An Explainable Deep Learning-Based Predictive Maintenance Solution for Air Compressor Condition Monitoring

Abstract

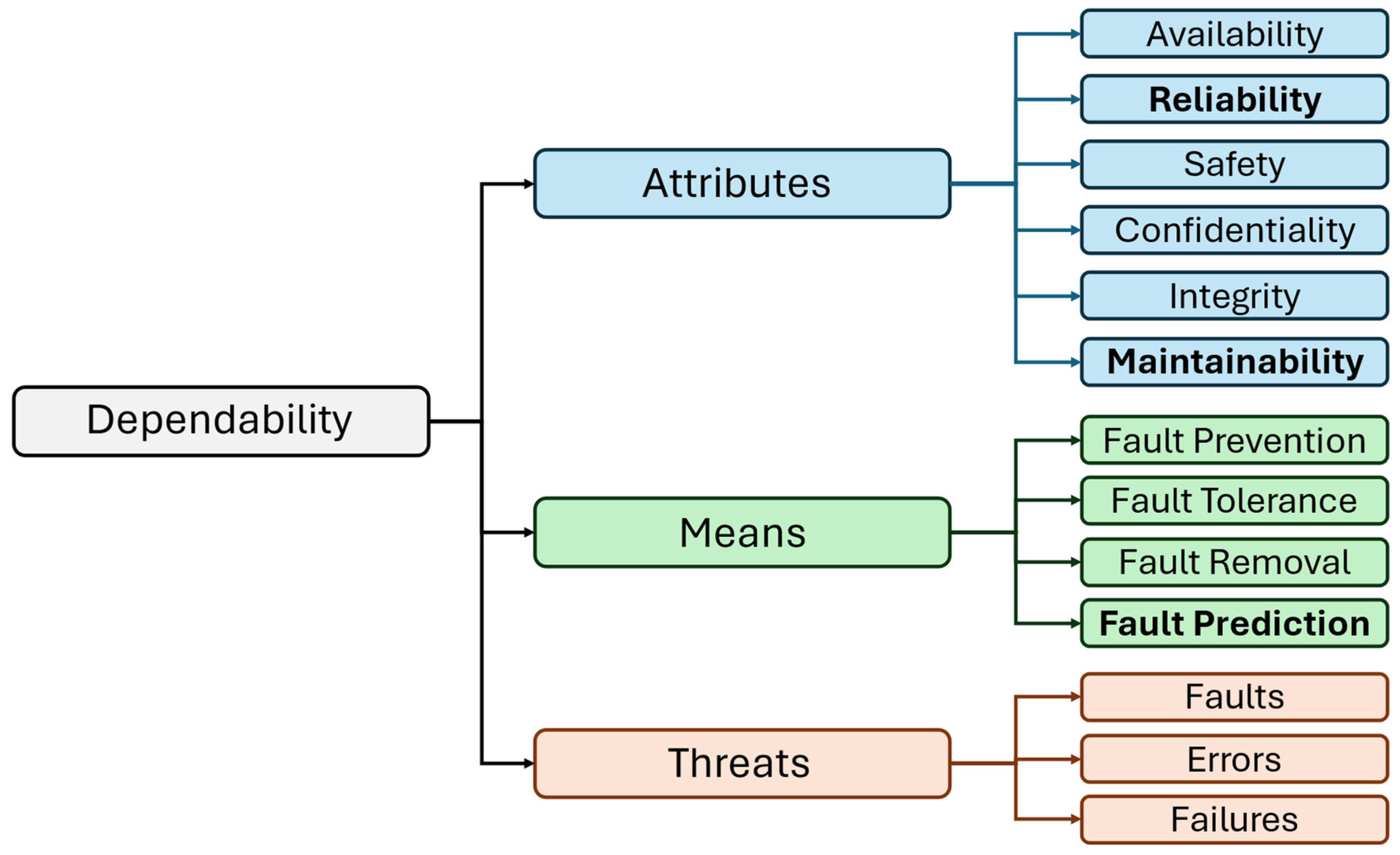

1. Introduction

| Ref. | Domain | Analyzed Machine | ML/DL Technique | Performance | XAI Techniques |

|---|---|---|---|---|---|

| [8] | Transport Domain | Air compressor (truck) | CART, C5.0, C5.0, Gradient Boosting | Accuracy—86% Recall—87% Precision—91% | × |

| [12] | Metro train air compressor | Isolation Forest, Logistic Regression, RF, XGBoost, CatBoost, LightGBM | Accuracy—99.7% F1 Score—99.7% | × | |

| [15] | Metro train AC system | XGBoost | Accuracy increase by 5.84–8.38% | SHAP | |

| [16] | Air pressure system | Explainable Boosting Machine | Accuracy—91.4% F1-Score—80% AUC—0.88 | Intrinsic (EBM) | |

| [9] | Industrial Domain | Oil-injected screw compressor | Linear Regression, KNN, SVM, Gradient Boosting | MSE—17.94 RMSE—4.24 MAE—1.95 R2—0.92 | × |

| [10] | Twin-screw oil-injected compressor | Optimizable Ensemble (e.g., boosted trees) | Accuracy—99.7% | × | |

| [11] | General purpose industrial compressor | Linear Regression | Accuracy—98% Decrease in Downtime by 20% | × | |

| [13] | Radiator in compressed air system | LSTM, Logistic Regression, RF, SVM, XGBoost, LightGBM | Accuracy—93% Energy savings by 2.24% | × | |

| [14] | Air screw compressor | Spectral and envelope analysis (FFT + Hilbert), RMS | Effective early fault detection via vibration signals. | × | |

| [21] | Single-stage air compressor | KNN, local KNN, locally weighted learning, random subspace ensemble KNN | Accuracy—100% | × | |

| [22] | Single-stage air compressor | Stacked ensemble (Linear Regression, Decision Tree, SVM, KNN, Naïve Bayes) | Accuracy—99.3% Precision—96.7% Recall—100% | × | |

| [23] | Twin-screw oil-injected air compressor | Ensemble-based model (24 classifiers) | Accuracy—99.7% Recall—95% | × | |

| [25] | Twin-screw air compressor | Principal Component Analysis and K-Means Clustering | Accurate clustered degradation levels. | × | |

| [27] | High-pressure industrial compressor | Hybrid Clustering and Classification (SVC, Random Forest, KNN) | Accuracy—97.9% | × | |

| [17] | HVAC Systems | Air handling units | XGBoost | Accuracy—99.6% F1-Score—99.7% | SHAP |

| [18] | Air handling units | XGBoost | F1-Score—97% | SHAP | |

| [19] | Screw chillers | 1D-Convolutional Neural Network | Accuracy—80.27% | Score-CAM | |

| [20] | Variable refrigerant flow | Decision Tree, Random Forest, KNN, SVM | Accuracy—99.3% Precision—99.4% Recall—99% | × | |

| [24] | Manufacturing Domain | General purpose air compressors | Stacked autoencoders | Anomaly scores highly correlate with failure. | × |

| [26] | Twin-screw air compressor | LSTM-Recurrent Neural Network with hierarchical clustering | Accuracy—97.4% | × | |

| This Paper * | Industrial Domain | Single-stage, water-cooled air compressor | DNN + SVM | Accuracy—98.58% Precision—99.11% Recall—98.27% F1-Score—98.62% | SHAP, LIME, and PDP |

| DNN | Accuracy—93.23% Precision—88.33% Recall—90.45% F1-Score—89.37% | ||||

| SVM | Accuracy—93.34% Precision—88.11% Recall—95.41% F1-Score—91.62% |

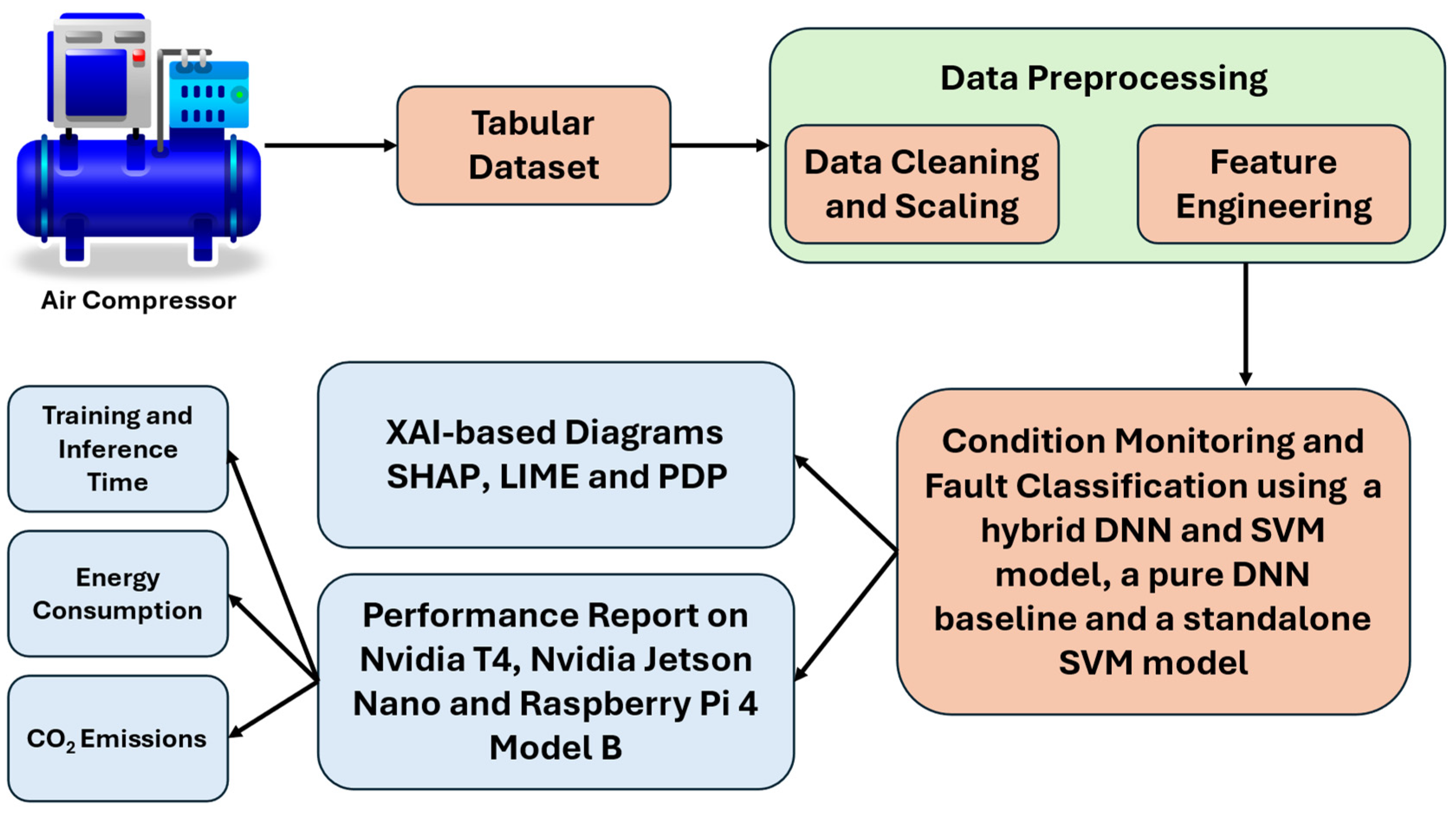

- A supervised PdM-based condition monitoring solution for the four principal components of an air compressor (i.e., the exhaust valve, bearings, water pump and radiator)

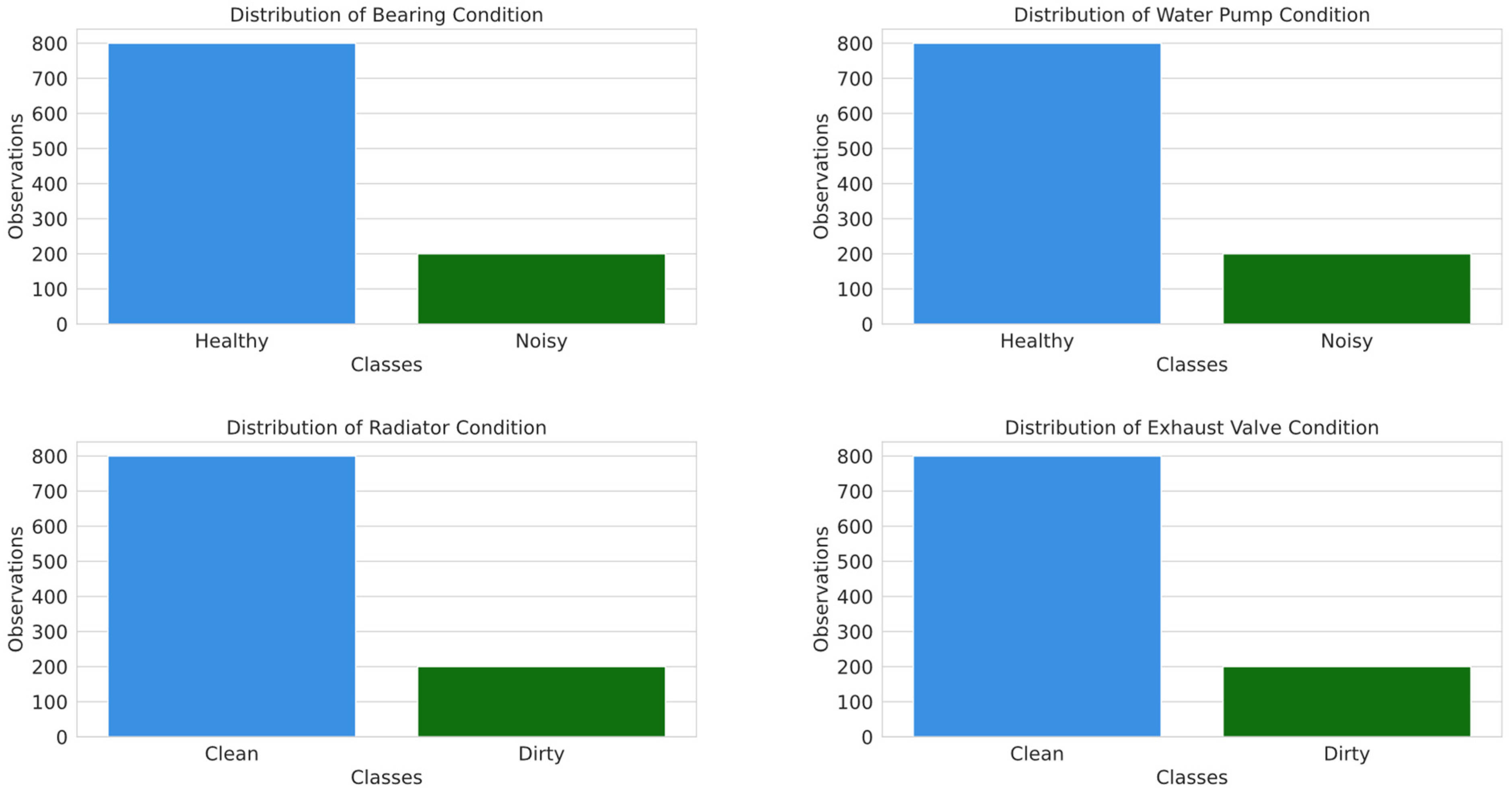

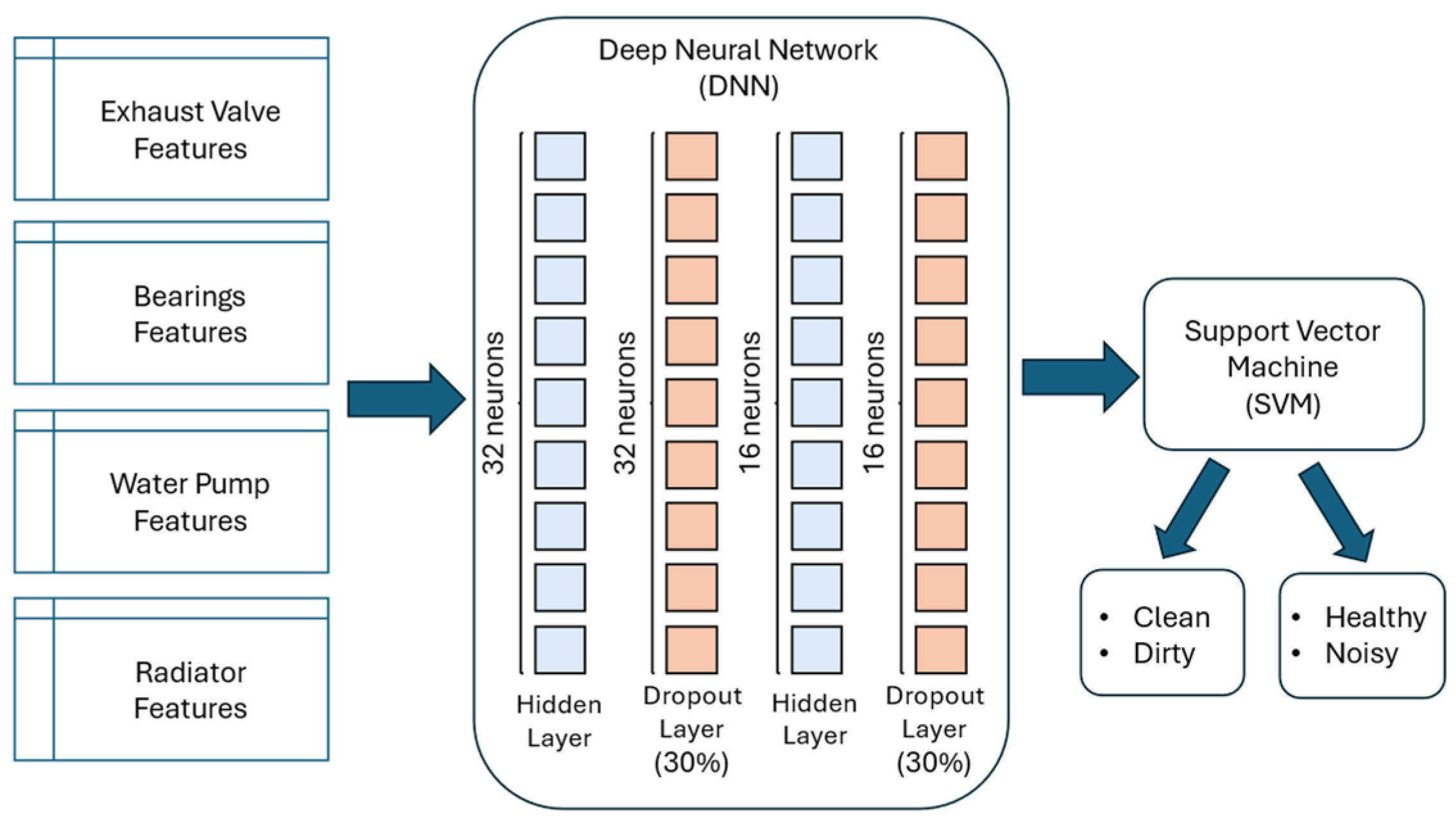

- A comparison between a hybrid deep learning (DL) model composed of a deep neural network (DNN) for feature extraction and support vector machines (SVM), a pure two-layer DNN model, and a standalone SVM model for fault classification (i.e., clean/dirty in the case of the exhaust valve and radiator and healthy/noisy in the case of the bearings and water pump).

- A comparison of the hybrid model performance on three devices: two general-purpose computing devices (i.e., a machine equipped with an NVIDIA T4 GPU and NVIDIA Jetson Nano) and one device with limited resources (i.e., Raspberry Pi 4 Model B) in terms of training and inference latency and energy consumption, as well as carbon oxide emissions.

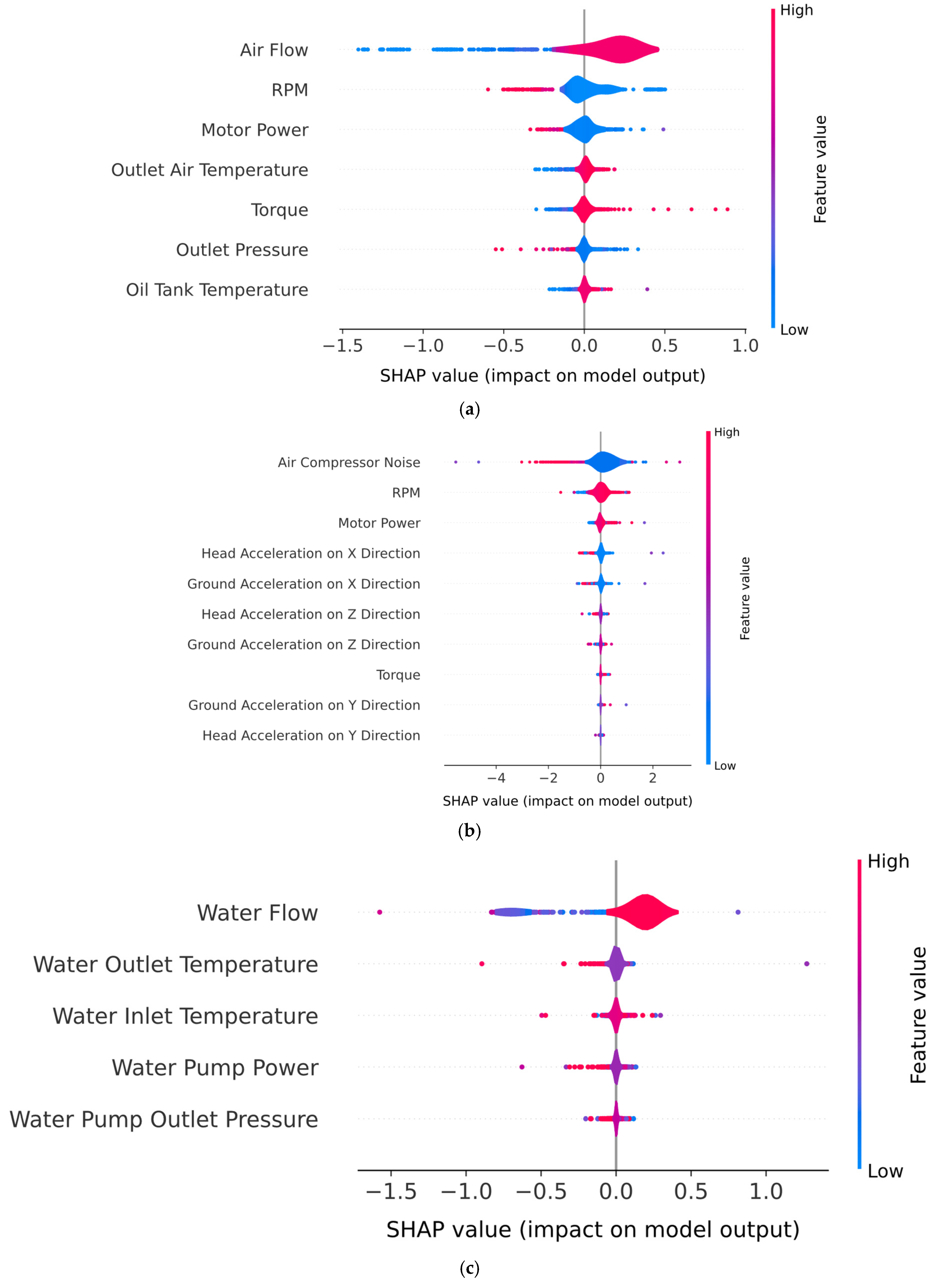

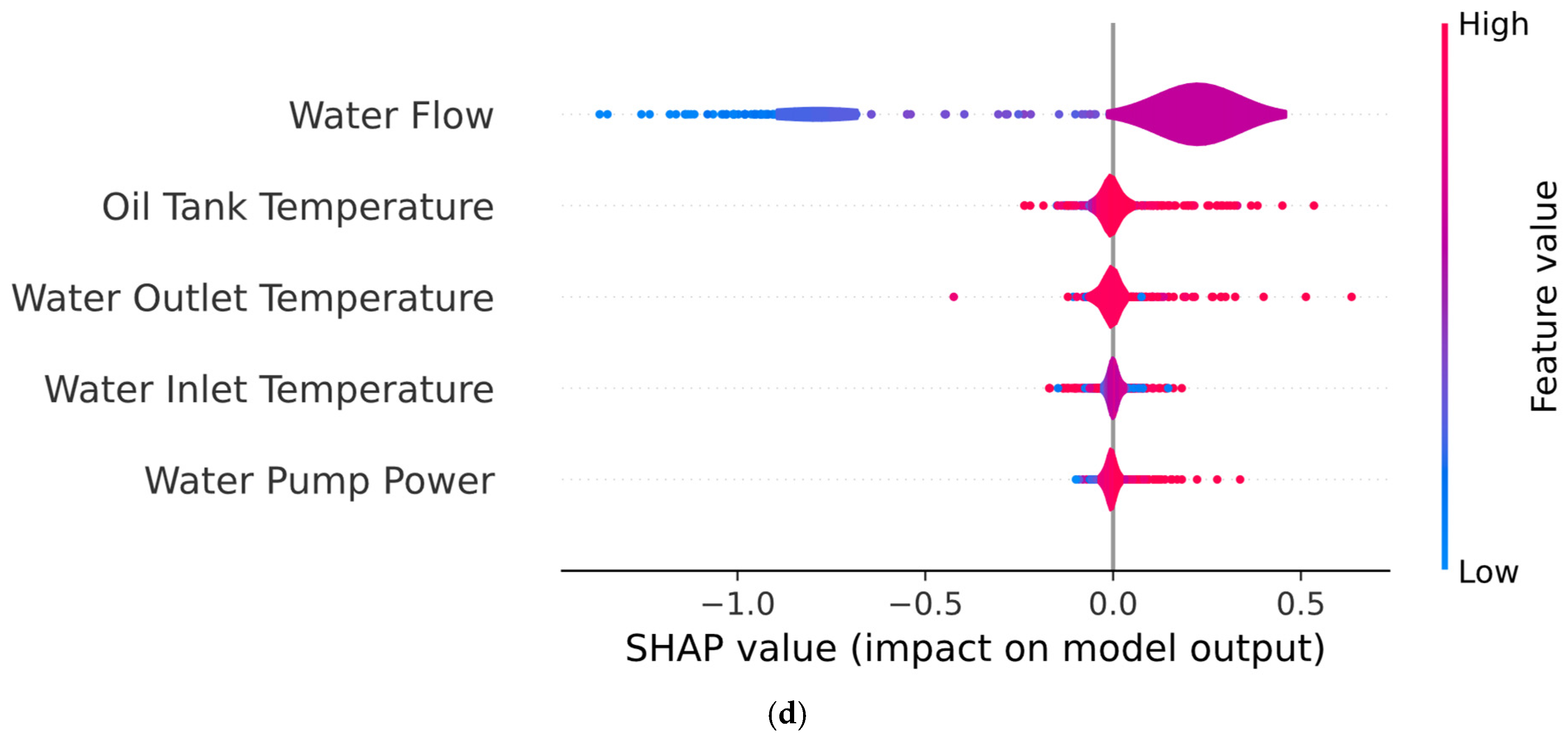

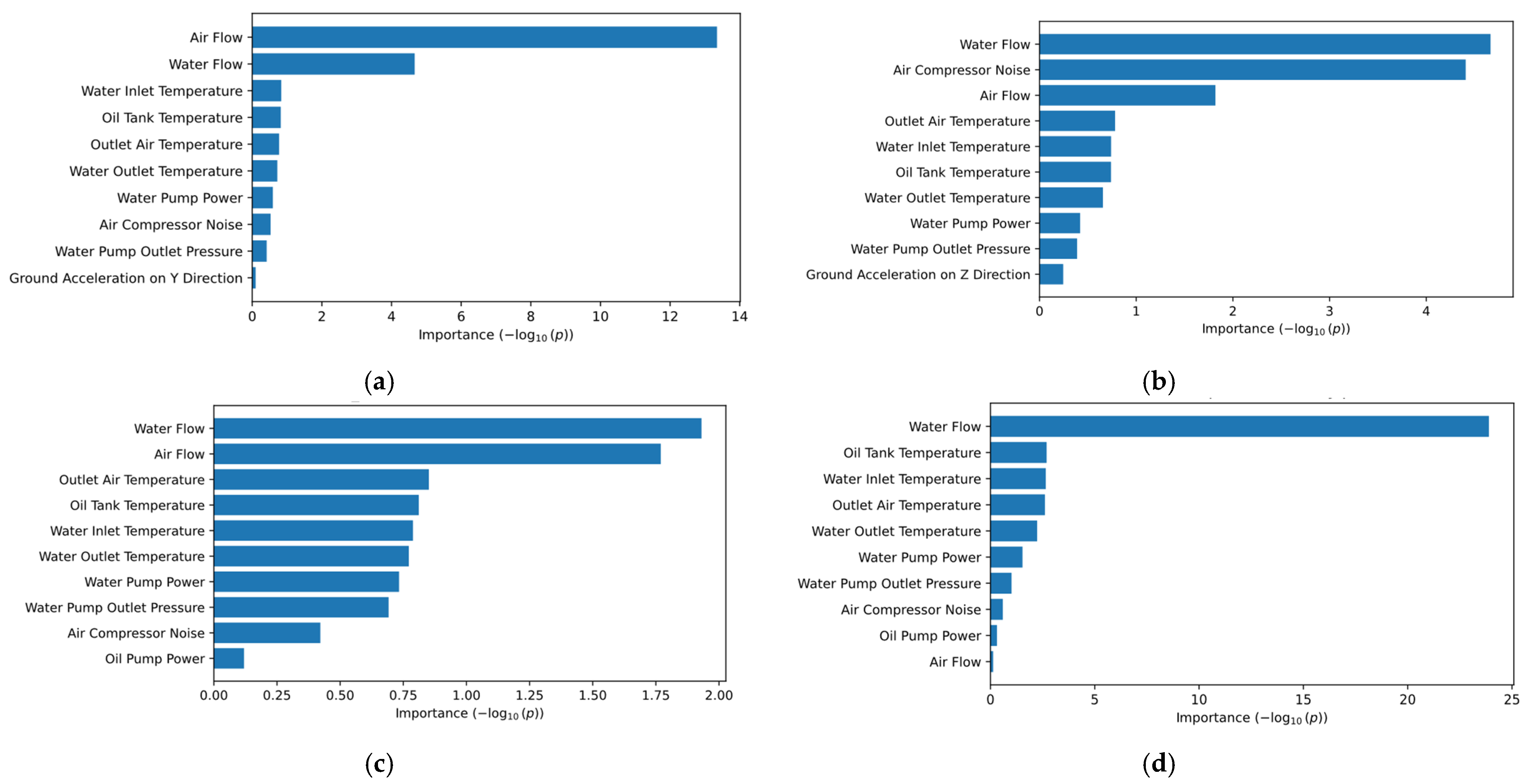

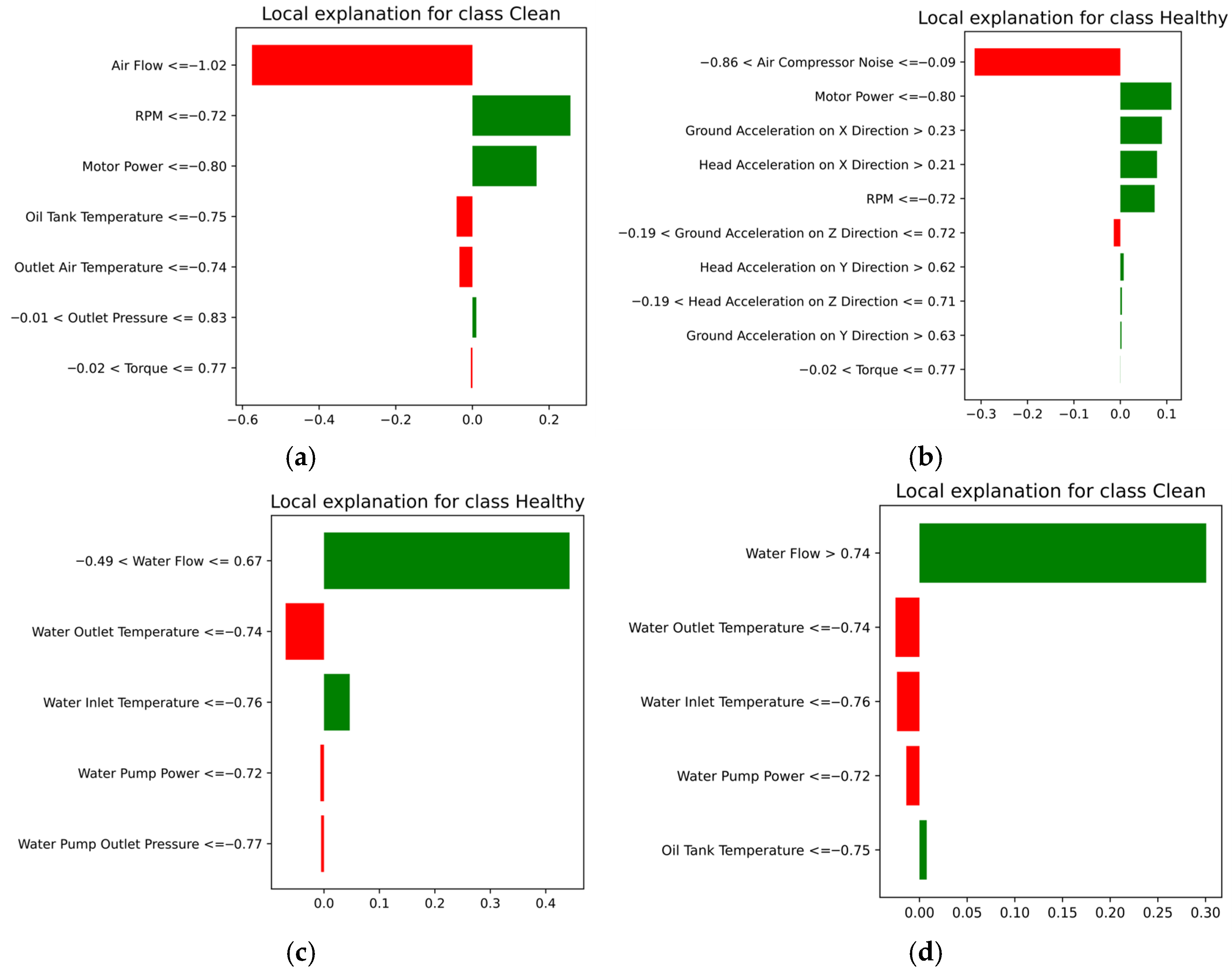

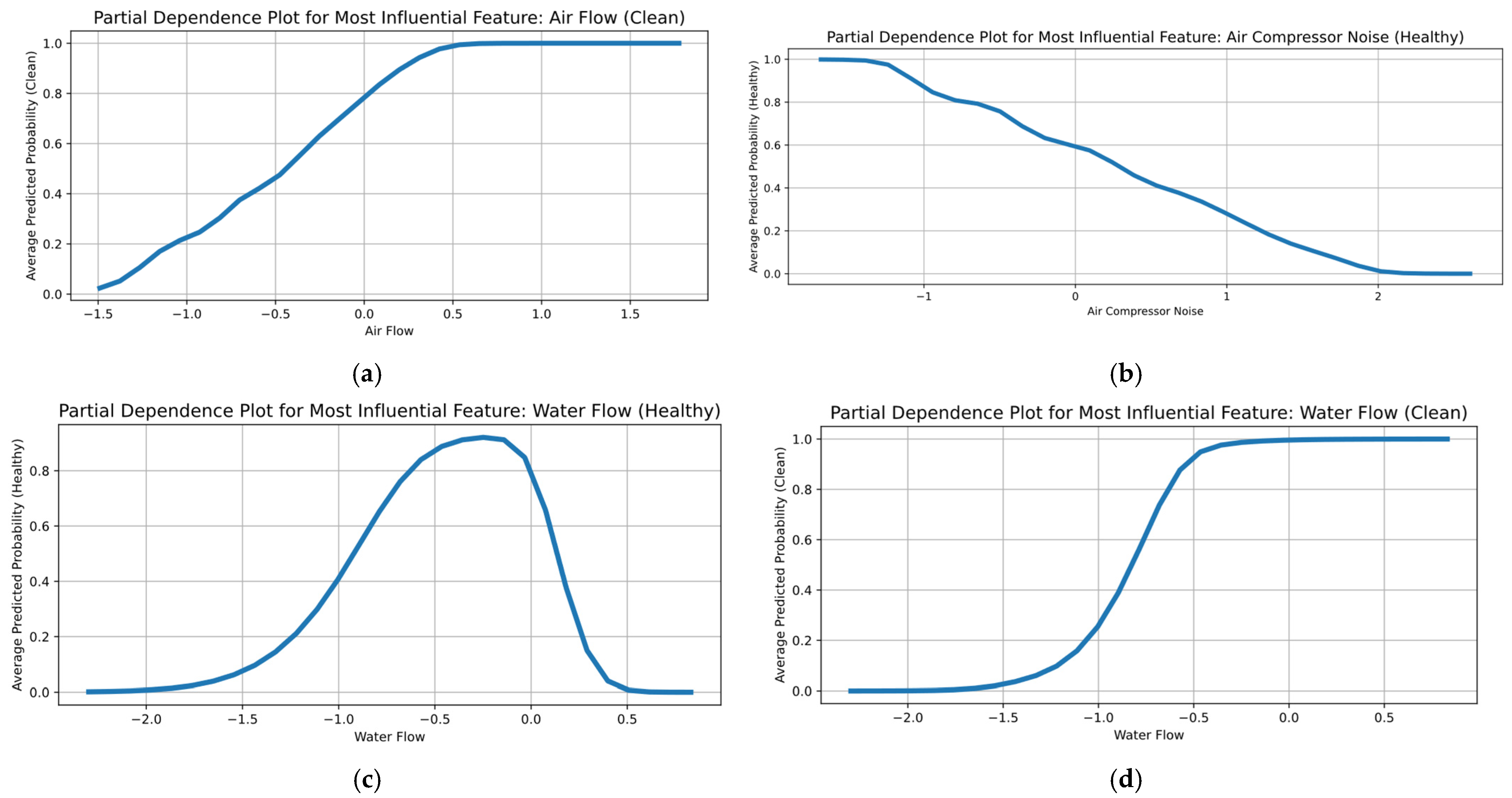

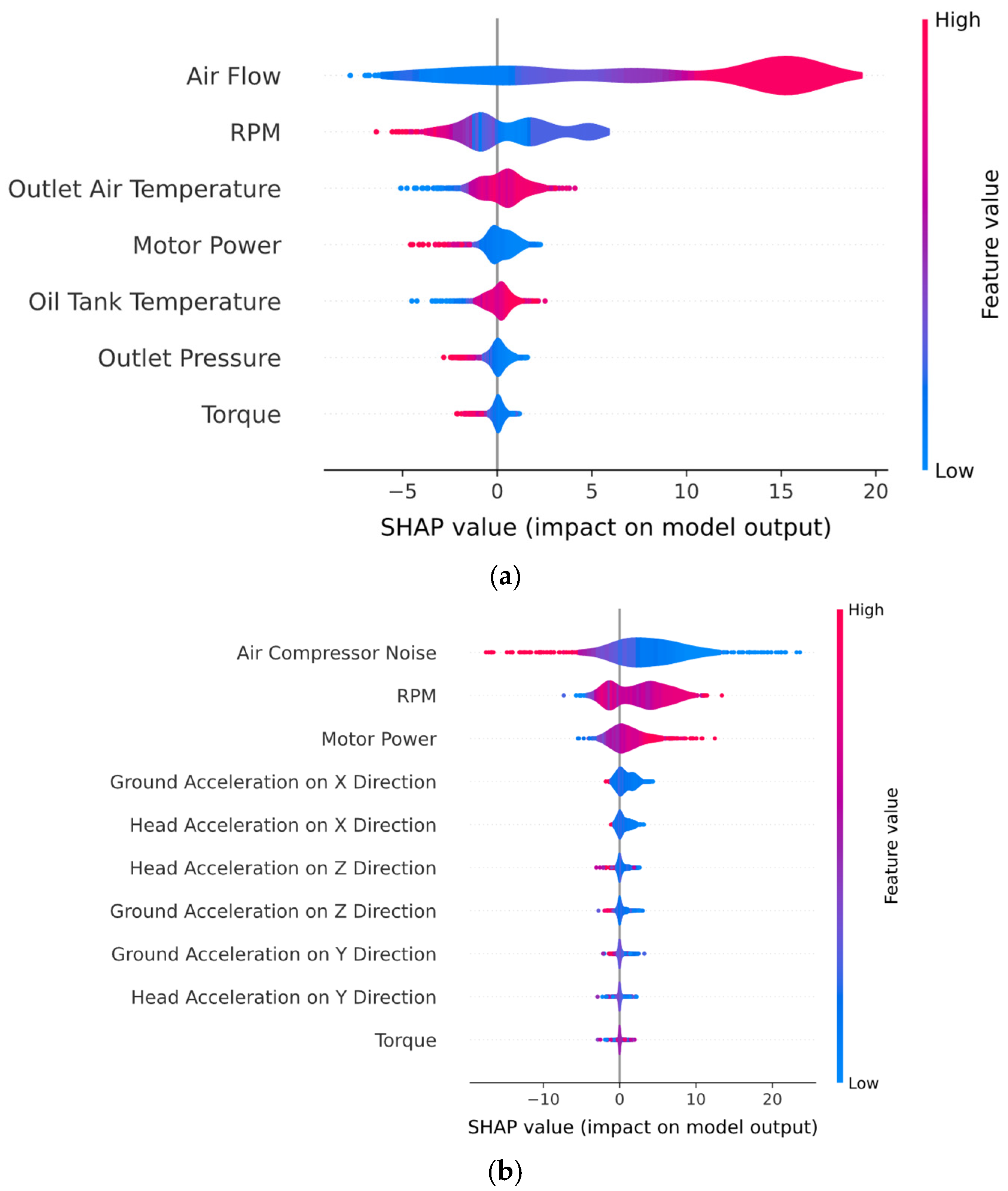

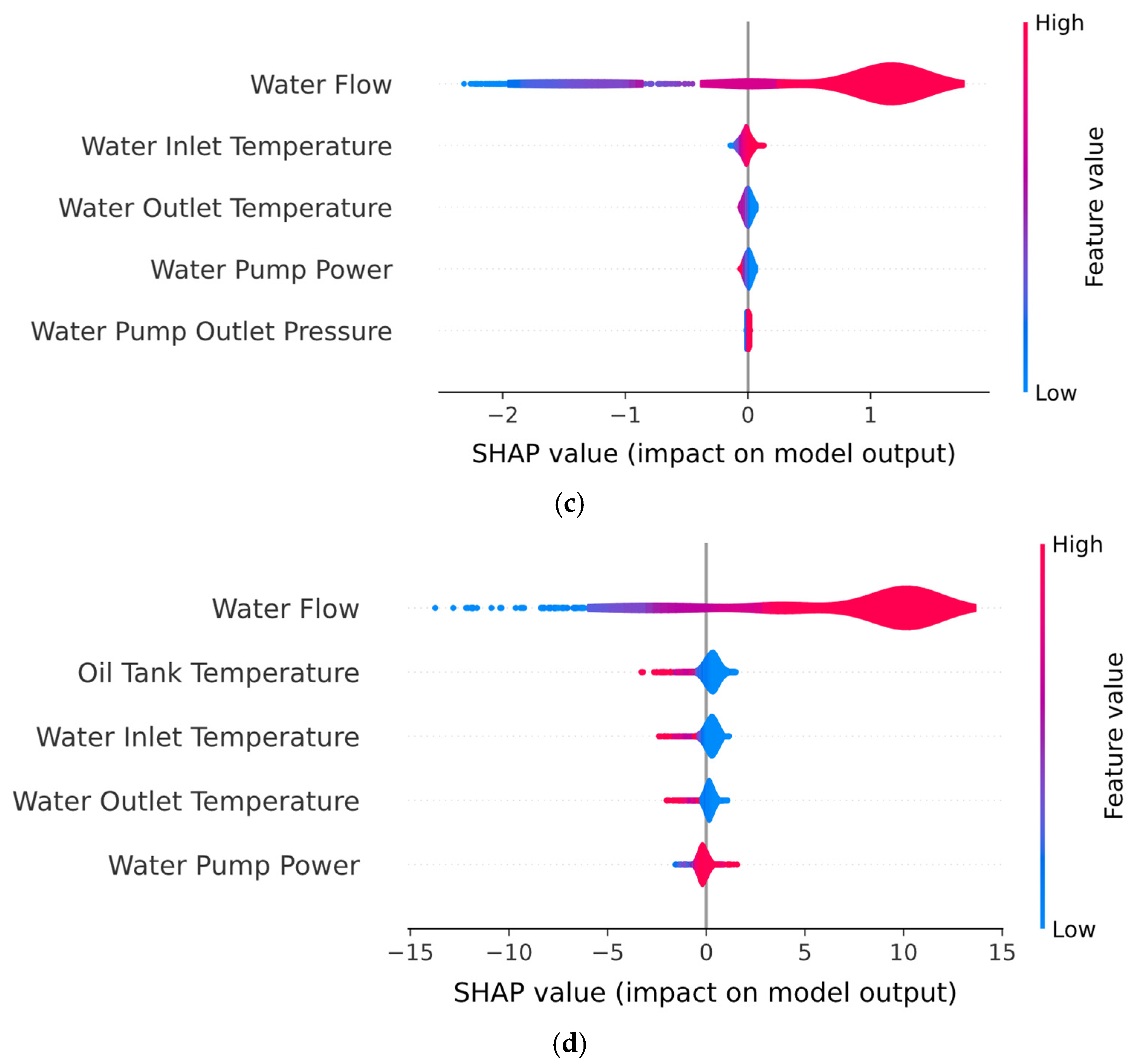

- The utilization of three explainable AI (XAI) techniques that enhance the hybrid architecture’s transparency and interpretability: two global model agnostic methods (i.e., SHAP and PDP) and one local model agnostic method (i.e., LIME).

- A comparison in terms of performance and impact on XAI interpretability between the hybrid model, two-layer DNN baseline, and the standalone SVM model using SHAP diagrams.

2. Methodology

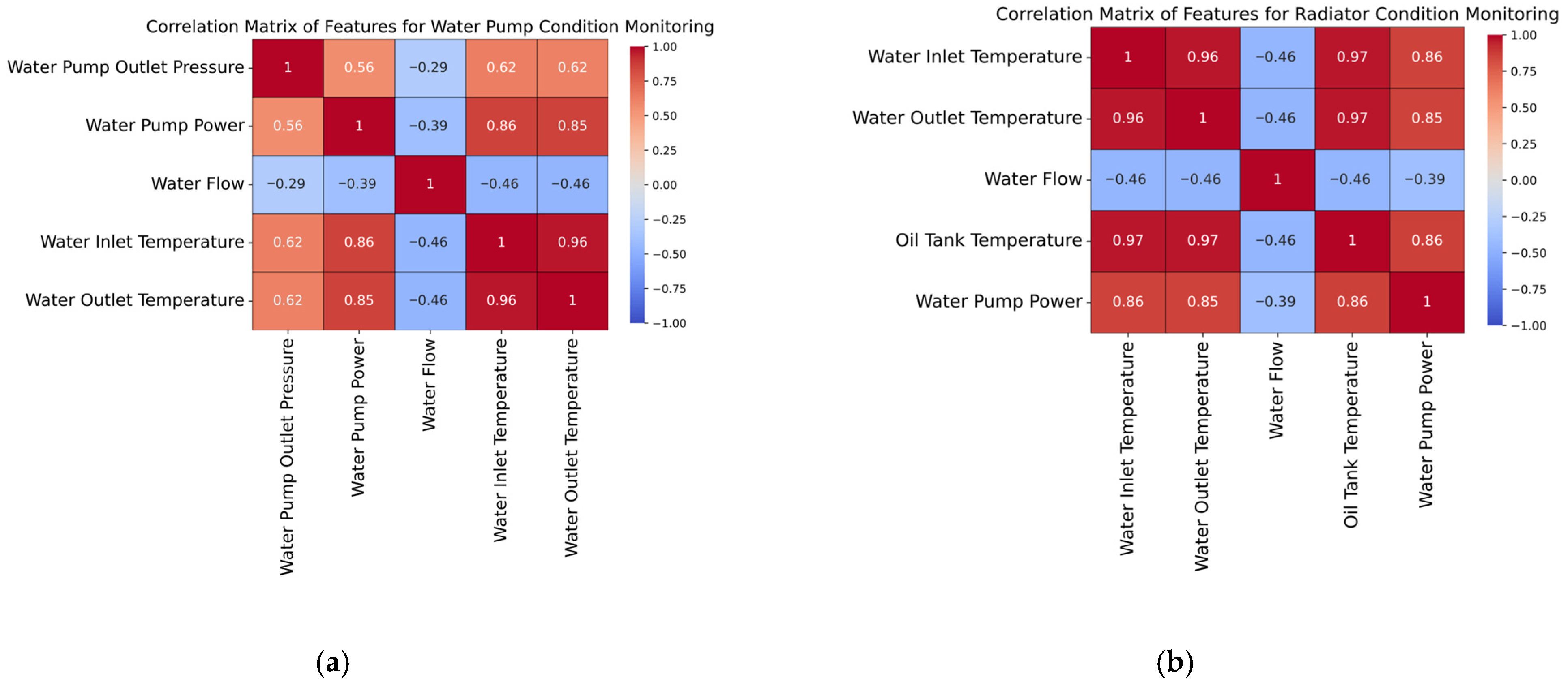

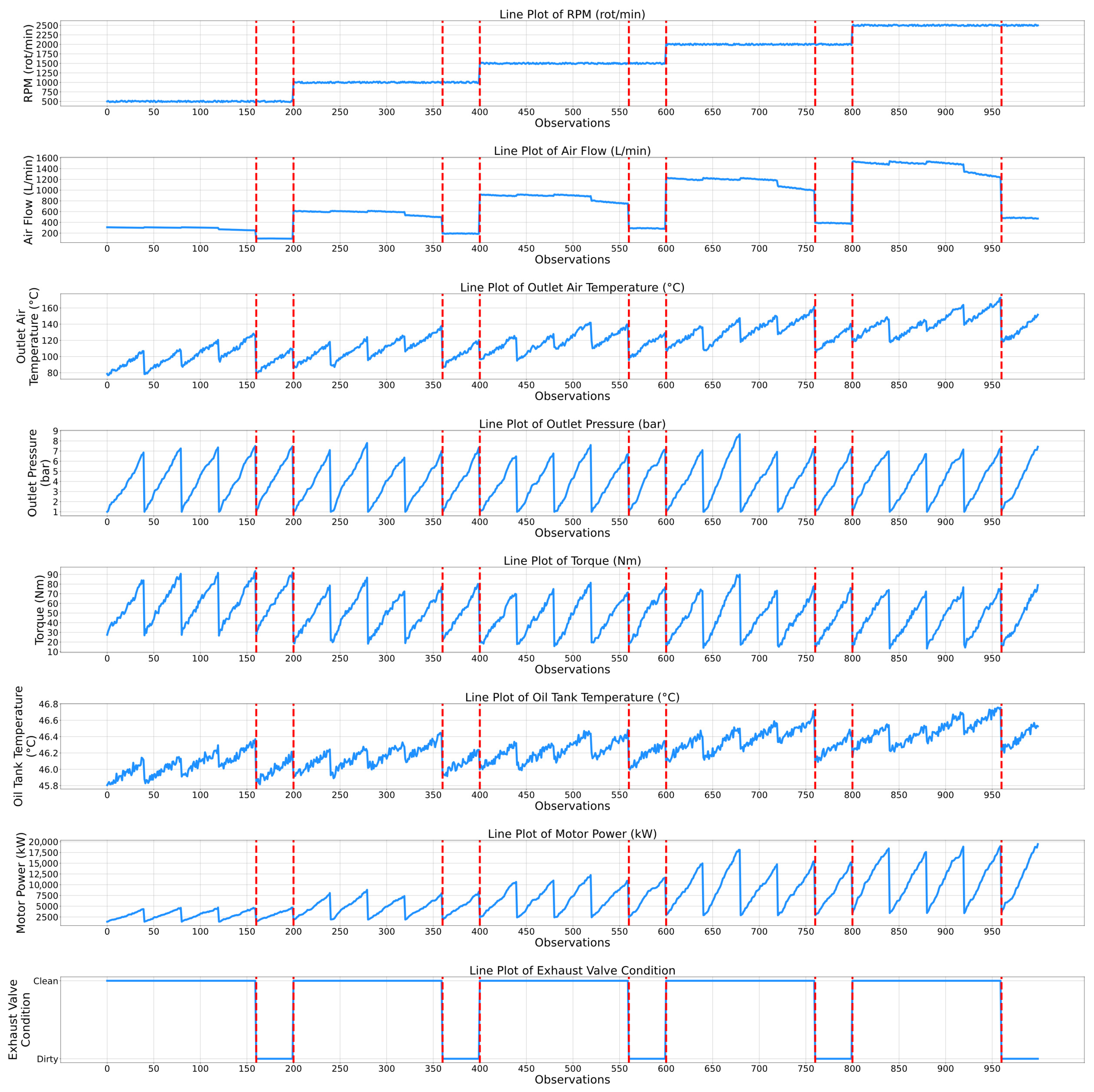

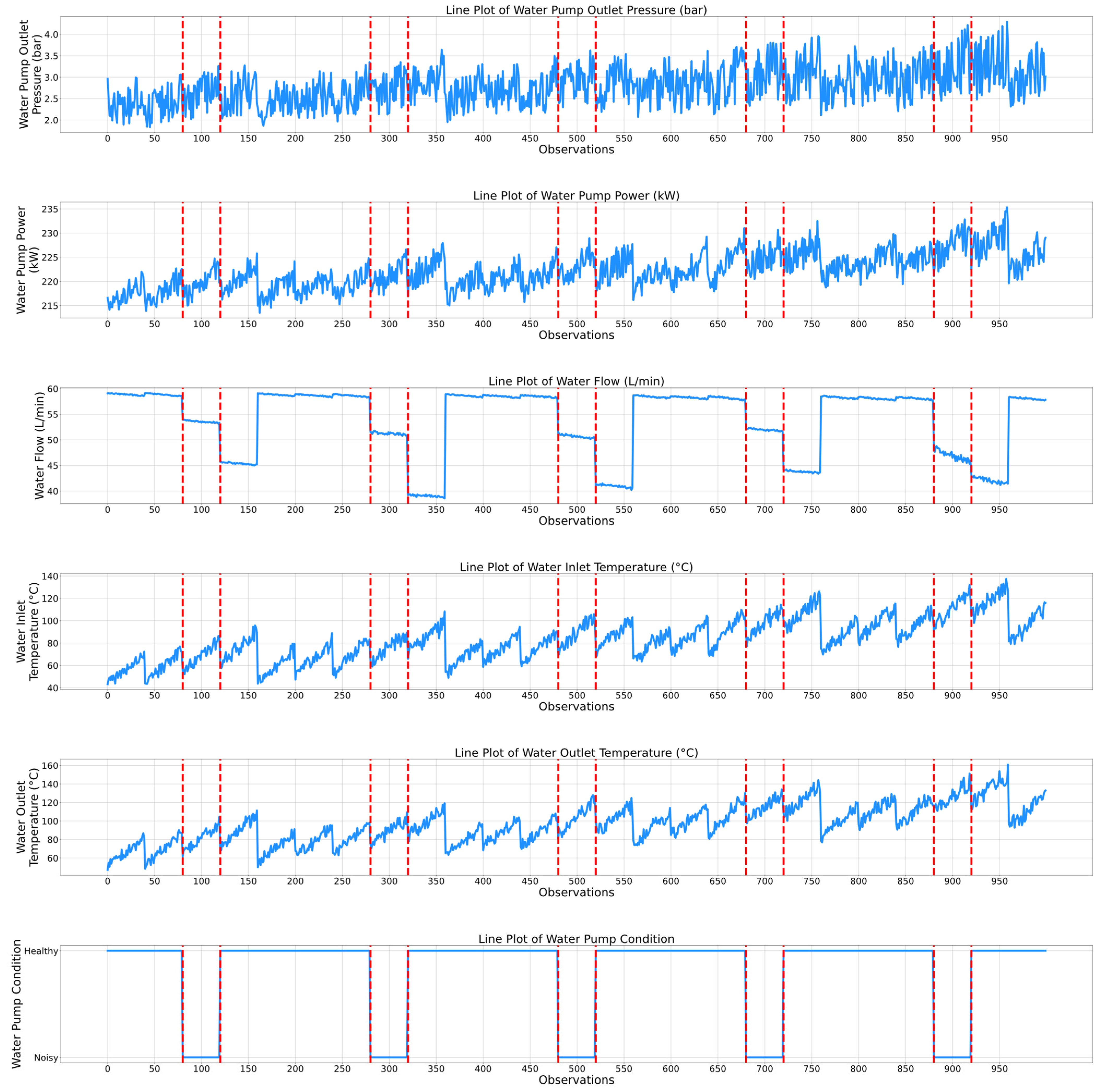

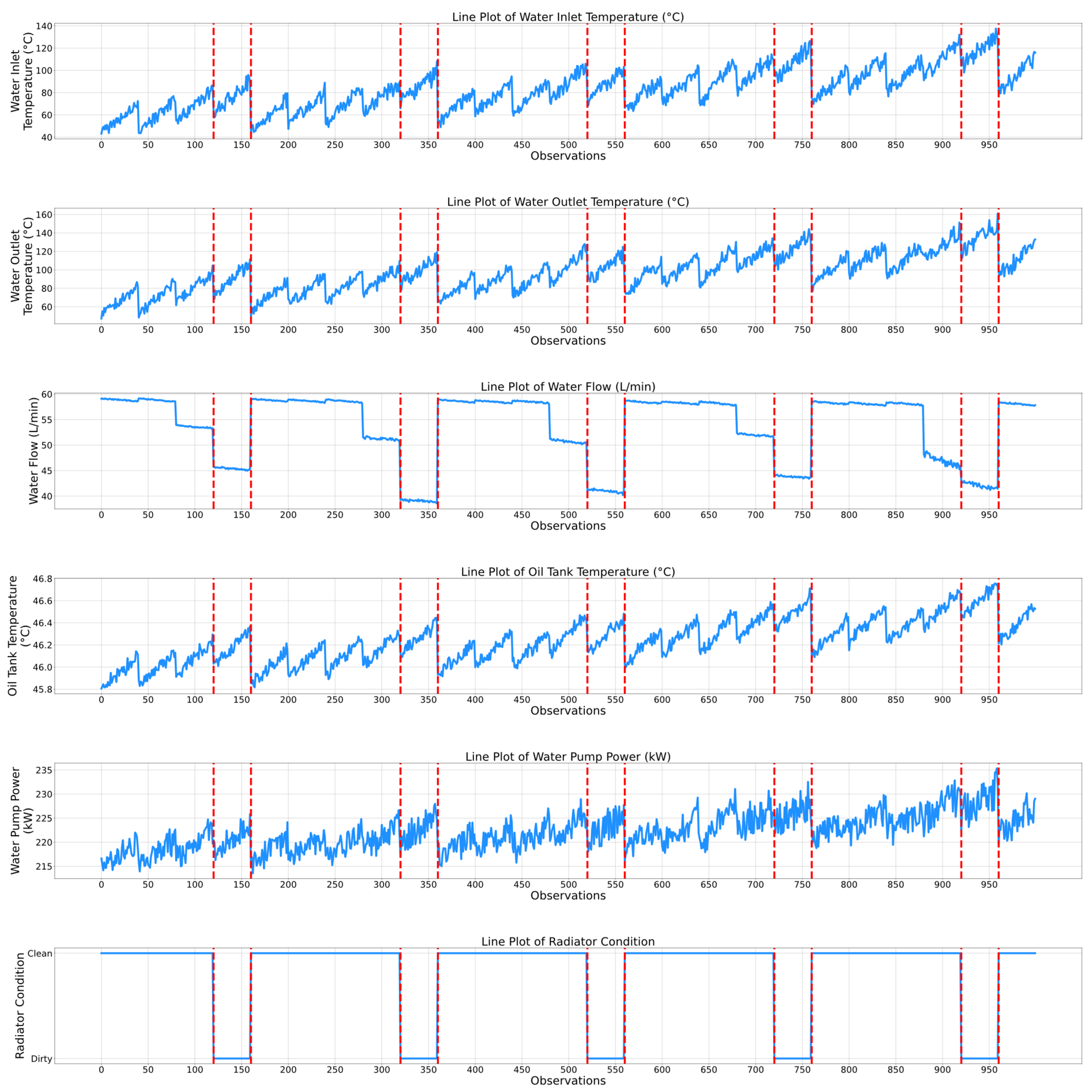

2.1. Exploratory Data Analysis of the Air Compressor Dataset

2.2. The Architecture of the DL-Based Model

2.3. Explainable AI Methods

| Algorithm 1: SHAP Visualization | ||

| , , number of folds K = 5 | ||

| 1: | for each fold k = 1, 2, …, K do: | |

| 2: | ||

| 3: | ) | |

| 4: | ||

| 5: | end for each | |

| 6: | across folds | |

| 7: | ||

| 8: | Visualize SHAP bar and beeswarm plots | |

| Algorithm 2: LIME Visualization | ||

| features of each air compressor component | ||

| 1: | Select top N features based on SHAP importance | |

| 2: | ||

| 3: | ||

| 4 | do: | |

| 5: | ||

| 6: | ||

| 7: | end for each | |

| Algorithm 3: PDP Explanations Visualization | ||

| , number of grid points G | ||

| 1: | ||

| 2: | do: | |

| 3: | ||

| 4: | ||

| 5: | ||

| 6: | ||

| 7: | end for each | |

| 8: | ||

3. Results and Discussions

3.1. Results Obtained Using Hybrid Architecture

3.2. Comparison Between a Pure DNN Baseline and a Standalone SVM Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADASYN | Adaptive Synthetic Oversampling |

| CPS | Cyber-Physical Systems |

| DL | Deep Learning |

| DNN | Deep Neural Network |

| EDA | Exploratory Data Analysis |

| GPU | Graphical Processing Unit |

| HVAC | Heating, Ventilation and Air Conditioning |

| LIME | Local Interpretable Model-agnostic Explanation |

| ML | Machine Learning |

| PdM | Predictive Maintenance |

| PDP | Partial Dependence Plot |

| SHAP | Shapley Additive Explanation |

| SVM | Support Vector Machines |

| XAI | Explainable AI |

References

- Sabah, S.; Moussa, M.; Shamayleh, A. Predictive Maintenance Application in Healthcare. In Proceedings of the 2022 Annual Reliability and Maintainability Symposium (RAMS), Tucson, AZ, USA, 24–27 January 2022; pp. 1–9. [Google Scholar] [CrossRef]

- Patel, M.; Vasa, J.; Patel, B. Predictive Maintenance: A Comprehensive Analysis and Future Outlook. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies (INCOFT), Belagavi, Karnataka, India, 24–26 November 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Manchadi, O.; Ben-Bouazza, F.-E.; Jioudi, B. Predictive Maintenance in Healthcare System: A Survey. IEEE Access 2023, 11, 61313–61330. [Google Scholar] [CrossRef]

- Predictive Maintenance Market Size, Share & Trends Analysis Report by Component, by Solution, by Service, by Deployment, by Enterprise Size, by Monitoring Technique, by End-Use, by Region, and Segment Forecasts, 2023–2030. Available online: https://www.grandviewresearch.com/industry-analysis/predictive-maintenance-market (accessed on 13 September 2025).

- Cao, J.; Lin, Y.; Fu, X.; Wang, Z.; Liu, G.; Zhang, Z.; Qin, Y.; Zhou, H.; Dong, S.; Cheng, G.; et al. Self-powered overspeed wake-up alarm system based on triboelectric nanogenerators for intelligent transportation. Nano Energy 2023, 107, 108150. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhu, L.; Wang, Z.; Zhang, X.; Li, Q.; Han, Q.; Yang, Z.; Qin, Z. Hybrid triboelectric-piezoelectric nanogenerator assisted intelligent condition monitoring for aero-engine pipeline system. Chem. Eng. J. 2025, 519, 165121. [Google Scholar] [CrossRef]

- Panda, C.; Singh, T.R. ML-based vehicle downtime reduction: A case of air compressor failure detection. Eng. Appl. Artif. Intell. 2023, 122, 106031. [Google Scholar] [CrossRef]

- Daoudi, N.; Zaki, S.; Aboussaleh, M. Predictive maintenance system for screw compressors using machine learning: A comparative study. Int. J. Adv. Manuf. Technol. 2025, 137, 3695–3708. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Hancha, M.S. Predictive Maintenance in Twin Screw Air Compressors: A Case Study. In Proceedings of the 2023 24th International Carpathian Control Conference (ICCC), Miskolc-Szilvásvárad, Hungary, 12–14 June 2023; pp. 483–488. [Google Scholar] [CrossRef]

- Aminzadeh, A.; Karganroudi, S.S.; Majidi, S.; Dabompre, C.; Azaiez, K.; Mitride, C.; Sénéchal, E. A Machine Learning Implementation to Predictive Maintenance and Monitoring of Industrial Compressors. Sensors 2025, 25, 1006. [Google Scholar] [CrossRef] [PubMed]

- Barpute, J.V.; Suryawanshi, S.; Kshirsagar, V.; Bhosale, D.; Patil, P.; Patil, A. Predictive Maintenance of a Metro’s Air Compressor. In Proceedings of the 2024 5th International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 7–9 August 2024; pp. 247–252. [Google Scholar] [CrossRef]

- Jeon, S.H.; Yoo, S.; Yoo, Y.-S.; Lee, I.-W. ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems. Energies 2024, 17, 1428. [Google Scholar] [CrossRef]

- Farid, A.; Fila, R.; Rafik, M.; Khaili, M.E. The Implementation of Predictive Maintenance Based on Prognostics and Health Management Concept: Case of Air Screw Compressor. In Proceedings of the 2024 4th International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Fez, Morocco, 16–17 May 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Jiang, M.; Chen, H.; Yang, C. A metro train air conditioning system fault diagnosis method based on explainable artificial intelligence: Considering interpretability and generalization. Int. J. Refrig. 2025, 174, 47–59. [Google Scholar] [CrossRef]

- Farea, S.M.; Mumcuoglu, M.E.; Unel, M. An Explainable AI approach for detecting failures in air pressure systems. Eng. Fail. Anal. 2025, 173, 109441. [Google Scholar] [CrossRef]

- Meas, M.; Machlev, R.; Kose, A.; Tepljakov, A.; Loo, L.; Levron, Y.; Petlenkov, E.; Belikov, J. Explainability and Transparency of Classifiers for Air-Handling Unit Faults Using Explainable Artificial Intelligence (XAI). Sensors 2022, 22, 6338. [Google Scholar] [CrossRef] [PubMed]

- Belikov, J.; Meas, M.; Machlev, R.; Kose, A.; Tepljakov, A.; Loo, L.; Petlenkov, E.; Levron, Y. Explainable AI based Fault Detection and Diagnosis System for Air Handling Units. In Proceedings of the 19th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Lisbon, Portugal, 14–16 July 2022. [Google Scholar] [CrossRef]

- Chen, K.; Chen, S.; Zhu, X.; Jin, X.; Du, Z. Interpretable mechanism mining enhanced deep learning for fault diagnosis of heating, ventilation and air conditioning systems. Build. Environ. 2023, 237, 110328. [Google Scholar] [CrossRef]

- Es-Sakali, N.; Zoubir, Z.; Kaitouni, S.I.; Mghazli, M.O.; Cherkaoui, M.; Pfafferott, J. Advanced predictive maintenance and fault diagnosis strategy for enhanced HVAC efficiency in buildings. Appl. Therm. Eng. 2024, 254, 123910. [Google Scholar] [CrossRef]

- Nambiar, A.; Naveen Venkatesh, S.; Aravinth, S.; Sugumaran, V.; Ramteke, S.M.; Marian, M. Prediction of air compressor faults with feature fusion and machine learning. Knowl.-Based Syst. 2024, 304, 112519. [Google Scholar] [CrossRef]

- Ojha, E.; Sharma, N.; Mangla, M. A novel deep copy stacked ensemble optimization technique for optimal predictive maintenance of air compressors. Iran J. Comput. Sci. 2025, 8, 379–391. [Google Scholar] [CrossRef]

- Zanoli, S.M.; Pepe, C.; Hancha, M.S. A Comparison Between Supervised Learning Techniques for Predictive Maintenance in Twin Screw Air Compressors. In Proceedings of the 2023 15th IEEE International Conference on Industry Applications (INDUSCON), São Bernardo do Campo, Brazil, 22–24 November 2023. [Google Scholar] [CrossRef]

- Chang, K.H.; Hsieh, T.C.; Kuo, C.M.; Lin, H.P. Unsupervised Learning-Based Prognostics and Health Management for Air Compressors in the Semiconductor Industry: An Empirical Study. 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4918336 (accessed on 13 September 2025).

- Zanoli, S.M.; Hancha, M.S.; Farooq, A.M.; Pepe, C. Predictive Maintenance in Twin Screw Air Compressors through Unsupervised Learning. In Proceedings of the 2024 25th International Carpathian Control Conference (ICCC), Krynica Zdrój, Poland, 22–24 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Joung, B.G.; Nath, C.; Li, Z.; Sutherland, J.W. Bearing anomaly detection in an air compressor using an LSTM and RNN-based machine learning model. Int. J. Adv. Manuf. Technol. 2024, 134, 3519–3530. [Google Scholar] [CrossRef]

- Costa, A.; Mastriani, E.; Incardona, F.; Munari, K.; Spinello, S. Predictive Maintenance Study for High-Pressure Industrial Compressors: Hybrid Clustering Models. arXiv 2024, arXiv:2411.13919. Available online: https://arxiv.org/abs/2411.13919 (accessed on 13 September 2025). [CrossRef]

- Air Compressor Dataset, Kaggle. Available online: https://www.kaggle.com/datasets/afumetto/predictive-maintenance-dataset-air-compressor/ (accessed on 12 September 2025).

- Dey, I.; Pratap, V. A Comparative Study of SMOTE, Borderline-SMOTE, and ADASYN Oversampling Techniques using Different Classifiers. In Proceedings of the 2023 3rd International Conference on Smart Data Intelligence (ICSMDI), Trichy, India, 30–31 March 2023. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. In Advances in Neural Information Processing Systems; Neural Information Processing Systems Foundation, Inc. (NeurIPS): La Jolla, CA, USA, 2017; Available online: https://proceedings.neurips.cc/paper/2017/hash/8a20a8621978632d76c43dfd28b67767-Abstract.html (accessed on 13 September 2025).

- Ribeiro, M.T.; Singh, S.; Guestrin, C. Why should I trust you? Explaining the predictions of any classifier. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 1135–1144. [Google Scholar] [CrossRef]

- Moosbauer, J.; Herbinger, J.; Casalicchio, G.; Lindauer, M.; Bischl, B. Explaining Hyperparameter Optimization via Partial Dependence Plots. In Advances in Neural Information Processing Systems; Neural Information Processing Systems Foundation, Inc. (NeurIPS): La Jolla, CA, USA, 2021; Volume 34, pp. 2280–2291. Available online: https://proceedings.neurips.cc/paper/2021/hash/12ced2db6f0193dda91ba86224ea1cd8-Abstract.html (accessed on 13 September 2025).

- CodeCarbon Library. Available online: https://codecarbon.io/#about (accessed on 13 September 2025).

| Hyperparameter | Value |

|---|---|

| Learning Rate | 10−3 |

| Batch Size | 256 |

| Activation Function | Leaky ReLU |

| Loss Function | Binary Cross-Entropy |

| Optimizer | Adam |

| Epochs per Fold | 7 |

| Exponential Decay Rates | |

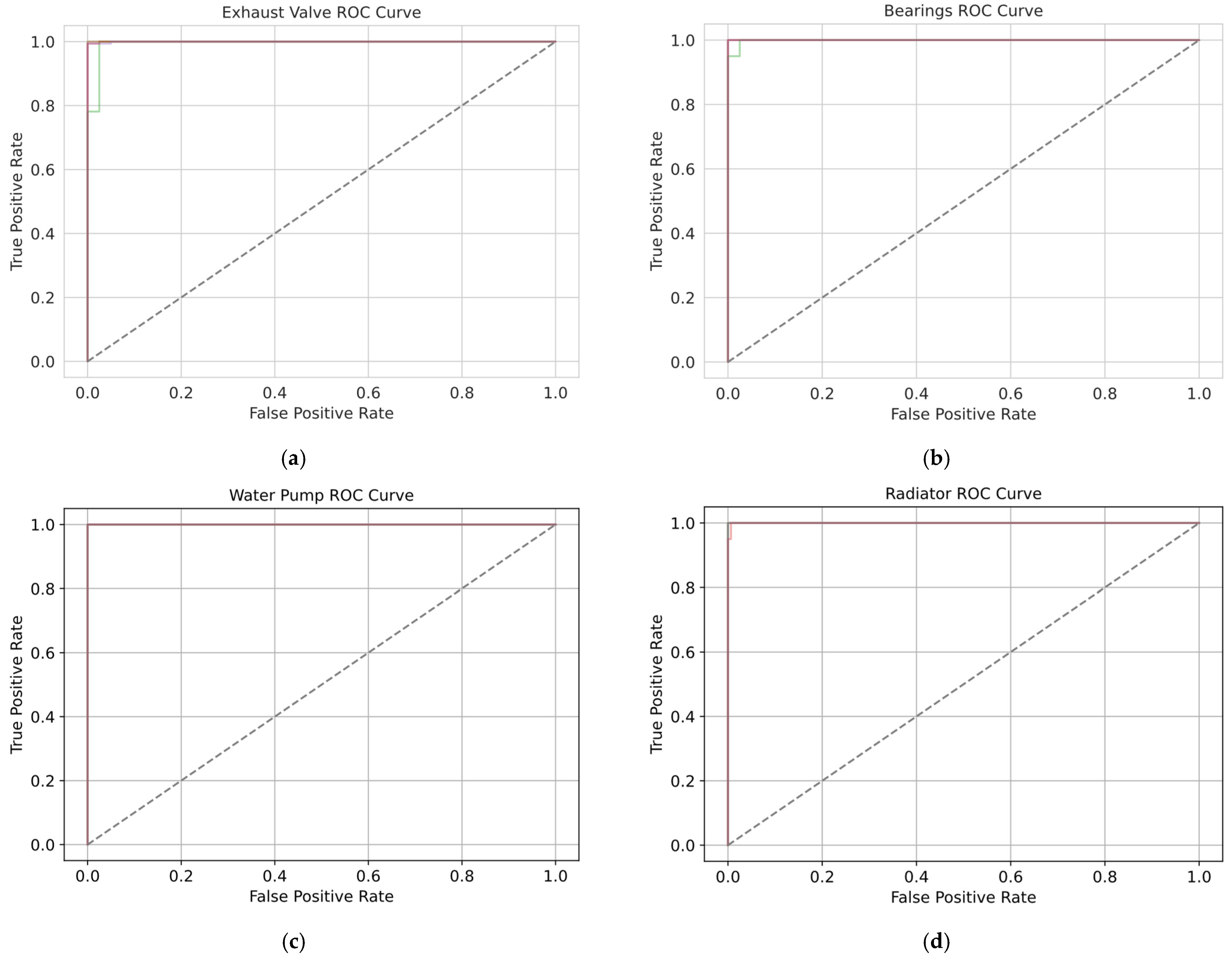

| Test Accuracy [%] | Precision [%] | Recall [%] | F1 Score [%] | |

|---|---|---|---|---|

| Exhaust Valve | 98.4 | 99.1 | 98.5 | 98.3 |

| Bearings | 98.6 | 99.3 | 98.3 | 98.6 |

| Water Pump | 99.3 | 99.6 | 99.4 | 99.5 |

| Radiator | 99.1 | 99.3 | 99.5 | 99.4 |

| Test Accuracy [%] | Precision [%] | Recall [%] | F1 Score [%] | |

|---|---|---|---|---|

| Exhaust Valve | 98.2 | 98.9 | 98.5 | 98.7 |

| Bearings | 98.5 | 98.9 | 98.4 | 98.6 |

| Water Pump | 99.1 | 99.5 | 99.3 | 99.3 |

| Radiator | 99.4 | 99.3 | 99.3 | 99.3 |

| Test Accuracy [%] | Precision [%] | Recall [%] | F1 Score [%] | |

|---|---|---|---|---|

| Exhaust Valve | 98.2 | 98.9 | 98.5 | 98.7 |

| Bearings | 98.5 | 99.4 | 98.4 | 98.9 |

| Water Pump | 99.1 | 99.5 | 99.3 | 99.3 |

| Radiator | 98.2 | 98.4 | 98.3 | 98.3 |

| Training Time per Epoch [ms] | Inference Time per Epoch [ms] | ||

|---|---|---|---|

| Exhaust Valve Condition | Fold 1 | 154.3 | 63.5 |

| Fold 2 | 152.9 | 61.2 | |

| Fold 3 | 138.5 | 61.4 | |

| Fold 4 | 141.6 | 62.6 | |

| Fold 5 | 136.2 | 62.3 | |

| Bearings Condition | Fold 1 | 149.1 | 80.1 |

| Fold 2 | 151.5 | 67.8 | |

| Fold 3 | 145.9 | 65.2 | |

| Fold 4 | 149.7 | 65.8 | |

| Fold 5 | 136.2 | 62.3 | |

| Water Pump | Fold 1 | 141.2 | 58.4 |

| Fold 2 | 127.9 | 59.5 | |

| Fold 3 | 136.5 | 63.1 | |

| Fold 4 | 142.6 | 62.4 | |

| Fold 5 | 132.3 | 63.1 | |

| Radiator | Fold 1 | 137.5 | 58.2 |

| Fold 2 | 122.9 | 57.3 | |

| Fold 3 | 126 | 57.2 | |

| Fold 4 | 115.7 | 58.1 | |

| Fold 5 | 115.2 | 56.7 | |

| Training Time per Epoch [ms] | Inference Time per Epoch [ms] | ||

|---|---|---|---|

| Exhaust Valve Condition | Fold 1 | 799.6 | 222.8 |

| Fold 2 | 680.5 | 225.3 | |

| Fold 3 | 650.1 | 236.2 | |

| Fold 4 | 706.4 | 227.6 | |

| Fold 5 | 651.3 | 227.3 | |

| Bearings Condition | Fold 1 | 665.7 | 218.9 |

| Fold 2 | 659.3 | 220.2 | |

| Fold 3 | 641.5 | 233.5 | |

| Fold 4 | 722.8 | 230 | |

| Fold 5 | 678.6 | 219.1 | |

| Water Pump | Fold 1 | 685.4 | 223.7 |

| Fold 2 | 700.3 | 225.6 | |

| Fold 3 | 662.7 | 222.1 | |

| Fold 4 | 705.7 | 223.4 | |

| Fold 5 | 613.4 | 224.1 | |

| Radiator | Fold 1 | 686.6 | 220.3 |

| Fold 2 | 627.7 | 223.1 | |

| Fold 3 | 643.2 | 232.6 | |

| Fold 4 | 673.1 | 224.6 | |

| Fold 5 | 642.4 | 222.2 | |

| Training Time per Epoch [ms] | Inference Time per Epoch [ms] | ||

|---|---|---|---|

| Exhaust Valve Condition | Fold 1 | 497.3 | 11.9 |

| Fold 2 | 523.3 | 12.9 | |

| Fold 3 | 501.2 | 13.6 | |

| Fold 4 | 535.1 | 13.4 | |

| Fold 5 | 586.4 | 17.3 | |

| Bearings Condition | Fold 1 | 616.7 | 17.9 |

| Fold 2 | 637.4 | 19.9 | |

| Fold 3 | 620.8 | 20.1 | |

| Fold 4 | 672.4 | 20.7 | |

| Fold 5 | 661.2 | 21.5 | |

| Water Pump | Fold 1 | 691.9 | 22.2 |

| Fold 2 | 706.6 | 22.9 | |

| Fold 3 | 724.7 | 24.5 | |

| Fold 4 | 739.1 | 24.7 | |

| Fold 5 | 73.51 | 25.4 | |

| Radiator | Fold 1 | 708.5 | 26.4 |

| Fold 2 | 799.8 | 26.6 | |

| Fold 3 | 785.8 | 27.3 | |

| Fold 4 | 805.9 | 28.2 | |

| Fold 5 | 819.6 | 28.9 | |

| Memory Usage [Mb] | Energy Consumption [Wh] | CO2 Emissions [g] | ||

|---|---|---|---|---|

| NVIDIA T4 GPU | Exhaust Valve | 2073.8 | 1.59 | 5.56 |

| Bearings | 2082.2 | 1.68 | 4.81 | |

| Water Pump | 2078.9 | 1.67 | 4.76 | |

| Radiator | 2073.5 | 1.63 | 4.67 | |

| NVIDIA Jetson Nano | Exhaust Valve | 1472.4 | 0.59 | 1.51 |

| Bearings | 1473.1 | 0.60 | 1.53 | |

| Water Pump | 1472.9 | 1.10 | 2.81 | |

| Radiator | 1477.2 | 0.71 | 1.87 | |

| Raspberry Pi 4 Model B | Exhaust Valve | 705.7 | 0.13 | 0.033 |

| Bearings | 688.2 | 0.12 | 0.091 | |

| Water Pump | 701.5 | 0.13 | 0.032 | |

| Radiator | 704.3 | 0.13 | 0.037 | |

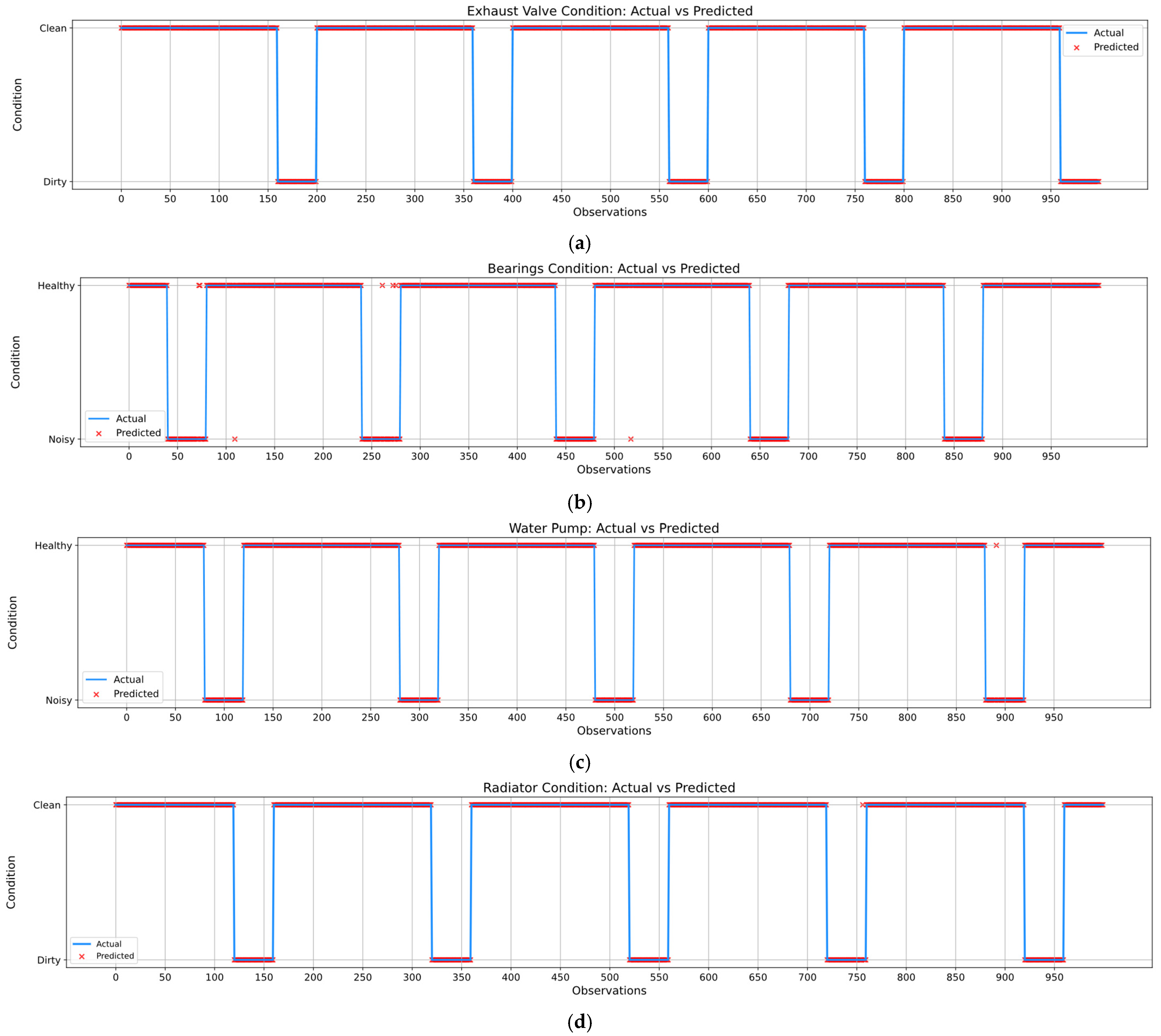

| Observations | Predicted Condition | Probability | Recommended Action |

|---|---|---|---|

| 0–159 | Clean | 98.64% | Monitoring |

| 160–200 | Dirty | 98.53% | Cleaning |

| 201–359 | Clean | 98.38% | Monitoring |

| 360–400 | Dirty | 99.1% | Cleaning |

| 401–559 | Clean | 98.79% | Monitoring |

| 560–599 | Dirty | 98.51% | Cleaning |

| 600–759 | Clean | 98.47% | Monitoring |

| 760–800 | Dirty | 99.12% | Cleaning |

| 801–959 | Clean | 98.24% | Monitoring |

| 960–1000 | Dirty | 98.49% | Cleaning |

| Observations | Predicted Condition | Probability | Recommended Action |

|---|---|---|---|

| 0–39 | Healthy | 98.67% | Monitoring |

| 40–79 | Noisy | 98.65% | Schedule Maintenance |

| 80–239 | Healthy | 99.07% | Monitoring |

| 240–279 | Noisy | 98.53% | Schedule Maintenance |

| 280–439 | Healthy | 98.71% | Monitoring |

| 440–479 | Noisy | 98.63% | Schedule Maintenance |

| 480–639 | Healthy | 98.11% | Monitoring |

| 640–679 | Noisy | 98.23% | Schedule Maintenance |

| 680–839 | Healthy | 98.55% | Monitoring |

| 840–879 | Noisy | 98.52% | Schedule Maintenance |

| 880–1000 | Healthy | 99.31% | Monitoring |

| Observations | Predicted Condition | Probability | Recommended Action |

|---|---|---|---|

| 0–79 | Healthy | 99.21% | Monitoring |

| 80–119 | Noisy | 98.65% | Schedule Maintenance |

| 120–279 | Healthy | 98.27% | Monitoring |

| 280–319 | Noisy | 98.31% | Schedule Maintenance |

| 320–479 | Healthy | 98.42% | Monitoring |

| 480–519 | Noisy | 98.23% | Schedule Maintenance |

| 520–679 | Healthy | 98.55% | Monitoring |

| 680–719 | Noisy | 98.51% | Schedule Maintenance |

| 720–879 | Healthy | 98.48% | Monitoring |

| 880–919 | Noisy | 98.57% | Schedule Maintenance |

| 920–100 | Healthy | 98.32% | Monitoring |

| Observations | Predicted Condition | Probability | Recommended Action |

|---|---|---|---|

| 0–119 | Clean | 98.32% | Monitoring |

| 120–159 | Dirty | 99.12% | Cleaning |

| 160–319 | Clean | 98.45% | Monitoring |

| 320–359 | Dirty | 98.55% | Cleaning |

| 360–519 | Clean | 98.49% | Monitoring |

| 520–559 | Dirty | 98.59% | Cleaning |

| 560–719 | Clean | 99.06% | Monitoring |

| 720–759 | Dirty | 98.73% | Cleaning |

| 760–919 | Clean | 98.52% | Monitoring |

| 920–959 | Dirty | 98.44% | Cleaning |

| 960–1000 | Clean | 98.51% | Monitoring |

| Component | Observations | Predicted Condition | Actual Condition | Probability |

|---|---|---|---|---|

| Bearings | 72 | Healthy | Noisy | 95% |

| 73 | Healthy | Noisy | 90% | |

| 109 | Noisy | Healthy | 65% | |

| 261 | Healthy | Noisy | 97% | |

| 272 | Healthy | Noisy | 76% | |

| 275 | Healthy | Noisy | 94% | |

| 517 | Healthy | Noisy | 88% | |

| 679 | Noisy | Healthy | 94% | |

| Water Pump | 891 | Healthy | Dirty | 86% |

| Test Accuracy [%] | Precision [%] | Recall [%] | F1-Score [%] | |||

|---|---|---|---|---|---|---|

| Two layer DNN with 32 and 16 neurons, respectively | NVIDIA T4 GPU | Exhaust Valve | 95.4 | 91.2 | 94.6 | 92.8 |

| Bearings | 93.8 | 92.1 | 84.5 | 88.1 | ||

| Water Pump | 90.5 | 85.2 | 83.2 | 84.2 | ||

| Radiator | 95.7 | 92.3 | 93.4 | 92.8 | ||

| NVIDIA Jetson Nano | Exhaust Valve | 94.3 | 88.6 | 95.2 | 91.7 | |

| Bearings | 89.4 | 82.5 | 82.4 | 82.4 | ||

| Water Pump | 93.1 | 87.3 | 91.4 | 89.3 | ||

| Radiator | 92.5 | 86.4 | 92.2 | 89.3 | ||

| Raspberry Pi 4 Model B | Exhaust Valve | 95.7 | 91.2 | 97.4 | 94.1 | |

| Bearings | 88.3 | 81.2 | 84.7 | 82.9 | ||

| Water Pump | 92.6 | 86.3 | 90.1 | 88.1 | ||

| Radiator | 97.2 | 95.7 | 96.4 | 96.1 | ||

| SVM Model | NVIDIA T4 GPU | Exhaust Valve | 91.3 | 84.5 | 94.3 | 89.1 |

| Bearings | 97.1 | 95.1 | 94.2 | 94.6 | ||

| Water Pump | 89.4 | 82.3 | 93.4 | 87.4 | ||

| Radiator | 96.5 | 93.6 | 98.1 | 95.7 | ||

| NVIDIA Jetson Nano | Exhaust Valve | 92.6 | 85.4 | 95.2 | 88.7 | |

| Bearings | 95.2 | 90.2 | 97.6 | 93.7 | ||

| Water Pump | 88.7 | 81.3 | 93.5 | 86.9 | ||

| Radiator | 97.5 | 94.4 | 97.2 | 95.7 | ||

| Raspberry Pi 4 Model B | Exhaust Valve | 91.3 | 84.1 | 94.7 | 89.1 | |

| Bearings | 95.6 | 90.3 | 97.2 | 93.6 | ||

| Water Pump | 88.1 | 81.2 | 93.1 | 86.7 | ||

| Radiator | 96.8 | 94.7 | 96.5 | 95.6 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciobotaru, A.; Corches, C.; Gota, D.; Miclea, L. An Explainable Deep Learning-Based Predictive Maintenance Solution for Air Compressor Condition Monitoring. Sensors 2025, 25, 5797. https://doi.org/10.3390/s25185797

Ciobotaru A, Corches C, Gota D, Miclea L. An Explainable Deep Learning-Based Predictive Maintenance Solution for Air Compressor Condition Monitoring. Sensors. 2025; 25(18):5797. https://doi.org/10.3390/s25185797

Chicago/Turabian StyleCiobotaru, Alexandru, Cosmina Corches, Dan Gota, and Liviu Miclea. 2025. "An Explainable Deep Learning-Based Predictive Maintenance Solution for Air Compressor Condition Monitoring" Sensors 25, no. 18: 5797. https://doi.org/10.3390/s25185797

APA StyleCiobotaru, A., Corches, C., Gota, D., & Miclea, L. (2025). An Explainable Deep Learning-Based Predictive Maintenance Solution for Air Compressor Condition Monitoring. Sensors, 25(18), 5797. https://doi.org/10.3390/s25185797