Correction: Gao et al. A Modeling Method for Thermal Error Prediction of CNC Machine Equipment Based on Sparrow Search Algorithm and Long Short-Term Memory Neural Network. Sensors 2023, 23, 3600

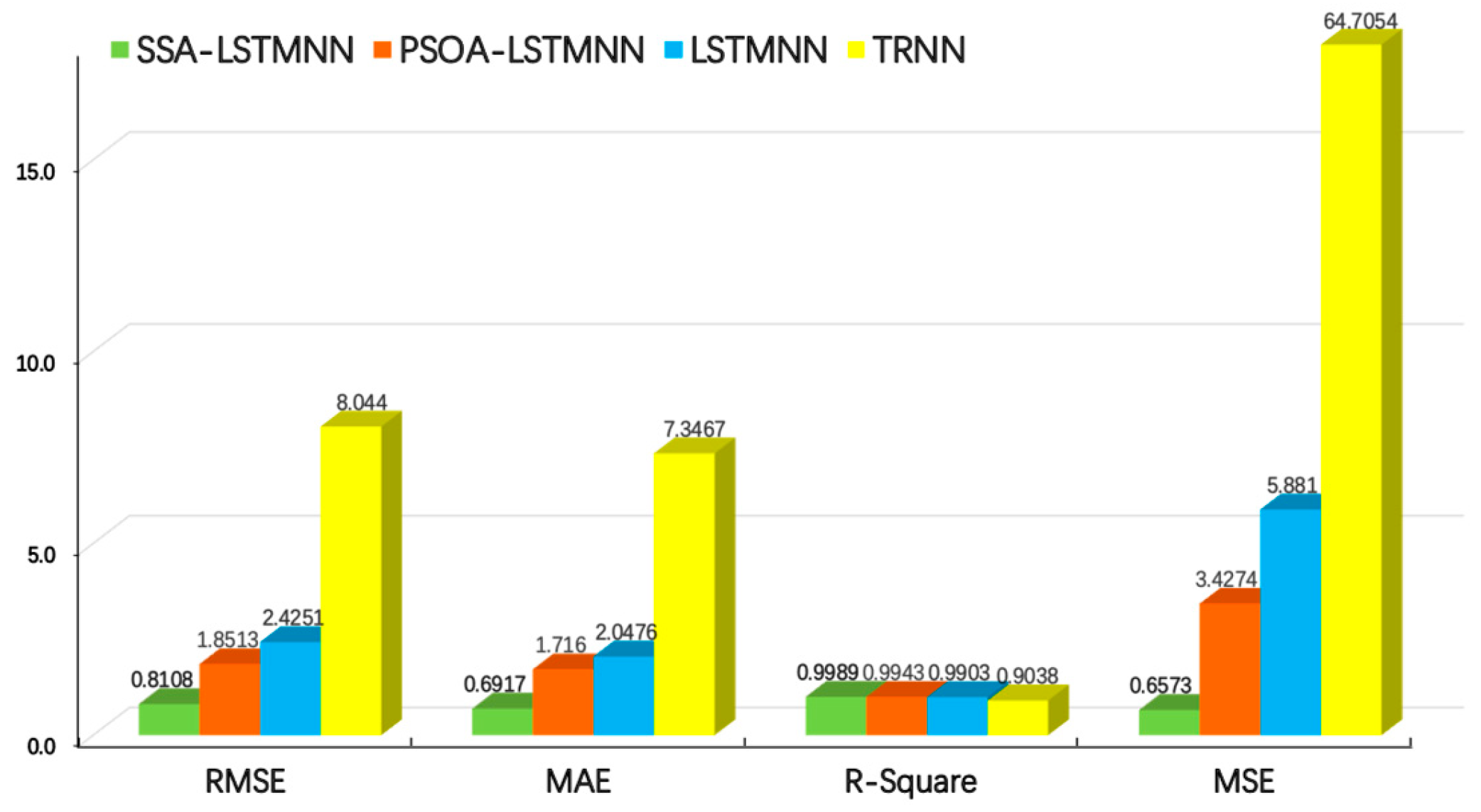

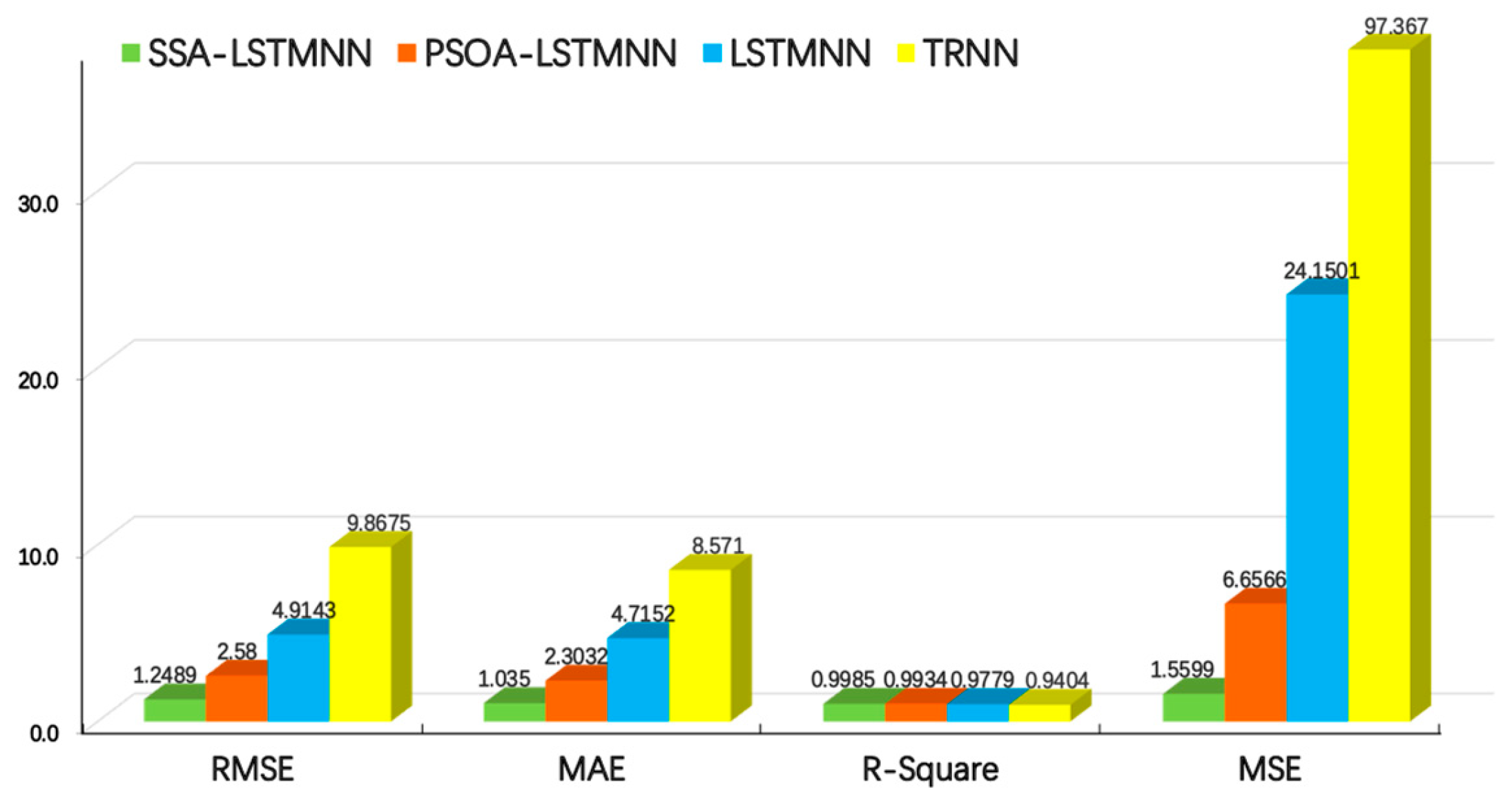

Error in Figure

Text Correction

Reference

- Gao, Y.; Xia, X.; Guo, Y. A Modeling Method for Thermal Error Prediction of CNC Machine Equipment Based on Sparrow Search Algorithm and Long Short-Term Memory Neural Network. Sensors 2023, 23, 3600. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Xia, X.; Guo, Y. Correction: Gao et al. A Modeling Method for Thermal Error Prediction of CNC Machine Equipment Based on Sparrow Search Algorithm and Long Short-Term Memory Neural Network. Sensors 2023, 23, 3600. Sensors 2024, 24, 2133. https://doi.org/10.3390/s24072133

Gao Y, Xia X, Guo Y. Correction: Gao et al. A Modeling Method for Thermal Error Prediction of CNC Machine Equipment Based on Sparrow Search Algorithm and Long Short-Term Memory Neural Network. Sensors 2023, 23, 3600. Sensors. 2024; 24(7):2133. https://doi.org/10.3390/s24072133

Chicago/Turabian StyleGao, Ying, Xiaojun Xia, and Yinrui Guo. 2024. "Correction: Gao et al. A Modeling Method for Thermal Error Prediction of CNC Machine Equipment Based on Sparrow Search Algorithm and Long Short-Term Memory Neural Network. Sensors 2023, 23, 3600" Sensors 24, no. 7: 2133. https://doi.org/10.3390/s24072133

APA StyleGao, Y., Xia, X., & Guo, Y. (2024). Correction: Gao et al. A Modeling Method for Thermal Error Prediction of CNC Machine Equipment Based on Sparrow Search Algorithm and Long Short-Term Memory Neural Network. Sensors 2023, 23, 3600. Sensors, 24(7), 2133. https://doi.org/10.3390/s24072133