Digital Image Correlation with a Prism Camera and Its Application in Complex Deformation Measurement

Abstract

1. Introduction

2. Algorithm

2.1. Principle

2.2. Integer-Pixel Matching

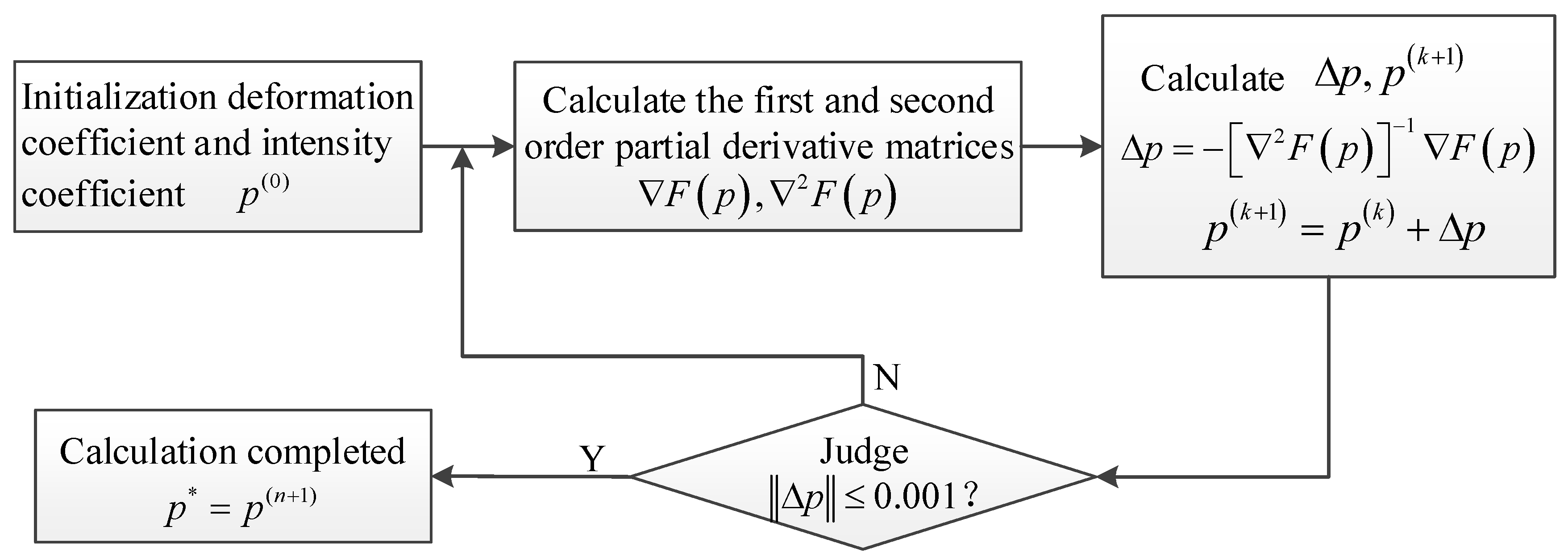

2.3. Sub-Pixels Matching

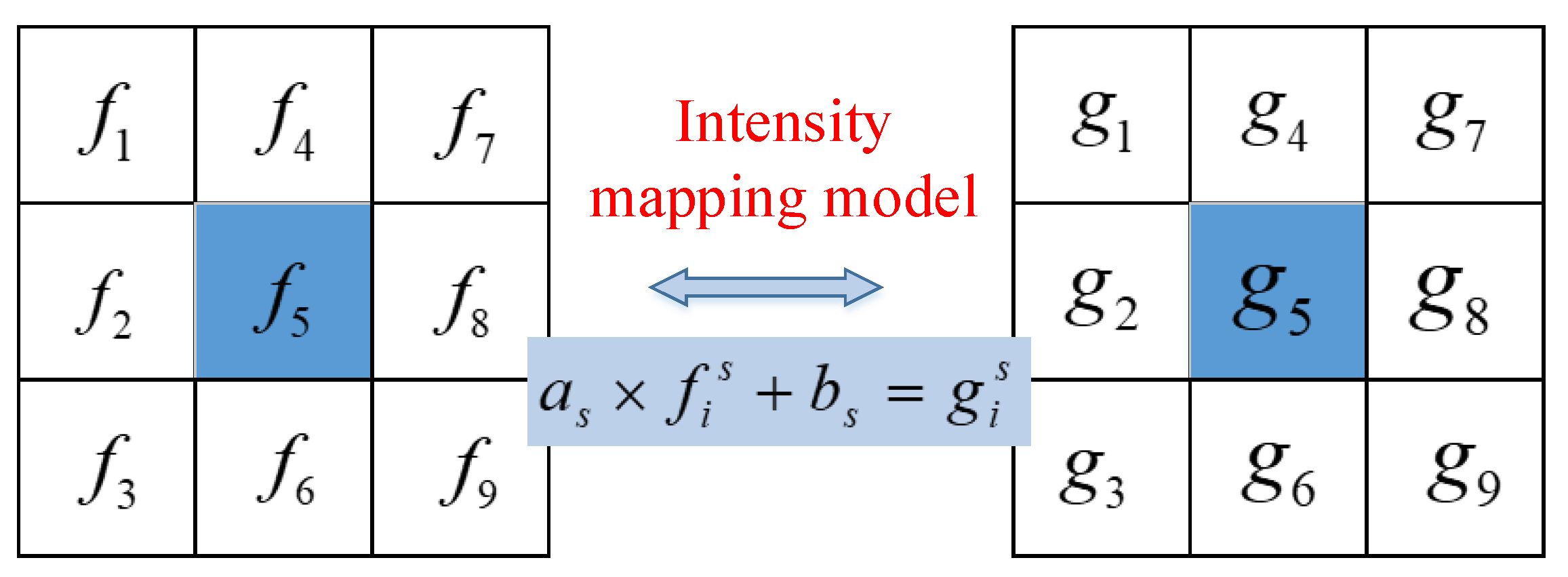

2.4. Initial Value Estimation of Light Intensity Coefficients

3. Numerical Simulation

3.1. Generate Speckle Image

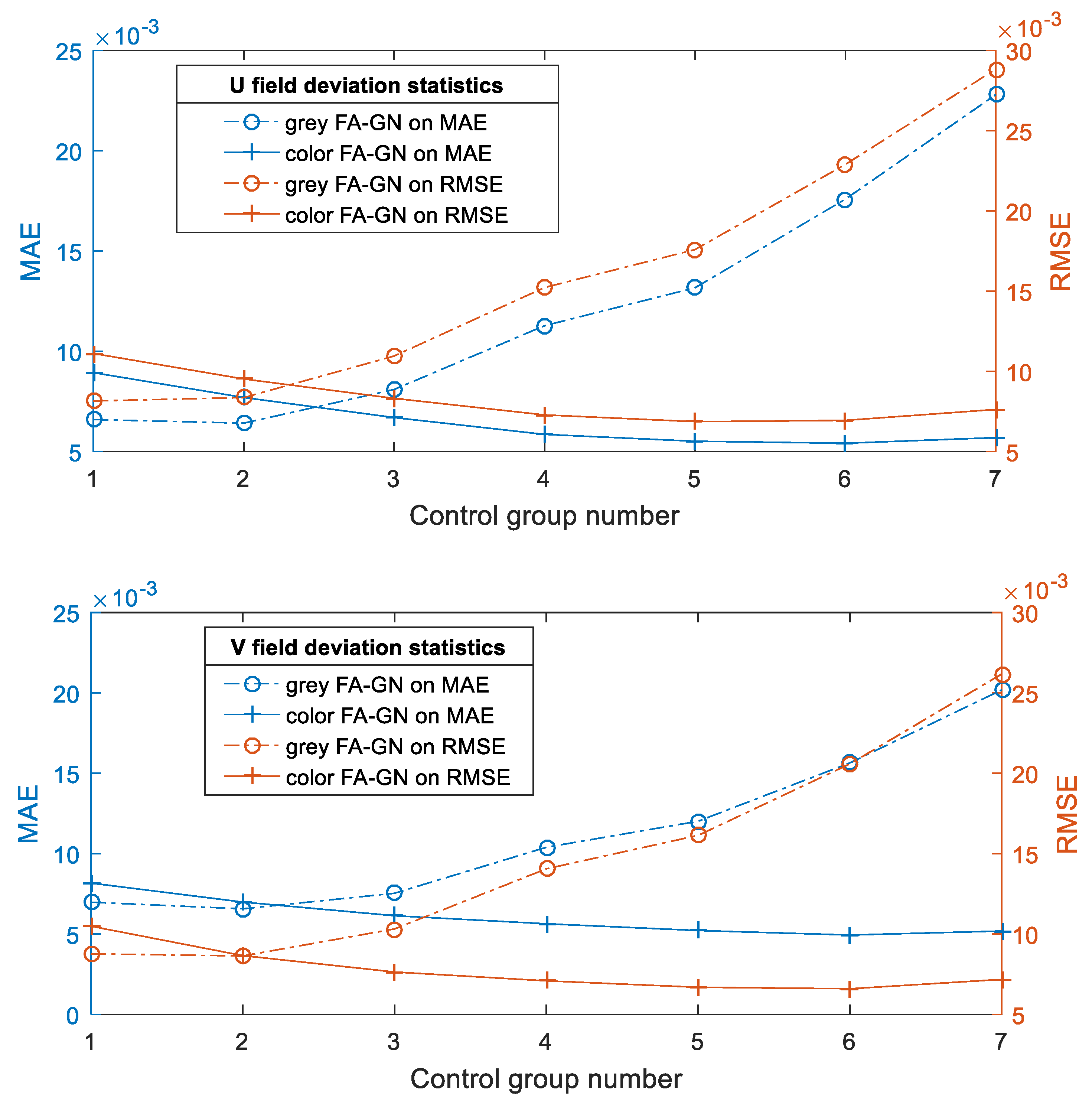

3.2. Result Analysis

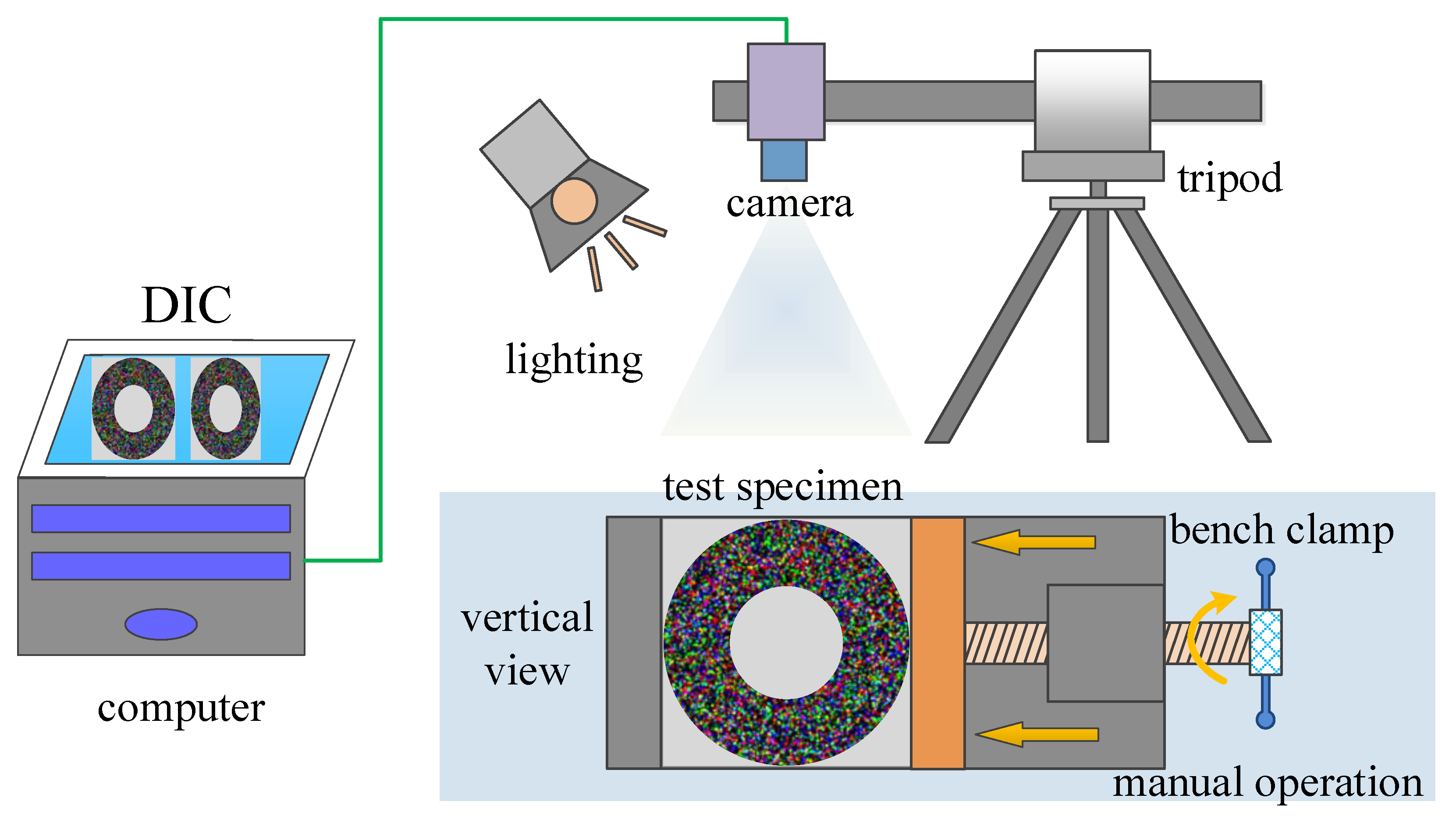

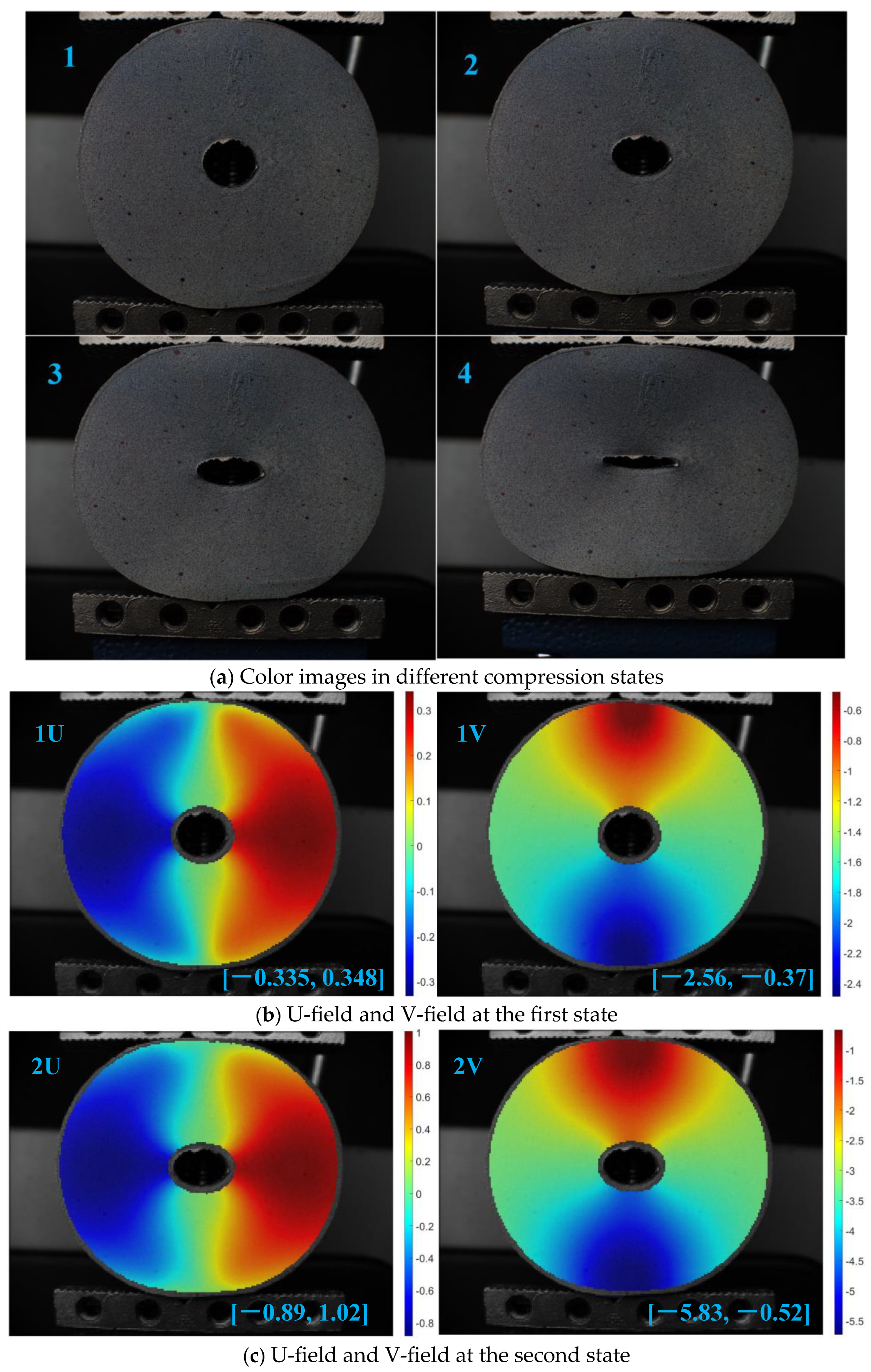

4. Application

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

IC-GN Matching Algorithm Based on Color Image

References

- Atkinson, D.; Becker, T.H. Stereo digital image correlation in MATLAB. Appl. Sci. 2021, 11, 4904. [Google Scholar] [CrossRef]

- Nguyen, H.; Liang, J.; Wang, Y.; Wang, Z. Accuracy assessment of fringe projection profilometry and digital image correlation techniques for three-dimensional shape measurements. J. Phys. Photonics 2021, 3, 014004. [Google Scholar] [CrossRef]

- Pan, B.; Asundi, A.; Xie, H.; Gao, J. Digital image correlation using iterative least squares and pointwise least squares for displacement field and strain field measurements. Opt. Lasers Eng. 2009, 47, 865–874. [Google Scholar] [CrossRef]

- Pan, B.; Li, K.; Tong, W. Fast, Robust and Accurate Digital Image Correlation Calculation without Redundant Computations. Exp. Mech. 2013, 53, 1277–1289. [Google Scholar] [CrossRef]

- Liu, G.; Li, M.; Zhang, W.; Gu, J. Subpixel Matching Using Double-Precision Gradient-Based Method for Digital Image Correlation. Sensors 2021, 21, 3140. [Google Scholar] [CrossRef]

- Zhang, M.; Ge, P.; Fu, Z.; Dan, X.; Li, G. Mechanical Property Test of Grass Carp Skin Material Based on the Digital Image Correlation Method. Sensors 2022, 22, 8364. [Google Scholar] [CrossRef]

- Bao, S.; Wang, Y.; Liu, L.; Lu, Y.; Yan, P. An error elimination method for high-temperature digital image correlation using color speckle and camera. Opt. Lasers Eng. 2019, 116, 47–54. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, X.; Zhong, M.; Liu, Z. A bilayer color digital image correlation method for the measurement of the topography of a liquid interface. Opt. Lasers Eng. 2023, 160, 107242. [Google Scholar] [CrossRef]

- Papanikolaou, A.; Garbat, P.; Kujawinska, M. Metrological Evaluation of the Demosaicking Effect on Colour Digital Image Correlation with Application in Monitoring of Paintings. Sensors 2022, 22, 7359. [Google Scholar] [CrossRef]

- Curt, J.; Capaldo, M.; Hild, F.; Roux, S. Optimal digital color image correlation. Opt. Lasers Eng. 2020, 127, 105896. [Google Scholar] [CrossRef]

- Forsey, A.; Gungor, S. Demosaicing images from colour cameras for digital image correlation. Opt. Lasers Eng. 2016, 86, 20–28. [Google Scholar] [CrossRef]

- Dong, B.; Zeng, F.; Pan, B. A Simple and Practical Single-Camera Stereo-Digital Image Correlation Using a Color Camera and X-Cube Prism. Sensors 2019, 19, 4726. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Dan, X.; Xu, W.; Wang, Y.; Yang, G.; Yang, L. 3D digital image correlation using single color camera pseudo-stereo system. Opt. Laser Technol. 2017, 95, 1–7. [Google Scholar] [CrossRef]

- Wang, Y.; Dan, X.; Li, J.; Wu, S.; Yang, L. Multi-perspective digital image correlation method using a single color camera. Sci. China Technol. Sci. 2017, 61, 61–67. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Full-frame, high-speed 3D shape and deformation measurements using stereo-digital image correlation and a single color high-speed camera. Opt. Lasers Eng. 2017, 95, 17–25. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Color Stereo-Digital Image Correlation Method Using a Single 3CCD Color Camera. Exp. Mech. 2017, 57, 649–657. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. High-speed stereo-digital image correlation using a single color high-speed camera. Appl. Opt. 2018, 57, 9257–9269. [Google Scholar] [CrossRef]

- Zhong, F.; Shao, X.; Quan, C. 3D digital image correlation using a single 3CCD colour camera and dichroic filter. Meas. Sci. Technol. 2018, 29, 045401. [Google Scholar] [CrossRef]

- Felipe-Sese, L.; Molina-Viedma, A.J.; Lopez-Alba, E.; Diaz, F.A. RGB Colour Encoding Improvement for Three-Dimensional Shapes and Displacement Measurement Using the Integration of Fringe Projection and Digital Image Correlation. Sensors 2018, 18, 3130. [Google Scholar] [CrossRef]

- Yoneyama, S.; Morimoto, Y. Accurate displacement measurement by correlation of colored random patterns. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2003, 46, 178–184. [Google Scholar] [CrossRef]

- Dinh, N.V.; Hassan, G.M.; Dyskin, A.V.; MacNish, C. Digital Image Correlation for Small Strain Measurement in Deformable Solids and Geomechanical Structures. In Proceedings of the 2015 IEEE International Conference on Image Processing (ICIP), Quebec City, QU, Canada, 27–30 September 2015; IEEE: New York, NY, USA, 2015; pp. 3324–3328. [Google Scholar]

- Hang, D.; Hassan, G.M.; MacNish, C.; Dyskin, A. Characteristics of Color Digital Image Correlation for Deformation Measurement in Geomechanical Structures. In Proceedings of the 2016 International Conference on Digital Image Computing: Techniques and Applications (DICTA), Gold Coast, QLD, Australia, 30 November–2 December 2016; IEEE: New York, NY, USA, 2016; pp. 1–8. [Google Scholar]

- Wang, L. Deformation Measurement of Scaling and Rotation Objects Based on Digital Image Correlation Method with Color Information. Photonics 2022, 9, 237. [Google Scholar] [CrossRef]

- Baldi, A. Digital Image Correlation and Color Cameras. Exp. Mech. 2017, 58, 315–333. [Google Scholar] [CrossRef]

- Zhou, P. Subpixel displacement and deformation gradient measurement using digital image/speckle correlation (DISC). Opt. Eng. 2001, 40, 1613. [Google Scholar] [CrossRef]

- Yuan, Y.; Huang, J.; Peng, X.; Xiong, C.; Fang, J.; Yuan, F. Accurate displacement measurement via a self-adaptive digital image correlation method based on a weighted ZNSSD criterion. Opt. Lasers Eng. 2014, 52, 75–85. [Google Scholar] [CrossRef]

- Hassan, G.M.; MacNish, C.; Dyskin, A.; Shufrin, I. Digital image correlation with dynamic subset selection. Opt. Lasers Eng. 2016, 84, 1–9. [Google Scholar] [CrossRef]

- Wang, B.; Pan, B. Random errors in digital image correlation due to matched or overmatched shape functions. Exp. Mech. 2015, 55, 1717–1727. [Google Scholar] [CrossRef]

- Feng, W.; Jin, Y.; Wei, Y.; Hou, W.; Zhu, C. Technique for two-dimensional displacement field determination using a reliability-guided spatial-gradient-based digital image correlation algorithm. Appl. Opt. 2018, 57, 2780–2789. [Google Scholar] [CrossRef]

| Group Number | Subset Size | U-Field Displacement Deviation Statistics (×10−3) | V-Field Displacement Deviation Statistics (×10−3) | Average Value of Iterations | |||

|---|---|---|---|---|---|---|---|

| MAE | RMSE | MAE | RMSE | Time (×10−4 s) | Times | ||

| (1) | (2 × 9 + 1)2 | 6.60 | 8.16 | 6.98 | 8.77 | 5.60 | 4.92 |

| (2 × 5 + 1)2 × 3 | 8.94 | 11.12 | 8.17 | 10.49 | 9.25 | 5.66 | |

| (2) | (2 × 11 + 1)2 | 6.42 | 8.37 | 6.57 | 8.64 | 6.51 | 4.78 |

| (2 × 6 + 1)2 × 3 | 7.70 | 9.53 | 6.99 | 8.66 | 9.57 | 5.39 | |

| (3) | (2 × 13 + 1)2 | 8.10 | 10.96 | 7.54 | 10.32 | 7.81 | 4.68 |

| (2 × 7 + 1)2 × 3 | 6.70 | 8.32 | 6.14 | 7.64 | 10.85 | 5.25 | |

| (4) | (2 × 15 + 1)2 | 11.28 | 15.23 | 10.40 | 14.06 | 9.36 | 4.68 |

| (2 × 8 + 1)2 × 3 | 5.86 | 7.29 | 5.64 | 7.09 | 13.83 | 5.12 | |

| (5) | (2 × 16 + 1)2 | 13.17 | 17.59 | 12.02 | 16.14 | 10.21 | 4.70 |

| (2 × 9 + 1)2 × 3 | 5.52 | 6.87 | 5.22 | 6.69 | 15.17 | 5.02 | |

| (6) | (2 × 18 + 1)2 | 17.59 | 22.90 | 15.65 | 20.59 | 11.58 | 4.64 |

| (2 × 10 + 1)2 × 3 | 5.42 | 6.95 | 4.94 | 6.60 | 17.06 | 4.98 | |

| (7) | (2 × 20 + 1)2 | 22.80 | 28.84 | 20.19 | 26.18 | 13.90 | 4.62 |

| (2 × 11 + 1)2 × 3 | 5.70 | 7.63 | 5.19 | 7.18 | 18.57 | 4.94 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Qian, B.; Zhang, Y.; Li, W. Digital Image Correlation with a Prism Camera and Its Application in Complex Deformation Measurement. Sensors 2023, 23, 5531. https://doi.org/10.3390/s23125531

Hu H, Qian B, Zhang Y, Li W. Digital Image Correlation with a Prism Camera and Its Application in Complex Deformation Measurement. Sensors. 2023; 23(12):5531. https://doi.org/10.3390/s23125531

Chicago/Turabian StyleHu, Hao, Boxing Qian, Yongqing Zhang, and Wenpan Li. 2023. "Digital Image Correlation with a Prism Camera and Its Application in Complex Deformation Measurement" Sensors 23, no. 12: 5531. https://doi.org/10.3390/s23125531

APA StyleHu, H., Qian, B., Zhang, Y., & Li, W. (2023). Digital Image Correlation with a Prism Camera and Its Application in Complex Deformation Measurement. Sensors, 23(12), 5531. https://doi.org/10.3390/s23125531