Advances in Nondestructive Technologies for External Eggshell Quality Evaluation

Abstract

1. Introduction

- (1)

- To summarize the research progress and working principles of mainstream NDT methods for eggshell quality assessment;

- (2)

- To compare the performance, advantages, and application scenarios of different detection techniques;

- (3)

- To identify current challenges related to detection accuracy, data acquisition, environmental variability, and industrial applicability; and

- (4)

- To explore future development directions, including artificial intelligence integration, multimodal sensing, and system-level optimization.

2. Evaluation Indicators of Poultry Eggshell Quality

2.1. Crack Detection

2.2. Eggshell Thickness Measurement

2.3. Eggshell Strength Assessment

2.4. Color and Cleanliness Detection

2.5. Other Indicators

3. Poultry Egg Crack Detection

| Type | Technique | Parameters | Model | Accuracy | Explanation | Ref. |

|---|---|---|---|---|---|---|

| Image processing (n = 5) | Modified pressure imaging system | 3 replicates, 360 eggs per replicate, Negative pressure (~200 mmHg, 0.5 s), digital imaging | None | 99.60% | Uses negative pressure to expand cracks and detect them through digital imaging. | [67] |

| OpenCV-based image processing | CCD camera, R-channel extraction, median filter | None | >90% | Separates color channels and applies filtering and morphological analysis. | [68] | |

| Canny edge detection + Hough line transform | 80 in total, including 45 healthy eggs and 35 cracked eggs, Canny edge detector, Hough line transform | LDA | 90.10% | Edge detection and line transformation combined with linear discriminant analysis. | [69] | |

| Wavelet transform + PCA reduction + SVM classification | 48 in total, 24 with artificially created cracks, 24 as controls, Wavelet transform (sym4, 2-layer), PCA reduction | SVM | 93.75% | Multi-feature extraction and classification using wavelet transform and PCA. | [70] | |

| Rotating mechanism + DoG + median filter | 50 in total, 30 with artificially created microcracks, 20 intact; 3 images per egg (150 images total), 750 surface images after 5 hold-out validations (450 for training set, 300 for test set), Rotating egg, DoG + median filter | ANN | 98% | Uses a rotating mechanism and feature extraction for crack detection. | [64] | |

| Deep learning (n = 4) | Multiple CNNs (YOLOv4/v7, Faster R-CNN, SSD) | 536 original images, 1280 images after preprocessing and augmentation (1116 for training set, 109 for validation set, 55 for test set), CLAHE preprocessing, YOLOv7 | YOLOv7 | mAP 0.792 | Compares multiple CNN architectures for crack detection. | [71] |

| Transfer learning with VGG16/VGG19 | 569 images in total, including 169 of cracked eggs, 200 of empty eggs, 200 of intact eggs, RGB images, VGG16/VGG19 | VGG19 | 95.10% | Multi-class crack classification using transfer learning. | [72] | |

| Custom patch-wise CNN | Training set: 216 cracked eggs, 122 intact eggs, 1920 image patches (10,000 after augmentation, 5000 each for cracked and intact); Test set: 65 cracked eggs, 65 intact eggs, 1300 image patches, Grayscale image patches, custom CNN | Custom CNN | 95.38% | Custom CNN trained on grayscale image patches. | [73] | |

| Image stitching + MobileNetV3_egg | 800 in total (400 cracked preserved eggs, 400 intact preserved eggs); 1200 images per splicing scheme (400 of each type), Image stitching, MobileNetV3_egg | MobileNetV3_egg | 96.30% | Detects cracks in high-throughput settings using image stitching. | [74] | |

| Acoustic detection (n = 9) | FPGA-controlled tapping + IGWO optimization | 300 in total, 150 with artificially created cracks, 150 intact; 2600 signal samples (1300 each for cracked and intact), Tapping signal, IGWO optimization | IGWO-LightGBM | 96.64% | Acoustic signal detection with optimized classification. | [75] |

| Rolling acoustic signals on inclined plate | 438 in total, including 146 intact eggs, 146 hairline cracked eggs, 146 star cracked eggs, Inclined plate rolling, impulse response | Neural Network | 92.3% (Inclined plate), 94.6% (Impulse) | Dual-mode acoustic excitation for crack detection. | [76] | |

| Solenoid-driven mechanical excitation | Training set: 200 (100 cracked, 100 intact); Test set: 500 (250 brown-shelled, 250 white-shelled, 150 with cracks each), Time/frequency features, F-ratio | Neural Network | 99.20% | Acoustic signal detection with feature optimization. | [65] | |

| Defined bandwidth sound signal acquisition | Calibration group: 60 (30 cracked, 30 intact); Validation group: 66 (34 intact, 32 cracked); 300 data points for calibration group, 330 for validation group (5 taps per egg), Frequencies (1500–10,000 Hz) | Logistic Regression | Training: 89.7%, Prediction: 87.6% | Acoustic signal regression analysis for crack detection. | [63] | |

| Full-spectrum acoustic spectroscopy | 705 measurements total, 693 valid after removing incorrect files; 20 tested weekly for 6 weeks, Spectrum shape, dominant frequencies | Not specified | 97.9% (2.1% classification error) | Analyzes broadband frequency features for crack detection. | [77] | |

| Equatorial excitation acoustic impulse response | Training set: 200 (100 cracked, 100 intact); Test set: 150 (55 cracked, 95 intact); Validation experiment: 240, Frequency-domain features | SVM | 98% (up to 98.77%) | Acoustic impulse response with feature fusion. | [78] | |

| Acoustic resonance with Pearson correlation | 1st batch: 25 chicken eggs, 25 duck eggs; 2nd batch: 4 chicken eggs, 4 duck eggs; 3rd batch: 100 chicken eggs, 100 duck eggs, Pearson coefficient, MANOVA | Linear Discriminant Function | 95.50% | Mixed-species analysis using acoustic resonance. | [79] | |

| High-speed mic + CVA classifier | 60 intact eggs 59 cracked eggs 10,000 signal samples per egg, Statistical signal features | CVA, ANN, SVM | 100% (CVA) | Mechanical tapping and signal classification. | [80] | |

| Triple-directional vibration sensing | 200 total eggs (100 intact + 100 cracked) 120 calibration eggs (60 intact + 60 cracked) 80 prediction eggs (40 intact + 40 cracked), Multiple impacts, DI values | LDA | 83.75–93.75% | Vibration signal correlation analysis for crack detection. | [81] | |

| Force-assisted acoustic sweeping + PCA | 180 micro-cracked eggs, 160 intact eggs, Pressure: 5 N, Sweep: 3–7.5 kHz | LS-SVM, BPNN, PNN | LS-SVM: 98.3% (intact), 95% (cracked) | Force-assisted acoustic scanning for crack detection. | [82] | |

| Multi-sensor fusion (n = 1) | Fusion of CVS and ARS | 300 training eggs (100 intact + 100 cracked) 50 testing eggs (25 intact + 25 cracked) 200 validation eggs (100 intact + 100 cracked), Acoustic parameters + geometric vision metrics | BPANN | CVS: 68%, ARS: 92%, Fusion: 98% | Data-level fusion of computer vision and acoustic response. | [83] |

| Electrical detection (n = 2) | Static and dynamic electrical modeling | 770 total eggs (367 intact + 403 cracked) 267 duck eggs (130 intact + 137 cracked), 1500 V DC excitation, feature domains (TF, FF, WF) | Random Forest, SVM, LDA, DT | Random Forest: >99% | Electrical signal feature fusion for microcrack detection. | [66] |

| Electric discharge detection | 500 total eggs 100 medium 100 large 100 extra-large 100 jumbo 100 processed eggs, 3000 V electric pulse, 15 kHz square waveform | None (physical discharge-based logic) | High visual precision, verified by spark location | Crack detection using high-voltage scanning and electrode array. | [84] |

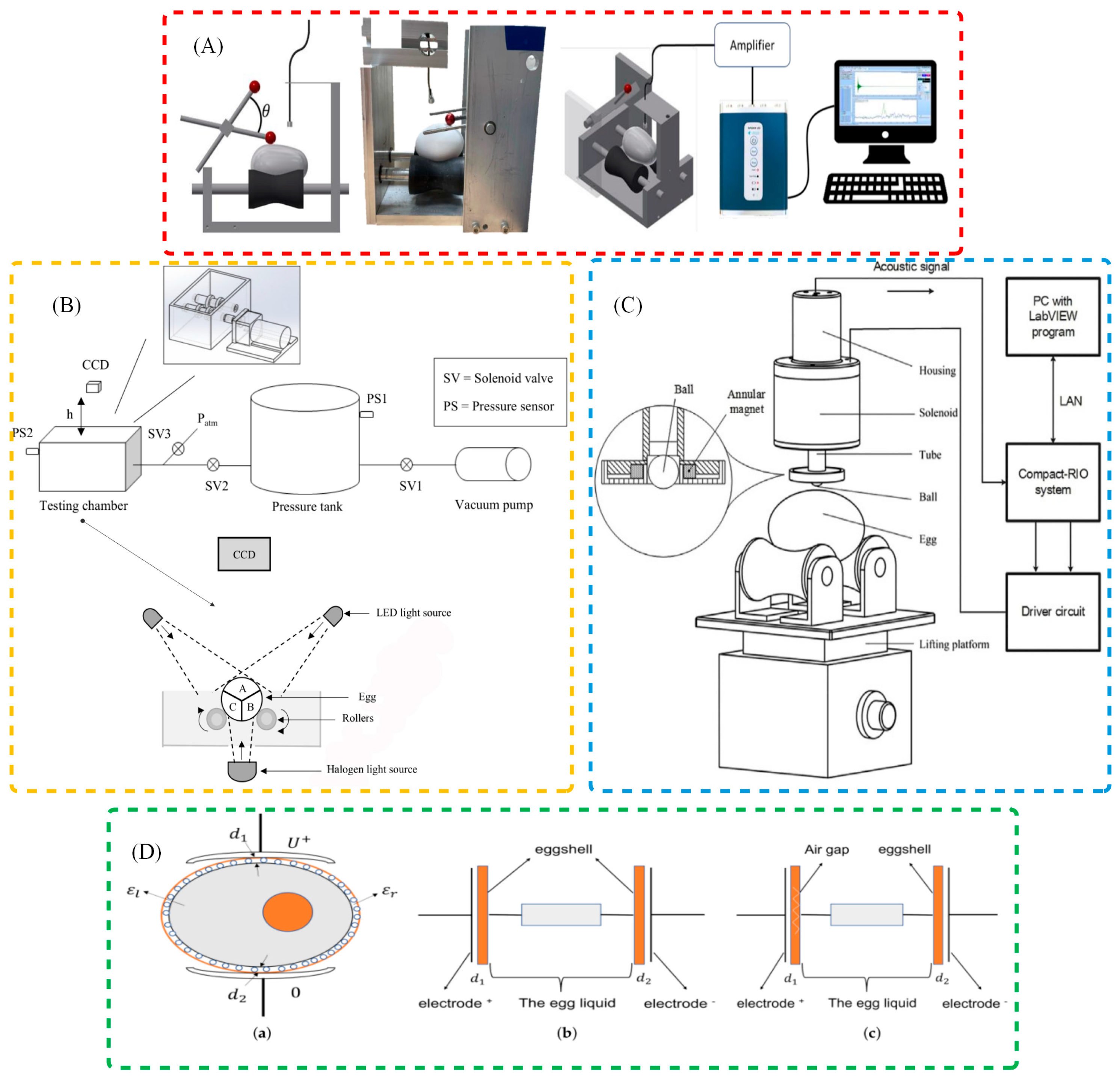

3.1. Traditional Vision for Crack Detection

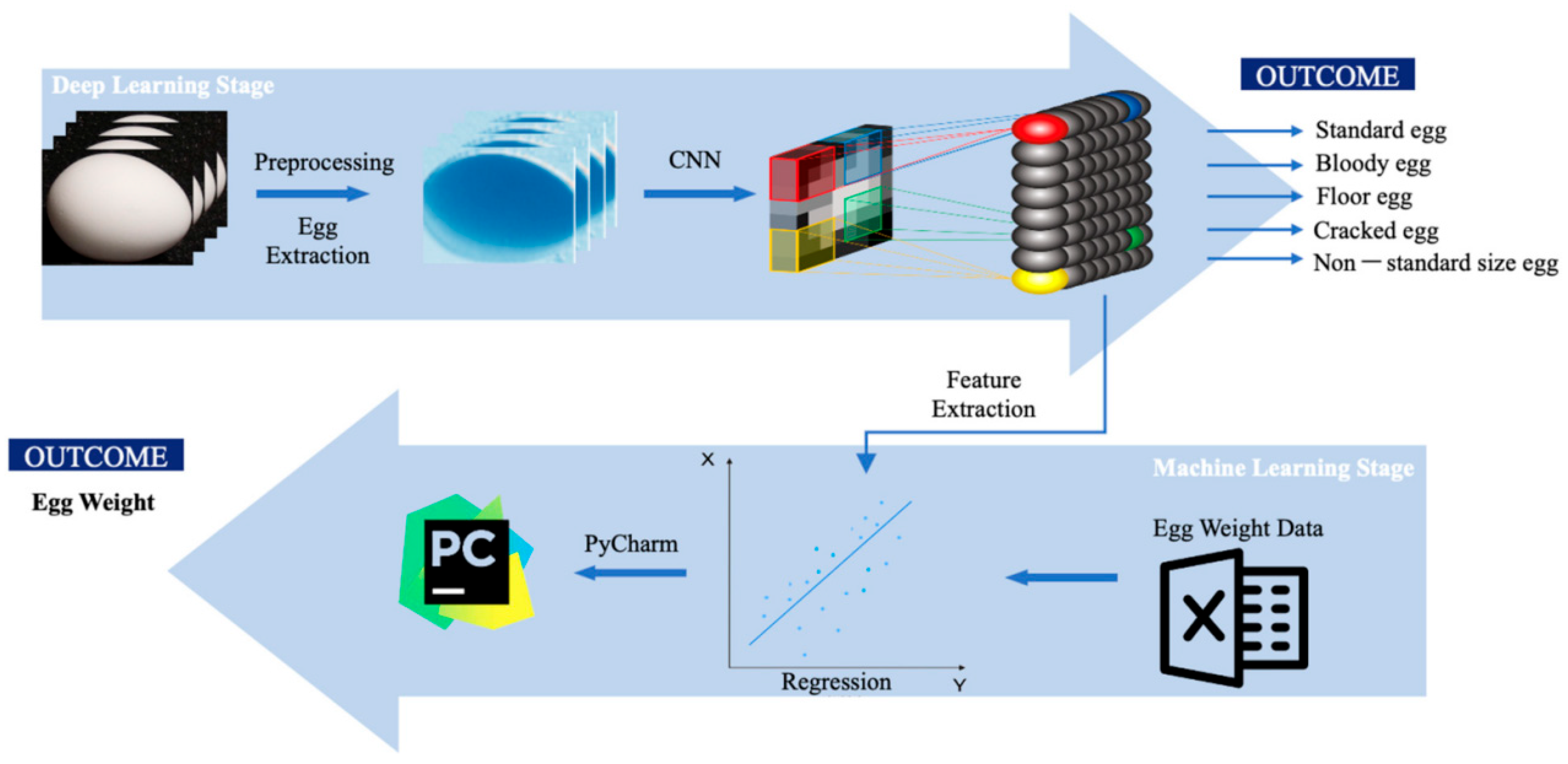

3.2. Vision and Deep Learning for Crack Detection

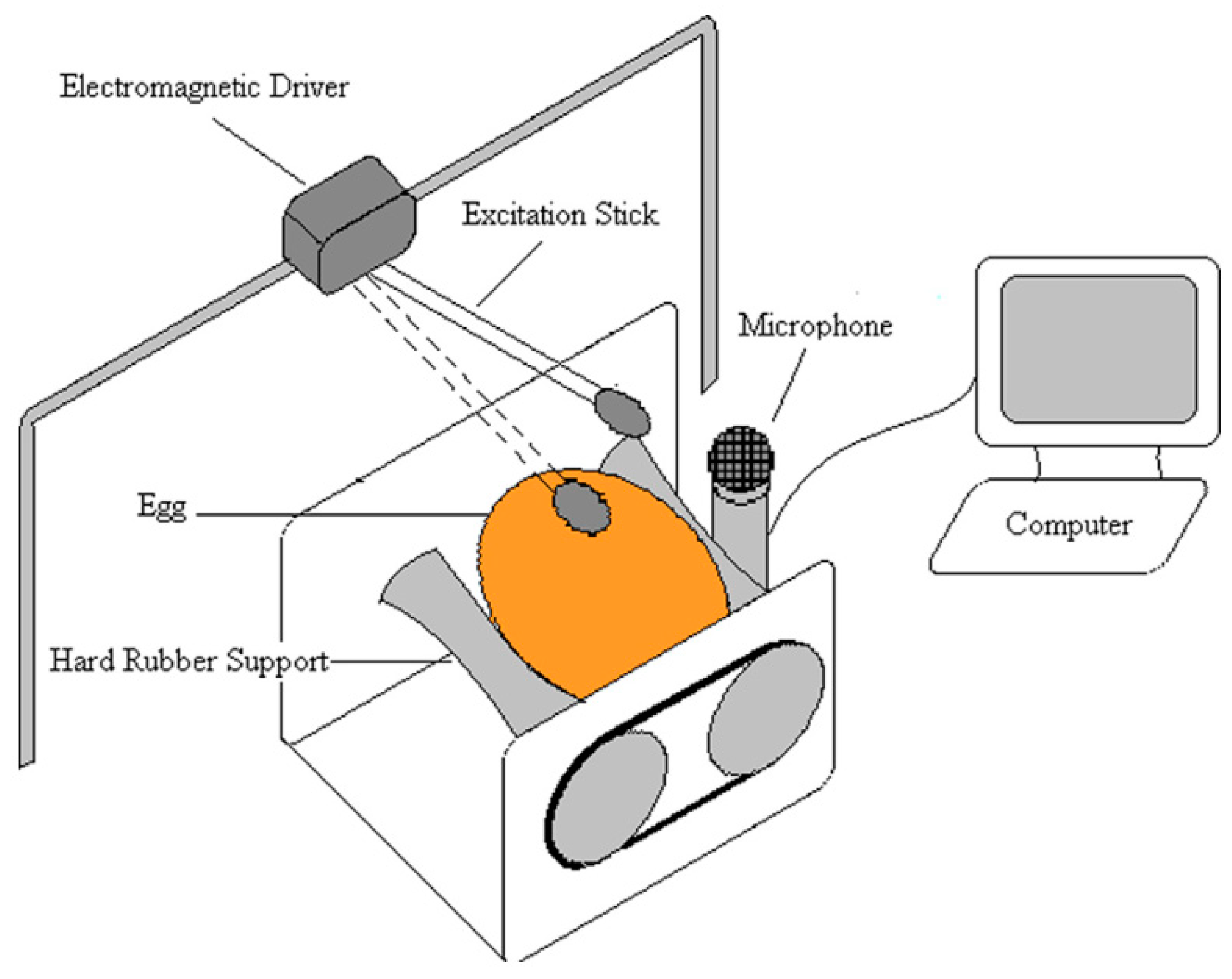

3.3. Acoustic for Crack Detection

3.4. Multi-Sensor Fusion for Crack Detection

3.5. Electrical Properties for Crack Detection

3.6. Challenges and Limitations in Industrial Implementation

4. Poultry Egg Thickness Detection

| Type | Technique | Parameters | Model | Accuracy | Explanation | Ref. |

|---|---|---|---|---|---|---|

| Acoustic detection | Non-contact acoustic resonance excitation using mechanical vibration | 30 eggs were used in the experiment, Mechanical tap excitation, microphone capture, calibration with compression tests | Linear regression of resonance vs. strength/thickness | Strength: r = 0.97, Thickness: r = 0.91 | Uses mechanical vibration to induce resonance and correlates frequency with strength and thickness. | [93] |

| Ultrasound detection | High-frequency ultrasound wave reflection technique | 180 eggs (Bovance breed, freshly produced, randomly sampled), Ultrasound transducer at equator, compared with micrometer readings | Regression vs. control (dial gauge) | Error 7.1% | Measures thickness using ultrasound reflection and compares with traditional micrometers. | [95] |

| Ultrasonic scanning at five angular positions (USG0, USG45, USG90, USG135, USG180) | 6939 eggs total 4525 Rhode Island White (RIW) 2414 Rhode Island Red (RIR), Commercial USG device, repeated measurements, compared with electronic micrometer | Heritability estimation, multiple-trait model | Repeatability >0.90, Heritability up to 0.23 | Scans eggshell thickness at multiple positions to ensure high reliability. | [96] | |

| Terahertz spectroscopy | Terahertz (THz) reflectance spectroscopy in the frequency domain | THz wave pulse (~0.2–1.2 THz), analyzed with linear regression using 1/Δf | Linear regression (1/Δf) | R2 = 0.93, RMSEP = 0.009 | Uses THz waves to measure thickness by analyzing the reflected frequency spectrum. | [94] |

| Time-domain THz spectroscopy using fiber-coupled source (0–4 THz) | Twelve egg samples were used, THz time-domain signal, verified via FESEM imaging | Spectral analysis + FESEM validation | By comparing the results with FESEM experiments, the method has been demonstrated to be relatively accurate and reliable. | Analyzes the time-domain THz signal to derive thickness and dielectric properties. | [97] | |

| Spectroscopy | Transmission VIS/NIR spectroscopy with preprocessing (MSC, derivatives) | The sample size was 70 eggs., VIS-NIR spectra (300–1100 nm) at equator, PLS regression | PLS (R2 = 0.84) | RMSE = 0.01 mm | Uses VIS/NIR spectroscopy to measure thickness with preprocessing techniques. | [98] |

| Near-infrared diffuse reflectance spectroscopy | a total of 88 pink-shelled eggs, Spectral data at three egg positions, PLS modeling with derivatives | PLS with preprocessed spectral data | Equator R = 0.69, RMSE ≈ 0.02 mm | Measures regional thickness using near-infrared spectroscopy with derivative preprocessing. | [99] |

4.1. Acoustic Resonance Method

4.2. Ultrasonic Measurement

4.3. Terahertz Spectroscopy Technology

4.4. Visible and Near-Infrared Spectroscopy (VIS/NIR) Technology

4.5. Comparative Summary of Thickness Detection Methods

5. Poultry Egg Strength Detection

5.1. Ultrasonic Method

5.2. Acoustic Resonance Method

5.3. Hertzian Contact Theory Method

5.4. Combination of NIR Spectroscopy and Artificial Intelligence (AI)

5.5. Practical Limitations and Industrial Challenges

6. Detection of Eggshell Color and Cleanliness

6.1. Color Detection and Classification

6.2. Cleanliness Detection

6.3. Limitations of Current Technologies

7. Detection of Other Indicators

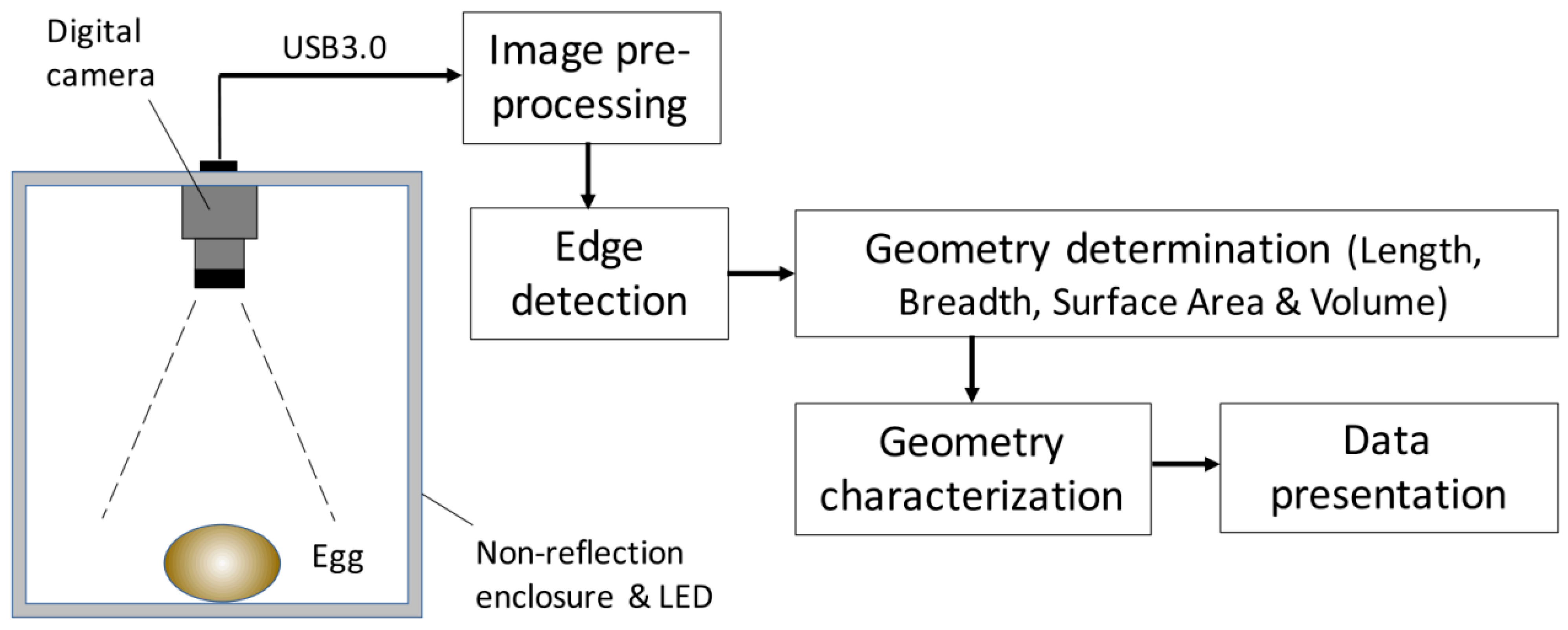

7.1. Nondestructive Measurement of Egg Volume and Surface Area

7.2. Egg Shape Index and Mechanical Properties

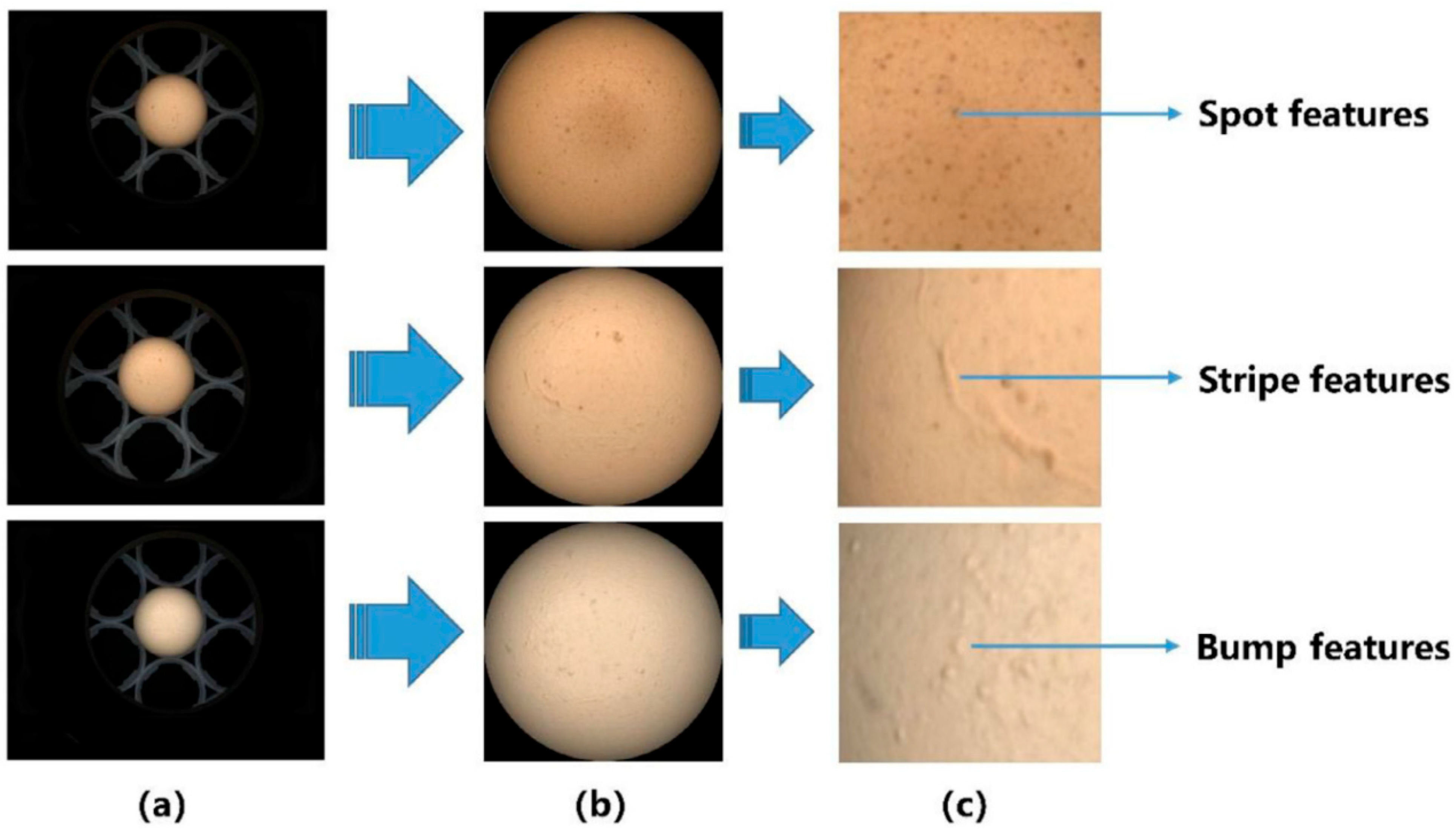

7.3. Eggshell Texture Features and Individual Identification

7.4. Practical Significance and Limitations

8. Challenges and Future Trends

9. Conclusions and Future Directions

Author Contributions

Funding

Conflicts of Interest

References

- Abebe, F.; Mulatu, H.; Kelemework, S. Review of Factors Affecting Egg Quality and Its Effect. J. Anim. Health 2023, 3, 17–32. [Google Scholar]

- Yao, K.; Sun, J.; Chen, C.; Xu, M.; Zhou, X.; Cao, Y.; Tian, Y. Non-Destructive Detection of Egg Qualities Based on Hyperspectral Imaging. J. Food Eng. 2022, 325, 111024. [Google Scholar] [CrossRef]

- Cui, H.; Ma, C.; Li, C.; Lin, L. Enhancing the Antibacterial Activity of Thyme Oil against Salmonella on Eggshell by Plasma-Assisted Process. Food Control 2016, 70, 183–190. [Google Scholar] [CrossRef]

- Lin, L.; Liao, X.; Li, C.; Abdel-Samie, M.A.; Cui, H. Inhibitory Effect of Cold Nitrogen Plasma on Salmonella Typhimurium Biofilm and Its Application on Poultry Egg Preservation. LWT-Food Sci. Technol. 2020, 126, 109340. [Google Scholar] [CrossRef]

- Shi, J.; Liang, J.; Pu, J.; Li, Z.; Zou, X. Nondestructive Detection of the Bioactive Components and Nutritional Value in Restructured Functional Foods. Curr. Opin. Food Sci. 2023, 50, 100986. [Google Scholar] [CrossRef]

- Zhu, Y.; Ma, Z.; Han, M.; Li, Y.; Xing, L.; Lu, E.; Gao, H. Quantitative Damage Detection of Direct Maize Kernel Harvest Based on Image Processing and BP Neural Network. Food Sci. Technol. 2022, 42, e54322. [Google Scholar] [CrossRef]

- Hongyang, T.; Daming, H.; Xingyi, H.; Aheto, J.H.; Yi, R.; Yu, W.; Ji, L.; Shuai, N.; Mengqi, X. Detection of Browning of Fresh-cut Potato Chips Based on Machine Vision and Electronic Nose. J. Food Process Eng. 2021, 44, e13631. [Google Scholar] [CrossRef]

- Huang, X.; Yu, S.; Xu, H.; Aheto, J.H.; Bonah, E.; Ma, M.; Wu, M.; Zhang, X. Rapid and Nondestructive Detection of Freshness Quality of Postharvest Spinaches Based on Machine Vision and Electronic Nose. J. Food Saf. 2019, 39, e12708. [Google Scholar] [CrossRef]

- Wang, H.; Gu, J.; Wang, M. A Review on the Application of Computer Vision and Machine Learning in the Tea Industry. Front. Sustain. Food Syst. 2023, 7, 1172543. [Google Scholar] [CrossRef]

- Tingting, S.; Xiaobo, Z.; Jiyong, S.; Zhihua, L.; Xiaowei, H.; Yiwei, X.; Wu, C. Determination Geographical Origin and Flavonoids Content of Goji Berry Using Near-Infrared Spectroscopy and Chemometrics. Food Anal. Methods 2016, 9, 68–79. [Google Scholar] [CrossRef]

- Zareef, M.; Chen, Q.; Hassan, M.M.; Arslan, M.; Hashim, M.M.; Ahmad, W.; Kutsanedzie, F.Y.H.; Agyekum, A.A. An Overview on the Applications of Typical Non-Linear Algorithms Coupled With NIR Spectroscopy in Food Analysis. Food Eng. Rev. 2020, 12, 173–190. [Google Scholar] [CrossRef]

- Lin, H.; Jiang, H.; Lin, J.; Chen, Q.; Ali, S.; Teng, S.W.; Zuo, M. Rice Freshness Identification Based on Visible Near-Infrared Spectroscopy and Colorimetric Sensor Array. Food Anal. Methods 2021, 14, 1305–1314. [Google Scholar] [CrossRef]

- Jun, S.; Yaoyao, M.; Hui, J.; Obadi, M.; Zhongwei, C.; Bin, X. Effects of Single- and Dual-Frequency Ultrasound on the Functionality of Egg White Protein. J. Food Eng. 2020, 277, 109902. [Google Scholar] [CrossRef]

- Zhou, C.; Okonkwo, C.E.; Inyinbor, A.A.; Yagoub, A.E.A.; Olaniran, A.F. Ultrasound, Infrared and Its Assisted Technology, a Promising Tool in Physical Food Processing: A Review of Recent Developments. Crit. Rev. Food Sci. Nutr. 2023, 63, 1587–1611. [Google Scholar] [CrossRef]

- Du, Z.; Hu, Y.; Buttar, N.A.; Mahmood, A. X-Ray Computed Tomography for Quality Inspection of Agricultural Products: A Review. Food Sci. Nutr. 2019, 7, 3146–3160. [Google Scholar] [CrossRef]

- Fakhlaei, R.; Babadi, A.A.; Sun, C.; Ariffin, N.M.; Khatib, A.; Selamat, J.; Xiaobo, Z. Application, Challenges and Future Prospects of Recent Nondestructive Techniques Based on the Electromagnetic Spectrum in Food Quality and Safety. Food Chem. 2024, 441, 138402. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Xu, B.; Sun, J.; Mujumdar, A.S. Artificial Intelligence Assisted Technologies for Controlling the Drying of Fruits and Vegetables Using Physical Fields: A Review. Trends Food Sci. Technol. 2020, 105, 251–260. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Qenawy, M.; Ali, M.; Hu, Z.; Adelusi, O.A.; Njobeh, P.B. Artificial Intelligence as a Tool for Predicting the Quality Attributes of Garlic (Allium sativum L.) Slices during Continuous Infrared-assisted Hot Air Drying. J. Food Sci. 2024, 89, 7693–7712. [Google Scholar] [CrossRef]

- Wu, P.; Lei, X.; Zeng, J.; Qi, Y.; Yuan, Q.; Huang, W.; Ma, Z.; Shen, Q.; Lyu, X. Research Progress in Mechanized and Intelligentized Pollination Technologies for Fruit and Vegetable Crops. Int. J. Agric. Biol. Eng. 2024, 17, 11–21. [Google Scholar] [CrossRef]

- Huang, Y.; Xiong, J.; Li, Z.; Hu, D.; Sun, Y.; Jin, H.; Zhang, H.; Fang, H. Recent Advances in Light Penetration Depth for Postharvest Quality Evaluation of Fruits and Vegetables. Foods 2024, 13, 2688. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Sun, Q.; Cai, J.; Wu, Z.; Ding, W. Online Detection of Eggshell Cracks Using Adaptive Light-source Intensity. J. Food Process Eng. 2024, 47, e14566. [Google Scholar] [CrossRef]

- Memon, M.S.; Chen, S.; Shen, B.; Liang, R.; Tang, Z.; Wang, S.; Zhou, W.; Memon, N. Automatic Visual Recognition, Detection and Classification of Weeds in Cotton Fields Based on Machine Vision. Crop Prot. 2025, 187, 106966. [Google Scholar] [CrossRef]

- Qiu, D.; Guo, T.; Yu, S.; Liu, W.; Li, L.; Sun, Z.; Peng, H.; Hu, D. Classification of Apple Color and Deformity Using Machine Vision Combined with CNN. Agriculture 2024, 14, 978. [Google Scholar] [CrossRef]

- Yang, N.; Yuan, M.; Wang, P.; Zhang, R.; Sun, J.; Mao, H. Tea Diseases Detection Based on Fast Infrared Thermal Image Processing Technology. J. Sci. Food Agric. 2019, 99, 3459–3466. [Google Scholar] [CrossRef]

- Kim, H.; Choi, Y.; Song, S.; Park, M.; Jang, A. Current Advances in Detection of Abnormal Egg: A Review. J. Anim. Sci. Technol. 2022, 64, 813–829. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Zhang, P.; Feng, S.; Qiang, M.; Cai, J. Eggshell Crack Detection Based on the Transient Impact Analysis and Cross-Correlation Method. Curr. Res. Food Sci. 2021, 4, 716–723. [Google Scholar] [CrossRef]

- Choi, W.-K.; Lee, K.-J.; Son, J.-R.; Lee, H.-Y.; Kim, H.-J. Automated Inspection System for On-Line Detection of Cracked Eggs. In Proceedings of the Food Processing Automation Conference Proceedings, Providence, RI, USA, 28–29 June 2008; p. 701P0508cd. [Google Scholar] [CrossRef]

- Mao, H.; Kumi, F.; Li, Q.; Han, L. Combining X-Ray Computed Tomography with Relevant Techniques for Analyzing Soil–Root Dynamics—An Overview. Acta Agric. Scand. B Soil. Plant Sci. 2016, 66, 1–19. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, Z. Assessment of Apple Bruise Resistance under Transient Collisions through X-Ray Computed Tomography and Image Processing. Biosyst. Eng. 2024, 244, 16–25. [Google Scholar] [CrossRef]

- Dhiman, T.; Lakshmi, G.; Kumar, R.; Asokan, K.; Solanki, P. Non-Enzymatic Detection of Glucose Using a Capacitive Nanobiosensor Based on PVA Capped CuO Synthesized via Co-Precipitation Route. IEEE Sens. J. 2020, 20, 10415–10423. [Google Scholar] [CrossRef]

- Zhang, B.; Zheng, T.; You, J.; Ma, C.; Liu, Y.; Zhang, L.; Xi, J.; Dong, G.; Liu, M.; Liu, S. Electron-Phonon Coupling Suppression by Enhanced Lattice Rigidity in 2D Perovskite Single Crystals for High-Performance X-Ray Detection. Adv. Mater. 2022, 35, 2208875. [Google Scholar] [CrossRef]

- Ito, Y.; Uomoto, T. Nondestructive Testing Method of Concrete Using Impact Acoustics. NDT E Int. 1997, 30, 217–222. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, W.; Li, Y.; Ou, M. Method for Estimating Canopy Thickness Using Ultrasonic Sensor Technology. Agriculture 2021, 11, 1011. [Google Scholar] [CrossRef]

- Zhao, Z.; Wei, H.; Liu, S.; Xue, Z. Estimation of Agricultural Soil Surface Roughness Based on Ultrasonic Echo Signal Characteristics. Soil. Tillage Res. 2024, 239, 106038. [Google Scholar] [CrossRef]

- Chen, J.; Song, J.; Guan, Z.; Lian, Y. Measurement of the Distance from Grain Divider to Harvesting Boundary Based on Dynamic Regions of Interest. Int. J. Agric. Biol. Eng. 2021, 14, 226–232. [Google Scholar] [CrossRef]

- Jin, J.; Moreno, M.G.; Rivière, J.; Shokouhi, P. Impact-Based Nonlinear Acoustic Testing for Characterizing Distributed Damage in Concrete. J. Nondestruct. Eval. 2017, 36, 51. [Google Scholar] [CrossRef]

- Kitamura, K.; Nomura, H. Feasibility of Nondestructive Testing Using Transient Vibrations Excited by Acoustic Radiation Force. Jpn. J. Appl. Phys. 2023, 62, SJ1013. [Google Scholar] [CrossRef]

- Mertens, K.; Bamelis, F.; Kemps, B.; Kamers, B.; Verhoelst, E.; De Ketelaere, B.; Bain, M.; Decuypere, E.; De Baerdemaeker, J. Monitoring of eggshell breakage and eggshell strength in different production chains of consumption eggs. Poult. Sci. 2006, 85, 1670–1677. [Google Scholar] [CrossRef] [PubMed]

- Sabuncu, M.; Akdoğan, M. Utilizing optical coherence tomography in the nondestructive and noncontact measurement of egg shell thickness. Sci. World J. 2014, 2014, 205191. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jiang, H.; Wu, J.; Shi, J.; Peng, Y. External Characteristic Determination of Eggs and Cracked Eggs Using Hyperspectral Imaging Techniques. Sci. Rep. 2016, 6, 21130. [Google Scholar]

- Radwan, L.M.; Galal, A.; Shemeis, A.R. Prediction of Eggshell Ultrastructure via Some Non-destructive and Destructive Measurements in Fayoumi Breed. Asian-Australas. J. Anim. Sci. 2015, 28, 993–998. [Google Scholar] [CrossRef][Green Version]

- Yao, K.; Sun, J.; Zhou, X.; Nirere, A.; Tian, Y.; Wu, X. Nondestructive Detection for Egg Freshness Grade Based on Hyperspectral Imaging Technology. J. Food Process Eng. 2020, 43, e13422. [Google Scholar] [CrossRef]

- Afraz, M.T.; Khan, M.R.; Roobab, U.; Noranizan, M.A.; Tiwari, B.K.; Rashid, M.T.; Inam-ur-Raheem, M.; Hashemi, S.M.B.; Aadil, R.M. Impact of Novel Processing Techniques on the Functional Properties of Egg Products and Derivatives: A Review. J. Food Process Eng. 2020, 43, e13568. [Google Scholar] [CrossRef]

- Wang, B.; Wei, W.; Aputexiakere, J.; Li, Y.; Ma, H. Surface Decontamination of Whole Eggs Using Pulsed Light Technology and Shelf Life Study of Combined Pulsed Light and Vaseline Coating during Room Temperature Storage. Food Control 2022, 137, 108411. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, B.; Cai, J.; Xu, Y.; Lu, F.; Ma, H. Inspection and Classification of Wheat Quality Using Image Processing. Qual. Assur. Saf. Crops Foods. 2023, 15, 43–54. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, J.; Chen, Q.; Cai, J.; Zhou, P. Eggshell Crack Detection Based on Acoustic Impulse Response and Supervised Pattern Recognition. Czech J. Food Sci. 2009, 27, 393–402. [Google Scholar] [CrossRef]

- Zhang, D.; Hao, X.; Liang, L.; Liu, W.; Qin, C. A Novel Deep Convolutional Neural Network Algorithm for Surface Defect Detection. J. Comput. Des. Eng. 2022, 9, 1616–1632. [Google Scholar] [CrossRef]

- Khanam, R.; Hussain, M.; Hill, R.; Allen, P. A Comprehensive Review of Convolutional Neural Networks for Defect Detection in Industrial Applications. IEEE Access 2024, 12, 94250–94295. [Google Scholar] [CrossRef]

- Sun, J.; Nirere, A.; Dusabe, K.D.; Yuhao, Z.; Adrien, G. Rapid and Nondestructive Watermelon (Citrullus lanatus) Seed Viability Detection Based on Visible Near-infrared Hyperspectral Imaging Technology and Machine Learning Algorithms. J. Food Sci. 2024, 89, 4403–4418. [Google Scholar] [CrossRef] [PubMed]

- Nordstrom, J.O.; Ousterhout, L.E. Estimation of Shell Weight and Shell Thickness from Egg Specific Gravity and Egg Weight. Poult. Sci. 1982, 61, 1991–1995. [Google Scholar] [CrossRef]

- Arzate-Vázquez, I.; Méndez-Méndez, J.V.; Flores-Johnson, E.A.; Nicolás-Bermúdez, J.; Chanona-Pérez, J.J.; Santiago-Cortés, E. Study of the Porosity of Calcified Chicken Eggshell Using Atomic Force Microscopy and Image Processing. Micron 2019, 118, 50–57. [Google Scholar] [CrossRef]

- Attard, M.R.G.; Bowen, J.; Portugal, S.J. Surface Texture Heterogeneity in Maculated Bird Eggshells. J. R. Soc. Interface 2023, 20, 20230293. [Google Scholar] [CrossRef]

- Kang, H.; Hu, Y.; Kaewunruen, S.; Hu, X.; Zhang, J. Geometric and Mechanical Analysis of Selenium-Enriched Eggs. J. Mar. Sci. Eng. 2025, 13, 525. [Google Scholar] [CrossRef]

- Wang, L.C.; Ruan, Z.; Wu, Z.W.; Yu, Q.; Chen, F.; Zhang, X.F.; Zhang, F.; Linhardt, R.; Liu, Z.G. Geometrical Characteristics of Eggs from 3 Poultry Species. Poult. Sci. 2020, 100, 100965. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira-Boreli, F.P.; Pereira, D.; Gonçalves, J.; da Silva, V.Z.; Nääs, I.A. Non-Destructive Assessment of Hens’ Eggs Quality Using Image Analysis and Machine Learning. Smart Agric. Technol. 2023, 4, 100161. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Guo, Y.; Li, W.; Song, J.; Xu, G.; Yang, N.; Zheng, J. Impact of Cuticle Quality and Eggshell Thickness on Egg Antibacterial Efficiency. Poult. Sci. 2019, 98, 940–948. [Google Scholar] [CrossRef]

- Makover, V.; Ronen, Z.; Lubin, Y.; Khalaila, I. Eggshell Spheres Protect Brown Widow Spider (Latrodectus geometricus) Eggs from Bacterial Infection. J. R. Soc. Interface 2019, 16, 20180581. [Google Scholar] [CrossRef]

- Min, L.; Gao, L.; Zhang, X.; Wang, Z. Surface Roughness Measurement Based on Image Texture Analysis. In Proceedings of the 2014 7th International Congress on Image and Signal Processing, Dalian, China, 14–16 October 2014; pp. 514–519. [Google Scholar]

- Peebles, E.; Brake, J. Relationship of Eggshell Porosity to Stage of Embryonic Development in Broiler Breeders. Poult. Sci. 1985, 64, 2388–2391. [Google Scholar] [CrossRef]

- Ar, A.; Rahn, H. Pores in Avian Eggshells: Gas Conductance, Gas Exchange and Embryonic Growth Rate. Respir. Physiol. 1985, 61, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Arai, F.; Kawahara, T. Egg-in-Cube: Design and Fabrication of a Novel Artificial Eggshell with Functionalized Surface. PLoS ONE 2015, 10, e0118624. [Google Scholar] [CrossRef] [PubMed]

- Damaziak, K.; Marzec, A.; Riedel, J.; Wójcik, W.; Pstrokoński, P.; Szudrowicz, H.; Gozdowski, D. Effect of Pearl Guinea Fowl Eggshell Ultrastructure and Microstructure on Keets Hatchability. Poult. Sci. 2023, 102, 102733. [Google Scholar] [CrossRef]

- 63Lai, C.-C.; Li, C.-H.; Huang, K.-J.; Cheng, C.-W. Duck Eggshell Crack Detection by Nondestructive Sonic Measurement and Analysis. Sensors 2021, 21, 7299. [Google Scholar] [CrossRef]

- Priyadumkol, J.; Kittichaikarn, C.; Thainimit, S. Crack Detection on Unwashed Eggs Using Image Processing. J. Food Eng. 2017, 209, 76–82. [Google Scholar] [CrossRef]

- Wang, H.; Mao, J.; Zhang, J.; Jiang, H.; Wang, J. Acoustic Feature Extraction and Optimization of Crack Detection for Eggshell. J. Food Eng. 2016, 171, 240–247. [Google Scholar] [CrossRef]

- Shi, C.; Wang, Y.; Zhang, C.; Yuan, J.; Cheng, Y.; Jia, B.; Zhu, C. Nondestructive Detection of Microcracks in Poultry Eggs Based on the Electrical Characteristics Model. Agriculture 2022, 12, 1137. [Google Scholar] [CrossRef]

- Jones, D.R.; Lawrence, K.C.; Yoon, S.C.; Heitschmidt, G.W. Modified Pressure Imaging for Egg Crack Detection and Resulting Egg Quality. Poult. Sci. 2010, 89, 761–765. [Google Scholar] [CrossRef]

- Li, F.; Zhang, Z.N. Detection Method of Egg Shell Crack Based on Image Processing. In Proceedings of the International Conference on Image, Signal Processing, and Pattern Recognition (ISPP 2023), Changsha, China, 8 June 2023; Batista, P., Bilas Pachori, R., Eds.; SPIE: Bellingham, WA, USA, 2023; p. 37. [Google Scholar]

- Abbaspour-Gilandeh, Y.; Azizi, A. Identification of Cracks in Eggs Shell Using Computer Vision and Hough Transform. YYU J. Agric. Sci. 2018, 28, 375–383. [Google Scholar] [CrossRef]

- Xiong, L.R.; Zhu, Z.H. An Identification Method for Cracked Eggs Based on Image Wavelet Transform and Multi-Features Synthesis. Appl. Mech. Mater. 2014, 704, 412–418. [Google Scholar] [CrossRef]

- Caballero, R.G.; Gucor, J.R.; Talledo, R.D.P.; Montemayor, J.J.M.; Maulana, M.M. Crack Detection on Duck Eggs Using CNN. Procedia Comput. Sci. 2025, 257, 631–636. [Google Scholar] [CrossRef]

- Taspinar, Y.S.; Cinar, I. Detection of Broken Eggs with Deep CNNs and Performance Analysis of Models. In Proceedings of the 2023 IEEE 12th International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Dortmund, Germany, 7–9 September 2023; pp. 724–728. [Google Scholar]

- Botta, B.; Gattam, S.S.R.; Datta, A.K. Eggshell Crack Detection Using Deep Convolutional Neural Networks. J. Food Eng. 2022, 315, 110798. [Google Scholar] [CrossRef]

- Tang, W.; Hu, J.; Wang, Q. High-Throughput Online Visual Detection Method of Cracked Preserved Eggs Based on Deep Learning. Appl. Sci. 2022, 12, 952. [Google Scholar] [CrossRef]

- Huang, S.; Wei, Y.; Zhang, L.; Yu, Y.; Shi, W. A Study on Duck Eggshell Crack Detection Method. In Proceedings of the Third International Conference on Machine Vision, Automatic Identification, and Detection (MVAID 2024), Kunming, China, 26–28 April 2024; Jin, R., Ed.; SPIE: Bellingham, WA, USA, 2024; p. 55. [Google Scholar]

- Lashgari, M.; Mohammadigol, R. Comparative Study of Acoustic Signals of Rolling Eggs on Inclined Plate and Impulse Response in Eggshell Crack Detection. Agric. Eng. Int. CIGR J. 2018, 20, 150–156. [Google Scholar]

- Kertész, I.; Zsom-Muha, V.; András, R.; Horváth, F.; Németh, C.; Felföldi, J. Development of a Novel Acoustic Spectroscopy Method for Detection of Eggshell Cracks. Molecules 2021, 26, 4693. [Google Scholar] [CrossRef]

- Deng, X.; Wang, Q.; Wu, L.; Gao, H.; Wen, Y.; Wang, S. Eggshell Crack Detection by Acoustic Impulse Response and Support Vector Machine. Adv. Agric. Agric. Sci. 2018, 4, 40–48. [Google Scholar]

- Sun, L.; Feng, S.; Chen, C.; Liu, X.; Cai, J. Identification of Eggshell Crack for Hen Egg and Duck Egg Using Correlation Analysis Based on Acoustic Resonance Method. J. Food Process Eng. 2020, 43, e13430. [Google Scholar] [CrossRef]

- Yumurtaci, M.; Balci, Z.; Ergin, S.; Yabanova, İ. The detection of eggshell cracks using different classifiers. Eskişehir Tech. Univ. J. Sci. Tech. Appl. Sci. Eng. 2022, 23, 161–172. [Google Scholar] [CrossRef]

- Lin, H.; Xu, P.; Sun, L.; Bi, X.; Zhao, J.; Cai, J. Identification of Eggshell Crack Using Multiple Vibration Sensors and Correlative Information Analysis. J. Food Process Eng. 2018, 41, e12894. [Google Scholar] [CrossRef]

- Luo, H.; Yan, S.; Lu, W.; Zhang, C.; Dai, D. Micro-cracked Eggs Online Detection Method Based on Force-Acoustic Features. Trans. Chin. Soc. Agric. Eng. 2016, 47, 224–230. [Google Scholar] [CrossRef]

- Pan, L.; Zhan, G.; Tu, K.; Tu, S.; Liu, P. Eggshell Crack Detection Based on Computer Vision and Acoustic Response by Means of Back-Propagation Artificial Neural Network. Eur. Food Res. Technol. 2011, 233, 457–463. [Google Scholar] [CrossRef]

- Joe, S.Y.; So, J.H.; Oh, S.E.; Jun, S.; Lee, S.H. Development of Cracked Egg Detection Device Using Electric Discharge Phenomenon. Foods 2024, 13, 2989. [Google Scholar] [CrossRef]

- You, J.; Li, D.; Wang, Z.; Chen, Q.; Ouyang, Q. Prediction and Visualization of Moisture Content in Tencha Drying Processes by Computer Vision and Deep Learning. J. Sci. Food Agric. 2024, 104, 5486–5494. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Liu, J.; Yue, R.; Zhang, T.; Yao, M.; Li, J. Method for the Navigation Line Recognition of the Ridge without Crops via Machine Vision. Int. J. Agric. Biol. Eng. 2024, 17, 230–239. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Liu, W.; Yue, R.; Shi, J.; Zhou, C.; Hu, J. SN-CNN: A Lightweight and Accurate Line Extraction Algorithm for Seedling Navigation in Ridge-Planted Vegetables. Agriculture 2024, 14, 1446. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Zhang, Y.; Zhou, J.; Wu, J.; Li, P. Real-Time Detection and Location of Potted Flowers Based on a ZED Camera and a YOLO V4-Tiny Deep Learning Algorithm. Horticulturae 2021, 8, 21. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Hu, X.; Li, Z.; Huang, X.; Liang, J.; Zhang, X.; Zheng, K.; Zou, X.; Shi, J. Nondestructive Discrimination of Analogous Density Foreign Matter inside Soy Protein Meat Semi-Finished Products Based on Transmission Hyperspectral Imaging. Food Chem. 2023, 411, 135431. [Google Scholar] [CrossRef]

- Yu, S.; Huang, X.; Wang, L.; Chang, X.; Ren, Y.; Zhang, X.; Wang, Y. Qualitative and Quantitative Assessment of Flavor Quality of Chinese Soybean Paste Using Multiple Sensor Technologies Combined with Chemometrics and a Data Fusion Strategy. Food Chem. 2023, 405, 134859. [Google Scholar] [CrossRef]

- Adade, S.Y.-S.S.; Lin, H.; Johnson, N.A.N.; Nunekpeku, X.; Aheto, J.H.; Ekumah, J.-N.; Kwadzokpui, B.A.; Teye, E.; Ahmad, W.; Chen, Q. Advanced Food Contaminant Detection through Multi-Source Data Fusion: Strategies, Applications, and Future Perspectives. Trends Food Sci. Technol. 2025, 156, 104851. [Google Scholar] [CrossRef]

- Shi, C.; Cheng, Y.; Zhang, C.; Yuan, J.; Wang, Y.; Jiang, X.; Zhu, C. Wavelet Scattering Convolution Network-Based Detection Algorithm on Nondestructive Microcrack Electrical Signals of Eggs. Agriculture 2023, 13, 730. [Google Scholar] [CrossRef]

- Attar, M.Z.; Fathi, M.M. Non-Destructive Acoustic Resonance Method for Evaluating Eggshell Strength and Thickness. Int. J. Biophys. 2014, 4, 9–15. [Google Scholar]

- Khaliduzzaman, A.; Konagaya, K.; Suzuki, T.; Kashimori, A.; Kondo, N.; Ogawa, Y. A Nondestructive Eggshell Thickness Measurement Technique Using Terahertz Waves. Sci. Rep. 2020, 10, 1052. [Google Scholar] [CrossRef]

- Amini, S.; MohamadZamani, D.; Javidan, S.M. Investigation of the Relationship Between Egg Shell Strength and Thickness Using Non-Destructive Ultrasound Method. J. Biosyst. Eng. 2022, 47, 263–269. [Google Scholar] [CrossRef]

- Kibala, L.; Rozempolska-Rucinska, I.; Kasperek, K.; Zieba, G.; Lukaszewicz, M. Ultrasonic Eggshell Thickness Measurement for Selection of Layers. Poult. Sci. 2015, 94, 2360–2363. [Google Scholar] [CrossRef]

- Iram, J.; Kumar, N.; Basha, A.; Chaudhary, A.K.; Jaleeli, K.; Purshotham, R. Use of Time-Domain Terahertz (THz) Spectroscopy for the Measurement of Thickness, Optical, and Dielectric Parameters of Table and Fertile Eggshells. Res. Sq. 2025, rs-5789303/v1. [Google Scholar] [CrossRef]

- Dong, X.; Tang, X.; Peng, Y.; Dong, J. Nondestructive Assessment of Eggshell Thickness by VIS/NIR Spectroscopy. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017; p. 1700888. [Google Scholar] [CrossRef]

- Han, Y.; Yu, Y.; Zhang, Q.; Dong, G.; Li, L. Research on the Detection and Analysis Method of Thickness of Different Parts of Eggshell Based on Near-infrared Spectroscopy. J. Mech. Eng. Technol. 2024, 53, 261–263. [Google Scholar] [CrossRef]

- Ou, M.; Hu, T.; Hu, M.; Yang, S.; Jia, W.; Wang, M.; Jiang, L.; Wang, X.; Dong, X. Experiment of Canopy Leaf Area Density Estimation Method Based on Ultrasonic Echo Signal. Agriculture 2022, 12, 1569. [Google Scholar] [CrossRef]

- Tong, Y.; Wang, S.; Han, K.; Song, X.; Zhang, W.; Ye, Y.; Ren, X. Development of a Novel Metal Grating and Its Applications of Terahertz Spectroscopic Detection of CuSO4 in Fruit. Food Anal. Methods 2021, 14, 1590–1599. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, P.; Mao, H.; Gao, H.; Li, Q. Detection of the Nutritional Status of Phosphorus in Lettuce Using THz Time-Domain Spectroscopy. Eng. Agríc. 2021, 41, 599–608. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, J.; Sun, L.; Chen, Q.; Sun, Z.; Zhou, F. Stiffness Measurement of Eggshell by Acoustic Resonance and PLS Models. J. Food Eng. 2011, 103, 351–356. [Google Scholar] [CrossRef]

- De Ketelaere, B.; Corion, M.; Adriaens, I.; Van Liedekerke, P.; Saeys, W. Non-Destructive Eggshell Strength Assessment Using Hertz Contact Theory—Part II: Implementation and Validation. Foods 2023, 12, 1340. [Google Scholar] [CrossRef]

- Ahmed, M.W.; Alam, S.; Khaliduzzaman, A.; Emmert, J.L.; Kamruzzaman, M. Non-destructive Measurement of Eggshell Strength Using NIR Spectroscopy and Explainable Artificial Intelligence. J. Sci. Food Agric. 2025, 105, 5550–5562. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, M.; Shujat, A.; Wu, J.; El-Seedi, H.R.; Shi, J.; Ouyang, Q.; Chen, Q.; Zou, X. Nondestructive Monitoring Storage Quality of Apples at Different Temperatures by Near-infrared Transmittance Spectroscopy. Food Sci. Nutr. 2020, 8, 3793–3805. [Google Scholar] [CrossRef]

- Vasileva, A.V.; Gorbunova, E.V.; Vasilev, A.S.; Peretyagin, V.S.; Chertov, A.N.; Korotaev, V.V. Assessing Exterior Egg Quality Indicators Using Machine Vision. Br. Poult. Sci. 2018, 59, 636–645. [Google Scholar] [CrossRef]

- Gorbunova, E.V.; Chertov, A.N.; Peretyagin, V.S.; Korotaev, V.V.; Arbuzova, E.A. Express Quality Control of Chicken Eggs by Machine Vision. In Automated Visual Inspection and Machine Vision II, Proceedings of the SPIE Optical Metrology, Munich, Germany, 25–29 June 2017; Beyerer, J., Puente León, F., Eds.; SPIE: Bellingham, WA, USA, 2017; Volume 10334, p. 103340U. [Google Scholar] [CrossRef]

- Drabik, K.; Karwowska, M.; Wengerska, K.; Próchniak, T.; Adamczuk, A.; Batkowska, J. The Variability of Quality Traits of Table Eggs and Eggshell Mineral Composition Depending on Hens’ Breed and Eggshell Color. Animals 2021, 11, 1204. [Google Scholar] [CrossRef]

- Beyaz, A.; Özlü, S.; Gerdan, D. Experimental Recognition System for Dirty Eggshell by Using Image Analysis Technique. Turk. J. Agric.-Food Sci. Technol. 2020, 8, 1122–1126. [Google Scholar] [CrossRef]

- 111Wang, C.; Zhou, J.; Wu, H.; Li, J.; Chunjiang, Z.; Liu, R. Research on the Evaluation Method of Eggshell Dark Spots Based on Machine Vision. IEEE Access 2020, 8, 160116–160125. [Google Scholar] [CrossRef]

- 112Wong, H.C.; Ng, E.Y.; Cheng, L.-H.; Gun, S.; Yen, K.S. Classification of Inhomogeneous Eggshell-Mottling Patterns Using a Pretrained Convolutional Neural Network. J. Electron. Imag. 2020, 29, 013013. [Google Scholar] [CrossRef]

- Yang, X.; Bist, R.B.; Subedi, S.; Chai, L. A Computer Vision-Based Automatic System for Egg Grading and Defect Detection. Animals 2023, 13, 2354. [Google Scholar] [CrossRef]

- Narushin, V.G.; Lu, G.; Cugley, J.; Romanov, M.N.; Griffin, D.K. A 2-D Imaging-Assisted Geometrical Transformation Method for Non-Destructive Evaluation of the Volume and Surface Area of Avian Eggs. Food Control 2020, 112, 107112. [Google Scholar] [CrossRef]

- Duman, M.; İekeroğlu, A.; Yıldırım, A.; Eleroğlu, H.; Camcı, Ö. Relation between Egg Shape Index and Egg Quality Characteristics. Eur. Poult. Sci. 2016, 80, 1–9. [Google Scholar] [CrossRef]

- Mota-Grajales, R.; Torres-Peña, J.C.; Camas-Anzueto, J.L.; Pérez-Patricio, M.; Grajales Coutiño, R.; López-Estrada, F.R.; Escobar-Gómez, E.N.; Guerra-Crespo, H. Defect Detection in Eggshell Using a Vision System to Ensure the Incubation in Poultry Production. Measurement 2019, 135, 39–46. [Google Scholar] [CrossRef]

- Altuntaş, E.; Şekeroğlu, A. Effect of Egg Shape Index on Mechanical Properties of Chicken Eggs. J. Food Eng. 2008, 85, 606–612. [Google Scholar] [CrossRef]

- Chen, Z.; He, P.; He, Y.; Wu, F.; Rao, X.; Pan, J.; Lin, H. Eggshell Biometrics for Individual Egg Identification Based on Convolutional Neural Networks. Poult. Sci. 2023, 102, 102540. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Gu, R. Research Status and Prospects on Plant Canopy Structure Measurement Using Visual Sensors Based on Three-Dimensional Reconstruction. Agriculture 2020, 10, 462. [Google Scholar] [CrossRef]

- Yuan, L.; Cai, J.; Sun, L.; Ye, C. A Preliminary Discrimination of Cluster Disqualified Shape for Table Grape by Mono-Camera Multi-Perspective Simultaneously Imaging Approach. Food Anal. Methods 2016, 9, 758–767. [Google Scholar] [CrossRef]

- 121Yang, N.; Qian, Y.; EL-Mesery, H.S.; Zhang, R.; Wang, A.; Tang, J. Rapid Detection of Rice Disease Using Microscopy Image Identification Based on the Synergistic Judgment of Texture and Shape Features and Decision Tree–Confusion Matrix Method. J. Sci. Food Agric. 2019, 99, 6589–6600. [Google Scholar] [CrossRef]

| Nutrient | Amount Per Serving | % Daily Value |

|---|---|---|

| Calories | ~72 kcal | |

| Total Fat | ~5 g | ~6% |

| Cholesterol | 186 mg | ~62% |

| Sodium | ~62–70 mg | ~3% |

| Total Carbohydrate | ~0.4–0.6 g | <1% |

| Vitamin D | ~1 μg (estimated) | ~5–7% |

| Calcium | ~28 mg (estimated) | ~2–3% |

| Iron | ~1 mg (estimated) | ~5–6% |

| Potassium | ~69–70 mg (estimated) | ~2% |

| Protein | ~−6.0–6.3 g | ~12% |

| Type | Technique | Parameters | Model | Accuracy | Explanation | Ref. |

|---|---|---|---|---|---|---|

| Ultrasonic detection | Non-destructive ultrasonic analysis | 180 eggs; Ultrasound transducer; Compared with micrometer, dial gauge, and photometric methods | Linear regression | Consistent with destructive method | Uses ultrasound wave propagation to measure shell thickness and infer strength | [95] |

| Acoustic detection | Acoustic resonance analysis | 110 eggs; Mechanical tapping; Frequency range 1000–8000 Hz; FFT and power spectral analysis | PLS, iPLS, GA-PLS, GA-siPLS | Best model R = 0.771, RMSEP = 3.6 | Analyzes frequency response to estimate shell stiffness | [103] |

| Impulse excitation acoustic resonance | 30 eggs; Hammer tap; Frequencies of shell, albumin, yolk analyzed | Multiple linear regression | Correlation evident | Uses tapping hammer and microphone to collect resonance signals | [93] | |

| Hertzian contact theory | Hertz contact theory-based test | 150 eggs; Steel ball (3 g, r = 4.5 mm); 50 kHz sampling | None (direct stiffness estimation) | R = 0.93 (vs. static stiffness) | Uses a steel ball and acoustic signal to estimate stiffness | [104] |

| Spectroscopy | Near-infrared spectroscopy with machine learning | 145 commercial eggs; Bruker TANGO FT-NIR spectrometer; Spectral preprocessing and machine learning | Random Forest (RFE) | R2p = 0.83, RMSEP = 1.49 N, RPD = 2.44 | Combines NIR spectroscopy with machine learning to predict strength | [105] |

| Detection Index | Type | Technique | Parameters | Model | Accuracy | Explanation | Ref. |

|---|---|---|---|---|---|---|---|

| Color, Shape, Surface Defects | Image Processing | Image thresholding and candling-based assessment | 400 eggs; shape index and mottling | None | Correlation (shape index) 0.93, SD diff 1.05% | Combines image processing with candling for accurate assessment | [107] |

| Chromatic and geometric analysis | The sample size was over 300 eggs, Color uniformity, egg dimensions, shape parameters | None | Effective for fine crack and marbling detection | Uses spectral measurements for detailed defect detection | [108] | ||

| Colorimetric Analysis | CIE Lab* analysis and elemental correlation | 180 eggs from different breeds; shell traits | Statistical correlation | Breed and color influence mineral content and strength | Analyzes shell color and mineral composition | [109] | |

| Cleanliness detection | Image Processing | LabVIEW-based image analysis | 100 clean vs. 100 dirty eggs; feces-based dirt analysis | LabVIEW software | 99.8% (painted grade), 98.5% (feces stain) | Detects dirt using dark level image analysis | [110] |

| K-means clustering and unsharp masking | initial collection of 416 eggs, yielding 360 valid samples, Real-time inspection; surface segmentation | K-means clustering | High-throughput and accurate detection | Detects dark spots using clustering and image enhancement | [111] | ||

| Deep Learning | Pretrained AlexNet CNN model | A total of 1160 eggshell image patches (695 accepted, 465 rejected) were split into 1000 training/validation and 160 test samples, Translucent mottling images; transfer learning | CNN (AlexNet) | 91.8% similarity to human graders | Classifies mottling severity using a pretrained model | [112] | |

| Two-stage AI model (RTMDet + Random Forest) | A dataset of 2100 egg images was created and randomly split into training (80%) and testing (20%) sets, Imaging and weighing system; detects various defects | RTMDet + RF | 94.8% classification, 96.0% weight prediction R2 | Uses deep learning for classification and weight prediction | [113] |

| Detection Index | Technology Type | Technique | Parameters | Model | Accuracy | Explanation | Ref. |

|---|---|---|---|---|---|---|---|

| Egg Volume and Surface Area | Image Processing | 2D Imaging and Geometric Transformation | Digital imaging; fitted with geometric models | Geometric transformation | High correlation with physical measures | Uses 2D imaging to calculate volume and surface area through geometric models | [114] |

| Egg shape index and mechanical properties | Correlation Study | Shape Index Classification | 1563 eggs; digital caliper, micrometer, colorimeter, Haugh unit | Statistical correlation and ANOVA | Significant relations with albumen and yolk indices | Analyzes correlations between shape index and internal quality metrics | [115] |

| Image Processing | Laser Line Scanning and Spline Analysis | 200 egg images; spline-based metric extraction | ANN | 97.5% classification accuracy | Detects surface defects using laser scanning and spline curve analysis | [116] | |

| Compression Testing | Compression Test on Axes | 270 Lohmann eggs; shape index classification | Compression model | Higher SI = higher rupture force | Tests mechanical strength under compression on different axes | [117] | |

| Texture features | Image Processing | CNN-Based Texture Recognition | 770 eggs; 7700 images; blunt-end captured | ResNeXt-50 | 99.96% correct recognition | Uses CNN to recognize individual eggs based on texture features | [118] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Shen, C.; Cheng, J.; Yin, X.; Liu, C.; Yu, Z. Advances in Nondestructive Technologies for External Eggshell Quality Evaluation. Sensors 2025, 25, 5796. https://doi.org/10.3390/s25185796

Yu P, Shen C, Cheng J, Yin X, Liu C, Yu Z. Advances in Nondestructive Technologies for External Eggshell Quality Evaluation. Sensors. 2025; 25(18):5796. https://doi.org/10.3390/s25185796

Chicago/Turabian StyleYu, Pengpeng, Chaoping Shen, Junhui Cheng, Xifeng Yin, Chao Liu, and Ziting Yu. 2025. "Advances in Nondestructive Technologies for External Eggshell Quality Evaluation" Sensors 25, no. 18: 5796. https://doi.org/10.3390/s25185796

APA StyleYu, P., Shen, C., Cheng, J., Yin, X., Liu, C., & Yu, Z. (2025). Advances in Nondestructive Technologies for External Eggshell Quality Evaluation. Sensors, 25(18), 5796. https://doi.org/10.3390/s25185796