Use of Carbon Nanotubes for the Functionalization of Concrete for Sensing Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

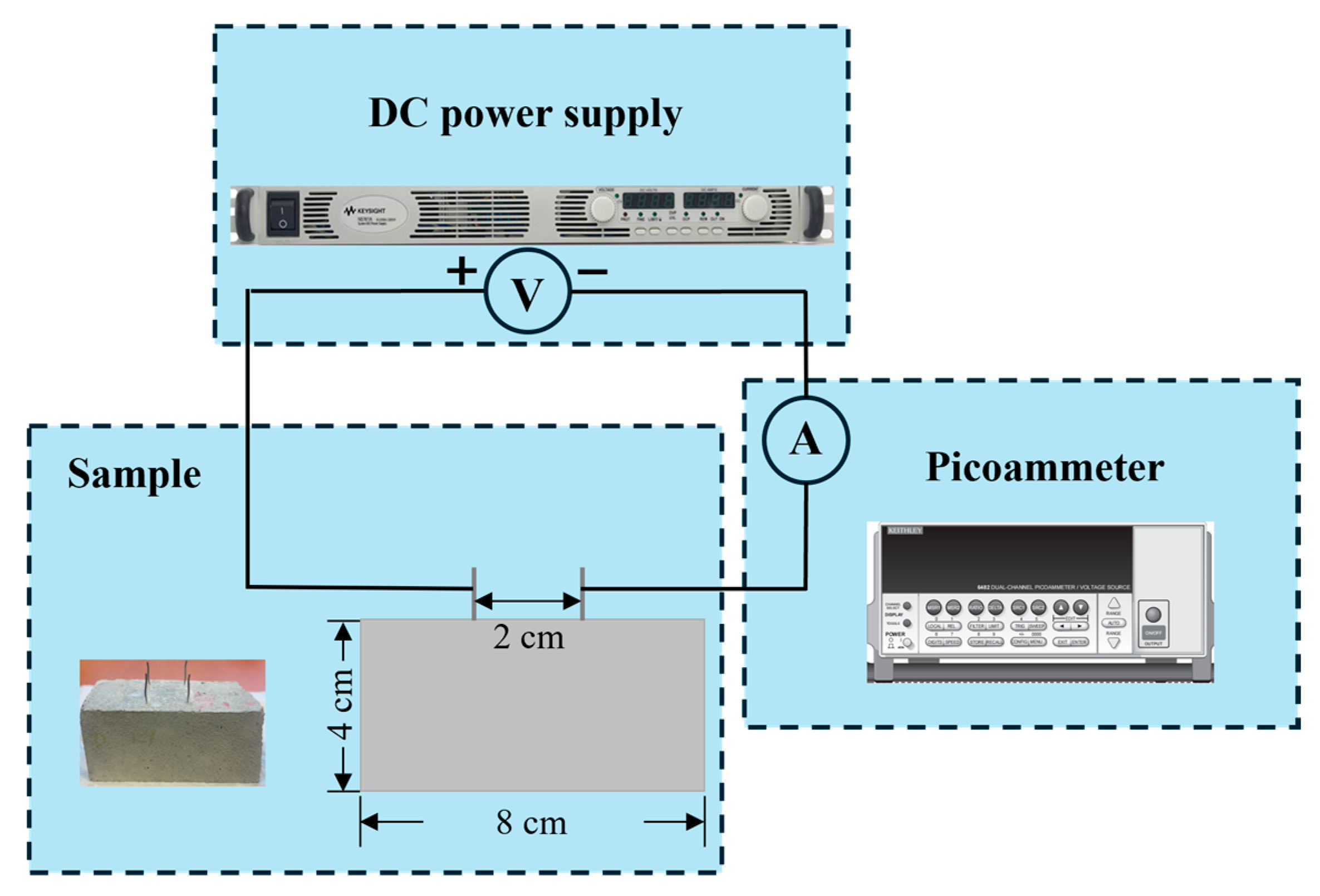

2.2. Conductivity Test Setup

2.3. Three-Point Bending Test Setup

2.4. Thermal Test Setup

3. Results

3.1. Conductivity Test

3.2. Three-Point Bending Test

3.2.1. 7-Day Concrete

3.2.2. 28-Day Concrete

3.3. Thermal Test

3.3.1. 7-Day Concrete

3.3.2. 28-Day Concrete

3.4. Mechanical and Thermal Sensitivity

4. Conclusions and Discussion

- (1)

- Electrical conductivity measurements on fully cured samples confirmed the semiconductive nature of the CNT-modified concrete. The optimal conductivity was observed at 0.006 wt.% CNTs, which reaches 2.81 × 10−4 S/m, indicating the formation of an effective conductive network. However, higher CNT concentrations did not lead to further improvement, likely due to agglomeration effects that disrupted conductive pathways.

- (2)

- From the three-point bending tests, the CNT content of 0.01 wt.% was identified as the optimal balance between mechanical behavior and electrical response in 7-day samples, with a peak load of 2.6615 kN and a maximum current of 2.89 × 10−6 A. For 28-day samples, the mechanical behavior remained relatively stable cross all CNT contents, except for the control group. The highest load (2.9365 kN) was observed at 0.006 wt.% CNT, while the highest electrical response (8.34 × 10−8 A) was recorded at 0.01 wt.%.The results suggest that a CNT content of 0.006 wt.% proves optimal for mechanical property enhancement, while 0.01 wt.% is optimal for electrical property enhancement. For studies targeting both properties simultaneously, 0.01 wt.% represents the optimal dosage.

- (3)

- The thermal response tests further support this conclusion. In 7-day samples, CNT concentrations between 0.006 wt.% and 0.018 wt.% exhibited a pronounced electrical response to thermal stimuli, with relatively small variations in peak current and time to reach the peak. The highest peak current (1.38 × 10−8 A) was recorded in the 0.018 wt.% sample. However, in 28-day samples, the peak current values were significantly lower, with the highest response (9.70 × 10−9 A) occurring at 0.01 wt.%. Furthermore, the correlation between heat flux and peak current became less evident, suggesting that hydration-related changes in microstructure affect the thermal–electrical behavior of CNT-modified concrete.

- (4)

- The sensitivity was analyzed for both mechanical and thermal changes to further evaluate the feasibility of using CNT-reinforced concrete as a sensor material. The 7-day cured samples exhibited higher sensitivity than the 28-day ones in response to both load and temperature variations. This enhanced sensitivity can be attributed to the incomplete hydration process at early ages, which results in higher internal moisture content and a more continuous conductive network. In terms of mechanical response, the specimens demonstrated high sensitivity at low loads, indicating the potential for early-age structural damage monitoring in concrete structures. Regarding thermal response, sensitivity became higher when the temperature exceeded the safety threshold (approximately 20 °C), highlighting the promise of CNT-modified concrete for high-temperature early warning in smart building applications.

- (5)

- Overall, our findings indicate that CNT-modified concrete with CNT concentration at 0.01 wt.%, can achieve an optimal combination of mechanical integrity and electrical sensitivity. This opens possibilities for using CNT-enhanced concrete as a self-sensing material for structural health monitoring, enabling the real-time assessment of mechanical stress and temperature variations. Future research could explore long-term durability, alternative CNT dispersion methods to enhance conductivity, and field-scale validation to further confirm the practical feasibility of CNT-based smart concrete applications in civil engineering and infrastructure maintenance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ashwini, B. Comparison of mechanical properties of concrete incorporated with Multiwalled Carbon nanotube and partial replacement of cement with flyash. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Deng, S.; Fan, J.; Yi, B.; Ye, J.; Li, G. Effect of industrial multi-walled carbon nanotubes on the mechanical properties and microstructure of ultra-high performance concrete. Cem. Concr. Compos. 2025, 156, 105850. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Sun, H.; Amin, M.N.; Qadir, M.T.; Arifeen, S.U.; Iftikhar, B.; Althoey, F. Investigating the effectiveness of carbon nanotubes for the compressive strength of concrete using AI-aided tools. Case Stud. Constr. Mater. 2024, 20, e03083. [Google Scholar] [CrossRef]

- Olivier, J.; Janssens-Maenhout, G.; Muntean, M.; Peters, J. Trends in Global CO2-Emissions: 2016 Report; PBL Netherlands Environmental Assessment Agency: Den Haa, The Netherlands, 2016. Available online: https://www.pbl.nl/en/publications/trends-in-global-co2-emissions-2016-report (accessed on 12 June 2025).

- United Nations Environment Programme. Emissions Gap Report 2024: No More Hot Air... Please! with a Massive Gap Between Rhetoric and Reality, Countries Draft New Climate Commitments; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar] [CrossRef]

- Sun, T.; Wang, X.; Ashour, A.; Ding, S.; Li, L.; Han, B. High-durability, low-carbon, and low-cost nano-engineered concrete for marine concrete infrastructures. Cem. Concr. Compos. 2025, 157, 105877. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, X. A comprehensive assessment of nanomaterials reinforced lightweight aggregate concrete containing high-volume artificial shale ceramsite. J. Build. Eng. 2024, 84, 108696. [Google Scholar] [CrossRef]

- Al-Zu’bi, M.; Fan, M.; Anguilano, L. Near-surface mounted-FRP flexural retrofitting of concrete members using nanomaterial-modified epoxy adhesives. J. Build. Eng. 2024, 84, 108549. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, X.; Shah, S.P. Reinforcing efficiency of nanomaterials on mechanical and interfacial characteristics of green concrete incorporating fly ash cenosphere. J. Clean. Prod. 2024, 447, 141531. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, W.; Wang, X.; Han, B. New-generation pavement empowered by smart and multifunctional concretes: A review. Constr. Build. Mater. 2023, 402, 132980. [Google Scholar] [CrossRef]

- Ramachandran, K.; Boopalan, V.; Bear, J.C.; Subramani, R. Multi-walled carbon nanotubes (MWCNTs)-reinforced ceramic nanocomposites for aerospace applications: A review. J. Mater. Sci. 2022, 57, 3923–3953. [Google Scholar] [CrossRef]

- Yan, X.; Tang, W.; Cui, H. Effect of MWCNTs-OH on the mechanical properties of cement composites: From macro to micro perspective. Constr. Build. Mater. 2024, 444, 137652. [Google Scholar] [CrossRef]

- Xu, L.; Liu, K.; Wang, R. Effect and mechanism of carbon nanotubes on the properties of polyacrylate/cement composite cementitious materials. Constr. Build. Mater. 2024, 443, 137687. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Lubloy, E.; Andrushia, D. Influence of Multi-walled Carbon Nanotube (MWCNT) on flexural behavior and microstructure characteristics of geopolymer concrete beams. Case Stud. Constr. Mater. 2024, 20, e03317. [Google Scholar] [CrossRef]

- Yahyaee, T.; Mofidi, S.R. The impact of multi-walled carbon nanotubes on the mechanical and environmental properties of porous concrete in removing pollutants for use in surface runoffs. Case Stud. Constr. Mater. 2024, 20, e02697. [Google Scholar] [CrossRef]

- Shahzad, S.; Toumi, A.; Balayssac, J.-P.; Turatsinze, A. Design of smart cementitious composites based on multi-walled carbon nanotubes (MWCNTs) using probe ultrasonicator for dispersion. MATEC Web Conf. 2022, 364, 05012. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, J.H.; Han, S.-J.; Yi, S.-T.; Kim, K.S. Self-sensing capability of ultra-high performance fiber-reinforced concrete with multiwalled carbon nanotubes. J. Build. Eng. 2024, 86, 108972. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Wang, J.; Han, X.; Aela, P.; Ni, Y.-Q.; Jing, G. Railway ballast track hanging sleeper defect detection using a smart CNT self-sensing concrete railway sleeper. Constr. Build. Mater. 2023, 399, 132487. [Google Scholar] [CrossRef]

- Graphistrength® Nanotubes De Carbone Multi-Parois-Arkema Group|Arkema Global n.d. Available online: https://www.arkema.com/global/fr/products/product-finder/product-range/incubator/graphistrength/ (accessed on 24 March 2025).

- Lushnikova, A.; Plé, O.; De Souza Gomes, Y.; Jia, X.; Yang, W. Strength and Electrical Properties of Cementitious Composite with Integrated Carbon Nanotubes. Materials 2023, 16, 4771. [Google Scholar] [CrossRef]

- Yakovlev, G.; Bazhenov, Y.; Buryanov, A.; Pudov, I. Increased durability concrete for generation of pillars power lines. MATEC Web Conf. 2016, 86, 04013. [Google Scholar] [CrossRef]

- Rennhofer, H.; Zanghellini, B. Dispersion State and Damage of Carbon Nanotubes and Carbon Nanofibers by Ultrasonic Dispersion: A Review. Nanomaterials 2021, 11, 1469. [Google Scholar] [CrossRef] [PubMed]

- Semiconductor. Wikipedia. Available online: https://en.wikipedia.org/wiki/Semiconductor (accessed on 12 June 2025).

- Almotlaq, T.; Huang, B.; Saafi, M.; Ye, J. Enhancing the self-sensing and energy storage capabilities of cementitious composites through marine sand doping. Constr. Build. Mater. 2024, 428, 136218. [Google Scholar] [CrossRef]

- Cunha Araújo, E.; Macioski, G.; Henrique Farias De Medeiros, M. Concrete surface electrical resistivity: Effects of sample size, geometry, probe spacing and SCMs. Constr. Build. Mater. 2022, 324, 126659. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Yilmaz, K. Investigation of specimen size, geometry and temperature effects on resistivity of electrically conductive concretes. Constr. Build. Mater. 2020, 250, 118864. [Google Scholar] [CrossRef]

- Seo, J.; Jang, D.; Yang, B.; Yoon, H.N.; Jang, J.G.; Park, S.; Lee, H.K. Material characterization and piezoresistive sensing capability assessment of thin-walled CNT-embedded ultra-high performance concrete. Cem. Concr. Compos. 2022, 134, 104808. [Google Scholar] [CrossRef]

- Shooshtari, M.; Salehi, A.; Vollebregt, S. Effect of Humidity on Gas Sensing Performance of Carbon Nanotube Gas Sensors Operated at Room Temperature. IEEE Sens. J. 2021, 21, 5763–5770. [Google Scholar] [CrossRef]

- Li, W.-W.; Ji, W.-M.; Wang, Y.-C.; Liu, Y.; Shen, R.-X.; Xing, F. Investigation on the Mechanical Properties of a Cement-Based Material Containing Carbon Nanotube under Drying and Freeze-Thaw Conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef]

- Kim, G.M.; Nam, I.W.; Yang, B.; Yoon, H.N.; Lee, H.K.; Park, S. Carbon nanotube (CNT) incorporated cementitious composites for functional construction materials: The state of the art. Compos. Struct. 2019, 227, 111244. [Google Scholar] [CrossRef]

- Heat Flux. Wikipedia. 2024. Available online: https://en.wikipedia.org/wiki/Heat_flux_n.d (accessed on 12 June 2025).

- Feng, C.; Liu, H.; Hang, Z.; Su, Y.; Xia, X.; Weng, G.J. Study on thermal conductivity of 0D/1D/2D carbon filler reinforced cement composites with phonon physical model. Cem. Concr. Compos. 2025, 157, 105917. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

| CNT Content (%) | Cement (g) | Water (g) | Sand (g) | CNT (g) | Masterbatch (g) |

|---|---|---|---|---|---|

| 0% | 450 | 225 | 1350 | 0 | 0 |

| 0.002% | 450 | 225 | 1350 | 0.009 | 0.02 |

| 0.006% | 450 | 225 | 1350 | 0.027 | 0.06 |

| 0.01% | 450 | 225 | 1350 | 0.045 | 0.1 |

| 0.018% | 450 | 225 | 1350 | 0.081 | 0.18 |

| 0.025% | 450 | 225 | 1350 | 0.1125 | 0.25 |

| 0.05% | 450 | 225 | 1350 | 0.225 | 0.5 |

| CNT Content | R1 (Ω) | ρ1 (Ω·m) | σ1 (S/m) | R2 (Ω) | ρ2 (Ω·m) | σ2 (S/m) | σ (S/m) |

|---|---|---|---|---|---|---|---|

| 0% | 8.17 × 104 | 6.54 × 103 | 1.53 × 10−4 | 8.10 × 104 | 6.84 × 103 | 1.54 × 10−4 | 1.54 × 10−4 |

| 0.002% | 7.49 × 104 | 5.99 × 103 | 1.67 × 10−4 | 7.52 × 104 | 6.01 × 103 | 1.66 × 10−4 | 1.67 × 10−4 |

| 0.006% | 4.48 × 104 | 3.59 × 103 | 2.79 × 10−4 | 4.42 × 104 | 3.53 × 103 | 2.83 × 10−4 | 2.81 × 10−4 |

| 0.010% | 5.38 × 104 | 4.30 × 103 | 2.32 × 10−4 | 5.46 × 104 | 4.37 × 103 | 2.29 × 10−4 | 2.31 × 10−4 |

| 0.018% | 5.92 × 104 | 4.74 × 103 | 2.11 × 10−4 | 5.90 × 104 | 4.72 × 103 | 2.12 × 10−4 | 2.11 × 10−4 |

| 0.025% | 7.49 × 104 | 6.00 × 103 | 1.67 × 10−4 | 7.55 × 104 | 6.04 × 103 | 1.66 × 10−4 | 1.66 × 10−4 |

| 0.05% | 7.36 × 104 | 5.89 × 103 | 1.70 × 10−4 | 7.45 × 104 | 5.96 × 103 | 1.68 × 10−4 | 1.69 × 10−4 |

| CNT Content | T0 (°C) | T1 (°C) | Heat Flux (W/m2) | Heating Time (s) | Max Current (nA) | Total Heat (J) |

|---|---|---|---|---|---|---|

| 0% | 23 | 50 | 200 | 447.00 | 4.51 | 572.16 |

| 0.002% | 23 | 50 | 200 | 344.00 | 5.41 | 440.32 |

| 0.006% | 23 | 50 | 200 | 544.50 | 13.30 | 696.96 |

| 0.010% | 23 | 50 | 200 | 535.50 | 11.43 | 685.44 |

| 0.018% | 23 | 50 | 200 | 500.00 | 13.84 | 640.00 |

| 0.025% | 23 | 50 | 200 | 426.50 | 9.05 | 545.92 |

| 0.05% | 23 | 50 | 200 | 345.00 | 3.19 | 441.60 |

| CNT Content | T0 (°C) | T1 (°C) | Heat Flux (W/m2) | Heating Time (s) | Max Current (nA) | Total Heat (J) |

|---|---|---|---|---|---|---|

| 0% | 23 | 50 | 200 | 1083 | 2.88 | 1386.24 |

| 0.002% | 23 | 50 | 200 | 256.5 | 4.46 | 328.32 |

| 0.006% | 23 | 50 | 200 | 350.5 | 6.12 | 448.64 |

| 0.010% | 23 | 50 | 200 | 546.5 | 9.70 | 699.52 |

| 0.018% | 23 | 50 | 200 | 444 | 5.90 | 568.32 |

| 0.025% | 23 | 50 | 200 | 700.5 | 6.83 | 896.64 |

| 0.05% | 23 | 50 | 200 | 683.5 | 2.78 | 874.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, X.; Lushnikova, A.; Plé, O. Use of Carbon Nanotubes for the Functionalization of Concrete for Sensing Applications. Sensors 2025, 25, 3755. https://doi.org/10.3390/s25123755

Jia X, Lushnikova A, Plé O. Use of Carbon Nanotubes for the Functionalization of Concrete for Sensing Applications. Sensors. 2025; 25(12):3755. https://doi.org/10.3390/s25123755

Chicago/Turabian StyleJia, Xiaohui, Anna Lushnikova, and Olivier Plé. 2025. "Use of Carbon Nanotubes for the Functionalization of Concrete for Sensing Applications" Sensors 25, no. 12: 3755. https://doi.org/10.3390/s25123755

APA StyleJia, X., Lushnikova, A., & Plé, O. (2025). Use of Carbon Nanotubes for the Functionalization of Concrete for Sensing Applications. Sensors, 25(12), 3755. https://doi.org/10.3390/s25123755