Real-Time Rail Electrification Systems Monitoring: A Review of Technologies

Highlights

- Identify the current limitations of pantograph–catenary monitoring systems;

- Realise the industry’s needs in terms of monitoring systems for rail electrification assets;

- Real-time knowledge of current collection performance during train service.

- Open perspectives for the development of novel technologies to monitor current collection performance;

- Reduce the frequency of maintenance interventions and extend the life-cycle of railway assets.

Abstract

1. Introduction

2. Rail Industry Requirements for Monitoring Systems

- Before detailing the criteria set by key stakeholders, it is important to identify the parameters that can be measured by pantograph–OCL monitoring systems. The physical quantities measurable by these systems vary depending on the capabilities of the sensing devices and the assets to be analysed. These parameters include the following:

- Contact Forces: Forces resulting from pantograph–catenary interaction dynamics.

- Contact Wire Uplift/Height Exceedances: Uplift of the OCL wires caused by the pantograph(s) passage.

- Arcing/Contact Loss: Contact loss events and electric arcing.

- Carbon Strip Wear: Pantograph strip conditions, namely strip wear, chipping, and cracking.

- OCL Hard Spots/Accelerations on Pantograph Head: Pantograph head dynamics caused by OCL singularities and discrete features.

- Contact Position/Wire Stagger/Dewirement: Lateral position of the contact point on the contact strips to obtain the dynamic stagger and evaluate the risk of dewirement.

- OCL/Pantograph Geometry: Catenary and pantograph geometric parameters.

- Dropper/Clamp/Component Defects: Defective critical OCL components and support devices, e.g., loosened, cracked, fractured, broken, or missing components such as the dropper, steady arm, insulator, claw, clevis, double tube joint, two diagonal tubes, pin, and cantilever.

- Worn Contact Wires: Wear state of catenary contact wire (thickness).

- Wire Tension: Tension of the contact and messenger wires.

- Temperature: Temperature of the contact and messenger wires.

- Reporting to Train: Reporting of the measurement data to the train.

- Accident Investigation/Pantograph–Catenary Imagery: Pantograph–catenary imagery to allow accident investigation.

- Trash in OCL: Foreign objects on the catenary, including bird nests, plastic bags, and rocks clipped in the insulators.

2.1. European Standard’s Requirements

2.2. Schunk Customer Survey

2.3. Network Rail’s Requirements (Requirements in the UK)

- Peak Contact Forces: This is crucial for preventing damage to OCL components, such as neutral sections, section insulators, and crossovers.

- Excessive Wire Stagger: Monitoring this can help prevent horn running and, ultimately, avoid dewirements.

- Longitudinal Acceleration: Monitoring can help prevent carbon chipping or the activation of the Automatic Dropping Device (ADD).

- Wire Height Exceedances (high and low): This monitoring focuses on safety aspects of the OCL.

- Wire Wear (including side wear): Particularly useful when there are converging/diverging wires—it can indicate incorrect setup.

- Pantograph Imagery: This assists in verifying faults and pinpointing where and when they occurred.

- Ability to Detect Defective Components: This enables the detection of detached droppers, incorrectly set up neutral sections, section insulators, and registration arms. Additionally, it can detect anything encroaching into the pantograph envelope, such as vegetation and trash in the OCL.

2.4. ProRail’s Requirements (Requirements in the Netherlands)

- Broken Droppers: Broken droppers can lead to the contact wire sagging, which in turn can accelerate its wear.

- Loose Dropper-Contact Wire Clamps: Loose clamps can result in slackened droppers or droppers sagging below the contact wire, causing damage to the pantograph and, ultimately, to the contact wire.

- Sagged Electrical Connections: Electrical connections between the contact wire and messenger wire, if incorrectly mounted or sagged over time, can skew the position of the contact wire clamp. This can cause uneven wear if both contact wires are not passed over equally. It is worth noting that two parallel contact wires are used for AC-100 catenaries in the Netherlands.

- Non-Equally Worn-Down Contact Wires: When the two contact wires are not parallel or at the same height, this can cause uneven wear among the two contact wires. Often, the cause is a skewed clamp position.

- Garbage in the Catenary System: Objects such as plastic bags or deceased birds can cause damage to the catenary system or become entangled in the pantograph, damaging it.

- Too-Thin Contact Wire: This can lead to contact wire rupture. The system must alarm on the detection of contact wire thickness less than 7.5 mm and must report the contact wire thickness at least every 25 cm.

- Hard Spots: These cause extra contact forces between the pantograph and the contact wire, causing extra wear of the contact wire just before and after these points.

- Parallel Incoming Contact Wire Hanging Too Low: If this occurs, it can damage both the overhead wire and the pantograph.

- Acceleration and Rotation of the Pantograph Head: These measures can indicate an incorrectly positioned OCL.

- Contact Forces on the Pantograph: Contact forces can be measured both horizontally and vertically. Deviations in these measures can indicate hard spots and other anomalies in the OCL.

- Detection of Contact Losses: Contact losses can occur due to various reasons and result in electric arcing that accelerates the wear of the carbon strips and of the contact wire.

2.5. Requirements from the CRC (Requirements in China)

- High-Frequency Acceleration: This parameter effectively describes the smoothness of the contact wire, which is relevant to service life, health status, and safety. This is a feasible measurement parameter compared to the high cost of the contact force measurement systems, and it remains important regardless of the current collection quality.

- Rotation of Gear Wheel: Monitoring the rotation of the catenary’s tensioning wheel can provide information on tension variations due to climate change and other dynamic performances.

- Steady-Arm Inclination: Monitoring the inclination of the steady arm can provide insights into the geometrical distortion of the catenary in long-term operation. This measurement can be used as an indicator to support effective maintenance strategies.

- Catenary Cantilever Imagery: Using a low-speed train to capture clear photos of the catenary cantilever system, for example, at night, can prove beneficial. Advanced image processing methods can then be used to automatically detect faults, providing an alternative to conventional visual inspection.

- Steady-Arm Uplift: The uplift of the steady arm should be monitored as it needs to be restricted within a certain safety range. This monitoring can be real time if the power supply and robustness of the system are properly addressed.

- Contact Point Position: Real-time monitoring of the contact point is a crucial indicator to evaluate the risk of dewirement. Advanced image processing methods are needed to automatically track the contact point during operation.

3. Data Acquisition Systems

- The Diagnostics Phase: Pattern recognition is used to identify signatures of defects and locate the faults in the pantograph–OCL system.

- The Prognostics Phase: Long-term measurement datasets are used for comprehensive assessment and to predict the degradation trends of the pantograph–OCL components.

- Condition-Based or Predictive Maintenance Phase: In line with the diagnostic and prognostic results, strategies are developed to improve maintenance efficiency and reduce life-cycle costs of the assets.

3.1. On-Board Measurement of Static Parameters (OMS)

3.1.1. Measurement Method

3.1.2. Application Examples

3.1.3. Current Issues and Perspectives

- Regarding static geometry detection, the results may be contaminated by the vibration of the inspection vehicle. An important technical issue is to develop high-precision compensation techniques for such vibrations.

- Regarding the catenary component detection, small catenary parts, such as isoelectric lines [51], clevis, and pins, are not visible and can be affected by trees and illumination conditions due to the complex environment. The crucial next step is to improve the identification rate by using advanced computer vision algorithms, e.g., artificial intelligence techniques and deep learning neural networks.

3.2. On-Board Measurement of Dynamic Parameters (OMD)

3.2.1. Measurement Method

3.2.2. Measurement of Contact Forces

3.2.3. Measurement of Arcing

3.2.4. Application Examples

3.2.5. Current Issues and Perspectives

- Inspection Vehicles: The current measurement of key pantograph–catenary dynamic parameters, e.g., contact forces and accelerations, is generally performed using special inspection vehicles. This only gives indications for standard periodic maintenance operations but cannot monitor short-term degradation or defects that may disrupt regular service. Real-time condition monitoring is highly desirable, with a tendency for more train fleets, which operate at commercial speeds, to have monitoring systems installed on board. Reliability and versatility of the measurement systems need to be improved to ensure efficient performance.

- Accuracy of Contact Force Measurement: Traditional sensors are susceptible to distortion by the electromagnetic environment. The temporary fitting of instrumentation may also affect the current collection quality and skew results at the testing stage.

- Assessment Indicators: Due to the difficulties existing in the measurement of contact forces, some researchers propose to use the accelerations to identify the behaviour of the contact forces. The statistics of the acceleration RMS value can be used to detect defects on the contact line and hard spots [61]. The advantage of this technique is that only two accelerometers are installed on the collector strip to capture the accelerations of the pantograph head, and the frequency can be extended up to 200 Hz. Such data can adequately describe the high-frequency characteristics of the flexible registration strips and the irregularities of the contact line.

- Arcing Measurement: Normal imaging techniques are easily affected by environmental and lighting conditions. Thermal imaging is a promising technique for detecting arcing. However, this technology can be expensive and challenging to implement in real time because of the considerable amount of data to be processed. Compared to thermal cameras, photosensitive devices are less expensive, giving a continuous signal output that is related to the presence of an electric arc. Another promising measurement method is to examine the current and voltage input signals that arrive at the train. The reliability of the arcing measurement for the assessment of current collection performance is still not clear, and it does not allow for measuring important safety thresholds such as contact wire uplifts and maximum forces.

3.3. Wayside Measurement of Pantographs (WMP)

3.3.1. Measurement Method

3.3.2. Application Examples

3.3.3. Current Issues and Perspectives

- The high-resolution cameras are expensive, which causes an increase in the cost of the measurement system.

- The image quality is restricted by the distance between the pantograph and the measurement equipment. Devices installed further away make it difficult to capture clear images, whereas a closer installation of equipment could introduce some safety issues.

- The measurement device should work during the day and night and under different weather conditions. The detection algorithm should have high robustness to all these conditions.

- Different styles of the pantograph and of the roof of the train may affect identification. The detection algorithm should be robust enough for all these cases.

3.4. Wayside Measurement of the OCL (WMO)

3.4.1. Measurement Method

3.4.2. Application Examples

3.4.3. Current Issues and Perspectives

- The wayside monitoring for catenary vibration is still in the laboratory stage. The interference of the device on the measured results, the electromagnetic effects, and the vibration robustness should be investigated further.

- There is no relevant standard regarding the wayside monitoring for catenary vibration. The selection of indicators and the definition of the threshold values require more research.

4. Conclusions and Perspectives

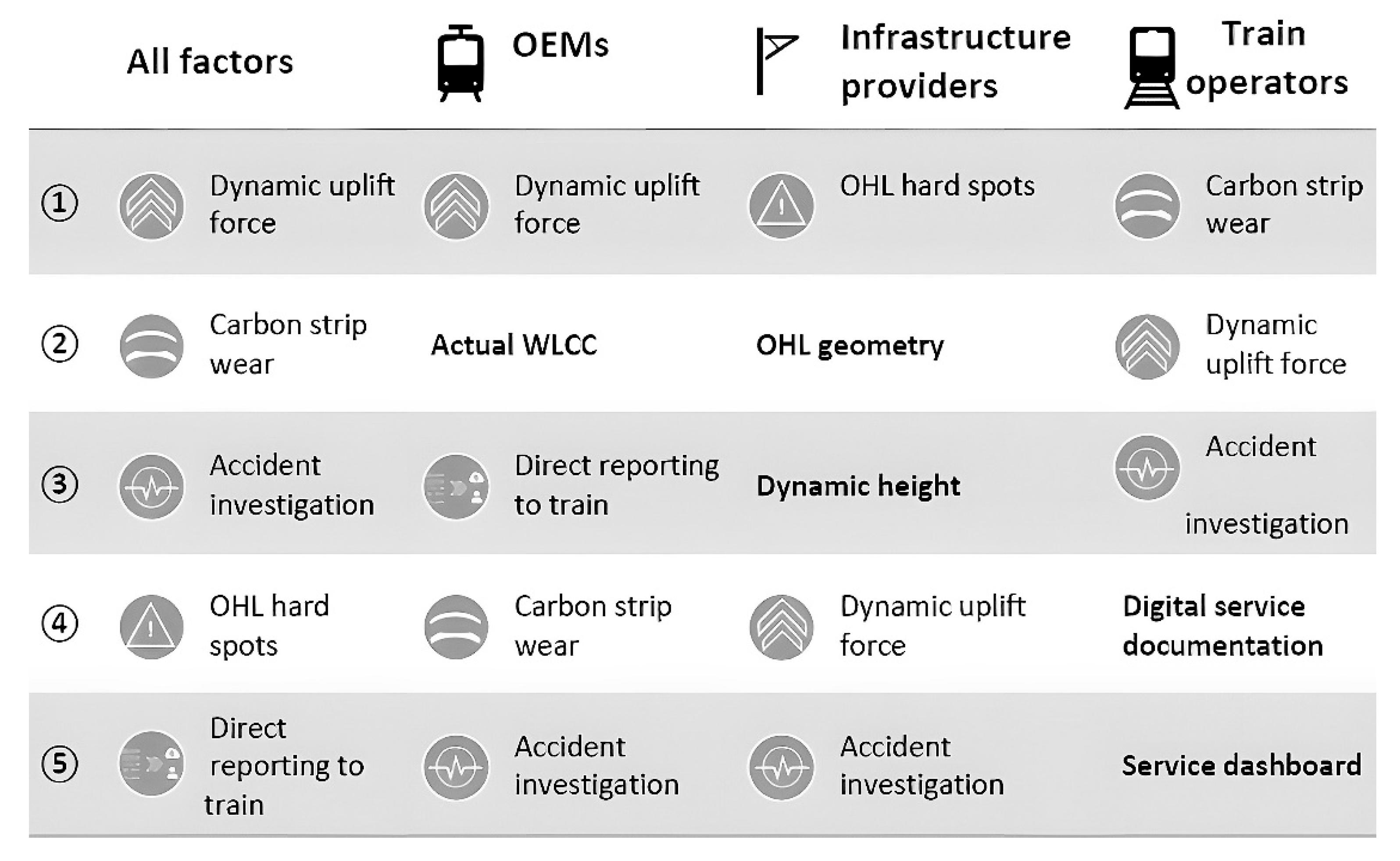

4.1. Rail Industry Requirements

4.2. Data Acquisition Systems

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADD | Automatic Dropping Device |

| CM | Condition monitoring |

| CRC | China Railway Corporation |

| CW | Contact wire |

| FBG | Fibre Bragg Grating |

| GPS | The Global Position System |

| MW | Messenger wire |

| NCC | Normalised Cross-Correlation |

| OCL | Overhead contact line |

| OEM | Original equipment manufacturer |

| OMD | On-board Measurement of Dynamic parameters |

| OMS | On-board Measurement of Static parameters |

| PHM | Prognostics and Health Management |

| WMO | Wayside Measurement of OCL |

| WMP | Wayside Measurement of Pantographs |

References

- Tjandra, S.; Kraus, S.; Ishmam, S.; Grube, T.; Linßen, J.; May, J.; Stolten, D. Model-based analysis of future global transport demand. Transp. Res. Interdiscip. Perspect. 2024, 23, 101016. [Google Scholar] [CrossRef]

- Gadonneix, P.; Sambo, A.; Tie’nan, L.; Choudhury, A.R.; Teyssen, J.; Lleras, J.A.V.; Naqi, A.A.; Meyers, K.; Shin, H.C.; Nadeau, M.-J.; et al. Global Transport Scenarios 2050; World Energy Council: London, UK, 2021. [Google Scholar]

- Zhong, H.; Liu, L.; Wang, J.; Fu, Q.; Yi, B. A real-time railway fastener inspection method using the lightweight depth estimation network. Measurement 2022, 189, 110613. [Google Scholar] [CrossRef]

- Jing, G.; Qin, X.; Wang, H.; Deng, C. Developments, challenges, and perspectives of railway inspection robots. Autom. Constr. 2022, 138, 104242. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Rail; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Nåvik, P.; Derosa, S.; Rønnquist, A. Development of an index for quantification of structural dynamic response in a railway catenary section. Eng. Struct. 2020, 222, 111154. [Google Scholar] [CrossRef]

- Yi, C.; Wang, D.; Zhou, L.; Lin, J. A simulation investigation on the influence of pantograph crack defect on graphite contact strip wear. Eng. Fail. Anal. 2022, 131, 105889. [Google Scholar] [CrossRef]

- Bruni, S.; Bucca, G.; Facchinetti, A.; Gregori, S.; Pombo, J. Recent developments on pantograph-overhead line interaction. Veh. Syst. Dyn. 2025, 63, 1358–1394. [Google Scholar] [CrossRef]

- Mei, G.; Luo, Q.; Qiao, W.; Huang, Z.; Lu, J.; Wang, J. Study of load spectrum compilation method for the pantograph upper frame based on multi-body dynamics. Eng. Fail. Anal. 2022, 135, 106099. [Google Scholar] [CrossRef]

- Bruni, S.; Bucca, G.; Carnevale, M.; Collina, A.; Facchinetti, A. Pantograph–catenary interaction: Recent achievements and future research challenges. Int. J. Rail Transp. 2018, 6, 57–82. [Google Scholar] [CrossRef]

- Lin, Y.; Shieh, N.; Liu, V. Optimal control for rail vehicle pantograph systems with actuator delays. IET Control Theory Appl. 2015, 9, 1917–1926. [Google Scholar] [CrossRef]

- Jackson, F.F.; Mishra, R.; Rebelo, J.M.; Santos, J.; Antunes, P.; Pombo, J.; Magalhães, H.; Wills, L. Modelling dynamic pantograph loads with combined numerical analysis. Railw. Eng. Sci. 2024, 32, 81–94. [Google Scholar] [CrossRef]

- Pombo, J.; Antunes, P. A Comparative Study between Two Pantographs in Multiple Pantograph High-Speed Operations. Int. J. Railw. Technol. 2013, 2, 83–108. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Wang, H.; Lu, X.; Zhang, J. Nonlinear analysis of wind-induced vibration of high-speed railway catenary and its influence on pantograph–catenary interaction. Veh. Syst. Dyn. 2016, 54, 723–747. [Google Scholar] [CrossRef]

- Kiessling, F.; Puschmann, R.; Schmieder, A.; Schneider, E. Contact Lines for Electric Railways: Planning, Design, Implementation, Maintenance, 3rd ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Keenor, G. Overhead Line Electrification for Railways, 5th ed.; The PWI: Brentwood, UK, 2021. [Google Scholar]

- Rebelo, J.; Antunes, P.; Ambrósio, J.; Pombo, J. Track and catenary reconstruction from aerial images for the realistic analysis of rail electrification systems. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2023, 238, 185–195. [Google Scholar] [CrossRef]

- Bucca, G.; Lo Conte, A.; Bocciolone, M.; Collina, A. Analysis of the failure of a tramcar pantograph component through combined experimental approaches. Eng. Fail. Anal. 2022, 141, 106725. [Google Scholar] [CrossRef]

- EN 50367:2020; Railway Applications—Current Collection Systems—Technical Criteria for the Interaction Between Pantograph and Overhead Line. British Standards Institution: London, UK, 2020.

- Song, Y.; Antunes, P.; Pombo, J.; Liu, Z. A methodology to study high-speed pantograph-catenary interaction with realistic contact wire irregularities. Mech. Mach. Theory 2020, 152, 103940. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Rxnnquist, A.; Navik, P.; Liu, Z. Contact Wire Irregularity Stochastics and Effect on High-speed Railway Pantograph-Catenary Interactions. IEEE Trans. Instrum. Meas. 2020, 69, 8196–8206. [Google Scholar] [CrossRef]

- Wang, H.; Núñez, A.; Liu, Z.; Song, Y.; Duan, F.; Dollevoet, R. Analysis of the evolvement of contact wire wear irregularity in railway catenary based on historical data. Veh. Syst. Dyn. 2018, 56, 1207–1232. [Google Scholar] [CrossRef]

- Bruni, S.; Ambrósio, J.; Carnicero, A.; Cho, Y.H.; Finner, L.; Ikeda, M.; Sam Young Kwon, S.Y.; Massat, J.-P.; Stichel, S.; Tur, M.; et al. The results of the pantograph–catenary interaction benchmark. Veh. Syst. Dyn. 2015, 53, 412–435. [Google Scholar] [CrossRef]

- Ambrósio, J.; Pombo, J.; Rauter, F.; Pereira, M. A Memory Based Communication in the Co-simulation of Multibody and Finite Element Codes for Pantograph-Catenary Interaction Simulation. In Multibody Dynamics; Springer: Dordrecht, The Netherlands, 2009; pp. 231–252. [Google Scholar] [CrossRef]

- Ambrósio, J.; Pombo, J.; Pereira, M.; Antunes, P.; Mósca, A. A Computational Procedure for the Dynamic Analysis of the Catenary-Pantograph Interaction in High-Speed Trains. J. Theor. Appl. Mech. 2012, 50, 681–699. [Google Scholar]

- Massat, J.-P.; Balmes, E.; Bianchi, J.-P.; Van Kalsbeek, G. OSCAR statement of methods. Veh. Syst. Dyn. 2015, 53, 370–379. [Google Scholar] [CrossRef]

- Ambrósio, J.; Pombo, J.; Antunes, P.; Pereira, M. PantoCat statement of method. Veh. Syst. Dyn. 2015, 53, 314–328. [Google Scholar] [CrossRef]

- Ikeda, M. ‘Gasen-do FE’ statement of methods. Veh. Syst. Dyn. 2015, 53, 357–369. [Google Scholar] [CrossRef]

- Shing, A.W.C.; Wong, P.P.L. Wear of pantograph collector strips. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2008, 222, 169–176. [Google Scholar] [CrossRef]

- Shing, W. A Survey of Contact Wire Wear Parameters and the Development of a Model to Predict Wire Wear by Using the Artifical Neural Network. Ph.D. Thesis, City University of Hong Kong, Hong Kong, China, 2011. [Google Scholar]

- Bucca, G.; Collina, A. A procedure for the wear prediction of collector strip and contact wire in pantograph-catenary system. Wear 2009, 266, 46–59. [Google Scholar] [CrossRef]

- Zou, D.; Zhong, S.; Geng, Y.; Cheng, Y.; Mo, Z.; Xu, K.; Song, B.; Cheng, B.; Zhang, S.; Wang, Z.; et al. Status Analysis and Prevention-treatment Technology Study of Abnormal Wear of Pantograph Catenary System in Urban Rail Transit. J. Mech. Eng. 2023, 59, 152. [Google Scholar] [CrossRef]

- Shi, H.; Chen, G.; Yang, Y. A comparative study on pantograph-catenary models and effect of parameters on pantograph-catenary dynamics under crosswind. J. Wind Eng. Ind. Aerodyn. 2021, 211, 104587. [Google Scholar] [CrossRef]

- Bocciolone, M.; Resta, F.; Rocchi, D.; Tosi, A.; Collina, A. Pantograph aerodynamic effects on the pantograph–catenary interaction. Veh. Syst. Dyn. 2006, 44, 560–570. [Google Scholar] [CrossRef]

- Pombo, J.; Ambrósio, J.; Pereira, M.; Rauter, F.; Collina, A.; Facchinetti, A. Influence of the aerodynamic forces on the pantograph–catenary system for high-speed trains. Veh. Syst. Dyn. 2009, 47, 1327–1347. [Google Scholar] [CrossRef]

- Wu, G.; Dong, K.; Xu, Z.; Xiao, S.; Wei, W.; Chen, H.; Li, J.; Huang, Z.; Li, J.; Gao, G.; et al. Pantograph–catenary electrical contact system of high-speed railways: Recent progress, challenges, and outlooks. Railw. Eng. Sci. 2022, 30, 437–467. [Google Scholar] [CrossRef]

- Brahimi, M.; Medjaher, K.; Leouatni, M.; Zerhouni, N. Prognostics and Health Management for an Overhead Contact Line System—A Review. Int. J. Progn. Health Manag. 2017, 8. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, D.; Tan, M.; Zhou, N.; Li, R.; Mei, G. Review of pantograph and catenary interaction. Front. Mech. Eng. 2018, 13, 311–322. [Google Scholar] [CrossRef]

- Xin, T.; Roberts, C.; Weston, P.; Stewart, E. Condition monitoring of railway pantographs to achieve fault detection and fault diagnosis. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 234, 289–300. [Google Scholar] [CrossRef]

- Santamato, G.; Chiaradia, D.; Solazzi, M.; Frisoli, A. A Robotic Device for the Structural Dynamics Inspection of Railway Pantographs through Nonlinearity Tests. IFAC-PapersOnLine 2020, 53, 8476–8481. [Google Scholar] [CrossRef]

- Xu, S.; Chen, C.; Lin, Z.; Zhang, X.; Dai, J.; Liu, L. Review and prospect of maintenance technology for traction system of high-speed train. Transp. Saf. Environ. 2021, 3, 17. [Google Scholar] [CrossRef]

- Spiryagin, M.; Bruni, S.; Cole, C. (Eds.) Handbook on Digital Twin and Artificial Intelligence Techniques for Rail Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2025; ISBN 9781003492146. [Google Scholar]

- Tang, R.; De Donato, L.; Bešinović, N.; Flammini, F.; Goverde, R.M.P.; Lin, Z.; Liu, R.; Tang, T.; Vittorini, V.; Wang, Z. A literature review of Artificial Intelligence applications in railway systems. Transp. Res. Part C Emerg. Technol. 2022, 140, 103679. [Google Scholar] [CrossRef]

- Sainz-Aja, J.A.; Ferreño, D.; Pombo, J.; Carrascal, I.A.; Casado, J.; Diego, S.; Castro, J. Parametric analysis of railway infrastructure for improved performance and lower life-cycle costs using machine learning techniques. Adv. Eng. Softw. 2023, 175, 103357. [Google Scholar] [CrossRef]

- Office of Rail and Road. OLE Incident Response: Targeted Assurance Review; Office of Rail and Road: London, UK, 2021. [Google Scholar]

- Liu, Z.; Liu, W.; Han, Z. A high-precision detection approach for catenary geometry parameters of electrical railway. IEEE Trans. Instrum. Meas. 2017, 66, 1798–1808. [Google Scholar] [CrossRef]

- Nagasawa, H.; Takahashi, T.; Horikawa, Y.; Tanabe, T. Development of Measuring Apparatus for Contact Wire Wear Using Sodium Vapor Lamps. IEEJ Trans. Ind. Appl. 2011, 116, 484–489. [Google Scholar] [CrossRef]

- Wu, X.; Yuan, P.; Peng, Q.; Ngo, C.W.; He, J.Y. Detection of bird nests in overhead catenary system images for high-speed rail. Pattern Recognit. 2016, 51, 242–254. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Z.; Wang, H.; Nunez, A.; Han, Z. Automatic defect detection of fasteners on the catenary support device using deep convolutional neural network. IEEE Trans. Instrum. Meas. 2018, 67, 257–269. [Google Scholar] [CrossRef]

- Gao, S.B.; Liu, Z.G.; Yu, L. Detection and monitoring system of the pantograph-catenary in high-speed railway (6C). In Proceedings of the 2017 7th International Conference on Power Electronics Systems and Applications—Smart Mobility, Power Transfer & Security (PESA), Hong Kong, China, 12–14 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, L.; Li, C.; Han, Z. A High-Precision Loose Strands Diagnosis Approach for Isoelectric Line in High-Speed Railway. IEEE Trans. Ind. Inform. 2018, 14, 1067–1077. [Google Scholar] [CrossRef]

- Kolbe, M.; Baldauf, W.; Tiffe, G. Compact contact force measurement system–online diagnosis of the overhead line system with regular trains. In Proceedings of the World Congress on Railway Research, Cologne, Germany, 25–29 November 2001. [Google Scholar]

- EN 50317:2012; Railway Applications—Current Collection Systems—Requirements for and Validation of Measurements of the Dynamic Interaction Between Pantograph and Overhead Contact Line. British Standards Institution: London, UK, 2012.

- Comolli, L.; Bucca, G.; Bocciolone, M.; Collina, A. First results from in line strain measurements with FBG sensors on the pantograph collector of underground trains. Opt. Sens. Detect. 2010, 7726, 772605. [Google Scholar] [CrossRef]

- Tan, M.; Zhou, N.; Cheng, Y.; Wang, J.; Zhang, W.; Zou, D. A temperature-compensated fiber Bragg grating sensor system based on digital filtering for monitoring the pantograph–catenary contact force. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 187–200. [Google Scholar] [CrossRef]

- Koyama, T.; Ikeda, M.; Kobayashi, S.; Nakamura, K.; Tabayashi, S.; Niwakawa, M. Measurement of the Contact Force of the Pantograph by Image Processing Technology. Q. Rep. Railw. Tech. Res. Inst. 2014, 55, 73–78. [Google Scholar] [CrossRef]

- Zhao, F.; Huang, Q.; Gao, W. Image Matching by Normalized Cross-Correlation. In Proceedings of the 2006 IEEE International Conference on Acoustics Speech and Signal Processing Proceedings, Toulouse, France, 14–19 May 2006; IEEE: Piscataway, NJ, USA, 2006; p. II. [Google Scholar] [CrossRef]

- Karakose, E.; Gencoglu, M.T.; Karakose, M.; Yaman, O.; Aydin, I.; Akin, E. A new arc detection method based on fuzzy logic using S-transform for pantograph–catenary systems. J. Intell. Manuf. 2018, 29, 839–856. [Google Scholar] [CrossRef]

- Boguslavskii, A.A.; Sokolov, S.M. Detecting objects in images in real-time computer vision systems using structured geometric models. Program. Comput. Softw. 2006, 32, 177–187. [Google Scholar] [CrossRef]

- Bruno, O.; Landi, A.; Papi, M.; Sani, L. Phototube sensor for monitoring the quality of current collection on overhead electrified railways. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2001, 215, 231–241. [Google Scholar] [CrossRef]

- Gregori, S.; Tur, M.; Gil, J.; Fuenmayor, F.J. Assessment of catenary condition monitoring by means of pantograph head acceleration and Artificial Neural Networks. Mech. Syst. Signal Process. 2023, 202, 110697. [Google Scholar] [CrossRef]

- Capece, P.; Chiesi, L.; Pinazzi, A.; Sabbatelli, M.; Sacchi, M.; Venturi, L.; Kelsey, T.; Wilson, C. PANTOBOT-3D: An automatic vision-based inspection system for locomotive pantographs. In Proceedings of the 7th IET Conference on Railway Condition Monitoring 2016 (RCM 2016), Birmingham, UK, 27–28 September 2016; IET: Stevenage, UK, 2016; pp. 1–5. [Google Scholar]

- Nåvik, P.; Rønnquist, A.; Stichel, S. A wireless railway catenary structural monitoring system: Full-scale case study. Case Stud. Struct. Eng. 2016, 6, 22–30. [Google Scholar] [CrossRef]

- Nåvik, P.; Rønnquist, A.; Stichel, S. Identification of system damping in railway catenary wire systems from full-scale measurements. Eng. Struct. 2016, 113, 71–78. [Google Scholar] [CrossRef]

- Zou, D.; Zhang, W.H.; Li, R.P.; Zhou, N.; Mei, G.M. Determining damping characteristics of railway-overhead-wire system for finite-element analysis. Veh. Syst. Dyn. 2016, 54, 902–917. [Google Scholar] [CrossRef]

- Zou, D.; Zhou, N.; Rui Ping, L.; Mei, G.M.; Zhang, W.H. Experimental and simulation study of wave motion upon railway overhead wire systems. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 231, 934–944. [Google Scholar] [CrossRef]

| 2019–2020 | 2020–2021 | |||||

|---|---|---|---|---|---|---|

| Railway Period | No. of Incidents | Trains Delayed | Delay Minutes | No. of Incidents | Trains Delayed | Delay Minutes |

| 1 | 3 | 2159 | 11,885 | 3 | 466 | 4959 |

| 2 | 3 | 3901 | 29,223 | 4 | 1499 | 11,254 |

| 3 | 6 | 3846 | 26,050 | 6 | 1900 | 12,536 |

| 4 | 2 | 1387 | 9885 | 1 | 315 | 1336 |

| 5 | 11 | 11,154 | 87,045 | 9 | 3393 | 31,127 |

| 6 | 0 | 0 | 0 | 1 | 689 | 5683 |

| 7 | 0 | 0 | 0 | 1 | 319 | 2297 |

| 8 | 3 | 6633 | 44,569 | 5 | 2317 | 23,132 |

| 9 | 2 | 2934 | 22,611 | 4 | 2156 | 12,957 |

| 10 | 1 | 362 | 2016 | 3 | 883 | 10,245 |

| 11 | 3 | 1923 | 14,724 | 3 | 999 | 5892 |

| 12 | 4 | 3925 | 28,567 | 3 | 1463 | 10,860 |

| 13 | 1 | 3763 | 21,654 | 3 | 765 | 4336 |

| Criterion | Threshold |

|---|---|

| Mean Contact Force (Fm) | Fm = 0.00097 v2 + 70 N |

| Standard Deviation (Smax) | Smax < 0.3 Fm |

| Maximum Contact Force (Fmax) | Fmax < 350 N |

| Maximum CW Uplift of Steady-arm (DUP) | DUP ≤ 120 mm (indicative value) |

| Percentage of Real Arching (NQ) | NQ ≤ 0.2% |

| Technology | Contact Forces | CW Uplift | Arcing | Strip Wear | Hard Spots | Contact Position | OCL Geometry | CW Wear | Report to Train | Imagery | Trash in OCL |

|---|---|---|---|---|---|---|---|---|---|---|---|

| High-Precision Catenary-Checking Monitor System (CRC) | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| Selectra Vision CAT-VW | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 |

| Selectra Vision CAT-LW | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 |

| MERMEC Longitudinal Defects Detection System | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 |

| MEIDENSHA Conventional Commercial Service Car | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| MEIDENSHA Maintenance Vehicle/Road–Rail Vehicle | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 |

| D. Wehrhahn: Online Contact Line Measuring System | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 |

| Century: Handheld Intelligent Catenary System | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 |

| Riegl: Mobile Mapping System | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| DMA: Catenary Monitoring | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| Technology | Contact Forces | CW Uplift | Arcing | Strip Wear | Hard Spots | Contact Position | OCL Geometry | CW Wear | Report to Train | Imagery | Trash in OCL |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Comprehensive Pantograph and Catenary Monitor System (CRC) | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| Catenary Checking Video Monitor System (CRC) | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Ricardo CatMon | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 |

| Transmission PANDAS | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 |

| MEIDENSHA Corporation | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Serco Overhead Line Monitoring Systems | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 |

| Serco Attended Pantograph Monitoring | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 |

| D-RAIL Technical Solution | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 |

| DTI: Pantograph and OHL Inspection System | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 |

| CONTACT: Pantograph Control System | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 |

| SenTech Analytics: IoT Pantographs | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 |

| Technology | Contact Forces | CW Uplift | Arcing | Strip Wear | Hard Spots | Contact Position | OCL Geometry | CW Wear | Report to Train | Imagery | Trash in OCL |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sengenia: Fibre optic sensing | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 |

| HBK railway pantograph overhead line monitoring | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 |

| MERMEC: Pantograph–catenary interaction measurement | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Deutzer: Position–shock system | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 |

| DraadData: Contact wire inspection | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 |

| DMA—Wire geometry + wear | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 |

| Pantohealth: Pantograph monitoring and diagnostic system | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 |

| OLErt: Overhead line and pantograph monitoring | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 |

| Balfour Beatty: Attended TrueOHL™ | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 |

| Balfour Beatty: Unattended TrueOHL™ | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 |

| Balfour Beatty: Unattended TruePan™ | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| Technology | Contact Forces | CW Uplift | Arcing | Strip Wear | Hard Spots | Contact Position | OCL Defects | CW Wear | Report to Train | Imagery | Trash in OCL |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Catenary and Pantograph Video Monitoring System (CRC) | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 |

| CAMLIN Group: PANTOBOT 3D | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| Ricardo Rail PanMon | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 0 |

| MEIDENSHA Pantograph Monitoring System | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| Duostech Automated Pantograph Inspection System | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| Image House: PANTOINSPECT | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| Selectra: PantoCheck | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| DMA: Pantograph Uplift System | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| Acoustic Diagnostic of Pantograph Current Collector | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| CRRC Dynamic Detection System for Pantograph | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 |

| Technology | Contact Force/ Position | CW Uplift | Arcing | Hard Spots | OCL Wear/ Geometry/ Defects | Report to Train | Imagery | Trash in OCL | Wire Tension | Temps |

|---|---|---|---|---|---|---|---|---|---|---|

| Ground Monitor System for Catenary and Power Supply (CRC) | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| SIEMENS Sicat CMS | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| Railway Catenary Structure Monitoring System (NTNU) | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| High-Speed Catenary Non-Contact Monitoring System (SWJTU) | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| Serco Attended/Unattended Trackside Measurement of Dynamic Wire Uplift | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| KRUCH: Contact Wire Uplift Sensor | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 |

| KRUCH: Contact Wire Temperature Sensor | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sainz-Aja, J.A.; Pombo, J.; Brant, J.; Antunes, P.; Rebelo, J.M.; Santos, J.; Ferreño, D. Real-Time Rail Electrification Systems Monitoring: A Review of Technologies. Sensors 2025, 25, 6625. https://doi.org/10.3390/s25216625

Sainz-Aja JA, Pombo J, Brant J, Antunes P, Rebelo JM, Santos J, Ferreño D. Real-Time Rail Electrification Systems Monitoring: A Review of Technologies. Sensors. 2025; 25(21):6625. https://doi.org/10.3390/s25216625

Chicago/Turabian StyleSainz-Aja, Jose A., João Pombo, Jordan Brant, Pedro Antunes, José M. Rebelo, José Santos, and Diego Ferreño. 2025. "Real-Time Rail Electrification Systems Monitoring: A Review of Technologies" Sensors 25, no. 21: 6625. https://doi.org/10.3390/s25216625

APA StyleSainz-Aja, J. A., Pombo, J., Brant, J., Antunes, P., Rebelo, J. M., Santos, J., & Ferreño, D. (2025). Real-Time Rail Electrification Systems Monitoring: A Review of Technologies. Sensors, 25(21), 6625. https://doi.org/10.3390/s25216625