Ultrasensitive Pressure Measurement Using an Extrinsic Fabry–Pérot Interferometer (EFPI) Sensor

Abstract

1. Introduction

Table of Comparative Sensors

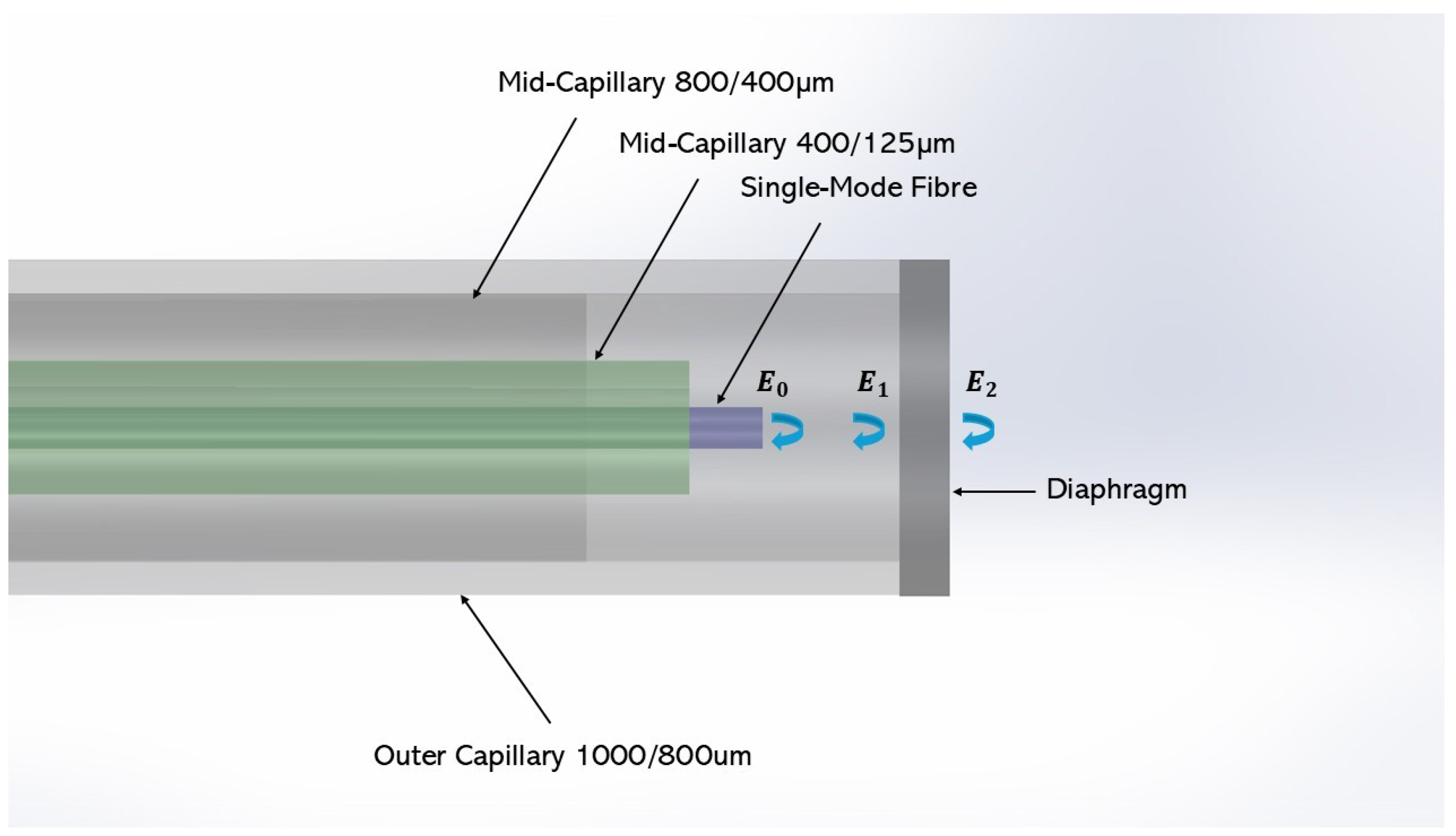

2. Sensor Theory and Design

2.1. Mechanical Design Considerations

2.2. Interferometer Theory

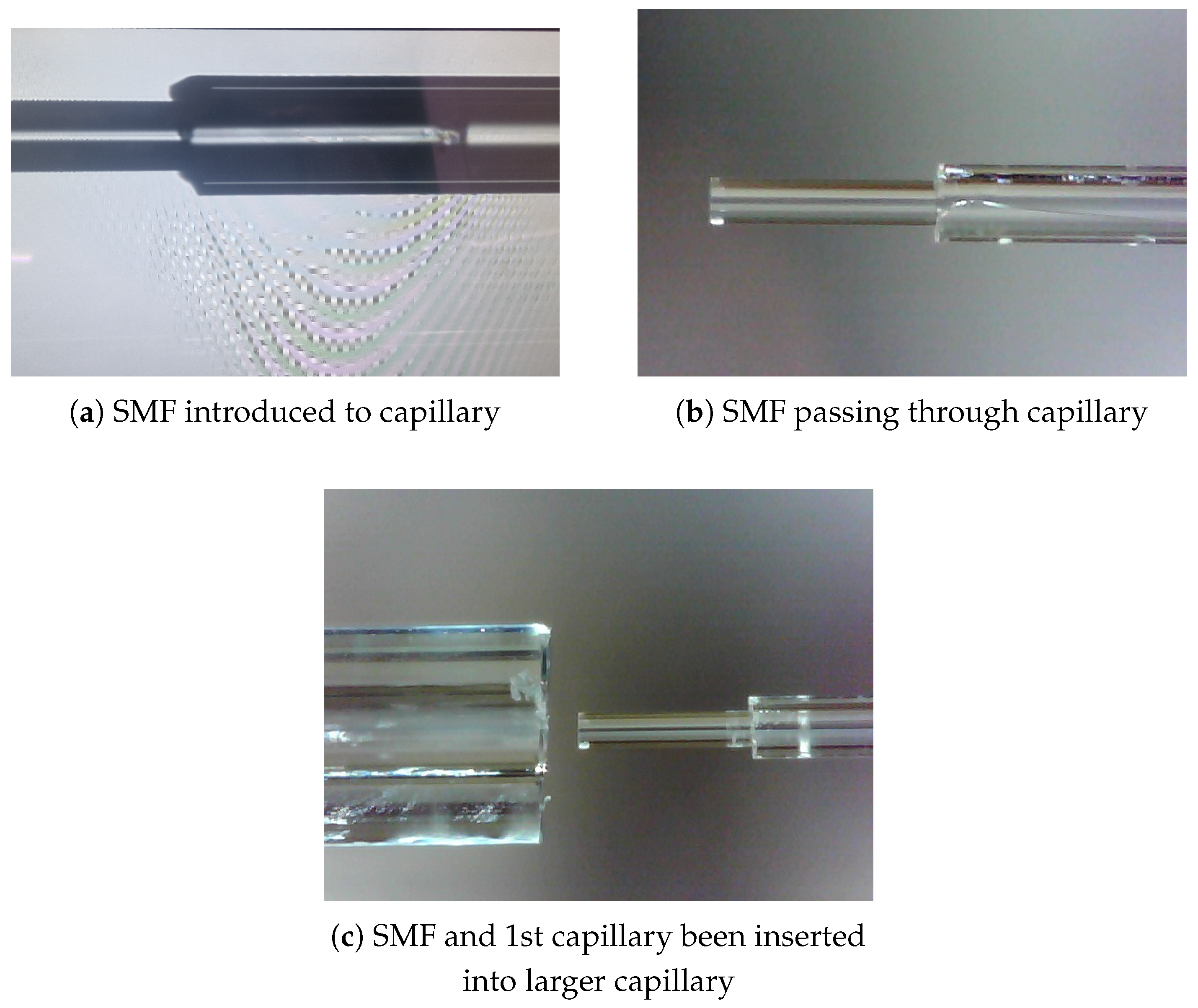

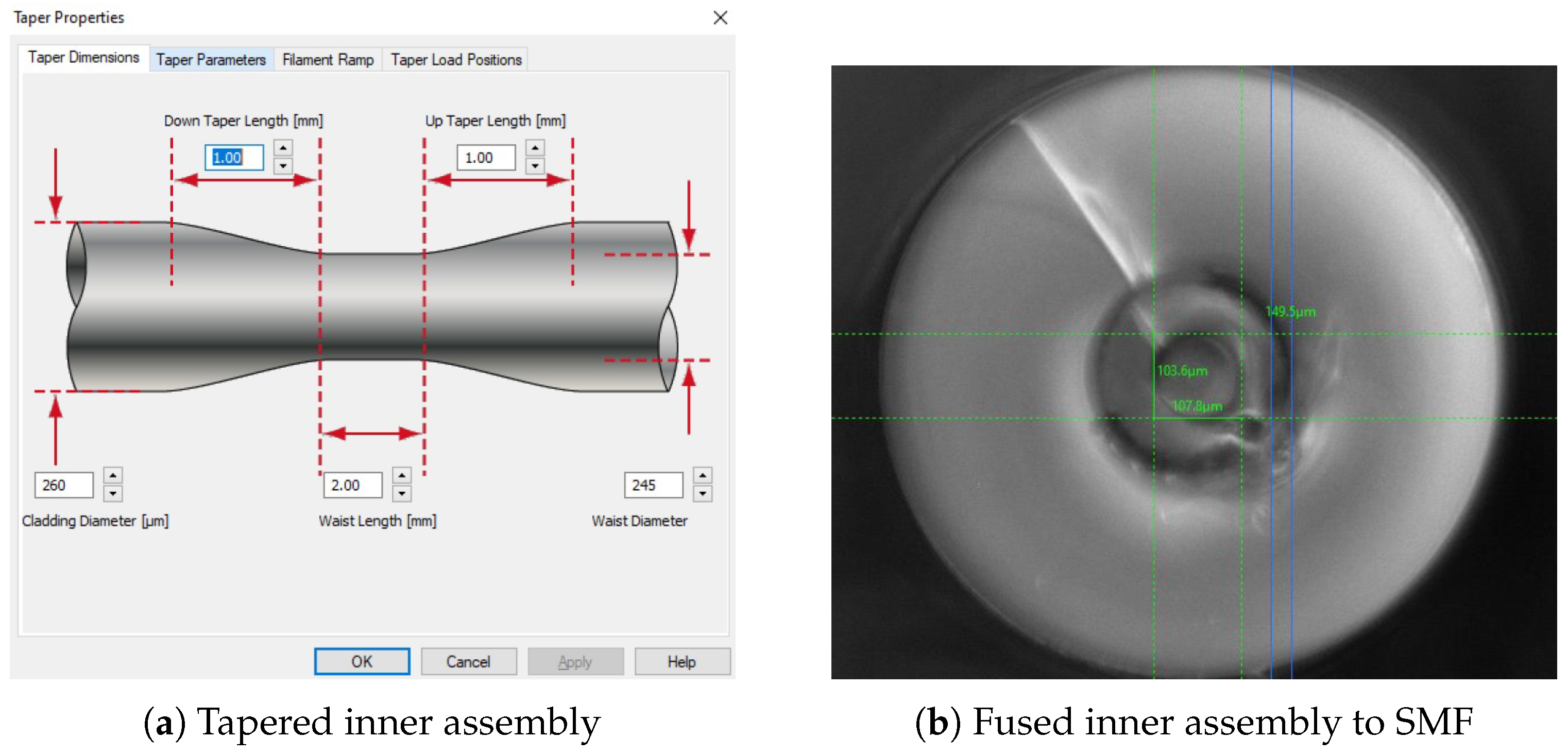

2.3. Sensor Design and Fabrication

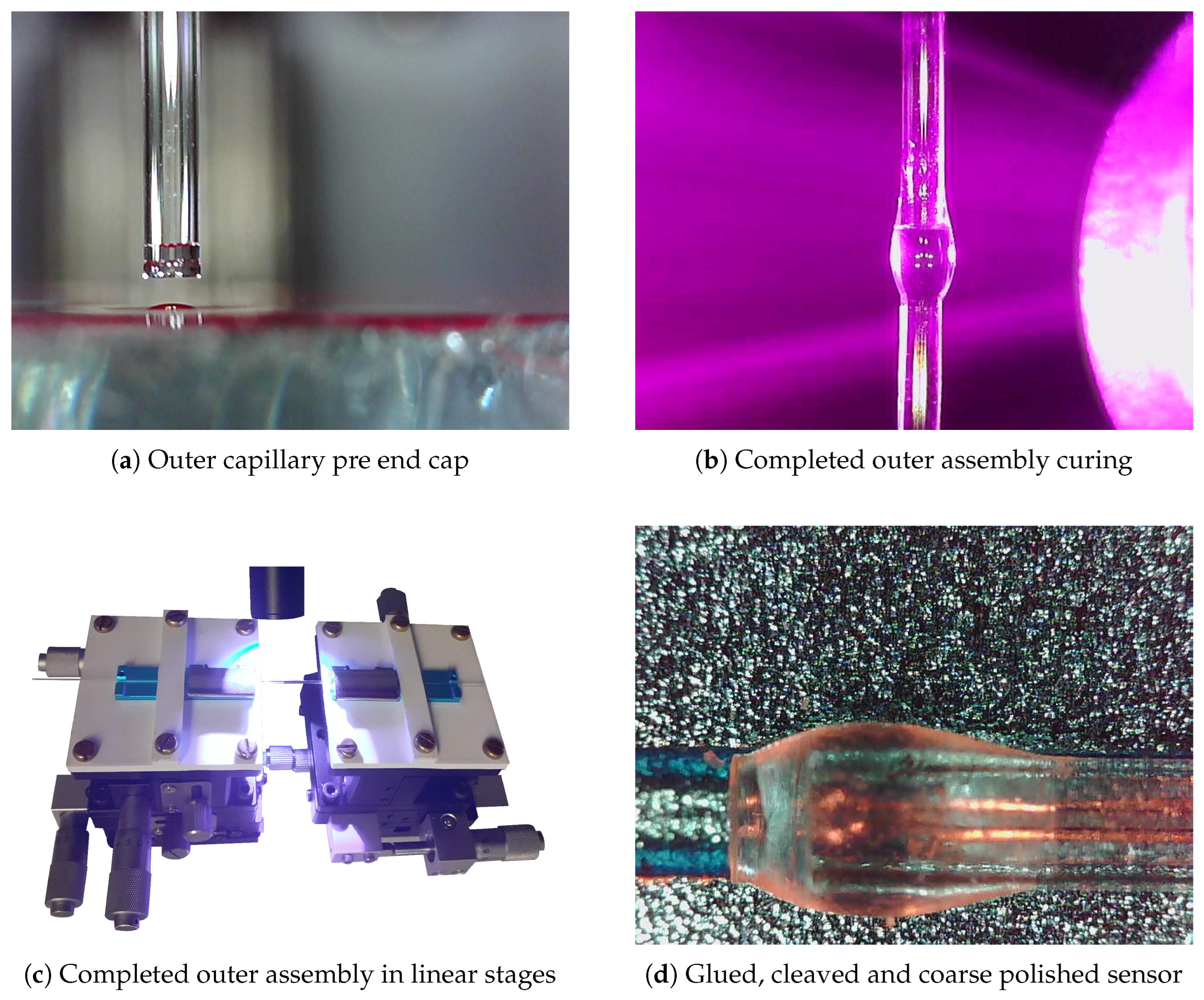

2.4. Outer Sensor Assembly with Adhesive

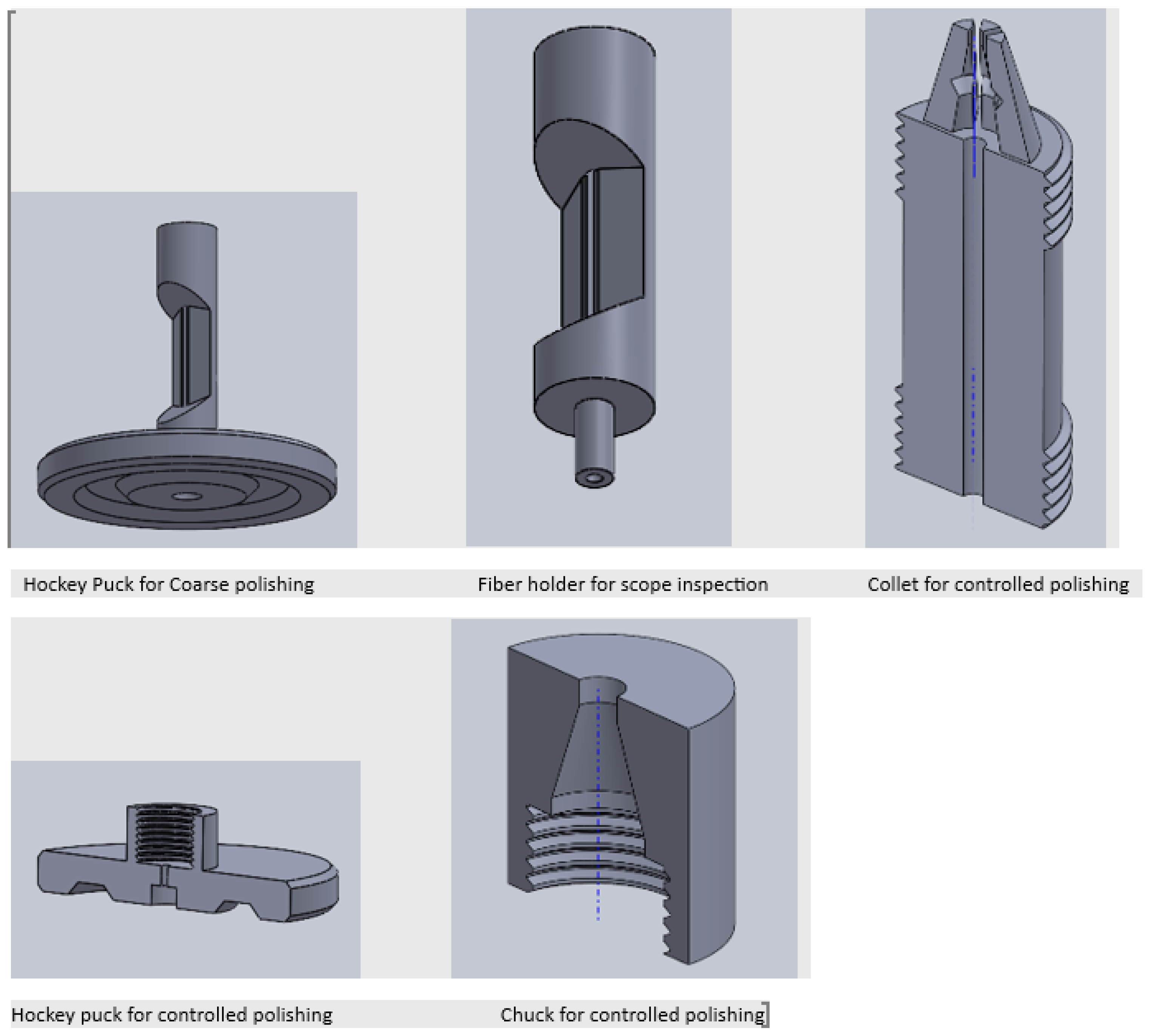

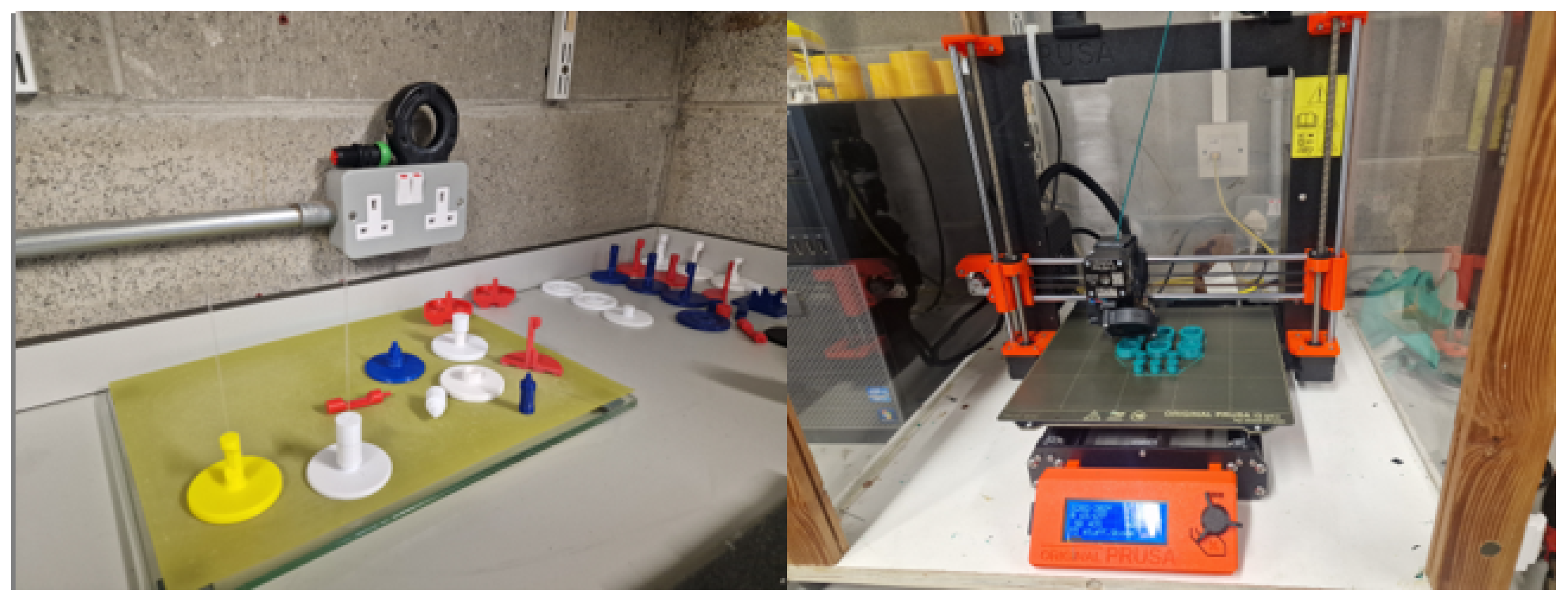

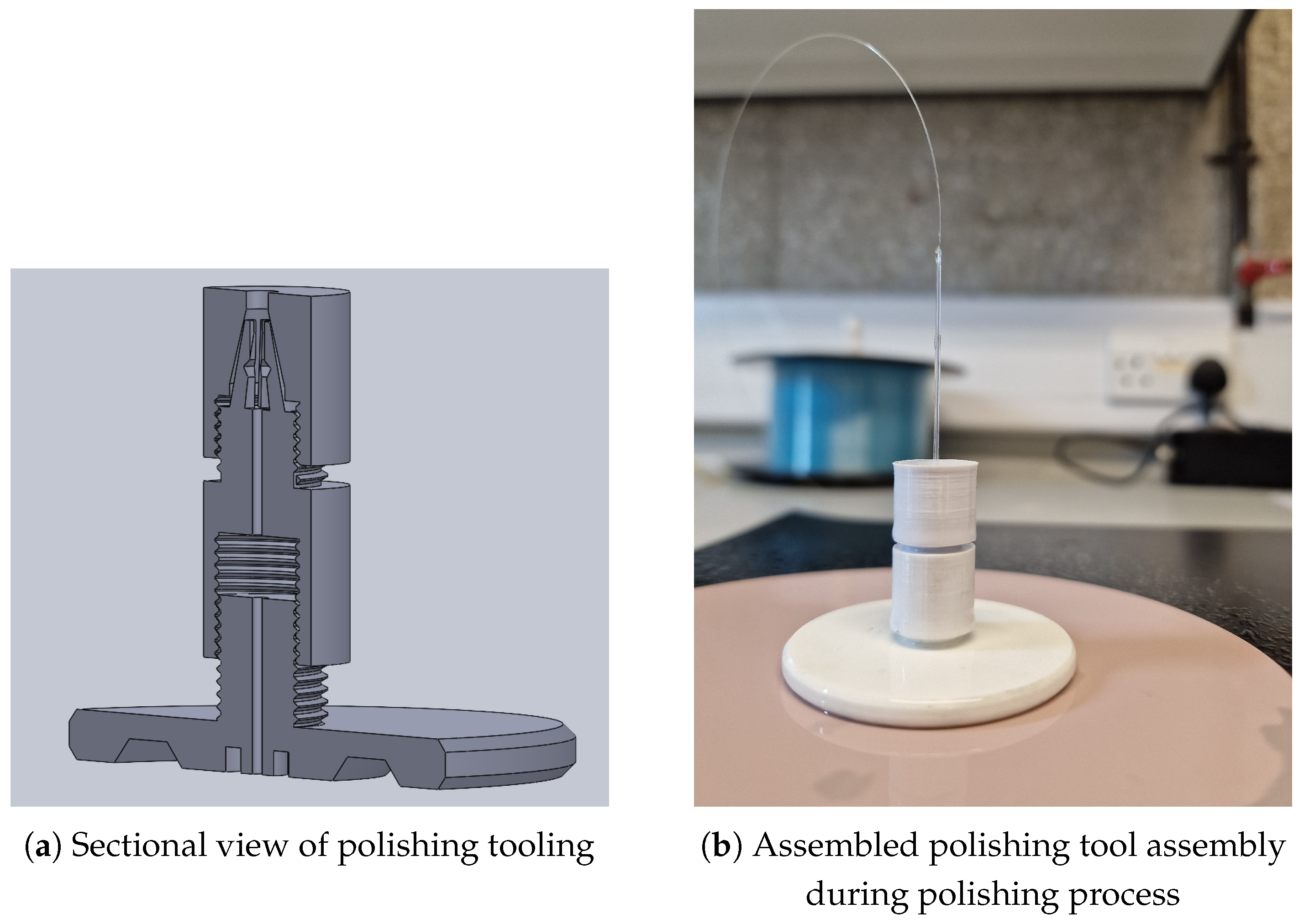

2.4.1. Polishing the 1 Capillary and Rod

2.4.2. Alignment of the Rod and Capillary

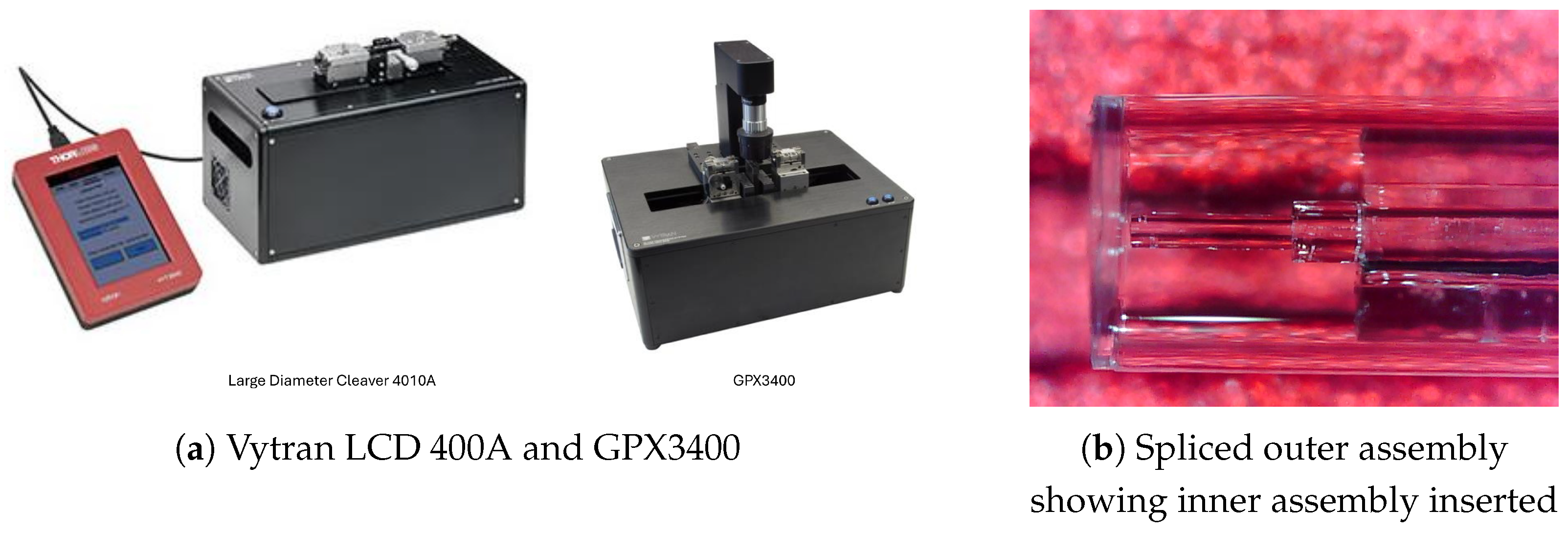

2.5. Outer Sensor Assembly by Splicing

2.6. Assembling the Complete Sensor

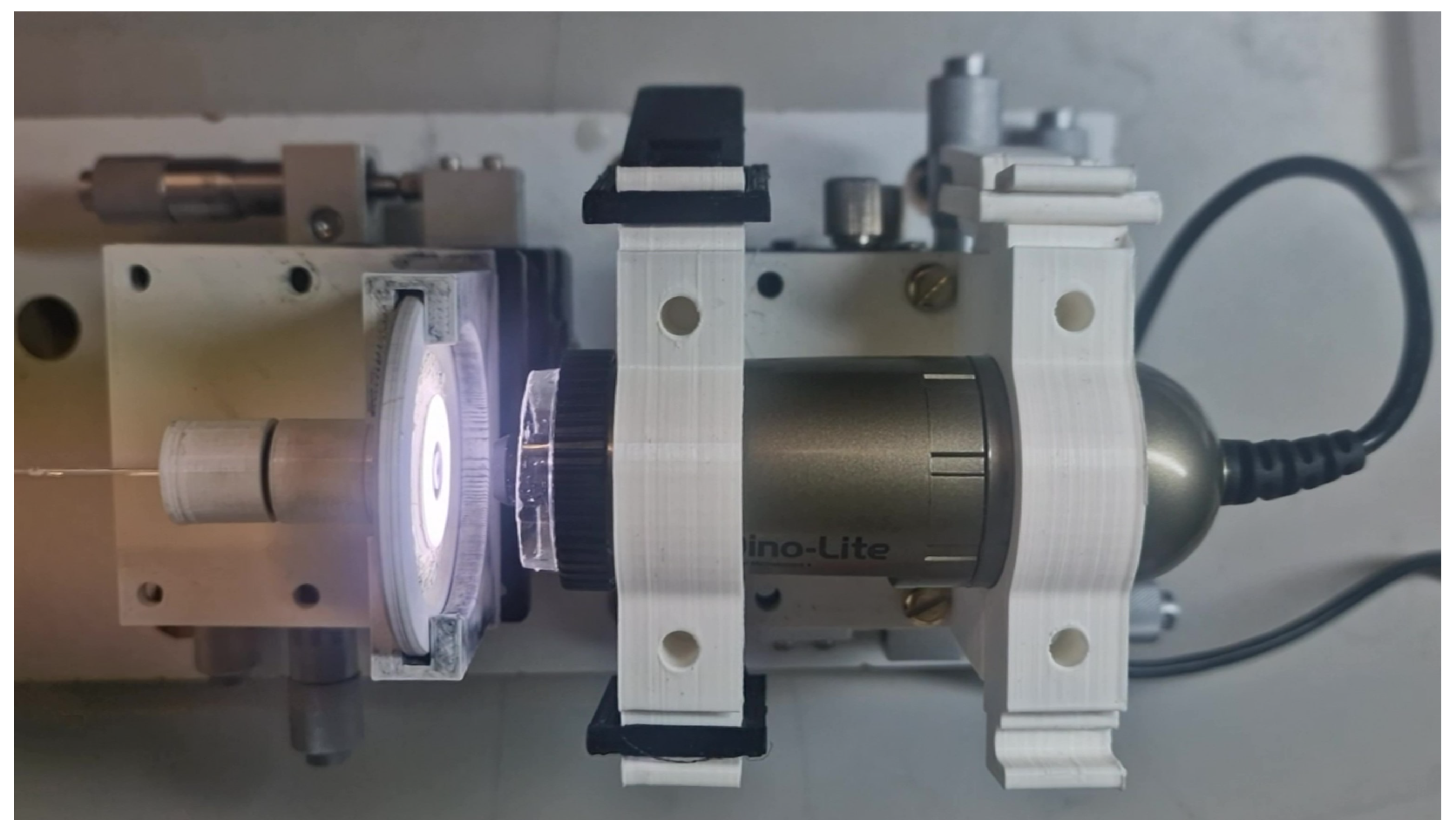

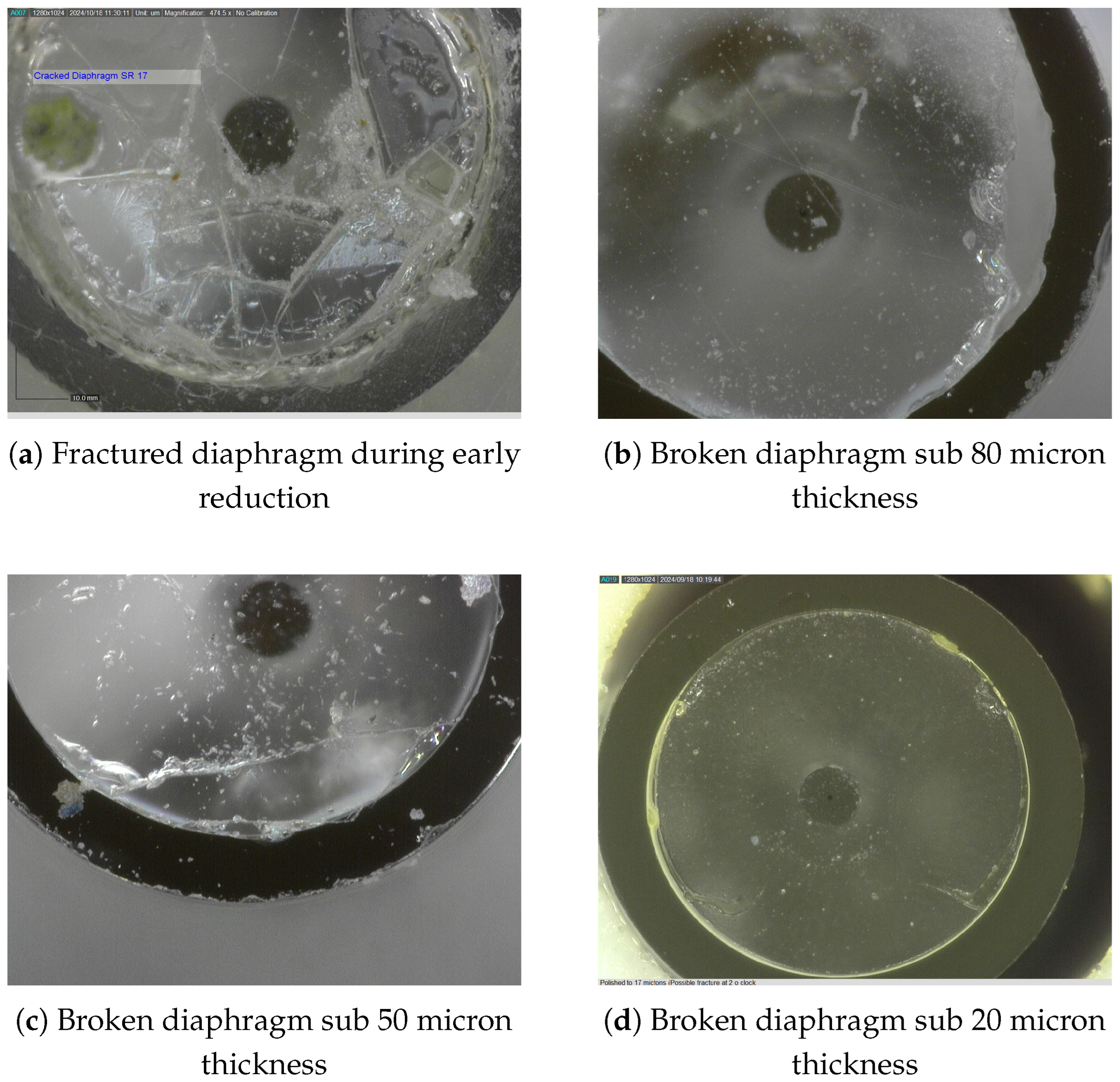

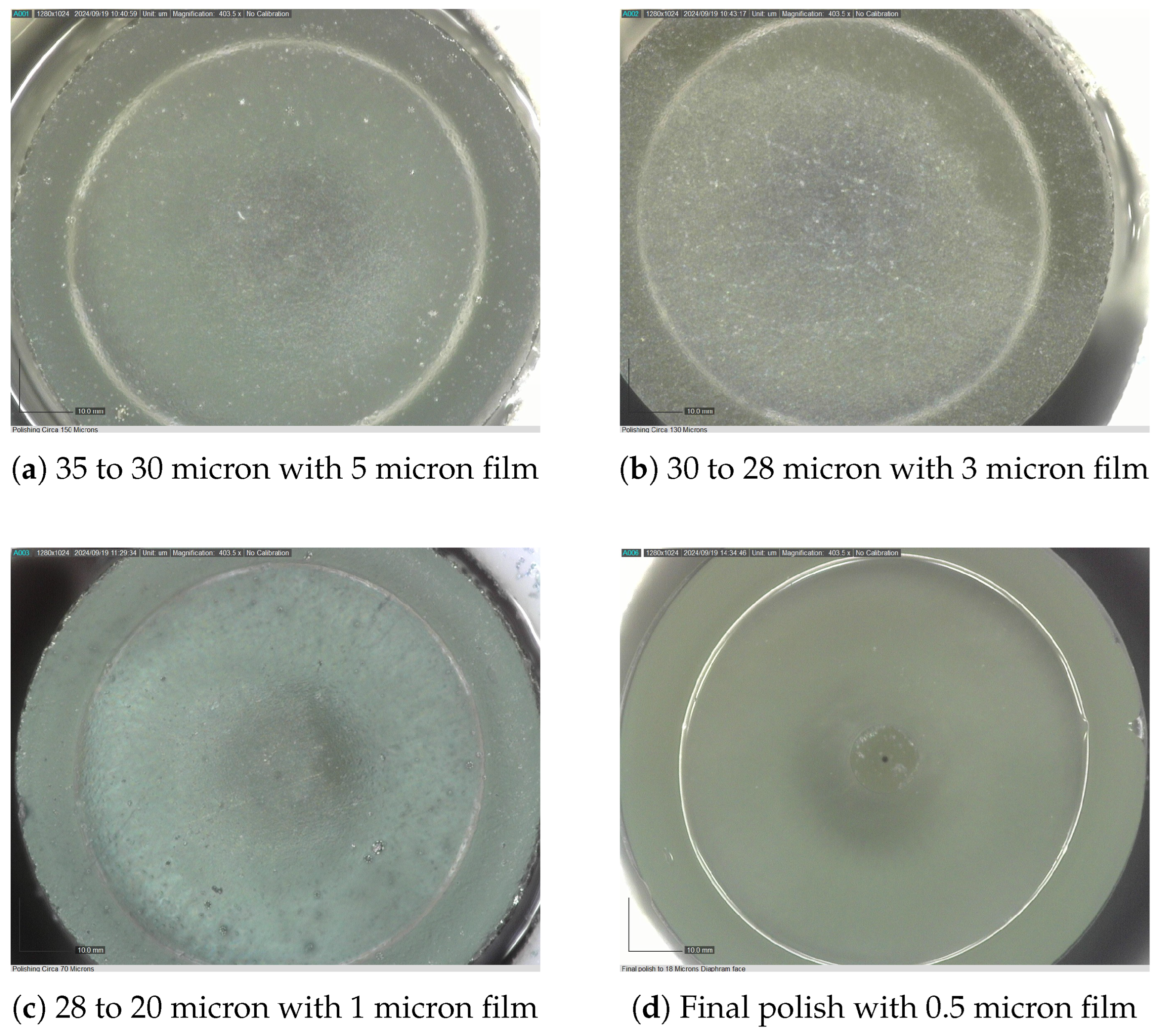

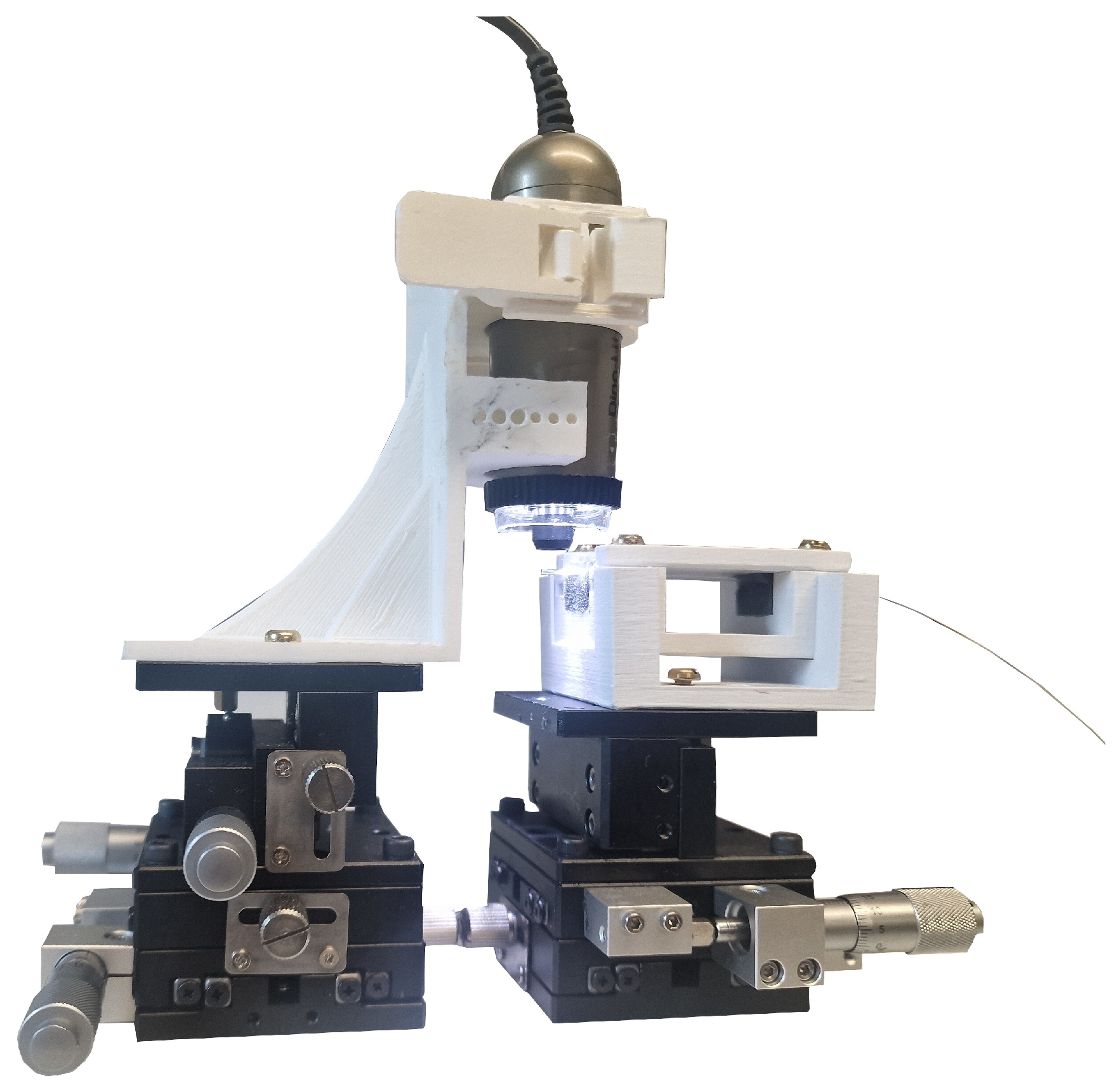

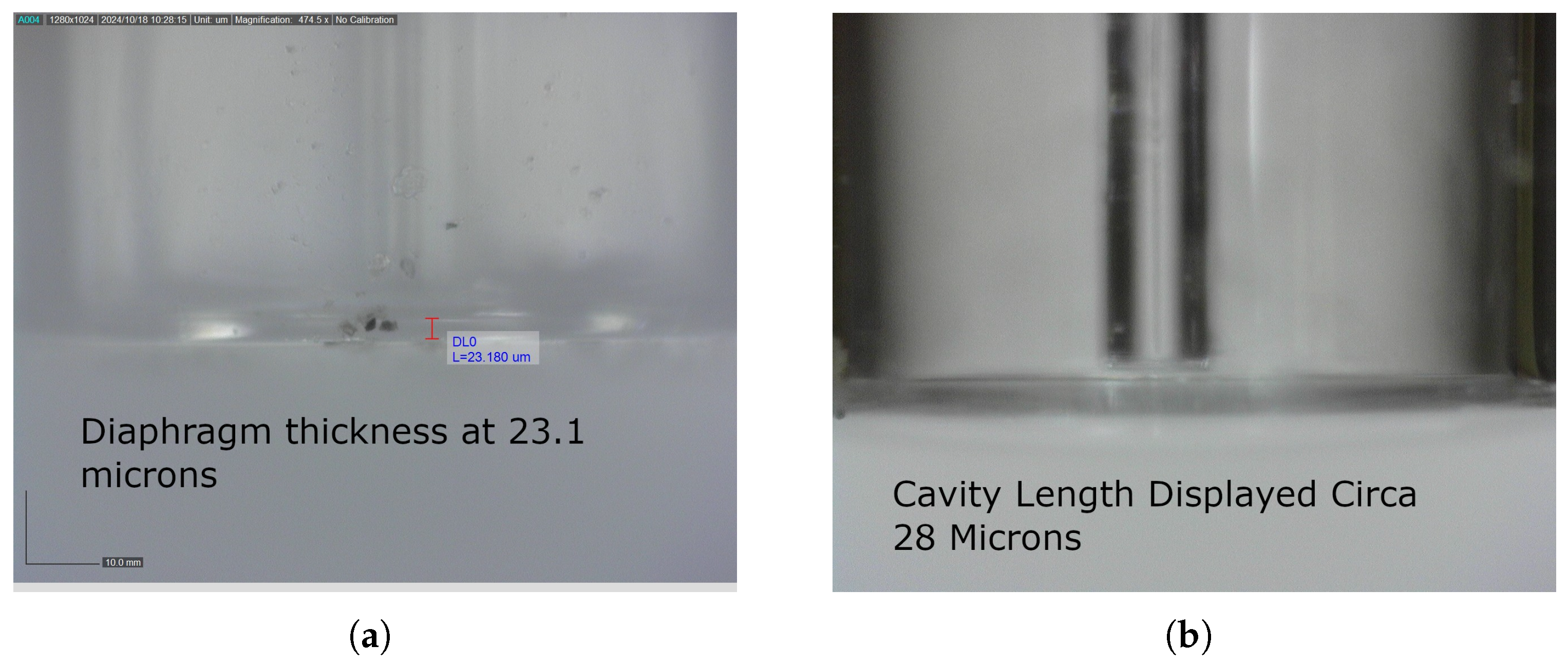

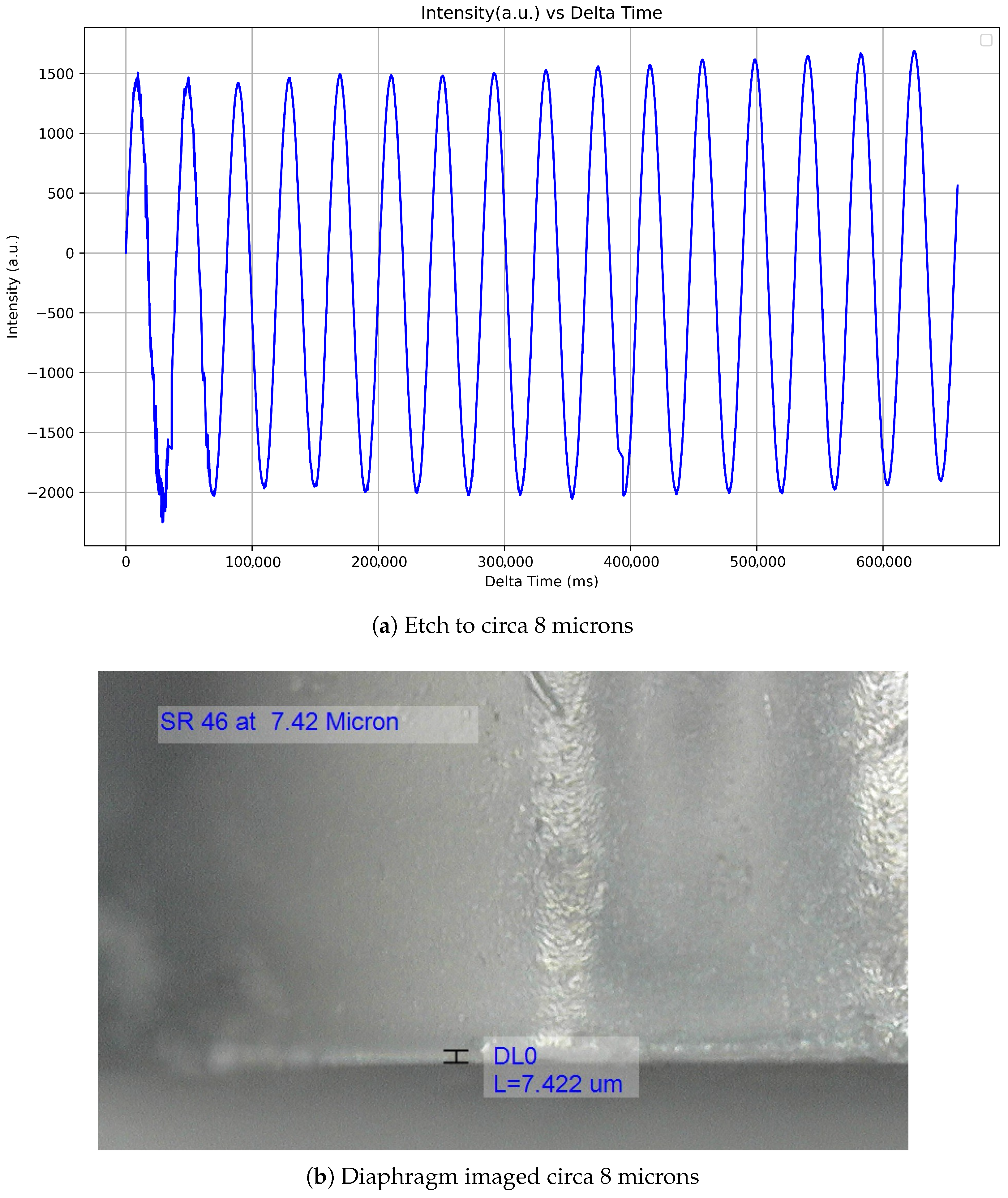

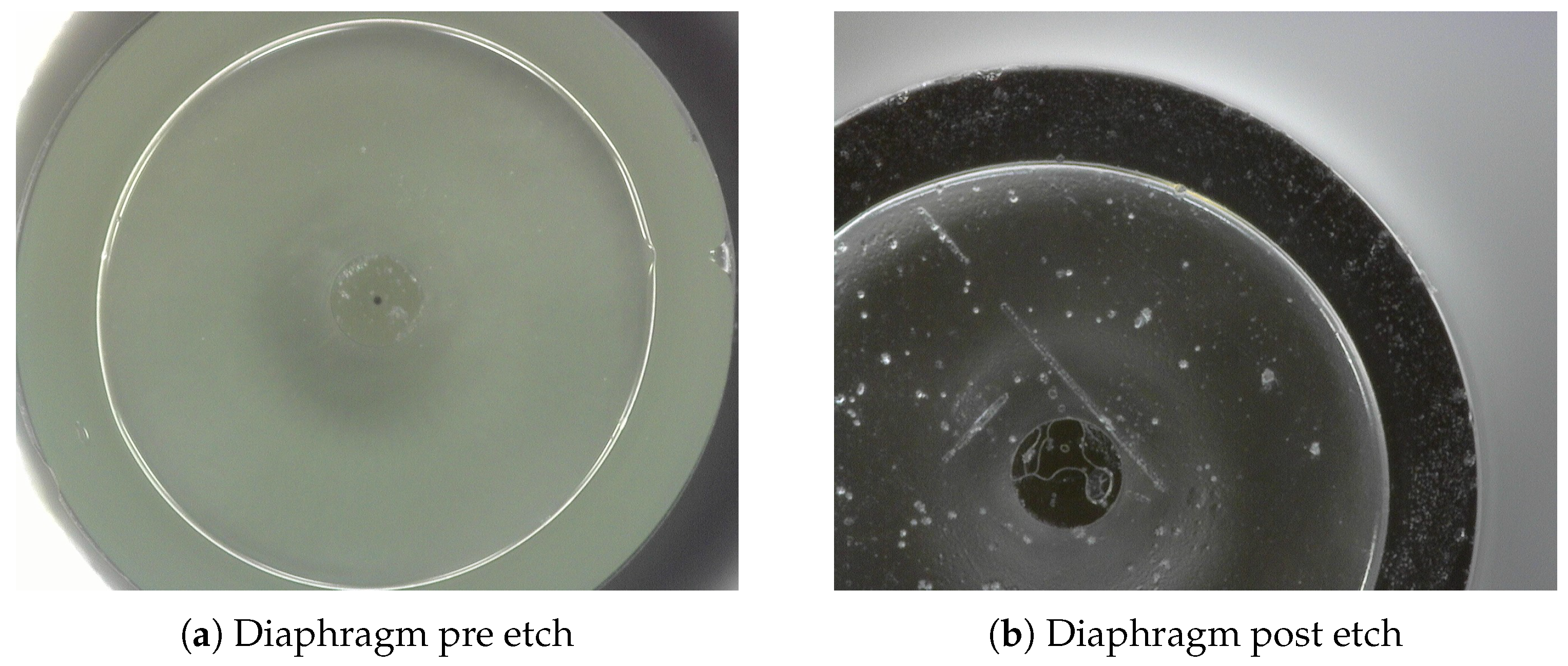

3. Assembled Sensor Diaphragm Reduction

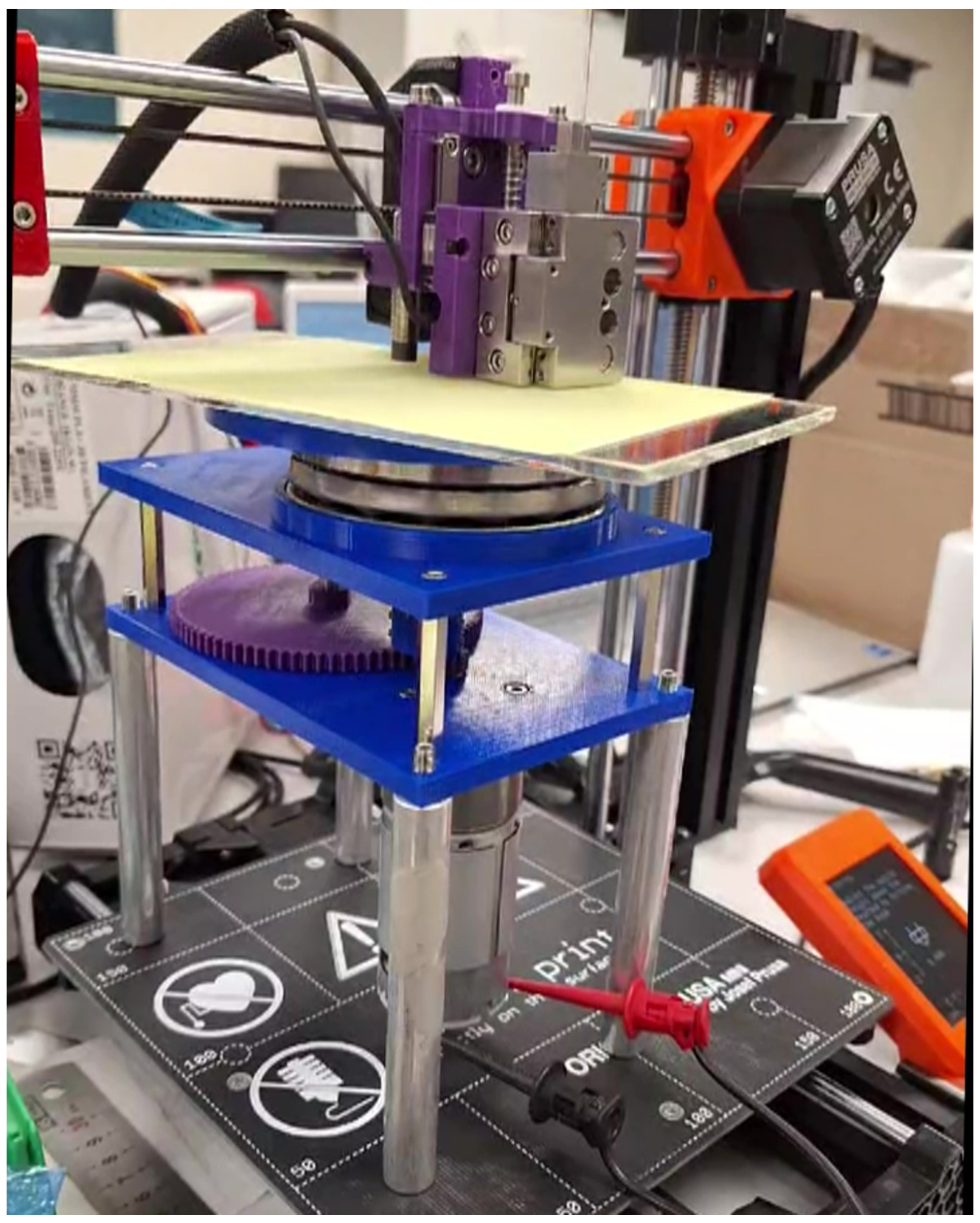

3.1. Reduction with Polish and Lapping Film

Final Reduction with HF Etching

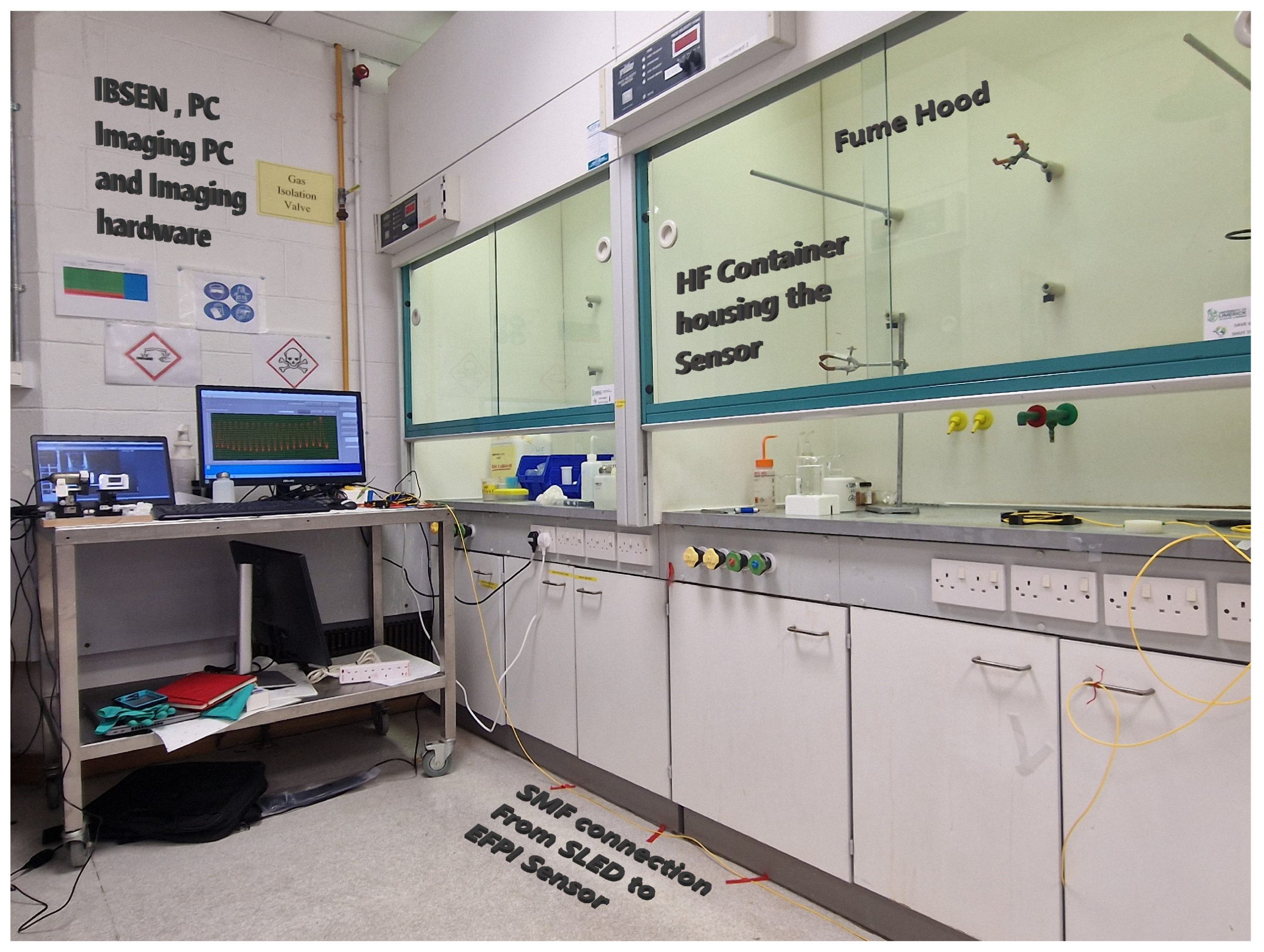

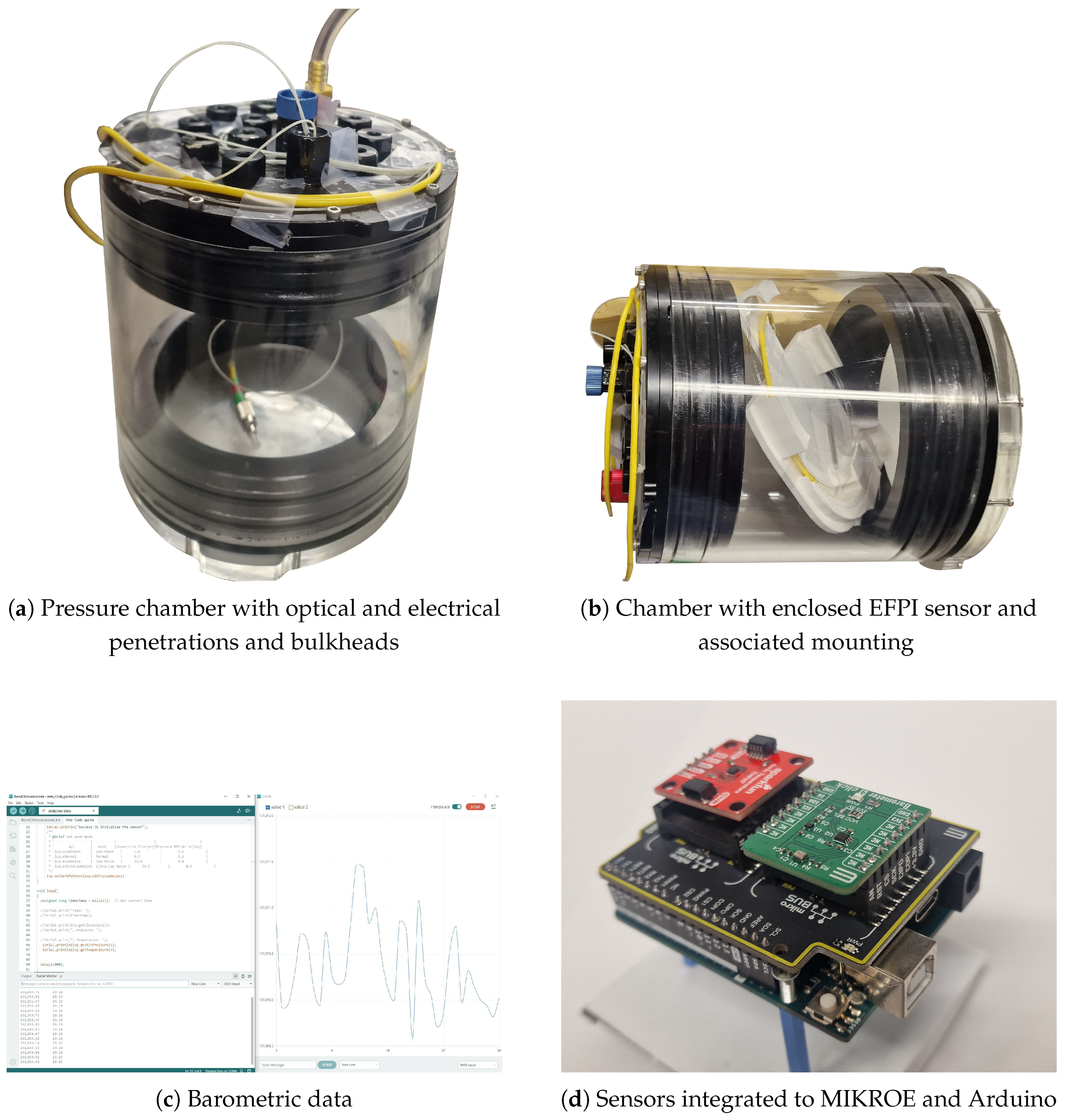

4. Experimental Setup

4.1. Optical Interrogation Setup

4.2. Experimental Setup

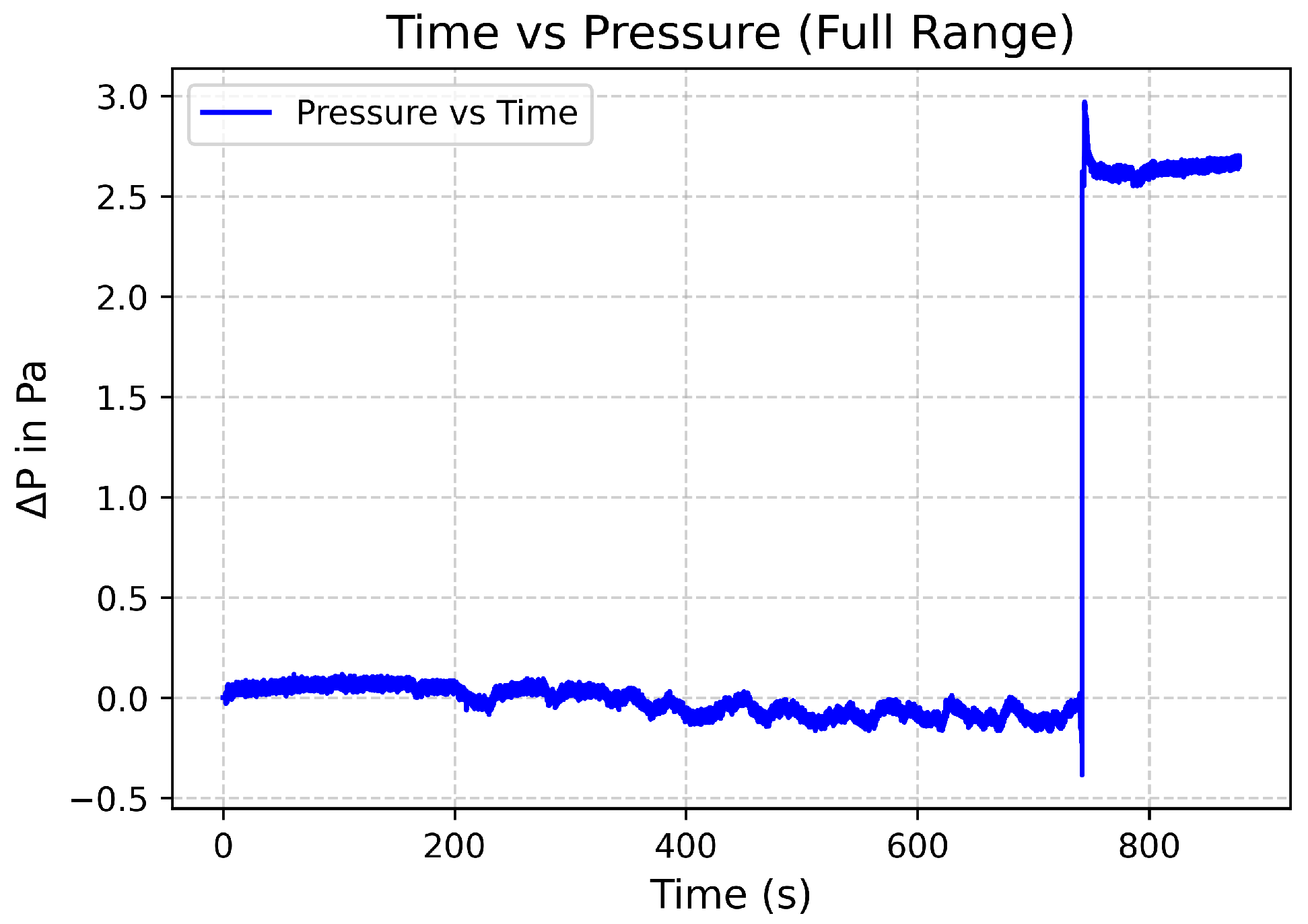

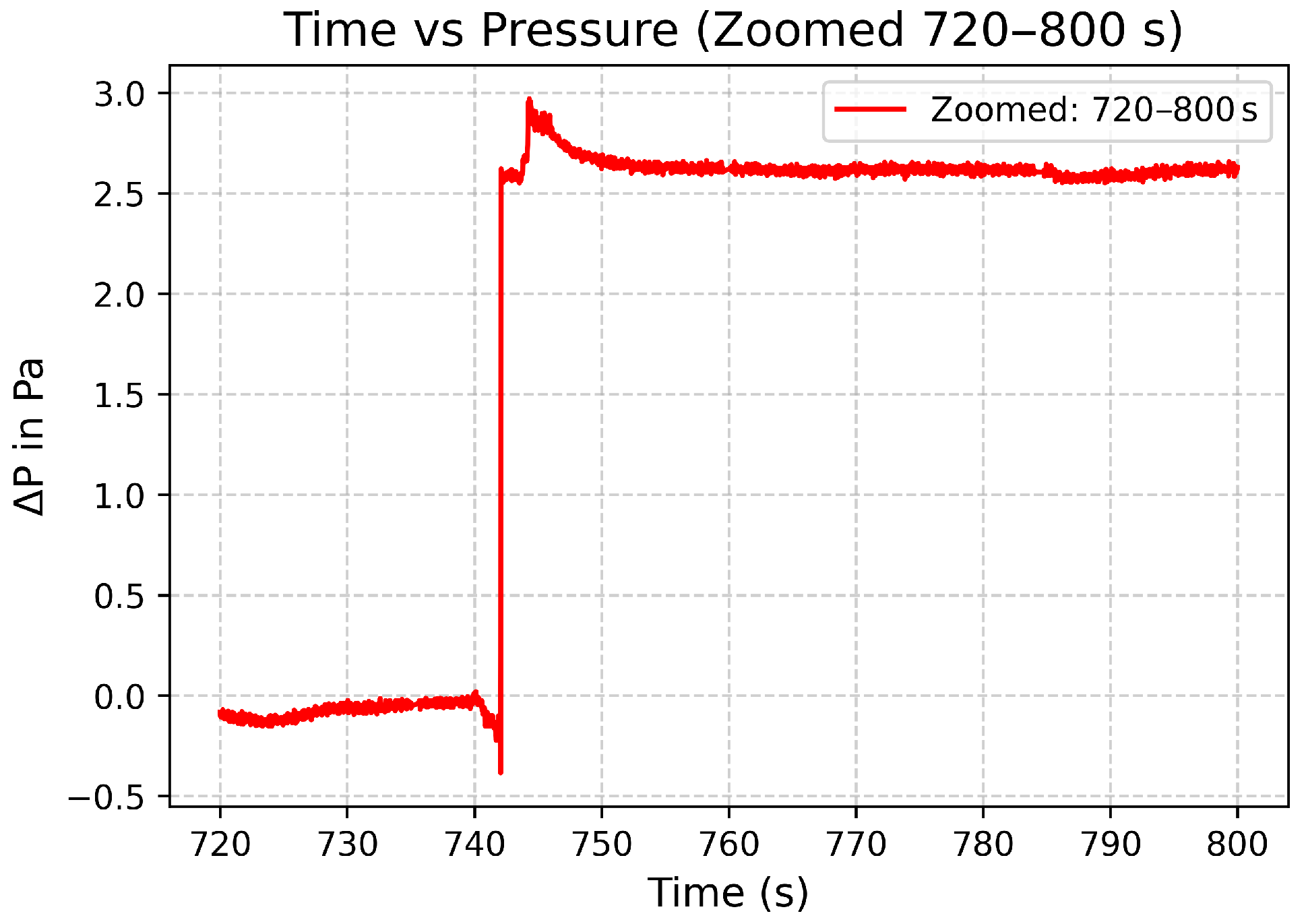

5. Results and Discussion

6. Conclusions and Future Development

Long Term Stability

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FPI | Fabry–Pérot Interferometer |

| EFPI | Extrinsic Fabry–Pérot interferometry |

| HF | Hydrofluoric Acid |

| ISA | Inner Sensor Assembly |

| OSA | Outer Sensor Assembly |

| FSV | Full-Scale Value |

| MMF | Multimode Fiber |

| SMF | Single-Mode Fiber |

| IA | Inner Assembly |

| OA | Outer Assembly |

| ID | Inner Diameter |

| OD | Outer Diameter |

| RHS | Right-Hand Side |

| LHS | Left-Hand Side |

| UV | Ultra Violet |

| OFS | OFS Optics |

| LDC | Large-Diameter Cleaver |

| OSA | Optical Spectrum Analyser |

| BBL | Broadband Light Source |

| PC | Personal Computer |

| SNR | Signal-to-Noise ratio |

| SR | Sensor |

| Pa | Pascal |

References

- Monteiro, M.; Martí, A.C. Using smartphone pressure sensors to measure vertical velocities of elevators, stairways, and drones. Phys. Educ. 2016, 52, 015010. [Google Scholar] [CrossRef]

- Fabry, C.; Pérot, A. Sur les franges des lames minces argentées et leur application à la mesure de petites épaisseurs d’air. Ann. Chim. Phys. 1897, 12, 459–501. [Google Scholar]

- Li, H.; Deng, H.; Zheng, G.; Shan, M.; Zhong, Z.; Liu, B. Reviews on Corrugated Diaphragms in Miniature Fiber-Optic Pressure Sensors. Appl. Sci. 2019, 9, 2241. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liao, C.; Wang, Y.; He, J.; Fu, C.; Yang, K.; Bai, Z.; Zhang, F. Nano silica diaphragm in-fiber cavity for gas pressure measurement. Sci. Rep. 2017, 7, 787. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Gao, H.; Xu, D.; Gao, Z.; Hou, Z.; Shen, J.; Li, C. A high precision fiber optic Fabry–Perot pressure sensor based on AB epoxy adhesive film. Photonics 2021, 8, 581. [Google Scholar] [CrossRef]

- Eom, J.; Park, C.J.; Lee, B.H.; Lee, J.H.; Kwon, I.B.; Chung, E. Fiber optic Fabry–Perot pressure sensor based on lensed fiber and polymeric diaphragm. Sens. Actuators A Phys. 2015, 225, 25–32. [Google Scholar] [CrossRef]

- Mishra, S. Design Analysis and Performance Evaluation of Fiberoptic Pressure Sensors Based on Fabry-Perot Interferometer. Ph.D. Thesis, Homi Bhabha National Institute, Mumbai, India, 2020. Available online: http://www.hbni.ac.in/phdthesis/engg/ENGG01201204012.pdf (accessed on 20 May 2025).

- Rao, Y.J. Recent progress in fiber-optic extrinsic Fabry–Perot interferometric sensors. Opt. Fiber Technol. 2006, 12, 227–237. [Google Scholar] [CrossRef]

- Shao, Z.; Wu, Y.; Sun, Z.; Wang, W.; Liu, Z.; Zhang, C.; Bi, J.; Song, E. Excellent repeatability, all-sapphire Fabry Perot optical Pressure sensor based on wet etching and direct bonding for Harsh Environment Applications. Opt. Express 2021, 29, 19831–19838. [Google Scholar] [CrossRef]

- Poeggel, S.; Tosi, D.; Leen, G.; Lewis, E. Low-cost miniature fiber optic extrinsic fabry-perot interferometric sensor for cardiovascular pressure measurement. In Proceedings of the European Conference on Lasers and Electro-Optics, Munich, Germany, 12–16 May 2013; p. CH_6_4. [Google Scholar]

- Tosi, D.; Saccomandi, P.; Schena, E.; Duraibabu, D.B.; Poeggel, S.; Leen, G.; Lewis, E. Intra-tissue pressure measurement in ex vivo liver undergoing laser ablation with fiber-optic Fabry-Perot probe. Sensors 2016, 16, 544. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, K.; Sun, Q.; Ni, X.; Ai, F.; Wang, S.; Yan, Z.; Liu, D. Diaphragm-based optical fiber sensor for pulse wave monitoring and cardiovascular diseases diagnosis. J. Biophotonics 2019, 12, e201900084. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Morizane, S.; Takenaka, A.; Ueki, M.; Matsunaga, T.; Lee, S.S. An Optical Grasping Force Sensor for Minimally Invasive Surgical Robotic Forceps. In Proceedings of the 2022 IEEE Sensors, Dallas, TX, USA, 30 October–2 November 2022; pp. 1–4. [Google Scholar]

- Kienitz, S.U.; Lohr, L.; Schmid, M.J.; Koch, A.W. Static and dynamic pressure measurement in flight test application with optical Fabry–Pérot sensors. IEEE Trans. Instrum. Meas. 2021, 70, 7004611. [Google Scholar] [CrossRef]

- Li, J.; Jia, P.; Fang, G.; Wang, J.; Qian, J.; Ren, Q.; Xiong, J. Batch-producible all-silica fiber-optic Fabry–Perot pressure sensor for high-temperature applications up to 800 °C. Sens. Actuators A Phys. 2022, 334, 113363. [Google Scholar] [CrossRef]

- Liao, C.; Liu, S.; Xu, L.; Wang, C.; Wang, Y.; Li, Z.; Wang, Q.; Wang, D. Sub-micron silica diaphragm-based fiber-tip Fabry–Perot interferometer for pressure measurement. Opt. Lett. 2014, 39, 2827–2830. [Google Scholar] [CrossRef]

- Donlagic, D.; Cibula, E. All-fiber high-sensitivity pressure sensor with SiO2 diaphragm. Opt. Lett. 2005, 30, 2071–2073. [Google Scholar] [CrossRef]

- Wang, W.; Wu, N.; Tian, Y.; Niezrecki, C.; Wang, X. Miniature all-silica optical fiber pressure sensor with an ultrathin uniform diaphragm. Opt. Express 2010, 18, 9006–9014. [Google Scholar] [CrossRef]

- Duraibabu, D.B.; Leen, G.; Toal, D.; Newe, T.; Lewis, E.; Dooly, G. Underwater depth and temperature sensing based on fiber optic technology for marine and fresh water applications. Sensors 2017, 17, 1228. [Google Scholar] [CrossRef] [PubMed]

- Balderrama, V.S.; Leon-Gil, J.A.; Fernández-Benavides, D.A.; Ponce-Hernández, J.; Bandala-Sánchez, M. MEMS Piezoresistive Pressure Sensor Based on Flexible PET Thin-Film for Applications in Gaseous-Environments. IEEE Sens. J. 2022, 22, 1939–1947. [Google Scholar] [CrossRef]

- Hosseini, E.S.; Manjakkal, L.; Shakthivel, D.; Dahiya, R. Glycine–Chitosan-Based Flexible Biodegradable Piezoelectric Pressure Sensor. ACS Appl. Mater. Interfaces 2020, 12, 9008–9016. [Google Scholar] [CrossRef] [PubMed]

- Sonlist. Understanding Pressure Sensor Accuracy, Precision, Resolution & Drift. 2024. Available online: https://www.solinst.com/onthelevel-news/water-level-monitoring/water-level-datalogging/understanding-pressure-sensor-accuracy-precision-resolution-drift/?utm_source=chatgpt.com (accessed on 10 March 2025).

- Kurup, L.A.; Cole, C.M.; Arthur, J.N.; Yambem, S.D. Graphene porous foams for capacitive pressure sensing. arXiv 2021, arXiv:2111.06052. [Google Scholar] [CrossRef]

- Poeggel, S.; Tosi, D.; Fusco, F.; Ippolito, J.; Lupoli, L.; Mirone, V.; Sannino, S.; Leen, G.; Lewis, E. Fiber-optic EFPI pressure sensors for in vivo urodynamic analysis. IEEE Sens. J. 2014, 14, 2335–2340. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, C.; Huang, Y.; Liang, H.; Guan, B.O. Silk fibroin diaphragm-based fiber-tip Fabry-Perot pressure sensor. Opt. Express 2016, 24, 19600–19606. [Google Scholar] [CrossRef]

- Wu, J.; Yao, M.; Xiong, F.; Zhang, A.P.; Tam, H.Y.; Wai, P.K.A. Optical fiber-tip Fabry–Perot interferometric pressure sensor based on an in situ μ-printed air cavity. J. Light. Technol. 2018, 36, 3618–3623. [Google Scholar] [CrossRef]

- Young, W.C.; Budynas, R.G.; Sadegh, A.M. Roark’s Formulas for Stress and Strain; McGraw-Hill: New York, NY, USA, 2002; Volume 7. [Google Scholar]

- Hutchinson, J.; Suo, Z. Mixed Mode Cracking in Layered Materials. Adv. Appl. Mech. 1991, 29, 63–191. [Google Scholar] [CrossRef]

- Dino-Lite. Dino-Lite. 2025. Available online: https://www.dino-lite.com/products_detail.php?index_m1_id=0&index_m2_id=0&index_id=98 (accessed on 10 June 2025).

- EXALOS. EBD2720003-03. 2025. Available online: https://www.indie.inc/spec-sheet/near-infrared-sledsvisible-sleds/ (accessed on 10 May 2025).

- IBSEN. I-MON E. Available online: https://forc-photonics.ru/data/files/Ibsen%20Product%20Sheet%20-%20I-MON-E-USB2_0.pdf (accessed on 1 April 2025).

- InvenSense. Barometric Pressure Sensor. 2025. Available online: https://invensense.tdk.com/wp-content/uploads/2021/06/DS-000177-ICP-10111-v1.3.pdf (accessed on 5 April 2025).

- Mikroe.com. Click Board. 2025. Available online: https://www.mikroe.com/click?srsltid=AfmBOorlxXJoTZqEkQSW29R2WLf4Ar1I3-EcA2-yRfG_jTy2J0ZS7b4w (accessed on 1 July 2025).

- Arduino. Arduino UNO. 2025. Available online: https://store.arduino.cc/products/arduino-uno-rev3 (accessed on 1 July 2025).

- McGuinness, F.; Cloonan, A.; Oubaha, M.; Duraibabu, D.B.; Ali, M.M.; Kilkelly, G.; Tobin, E.; Leen, G. Fabrication and qualitative analysis of an optical fibre EFPI-based temperature sensor. Sensors 2021, 21, 4445. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Shao, T.; Zhou, X.; Li, W.; Li, F.; Ye, X.; Huang, J.; Chen, S.; Li, B.; Yang, L.; et al. Understanding the effect of HF-based wet shallow etching on optical performance of reactive-ion-etched fused silica optics. RSC Adv. 2021, 11, 29323–29332. [Google Scholar] [CrossRef]

- Chen, X. Fiber Optic Pressure Sensor Fabrication Using MEMS Technology. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2003. [Google Scholar]

- Kesavan, K.; Ravisankar, K.; Parivallal, S.; Sreeshylam, P.; Sridhar, S. Assessment of Long-term Performance of EFPI Fibre Optic Sensors. Int. J. COMADEM 2007, 10, 37. [Google Scholar]

| Sensor Construction and Materials | Ref | Fabrication Method | Pressure Range (kPa) | Sensitivity (nm/kPa) | Resolution (Pa) | Diaphragm Diameter (Microns) | Diaphragm Thickness (Microns) |

|---|---|---|---|---|---|---|---|

| All-fibre high-sensitivity pressure sensor | [17] | Fusion splicing, Etching, Polishing | 3.4 | 300 | 125 | ||

| SMF, MM diaphragm & silica capillary | [19] | Fusion splicing, Wet polishing & Etching | 15 | 78 | 130 | 2–3 | |

| SMF, Capillary & Epoxy adhesive film | [5] | Epoxy Adhesive and Fusion splicing | 0–70 | 0.257 | 150 | 8.74 | |

| Single-mode fibre, silica capillary and Diaphragm Fusion splicing and etching. | [24] | Silica Capillary, Diaphragm and SMF | 1–1.6 | 28 | 130 | 2.3 | |

| Silk Fibroin, Silica Capillary | [25] | Epoxy adhesive to bond the Capillary to the SMF& aminopropylitrieethoxysilane on the end face of the capillary to bond to the Fibroin diaphragm | 12.3 | 127 | 20 | ||

| SU-8 epoxy Polymer diaphragm, SMF, Ceramic ferrule | [26] | 3D Printing | 0–700 | 0.00293 | 80 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weir, A.; Bartlett, B.; Dooly, G.; Duraibabu, D.B. Ultrasensitive Pressure Measurement Using an Extrinsic Fabry–Pérot Interferometer (EFPI) Sensor. Sensors 2025, 25, 5757. https://doi.org/10.3390/s25185757

Weir A, Bartlett B, Dooly G, Duraibabu DB. Ultrasensitive Pressure Measurement Using an Extrinsic Fabry–Pérot Interferometer (EFPI) Sensor. Sensors. 2025; 25(18):5757. https://doi.org/10.3390/s25185757

Chicago/Turabian StyleWeir, Anthony, Ben Bartlett, Gerard Dooly, and Dinesh Babu Duraibabu. 2025. "Ultrasensitive Pressure Measurement Using an Extrinsic Fabry–Pérot Interferometer (EFPI) Sensor" Sensors 25, no. 18: 5757. https://doi.org/10.3390/s25185757

APA StyleWeir, A., Bartlett, B., Dooly, G., & Duraibabu, D. B. (2025). Ultrasensitive Pressure Measurement Using an Extrinsic Fabry–Pérot Interferometer (EFPI) Sensor. Sensors, 25(18), 5757. https://doi.org/10.3390/s25185757