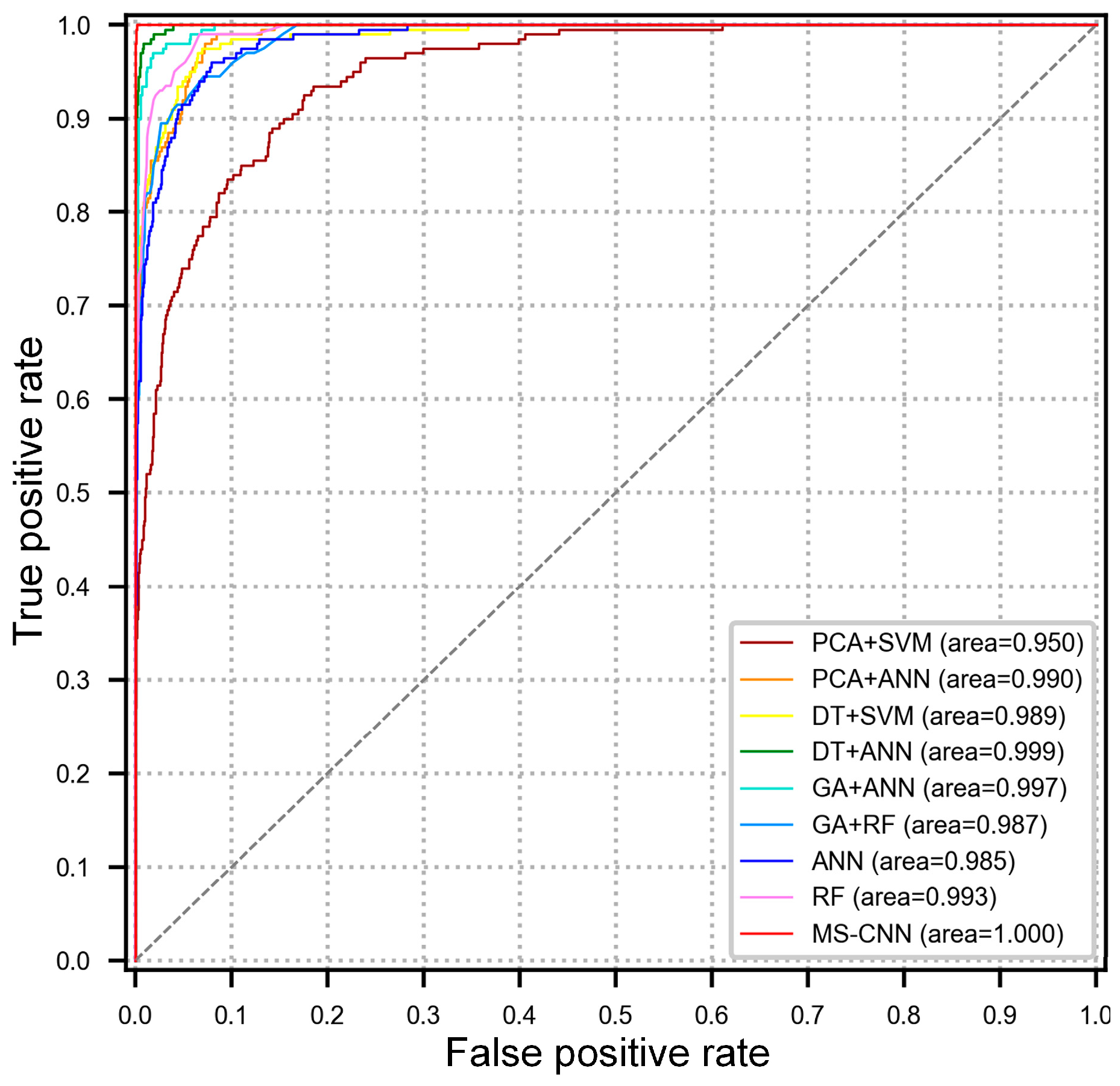

This paper focuses on real-time fault diagnosis of an electric-hydraulic system using multi-sensor data. In hydraulic systems, information contained in the single sensor data is usually insufficient to improve the diagnosis accuracy, because the features extracted from single sensor data are often subjected to variations in the operating conditions. Therefore, multi-sensor data that contain information of different physics variables have been widely utilized in data-driven diagnostic methods in recent studies. However, processing of multi-sensor data with numerous channels requires high computational power. In addition, not all the channels are valuable for diagnosis and the redundant channels will make this model more difficult to train and will decrease the diagnostic accuracy. To make use of the multi-sensor data more effectively, this paper proposes a multi-sensor CNN (MS-CNN) that can learn fault features for both sensor selection and fault detection.

3.1. Framework for Proposed MS-CNN Model

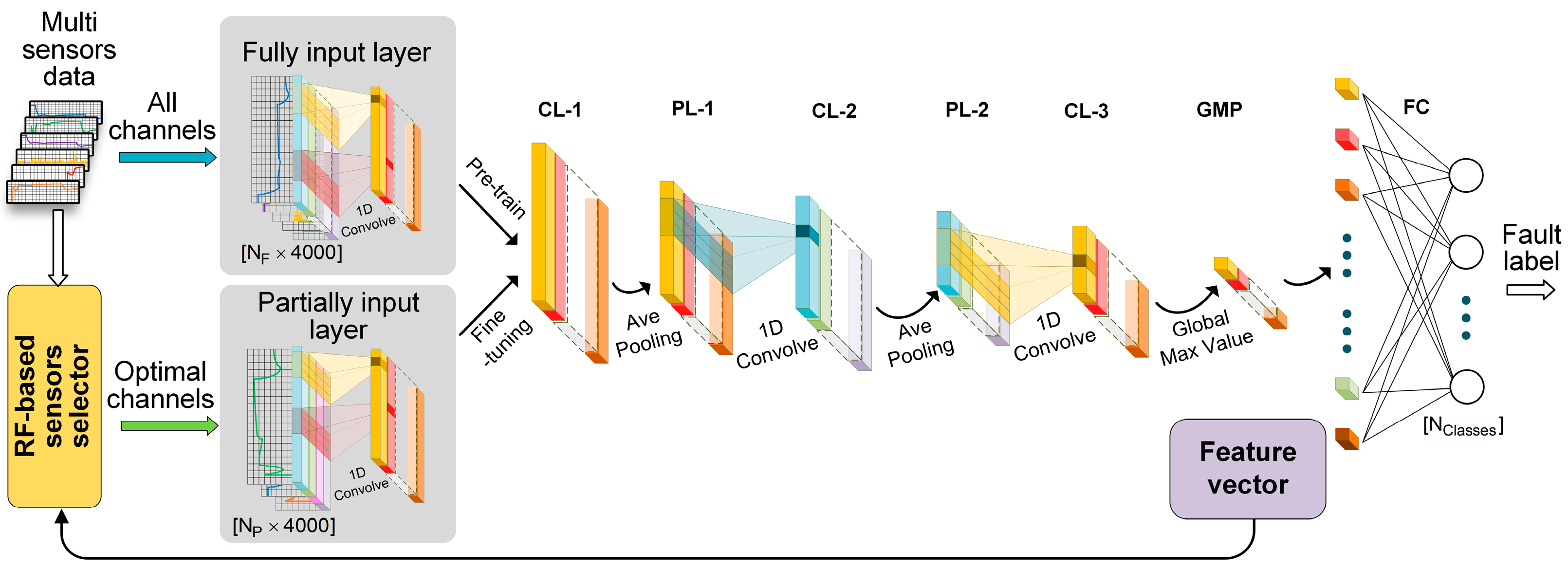

The framework for the proposed MS-CNN model is shown in

Figure 1. The MS-CNN model consists of three main parts: a convolutional feature learning structure, a fault classifier, and a RF-based sensor selector. Furthermore, a random forest (RF)-based sensor selector is used to select fault-related sensor channels.

3.1.1. Convolutional Feature Learning Structure

The convolutional feature learning structure is used to extract abstract features from the sensor signal’s time series for fault classification and sensor selection. Similar to traditional CNNs, the convolutional feature learning structure of the MS-CNN is generally a cascaded structure composed of 1D convolutional layers and average pooling layers, followed by a global max pooling layer. The input format for the structure is a 2D matrix, formed by the 1D signal time series of multiple sensor channels. The main difference between the convolutional feature learning structure of MS-CNN and traditional CNNs is that there are two different 1D convolution layers that are used as the first layers of the convolutional feature learning structure at different stages, called the partial-input layer and the full-input layer; the input channel numbers for these layers are and , (), respectively. Therefore, the input channel number for the MS-CNN is adaptive. By switching the structure of the first layer, the model can extract features from the signals from either all sensor channels or selected sensor channels.

In a 1D convolutional layer, the input matrix

is formed by

N channels. The 1D time series for each channel is

,where

is the length of the time series and

is the channel index. The input matrix is convolved with a group of filters

with a shape of

, where

is the filter size. The layer contains

M filters, and each filter outputs a transformed feature map that forms a channel in the output matrix

Z, which is given as follows:

where

is the

transformed feature map and

is its value in the

time step,

is a bias term, and

is a nonlinear activation function, which is a rectified linear unit (ReLU) function here. There are no padding methods in the convolutional layer, and thus the length of the output feature map is

.

Then, in the average pooling layer, the pooling operation is performed on the output matrix

Z, and the output is the down-sampled matrix

, which is given as follows:

where

is the

channel of the pooled matrix,

is the pooling rate, and

is the integer ceiling function. For each time patch in the feature maps, the average pooling layer abstracts the average value to represent the entire patch. This operation can greatly reduce the number of feature dimensions while retaining the most important information to accelerate the calculation. Furthermore, the down-sampling characteristic of the pooling layers expands the receptive field of the next convolutional layer, which means that the model can extract the features on larger temporal scales.

The

matrix is then fed into the next convolutional and pooling layer pair, where the multilayer nonlinear transformation of this cascaded learning structure allows the model to extract more abstract high-level features. After the last convolutional layer, a global max pooling layer was used to extract the global maximum value of each feature map; the output of this layer is a feature vector that contains the most representative features of the input multi-sensor signals. The feature vector

is represented by the following:

where

is the

channel of the output matrix of the last convolutional layer

, and

and

are the length and the channel number of the output matrix of

, respectively.

The model can extract the corresponding feature vector from the input multi-sensor signal matrix

. The feature vector of the sample can also be represented by the following:

where

represents the mapping relationship of the partial-input layer-based model,

represents the mapping relationship of the full-input layer-based model, and

is the

channel of the input matrix.

3.1.2. Fault Classifier

The fault classifier is used to predict the fault conditions with the extracted features. The classifier only contains a fully connected (FC) layer with a soft-max activation function. The FC layer transforms the obtained feature vector

into a multi-class probability vector that indicates the predicted health conditions of the system. The probability vector is calculated as follows:

where

is the probability vector of the shape

,

is the predicted probability value of each class for the input sample,

is the number of labels,

is the weight matrix of the shape

,

is the bias vector, and

is the softmax active function, which can be expressed as the following:

Note that a dropout operation with a drop rate of 20% is used in the FC layer. In each training epoch, 20% of the nodes in the multi-sensor feature vector are selected randomly and set to zero. This operation can prevent overfitting and increases the training speed.

To train the diagnosis model, we feed the training samples into the model and acquire the corresponding predicted probability vectors. Then, the binary cross-entropy loss between the probability vectors and the label vectors of all the training samples in a training batch is calculated as the loss function, which is represented by the following:

where

is the number of samples in a training batch, and

,

, and

are the training label, the predicted probability, and the corresponding loss of the

label and the

sample, respectively.

In each training epoch, the loss is backpropagated to the weights and biases in the FC layers and the convolutional layers. The Adam optimizer then adjusts these parameters to minimize the loss. Through an epoch-wise parameter update, the model is trained to extract fault-related features from the input multi-sensor signal matrix and use them to classify the system’s health conditions.

3.2. Training of MS-CNN

The MS-CNN training process can be divided into three stages: the pre-training stage, the sensor selection stage, and the fine-tuning stage. The pre-training stage gives the model its primary ability to extract the fault features required for fault classification and sensor selection. At this stage, the model is trained on the pre-training dataset, which is a randomly selected subset of the training dataset. The full-input layer is used as the first layer of the model during this stage, and the model thus takes all

sensor channels as its input. For each sample, the input matrix is given by the following:

where

is the signal time series of the

sensor channel and

is the sample index.

During the supervised pre-training, the model can learn fault-related features from all sensor channels automatically. Values in vector are the representation of the fault-related information in sensor signals. We proposed a sensor selection method based on the feature vectors to find the sensor channels that contain the most discriminative fault-related features.

After pre-training, the sensor selection operation is performed. During the sensor selection stage, the well pre-trained model with the full-input layer is used to select the optimal sensor channels required for further training and testing. First, we create a single-sensor signal matrix composed of one signal time series and another

zero time series for each sensor channel. The new single-sensor signal matrices have the same shape as the

-channel multi-sensor signal matrix, and these new single-sensor signal matrices can be given as the following:

where

is the single-sensor signal matrix of the

sample and the

sensor channel. The

channel of the matrix

is the same as the

channel of the multi-sensor signal matrix

, while the other channels are zero time series.

The feature vector of each sensor is

, where

is the output channel number of the last convolutional layer, it can be denoted as the following:

where

represents the mapping relationship of the full-input layer-based model, which outputs the feature vector of the input single-sensor signal matrix. The feature vector

only relates to sensor signal

, and it is the representation of the fault-related information in its corresponding sensor channel. Therefore, the features in vector

can be used for sensor selection.

The global feature vector is denoted as the follows:

Then, a random forest classifier is trained on these features and gains the mean decrease in Gini impurity (

MDG) of each feature, which can be denoted as

where

is the collection of observations falling in node

,

, and

are the observations collections of its left and right child nodes, respectively.

,

, and

are the number of observations in

,

, and

respectively.

is the collection of nodes using feature

in the random forest classifier.

is the number of trees in the random forest classifier.

is the Gini impurity of

, which is calculated as follows:

where

is the proportion of class

in collection

, and

is the number of classes in collection

.

The corresponding feature score of each sensor channel is calculated as follows:

where

is the sample number in the training dataset. This metric measures the forest-wide contribution of the sensor channel at separating the different classes and constitutes one measure of sensor importance. The eight sensor channels with the highest feature scores are selected. In order to further reduce the redundant information, the Pearson correlation coefficient is used to measure the correlation between selected sensor channels, which is calculated follows:

The sensors with high absolute values of correlation coefficients are screened because they contain similar information. After sensor selection, the number of sensor channels is reduced from to .

Next, the selected sensor channels are used as the input channels for the partial-input layer for further fine-tuning and testing. Sensor channels with higher feature scores are more likely to contain more discriminating fault features. Therefore, when compared with the channels with lower feature scores, the selected channels are considered to be more relevant to the fault conditions, making them more suitable for further training and online diagnosis.

To accelerate convergence and reduce the computational costs during the pre-training stage, the pre-training dataset only takes a small proportion of the entire training dataset so that it does not have a sufficient sample volume to allow the model to achieve satisfactory diagnostic results. Therefore, the model should be further fine-tuned on the training dataset in the fine-tuning training stage. During the fine-tuning training stage, the partial-input-layer is used as the first layer of the model, and the input multi-sensor signal matrix, which is formed by the selected channels, is given by the following:

Because only the data from selected sensor channels, rather than from all channels, are selected as inputs to the model during both the fine-tuning and online diagnosis stages, the model complexity and the computational cost are greatly reduced. More importantly, the sensor selection operation ensures that the model is trained on optimal sensor channels that contain more features that contribute to the prediction accuracy, which accelerates the model convergence and increases training efficiency.

3.3. MS-CNN-Based Fault Diagnosis Method

The framework of the proposed fault diagnostic method is shown in

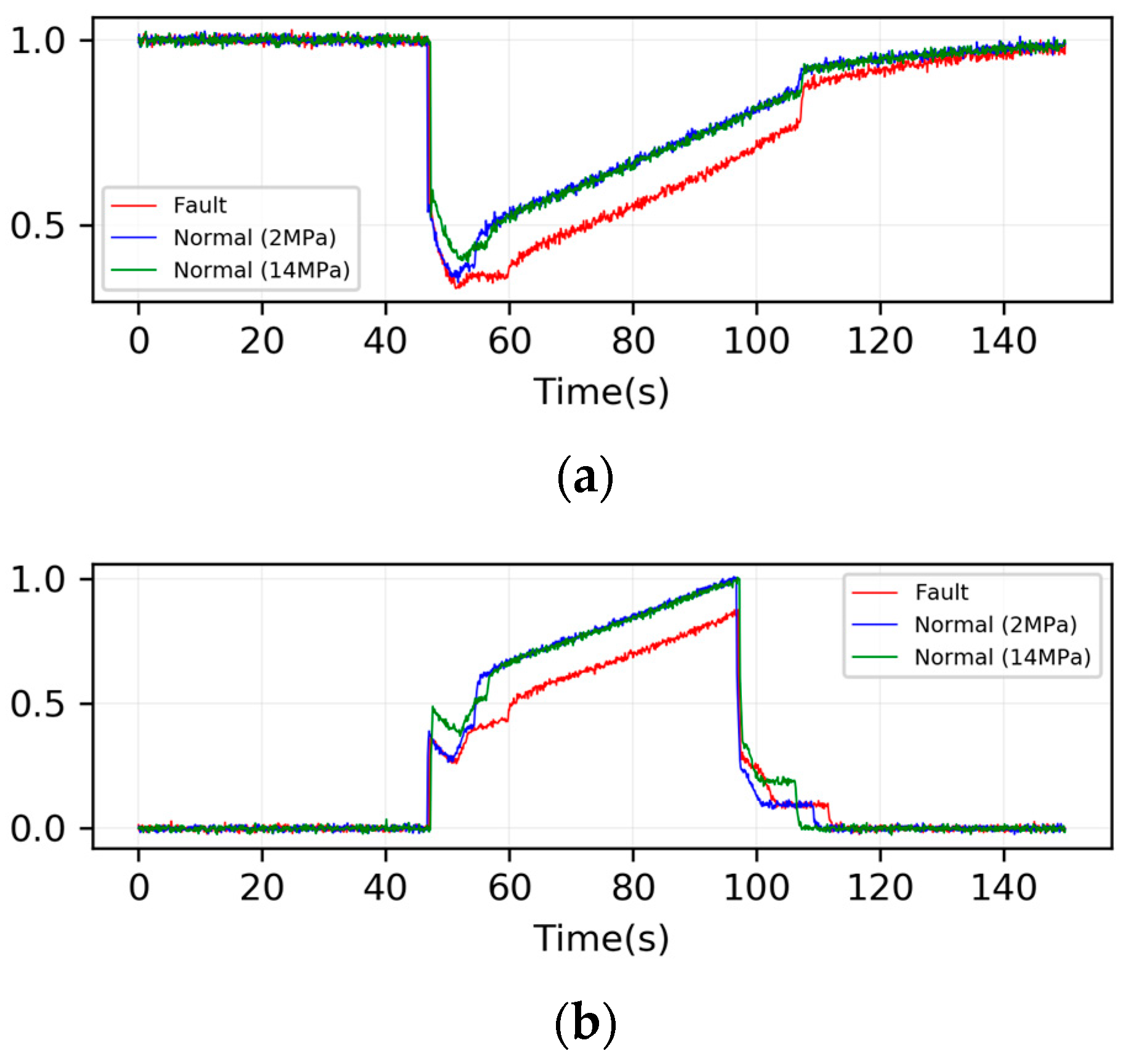

Figure 2. This framework is built to detect faults in an electric-hydraulic system in real time using raw multi-sensor data signals. The process to establish this framework can generally be described as follows.

The multi-sensor data and the corresponding working conditions are acquired from the historical data and the records of the target hydraulic system. Multi-sensor data are split into 400 s long time segments that are used as training and testing samples while the corresponding working conditions are used as labels for these samples. The training dataset and the testing dataset are selected randomly from these labeled samples. The MS-CNN-based diagnostic model is constructed and trained on the training dataset. The training stage contains the processes of pre-training, sensor selection, and fine-tuning, and is performed offline. During training, the optimal sensor channels are selected from all channels. After training, the model will be tested using the test dataset to assess the diagnosis accuracy and then used for real-time diagnosis.

During the real-time diagnosis stage, the sensor signals are collected from the target hydraulic system in real time. Diagnosis is performed every 10 s to predict the system’s health condition periodically. The input of the model is the matrix of 400 s long signals from the selected optimal channels, the format of which is the same as the training samples.

Similar to the proposed MS-CNN, in [

22,

26], the 1D signals from different sensors are channel-wise packaged to form the input matrix for a deep learning-based diagnosis model which also enable the model to take advantage of multi-sensor data. However, in these studies, sensor selection was neglected, which will introduce redundant information into the deep learning model and limit the diagnostic performance. In contrast, the MS-CNN proposed in this paper eliminates the redundant sensors automatically and simplifies the model. Using this simpler model, the training and online diagnosis process can be performed rapidly. In addition, monitoring of the eliminated sensors can be conducted at a lower sampling frequency, which also reduces the communication and data storage costs. All these advantages make the proposed method more suitable for use in real-time diagnosis applications.