3D-Printed Graphene Nanoplatelets/Polymer Foams for Low/Medium-Pressure Sensors

Abstract

1. Introduction

2. Materials and Methods

2.1. ABS Sacrificial Templates

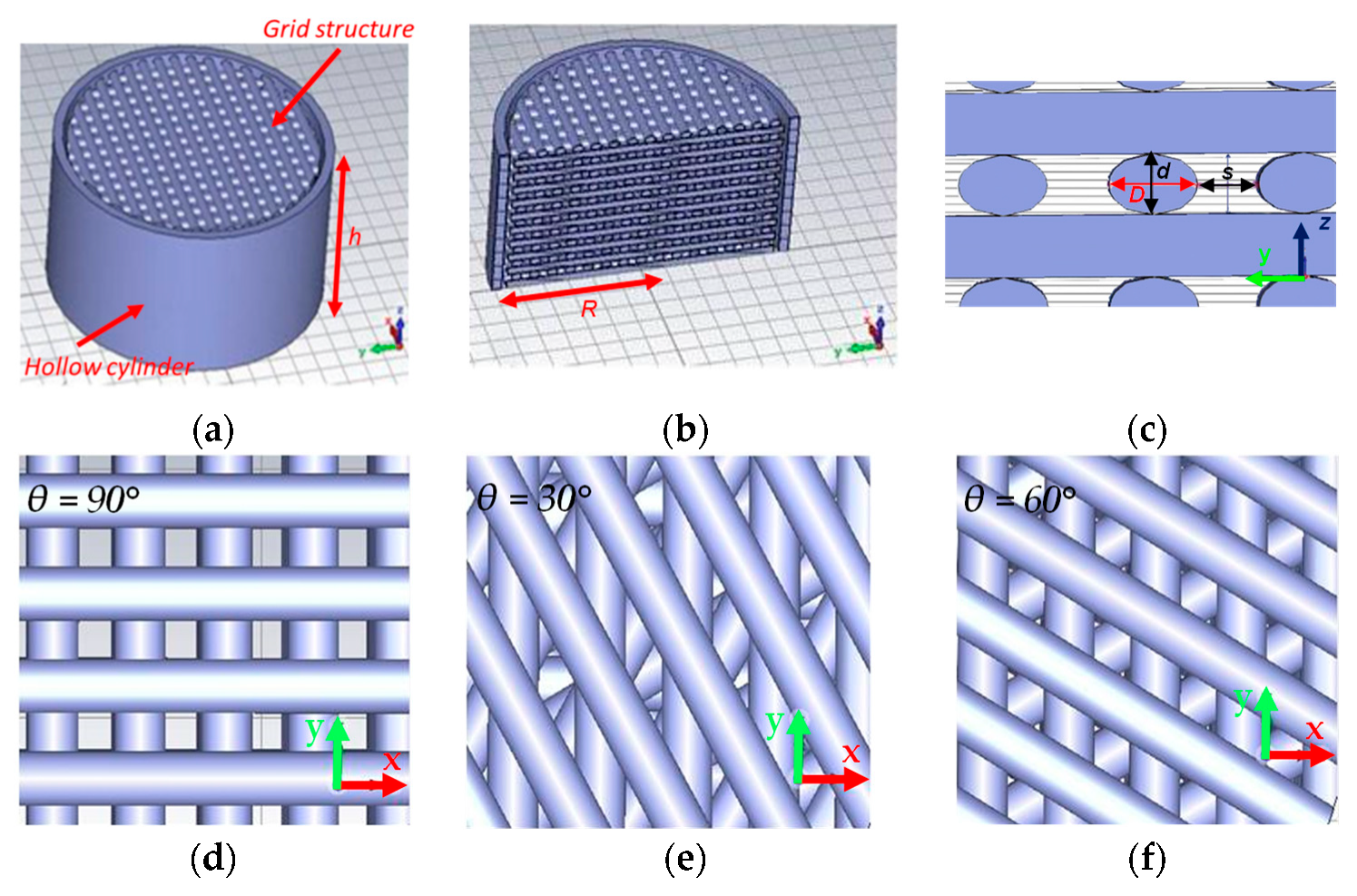

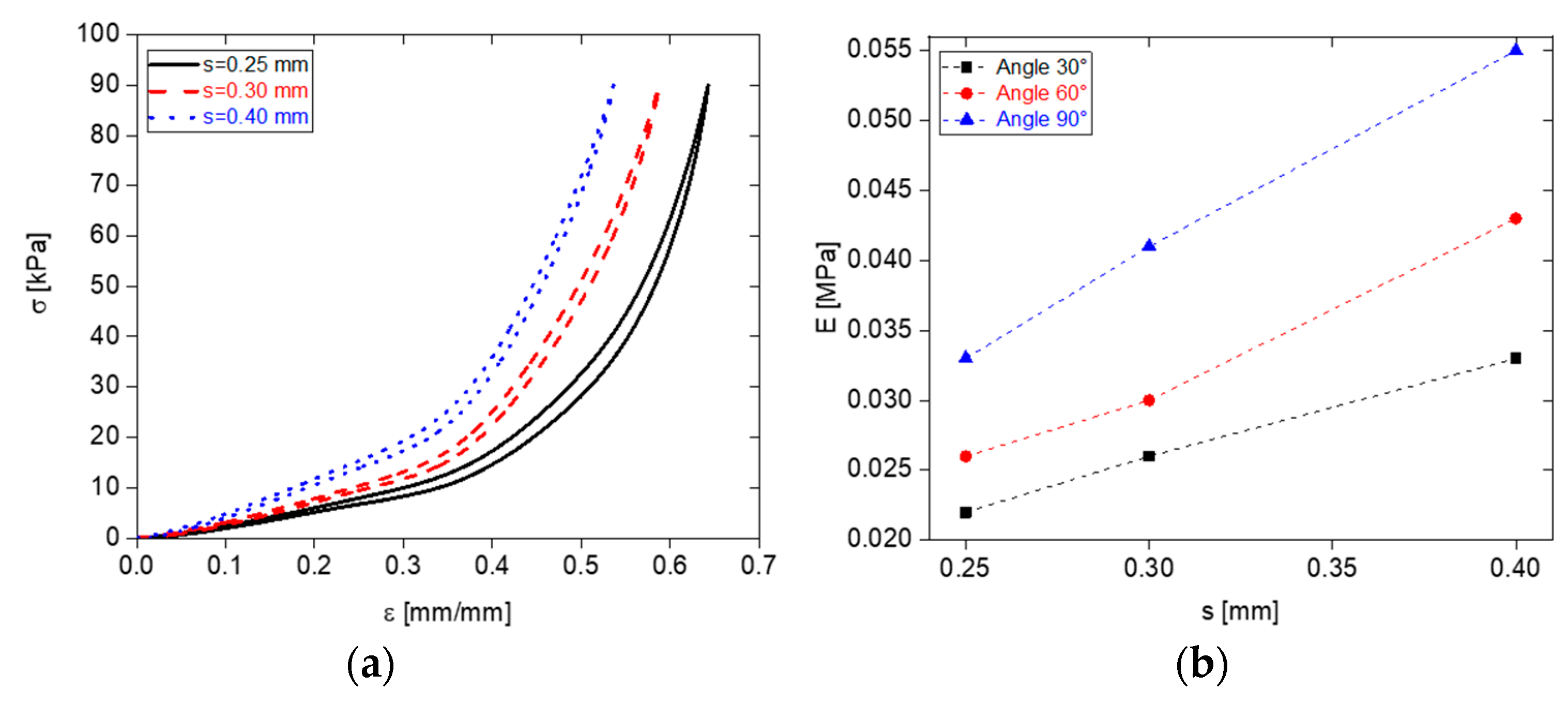

2.1.1. Grid Structures (GS)

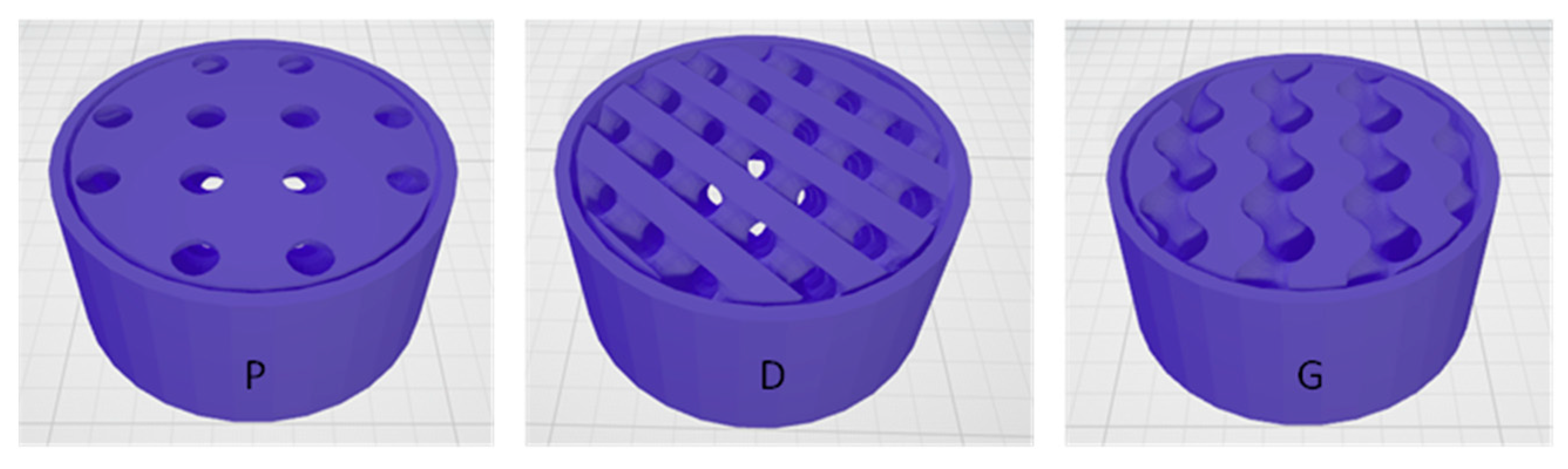

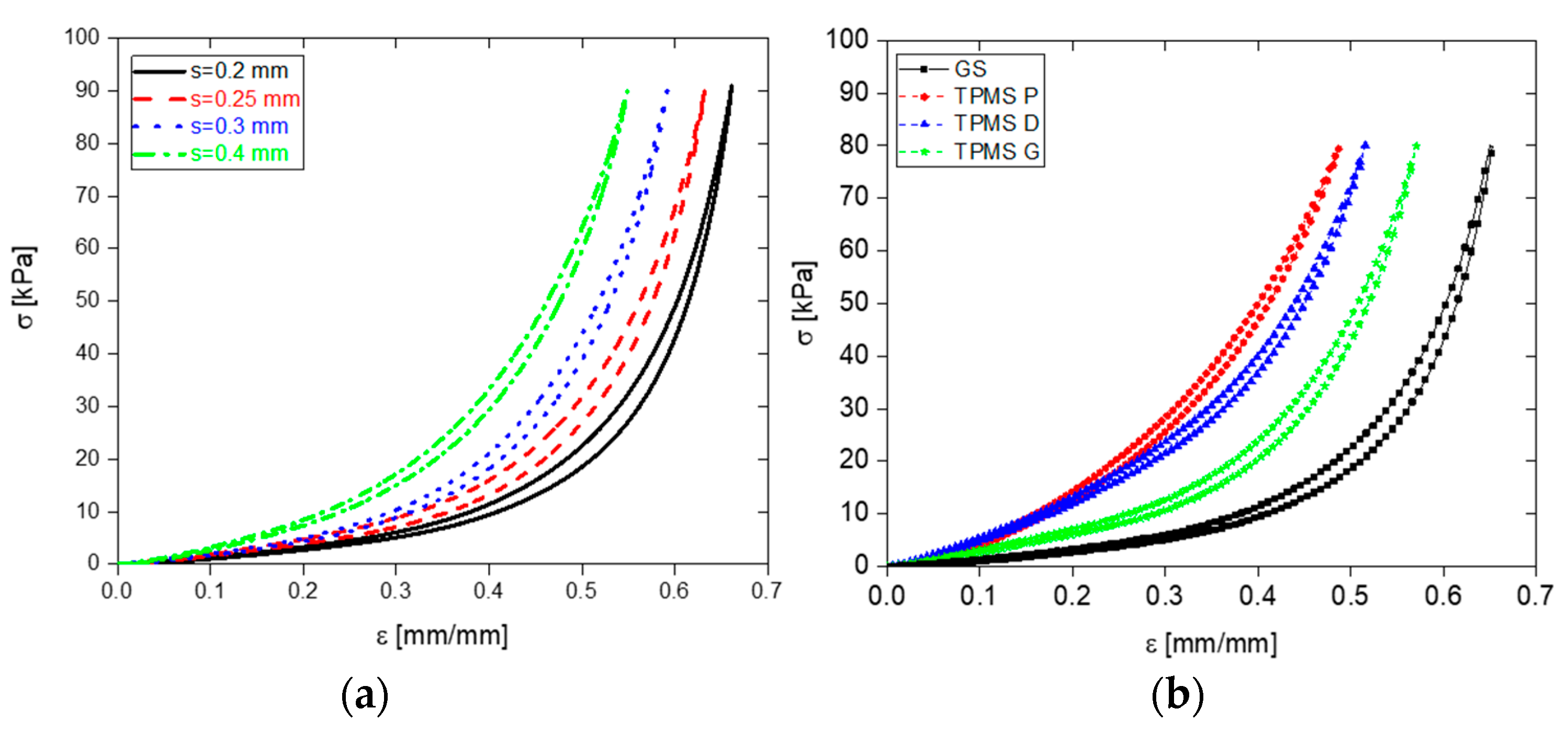

2.1.2. TPMS Structures (TPMSS)

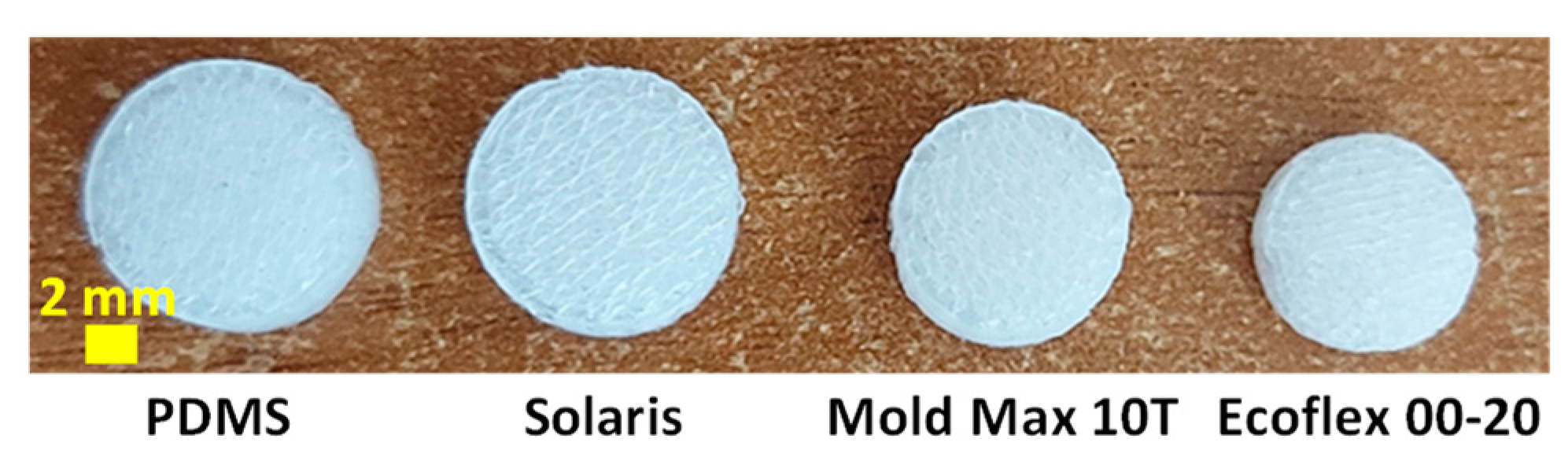

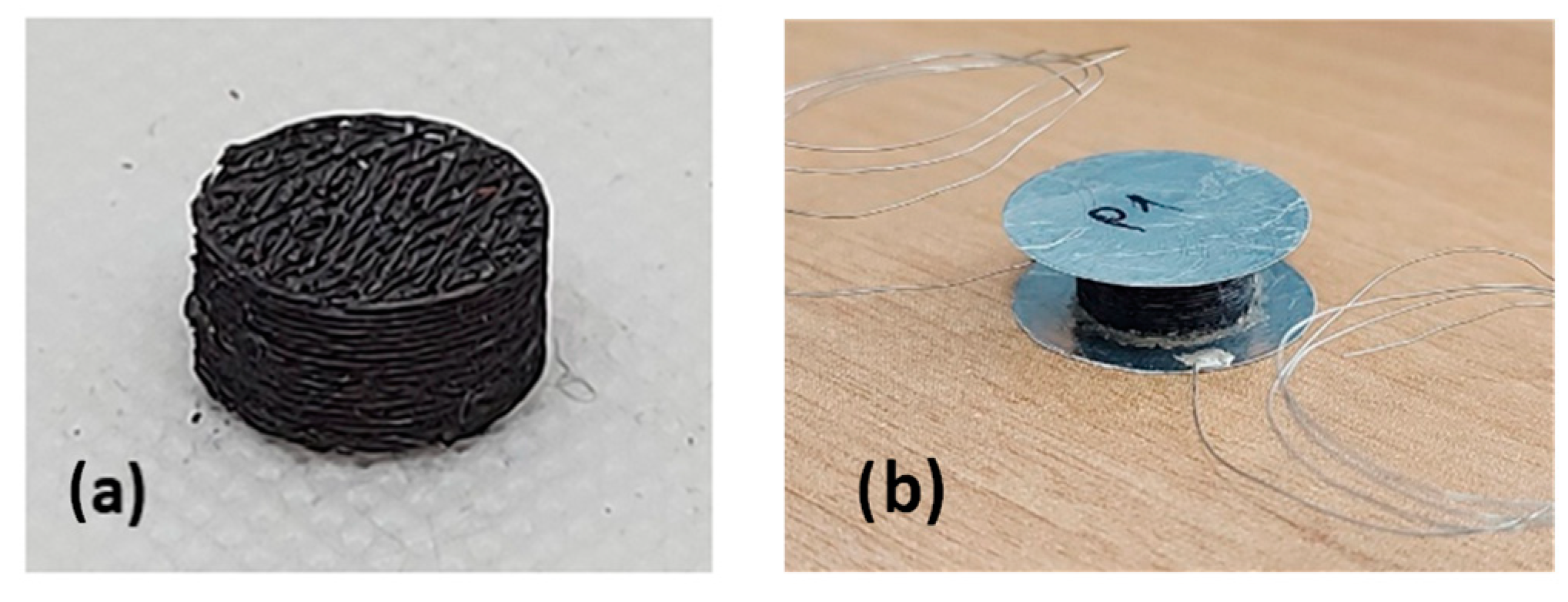

2.2. Production of Polymeric Cell Structures

2.2.1. Foam Production

2.2.2. GNPs Infiltration Process

- Dispersing the GNPs in 1-propanol with a concentration of 0.1 mg/mL and exfoliating them through ultrasonication using a sonotrode tip (Sonics & Materials Vibracell VC505, Sonics, Newtown, CT, USA) operating with a symmetric duty cycle (1 s on-phase, 1 s off-phase).

- Evaporating the solvent to obtain a final concentration of 1 mg/mL of GNPs.

- Infiltrating the polymeric structures with the GNPs/1-propanol solution using a 100 µL micropipette. To ensure a homogeneous distribution of GNPs, we alternated the faces of the sample every 60 s.

3. Results and Discussion

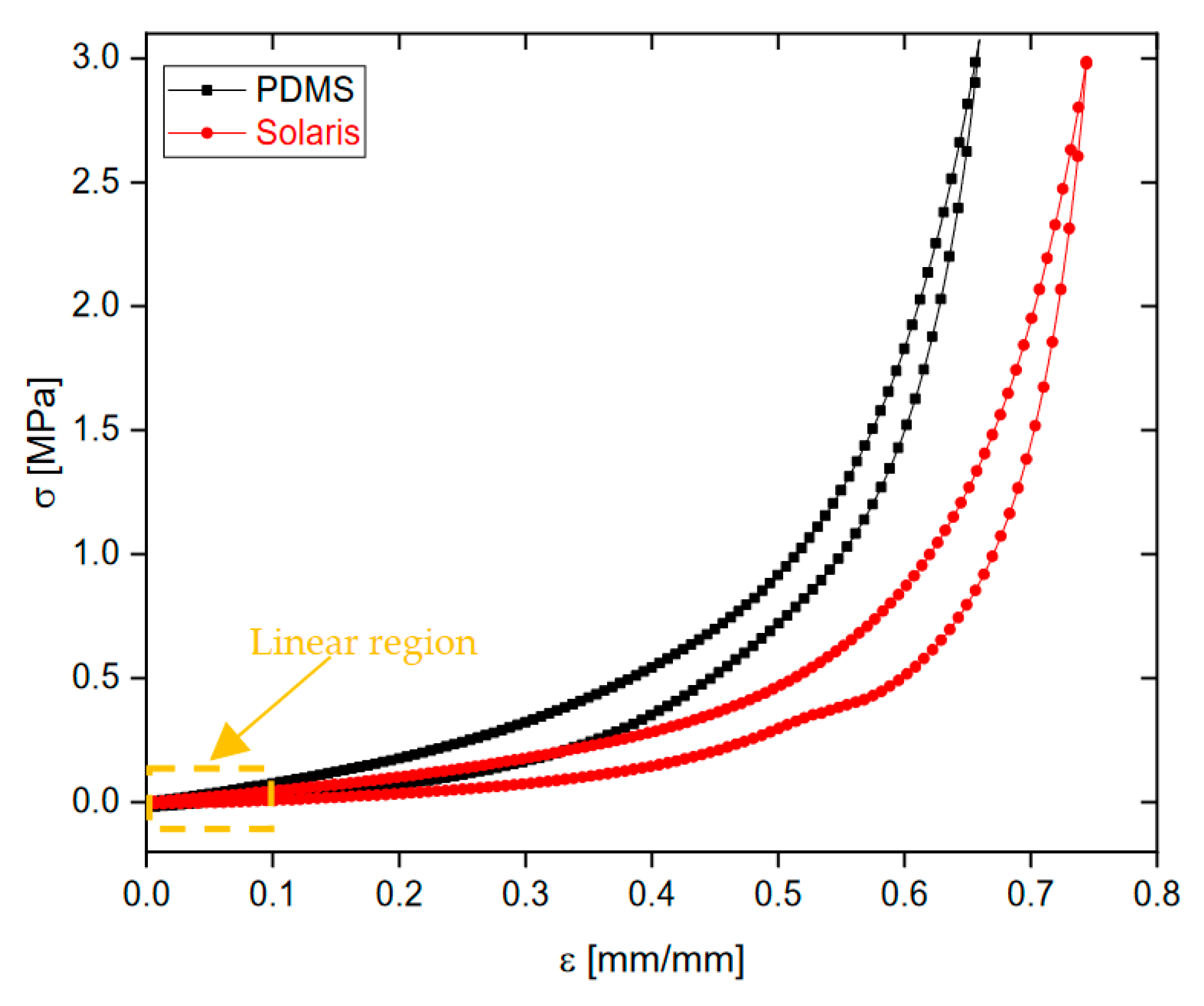

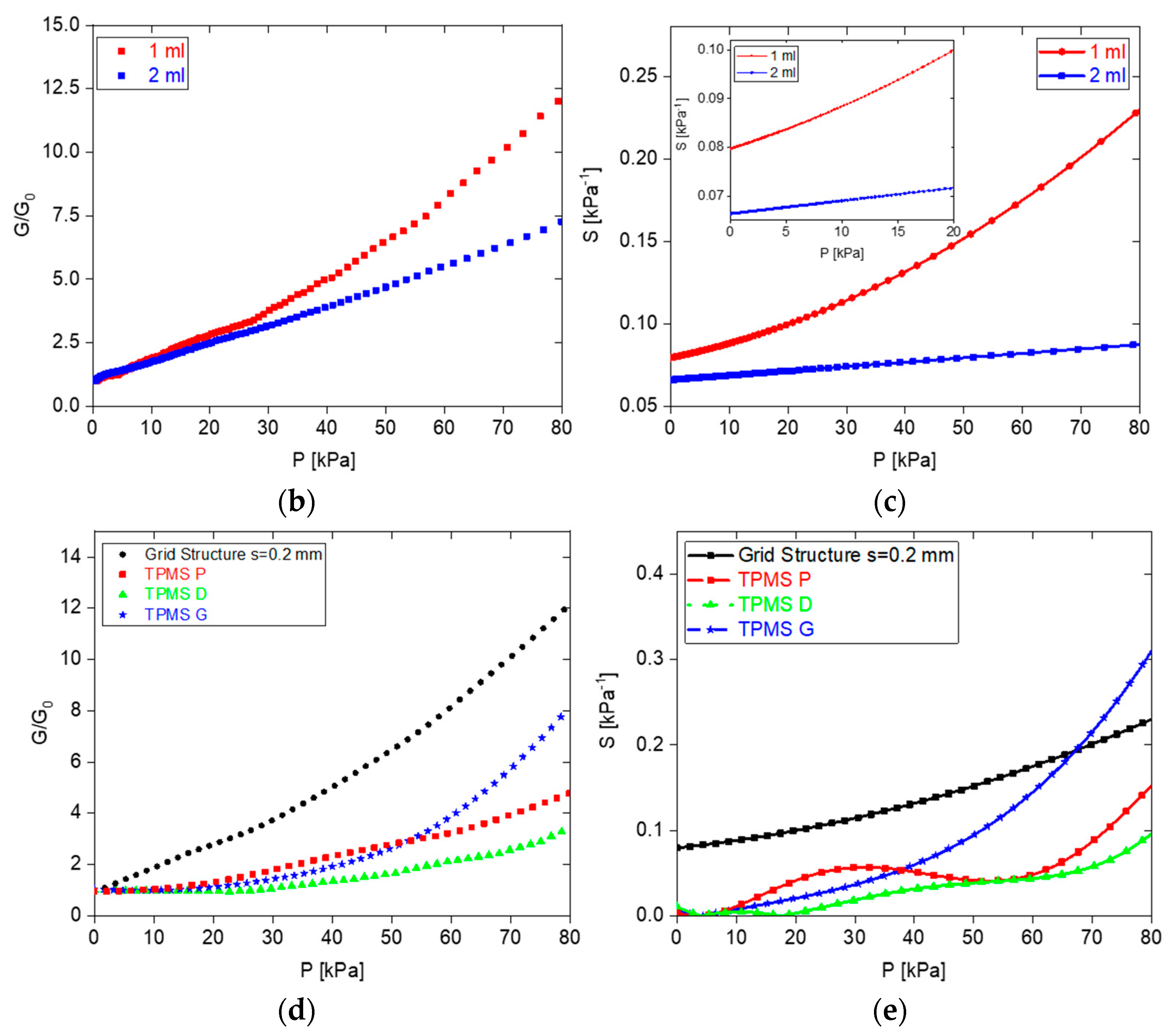

3.1. Mechanical Characterizations

3.1.1. Comparison with TPMSS

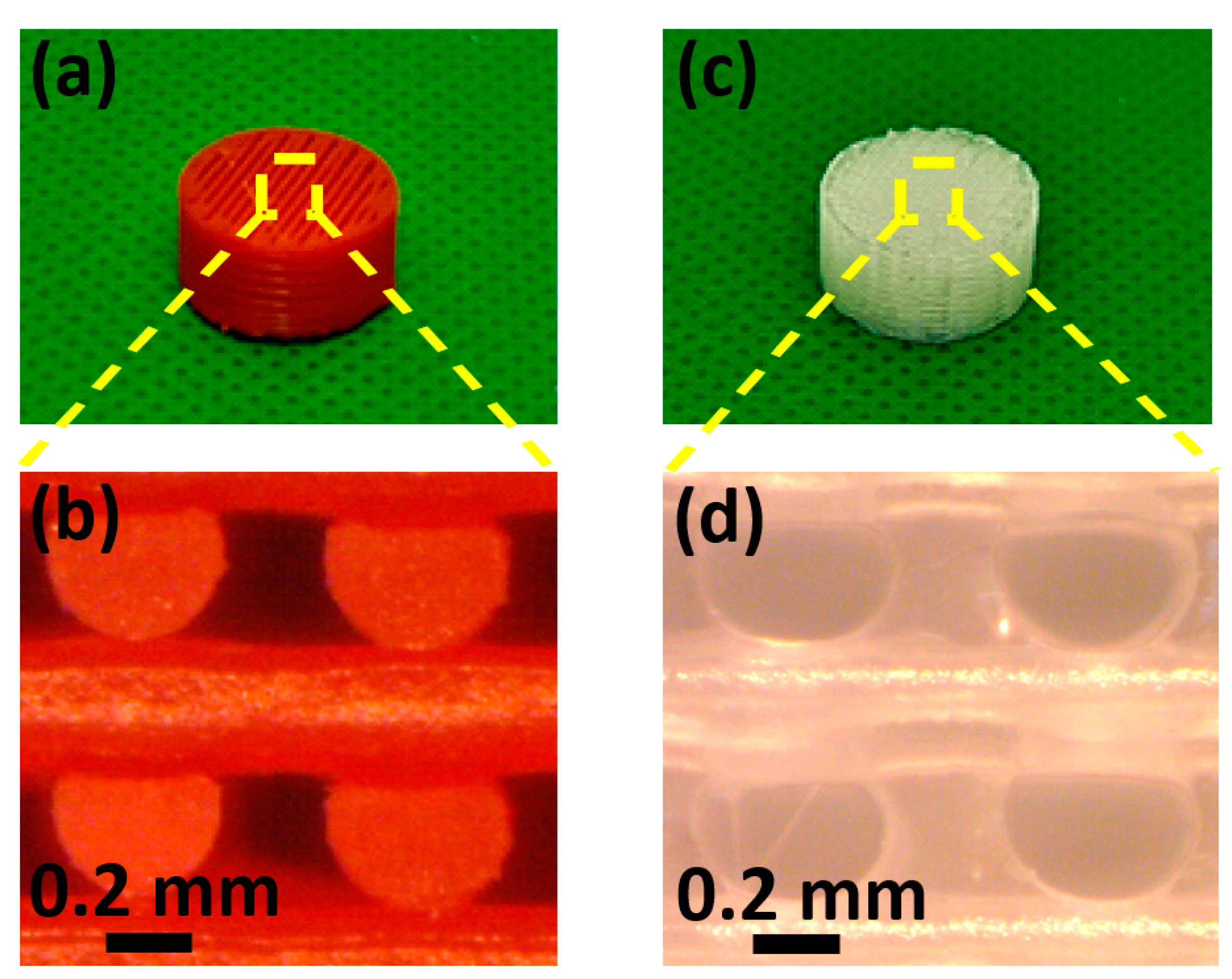

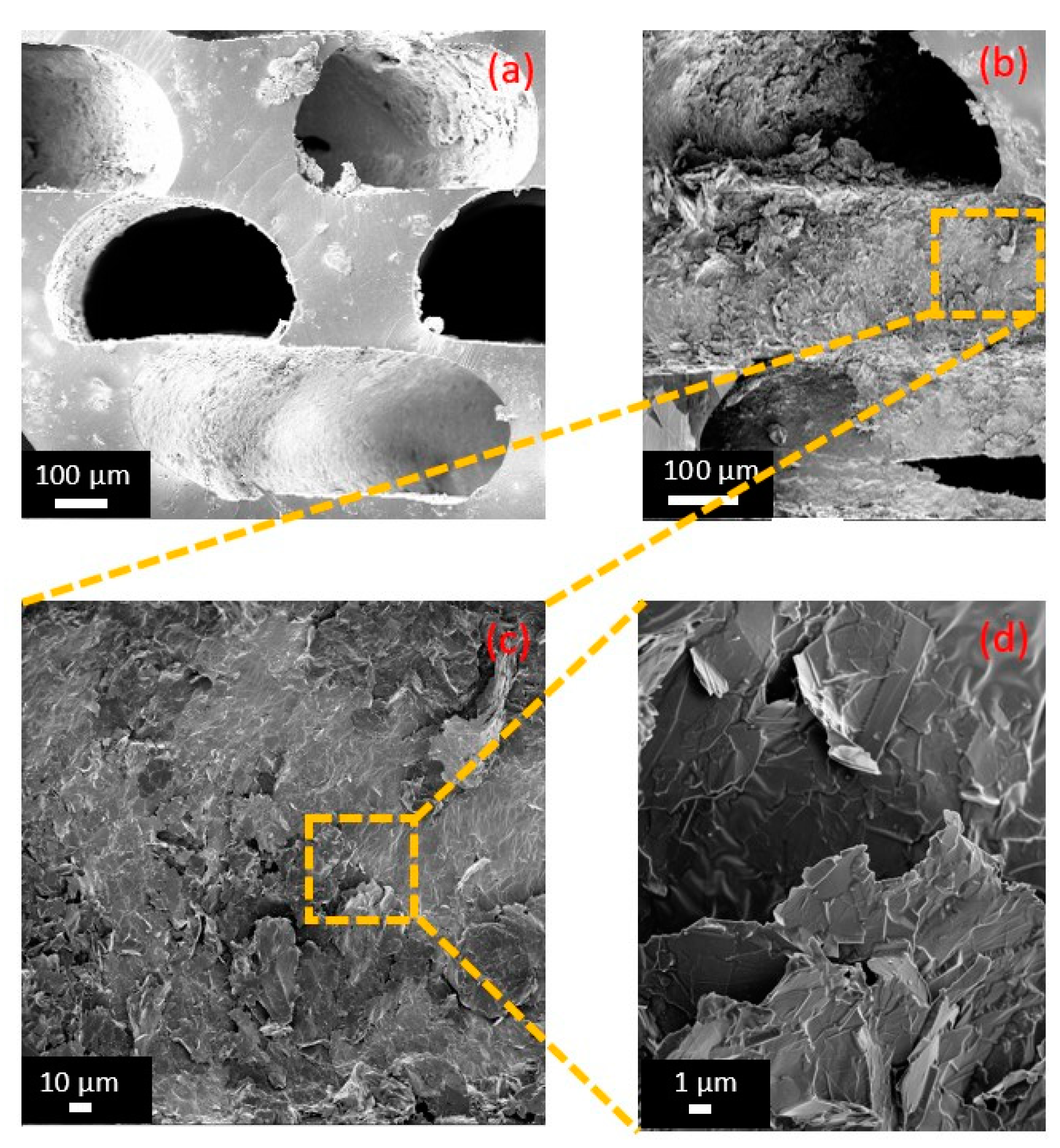

3.2. Morphological Characterization

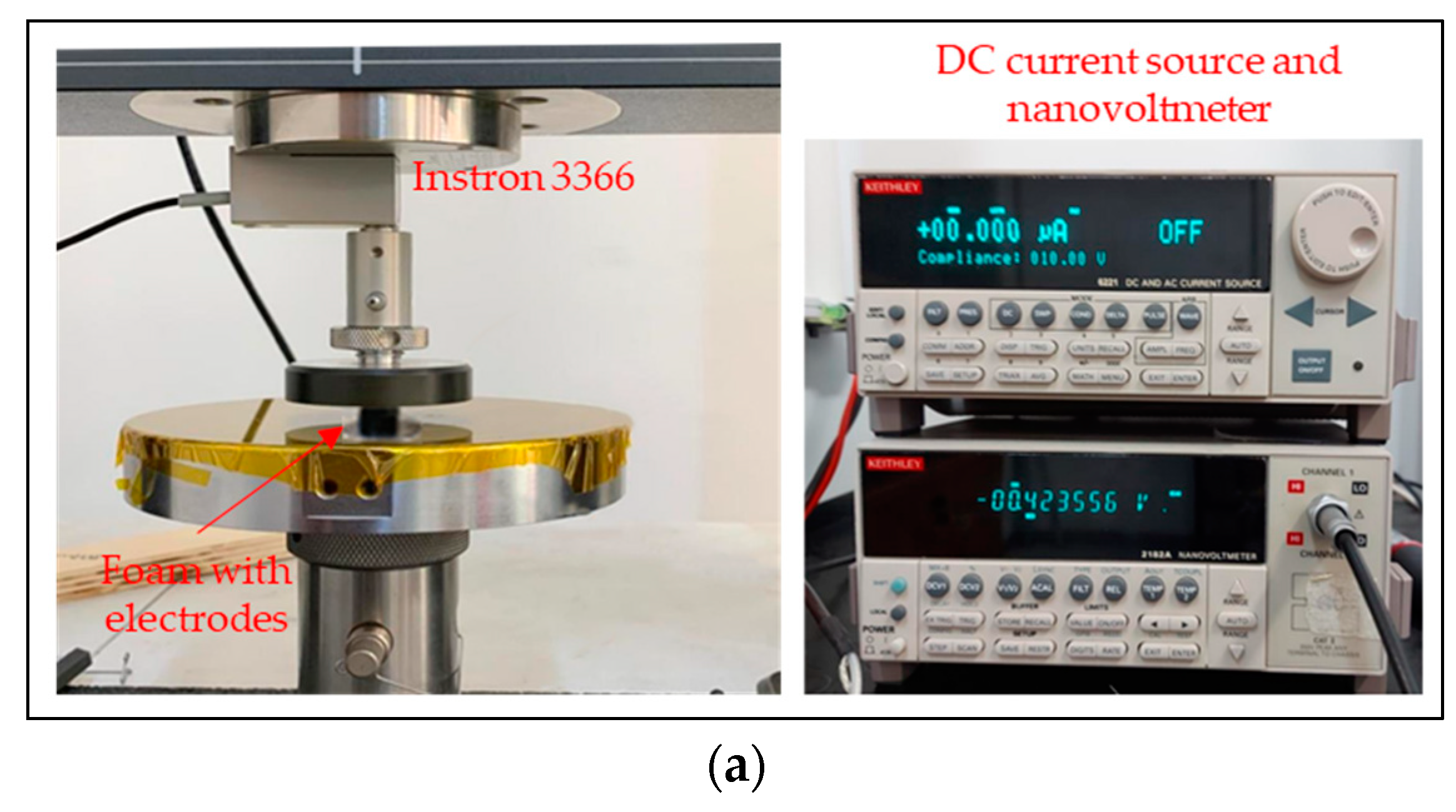

3.3. Electrical Characterizations

3.4. Electromechanical Characterizations

3.5. Development of Heart Rate Sensors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fraden, J. Handbook of Modern Sensors; Springer: New York, NY, USA, 2010; ISBN 9781441964656. [Google Scholar]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, technology and applications of piezoresistive sensors: A review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Niu, D.; Jiang, W.; Ye, G.; Wang, K.; Yin, L.; Shi, Y.; Chen, B.; Luo, F.; Liu, H. Graphene-elastomer nanocomposites based flexible piezoresistive sensors for strain and pressure detection. Mater. Res. Bull. 2018, 102, 92–99. [Google Scholar] [CrossRef]

- Alluri, N.R.; Vivekananthan, V.; Chandrasekhar, A.; Kim, S.-J. Adaptable piezoelectric hemispherical composite strips using a scalable groove technique for a self-powered muscle monitoring system. Nanoscale 2018, 10, 907–913. [Google Scholar] [CrossRef] [PubMed]

- Zhong, L.; Liu, S.; Xu, D.; Zhu, Z. Voltage Control Ratiometric Readout Technique with Improved Dynamic Range and Power-Efficiency for Open-Loop MEMS Capacitive Accelerometer. IEEE Trans. Circuits Syst. I Regul. Pap. 2022, 69, 5085–5095. [Google Scholar] [CrossRef]

- Qin, Z.; Sun, X.; Yu, Q.; Zhang, H.; Wu, X.; Yao, M.; Liu, W.; Yao, F.; Li, J. Carbon Nanotubes/Hydrophobically Associated Hydrogels as Ultrastretchable, Highly Sensitive, Stable Strain, and Pressure Sensors. ACS Appl. Mater. Interfaces 2020, 12, 4944–4953. [Google Scholar] [CrossRef] [PubMed]

- Al-Handarish, Y.; Omisore, O.M.; Duan, W.; Chen, J.; Zebang, L.; Akinyemi, T.O.; Du, W.; Li, H.; Wang, L. Facile Fabrication of 3D Porous Sponges Coated with Synergistic Carbon Black/Multiwalled Carbon Nanotubes for Tactile Sensing Applications. Nanomaterials 2020, 10, 1941. [Google Scholar] [CrossRef] [PubMed]

- Bian, Y.; Li, Y. Porous conductive elastomeric composites with carbon nanotubes suspended in the narrow pores from Co-continuous polymer blend nanocomposites. Compos. Sci. Technol. 2022, 218, 109116. [Google Scholar] [CrossRef]

- Herren, B.; Webster, V.; Davidson, E.; Saha, M.C.; Altan, M.C.; Liu, Y. PDMS Sponges with Embedded Carbon Nanotubes as Piezoresistive Sensors for Human Motion Detection. Nanomaterials 2021, 11, 1740. [Google Scholar] [CrossRef] [PubMed]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Roshanghias, A.; Araee, A.; Baniassadi, M.; Oberlercher, H.; Zangl, H. Impedance analysis for condition monitoring of single lap CNT-epoxy adhesive joint. Int. J. Adhes. Adhes. 2019, 88, 59–65. [Google Scholar] [CrossRef]

- Zheng, Q.; Lee, J.; Shen, X.; Chen, X.; Kim, J.-K. Graphene-based wearable piezoresistive physical sensors. Mater. Today 2020, 36, 158–179. [Google Scholar] [CrossRef]

- Matsuda, R.; Mizuguchi, S.; Nakamura, F.; Endo, T.; Inamori, G.; Isoda, Y.; Ota, H. Stretchable Array of Resistive Pressure Sensors Ignoring the Effect of Strain-Induced Deformation. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 803–805. [Google Scholar]

- Rinaldi, A.; Tamburrano, A.; Fortunato, M.; Sarto, M.S. A flexible and highly sensitive pressure sensor based on a PDMS foam coated with graphene nanoplatelets. Sensors 2016, 16, 2148. [Google Scholar] [CrossRef] [PubMed]

- Fortunato, M.; Bellagamba, I.; Tamburrano, A.; Sarto, M.S. Flexible Ecoflex®/Graphene Nanoplatelet Foams for Highly Sensitive Low-Pressure Sensors. Sensors 2020, 20, 4406. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Wang, Y.; Luo, Z.; Wang, B. Durable, Sensitive, and Wide-Range Wearable Pressure Sensors Based on Wavy-Structured Flexible Conductive Composite Film. Macromol. Mater. Eng. 2020, 305, 2000206. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Khademhosseini, A.; Toyserkani, E. Sacrificial 3D printing of shrinkable silicone elastomers for enhanced feature resolution in flexible tissue scaffolds. Acta Biomater. 2020, 117, 261–272. [Google Scholar] [CrossRef] [PubMed]

- Davoodi, E.; Montazerian, H.; Haghniaz, R.; Rashidi, A.; Ahadian, S.; Sheikhi, A.; Chen, J.; Khademhosseini, A.; Milani, A.S.; Hoorfar, M.; et al. 3D-Printed Ultra-Robust Surface-Doped Porous Silicone Sensors for Wearable Biomonitoring. ACS Nano 2020, 14, 1520–1532. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Dong, S.; Yang, J.; Yan, J. Three-dimensional printing of a tunable graphene-based elastomer for strain sensors with ultrahigh sensitivity. Carbon N. Y. 2019, 143, 63–72. [Google Scholar] [CrossRef]

- Jung, G.S.; Buehler, M.J. Multiscale Mechanics of Triply Periodic Minimal Surfaces of Three-Dimensional Graphene Foams. Nano Lett. 2018, 18, 4845–4853. [Google Scholar] [CrossRef] [PubMed]

- Tewari, A.; Gandla, S.; Bohm, S.; McNeill, C.R.; Gupta, D. Highly Exfoliated MWNT–rGO Ink-Wrapped Polyurethane Foam for Piezoresistive Pressure Sensor Applications. ACS Appl. Mater. Interfaces 2018, 10, 5185–5195. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Fu, J.; Shang, C.; Lin, Z.; Li, B. Porous scaffold design by solid T-splines and triply periodic minimal surfaces. Comput. Methods Appl. Mech. Eng. 2018, 336, 333–352. [Google Scholar] [CrossRef]

- Biswas, D.; Simoes-Capela, N.; Van Hoof, C.; Van Helleputte, N. Heart Rate Estimation from Wrist-Worn Photoplethysmography: A Review. IEEE Sens. J. 2019, 19, 6560–6570. [Google Scholar] [CrossRef]

| Polymer | Initial Weight [g] | Final Weight [g] | Δ [g] |

|---|---|---|---|

| Solaris | 0.242 | 0.208 | 0.034 |

| Mold Max 10T | 0.285 | 0.170 | 0.115 |

| Ecoflex® 00-20 | 0.250 | 0.126 | 0.124 |

| PDMS | 0.255 | 0.222 | 0.033 |

| Polymer | E [MPa] |

|---|---|

| Solaris | 0.369 |

| PDMS | 0.699 |

| Structure | E [kPa] |

|---|---|

| Grid | 16 |

| TPMS P | 68 |

| TPMS D | 62 |

| TPMS G | 35 |

| GNPs Suspension [mL] | G0 |

|---|---|

| 2 | (1.00 ± 0.38) mS |

| 1 | (73.81 ± 8.58) μS |

| 0.6 | <1 μS |

| Structure | E [kPa] | G0 [μS] | S [kPa−1] @ 10 kPa | S [kPa−1] @ 80 kPa |

|---|---|---|---|---|

| Grid | 16 | 73.81 | 0.088 | 0.24 |

| TPMS P | 68 | 52.49 | 0.011 | 0.15 |

| TPMS D | 62 | 97.91 | 0.005 | 0.10 |

| TPMS G | 35 | 67.07 | 0.008 | 0.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fortunato, M.; Pacitto, L.; Pesce, N.; Tamburrano, A. 3D-Printed Graphene Nanoplatelets/Polymer Foams for Low/Medium-Pressure Sensors. Sensors 2023, 23, 7054. https://doi.org/10.3390/s23167054

Fortunato M, Pacitto L, Pesce N, Tamburrano A. 3D-Printed Graphene Nanoplatelets/Polymer Foams for Low/Medium-Pressure Sensors. Sensors. 2023; 23(16):7054. https://doi.org/10.3390/s23167054

Chicago/Turabian StyleFortunato, Marco, Luca Pacitto, Nicola Pesce, and Alessio Tamburrano. 2023. "3D-Printed Graphene Nanoplatelets/Polymer Foams for Low/Medium-Pressure Sensors" Sensors 23, no. 16: 7054. https://doi.org/10.3390/s23167054

APA StyleFortunato, M., Pacitto, L., Pesce, N., & Tamburrano, A. (2023). 3D-Printed Graphene Nanoplatelets/Polymer Foams for Low/Medium-Pressure Sensors. Sensors, 23(16), 7054. https://doi.org/10.3390/s23167054