google Scholar] [CrossRef]

- Watson, S.J.; Xiang, B.J.; Yang, W.; Tavner, P.J.; Crabtree, C.J. Condition Monitoring of the Power Output of Wind Turbine Generators Using Wavelets. IEEE Trans. Energy Convers. 2010, 25, 715–721. [Google Scholar] [CrossRef]

- Ergin, S.; Uzuntas, A.; Gulmezoglu, M.B. Detection of Stator, Bearing and Rotor Faults in Induction Motors. Procedia Eng. 2012, 30, 1103–1109. [Google Scholar] [CrossRef]

- Barai, V.; Ramteke, S.M.; Dhanalkotwar, V.; Nagmote, Y.; Shende, S.; Deshmukh, D. Bearing fault diagnosis using signal processing and machine learning techniques: A review. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1259, 012034. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, H.; Wu, Q.; Li, Y.; Diao, L. Demagnetization Characteristics Diagnosis of Permanent Magnet Synchronous Motors. In Proceedings of the 6th International Conference on Electrical Engineering and Information Technologies for Rail Transportation (EITRT) 2023, Singapore, 19–21 October 2023; pp. 331–338. [Google Scholar]

- Thomson, W.T.; Culbert, I. Current Signature Analysis for Condition Monitoring of Cage Induction Motors: Industrial Application and Case Histories; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Giussani, R.; Zachariades, C.; Foxall, M.; Renforth, L.; Seltzer-Grant, M. A Novel Electrical Sensor for Combined Online Measurement of Partial Discharge (OLPD) and Power Quality (PQ). In Proceedings of the 19th International Symposium on High Voltage Engineering, Pilsen, Czech Republic, 23–28 August 2015. [Google Scholar]

- Qiu, M.; Li, W.; Zhu, Z.; Jiang, F.; Zhou, G. Fault Diagnosis of Bearings with Adjusted Vibration Spectrum Images. Shock. Vib. 2018, 2018, 6981760. [Google Scholar] [CrossRef]

- Shi, C.; Peng, L.; Zhang, Z.; Shi, T. Analytical Modeling and Analysis of Permanent-Magnet Motor with Demagnetization Fault. Sensors 2022, 22, 9440. [Google Scholar] [CrossRef]

- AlShorman, O.; Alkahatni, F.; Masadeh, M.; Irfan, M.; Glowacz, A.; Althobiani, F.; Kozik, J.; Glowacz, W. Sounds and acoustic emission-based early fault diagnosis of induction motor: A review study. Adv. Mech. Eng. 2021, 13, 1687814021996915. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, Z.; Xia, Z.; Li, B.; Gu, X.; Shi, T. Application of Teager–Kaiser Energy Operator in the Early Fault Diagnosis of Rolling Bearings. Sensors 2022, 22, 6673. [Google Scholar] [CrossRef]

- Jaros, R.; Byrtus, R.; Dohnal, J.; Danys, L.; Baros, J.; Koziorek, J.; Zmij, P.; Martinek, R. Advanced Signal Processing Methods for Condition Monitoring. Arch. Comput. Methods Eng. 2023, 30, 1553–1577. [Google Scholar] [CrossRef]

- Badihi, H.; Zhang, Y.; Jiang, B.; Pillay, P.; Rakheja, S. A Comprehensive Review on Signal-Based and Model-Based Condition Monitoring of Wind Turbines: Fault Diagnosis and Lifetime Prognosis. Proc. IEEE 2022, 110, 754–806. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z.; Zi, Y.; Chen, X. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Rehman, A.U.; Jiao, W.; Sun, J.; Sohaib, M.; Jiang, Y.; Shahzadi, M.; Khan, M.I. Efficient Fault Detection of Rotor Minor Inter-Turn Short Circuit in Induction Machines Using Wavelet Transform and Empirical Mode Decomposition. Sensors 2023, 23, 7109. [Google Scholar] [CrossRef]

- Aguayo-Tapia, S.; Ávalos-Almazán, G.; Rangel-Magdaleno, J.; Paternina, M.R.A. Broken Rotor Bar Detection in Induction Motors using Digital Taylor-Fourier Transform. In Proceedings of the 2022 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 9–11 November 2022; pp. 1–6. [Google Scholar]

- Ramu, S.K.; Irudayaraj, G.C.R.; Devarajan, G.; Indragandhi, V.; Subramaniyaswamy, V.; Sam Alaric, J. Diagnosis of Broken Bars in V/F Control Induction Motor Drive Using Wavelets and EEV Estimation for Electric Vehicle Applications. Int. Trans. Electr. Energy Syst. 2022, 2022, 9474640. [Google Scholar] [CrossRef]

- Talhaoui, H.; Menacer, A.; Kessal, A.; Tarek, A. Experimental diagnosis of broken rotor bars fault in induction machine based on Hilbert and discrete wavelet transforms. Int. J. Adv. Manuf. Technol. 2018, 95, 1399–1408. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.T.; Iqbal, J. A review on fault detection and diagnosis techniques: Basics and beyond. Artif. Intell. Rev. 2021, 54, 3639–3664. [Google Scholar] [CrossRef]

- Tibshirani, R. Regression Shrinkage and Selection via the Lasso. J. R. Stat. Society. Ser. B (Methodol.) 1996, 58, 267–288. [Google Scholar] [CrossRef]

- Aleem, S.A.; Shahid, N.; Naqvi, I.H. Methodologies in power systems fault detection and diagnosis. Energy Syst. 2015, 6, 85–108. [Google Scholar] [CrossRef]

- Pan, S.; Han, T.; Tan, A.C.C.; Lin, T.R. Fault Diagnosis System of Induction Motors Based on Multiscale Entropy and Support Vector Machine with Mutual Information Algorithm. Shock Vib. 2016, 2016, 5836717. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.; Han, S.; Lin, J.; Han, Q. Fault Diagnosis for Abnormal Wear of Rolling Element Bearing Fusing Oil Debris Monitoring. Sensors 2023, 23, 3402. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, M.; Ouyang, T.; Che, F. A wind turbine bearing fault diagnosis method based on fused depth features in time–frequency domain. Energy Rep. 2022, 8, 12727–12739. [Google Scholar] [CrossRef]

- Huo, Z.; Zhang, Y.; Shu, L.; Gallimore, M. A New Bearing Fault Diagnosis Method Based on Fine-to-Coarse Multiscale Permutation Entropy, Laplacian Score and SVM. IEEE Access 2019, 7, 17050–17066. [Google Scholar] [CrossRef]

- Yaqub, R.; Ali, H.; Wahab, M.H.B.A. Electrical Motor Fault Detection System using AI’s Random Forest Classifier Technique. In Proceedings of the 2023 IEEE International Conference on Advanced Systems and Emergent Technologies (IC_ASET), Hammamet, Tunisia, 29 April–1 May 2023; pp. 1–5. [Google Scholar]

- Tian, J.; Morillo, C.; Azarian, M.H.; Pecht, M. Motor Bearing Fault Detection Using Spectral Kurtosis-Based Feature Extraction Coupled With K-Nearest Neighbor Distance Analysis. IEEE Trans. Ind. Electron. 2016, 63, 1793–1803. [Google Scholar] [CrossRef]

- Zhang, B.; Mao, Y.; Chen, X.; Chai, Y.; Yang, Z. Self-supervised Learning Advance Fault Diagnosis of Rotating Machinery. In Proceedings of the Neural Computing for Advanced Applications, Guangzhou, China, 27–30 August 2021; pp. 319–332. [Google Scholar]

- Barraza, S.M.d.C. Unsupervised Feature Learning Applied to Condition Monitoring. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2017. [Google Scholar]

- Martins, J.F.; Pires, V.F.; Pires, A.J. Unsupervised Neural-Network-Based Algorithm for an On-Line Diagnosis of Three-Phase Induction Motor Stator Fault. IEEE Trans. Ind. Electron. 2007, 54, 259–264. [Google Scholar] [CrossRef]

- Bazan, G.H.; Goedtel, A.; Duque-Perez, O.; Morinigo-Sotelo, D. Multi-Fault Diagnosis in Three-Phase Induction Motors Using Data Optimization and Machine Learning Techniques. Electronics 2021, 10, 1462. [Google Scholar] [CrossRef]

- Aljemely, A.H.; Xuan, J.; Jawad, F.K.J.; Al-Azzawi, O.; Alhumaima, A.S. A novel unsupervised learning method for intelligent fault diagnosis of rolling element bearings based on deep functional auto-encoder. J. Mech. Sci. Technol. 2020, 34, 4367–4381. [Google Scholar] [CrossRef]

- Feng, J.; Bao, S.; Xu, X.; Zhang, Z.; Hou, P.; Steyskal, F.; Dustdar, S. Rotating machinery fault diagnosis based on feature extraction via an unsupervised graph neural network. Appl. Intell. 2023, 53, 21211–21226. [Google Scholar] [CrossRef]

- Barrera-Llanga, K.; Burriel-Valencia, J.; Sapena-Bañó, Á.; Martínez-Román, J. A Comparative Analysis of Deep Learning Convolutional Neural Network Architectures for Fault Diagnosis of Broken Rotor Bars in Induction Motors. Sensors 2023, 23, 8196. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, K.; Peng, T.; Wang, Y. Multi-Condition PMSM Fault Diagnosis Based on Convolutional Neural Network Phase Tracker. Symmetry 2022, 14, 295. [Google Scholar] [CrossRef]

- Peng, B.; Xia, H.; Lv, X.; Annor-Nyarko, M.; Zhu, S.; Liu, Y.; Zhang, J. An intelligent fault diagnosis method for rotating machinery based on data fusion and deep residual neural network. Appl. Intell. 2022, 52, 3051–3065. [Google Scholar] [CrossRef]

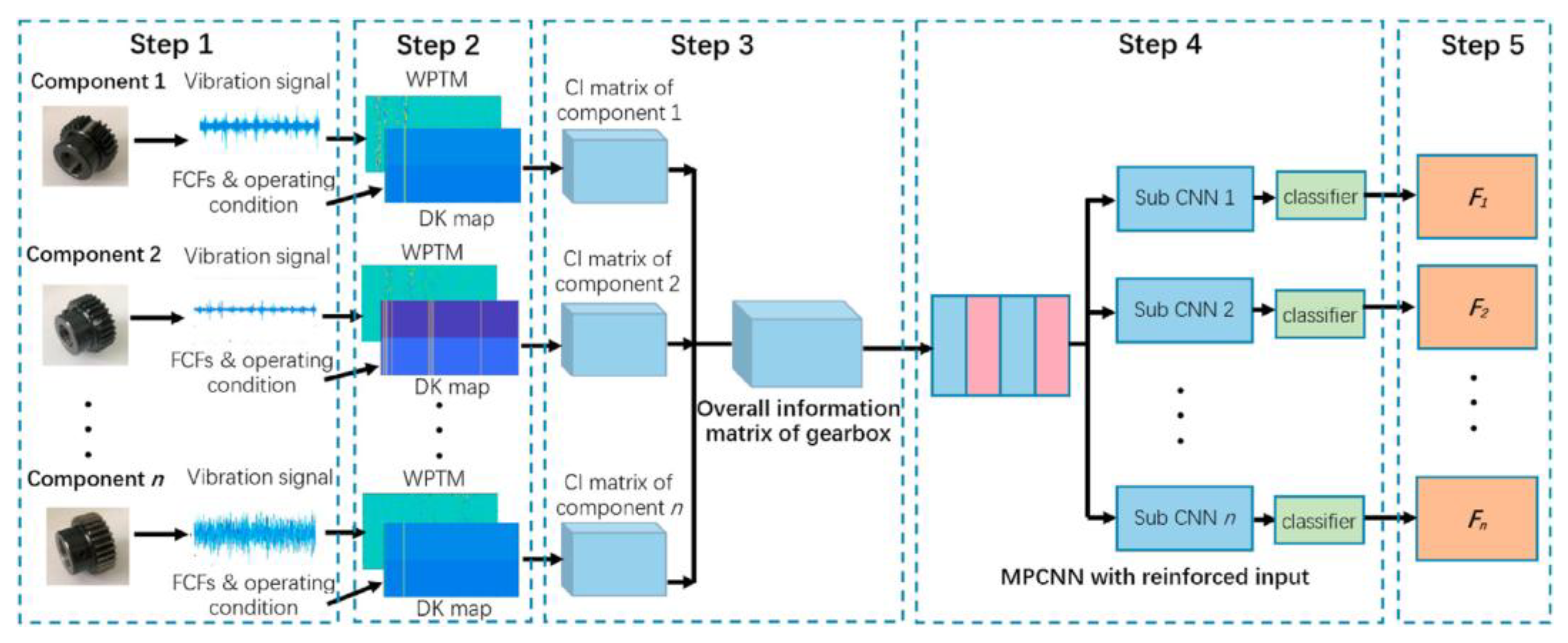

- Guo, S.; Yang, T.; Hua, H.; Cao, J. Coupling fault diagnosis of wind turbine gearbox based on multitask parallel convolutional neural networks with overall information. Renew. Energy 2021, 178, 639–650. [Google Scholar] [CrossRef]

- Fu, G.; Wei, Q.; Yang, Y. Bearing fault diagnosis with parallel CNN and LSTM. Math. Biosci. Eng. 2024, 21, 2385–2406. [Google Scholar] [CrossRef]

- Xu, L.; Teoh, S.S.; Ibrahim, H. A deep learning approach for electric motor fault diagnosis based on modified InceptionV3. Sci. Rep. 2024, 14, 12344. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, F.; Wang, Y.; Yu, Q.; Lang, G.; Zeng, L. Bearing fault diagnosis based on efficient cross space multiscale CNN transformer parallelism. Sci. Rep. 2025, 15, 12344. [Google Scholar] [CrossRef]

- Lei, J.; Liu, C.; Jiang, D. Fault diagnosis of wind turbine based on Long Short-term memory networks. Renew. Energy 2019, 133, 422–432. [Google Scholar] [CrossRef]

- Sabir, R.; Rosato, D.; Hartmann, S.; Guehmann, C. LSTM Based Bearing Fault Diagnosis of Electrical Machines using Motor Current Signal. In Proceedings of the 2019 18th IEEE International Conference On Machine Learning and Applications (ICMLA), Boca Raton, FL, USA, 16–19 December 2019; pp. 613–618. [Google Scholar]

- Ayman, M.; Othman, M.; Mahmoud, N.; Tamer, Z.; Sayed, M.; Hassan, Y.M.I. Fault Detection in Wind Turbines using Deep Learning. In Proceedings of the 2022 2nd International Mobile, Intelligent, and Ubiquitous Computing Conference (MIUCC), Cairo, Egypt, 8–9 May 2022; pp. 272–278. [Google Scholar]

- Tavares, T.M.; Santos, L.D.; Quiles, M.G.; Giesbrecht, M. A Hybrid CNN-LSTM Based Network for Rolling Bearing Fault Detection. In Proceedings of the IECON 2024—50th Annual Conference of the IEEE Industrial Electronics Society, Chicago, IL, USA, 3–6 November 2024; pp. 1–6. [Google Scholar]

- Huang, T.; Zhang, Q.; Tang, X.; Zhao, S.; Lu, X. A novel fault diagnosis method based on CNN and LSTM and its application in fault diagnosis for complex systems. Artif. Intell. Rev. 2022, 55, 1289–1315. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, G.; Wang, X.; Xie, P.; Li, X. A Multi-Level-Denoising Autoencoder Approach for Wind Turbine Fault Detection. IEEE Access 2019, 7, 59376–59387. [Google Scholar] [CrossRef]

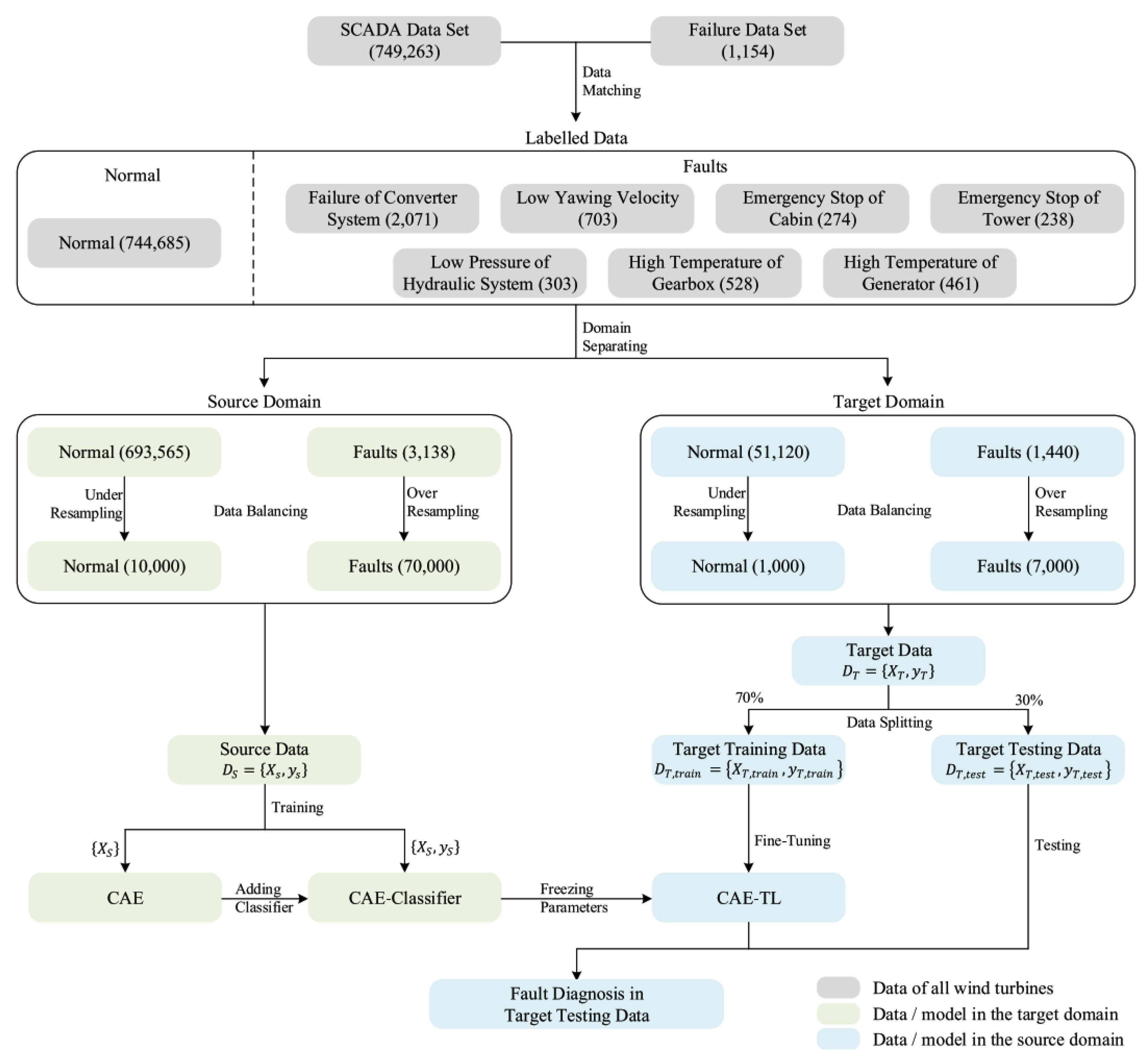

- Li, Y.; Jiang, W.; Zhang, G.; Shu, L. Wind turbine fault diagnosis based on transfer learning and convolutional autoencoder with small-scale data. Renew. Energy 2021, 171, 103–115. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Y.; Du, J.; Wen, Q.; Liu, Y.; Qin, M. Parameter identification of PMSM using deep reinforcement learning. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; pp. 4251–4256. [Google Scholar]

- Li, X.; Zhang, W.; Ding, Q.; Sun, J.-Q. Intelligent rotating machinery fault diagnosis based on deep learning using data augmentation. J. Intell. Manuf. 2020, 31, 433–452. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A.V. Fault Diagnosis using eXplainable AI: A transfer learning-based approach for rotating machinery exploiting augmented synthetic data. Expert Syst. Appl. 2023, 232, 120860. [Google Scholar] [CrossRef]

- Sun, B.; Saenko, K. Deep CORAL: Correlation Alignment for Deep Domain Adaptation. In Proceedings of the Computer Vision—ECCV 2016 Workshops, Amsterdam, The Netherlands, 8–10 October 2016; pp. 443–450. [Google Scholar]

- Li, Z.; Wang, X.; Yang, R. Fault Diagnosis of Bearings Under Different Working Conditions based on MMD-GAN. In Proceedings of the 2021 33rd Chinese Control and Decision Conference (CCDC), Kunming, China, 22–24 May 2021; pp. 2906–2911. [Google Scholar]

- Zhong, Z.; Xie, H.; Wang, Z.; Zhang, Z. Domain Adversarial Transfer Learning Bearing Fault Diagnosis Model Incorporating Structural Adjustment Modules. Sensors 2025, 25, 1851. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Yang, C.; Liu, J.; Xu, Q. Deep graph feature learning-based diagnosis approach for rotating machinery using multi-sensor data. J. Intell. Manuf. 2023, 34, 1965–1974. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Meng, D.; Zhao, X.; Zhang, K. Fault Diagnosis of PMSMs Based on Image Features of Multi-Sensor Fusion. Sensors 2023, 23, 8592. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Cheng, H.; Kong, X.; Wang, Q.; Cui, H. Intelligent wind turbine blade icing detection using supervisory control and data acquisition data and ensemble deep learning. Energy Sci. Eng. 2019, 7, 2633–2645. [Google Scholar] [CrossRef]

- Attallah, O.; Ibrahim, R.A.; Zakzouk, N.E. Fault diagnosis for induction generator-based wind turbine using ensemble deep learning techniques. Energy Rep. 2022, 8, 12787–12798. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Hassan, M.A.M.; Albalawi, F.; Ghoneim, S.S.M.; Ali, Z.M.; Dardeer, M. Diagnostic Modelling for Induction Motor Faults via ANFIS Algorithm and DWT-Based Feature Extraction. Appl. Sci. 2021, 11, 9115. [Google Scholar] [CrossRef]

- Toma, R.N.; Prosvirin, A.E.; Kim, J.-M. Bearing Fault Diagnosis of Induction Motors Using a Genetic Algorithm and Machine Learning Classifiers. Sensors 2020, 20, 1884. [Google Scholar] [CrossRef]

- Ding, J.; Huang, L.; Xiao, D.; Li, X. GMPSO-VMD Algorithm and Its Application to Rolling Bearing Fault Feature Extraction. Sensors 2020, 20, 1946. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Maceren, E.D.C. Induction motor bearing fault classification using deep neural network with particle swarm optimization-extreme gradient boosting. IET Electr. Power Appl. 2024, 18, 297–311. [Google Scholar] [CrossRef]

- Djaballah, S.; Saidi, L.; Meftah, K.; Hechifa, A.; Bajaj, M.; Zaitsev, I. A hybrid LSTM random forest model with grey wolf optimization for enhanced detection of multiple bearing faults. Sci. Rep. 2024, 14, 23997. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Rong, X.; Wang, H.; Yu, S.; Zhang, Y. Method for Identifying Stator and Rotor Faults of Induction Motors Based on Machine Vision. Math. Probl. Eng. 2021, 2021, 6658648. [Google Scholar] [CrossRef]

- Kim, M.-C.; Lee, J.-H.; Wang, D.-H.; Lee, I.-S. Induction Motor Fault Diagnosis Using Support Vector Machine, Neural Networks, and Boosting Methods. Sensors 2023, 23, 2585. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhou, T.; Liu, J.; Zhang, C.; Liu, Y. Fault Diagnosis Approach for Rotating Machinery Based on Feature Importance Ranking and Selection. Shock Vib. 2021, 2021, 8899188. [Google Scholar] [CrossRef]

- Tang, Z.; Shi, X.; Zou, H.; Zhu, Y.; Yang, Y.; Zhang, Y.; He, J. Fault Diagnosis of Wind Turbine Generators Based on Stacking Integration Algorithm and Adaptive Threshold. Sensors 2023, 23, 6198. [Google Scholar] [CrossRef]

- Inyang, U.I.; Petrunin, I.; Jennions, I. Diagnosis of Multiple Faults in Rotating Machinery Using Ensemble Learning. Sensors 2023, 23, 1005. [Google Scholar] [CrossRef]

- Ali, U.; Ramzan, U.; Ali, W.; Al-Jaafari, K.A. An Improved Fault Diagnosis Strategy for Induction Motors Using Weighted Probability Ensemble Deep Learning. IEEE Access 2025, 13, 106958–106973. [Google Scholar] [CrossRef]

- Chen, M.; Wang, H.; Zhang, F. Self-supervised learning for machinery fault diagnosis under strong background noise and limited epochs. Meas. Sci. Technol. 2025, 36, 026135. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, H.; Ye, Z.; Luo, N.; Zhou, M. Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines. Sensors 2025, 25, 2625. [Google Scholar] [CrossRef]

| Method | Strengths | Limitations | |

|---|---|---|---|

| Supervised Learning Methods | Support Vector Machine (SVM) |

|

|

| Decision Tree and Random Forest |

|

| |

| k-Nearest Neighbor (k-NN) |

|

| |

| Unsupervised Learning Methods | Principal Component Analysis (PCA) |

|

|

| K-means Clustering |

|

| |

| Deep Learning Approaches | Convolutional Neural Networks (CNNs) |

|

|

| Recurrent Neural Networks (RNNs) |

|

| |

| Autoencoders |

|

| |

| Hybrid and Ensemble Methods | Neuro-Fuzzy Systems |

|

|

| Evolutionary Algorithms |

|

| |

| Ensemble Methods |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zachariades, C.; Xavier, V. A Review of Artificial Intelligence Techniques in Fault Diagnosis of Electric Machines. Sensors 2025, 25, 5128. https://doi.org/10.3390/s25165128

Zachariades C, Xavier V. A Review of Artificial Intelligence Techniques in Fault Diagnosis of Electric Machines. Sensors. 2025; 25(16):5128. https://doi.org/10.3390/s25165128

Chicago/Turabian StyleZachariades, Christos, and Vigila Xavier. 2025. "A Review of Artificial Intelligence Techniques in Fault Diagnosis of Electric Machines" Sensors 25, no. 16: 5128. https://doi.org/10.3390/s25165128

APA StyleZachariades, C., & Xavier, V. (2025). A Review of Artificial Intelligence Techniques in Fault Diagnosis of Electric Machines. Sensors, 25(16), 5128. https://doi.org/10.3390/s25165128