A Fault-Detection System Approach for the Optimization of Warship Equipment Replacement Parts Based on Operation Parameters

Abstract

1. Introduction

2. Related Work

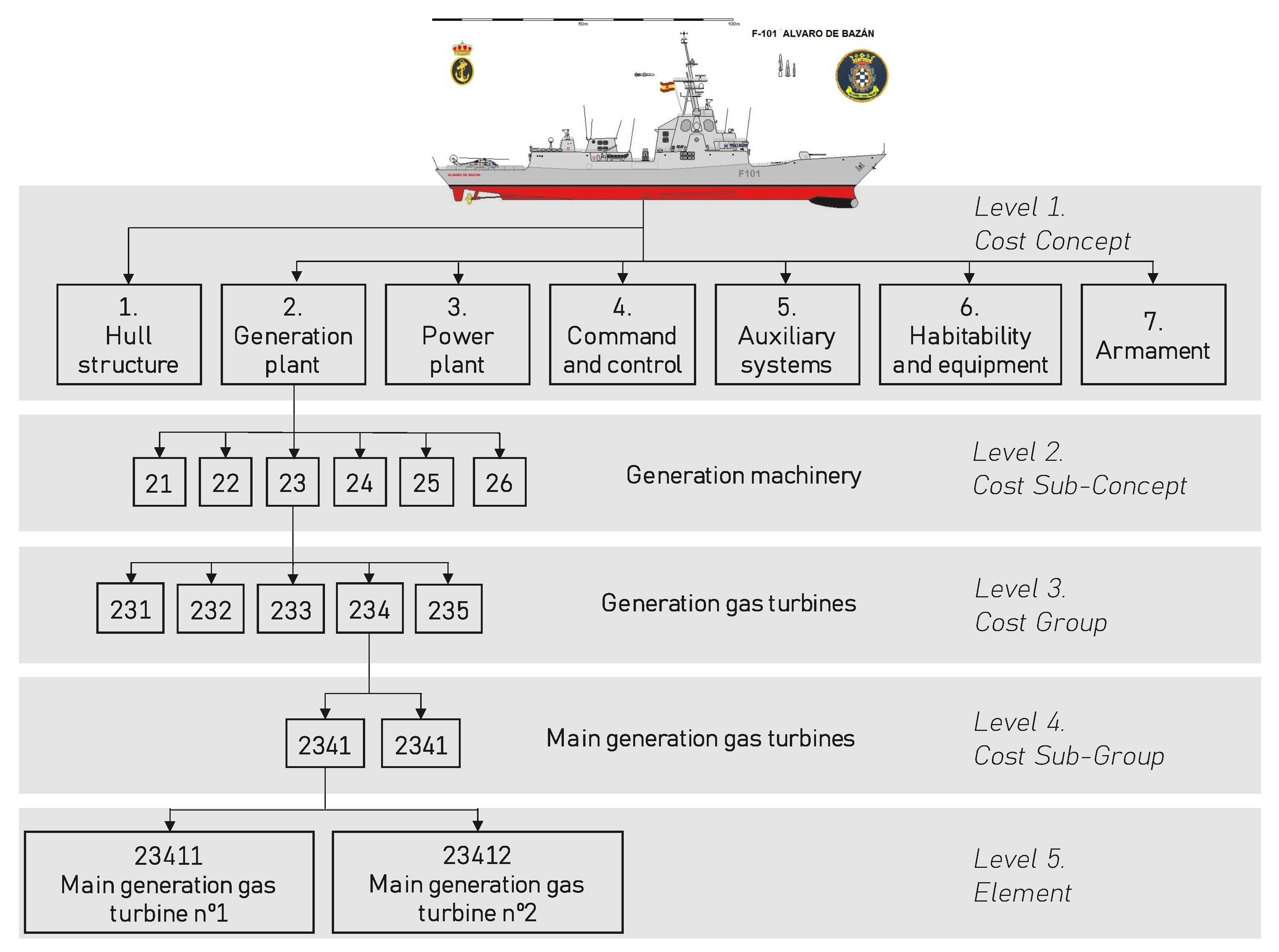

3. Case of Study

3.1. Equipment

3.2. Warship Information System Structure

4. Materials and Methods

4.1. Employed Methods

4.1.1. Statistical Models

Gaussian Model

- is the training set mean value;

- is the training set covariance matrix.

4.1.2. Geometric Boundaries

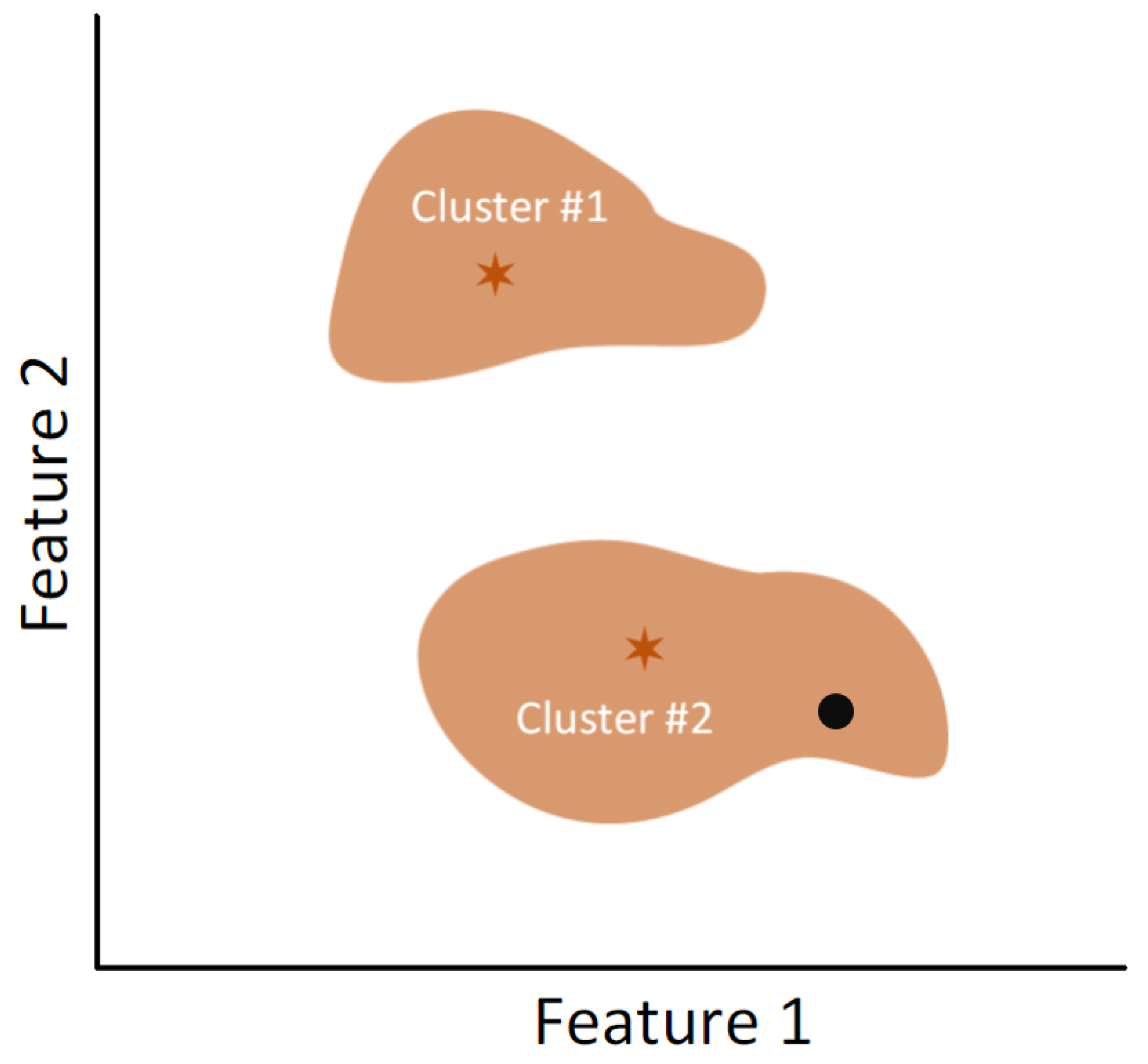

K-Means

- x represents a new input vector;

- denotes the centroid of the k cluster.

4.1.3. Dimensional Reduction

Autoencoder

- defines the output of the hidden layer;

- is the hidden layer activation function;

- corresponds to the weight matrix between input and hidden layer;

- is the input vector;

- denotes the bias vector.

- is the ANN output.

- denotes the activation function of the output layer.

- define the weight matrix between hidden and output layers.

- is the bias vector.

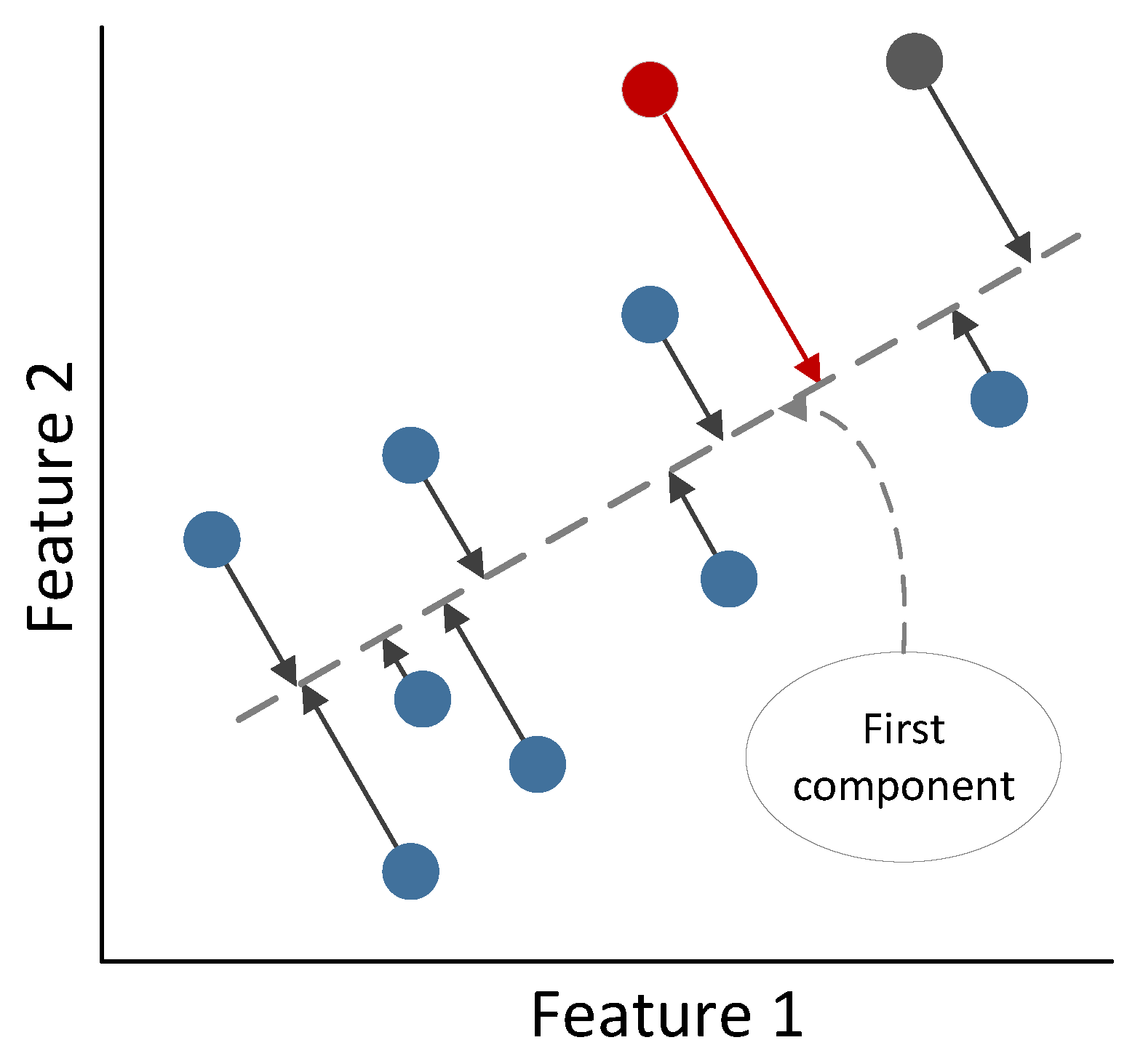

Principal Component Analysis

4.2. Dataset

- Dataset 1 contains two variables and a total of 902,796 samples, of which 219 correspond to anomalous data.

- Dataset 2 contains two variables and 897,191 samples, of which 101 correspond to anomalous data.

- Dataset 3 contains twenty-five variables and 887,294 samples, of which 233 correspond to anomalous data.

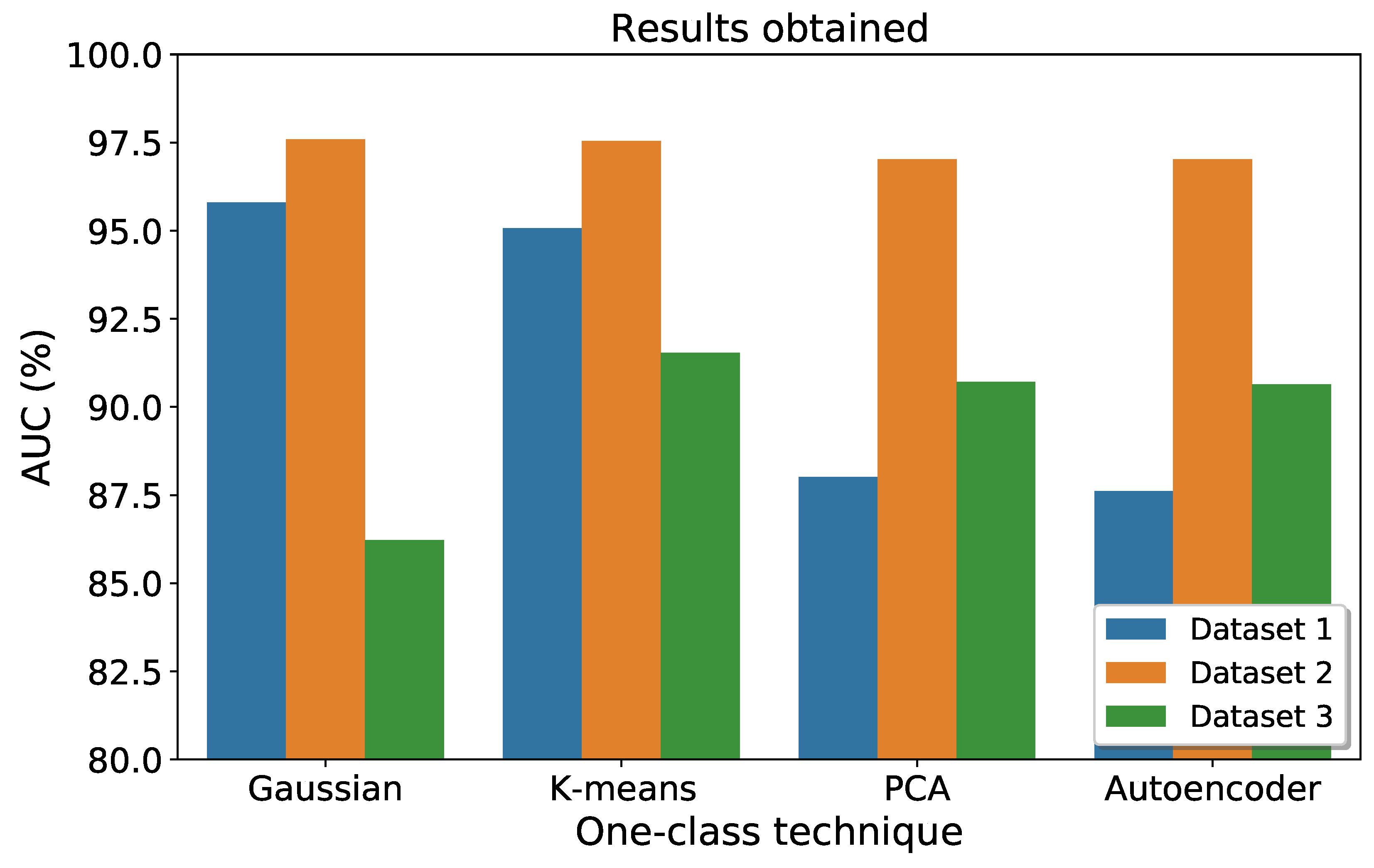

5. Experiments Description (Setup) and Results

5.1. Experimental Setup and Assessment

- Gaussian Model

- −

- Data normalization

- −

- Data regularization

- −

- Outlier factor

- K-means

- −

- Data normalization

- −

- Number of clusters

- −

- Outlier factor

- Autoencoder

- −

- Data normalization

- −

- Neurons in the hidden layer

- −

- Outlier factor

- Principal Component Analysis

- −

- Data normalization

- −

- Number of components considered

- −

- Outlier factor

5.2. Results

6. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Khastgir, S.; Birrell, S.; Dhadyalla, G.; Sivencrona, H.; Jennings, P. Towards increased reliability by objectification of Hazard Analysis and Risk Assessment (HARA) of automated automotive systems. Saf. Sci. 2017, 99, 166–177. [Google Scholar] [CrossRef]

- Wahidi, S.; Pribadi, S.; Pribadi, T.; Wardhana, N.; Arif, M. Fixed Manpower Reduction Analysis to Reduce Indirect Cost of Ship Production. In Proceedings of the 5th International Conference on Marine Technology (SENTA 2020), Surabaya, Indonesia, 8 December 2020; IOP Publishing: Bristol, UK, 2021; Volume 1052, p. 012048. [Google Scholar]

- Hannaford, E.; Hassel, E.V. Risks and Benefits of Crew Reduction and/or Removal with Increased Automation on the Ship Operator: A Licensed Deck Officer’s Perspective. Appl. Sci. 2021, 11, 3569. [Google Scholar] [CrossRef]

- Manis, K.; Madhavaram, S. AI-Enabled marketing capabilities and the hierarchy of capabilities: Conceptualization, proposition development, and research avenues. J. Bus. Res. 2023, 157, 113485. [Google Scholar] [CrossRef]

- Ang, J.H.; Goh, C.; Saldivar, A.A.F.; Li, Y. Energy-efficient through-life smart design, manufacturing and operation of ships in an industry 4.0 environment. Energies 2017, 10, 610. [Google Scholar] [CrossRef]

- Thompson, J.H. An Unpopular War: From Afkak to Bosbefok; Penguin Random House: Saxonwold, South Africa, 2011. [Google Scholar]

- La Monaca, U.; Bertagna, S.; Marinò, A.; Bucci, V. Integrated ship design: An innovative methodological approach enabled by new generation computer tools. Int. J. Interact. Des. Manuf. (IJIDeM) 2020, 14, 59–76. [Google Scholar] [CrossRef]

- Xing, T.; Song, B.; Ye, J.; Zhao, Z. General Analysis Method of Warship Service Life. In Proceedings of the 2010 Second WRI Global Congress on Intelligent Systems, Wuhan, China, 16–17 December 2010; IEEE: Piscataway, NJ, USA, 2010; Volume 3, pp. 223–228. [Google Scholar]

- Stanić, V.; Hadjina, M.; Fafandjel, N.; Matulja, T. Toward shipbuilding 4.0-an industry 4.0 changing the face of the shipbuilding industry. Brodogr. Teor. Praksa Brodogr. Pomor. Teh. 2018, 69, 111–128. [Google Scholar] [CrossRef]

- Fernández Jove, A.; Mackinlay, A.; Riola, J.M. Optimization of the Life Cycle in the Warships: Maintenance Plan and Monitoring for Costs Reduction. In Proceedings of the International Ship Design & Naval Engineering Congress, Pan American Congress of Naval Engineering, Maritime Transport and Port Engineering, Cartagena, Colombia, 13–15 March 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 391–401. [Google Scholar]

- Jove, E.; Casteleiro-Roca, J.L.; Quintián, H.; Méndez-Pérez, J.A.; Calvo-Rolle, J.L. A new method for anomaly detection based on non-convex boundaries with random two-dimensional projections. Inf. Fusion 2021, 65, 50–57. [Google Scholar] [CrossRef]

- Jove, E.; Casteleiro-Roca, J.; Quintián, H.; Méndez-Pérez, J.; Calvo-Rolle, J. Anomaly detection based on intelligent techniques over a bicomponent production plant used on wind generator blades manufacturing. Rev. Iberoam. Autom. Inform. Ind. 2020, 17, 84–93. [Google Scholar]

- Chandola, V.; Banerjee, A.; Kumar, V. Anomaly detection: A survey. ACM Comput. Surv. (CSUR) 2009, 41, 1–58. [Google Scholar] [CrossRef]

- Ahmed, M.; Mahmood, A.N.; Hu, J. A survey of network anomaly detection techniques. J. Netw. Comp. Appl. 2016, 60, 19–31. [Google Scholar] [CrossRef]

- Casteleiro-Roca, J.L.; Jove, E.; Sánchez-Lasheras, F.; Méndez-Pérez, J.A.; Calvo-Rolle, J.L.; de Cos Juez, F.J. Power cell SOC modelling for intelligent virtual sensor implementation. J. Sens. 2017, 2017. [Google Scholar] [CrossRef]

- Kimera, D.; Nangolo, F.N. Maintenance practices and parameters for marine mechanical systems: A review. J. Qual. Maint. Eng. 2020, 26, 459–488. [Google Scholar] [CrossRef]

- Cullum, J.; Binns, J.; Lonsdale, M.; Ambassi, R.; Garaniya, V. Risk-Based Maintenance Scheduling with application to naval vessels and ships. Ocean Eng. 2018, 148, 476–485. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Cao, L.; Dong, F.; Zou, Y.; Wang, K.; Zhang, Y.; Sun, P. Marine Systems and Equipment Prognostics and Health Management: A Systematic Review from Health Condition Monitoring to Maintenance Strategy. Machines 2022, 10, 72. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. A review of online condition monitoring and maintenance strategy for cylinder liner-piston rings of diesel engines. Mech. Syst. Signal Proc. 2022, 165, 108385. [Google Scholar] [CrossRef]

- Xie, T.; Wang, T.; He, Q.; Diallo, D.; Claramunt, C. A review of current issues of marine current turbine blade fault detection. Ocean Eng. 2020, 218, 108194. [Google Scholar] [CrossRef]

- Cipollini, F.; Oneto, L.; Coraddu, A.; Murphy, A.J. Condition-based maintenance of naval propulsion systems: Data analysis with minimal feedback. Reliab. Eng. Syst. Saf. 2018, 177, 12–23. [Google Scholar] [CrossRef]

- Karatug, C.; Arslanoglu, Y.; Guedes Soares, C. Trends in Maritime Technology and Engineering; Maintenance Strategies for Machinery Systems of Autonomous Ships; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Emovon, I.; Norman, R.A.; Murphy, A.J. Elements of maintenance system and tools for implementation within framework of Reliability Centred Maintenance- A review. Mech. Eng. Technol. 2016, 8, 1–34. [Google Scholar]

- Abbas, M.; Shafiee, M. An overview of maintenance management strategies for corroded steel structures in extreme marine environments. Marine Struct. 2020, 71, 102718. [Google Scholar] [CrossRef]

- Jimenez, V.J.; Bouhmala, N.; Gausdal, A.H. Developing a predictive maintenance model for vessel machinery. J. Ocean Eng. Sci. 2020, 5, 358–386. [Google Scholar] [CrossRef]

- Song, T.; Tan, T.; Han, G. Research on Preventive Maintenance Strategies and Systems for in-Service Ship Equipment. Polish Maritime Res. 2022, 29, 85–96. [Google Scholar] [CrossRef]

- Emovon, I.; Norman, R.A.; Murphy, A.J. Hybrid MCDM based methodology for selecting the optimum maintenance strategy for ship machinery systems. J. Intell. Manuf. 2018, 29, 519–531. [Google Scholar] [CrossRef]

- Michala, A.L.; Lazakis, I.; Theotokatos, G. Predictive maintenance decision support system for enhanced energy efficiency of ship machinery. In Proceedings of the International Conference on Shipping in Changing Climates, Glasgow, UK, 24–26 November 2015; pp. 195–205. [Google Scholar]

- Asuquo, M.P.; Wang, J.; Zhang, L.; Phylip-Jones, G. Application of a multiple attribute group decision making (MAGDM) model for selecting appropriate maintenance strategy for marine and offshore machinery operations. Ocean Eng. 2019, 179, 246–260. [Google Scholar] [CrossRef]

- Lazakis, I.; Turan, O.; Alkaner, S.; Olcer, A. Effective ship maintenance strategy using a risk and criticality based approach. In Proceedings of the 13th International Congress of the International Maritime Association of the Mediterranean (IMAM 2009), Genova, Italy, 13–16 September 2009. [Google Scholar]

- Diagkinis, I.; Nikitakos, N. Application of analytic hierarchy process and TOPSIS methodology on ships’ maintenance strategies. J. Pol. Saf. Reliab. Assoc. 2013, 4, 21–28. [Google Scholar]

- Emovon, I. Ship system maintenance strategy selection based on DELPHI-AHP-TOPSIS methodology. World J. Eng. Technol. 2016, 4, 252–260. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, L. A bi-objective model for vessel emergency maintenance under a condition-based maintenance strategy. Simulation 2018, 94, 609–624. [Google Scholar] [CrossRef]

- Barrero, D.; Fontenla-Romero, O.; Lamas-López, F.; Novoa-Paradela, D.; R-Moreno, M.; Sanz, D. SOPRENE: Assessment of the Spanish Armada’s Predictive Maintenance Tool for Naval Assets. Appl. Sci. 2021, 11, 7322. [Google Scholar] [CrossRef]

- Samanta, B.; Al-Balushi, K.R. Artificial Neural Network based fault diagnostics of rolling element bearings using time-domain features. Mech. Syst. Signal Process. 2003, 17, 317–328. [Google Scholar] [CrossRef]

- Quinlan, J. Improved Use of Continuous Attributes in C4.5. Artif. Intell. Res. 1996, 4, 77–90. [Google Scholar] [CrossRef]

- Chen, Y.; He, Y.; Li, Z.; Chen, L.; Zhang, C. Remaining Useful Life Prediction and State of Health Diagnosis of Lithium-Ion Battery Based on Second-Order Central Difference Particle Filter. IEEE Access 2020, 8, 37305–37313. [Google Scholar] [CrossRef]

- Ratsch, G.; Mika, S.; Scholkopf, B.; Muller, K.R. Constructing boosting algorithms from SVMs: An application to one-class classification. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 1184–1199. [Google Scholar] [CrossRef]

- Susto, G.; Schirru, A.; Pampuri, S.; McLoone, S.; Beghi, A. Machine Learning for Predictive Maintenance: A Multiple Classifier Approach. IEEE Trans. Ind. Inf. 2015, 11, 812–820. [Google Scholar] [CrossRef]

- Ma, M.; Sun, C.; Chen, X. Deep Coupling Autoencoder for Fault Diagnosis with Multimodal Sensory Data. IEEE Trans. Ind. Inf. 2018, 14, 1137–1145. [Google Scholar] [CrossRef]

- Yuan, J.; Tian, Y. An Intelligent Fault Diagnosis Method Using GRU Neural Network towards Sequential Data in Dynamic Processes. Processes 2019, 7, 152. [Google Scholar] [CrossRef]

- Yang, R.; Huang, M.; Lu, Q.; Zhong, M. Rotating Machinery Fault Diagnosis Using Long-short-term Memory Recurrent Neural Network. IFAC-PapersOnLine 2018, 51, 228–232. [Google Scholar] [CrossRef]

- Zhu, R.; Peng, W.; Wang, D.; Huang, C.G. Bayesian transfer learning with active querying for intelligent cross-machine fault prognosis under limited data. Mech. Syst. Signal Process. 2023, 183, 109628. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.T.; Iqbal, J. A review on fault detection and diagnosis techniques: Basics and beyond. Artif. Intell. Rev. 2021, 54, 3639–3664. [Google Scholar] [CrossRef]

- Yamei, J.; Xin, T.; Hongjian, L.; Lifeng, M. Fault detection of networked dynamical systems: A survey of trends and techniques. Int. J. Syst. Sci. 2021, 52, 3390–3409. [Google Scholar]

- Xu, X.; Karney, B. Modeling and Monitoring of Pipelines and Networks: An Overview of Transient Fault Detection Techniques; ACM: New York, NY, USA, 2017; pp. 13–37. [Google Scholar]

- Madeti, S.R.; Singh, S.N. A comprehensive study on different types of faults and detection techniques for solar photovoltaic system. Solar Energy 2017, 158, 161–185. [Google Scholar] [CrossRef]

- Appiah, A.Y.; Zhang, X.; Ayawli, B.B.K.; Kyeremeh, F. Review and performance evaluation of photovoltaic array fault detection and diagnosis techniques. Int. J. Photoenergy 2019, 2019, 6953530. [Google Scholar] [CrossRef]

- Gangsar, P.; Tiwari, R. Signal based condition monitoring techniques for fault detection and diagnosis of induction motors: A state-of-the-art review. Mech. Syst. Signal Process. 2020, 144, 106908. [Google Scholar] [CrossRef]

- Mishra, D.P.; Ray, P. Fault detection, location and classification of a transmission line. Neural Comput. Appl. 2020, 30, 1377–1424. [Google Scholar] [CrossRef]

- Jove, E.; Casteleiro-Roca, J.L.; Quintián, H.; Méndez-Pérez, J.A.; Calvo-Rolle, J.L. A fault detection system based on unsupervised techniques for industrial control loops. Exp. Syst. 2019, 36, e12395. [Google Scholar] [CrossRef]

- Jove, E.; Casteleiro-Roca, J.L.; Quintián, H.; Simić, D.; Méndez-Pérez, J.A.; Calvo-Rolle, J.L. Anomaly detection based on one-class intelligent techniques over a control level plant. Logic J. IGPL 2020, 28, 502–518. [Google Scholar] [CrossRef]

- Reis, G.; Chang, J.; Vachharajani, N.; Mukherjee, S.S.; Rangan, R.; August, D.I. Design and evaluation of hybrid fault-detection systems. In Proceedings of the 32nd International Symposium on Computer Architecture (ISCA’05), Madison, WI, USA, 4–8 June 2005; pp. 148–159. [Google Scholar]

- NATO. Guidance on Integrated Logistics Support for Multinational Armament Programmes; ALP-10: Brussels, Belgium, 2017. [Google Scholar]

- Macías Gaya, J.M. El control de la configuración en la Armada del siglo XXI. Rev. Gen. Mar. 2019, 276, 77–89. [Google Scholar]

- NATO. Configuration management in system life cycle management. STANAG 4427 2014. [Google Scholar]

- Tax, D.M.J. One-Class Cassification: Concept-Learning in the Absence of Counter-Examples. Ph.D. Thesis, Delft University of Technology, Delft, The Nethlands, 2001. [Google Scholar]

- Casale, P.; Pujol, O.; Radeva, P. Approximate polytope ensemble for one-class classification. Pattern Recognit. 2014, 47, 854–864. [Google Scholar] [CrossRef]

- Jeon, B.; Landgrebe, D.A. Fast Parzen density estimation using clustering-based branch and bound. IEEE Trans. Pattern Anal. Mach. Intell. 1994, 16, 950–954. [Google Scholar] [CrossRef]

- Chiang, L.H.; Russell, E.L.; Braatz, R.D. Fault Detection and Diagnosis in Industrial Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Sakurada, M.; Yairi, T. Anomaly detection using autoencoders with nonlinear dimensionality reduction. In Proceedings of the MLSDA 2014 2nd Workshop on Machine Learning for Sensory Data Analysis, Gold Coast, QLD, Australia, 2 December 2014; p. 4. [Google Scholar]

- Wu, J.; Zhang, X. A PCA classifier and its application in vehicle detection. In Proceedings of the IJCNN’01, International Joint Conference on Neural Networks, (Cat. No. 01CH37222), Washington, DC, USA, 15–19 July 2001; IEEE: Piscataway, NJ, USA, 2001; Volume 1, pp. 600–604. [Google Scholar]

- Al Shalabi, L.; Shaaban, Z. Normalization as a preprocessing engine for data mining and the approach of preference matrix. In Proceedings of the 2006 International Conference on Dependability of Computer Systems, Szklarska Poreba, Poland, 25–27 May 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 207–214. [Google Scholar]

- Jove, E.; Casteleiro-Roca, J.L.; Quintián, H.; Zayas-Gato, F.; Vercelli, G.; Calvo-Rolle, J.L. A one-class classifier based on a hybrid topology to detect faults in power cells. Logic J. IGPL 2022, 30, 679–694. [Google Scholar] [CrossRef]

| Evaluated Technique | Evaluated Configuration | Tested Values |

|---|---|---|

| Gaussian Model | Data normalization Data regularization Outlier factor (\%) | NoNorm, Norm, Zscore 0:0.003:0.009 0:5:15 |

| K-means | Data nomalization Number of clusters Outlier factor (\%) | NoNorm, Norm, Zscore 2:2:6 0:5:15 |

| Autoencoder | Data nomalization Neurons in the hidden layer Outlier factor (\%) | NoNorm, Norm, Zscore 1:1: 0:5:15 |

| PCA | Data nomalization Number of components Outlier factor (\%) | NoNorm, Norm, Zscore 1:1: 0:5:15 |

| Norm. | Regul. | Out. Factor (%) | Dataset 1 | Dataset 2 | Dataset 3 | |||

|---|---|---|---|---|---|---|---|---|

| AUC (%) | T. Time (s) | AUC (%) | T. Time (s) | AUC (%) | T. Time (s) | |||

| NoNorm | 0 | 0 | 50.000 | 0.094 | 50.000 | 0.112 | 50.000 | 0.863 |

| NoNorm | 0 | 5 | 81.317 | 0.082 | 97.501 | 0.089 | 48.365 | 0.937 |

| NoNorm | 0 | 10 | 81.260 | 0.082 | 95.136 | 0.090 | 56.761 | 0.784 |

| NoNorm | 0 | 15 | 82.460 | 0.072 | 92.507 | 0.086 | 64.647 | 0.921 |

| NoNorm | 0.003 | 0 | 50.000 | 0.077 | 50.000 | 0.087 | 50.000 | 0.874 |

| NoNorm | 0.003 | 5 | 89.071 | 0.077 | 97.537 | 0.091 | 55.218 | 0.936 |

| NoNorm | 0.003 | 10 | 93.209 | 0.079 | 95.019 | 0.090 | 72.345 | 1.056 |

| NoNorm | 0.003 | 15 | 92.529 | 0.076 | 92.565 | 0.092 | 85.718 | 0.773 |

| NoNorm | 0.006 | 0 | 50.000 | 0.079 | 50.000 | 0.082 | 50.000 | 0.965 |

| NoNorm | 0.006 | 5 | 93.676 | 0.073 | 97.584 | 0.079 | 55.942 | 0.748 |

| NoNorm | 0.006 | 10 | 95.048 | 0.074 | 95.065 | 0.082 | 74.366 | 0.967 |

| NoNorm | 0.006 | 15 | 92.528 | 0.076 | 92.562 | 0.082 | 86.222 | 0.946 |

| NoNorm | 0.009 | 0 | 50.000 | 0.077 | 50.000 | 0.075 | 50.000 | 0.796 |

| NoNorm | 0.009 | 5 | 95.797 | 0.076 | 97.592 | 0.074 | 56.158 | 1.059 |

| NoNorm | 0.009 | 10 | 95.045 | 0.075 | 95.021 | 0.086 | 76.098 | 0.814 |

| NoNorm | 0.009 | 15 | 92.516 | 0.075 | 92.583 | 0.095 | 86.222 | 0.739 |

| Norm | 0 | 0 | 50.000 | 0.074 | 50.000 | 0.083 | 50.000 | 1.085 |

| Norm | 0 | 5 | 81.384 | 0.078 | 97.501 | 0.093 | 48.366 | 0.920 |

| Norm | 0 | 10 | 81.254 | 0.076 | 95.136 | 0.101 | 56.688 | 0.928 |

| Norm | 0 | 15 | 82.453 | 0.078 | 92.507 | 0.095 | 64.648 | 0.770 |

| Norm | 0.003 | 0 | 50.076 | 0.078 | 50.000 | 0.076 | 50.000 | 0.925 |

| Norm | 0.003 | 5 | 81.313 | 0.074 | 97.501 | 0.089 | 48.150 | 0.819 |

| Norm | 0.003 | 10 | 81.243 | 0.072 | 95.088 | 0.084 | 53.658 | 0.741 |

| Norm | 0.003 | 15 | 82.469 | 0.085 | 92.511 | 0.100 | 62.551 | 0.839 |

| Norm | 0.006 | 0 | 50.000 | 0.073 | 50.000 | 0.077 | 50.000 | 0.852 |

| Norm | 0.006 | 5 | 81.376 | 0.074 | 97.504 | 0.077 | 48.150 | 1.051 |

| Norm | 0.006 | 10 | 81.183 | 0.074 | 95.046 | 0.082 | 54.234 | 0.928 |

| Norm | 0.006 | 15 | 82.473 | 0.072 | 92.504 | 0.087 | 62.771 | 0.839 |

| Norm | 0.009 | 0 | 50.000 | 0.078 | 50.000 | 0.089 | 50.000 | 0.883 |

| Norm | 0.009 | 5 | 81.307 | 0.078 | 97.515 | 0.086 | 48.149 | 0.883 |

| Norm | 0.009 | 10 | 81.112 | 0.079 | 95.074 | 0.089 | 54.667 | 0.950 |

| Norm | 0.009 | 15 | 82.488 | 0.078 | 92.501 | 0.094 | 64.002 | 0.822 |

| Zscore | 0 | 0 | 50.000 | 0.077 | 50.000 | 0.084 | 50.000 | 0.862 |

| Zscore | 0 | 5 | 81.388 | 0.079 | 97.501 | 0.089 | 48.365 | 0.852 |

| Zscore | 0 | 10 | 81.193 | 0.075 | 95.137 | 0.091 | 56.689 | 0.841 |

| Zscore | 0 | 15 | 82.467 | 0.074 | 92.506 | 0.091 | 64.649 | 0.951 |

| Zscore | 0.003 | 0 | 50.000 | 0.075 | 50.000 | 0.090 | 50.000 | 0.925 |

| Zscore | 0.003 | 5 | 81.386 | 0.077 | 97.501 | 0.083 | 48.149 | 0.753 |

| Zscore | 0.003 | 10 | 81.261 | 0.076 | 95.137 | 0.090 | 53.585 | 0.993 |

| Zscore | 0.003 | 15 | 82.477 | 0.080 | 92.531 | 0.090 | 62.556 | 0.946 |

| Zscore | 0.006 | 0 | 50.000 | 0.078 | 50.000 | 0.088 | 50.000 | 0.900 |

| Zscore | 0.006 | 5 | 81.534 | 0.074 | 97.504 | 0.088 | 48.148 | 0.820 |

| Zscore | 0.006 | 10 | 81.155 | 0.076 | 95.145 | 0.090 | 53.730 | 0.809 |

| Zscore | 0.006 | 15 | 82.478 | 0.077 | 92.514 | 0.094 | 62.340 | 0.958 |

| Zscore | 0.009 | 0 | 50.000 | 0.075 | 50.000 | 0.085 | 50.000 | 0.874 |

| Zscore | 0.009 | 5 | 81.532 | 0.076 | 97.503 | 0.099 | 48.148 | 0.872 |

| Zscore | 0.009 | 10 | 81.194 | 0.074 | 95.118 | 0.093 | 54.523 | 0.878 |

| Zscore | 0.009 | 15 | 82.470 | 0.078 | 92.517 | 0.082 | 62.267 | 0.865 |

| Norm. | N° of Clusters | Out. Factor (%) | Dataset 1 | Dataset 2 | Dataset 3 | |||

|---|---|---|---|---|---|---|---|---|

| AUC (%) | T. Time (s) | AUC (%) | T. Time (s) | AUC (%) | T. Time (s) | |||

| NoNorm | 2 | 0 | 50.228 | 0.263 | 50.000 | 0.271 | 50.000 | 4.756 |

| NoNorm | 2 | 5 | 88.435 | 0.229 | 97.509 | 0.273 | 47.716 | 4.473 |

| NoNorm | 2 | 10 | 91.251 | 0.280 | 95.045 | 0.241 | 61.300 | 4.746 |

| NoNorm | 2 | 15 | 88.648 | 0.304 | 92.559 | 0.278 | 86.572 | 4.692 |

| NoNorm | 4 | 0 | 50.000 | 0.642 | 50.000 | 0.413 | 50.000 | 6.553 |

| NoNorm | 4 | 5 | 91.340 | 0.529 | 97.520 | 0.398 | 48.004 | 6.977 |

| NoNorm | 4 | 10 | 89.028 | 0.663 | 95.052 | 0.361 | 73.487 | 5.410 |

| NoNorm | 4 | 15 | 86.670 | 0.593 | 92.540 | 0.514 | 56.844 | 7.174 |

| NoNorm | 6 | 0 | 50.076 | 0.625 | 50.000 | 0.492 | 50.000 | 7.230 |

| NoNorm | 6 | 5 | 90.155 | 0.650 | 94.489 | 0.670 | 58.692 | 7.526 |

| NoNorm | 6 | 10 | 84.190 | 0.473 | 95.015 | 0.586 | 45.210 | 7.120 |

| NoNorm | 6 | 15 | 88.033 | 0.910 | 92.515 | 0.630 | 42.706 | 8.634 |

| Norm | 2 | 0 | 50.000 | 0.271 | 50.000 | 0.300 | 50.000 | 7.109 |

| Norm | 2 | 5 | 84.373 | 0.353 | 97.524 | 0.314 | 62.796 | 9.290 |

| Norm | 2 | 10 | 85.206 | 0.326 | 95.040 | 0.340 | 89.068 | 8.206 |

| Norm | 2 | 15 | 86.559 | 0.334 | 92.559 | 0.328 | 89.902 | 6.341 |

| Norm | 4 | 0 | 50.000 | 0.569 | 50.000 | 1.018 | 50.000 | 12.225 |

| Norm | 4 | 5 | 89.866 | 0.540 | 89.801 | 0.937 | 78.969 | 10.016 |

| Norm | 4 | 10 | 90.562 | 0.843 | 90.328 | 0.600 | 76.912 | 9.586 |

| Norm | 4 | 15 | 89.376 | 0.599 | 92.522 | 0.637 | 86.655 | 14.039 |

| Norm | 6 | 0 | 50.000 | 0.802 | 50.000 | 1.123 | 50.000 | 11.278 |

| Norm | 6 | 5 | 93.246 | 1.094 | 97.544 | 1.223 | 53.423 | 18.574 |

| Norm | 6 | 10 | 91.043 | 1.130 | 94.989 | 1.107 | 66.796 | 9.461 |

| Norm | 6 | 15 | 88.726 | 1.232 | 92.517 | 0.770 | 62.852 | 15.000 |

| Zscore | 2 | 0 | 50.000 | 0.344 | 50.000 | 0.373 | 50.000 | 8.096 |

| Zscore | 2 | 5 | 85.232 | 0.269 | 97.503 | 0.358 | 78.669 | 14.072 |

| Zscore | 2 | 10 | 95.075 | 0.274 | 95.076 | 0.400 | 90.743 | 13.373 |

| Zscore | 2 | 15 | 92.559 | 0.281 | 92.553 | 0.330 | 89.685 | 12.033 |

| Zscore | 4 | 0 | 50.076 | 0.789 | 50.000 | 1.016 | 50.000 | 16.391 |

| Zscore | 4 | 5 | 95.003 | 0.641 | 97.527 | 0.634 | 90.428 | 17.606 |

| Zscore | 4 | 10 | 89.446 | 0.713 | 95.020 | 0.645 | 91.539 | 18.379 |

| Zscore | 4 | 15 | 90.092 | 1.038 | 92.509 | 1.104 | 89.689 | 15.503 |

| Zscore | 6 | 0 | 50.000 | 1.298 | 50.000 | 1.121 | 50.000 | 17.635 |

| Zscore | 6 | 5 | 94.997 | 1.076 | 97.530 | 1.268 | 62.290 | 18.634 |

| Zscore | 6 | 10 | 91.536 | 1.368 | 95.009 | 1.400 | 70.902 | 23.149 |

| Zscore | 6 | 15 | 90.209 | 1.306 | 92.529 | 1.493 | 74.332 | 20.021 |

| Norm. | Comp. | Out. Factor (%) | Dataset 1 | Dataset 2 | ||

|---|---|---|---|---|---|---|

| AUC (%) | T. Time (s) | AUC (%) | T. Time (s) | |||

| NoNorm | 1 | 0 | 50.000 | 0.484 | 50.000 | 0.488 |

| NoNorm | 1 | 5 | 59.834 | 0.518 | 48.026 | 0.459 |

| NoNorm | 1 | 10 | 58.336 | 0.486 | 46.032 | 0.439 |

| NoNorm | 1 | 15 | 55.814 | 0.470 | 44.536 | 0.441 |

| Norm | 1 | 0 | 50.000 | 0.457 | 50.000 | 0.461 |

| Norm | 1 | 5 | 85.668 | 0.523 | 97.027 | 0.438 |

| Norm | 1 | 10 | 86.524 | 0.565 | 95.021 | 0.451 |

| Norm | 1 | 15 | 88.009 | 0.484 | 92.552 | 0.478 |

| Zscore | 1 | 0 | 50.000 | 0.462 | 50.000 | 0.441 |

| Zscore | 1 | 5 | 70.969 | 0.458 | 69.237 | 0.440 |

| Zscore | 1 | 10 | 69.865 | 0.507 | 76.894 | 0.441 |

| Zscore | 1 | 15 | 68.618 | 0.484 | 80.425 | 0.460 |

| Norm. | Comp. | Out. Factor (%) | Dataset 3 | |

|---|---|---|---|---|

| AUC (%) | T. Time (s) | |||

| Norm | 1 | 5 | 90.357 | 2.603 |

| Norm | 2 | 5 | 90.717 | 3.353 |

| NoNorm | 3 | 15 | 72.586 | 3.045 |

| Norm | 4 | 15 | 53.828 | 3.138 |

| NoNorm | 5 | 15 | 70.494 | 3.497 |

| NoNorm | 6 | 15 | 75.689 | 3.229 |

| NoNorm | 7 | 15 | 59.308 | 2.679 |

| NoNorm | 8 | 0 | 50.000 | 3.126 |

| NoNorm | 9 | 15 | 50.148 | 2.608 |

| NoNorm | 10 | 0 | 50.000 | 3.182 |

| NoNorm | 11 | 15 | 51.809 | 3.233 |

| NoNorm | 12 | 15 | 57.290 | 2.819 |

| Norm | 13 | 15 | 52.603 | 3.083 |

| Norm | 14 | 15 | 58.655 | 3.468 |

| Zscore | 15 | 15 | 59.890 | 3.121 |

| Zscore | 16 | 15 | 63.352 | 2.979 |

| Zscore | 17 | 15 | 63.352 | 3.097 |

| NoNorm | 18 | 5 | 53.130 | 3.132 |

| Norm | 19 | 15 | 54.117 | 3.030 |

| Norm | 20 | 15 | 61.113 | 3.461 |

| Zscore | 21 | 15 | 63.493 | 2.766 |

| Norm | 22 | 15 | 66.233 | 3.058 |

| NoNorm | 23 | 15 | 54.984 | 3.177 |

| Zscore | 24 | 15 | 62.700 | 3.105 |

| Norm. | N° Neurons | Out. Factor (%) | Dataset 1 | Dataset 2 | ||

|---|---|---|---|---|---|---|

| AUC (%) | T. Time (s) | AUC (%) | T. Time (s) | |||

| NoNorm | 1 | 0 | 50.000 | 357.132 | 50.000 | 147.926 |

| NoNorm | 1 | 5 | 84.857 | 352.384 | 48.031 | 157.925 |

| NoNorm | 1 | 10 | 71.600 | 189.100 | 46.035 | 197.221 |

| NoNorm | 1 | 15 | 79.714 | 285.890 | 44.568 | 128.557 |

| Norm | 1 | 0 | 50.000 | 30.100 | 50.000 | 31.605 |

| Norm | 1 | 5 | 85.826 | 32.068 | 97.026 | 45.150 |

| Norm | 1 | 10 | 86.513 | 39.528 | 95.020 | 55.993 |

| Norm | 1 | 15 | 87.617 | 41.665 | 92.550 | 41.893 |

| Zscore | 1 | 0 | 50.000 | 34.112 | 50.000 | 21.486 |

| Zscore | 1 | 5 | 70.883 | 21.553 | 69.231 | 32.899 |

| Zscore | 1 | 10 | 70.133 | 13.587 | 76.874 | 50.331 |

| Zscore | 1 | 15 | 68.329 | 14.634 | 81.100 | 27.728 |

| Norm. | N° Neurons | Out. Factor (%) | Dataset 3 | |

|---|---|---|---|---|

| AUC (%) | T. Time (s) | |||

| Norm | 1 | 5 | 90.358 | 578.872 |

| Norm | 2 | 5 | 90.646 | 746.915 |

| Zscore | 3 | 15 | 71.300 | 699.515 |

| Zscore | 4 | 5 | 54.426 | 957.287 |

| Zscore | 5 | 15 | 52.447 | 1787.564 |

| Zscore | 6 | 0 | 50.000 | 1621.264 |

| Norm | 7 | 15 | 75.036 | 2483.040 |

| Zscore | 8 | 15 | 64.628 | 2248.230 |

| Zscore | 9 | 0 | 50.000 | 2473.127 |

| Zscore | 10 | 0 | 50.000 | 2539.572 |

| Zscore | 11 | 0 | 50.000 | 2636.626 |

| Zscore | 12 | 0 | 50.000 | 2682.045 |

| Norm | 13 | 15 | 57.131 | 3221.705 |

| Zscore | 14 | 15 | 57.675 | 2962.068 |

| Zscore | 15 | 15 | 56.630 | 3085.607 |

| Norm | 16 | 15 | 54.603 | 3490.254 |

| Norm | 17 | 15 | 56.859 | 3835.607 |

| Norm | 18 | 15 | 59.668 | 3910.105 |

| Zscore | 19 | 15 | 61.986 | 3670.120 |

| Zscore | 20 | 15 | 62.389 | 3764.557 |

| Zscore | 21 | 15 | 61.268 | 3992.231 |

| Norm | 22 | 15 | 64.799 | 3722.349 |

| Norm | 23 | 15 | 62.389 | 4018.956 |

| Norm | 24 | 15 | 60.247 | 4125.477 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michelena, Á.; López, V.; López, F.L.; Arce, E.; Mendoza García, J.; Suárez-García, A.; García Espinosa, G.; Calvo-Rolle, J.-L.; Quintián, H. A Fault-Detection System Approach for the Optimization of Warship Equipment Replacement Parts Based on Operation Parameters. Sensors 2023, 23, 3389. https://doi.org/10.3390/s23073389

Michelena Á, López V, López FL, Arce E, Mendoza García J, Suárez-García A, García Espinosa G, Calvo-Rolle J-L, Quintián H. A Fault-Detection System Approach for the Optimization of Warship Equipment Replacement Parts Based on Operation Parameters. Sensors. 2023; 23(7):3389. https://doi.org/10.3390/s23073389

Chicago/Turabian StyleMichelena, Álvaro, Víctor López, Francisco Lamas López, Elena Arce, José Mendoza García, Andrés Suárez-García, Guillermo García Espinosa, José-Luis Calvo-Rolle, and Héctor Quintián. 2023. "A Fault-Detection System Approach for the Optimization of Warship Equipment Replacement Parts Based on Operation Parameters" Sensors 23, no. 7: 3389. https://doi.org/10.3390/s23073389

APA StyleMichelena, Á., López, V., López, F. L., Arce, E., Mendoza García, J., Suárez-García, A., García Espinosa, G., Calvo-Rolle, J.-L., & Quintián, H. (2023). A Fault-Detection System Approach for the Optimization of Warship Equipment Replacement Parts Based on Operation Parameters. Sensors, 23(7), 3389. https://doi.org/10.3390/s23073389