Featured Application

This article is focused on a literature review to provide a valuable resource for understanding the latest developments in the Maintenance 4.0 approach. The conducted research will be helpful for many people, including maintenance managers, maintenance engineers, and researchers, who are interested in the issues of maintenance performance in the context of Industry 4.0 technologies implementation. The conducted literature review intends to introduce the readers to the major up-to-date theory and practice in Maintenance 4.0 main research directions. The presented study makes it possible to identify the thematic structure related to maintenance performance. In addition, it shows which topics from the studied scientific area are the most investigated in a given country/region. At the same time, the conducted analysis allowed the development of future research directions in the areas identified as research and knowledge gaps.

Abstract

Recently, there has been a growing interest in issues related to maintenance performance management, which is confirmed by a significant number of publications and reports devoted to these problems. However, theoretical and application studies indicate a lack of research on the systematic literature reviews and surveys of studies that would focus on the evolution of Industry 4.0 technologies used in the maintenance area in a cross-sectional manner. Therefore, the paper reviews the existing literature to present an up-to-date and content-relevant analysis in this field. The proposed methodology includes bibliometric performance analysis and a review of the systematic literature. First, the general bibliometric analysis was conducted based on the literature in Scopus and Web of Science databases. Later, the systematic search was performed using the Primo multi-search tool following Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines. The main inclusion criteria included the publication dates (studies published from 2012–2022), studies published in English, and studies found in the selected databases. In addition, the authors focused on research work within the scope of the Maintenance 4.0 study. Therefore, papers within the following research fields were selected: (a) augmented reality, (b) virtual reality, (c) system architecture, (d) data-driven decision, (e) Operator 4.0, and (f) cybersecurity. This resulted in the selection of the 214 most relevant papers in the investigated area. Finally, the selected articles in this review were categorized into five groups: (1) Data-driven decision-making in Maintenance 4.0, (2) Operator 4.0, (3) Virtual and Augmented reality in maintenance, (4) Maintenance system architecture, and (5) Cybersecurity in maintenance. The obtained results have led the authors to specify the main research problems and trends related to the analyzed area and to identify the main research gaps for future investigation from academic and engineering perspectives.

1. Introduction

One of the most important issues in ensuring the high availability and reliability of technical facilities and systems is maintaining them in operational conditions [1]. Maintenance has recently been an important area of interest and research for engineers and managers, as improperly maintained equipment can lead to more frequent failures of facilities and their components, low operational efficiency, or delays in meeting operational schedules [2,3]. A poorly chosen or planned maintenance strategy for any equipment can result in, among other things, obtaining products of questionable quality, decreasing energy efficiency in some areas, or under/over utilization of maintenance personnel [4,5]. Following this, more and more companies are taking steps to improve the efficiency of the maintenance function of their physical assets [1,6,7]. In addition, the problem of maintenance cost modeling and optimization is gaining attention [8].

Recently, there has been a lot of research and publications in the field of maintenance models and decision-making techniques aimed at improving the efficiency of the maintenance process (for an overview, see, for example, [1,9]). Known solutions have evolved from Maintenance 1.0 to Maintenance 4.0 [9]. On the other hand, organizations strive to improve their maturity in implementing maintenance strategies. According to the authors of a report [10] that surveyed the implementation of maintenance strategies in companies in Belgium, Germany, and the Netherlands, only 11% of respondents (a total of 280 people) indicated that their companies had reached Level 4.0. Following the report [11], the global predictive maintenance market size was valued at USD 3.18 billion in 2018. In addition, according to the consulting group Next Move Strategy Consulting [12], the global predictive maintenance market is expected to register a CAGR (Compound Annual Growth Rate) of 30.47% between 2020 and 2030. Therefore, it is imperative to examine the main trends occurring in the maintenance area in the context of Maintenance 4.0.

A preliminary analysis of the resources from such databases as Web of Science and Scopus allows us to state that more than 50 review papers on predictive maintenance (PdM)/Maintenance 4.0 have been published in the last decade (Note: The main search procedure was performed for the key term: “Maintenance 4.0 review”, and the results were limited to the relevant time period and research field). On the one hand, the growing number of publications focused on reviewing recent developments for Maintenance 4.0 confirms the relevance of the issue and the potential for its development. On the other hand, it shows how much the subject has developed in one decade in many aspects of industry sectors. A short summary of recent papers focused on the Maintenance 4.0 literature reviews is presented in Table 1.

Table 1.

A summary of the recent papers focused on the literature overview in the area of Maintenance 4.0.

This briefly presented background of conducted and published literature reviews on predictive maintenance/Maintenance 4.0 allowed us to conclude that there is currently a lack of studies that summarize recent developments in a cross-sectional manner. Most of the conducted reviews focus on a particular application area or the industry sector (see, e.g., [13,14,15]). The literature specializes in specific topics, treating them separately (e.g., [16,17]). As a result, treating this as a research gap, the authors decided to provide a complete review of the existing literature to present an up-to-date and content-relevant analysis in this field, focusing on both bibliometric performance analysis and a systematic literature review.

Following this, the research questions are as follows:

RQ1: What are the current trends in Maintenance 4.0 approaches, and how have these trends evolved over the last decade?

RQ2: What are the future research directions and perspectives in Maintenance 4.0 in the context of the defined application fields?

Therefore, the article aims to develop a literature review in the area of Maintenance 4.0 main application fields, including (1) bibliometric performance analysis of research works from the period 2012–2022 being published in two scientific databases—Web of Sciences and Scopus, and (2) systematic analysis using the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) method, aimed at summarizing and identification of the main research areas in the identified application fields. Following this, the main contributions of this paper include the following:

- A summary of the research developed in Maintenance 4.0 application fields in the last decade, focusing on (a) augmented and virtual reality, (b) system architecture, (c) cybersecurity, (d) data-driven decision, and (e) Operator 4.0;

- Identification of research gaps and knowledge gaps in the identified application fields of the Maintenance 4.0 approach.

In conclusion, the article is organized into seven sections (Figure 1). After the Introduction (Section 1), the Theoretical Background (Section 2) introduces the concept of Industry 4.0 and discusses the evolution of maintenance approaches, focusing on the Maintenance 4.0 concept. Review methodology (Section 3) explains the main methods used for the review. This section also describes the strategy used for the literature search process performance and criteria that were applied to assess the relevance of analyzed documents. Section 4 describes the main results of conducted bibliometric performance analysis in the macro-view and for the selected papers on the five identified application fields. Later, Section 5 focuses on presenting the results of the identified application fields. Section 6 provides a discussion of the obtained results. Here, the literature research and knowledge gaps are also identified. The last part contains conclusions (Section 7) with a summary of contributions, limitations definition, and recommendations for future studies’ presentation.

Figure 1.

The structure of the article. Source: own contribution.

2. Theoretical Background

2.1. Industry 4.0

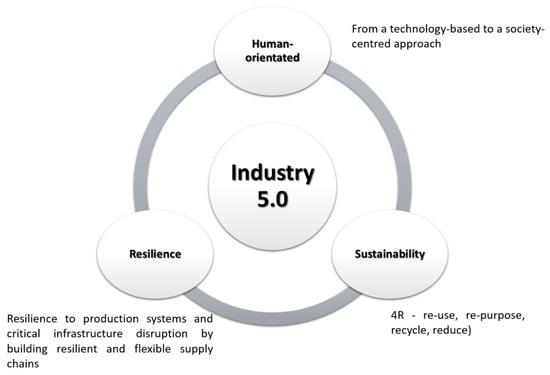

The first studies on the Industry 4.0 emerged in 2011 [43]. They highlighted the new high-tech techniques, such as Internet of Things (IoT) platforms, advanced human–machine interfaces, smart sensors, big data-based analytics, augmented reality-based solutions, and the concept of the smart factory have become part of industrial production [37]. In line with the observed rapid technical and technological development of the global economy, the so-called fourth industrial revolution started only 42 years after the third revolution, relatively short compared to the 99 years recorded between the second and third industrial revolutions (Figure 2) [44]. At the same time, it posed new challenges to managers in terms of building the so-called Operator 4.0 competence or effectively implementing modern technologies in practice.

Figure 2.

Fundamental trends of the industrial revolution. Source: own contribution based on [44,45].

The Fourth Industrial Revolution is the next stage of socio-economic development. This revolution is associated with [44,45]:

- Widespread digitalization and the provision of constant communication between people, people with devices, and devices between one another;

- An increase in the implementation of disruptive innovations;

- A leap in the efficiency of the socio-economic system performance;

- The development of machines capable of autonomous operation through the use of artificial intelligence (AI);

- The implementation of modern communication using technology and the capabilities of modern networks throughout the supply chain;

- Adaptive automation;

- The use of intelligent approaches to information processing;

- The use of future-oriented techniques.

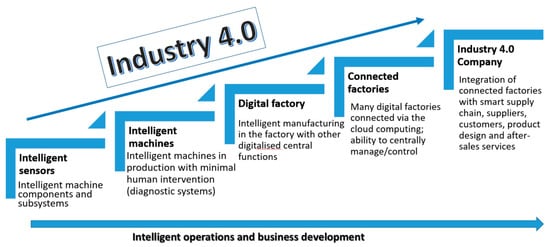

The term Industry 4.0 refers to the combination of several significant innovations in digital technology. These technologies include, among others, advanced robotics and artificial intelligence, digital manufacturing (including 3D printing), software as a service, and other new business models (robot as a service, machine as a service, software as a service, etc.) as well as support in decision-making processes [46]. In addition, in the recent literature, the term smart industry is used concerning the Industry 4.0 concept. Both terms are often used interchangeably (see, e.g., [47]). However, the first works focused on the smart industry concept mostly referred to industrial IoT technologies use. The main goal was to interconnect various industrial objects through sensors, GPS devices, radio frequency identifiers, actuators, and other wireless and mobile devices [47]. Recent works extend this approach by implementing other Industry 4.0 technologies in the context of smart industry performance, such as big data, digital twins, or artificial intelligence (see, e.g., [48]). Indeed, smart industry enables organizations to maximize the yield from existing operational capabilities and to develop the next generation of operational capabilities necessary to compete in a digital economy [49]. As a result, the term Industry 4.0 may be perceived in the context of developing smart connections between products, machines, and people using the latest technologies to provide more efficient, intelligent, and aware factory performance. It is also connected with the e-commerce sector’s rapid development [50,51] (Figure 3).

It has become commonplace to use smartphones or other mobile devices and platforms that use algorithms to drive motor vehicles (including navigation tools, ride-sharing apps, delivery and transportation services, and autonomous vehicles) in daily operations and to embed all these elements in an interoperable global value chain shared by many companies from many countries (Figure 4) [44,52].

Figure 4.

Development directions in Industry 4.0—what are businesses working towards? Source: own contribution based on [52].

Figure 3.

Technologies prevalent in Industry 4.0. Source: own contribution based on [53].

Simultaneously, the high complexity, automation, and flexibility of the so-called smart factory bring new challenges regarding reliability and safety [54]. The digital factory requires the exchange of data between machines or the exchange of data on production and operation and is intended to optimize costs, improve availability and reliability, or ensure an adequate level of overall equipment effectiveness (OEE) [55]. Therefore, to gain maximum benefit from the implementation of the Industry 4.0 concept, the production system and the factory itself must be connected internally (using the Intranet) throughout the organization and externally with suppliers and customers, so that important information and data can be exchanged (promptly) within the complete supply chain (using the Internet) [56,57]. Further, networks can be developed into connected factories operating in different regions. In this approach, business data are combined, compared, and processed in one place. At the same time, such cooperation can concern the level of a single department or the entire business organization [52]. The highest level of organizational maturity is the so-called Industry 4.0 enterprise, in which we combine the supply chain with product design and after-sales service using Industry 4.0 technologies. This way, product customization can be achieved in a highly flexible production environment [54].

Smart production is designed based on a modular structure, where production facilities and logistics systems are organized without human intervention [58]. Production is supervised using a number of intelligent sensors, cameras, and indicators. Where information is not exchanged online, data are stored in the device’s memory and exchanged on demand. In addition to data on the condition of the product itself, data on the condition of the machinery and equipment operating in the factory are also collected [59,60]. The collection and analysis of this data lead to the Maintenance 4.0 concept, which is described in detail in Section 2.3 [61].

2.2. Maintenance Approaches Evolution

Currently, in the available literature, we can distinguish many definitions of the concept of technical maintenance [1]. For the purpose of this paper, the literature survey carried out is based on the definition proposed in the European standard BS EN 13306: 2017 [62], where “maintenance/operation is a set of all technical, organizational and managerial activities during the life cycle of an object, the purpose of which is to maintain or renew the state in which it can be used to fulfil the required function”. A similar definition is given in IEC 60300-3-10: 2001 [63], in which maintenance of a technical system is defined as “all activities necessary to preserve/maintain or restore a specific state of an object”. Maintenance management, on the other hand, according to BS EN 13306: 2010 [62], is defined as “all management activities that determine the objectives and strategies of maintenance and their implementation through appropriate tools, such as maintenance planning, control and supervision, improvement of methods in the organization, together with consideration of the economics of operation”.

Based on the definitions presented, one may state that the main objectives of the maintenance of technical systems are related to [64]:

- Ensuring the basic functional parameters of the facility (e.g., availability, efficiency, reliability);

- Efficient management of resources to provide the required durability of equipment;

- Ensuring efficient use of resources, energy, and raw materials/replaceable parts;

- Ensuring the safety of a technical facility, people, and the environment;

- Taking into account the financial requirements of the implemented operation process.

The achievement of such objectives is based on the use of appropriate maintenance approaches. The evolution of known approaches to maintenance that have been developed over the last fifty years is shown in the scheme included in Figure 5. At the same time, a primary classification of known and widely used maintenance strategies is given in EN 13306 [62]. A recent review of the literature on technical maintenance of systems and facilities can be found, for example, in works [35,65,66], and an analysis of the development of maintenance philosophies can be found in [67]. A general classification of maintenance strategies can be found in [1].

Figure 5.

Main approaches to maintenance. Source: own contribution based on [1].

The first approach to maintenance (Maintenance 1.0), often referred to as the ‘run to failure’ or Corrective Maintenance (CM) strategy, was prevalent between 1940 and 1960 [1]. CM is a reactive strategy and refers to all unplanned maintenance activities performed to restore the system’s operability after a failure by carrying out repair operations or replacing failed components, implying that there is no optimization in the maintenance activities undertaken concerning economic or reliability criteria. On the other hand, this maintenance strategy is still popular due to the low cost of its implementation [1].

When it is necessary to avoid a system failure during operation, especially when such an event is costly and/or dangerous, it is important to carry out planned maintenance activities [1,8]. Therefore, the Maintenance 2.0 approach related to Preventive Maintenance (PM) is being implemented. PM, according to MIL-STD-721C [68], refers to “all activities undertaken to maintain a facility/system in a specified condition by systematically inspecting, detecting and preventing incipient failures, with the objective of reducing the probability of failure or slowing the degradation processes of a system in operation”. In general, the approach is geared toward optimizing the length of maintenance intervals in relation to the wear and tear process of the investigated system. In this area, time-based PM and on-condition maintenance (CBM) strategies are the most frequently mentioned in the literature [9]. Furthermore, the differences between CM and PM are presented in [69], and a comparison of the leading maintenance strategies is in [70].

A periodic maintenance strategy involves planned and periodic repairs/replacements of equipment. It is still one of the predominant maintenance strategies used in practice for those technical assets for which it is impossible to implement diagnostic measures, e.g., for technical or economic reasons [71]. For example, more information can be found in the works [72,73].

A condition-based maintenance approach is considered the first maintenance strategy to be included in Maintenance 3.0 [9]. CBM is based on monitoring the parameters that define the technical condition of a system or its components using diagnostic methods/measures [74]. For selected cases, the CBM strategy even offers the possibility to implement maintenance activities just before the failure of the system/its components occurs. Thus, CBM can be regarded as a method used to reduce the uncertainty of maintenance activities for technical systems [75]. A literature review of CBM policies is presented, for example, in the works [74,76,77].

Another maintenance policy, which in the literature is often considered synonymous with the CBM concept, is predictive maintenance (PdM) [17]. This maintenance policy is used in those sectors where reliability is of strategic importance, such as nuclear power, transport, or energy industry solutions [1,9]. Its main task is to predict faults or failures in a degrading system to optimize maintenance tasks by monitoring system operating conditions to detect any signs of wear and tear that lead to component failure [10]. The PdM program aims to track component degradation/wear using a methodology that ensures the detection of any impending failure [78]. Some commonly used monitoring and diagnostic techniques include vibration monitoring, thermography, or visual inspection [79].

A proactive approach to maintenance in line with the Maintenance 4.0 concept is currently the most technologically advanced form of maintenance for technical systems. In the literature and practice of the issue under study, it is often emphasized that the Maintenance 4.0 concept is a practical implementation of PdM and SMART PdM solutions [80,81]. Therefore, references can be found to the so-called Predictive Maintenance 4.0 concept.

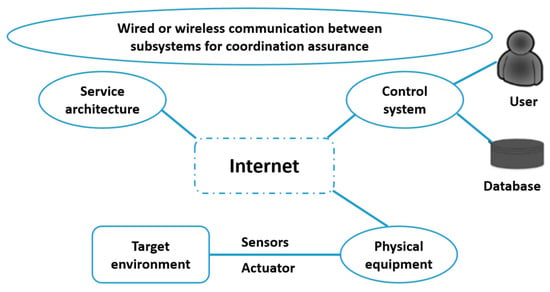

2.3. Maintenance 4.0 and the Leading Technologies

If the main elements of Industry 4.0 are the Industrial Internet of Things (IoT), cloud computing, and technologies such as augmented reality (AR) and virtual reality (VR), Maintenance 4.0 is based on the implementation of these technologies in the company’s maintenance practices [82]. Maintenance 4.0 is thus about using smart technologies to improve daily factory operations [83]. The aim is to maximize uptime by eliminating unplanned, reactive maintenance activities. One of the concepts used here is the Internet of Things, which takes machine-to-machine technology to the next level by including a third element: data. According to [84], all machine data are to be available on a single virtual network, giving manufacturers the ability to aggregate and analyze data to generate better predictive analytical models. For more information, the author recommends reading, for example, [10,17]. On the other hand, a literature review on Maintenance 4.0 and the smart industry can be found among others in [15,36,42].

Against this background, it is possible to define the directions for developing the Maintenance 4.0 concept in business practice as a general overview observed in polish companies (mainly from the automotive sector) (Figure 6). In the first step of implementing the solutions of the Maintenance 4.0 concept, investments are made in the so-called intelligent components—a system of diagnostic sensors, which usually refers to the possibility of vibration analysis performance [32,52]. In the next step, a monitoring and diagnostic system are developed for the selected machine, and PdM-type systems based on fundamental, predictive analyses are introduced The smart factory is already at the level of developing dynamic self-diagnostic systems, the so-called SMART PdM—based on acquired diagnostic data, failure prediction, and automation of maintenance processes. The level of connected factories includes designing and implementing a so-called centralized control system for maintenance processes based on solutions such as asset sharing or IoS business models [85].

Figure 6.

Development directions in Maintenance 4.0. Source: own contribution based on [52].

The highest level of organizational maturity allows the implementation of intelligent maintenance methodologies already at the product design level [85].

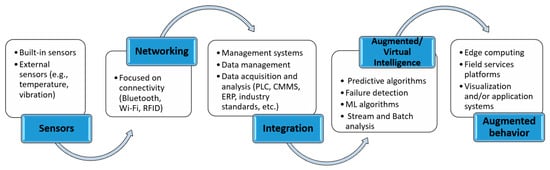

Based on the presented developments in the implementation of Maintenance 4.0, it can be concluded that this approach allows the design and implementation of so-called self-aware (self-diagnose) and self-service (self-service) equipment systems that can self-assess their technical condition and degradation process and use information from other machines to make intelligent maintenance decisions [60]. The Deloitte report classifies the technologies that underpin PdM 4.0 under five categories [53]. These are sensors, networking, integration, augmented intelligence, and augmented behavior (Figure 7).

Figure 7.

Technologies enabling PdM processes in the context of Industry 4.0. Source: own contribution based on [53,86,87].

A key issue, therefore, is the continuous monitoring and analysis of the physical asset network, which enables [88]:

- Predicting and notifying of potential failures/damages;

- Maintenance scheduling and planning of spare parts requirements;

- Automation of specific maintenance tasks.

In summary, Maintenance 4.0 encompasses a holistic view of data sources, how they are combined, collected, analyzed, and are recommended actions to provide digital support to the function (reliability) and value (management) of assets. As a result, a holistic approach enables effective plant-wide communication between machine operators, maintenance and engineering teams, and management, allowing informed decisions and better utilization of resources [89]. In addition, implementing a holistic approach to predictive maintenance provides that individual components are assessed for their value in the entire production chain and sensors are applied accordingly. Indeed, a wide range of complex, interconnected assets must be considered for interdependencies rather than their singular function alone [90]. Properly developed, a holistic approach is to be shown to ensure the maximum potential for early warning analysis and root cause identification in technical systems [91].

As a result, it is essential to analyze the main trends in developing the Maintenance 4.0 concept in practice and literature. This issue is the subject of the next sections of this paper.

3. Review Methodology

The main goal of the conducted review is to investigate the five main research areas developed under the Maintenance 4.0 concept. As part of our literature review, we analyzed, evaluated, and discussed scientific publications from prestigious databases related to engineering fields. Therefore, a two-phase review methodology was implemented, incorporating the following:

- Bibliometric analysis of the literature within the scope of application.

The main focus of the bibliometric analysis of the literature is to present a macro-view of Maintenance 4.0 and its leading research areas investigated over time. The first phase also allowed for properly defining the main inclusion criteria for SLR performance in the second step of the reviewing methodology.

- Systematic analysis of the selected papers within the scope of application.

The main focus of systematic analysis is to define the main aspects and trends occurring in the area of Maintenance 4.0 research.

The first of these methods is a form of quantitative analysis, while the second is both quantitative and qualitative. As a whole, this methodology adequately presents the full spectrum of publications connected to the Maintenance 4.0 concept, both in quantitative and qualitative terms. In addition, it allows for presenting a macro and micro view of the investigated issues. Following this, the research procedure and review strategy phases are shown in Figure 8.

Figure 8.

Research framework and methods/tools used. Source: own contribution.

First, we defined research questions that helped with keyword selection. In the next step, the main keyword, “Maintenance 4.0”, was described to identify in the broadest possible way the relevant articles related to the maintenance issue in the context of the Industry 4.0 concept. The next steps are connected with the performance of meta-analysis and systematic analysis of the identified literature. A detailed description of the conducted research procedure is presented in the following subsections.

3.1. Meta-Analysis of the Literature

A meta-analysis is the statistical pooling of data across studies to generate summary estimates of effects [92]. This paper conducted such an analysis based on a bibliometric performance analysis approach following the PRISMA guidelines, as defined in [93,94]. PRISMA is an evidence-based approach for reporting in systematic reviews and meta-analyses [92]. Therefore, it was used in both phases of the conducted literature review in Maintenance 4.0.

Bibliometrics is a branch of scientometrics that uses mathematical and statistical methods to assess scientific activities’ performance. The bibliometric analysis allows us to study the networks formed around the most representative keywords and presents how citations, scholars, affiliations, counties, and publications indicate the importance of specific topics in the field of research. At the same time, we can see a noticeable increase in interest in bibliometric studies in science (see, e.g., [95,96,97,98]). As a result, the analysis’s objective is to identify the main trends in Maintenance 4.0 research through bibliometric analysis.

A preliminary bibliometric analysis was conducted using two available databases: Web of Science [99] and Scopus [100]. The investigation was completed in October 2022, and the search term was the keyword “Maintenance 4.0”.

The selection of two databases, Web of Science and Scopus, is related to the fact that both of these databases have similar bibliographic attributes, such as literature searching and citation analysis of bibliometric records. As a result, it was considered that an analysis of both scientific databases would provide a compatible and complementary view of Maintenance 4.0 issues.

At first, the Web of Science database was under investigation. The initial search procedure was based on the following search term “Maintenance 4.0” regardless of where it occurred (filtering by “all fields”). The first step of the searching procedure provided the opportunity to identify 4944 relevant records. In the next step, an objective screening was performed based on the title and keywords. To evaluate the eligibility, the research team analyzed the title and keywords of publications. For this purpose, we have defined criteria for exclusion. First, to focus on relatively new problems and technologies, the search results were limited to papers published within the last ten years.

Additionally, articles written in English were considered. In addition, the search was limited to citation topics related to production, logistics, or maintenance (non-topically related publications were excluded). Indeed, papers that do not have a production/logistics/factory focus were excluded from the further analysis (for example, we eliminated documents related to medicine, biology, and agriculture). The indicated exclusion criteria were included as subject area filters within the WoS search string. Indeed, within the framework of the selection process, the authors have selected the subject area filters available in the WoS database that are related to these three indicated citation topic areas. As a result, such citation topics as nutrition and dietetics, urology and nephrology, dairy and animal sciences, anesthesiology, and dentistry and oral medicine have been excluded from further research.

Based on these exclusion criteria, 1113 records were identified and subjected to fundamental bibliometric analysis.

The Web of Science database final search engine:

| (ALL = (Maintenance 4.0)) AND LA = (English) and Design & Manufacturing or Safety & Maintenance or Friction & Vibration or Telecommunications or Human Computer Interaction or Management or Supply Chain & Logistics or Artificial Intelligence & Machine Learning or Software Engineering or Transportation or Robotics |

An analogous bibliometric analysis was carried out for publications included in the Scopus database. The first stage of the study identified 24,603 relevant records (searching by Maintenance 4.0 keyword and filtering by “all fields”). Subsequent filtering by “abstract/title/keywords” reduced the number of records searched to 3747 publications. In the final step, the analysis was again narrowed down to publications from 2013-2023, and only texts in English were included. Non-topically related publications were also excluded. Indeed, the filtered subject areas also have been related to the production/logistic/maintenance issues. Therefore, subjects such as medicine, mathematics, energy, biochemistry, genetic and molecular biology, chemistry, or nursing were excluded from further analysis.

This allowed 1933 publications to be highlighted, which were then analyzed.

The Scopus database final search engine:

| (TITLE-ABS-KEY (Maintenance 4.0) AND LANGUAGE (English)) AND PUBYEAR > 2012 AND (LIMIT-TO (SUBJAREA, “ENGI”) OR LIMIT-TO (SUBJAREA, “COMP”) OR LIMIT-TO (SUBJAREA, “MATH”) OR LIMIT-TO (SUBJAREA, “DECI”) OR LIMIT-TO (SUBJAREA, “MATE”) OR LIMIT-TO (SUBJAREA, “BUSI”) OR LIMIT-TO (SUBJAREA, “SOCI”) OR LIMIT-TO (SUBJAREA, “ECON”) OR LIMIT-TO (SUBJAREA, “PSYC”)) |

As a result of the selection process for both databases, we finally received 1133 records for the Web of Sciences database and 1933 records for the Scopus database. In the next step, the obtained results for both databases were separately subjected to analysis and synthesis. First, the analysis was performed using Mendeley reference manager and Microsoft Excel software. This allows us to perform content-based analysis for trends or frequency of occurrence. Next, we used the clustering method during the analysis based on the use of VOSviewer software [101]. Based on [102], the VOSviewer is a program developed for constructing and viewing bibliometric maps that can be examined in full detail. Following its functionality, we performed a co-occurrence analysis of keywords. The distance-based bibliometric maps reflect the strength of the relation between the selected keywords. Indeed, the cluster analysis results clearly capture the knowledge structure of the research fields. They were also used for adequately selecting inclusion criteria for systematic analysis performance.

3.2. Systematic Analysis of the Literature

The review’s second phase focused on systematic analysis (Figure 8). A systematic review is “connected with identifying, evaluating and interpreting all available research relevant to a particular research question, or topic area, or phenomenon of interest” [103]. It follows a standard procedure for developing, conducting, and reporting processes, reported in detail in [92,104]. The basis for reporting systematic review conducted by the research team was PRISMA guidelines. The chosen method gives the possibility to properly search and select the relevant scientific literature on the given topic by defining research objectives and providing clear quantification of scientific developments in a specific field of knowledge (see, e.g., [13,105,106]).

Following this, the next subsections explain the document search and selection process with a definition of eligibility criteria and identification of relevant papers for further investigation.

3.2.1. Collection of Publications for Review

The literature searching process was based on using the multi-search tool Primo [107], which allowed the analysis of many information resources, including, among others, the ScienceDirect database, Elsevier, Wiley, and Springer publishers’ databases. The literature search was conducted between 2 October 2022 and 10 October 2022.

The initial search procedure was based on the following “Maintenance 4.0” search term. The first step of the search procedure allowed the identification of 309,994 relevant records. In the next step, to focus on relatively new applications, problems, and technologies, the searches were limited to studies published during the last ten years. Additionally, only documents written in English were considered. Based on these exclusion criteria, 219,725 records were identified and further analyzed based on the filtering and extraction process.

3.2.2. Filtering and Extraction

The authors focused on filtering studies, considering six inclusion criteria. The criteria were defined based on the results obtained from the first phase of the conducted literature review.

Based on the meta-analysis, we could identify the primary clusters with relationships occurring between critical keywords. With the use of VOSViewer software, the authors conducted an in-depth analysis of the main keywords’ co-occurrence. First, they focus on the 223 most frequently used keywords for the WoS database (keywords occurred at least five times). This analysis made it possible to identify nine main clusters. Within the defined clusters, the first cluster was connected with data collection, analysis, and decision-making processes (58 items selected). The second cluster focused on digitalization and smart maintenance as synonyms of the Maintenance 4.0 term (35 items). The third cluster includes keywords connected with cyber–physical systems and human–machine interactions (31 items). The next cluster focused on maintenance planning and scheduling (26 items). Cluster no. 5 (22 items) and Cluster no. 6 (19 items) regarded virtual and augmented reality.

Next, a similar analysis for the Scopus database was performed. On the one hand, it confirmed the main research findings obtained from WoS database analysis (for 792 keywords and 12 clusters). Conversely, it allowed identifying another significant cluster connected with cybersecurity (Cluster no. 7, 48 items). The six main inclusion criteria were defined based on this initial scientometric analysis and following the reviews on this topic (e.g., [25,27]). As in the case of the definition of the basic keywords “Maintenance 4.0”, inclusion criteria were defined at a general level. This made it possible to encompass a broad spectrum of investigated problems related to maintenance. The main inclusion criteria were as follows:

- “data-driven maintenance”;

- “system architecture”;

- “Operator 4.0”;

- “virtual reality”;

- “augmented reality”;

- “cybersecurity”;

The screening process had the purpose of filtering out papers that were not related to the main topic. Therefore, the identified records were scanned by title. The filtering process was performed manually by the research team based on the filtering options available in the Primo search tool. The filtering process was carried out separately for each inclusion criteria according to the filtering procedure:

All fields = “Maintenance 4.0” AND Title = “inclusion criterion”.

The results of this procedure are presented in Table 2.

Table 2.

A summary of the conducted filtering procedure.

As a result of the filtering process considering the inclusion criteria, 218,918 were eliminated out of the initial 219,725 records (based on Table 2 results).

In the next step of the filtering and extraction procedure, the search was limited to the following documents: articles (Note: In the Primo search tool, the term “articles” relates to scientific articles published in journals and conference articles published in high-quality proceedings from, e.g., Elsevier’s journals (e.g., Procedia CIRP)), books, and book chapters for a higher data quality.

The last exclusion criterion regarded the type of online databases used. The search procedure was limited to online databases like ProQuest Central, EBSCO, IEEE Electronic Library, Springer (All available), or Elsevier with ScienceDirect. The excluded databases from the further analysis were:

- Health and Medical collection;

- Earth, Atmospheric, and Aquatic Science Database;

- GFMER Free Medical Journals;

- Environmental Science Database.

This choice was connected with eliminating work unrelated to the production/logistics/factory maintenance areas.

After applying these rejection criteria, the documents were reduced to 517. Moreover, 31 publications were deleted as duplicates. As a result, 486 papers were defined, which were later fully read to identify the most relevant papers during the selection process.

3.2.3. Selection Process

The authors later examined 486 papers to verify their eligibility for further qualitative and quantitative analysis. The main criterion applied in the full-text research was its relevance to the investigated thematic area and defined groups. The authors evaluated the publications first individually. Later, at research team meetings, we compared team members’ opinions. In case of discrepancies in assessing the paper’s suitability, the team members focused on reviewing the whole document more thoroughly. In addition, the studies that describe maintenance issues concerning, e.g., chemical engineering or medicine applications were excluded. After a consensus between the authors of this systematic review, 272 papers were rejected as being out of scope after reviewing the full document.

Consequently, a total of 214 manuscripts were included for further qualitative and quantitative analysis. Figure 9 represents the flow diagram of the selection of studies according to PRISMA statements. The PRISMA checklist is available in supplementary materials (Table S1).

Figure 9.

PRISMA-based flowchart of the systematic selection of the relevant studies in the analyzed research area. Source: own contribution based on [93].

3.2.4. Content Analysis and Synthesis

The selected papers were further subject to analysis and synthesis. As during the meta-analysis, to carry out this analyses we used Mendeley reference manager and Microsoft Excel software. In addition, VOSviewer software was used for cluster analysis.

First, the bibliometric analysis for the five selected research areas in Maintenance 4.0 was performed. The main results are presented in relation to, among others, authors’ location, publication time, or most frequently used keywords. The results are shown in Section 4.2.

4. Bibliometric Performance Analysis of the Literature within the Scope of Application

4.1. General Bibliometric Performance Analysis

First, the meta-analysis results for the Maintenance 4.0 concept’s macro-view and main research fields were investigated. The data are sourced from the Web of Sciences [99] and Scopus [100], one of the largest scientific literature databases. They were accessed on 2 October 2022. The conducted analysis provided a curated dataset of relevant publications for further state-of-the-art research.

The publications year-on-year for the analyzed period of time for both datasets are presented in Figure 10. The results confirm a considerable rise in year-on-year Maintenance 4.0 publications, especially in the last five years. The exception is 2020, which annotated a decline in publications in the scientific area under study. This may be due to the pandemic period, in which engineering issues related to the development of technologies such as augmented or virtual reality may have been given lower priority over, for example, research areas such as risk analysis or resilience engineering. 2022 is not finished yet, so we do not have a complete picture of the development trend of the number of publications in a given area. Additionally, 2023 is also excluded from the visualization.

Figure 10.

Publications in engineering disciplines from 2013–2022 that included the term Maintenance 4.0 and were published in Scopus and Web of Science databases.

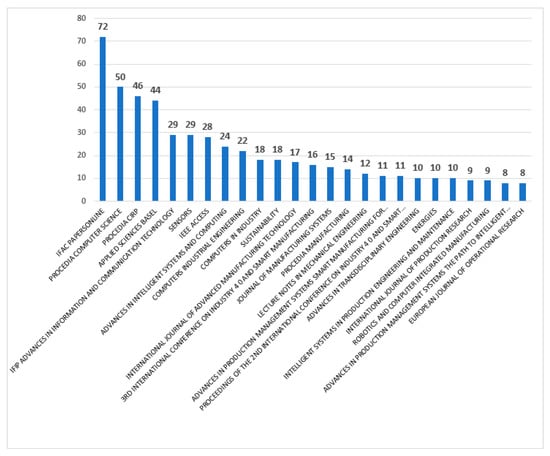

In the Web of Science database, each paper can be classified according to the publication titles. In the case of the investigated research area, the most frequently selected publication titles, where the documents on Maintenance 4.0 appeared, are presented in Figure 11. During the analyzed time period, the most significant number of publications appeared in the journal IFAC-PapersOnLine series (72 articles). Numerous publications can also be found in Proceedia Computer Science (50 articles), Procedia CIRP (46 articles), and Applied Sciences (44 articles). This paper distribution indicates that during the analyzed period of time, researchers were very keen to publish the results of their research at conferences across all topics of, among others, computer science, mechanical engineering, and manufacturing engineering areas.

Figure 11.

Publication titles in which the Maintenance 4.0 research area papers were the most frequently published (for the Web of Science database).

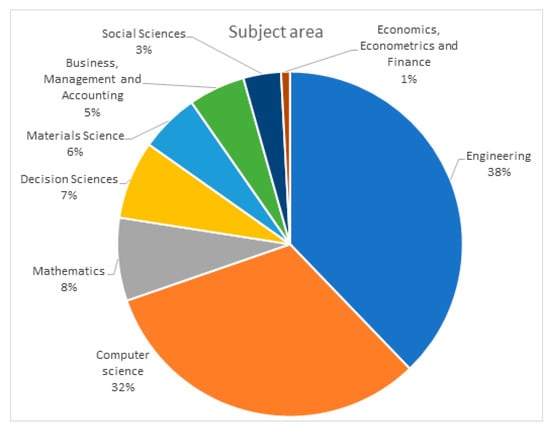

The presented analysis can be supplemented with the results obtained from the Scopus database. In the Scopus database, each paper is classified by subject area. In the investigated case, one can distinguish eight subject areas that include the most significant number of publications (Figure 12). The obtained results are compatible with Web of Science database analysis conclusions. The engineering and computer science publications account for 70% of all results analyzed.

Figure 12.

Subject areas in which Maintenance 4.0 papers were the most frequently published (for the Scopus database).

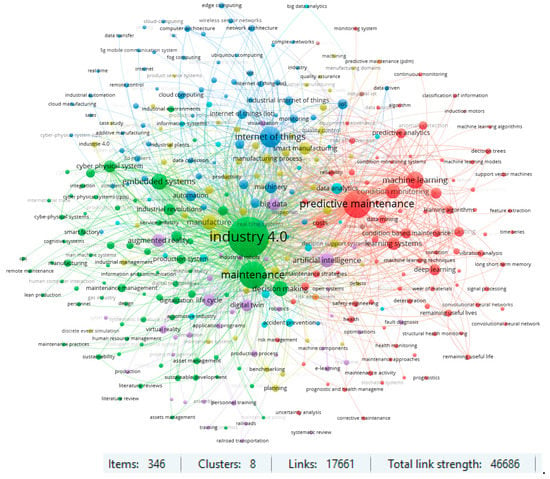

Another important aspect was investigating the main keywords in the analyzed publications. First, the Web of Science dataset was under investigation. The analysis was performed for the keywords which occurred in the database at least ten times. This restriction identified the 97 most popular keywords, which formed five main clusters, with a link strength of 2503 and a total link strength equal to 8762. The results are shown in Figure 13.

Figure 13.

Analysis of keyword strength for the analyzed 1113 publications from the WoS database. Source: own development using VOSviewer software [101].

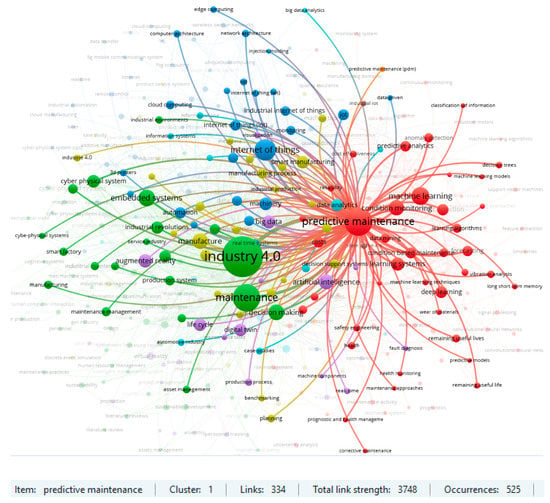

Two clusters for the item ‘predictive maintenance’ and for ‘Industry 4.0’ are particularly noteworthy in the area under review. The results of the strength of the links in the respective clusters are shown in Figure 14 and Figure 15. The strength of linkages indicates a strong interest in Maintenance 4.0 issues in the context of predictive strategy and the Industry 4.0 concept. Previous review publications in the field of Maintenance 4.0 also confirm such results. On the other hand, such keywords, like augmented reality, machine learning, or digital twin, also indicate the high strength of the links and suggest a potential direction for research in the area under consideration. An analysis of the database confirms this conclusion in the context of the publication date. According to the results obtained, the most recent studies are about digital twins, deep learning, or smart factories.

Figure 14.

Analysis of keyword strength for the first cluster of publications from the WoS database. Source: own development using VOSviewer software [101].

Figure 15.

Analysis of keyword strength for the third cluster of publications from the WoS database. Source: own development using VOSviewer software [101].

A similar analysis was performed for the Scopus database. The selected 1933 papers were reviewed for highlighting all keywords that have occurred a minimum of 10 times in the database. The obtained results are presented in Figure 16. The clusters for ‘predictive maintenance’ and for ‘Industry 4.0’ are shown in Figure 17 and Figure 18. The obtained results confirm the previously defined conclusions. Additionally, an interesting aspect is the occurrence of a cluster related to keywords such as ‘automated maintenance’, ‘intelligent operations’ or ‘digital storage’. This is confirmed by the emergence of a number of publications that target solutions related to the digitalization and automation of industrial processes.

Figure 16.

Analysis of keyword strength for the analyzed 11933 publications from the Scopus database. Source: Own development using VOSviewer software [101].

Figure 17.

Analysis of keyword strength for the first cluster of publications from the Scopus database. Source: own development using VOSviewer software [101].

Figure 18.

Analysis of keyword strength for the second cluster of publications from the Scopus database. Source: own development using VOSviewer software [101].

4.2. Bibliometric Performance Analysis of the Papers Selected in the Investigated Five Research Fields

The second step of the conducted bibliometric analysis includes the detailed investigations carried out for selected articles from five thematic groups for Maintenance 4.0 from the last decade.

Two hundred fourteen articles from five analyzed areas were adopted for detailed analysis. Most publications were found for the keywords ‘augmented reality’ and ‘virtual reality’, which accounted for almost 45% of all the analyzed texts. The number of publications for each of the analyzed search terms was:

- In the area of augmented and virtual reality: 96 publications;

- In the area of system architecture: 41 publications;

- In the area of cybersecurity: 37 publications;

- In the area of data-driven decisions: 23 publications;

- In the area of Operator 4.0: 17 publications.

The analysis of the authors’ and scientific centers’ origins allows us to state that most of the publications from the studied area come from the USA (24 papers), China, and Italy (17 papers per country), Germany (15 papers), and three countries: Poland, Greece, and the United Kingdom (UK) (10 papers per country). The regions of origin of the analyzed publications’ authors are shown in Figure 19.

Figure 19.

A number of papers by the location where the investigated study took place.

The analyzed publications were limited in the second step of the adopted methodology to those published during the last decade. The adopted limitation seems to be correct, as the verification of the years in which subsequent articles were published indicates a generally high increase in publication frequency from 2017. As shown in Figure 20, the annual number of publications has been about 30 or higher for the last five years, while in previous years, it did not exceed four articles per year. This suggests that the research issues connected with Maintenance 4.0 are far from being exhausted, and its popularity among researchers should be still rising. It is safe to say that further developments regarding this field of knowledge will keep appearing in the near future.

Figure 20.

A number of papers by publication year.

The publications on Maintenance 4.0 have appeared in many scientific databases. The investigated 214 papers include 124 articles published in scientific journals, 22 book chapters, and 68 papers published in international conference materials.

The investigated articles have appeared in 83 journals. Of the publishing titles, 50% include one article. A detailed list of journals in which the analyzed research results were published is shown in Figure 21. The journals in which at least two papers have been published are presented. The analysis includes 50 selected articles from 12 journals.

Figure 21.

A number of papers in each investigated journal (for journals with at least two published papers from the analyzed 214 articles).

The most significant number of publications appeared in Economics, Management, and Financial Markets (10 articles). Numerous publications can also be found in the International Journal of Advanced Manufacturing Technology (9 articles) and the International Journal of Advanced Manufacturing Technology (6 articles). Due to the significant diversity of topics covered in the research field under study, there were also singled-out publications on decision science (e.g., Computers in Industry), manufacturing engineering (e.g., International Journal of Production Research), or sensors (e.g., Sensors).

The conducted biometric analysis also concerned identifying the most frequently used keywords. The results of the conducted study are presented in Figure 22. Those keywords were included, which occurred in the articles at least two times. This limitation made it possible to identify 85 main keywords in 9 clusters. The largest cluster, “augmented reality,” contains 14 items with 53 links and a total link strength of 111, whereas the second cluster, “Industry 4.0”, encompasses 13 items, 57 links, and a total link strength of 152. This indicates the main area of research to which the publications on Maintenance 4.0 are devoted. It is worth noting the “smart factory” cluster, which has 27 links and a total link strength equal to 47. The term smart factory is mostly in relation to such keywords as big data, manufacturing, maintenance, and Industry 4.0.

Figure 22.

A number of the most frequently occurring keywords in the analyzed papers. Source: own development using VOSviewer software [101].

5. Systematic Literature Review of the Selected Papers within the Scope of the Application

The identification of the main problems and issues raised in the context of Maintenance 4.0 was based on an extensive review of the available literature. The prepared literature analysis was also supplemented by review publications in the area of Industry 4.0 or Maintenance 4.0 (e.g., works [17,38,42,80]) or reports in the field of Maintenance 4.0 and PdM 4.0 (e.g., [10,53,108]). As a result of the research carried out, five primary research areas were defined, which have been most extensively developed over the past few years. Additionally, the selected research areas appeared in review publications as those research directions that will be mainly developed in the coming years from both a research and industrial perspective (Figure 23). These are discussed in detail in the next subsections.

Figure 23.

Main issues addressed in the context of the Maintenance 4.0 concept.

5.1. Data-Driven Decision-Making in Maintenance 4.0

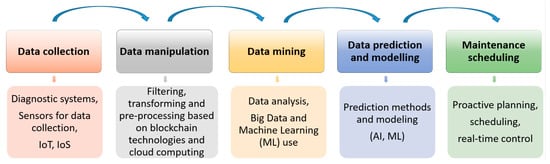

The first research area under consideration is data-driven decision-making in Maintenance 4.0. In this context, Maintenance 4.0 solutions are most easily characterized in terms of the individual stages of the decision-making process (Figure 24).

Figure 24.

Data-driven decision-making in maintenance. Source: own contribution based on [17].

Data-driven models most common in the current evolution of Maintenance 4.0 solutions are those based on statistics, pattern recognition, or artificial intelligence (AI) and those based on machine learning algorithms. The application of sensors in smart factories lies mainly in the area of control, emphasizing processes [17].

In this area, issues such as knowledge management (e.g., [109]), machine learning (e.g., [22,88]), artificial intelligence (e.g., [110,111,112]), IoT technologies (e.g., [113]), or big data analyses (e.g., [114]) are addressed.

Additionally, one of the investigated research areas is data storage and processing technologies. Here, big data applications are of utmost importance. An example of a big data application for predictive maintenance is presented in [115]. The paper presents challenges encountered when building the data value chain for predictive maintenance of a grinding machine in 5G-enabled manufacturing. The data-driven value chain is also investigated by Albert in his work [116].

Another interesting problem is investigated in work [117]. The authors focus on developing and testing a data-driven condition-based maintenance tool for enabling risk-informed decision-making. The proposed approach integrates prior knowledge obtained from Preliminary Hazard Analysis–Fault Tree (PHA–FT) analysis with cyberspace defined by data-driven knowledge of system conditions.

Additionally, the data-driven decision-making process, presented in Figure 24, is also investigated by Graham for pharmaceutical manufacturing processes based on the effective use of a process analytical technology (PAT) methodology [118].

At the same time, issues related to the design and implementation of so-called digital twins are currently being developed very intensively. According to the definition, a digital twin is “a digital copy of physical assets, processes and systems with static or dynamic characteristics; often also a software term for creating virtual representations of physical systems and simulating them” [119]. Digital Twins are a source of data that can improve the design of new products, machines, or processes. They are also used for the ongoing analysis of existing solutions to assess their capabilities, optimization, or verification of as-built documentation. With their help, it is possible to simulate optimization opportunities, conduct sensitivity analyses, or assess modification/expansion opportunities [120]. A literature review in the area of the applicability of digital twins in complex control systems was presented in the paper [121]. The digital twins’ implementation in the predictive maintenance area is reviewed in [122]. The review of applications is provided in [123].

A literature review of the area under study indicates that the basic methods used in decision-making in Industry 4.0 enterprises can be found in the works [61,124]. In addition, a significant proportion of the publications that have been selected for the literature review presented here focus on providing summaries of ongoing surveys and reports published by consulting companies such as PwC. For example, the relationships between cyber–physical systems (CPSs), AI-based decision-making algorithms, and big data-driven innovation are surveyed in [125]. In addition, the problem of robotic wireless sensor networks and real-time monitoring is studied in [126]. The survey works focus on the following:

- AI-based decision-making (see, e.g., [110,112,125]);

- Big data-driven decision-making (see, e.g., [127,128,129,130]);

- Business models and business processes optimization (see, e.g., [131,132]);

- Information systems and sensor networks for decision-making (see, e.g., [133,134,135,136]);

- Cyber–physical manufacturing systems (see, e.g., [136,137,138]).

5.2. Operator 4.0 to Support Balanced and/or Symbiotic Interaction between Humans and Machines

The history of operators’ interaction with various industrial and digital manufacturing technologies can be depicted as a so-called generational evolution (Figure 25). Operator Generation 1.0 is defined as people doing ‘manual and skilled work’ with some support from mechanical tools and manually operated machine tools. Operator Generation 2.0 represents people doing ‘assisted work’ with the support of computer tools, ranging from CAx tools to NC operating systems (e.g., CNC machine tools), as well as enterprise information systems. Operator Generation 3.0 embodies the human being engaged in ‘cooperative work’ with robots and other machines and computer tools, also known as human–robot collaboration. Operator Generation 4.0 represents the ‘operator of the future’, an intelligent and skilled operator who does ‘machine-assisted work’. It represents a new philosophy of designing and engineering adaptive manufacturing systems, emphasizing treating automation to enhance humans’ physical, sensory, and cognitive capabilities through integrating cyber–physical systems. So, we are presently focused on new cyber–physical systems with human participation—Human Cyber–Physical Systems (H-CPS), which are being designed for the following purposes [45]:

Figure 25.

(R) Evolution of the Operator Concept Generation. Source: own contribution based on [45,139,140].

- Improve the ability of humans to interact dynamically with machines in the cyber and physical worlds through ‘intelligent’ human–machine interfaces, using human–computer interaction techniques designed to match the cognitive and physical needs of the operators’

- Improve humans’ physical, sensory, and cognitive capabilities using various enriched and enhanced technologies.

Both H-CPS goals are achieved through computational and communication techniques, similar to human-in-the-loop (H-in-the-loop) adaptive control systems [45].

As a consequence of the introduction of Industry 4.0 technologies, new skills are required from maintenance operators in terms of “enhancing physical, sensory and cognitive capabilities and the ability to support major aspects of maintenance processes” [141].

This is aimed at fostering a socially sustainable environment for production workers in the factories of the future, where “intelligent and skilled operators should not only perform ‘collaborative work’ with robots but also ‘assisted work’ by machines when needed through human cyber-physical systems, advanced human-machine interaction technologies and adaptive automation towards a ‘human-automation symbiosis’” [141].

In this context, Maintenance Operator 4.0 refers to an operator with the ability to improve their own perception of the real world through augmented reality technology, analyzing digital data collected in collaboration with robots, with the consequent improvement of maintenance tasks in the area of their execution and control [142].

The main issues in the literature in the context of the analysis of Maintenance Operator 4.0 mainly include:

The definition of core skills in the context of Industry 4.0 requirements (e.g., [143,144]) and operator training issues (e.g., [145,146]);

The relationship between CPS and maintenance tasks and the control role of the human (e.g., [139,147,148]);

The ways in which CPS interacts with humans (e.g., [140,149]).

Additionally, studies are devoted to knowledge management within the smart operator domain (e.g., [150,151]). In another study [152], the authors focused on new technologies implementation for Operator 4.0. They investigated the 5G-aided solutions’ influence on necessary network infrastructure for the human–machine symbiosis in the smart factory. The visual computing and simulation technologies implementation for Operator 4.0 was investigated in work [153]. The role of Operator 4.0 in the context of logistics and transportation systems was analyzed in [154] and continued in work [155], where intralogistics activities in relation to the Operator 4.0 concept are discussed via case studies. Another example may be the hybrid-augmented intelligence system developed in [156], where the intelligent digital assistant interacts with experts and operators during predictive maintenance performance.

As a result, the main challenge in this research area is how to steer the design and deployment of the Maintenance 4.0 paradigm in enterprises in the context of integrating people within CPS to achieve the desired goals.

5.3. Virtual and Augmented Reality in Maintenance

Currently, the issue of the application of virtual/augmented reality solutions in the maintenance field is gaining increasing importance. Thanks to the application of augmented/virtual reality in maintenance, we can see a new perspective on the work of the maintenance employee, where it is possible to superimpose 2D and 3D documentation on the actual machine in the field, helping the technician to carry out the maintenance operation [157]. This means the online transmission of operating instructions and so-called virtual support in the process of disassembly/repair or component replacement/reassembly [158,159,160]. Using this type of solution, we can reduce the risk of individual failures/damages due to maintenance tasks carried out by a service technician with little experience. In addition, the problem of employee learning by means of trial and error is eliminated [161].

A literature review of the applicability of virtual/augmented reality in the maintenance area can be found among others in the works [17,29,158,162]. The industry’s augmented reality (AR) technologies are reviewed in [163]. The problem of integrating an AR system with an available enterprise information system was analyzed, for example, in work [164]. The overview of managerial-focused applications of AR is presented in [165]. In addition, the literature reviews focus on AR implementation in robotics (see, e.g., [166]), supply chain management (see, e.g., [167]), shipbuilding industry (see, e.g., [168]), and smart manufacturing (see, e.g., [169,170,171,172]). The AI technologies implementation possibilities in AR are reviewed in [173]. A summary of the existing knowledge on AR-powered digital twins is given in [174]. In addition, an overview of the current knowledge and future challenges of augmented reality smart glasses (ARSG) for use by industrial operators in presented in [175]. The authors focus on such categories as assembly instructions, human factors, design, support, and training. The developments in virtual reality (VR) are reviewed and summarized in [176,177], among others.

Figure 26.

Virtual and Augmented reality main application fields. Source: own contribution.

- Industrial Maintenance and Assembly (IMA);

- Design and Prototyping (D&P) stages of the product/system development cycle;

- Collaborative Virtual Environment (CVE).

In addition, the implementation of VR-based technologies should be discussed with the applied knowledge-based approach to classify them by the type of contained and presented knowledge about a product/system or a process [178]. Generally, we may distinguish three levels of knowledge of industrial VR applications [178]:

- General knowledge: based on interactive product/system/process visualizations. As an output, we may receive a virtual design of the investigated object;

- Procedural knowledge: focused on process sequence presentations and interactive machine manuals development;

- Applied knowledge (practical skills), which includes machine operator training simulators, “Virtual Factory” training, and ergonomics developments.

Following this, the IMA application field needs to be characterized. In this area, the research focuses on VR training in relation to knowledge transfer and an increase in the performance and accuracy of maintenance technicians [176]. A comprehensive literature review on this area is given in [158].

The VR-based training for a manufacturing assembly process is presented in [179]. The authors propose the integration of training simulations with virtual reality to increase assembly training effectiveness based on the “learning by doing” approach. The extension of this work is given in [180], where the authors describe a process of building a virtual training system for operators of production (assembly) workplaces in an intelligent factory. The prototype of virtual training is dedicated to use by inexperienced operators of particular stands and consists of an application (e.g., virtual environment, user interface) and specific peripheral devices. In another work [181], the authors focus on manufacturability and maintainability in the context of VR-based training implementation possibilities. They introduce Virtual Reality for the Maintainability and Assemblability Tests (VR_MATE), which encompasses VR hardware, software, and a simulation manager. In addition, two case studies demonstrate the VR training system’s ability for maintainability tests and assembly analysis. The case studies were presented for an aircraft carriage and railway coach cooling system. Another work focused on the development of VR-based training system prototype for aviation maintenance is [182]. The solution helps practitioners in the process of carrying out specific maintenance activities as removing and positioning components into aircraft structures.

The problem of a VR-based ergonomic design process for the IMA task is investigated in [183]. The authors provide a method to quickly build a virtual IMA scenario for immersive simulation based on the traditional design platform DELMIA.

Another application area is the implementation of VR-based training for industrial robots’ proper operation and maintenance. First, the aspect of VR technologies application for machining industrial robots to improve the accuracy of teaching repetition is presented in work [184]. Next, in work [185], the authors propose using VR to train the service and maintenance of robots and robotic stations.

In addition, the investigation of teaching design and its influence on learning performance in the operation training for CNC milling machine tools under a VR-based environment is presented in [186]. The authors analyze the sequence- (traditional) and context-based teaching designs.

The impact of VR on learning in the context of the safety training of power producer companies is investigated in work [187]. An experiment was aimed at comparing VR training with traditional classroom training.

Simultaneously, the problem of identifying how VR training technology can be implemented in a generic operating cycle is investigated in [146]. Modular teaching is the problem studied in [188]. In addition, a methodology to develop VR tutorials and training courses for professional preparation in industrial jobs is given in [189]. An open approach to knowledge formalization and management in virtual reality applications for use in industry, especially for design and training purposes, is given in [190]. Subjective visual vertical (SVV) and subjective visual horizontal (SVH) tests are investigated in [191].

The second VR application field is D&P. In this area, the VR has the potential to support the design stage of the product development cycle via, among others, product testing or maintenance/manufacturing process review. In this area, a comprehensive review is presented in [192], where the authors investigate how VR supports different design functions and how they can benefit from the different degrees of immersion and additional tools. This is complemented by the work [193], where the application of VR in the assembly validation stage is presented. The authors present a developed assembly simulation to validate the feasibility of virtual assembly models. The designed system integrates low-cost, commercially available hardware to facilitate hand tracking and VR display. It is also worth mentioning [194], wherein the authors focus on the development cycle of a production system. The authors implement virtual reality (VR) into the virtual commissioning (VC) method to verify the mutual interaction of signals between the simulation in the VR environment, the digital model of the selected production system, and the control system. They focus on a real production robotic system (assembly line).

The last application field of VR is CVE. Collaborative virtual environments are computer-enabled, distributed virtual spaces where people can meet and interact with others, with agents, and with virtual objects. In this area, we may distinguish two main research problems investigated in the reviewed papers. First, the CVE supports synchronous and asynchronous collaboration and may increase the quality of communication, knowledge sharing, and interactions among stakeholders and multidisciplinary teams. In this context, a virtual reality collaborative platform for remote teams able to work in a fully equipped environment is presented in work [195]. The problem of the utilization of virtual reality (VR) to facilitate the asynchronous collaboration of globally dispersed departments involved in the pipeline of maintenance methods and documentation creation is under investigation by the researchers in work [176]. The authors present the designed COVE-VR platform, which was developed as an academia–industry collaboration and was evaluated iteratively with subject matter experts.

Second, regarding CVE as a support for decision-making processes based on immersive VR applications, the work in [177] presents one of the investigated problems in this area. The authors review recent research on VR applications in Building Information Modeling (BIM). They discuss the current status, use cases, technologies used, and relevant future research in the field of AEC (Note: architecture, engineering, and construction)/BIM.

The use of digital twins and VR for decision-making processes in production systems is presented in [196]. The authors propose a co-simulation and communication architecture between the digital twin and virtual reality software to make optimal decisions during the design of industrial workstations.

In another work [197], the authors introduce an architecture based on virtual reality to evaluate the civil aircraft’s maintainability. The prototype system mainly focused on accessibility during maintenance activities and was tested by importing digital 3D models of Boeing 737 and A320.

Another aspect is the problem of VR application systems designing and development. Following this, in work [198], the authors focus on VR technologies—their aspects and limitations for supporting VR developers in creating VR industrial environments. They analyze the VR technologies based on cost, reliability, or usability criteria, among other considerations. The continuation of this problem is given in work [190], where the authors focus on a selected aspect of a methodology of building open VR systems and applications—knowledge formalization and management in industrial VR apps. In another study [199], the authors propose a distributed system monitoring tool based on VR technology. The paper discusses the design and implementation of the proposed tool and verifies the technical feasibility for further distributed system monitoring applications.

One can also identify the works focused on both AR and VR implementation. A qualitative literature review focused on investigating the current state of these two innovative technologies and their practical application in industrial systems is presented in the works [200,201]. AR and VR are compared in [202,203,204,205]. A methodology that helps programmers to build virtual and augmented reality systems for a broad number of industrial plants is given in [206]. In addition, an overview of the opportunities for using VR and AR in a standardized value chain in various industries is presented in [207].

In work [208], the authors introduce the AR-based environment to support the virtual user during the assembly process. The use of AR and VR in a dynamic welding environment is given in [209]. Additive manufacturing (AM) and augmented reality technologies for supporting the workflow of producing special components are provided in work [210]. Next, in the work [211], a virtual and augmented reality in the lifecycle of semi-trailers is presented. At the exploitation stage, they support users in activities realized by operators (drivers) and service technicians. Another interesting work focuses on mixed reality applications to monitor the data of a fuel cell’s spatially resolved current density distribution [212]. In the presented case, the fuel cell represents a machine that delivers sensor values, whereas a HoloLens is the monitoring application. The use of AR with a digital twin in the area of predictive maintenance is given in work [213]. In addition, the method to visualize digital twin data by using AR technology in a real environment is presented in work [214].

Additionally, we may distinguish a growing number of research works focused on AR applications. Recent overviews of AR implementation possibilities in the industry sector and key success factors are given in [171,215,216]. The overview of AR technical components and their practical application in the industry (especially in manufacturing, maintenance, assembly, training and collaborative operations) is presented in [217,218]. Works focused on comparing traditional and AR-based learning are [219,220]. The discussion of AR technologies’ implementation possibility in decision-support processes is presented in [221].

The AR-based technologies implementation for ultrasonic pipework inspection is presented in [222]. The proposed solution is to improve the learning curve in non-destructive ultrasonic testing and to decrease the costs involved in traditional training. The discussion of AR-based technologies implementation for pipes operation and maintenance in the HVAC&R industry is given [223].

The AR-based solution that supports visual inspection performance on a production line is presented in [224]. The application was developed in the automotive industry. An application of acoustic processing of conditioned machine sounds and operation-related data is given in [225].

The introduction of a generic use case in the context of retrofitting and visualization of the data for real-time monitoring using a web-based AR application is given in [226].

The use of AR to help operators in the correct understanding of a plant and to retrieve useful information about the plant (e.g., machines layout, history of maintenance) is given in [227]. The main task is to augment the Piping and Instrumentation Diagrams (P&ID) of a selected plant/group of plants. This problem is later extended in work [227], where the authors compare the AR application with the currently applied practice, based on paper documentation, for an information retrieval task within a maintenance procedure.

The analysis of possibilities of the practical application of modern AR solutions in the industry, with a particular focus on remote support for maintenance operations and training of production employees, is given in [228]. Two experiments are described to determine the impact of various environmental conditions on the possibility of using AR Remote Support.

A solution for remote maintenance based on off-the-shelf mobile and AR technologies is provided in [229]. The proposed application allows for the remote connection of a skilled operator in a control room with an unskilled one located where the maintenance task has to be performed. The AR application possibilities to support remote maintenance as a service in the robotics industry are given in [230]. The main objective of this paper is to develop an internet-based, service-oriented system that implements AR technology for enabling tele-maintenance by the cooperation of the end user and the manufacturer. In another work [231], the authors focus on AR-based remote maintenance processes supported by cutting-edge optical head-mounted display technology. The proposed solution is based on the remote connection between a maintenance worker who wears the HoloLens and an expert who observes the live-stream video on a laptop. The expert provides advice orally or via 3D virtual annotations that are transferred back to the maintenance worker.