Revised Control Barrier Function with Sensing of Threats from Relative Velocity Between Humans and Mobile Robots

Abstract

1. Introduction

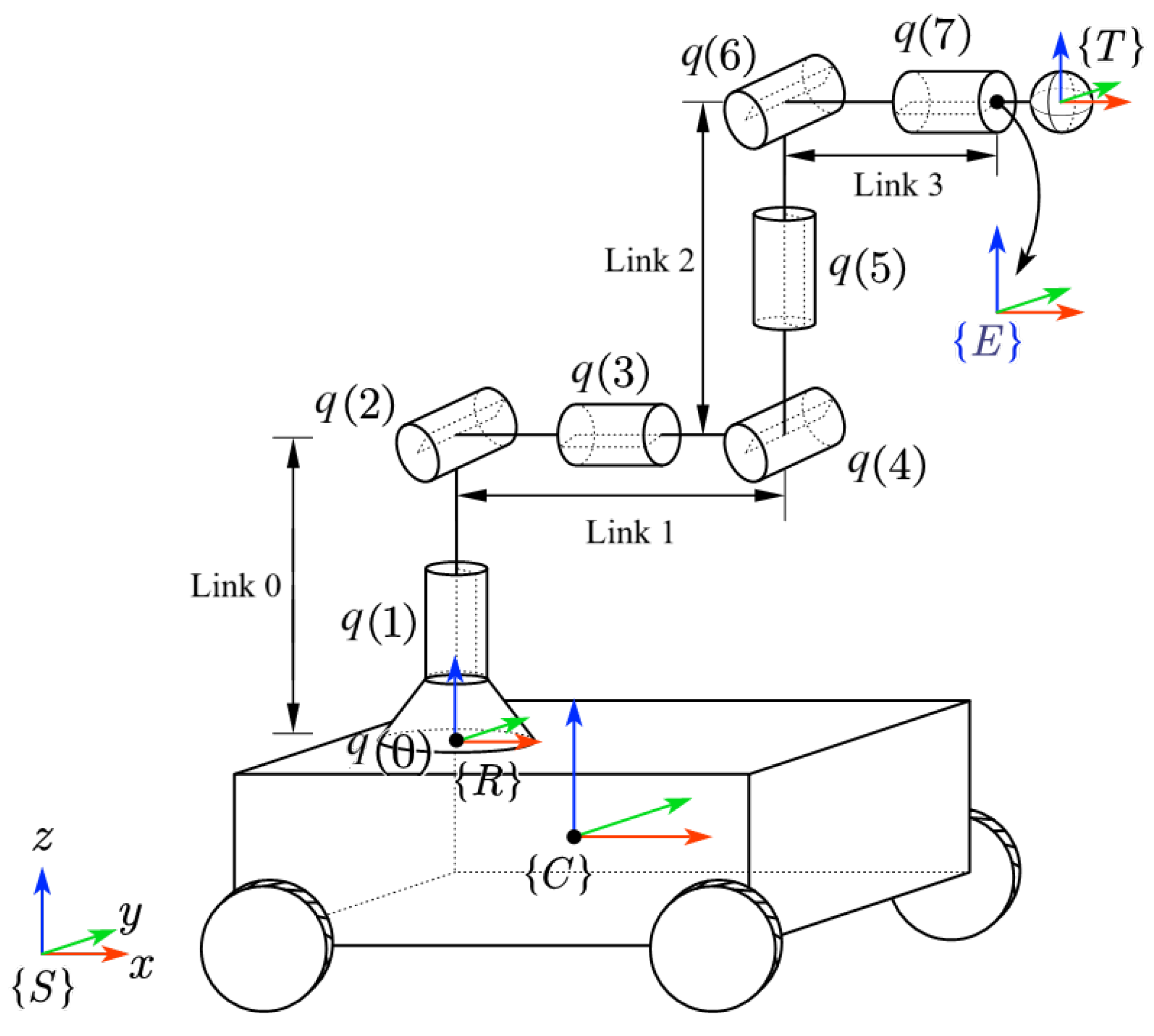

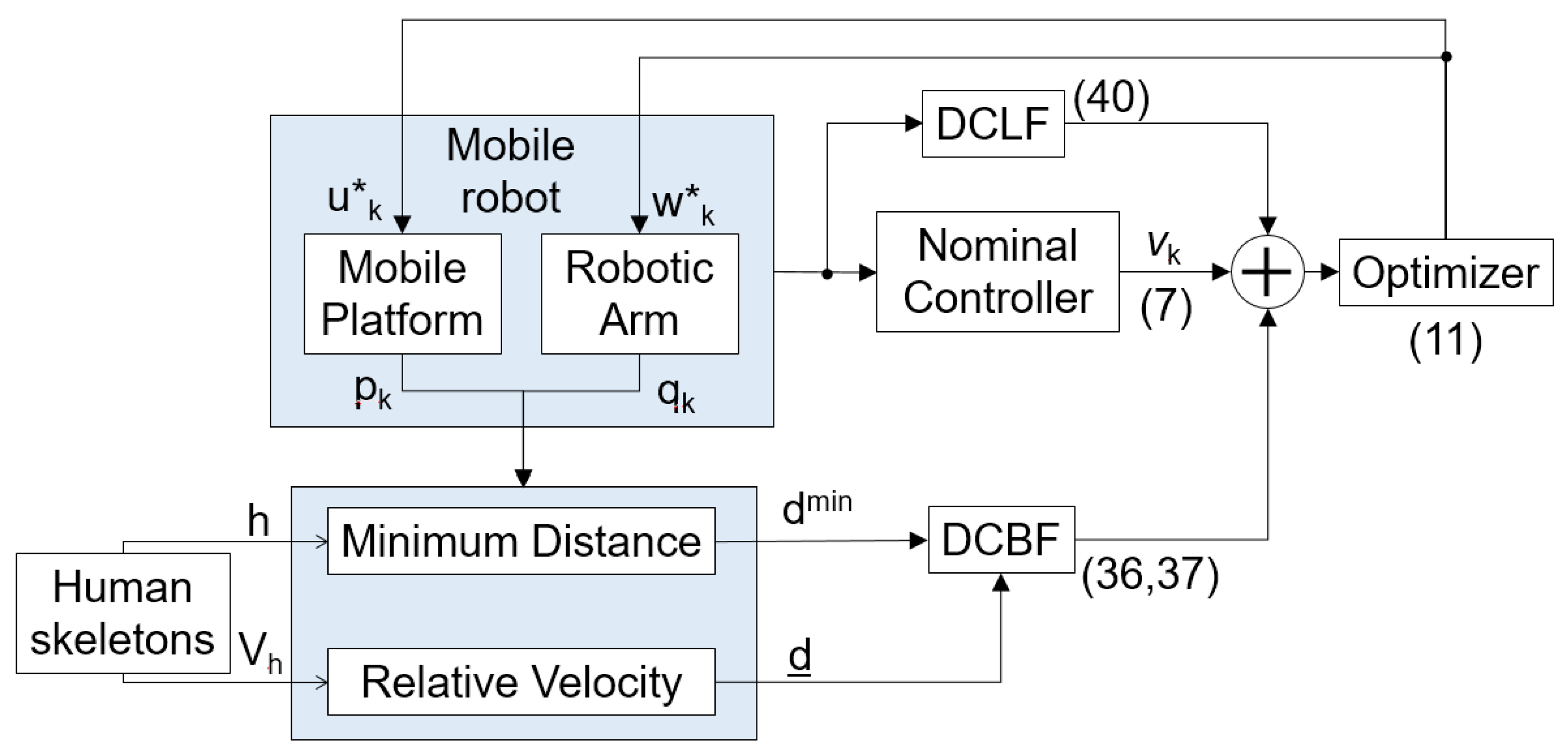

- The coupling kinematics of the mobile robot with a mobile platform and a robotic arm is formed in the kinematic sense rather than solely with the fixed-base robot arm in [22], so that the kinematic control problem in human–robot environments is set up with a discrete-time control barrier function (DCBF) and discrete-time control Lyapunov function (DCLF).

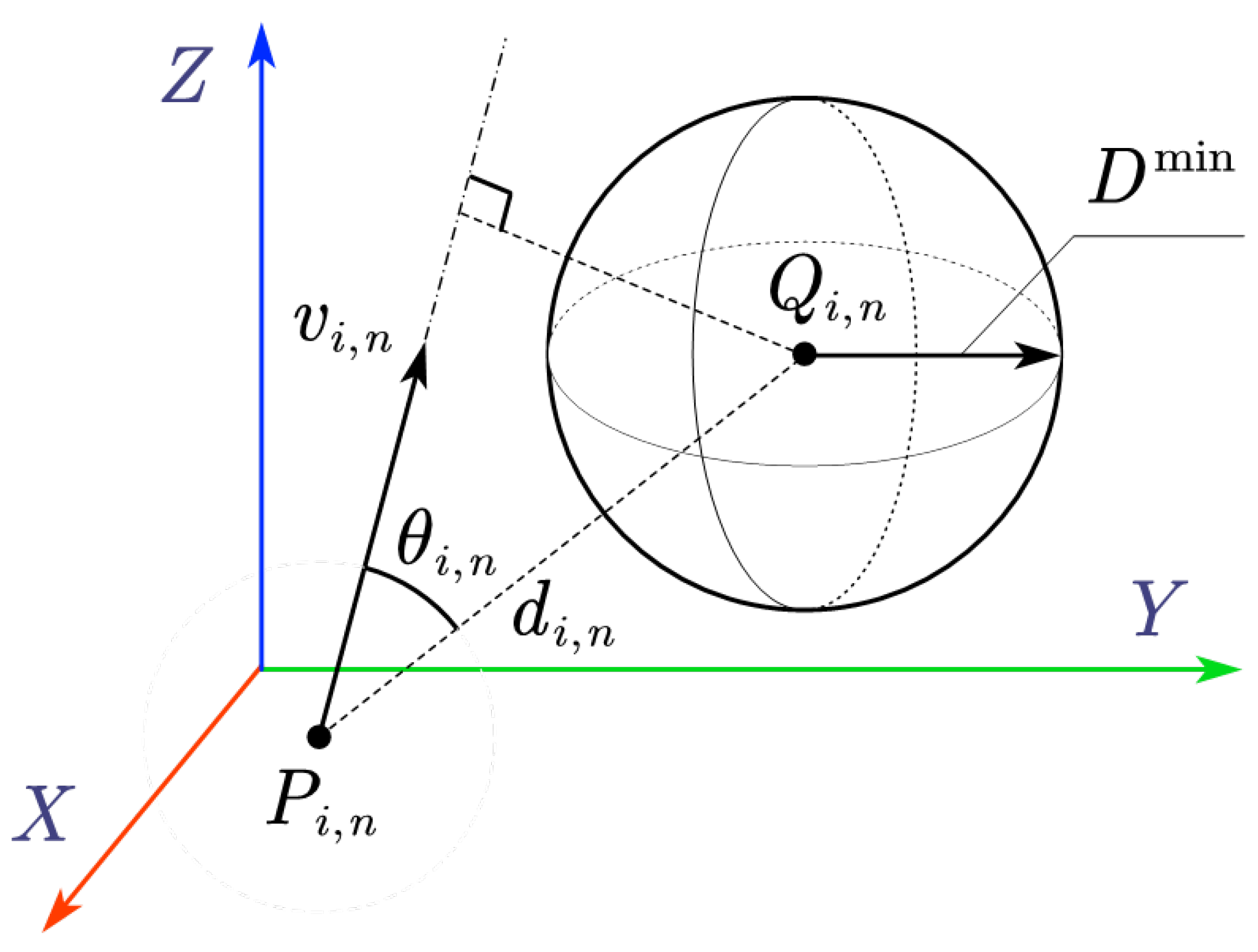

- By setting up the parametric description of skew line segments, the minimum distance between a pair of human skeletons and a link of a robotic arm (or an outline of a mobile platform) is efficiently solved in real time by convex programming. Compared with [22,28], it is no longer necessary to make a case-by-case analysis depending on the relative locations of the skew line segments and their common normal.

- By mutual projections of relative velocity of parts of a human and a mobile robot and their common normal vector, two projection indexes are given. Thereafter, a novel threat index is formed to give a normalized “distance” to select the most threatened human parts. In this way, the relative velocities between parts of humans and mobile robots are successfully incorporated into the DCBF-based constraint rather than just their absolute velocities [27,28].

2. Related Works

3. Problem Formulation

3.1. Control of a Mobile Robot

3.2. Safety and Stability Constraints

4. Main Results

4.1. Distance Between a Mobile Robot and Human

4.2. The Threatening Index Based on Relative Velocity

- When , it indicates that the robot moving at the current relative velocity will not intrude into the safety range of the obstacle. Thus, the threatening index is set to zero.

- When , the robot has the risk of intruding into the safety range of the obstacle at the current relative velocity. In this case, is set to , where ensures that the threat coefficient is at least when . Thus, a non-zero threatening index is issued.

4.3. Revised Safety Constraints

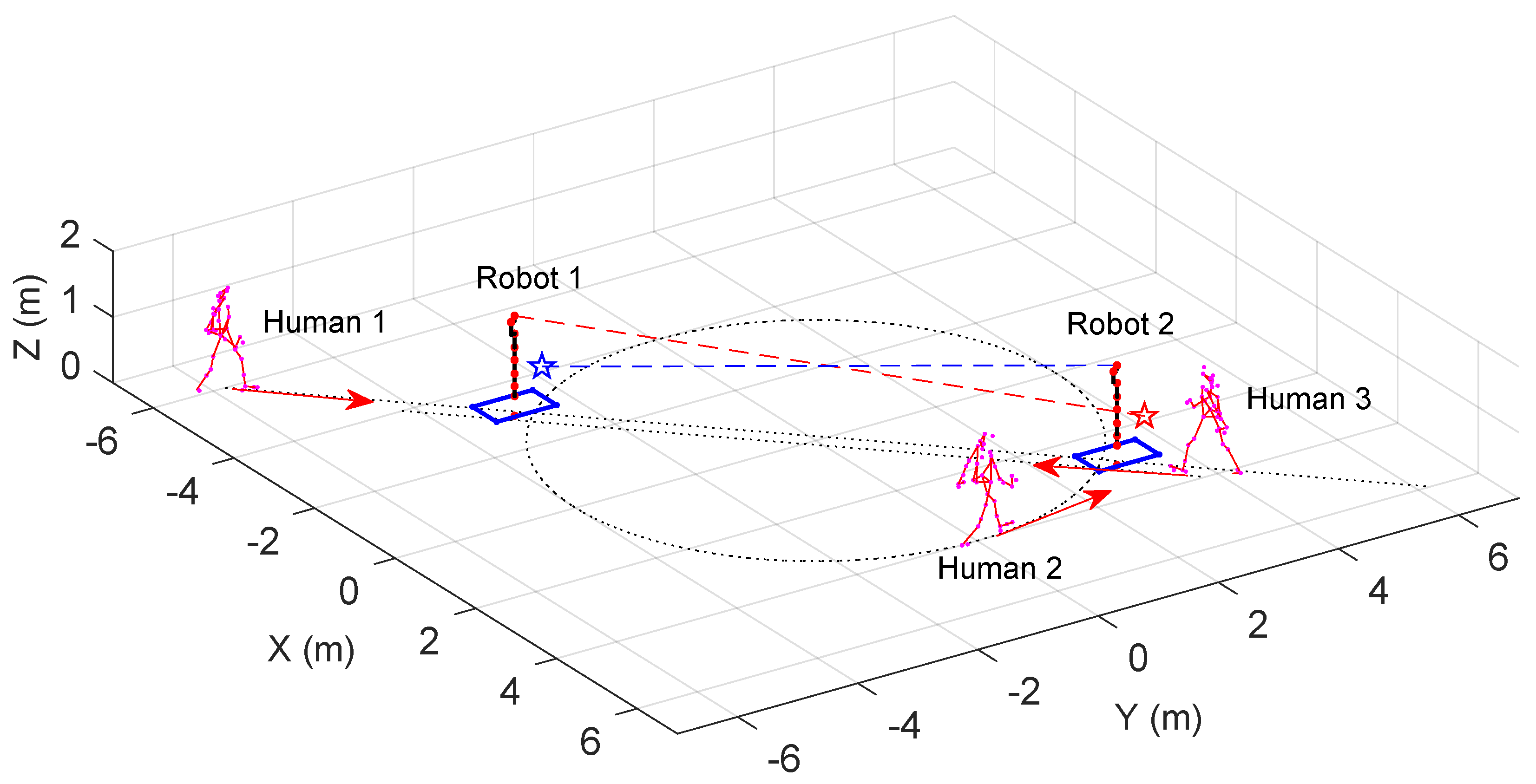

5. Simulation

5.1. The Setting of Simulation

- Limits of wheels’ velocity: ;

- Limits of joints’ velocity for the robotic arm: ;

- Limits of joints’ position limits for the robotic arm: .

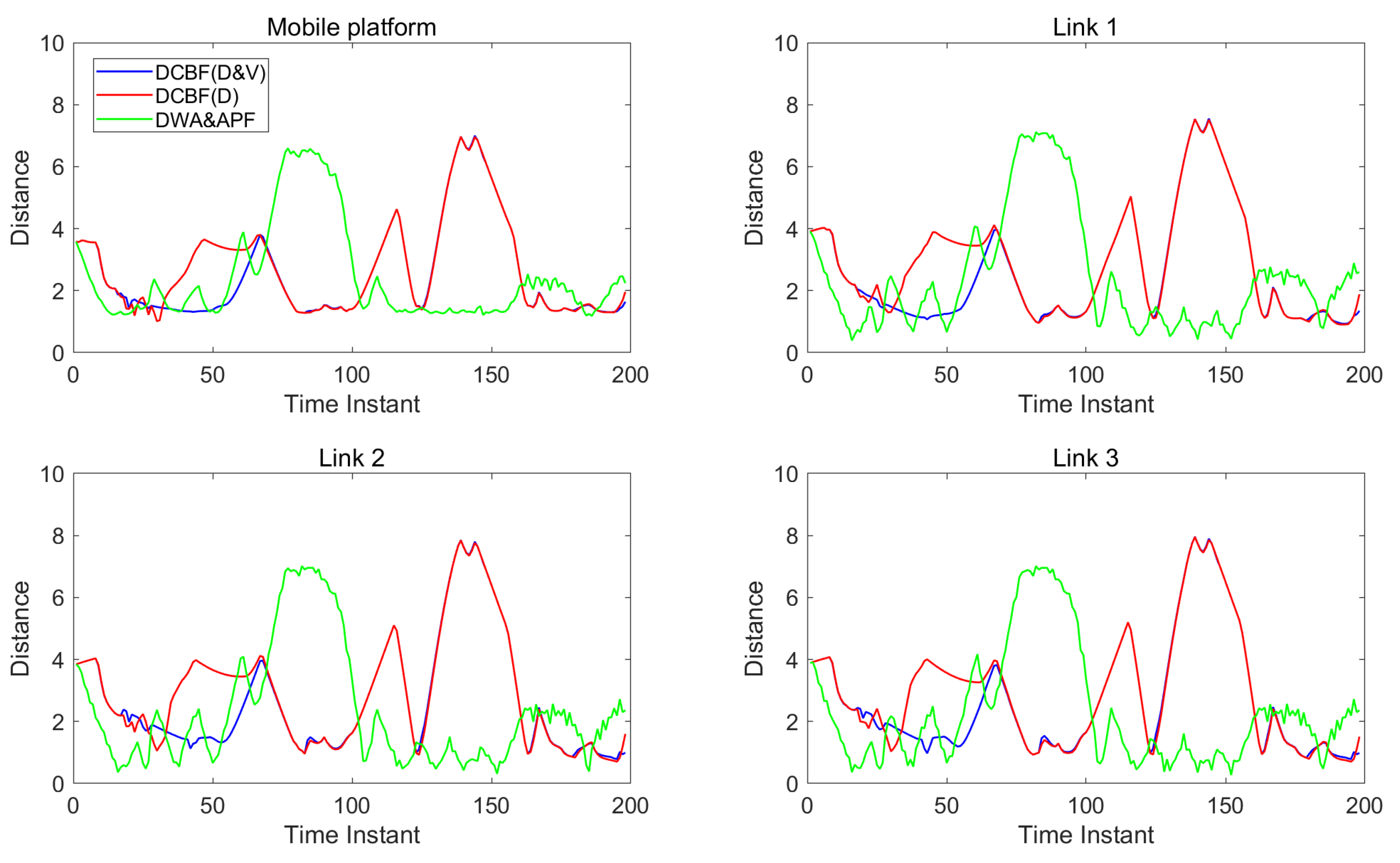

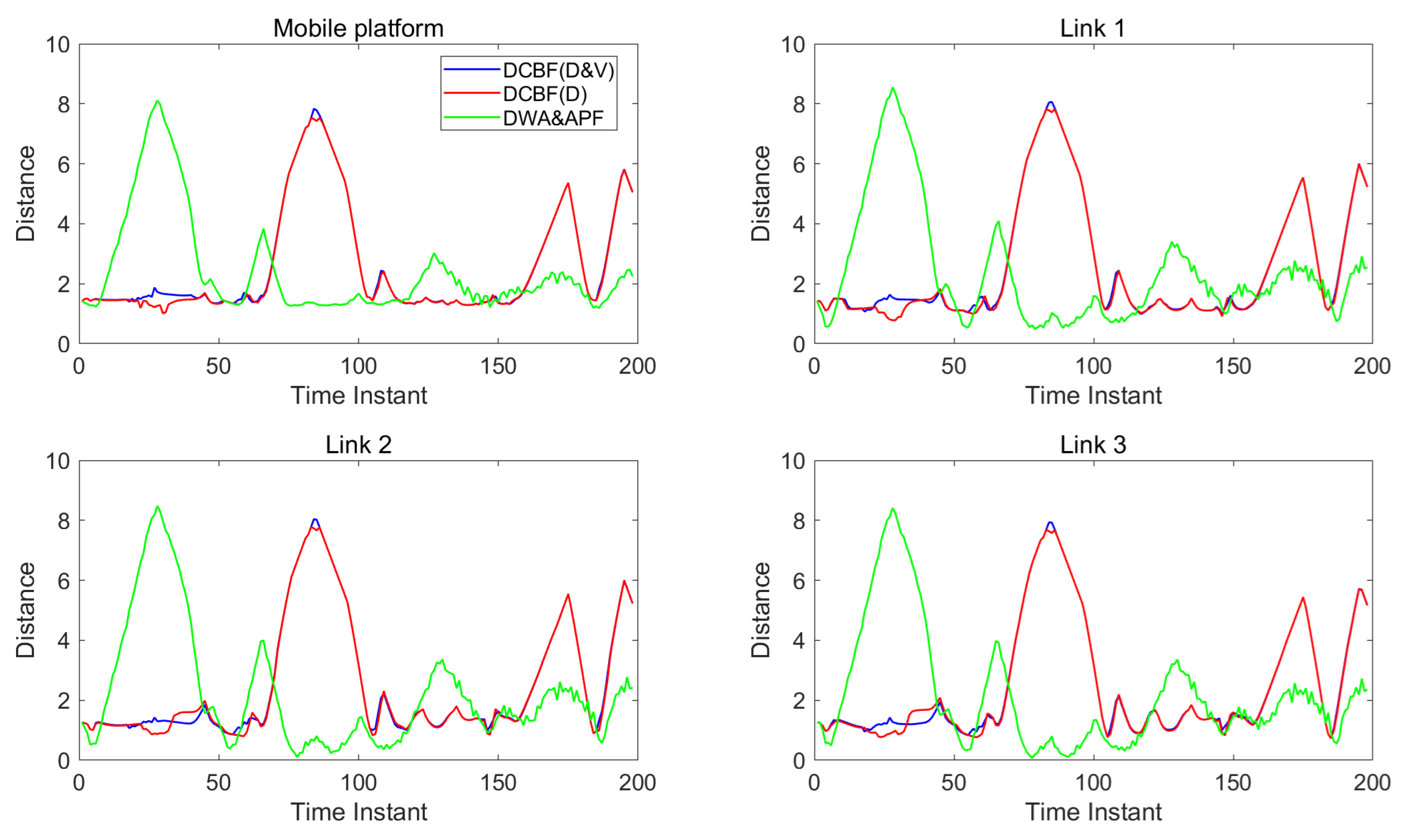

5.2. Results and Discussions

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| APF | Artificial Potential Field |

| CBF | Control Barrier Function |

| CSRL | CBF-based Safe Reinforcement Learning |

| DCBF | Discrete-time Control Barrier Function |

| DCLF | Discrete-time Control Lyapunov Function |

| DRL | Deep Reinforcement Learning |

| DWA | Dynamic Window Approach |

| GNN | Graph Neural Networks |

| MPC | Model Predictive Control |

| NBT | Neural Belief Tracking |

References

- Ehrmann, C.; Min, J.; Zhang, W. Hig y flexible robotic manufacturing cell based on holistic real-time model-based control. Procedia CIRP 2024, 127, 20–25. [Google Scholar] [CrossRef]

- Stillström, C.; Jackson, M. The concept of mobile manufacturing. J. Manuf. Syst. 2007, 26, 188–193. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Park, D.H.; Hoffmann, H.; Pastor, P.; Schaal, S. Movement reproduction and obstacle avoidance with dynamic movement primitives and potential fields. In Proceedings of the Humanoids 2008-8th IEEE-RAS International Conference on Humanoid Robots, Daejeon, Republic of Korea, 1–3 December 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 91–98. [Google Scholar] [CrossRef]

- Merkt, W.; Ivan, V.; Vijayakumar, S. Continuous-time collision avoidance for trajectory optimization in dynamic environments. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Venetian Macao, Macau, 3–8 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 7248–7255. [Google Scholar]

- Lacevic, B.; Rocco, P.; Zanchettin, A.M. Safety assessment and control of robotic manipulators using danger field. IEEE Trans. Robot. 2013, 29, 1257–1270. [Google Scholar] [CrossRef]

- Ames, A.D.; Grizzle, J.W.; Tabuada, P. Control barrier function based quadratic programs with application to adaptive cruise control. In Proceedings of the 53rd IEEE Conference on Decision and Control, Los Angeles, CA, USA, 15–17 December 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 6271–6278. [Google Scholar]

- Taylor, A.J.; Ames, A.D. Adaptive safety with control barrier functions. In Proceedings of the 2020 American Control Conference (ACC), Denver, CO, USA, 1–3 July 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1399–1405. [Google Scholar]

- AbuJabal, N.; Baziyad, M.; Fareh, R.; Brahmi, B.; Rabie, T.; Bettayeb, M. A comprehensive study of recent path-planning techniques in dynamic environments for autonomous robots. Sensors 2024, 24, 8089. [Google Scholar] [CrossRef]

- Mrkšic, N.; Séaghdha, D.O.; Wen, T.H.; Thomson, B.; Young, S. Neural belief tracker: Data-driven dialogue state tracking. arXiv 2017, arXiv:1606.03777. [Google Scholar] [CrossRef]

- Zou, A.M.; Hou, Z.G.; Fu, S.Y.; Tan, M. Neural networks for mobile robot navigation: A survey. In Proceedings of the Advances in Neural Networks—ISNN 2006, Chengdu, China, 28 May–1 June 2006; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1218–1226. [Google Scholar]

- Abdelrahman, A.F.; Valdenegro-Toro, M.; Bennewitz, M.; Plöger, P.G. A neuromorphic approach to obstacle avoidance in robot manipulation. arXiv 2024, arXiv:2404.05858. [Google Scholar] [CrossRef]

- Singh, R.; Ren, J.; Lin, X. A review of deep reinforcement learning algorithms for mobile robot path planning. Vehicles 2023, 5, 1423–1451. [Google Scholar] [CrossRef]

- Hart, F.; Waltz, M.; Okhrin, O. Two-step dynamic obstacle avoidance. Knowl.-Based Syst. 2024, 302, 112402. [Google Scholar] [CrossRef]

- Deng, Y.; Gao, J.; Feroskhan, M. Ensuring safety in target pursuit control: A CBF-safe reinforcement learning approach. arXiv 2024, arXiv:2411.17552. [Google Scholar]

- Zhang, Y.; Tian, G.; Wen, L.; Yao, X.; Zhang, L.; Bing, Z.; He, W.; Knoll, A. Online efficient safety-critical control for mobile robots in unknown dynamic multi-obstacle environments. arXiv 2024, arXiv:2402.16449. [Google Scholar] [CrossRef]

- Li, Z.; Shi, N.; Zhao, L.; Zhang, M. Deep reinforcement learning path planning and task allocation for multi-robot collaboration. Alex. Eng. J. 2024, 109, 408–423. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human–robot collaboration trends and safety aspects: A systematic review. J. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- Katona, K.; Neamah, H.A.; Korondi, P. Obstacle avoidance and path planning methods for autonomous navigation of mobile robot. Sensors 2024, 24, 3573. [Google Scholar] [CrossRef]

- Finean, M.N.; Petrović, L.; Merkt, W.; Havoutis, I.M.I. Motion planning in dynamic environments using context-aware human trajectory prediction. Robot. Auton. Syst. 2023, 166, 104450. [Google Scholar] [CrossRef]

- Schneier, M.; Schneier, M.; Bostelman, R. Literature Review of Mobile Robots for Manufacturing; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015. [Google Scholar]

- Zhu, Y.; Chen, S.; Zhang, C.; Piao, Z.; Yang, G. Development of adaptive safety constraint by predicting trajectories of closest points between human and co-robot. J. Intell. Manuf. 2024, 35, 1197–1206. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, Y.; Liu, Y.; Zhang, C.; Piao, Z.; Yang, G. A “look-backward-and-forward” adaptation strategy for assessing parameter estimation error of human motion prediction model. IEEE Robot. Autom. Lett. 2022, 7, 2629–2636. [Google Scholar] [CrossRef]

- Giallanza, A.; Scalia, G.L.; Micale, R.; Fata, C.M.L. Occupational health and safety issues in human-robot collaboration: State of the art and open challenges. Saf. Sci. 2024, 169, 106313. [Google Scholar] [CrossRef]

- Han, D.; Park, M.Y.; Choi, J.; Shin, H.; Rhim, S. Analysis of human-robot physical interaction at collision. In Proceedings of the 2021 IEEE International Conference on Intelligence and Safety for Robotics (ISR), Nagoya, Japan, 4–6 March 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 153–156. [Google Scholar]

- Koppenborg, M.; Nickel, P.; Naber, B.; Lungfiel, A.; Huelke, M. Effects of movement speed and predictability in human–robot collaboration. Hum. Factors Ergon. Manuf. Serv. Ind. 2017, 27, 197–209. [Google Scholar] [CrossRef]

- Ferraguti, F.; Landi, C.T.; Costi, S.; Bonfè, M.; Farsoni, S.; Secchi, C.; Fantuzzi, C. Safety barrier functions and multi-camera tracking for human–robot shared environment. Robot. Auton. Syst. 2020, 124, 103388. [Google Scholar] [CrossRef]

- Merckaert, K.; Convens, B.; Wu, C.j.; Roncone, A.; Nicotra, M.M.; Vanderborght, B. Real-time motion control of robotic manipulators for safe human–robot coexistence. Robot. Comput.-Integr. Manuf. 2022, 73, 102223. [Google Scholar] [CrossRef]

- Ames, A.D.; Xu, X.; Grizzle, J.W.; Tabuada, P. Control Barrier Function Based Quadratic Programs for Safety Critical Systems. IEEE Trans. Autom. Control 2017, 62, 3861–3876. [Google Scholar] [CrossRef]

- Sabouni, E.; Ahmad, H.M.S.; Xiao, W.; Cassandras, C.G.; Li, W. Optimal Control of Connected Automated Vehicles with Event-Triggered Control Barrier Functions: A Test Bed for Safe Optimal Merging. arXiv 2023, arXiv:2306.01871. [Google Scholar] [CrossRef]

- Shi, K.; Chang, J.; Feng, S.; Fan, Y.; Wei, Z.; Hu, G. Safe Human Dual-Robot Interaction Based on Control Barrier Functions and Cooperation Functions. IEEE Robot. Autom. Lett. 2024, 9, 9581–9588. [Google Scholar] [CrossRef]

- Yang, T.; Miao, Z.; Yi, G.; Wang, Y. Safety-Critical Control of Quadrotor UAVs with Control Barrier Functions. In Proceedings of the 2022 IEEE International Conference on Robotics and Biomimetics (ROBIO), Xishuangbanna, China, 5–9 December 2022; pp. 1074–1079. [Google Scholar]

- Xiao, W.; Belta, C. High-Order Control Barrier Functions. IEEE Trans. Autom. Control 2022, 67, 3655–3662. [Google Scholar] [CrossRef]

- Liu, J.; Li, M.; Huang, J.K.; Grizzle, J.W. Realtime Safety Control for Bipedal Robots to Avoid Multiple Obstacles via CLF-CBF Constraints. arXiv 2023, arXiv:2301.01906. [Google Scholar] [CrossRef]

- van Wijk, D.E.J.; Coogan, S.; Molnar, T.G.; Majji, M.; Hobbs, K.L. Disturbance-Robust Backup Control Barrier Functions: Safety Under Uncertain Dynamics. IEEE Control Syst. Lett. 2024, 8, 2817–2822. [Google Scholar] [CrossRef]

- Min, X.; Baldi, S.; Shi, Y.; Yu, W. Safe Control of Multi-Agent Systems via Low-Complexity Control Barrier Functions. IEEE Trans. Autom. Control 2025, 1–14. [Google Scholar] [CrossRef]

- Buyukkocak, A.T.; Aksaray, D.; Yazıcıoğlu, Y. Control Barrier Functions with Actuation Constraints under Signal Temporal Logic Specifications. In Proceedings of the 2022 European Control Conference (ECC), London, UK, 12–15 July 2022; pp. 162–168. [Google Scholar]

- Emam, Y.; Notomista, G.; Glotfelter, P.; Kira, Z.; Egerstedt, M. Safe Reinforcement Learning Using Robust Control Barrier Functions. arXiv 2022, arXiv:2110.05415. [Google Scholar] [CrossRef]

- Garg, K.; Usevitch, J.; Breeden, J.; Black, M.; Agrawal, D.; Parwana, H.; Panagou, D. Advances in the Theory of Control Barrier Functions: Addressing practical challenges in safe control synthesis for autonomous and robotic systems. Annu. Rev. Control 2024, 57, 100945. [Google Scholar] [CrossRef]

- Qin, W.; Yi, H.; Fan, Z.; Zhao, J. Haptic Shared Control Framework with Interaction Force Constraint Based on Control Barrier Function for Teleoperation. Sensors 2025, 25, 405. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Tang, L.; Cao, S.; Sun, Q.; Zhou, G. Smooth Optimised A*-Guided DWA for Mobile Robot Path Planning. Appl. Sci. 2025, 15, 6956. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Chen, S.; Kong, X.; Li, X.; Zhang, C.; Yang, G. Revised Control Barrier Function with Sensing of Threats from Relative Velocity Between Humans and Mobile Robots. Sensors 2025, 25, 4005. https://doi.org/10.3390/s25134005

Zeng Z, Chen S, Kong X, Li X, Zhang C, Yang G. Revised Control Barrier Function with Sensing of Threats from Relative Velocity Between Humans and Mobile Robots. Sensors. 2025; 25(13):4005. https://doi.org/10.3390/s25134005

Chicago/Turabian StyleZeng, Zihan, Silu Chen, Xiangjie Kong, Xiaojuan Li, Chi Zhang, and Guilin Yang. 2025. "Revised Control Barrier Function with Sensing of Threats from Relative Velocity Between Humans and Mobile Robots" Sensors 25, no. 13: 4005. https://doi.org/10.3390/s25134005

APA StyleZeng, Z., Chen, S., Kong, X., Li, X., Zhang, C., & Yang, G. (2025). Revised Control Barrier Function with Sensing of Threats from Relative Velocity Between Humans and Mobile Robots. Sensors, 25(13), 4005. https://doi.org/10.3390/s25134005