Nonlinear Model Predictive Impedance Control of a Fully Actuated Hexarotor for Physical Interaction

Abstract

1. Introduction

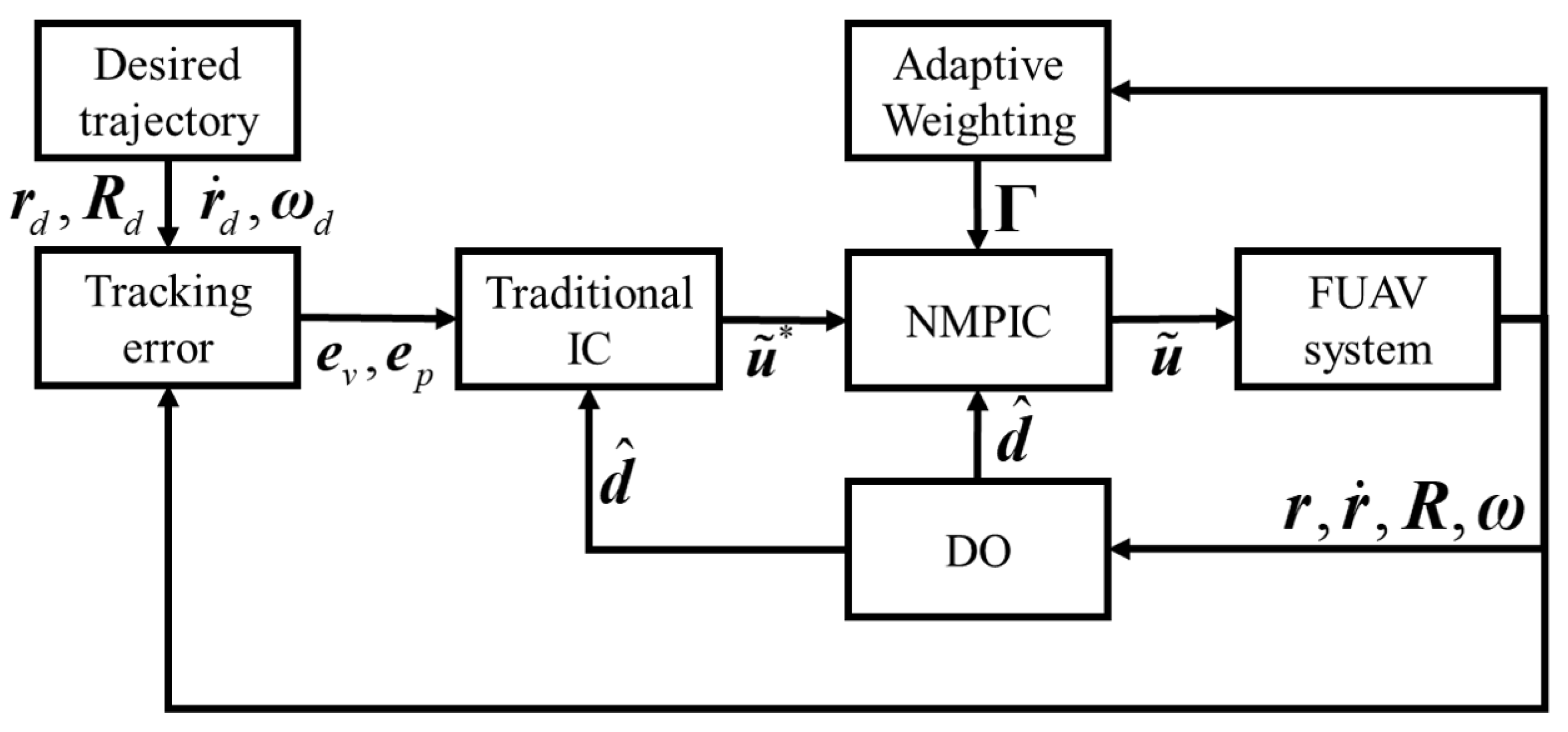

- A novel control scheme combining NMPC and IC is proposed to handle the constraints and maintain the compliant behavior for physical interactions with a FUAV.

- A weight-adaptive strategy is proposed for NMPIC to handle the inherent conflict between the reference signals and the constraints.

- Comparative simulations are conducted to verify the effectiveness and advantages of the proposed method in different scenarios.

- The proposed method also opens a new way for interaction force regulation.

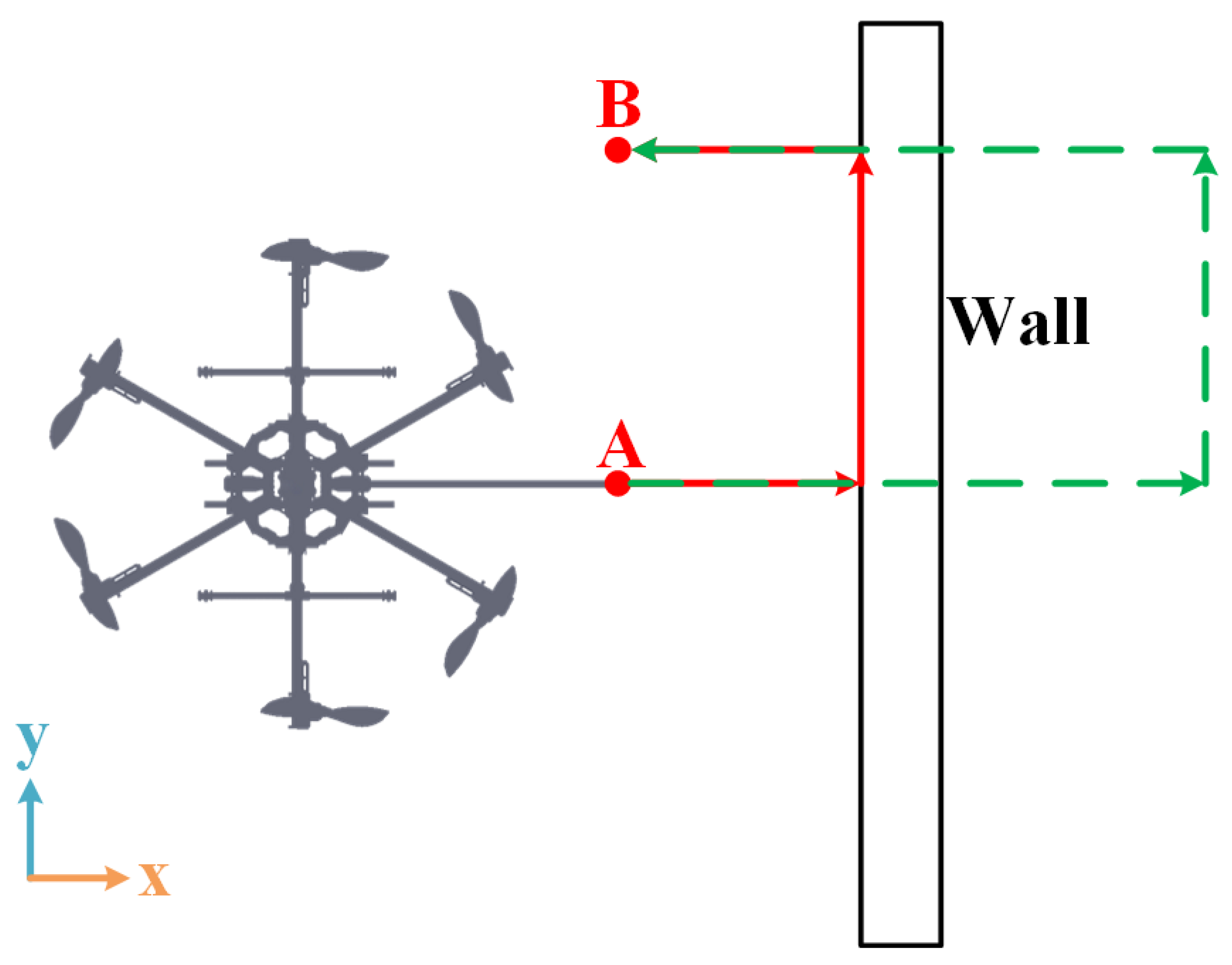

2. Problem Formulation

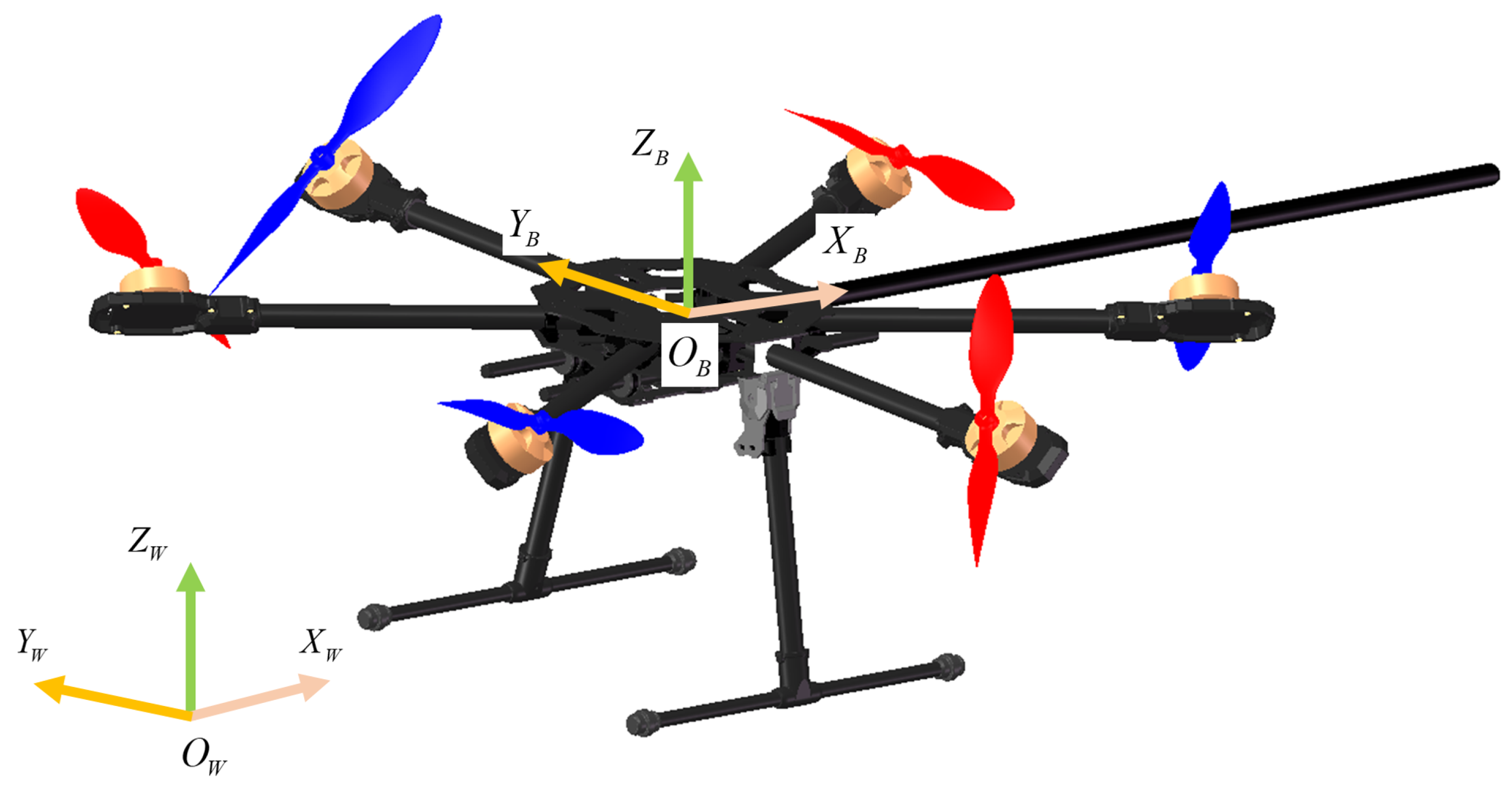

2.1. System Model

2.2. Impedance Control

2.3. Disturbance Observer

3. Nonlinear Model Predictive Impedance Control

3.1. NMPIC Design

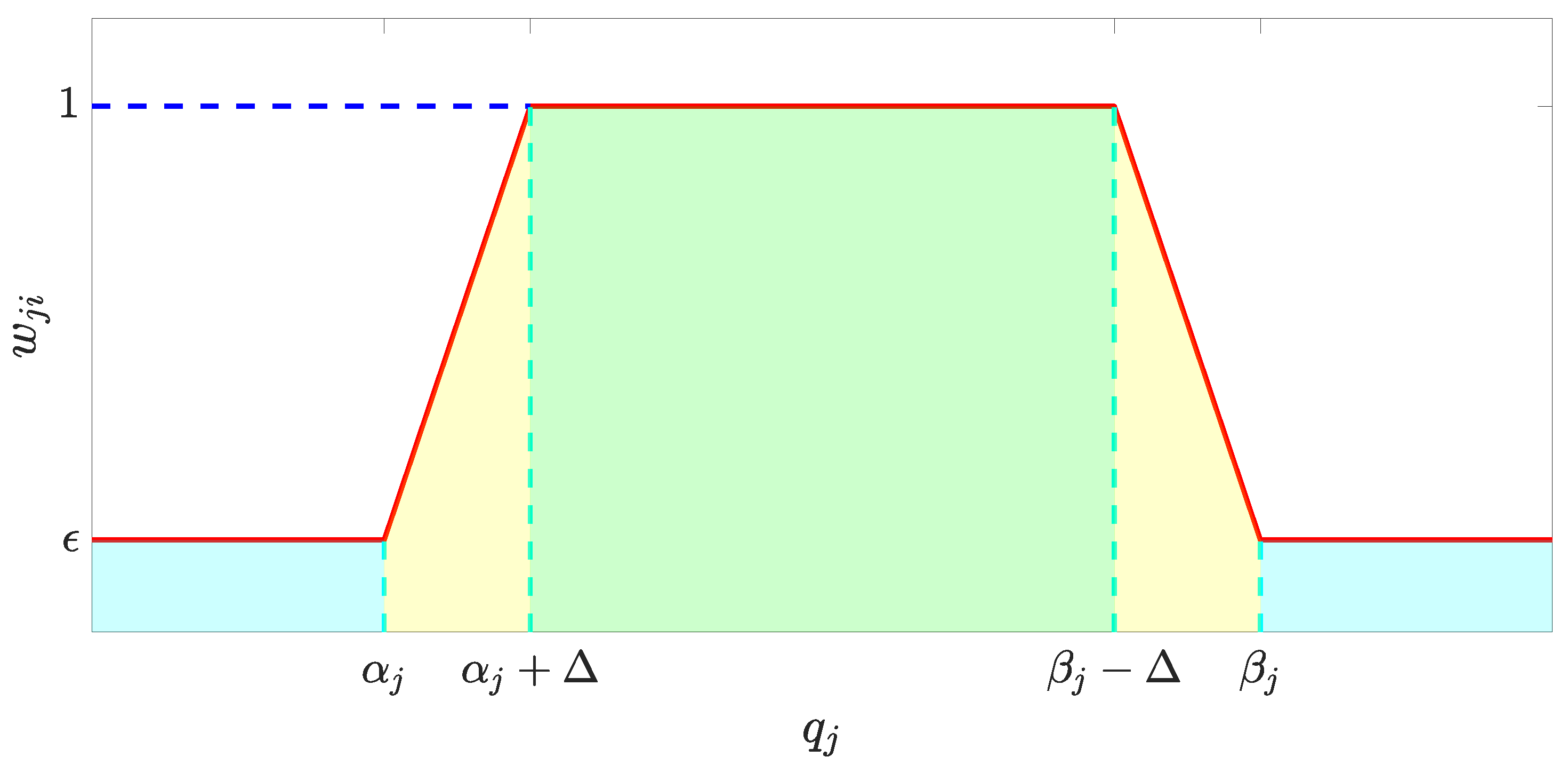

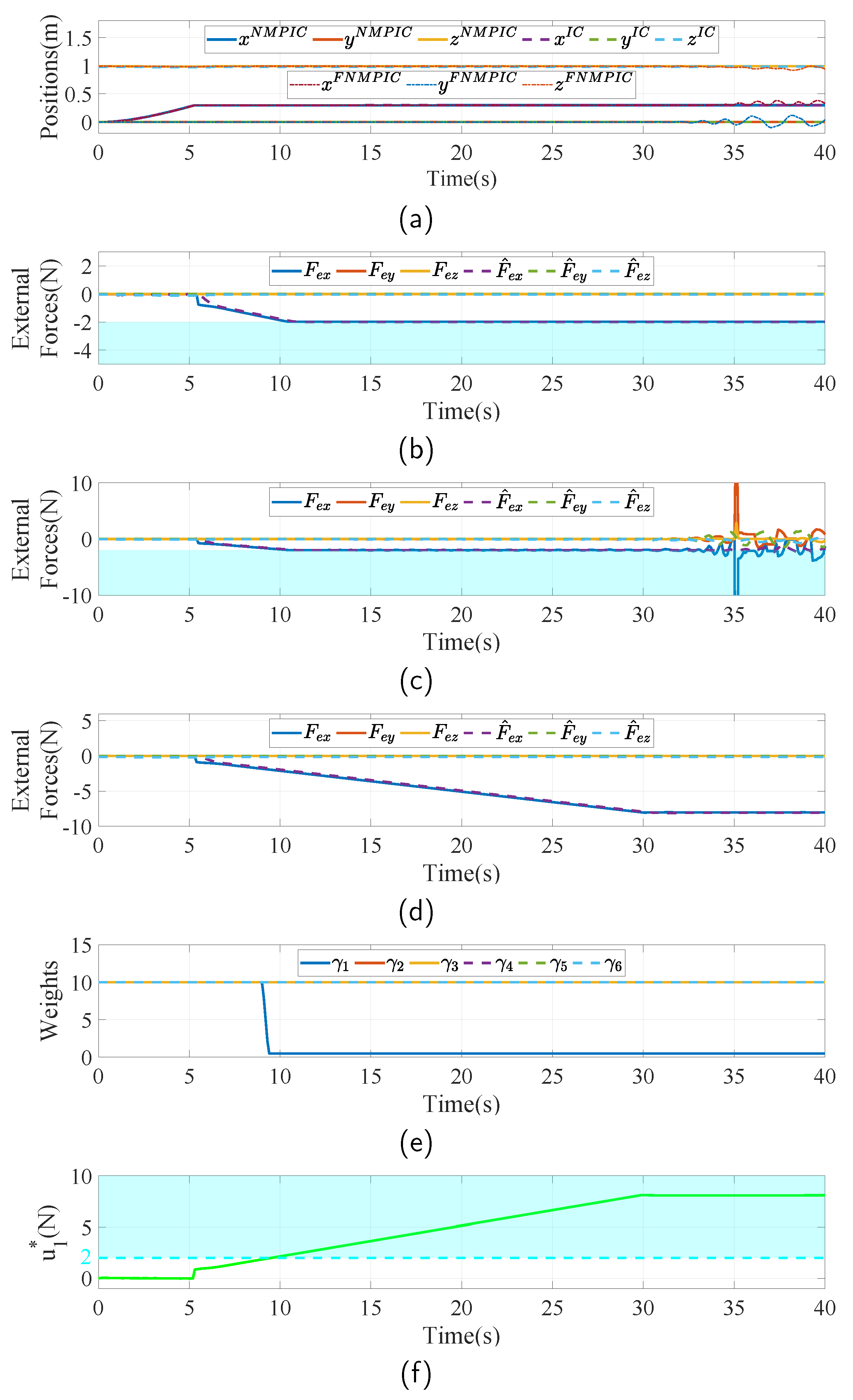

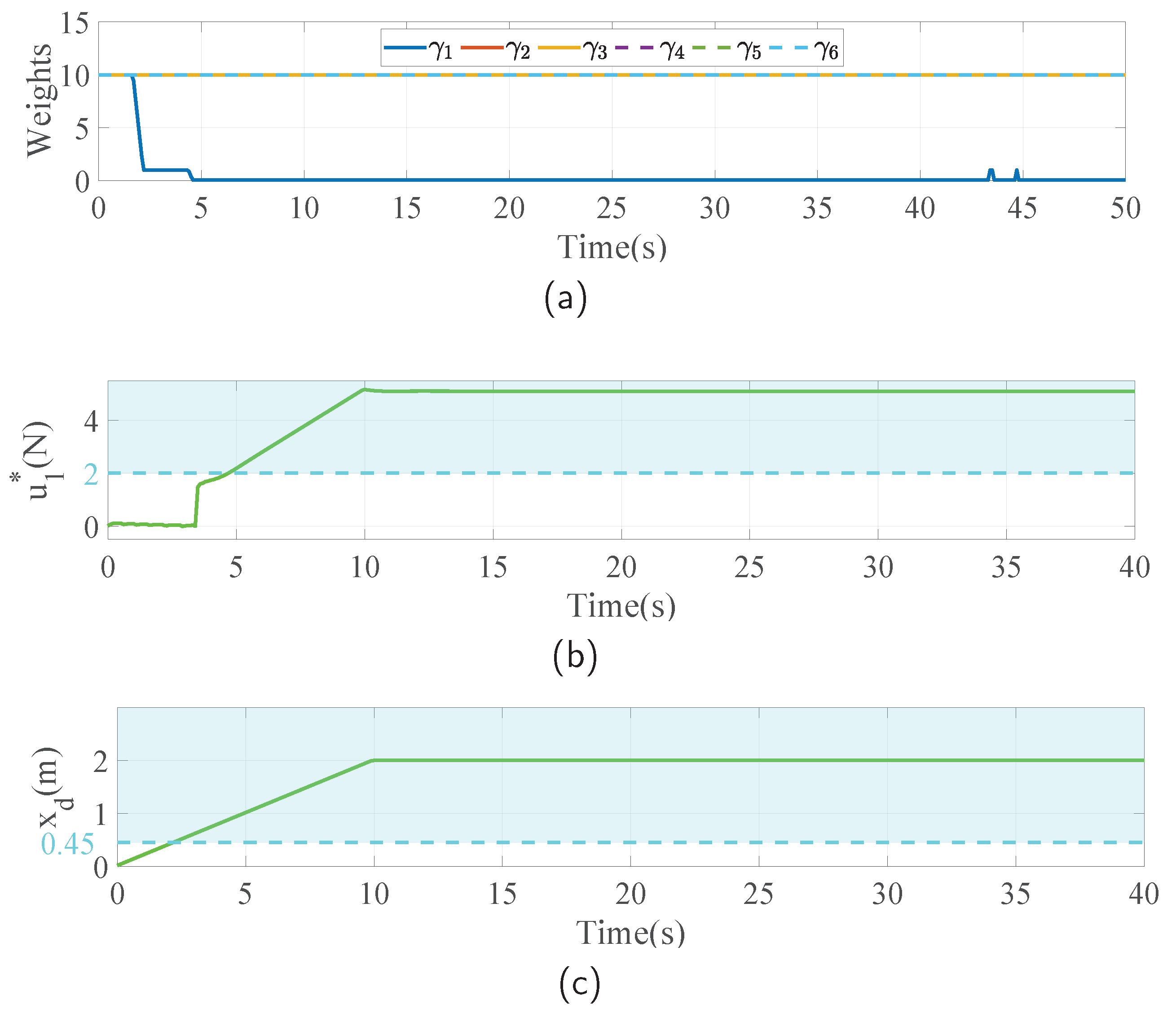

3.2. Weight Adaptive Strategy

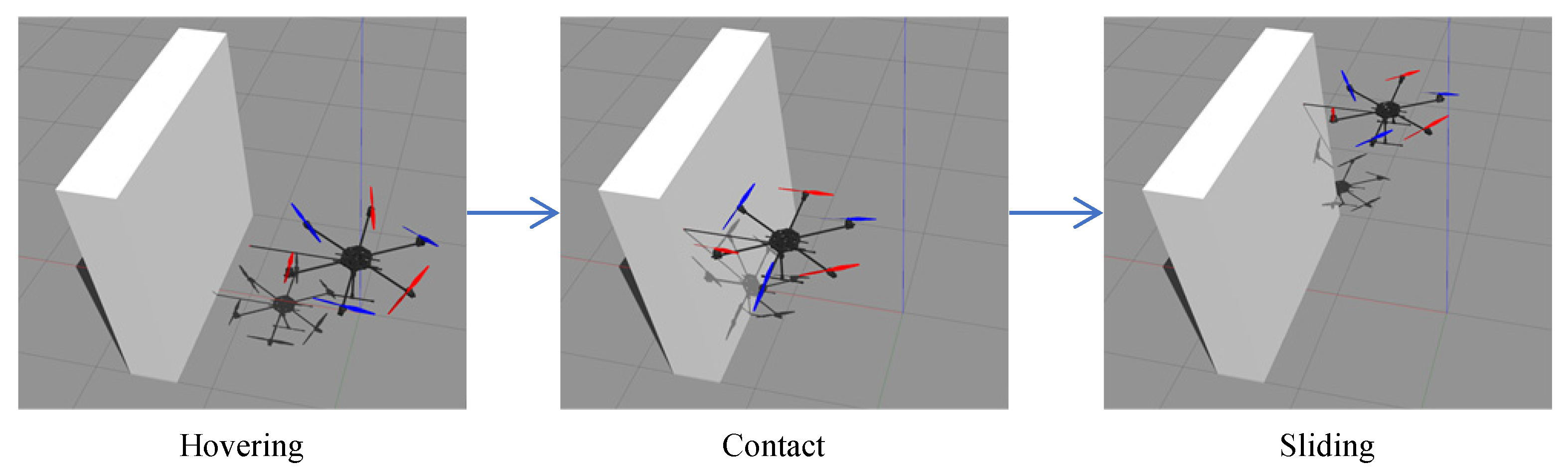

4. Simulations

4.1. Implementation Details

4.2. Simulation Results

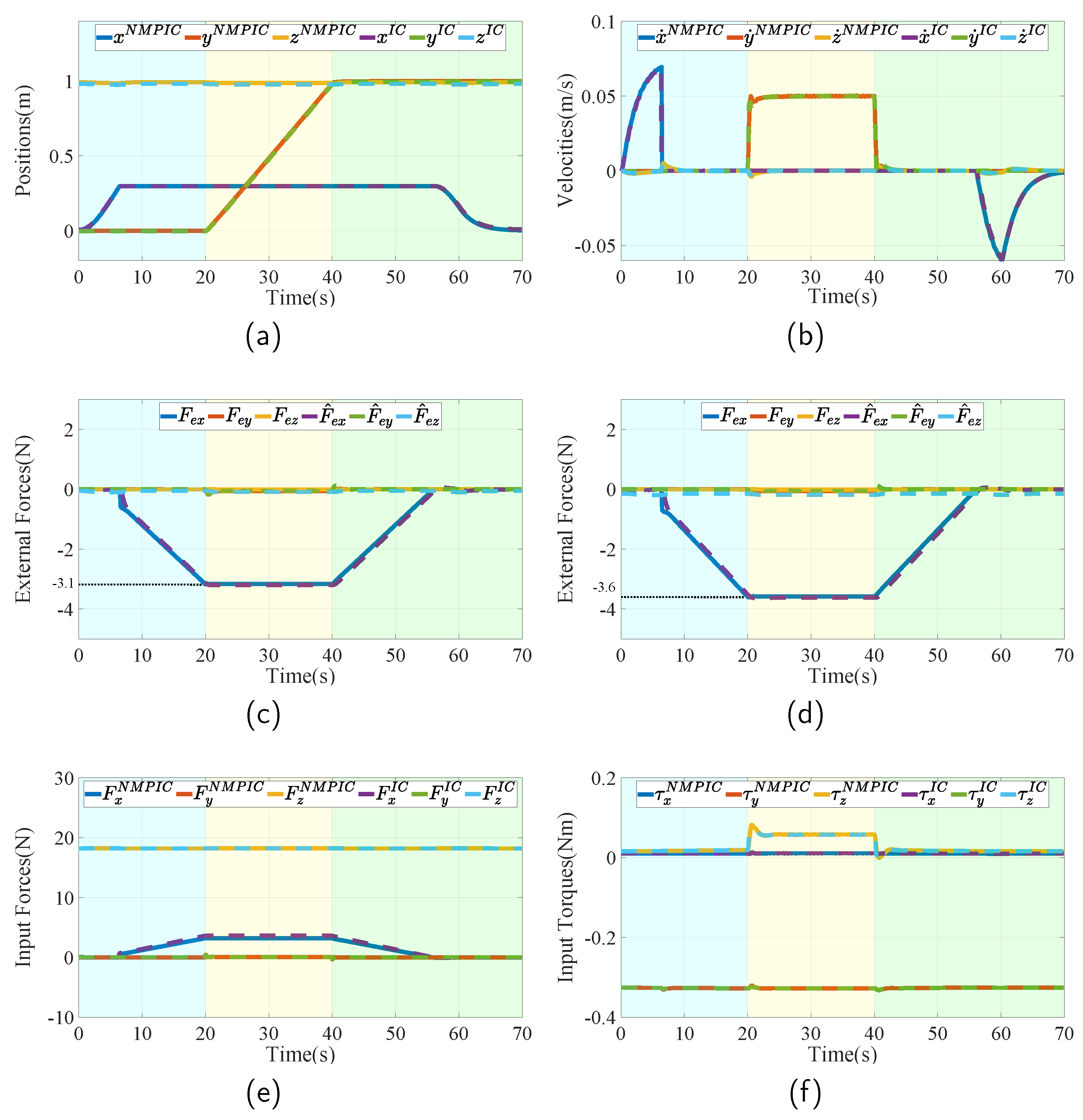

4.2.1. Normal Case

4.2.2. Force Constraints

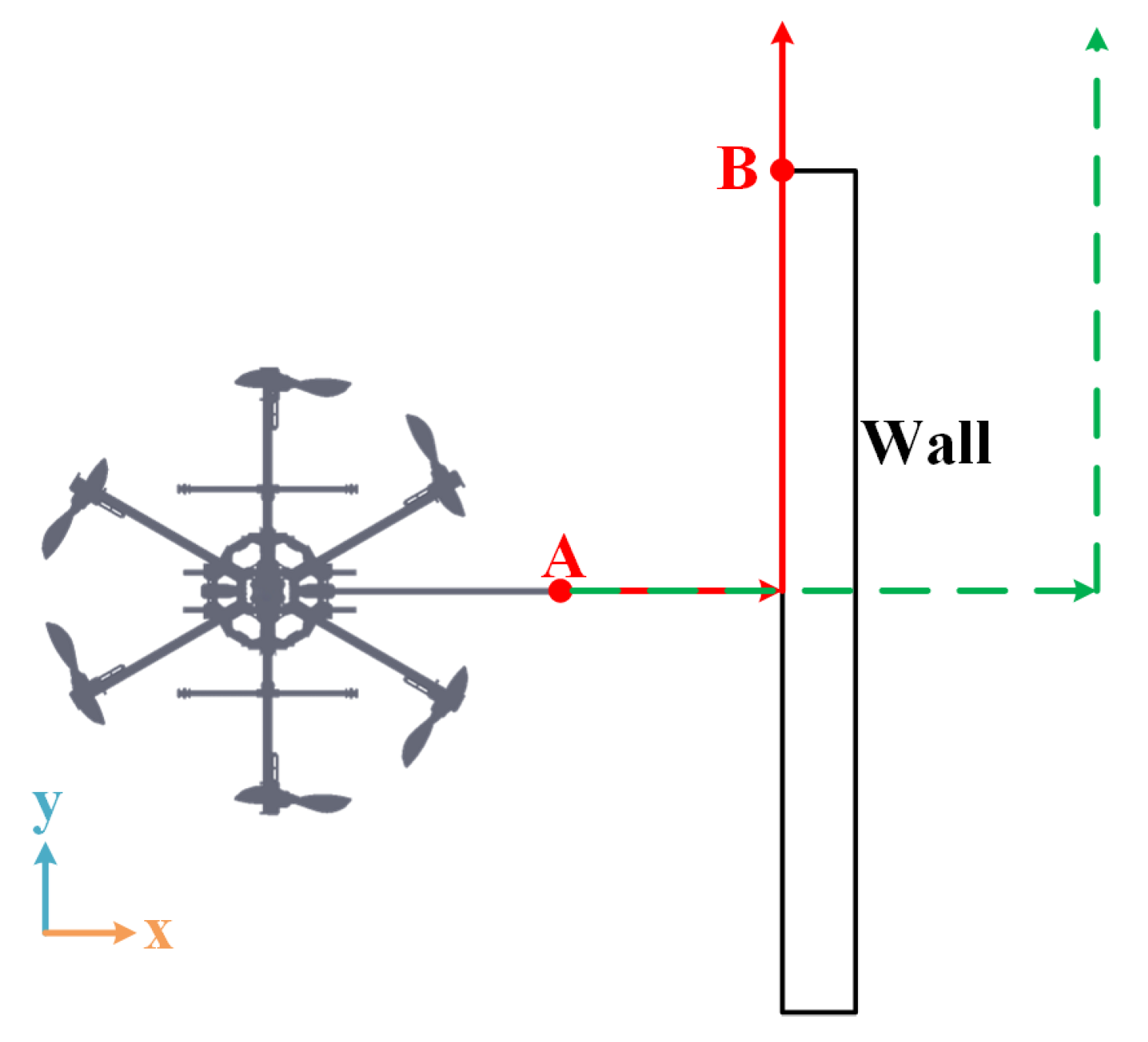

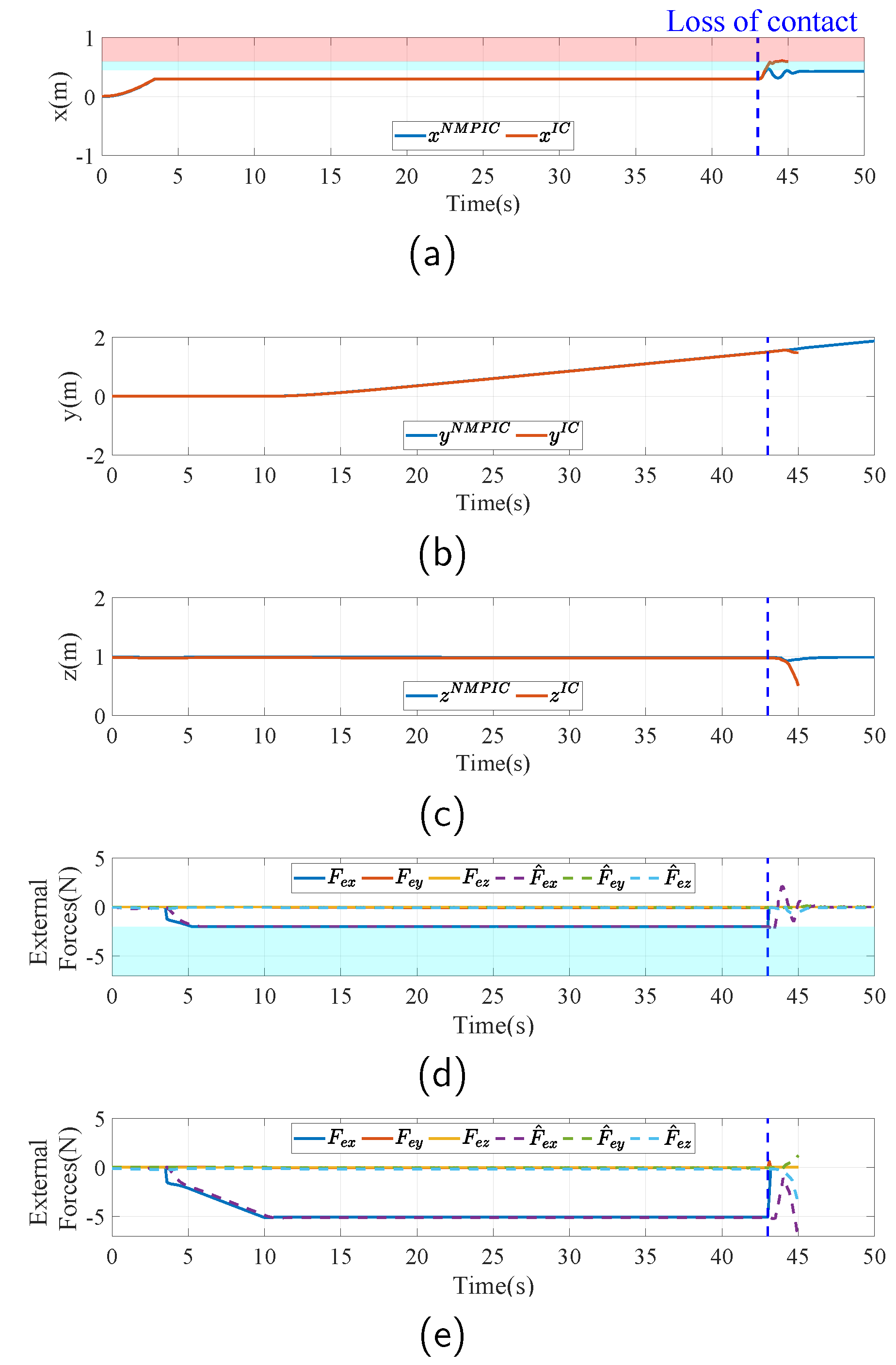

4.2.3. Loss of Contact

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hanif, A.S.; Han, X.; Yu, S.H. Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review. Drones 2022, 6, 383. [Google Scholar] [CrossRef]

- Cao, Y.; Cheng, X.; Mu, J. Concentrated Coverage Path Planning Algorithm of UAV Formation for Aerial Photography. IEEE Sens. J. 2022, 22, 11098–11111. [Google Scholar] [CrossRef]

- Padró, J.C.; Muñoz, F.J.; Planas, J.; Pons, X. Comparison of four UAV georeferencing methods for environmental monitoring purposes focusing on the combined use with airborne and satellite remote sensing platforms. Int. J. Appl. Earth Obs. Geoinf. 2019, 75, 130–140. [Google Scholar] [CrossRef]

- Jayaweera, H.M.P.C.; Hanoun, S. UAV Path Planning for Reconnaissance and Look-Ahead Coverage Support for Mobile Ground Vehicles. Sensors 2021, 21, 4595. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Ullah, I.; Alkhalifah, A.; Rehman, S.U.; Shah, J.A.; Uddin, M.I.; Alsharif, M.H.; Algarni, F. A provable and privacy-preserving authentication scheme for UAV-enabled intelligent transportation systems. IEEE Trans. Ind. Inform. 2021, 18, 3416–3425. [Google Scholar] [CrossRef]

- Ollero, A.; Heredia, G.; Franchi, A.; Antonelli, G.; Kondak, K.; Sanfeliu, A.; Viguria, A.; Martinez-de Dios, J.R.; Pierri, F.; Cortés, J.; et al. The aeroarms project: Aerial robots with advanced manipulation capabilities for inspection and maintenance. IEEE Robot. Autom. Mag. 2018, 25, 12–23. [Google Scholar] [CrossRef]

- Sun, Y.; Jing, Z.; Dong, P.; Huang, J.; Chen, W.; Leung, H. A switchable unmanned aerial manipulator system for window-cleaning robot installation. IEEE Robot. Autom. Lett. 2021, 6, 3483–3490. [Google Scholar] [CrossRef]

- Park, S.; Lee, J.; Ahn, J.; Kim, M.; Her, J.; Yang, G.H.; Lee, D. Odar: Aerial manipulation platform enabling omnidirectional wrench generation. IEEE/ASME Trans. Mechatronics 2018, 23, 1907–1918. [Google Scholar] [CrossRef]

- Acosta, J.; de Cos, C.; Ollero, A. Accurate control of Aerial Manipulators outdoors. A reliable and self-coordinated nonlinear approach. Aerosp. Sci. Technol. 2020, 99, 105731. [Google Scholar] [CrossRef]

- Rashad, R.; Bicego, D.; Jiao, R.; Sanchez-Escalonilla, S.; Stramigioli, S. Towards vision-based impedance control for the contact inspection of unknown generically-shaped surfaces with a fully-actuated uav. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 1605–1612. [Google Scholar]

- Gray, A.G.; Gonzalez, F.; Vanegas, F.; Galvez-Serna, J.; Morton, K. Design and Flight Testing of a UAV with a Robotic Arm. In Proceedings of the 2023 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2023; pp. 1–13. [Google Scholar]

- Meng, X.; He, Y.; Han, J. Hybrid Force/Motion Control and Implementation of an Aerial Manipulator towards Sustained Contact Operations. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 3678–3683. [Google Scholar]

- Rashad, R.; Goerres, J.; Aarts, R.G.; Engelen, J.B.; Stramigioli, S. Fully Actuated Multirotor UAVs: A Literature Review. IEEE Robot. Autom. Mag. 2020, 27, 97–107. [Google Scholar] [CrossRef]

- Susanto, T.; Setiawan, M.B.; Jayadi, A.; Rossi, F.; Hamdhi, A.; Sembiring, J.P. Application of Unmanned Aircraft PID Control System for Roll, Pitch and Yaw Stability on Fixed Wings. In Proceedings of the 2021 International Conference on Computer Science, Information Technology, and Electrical Engineering (ICOMITEE), Banyuwangi, Indonesia, 27–28 October 2021; pp. 186–190. [Google Scholar]

- Yu, Z.; Zhang, Y.; Jiang, B.; Su, C.-Y.; Fu, J.; Jin, Y.; Chai, T. Fractional order PID-based adaptive fault-tolerant cooperative control of networked unmanned aerial vehicles against actuator faults and wind effects with hardware-in-the-loop experimental validation. Control Eng. Pract. 2021, 114, 104861. [Google Scholar] [CrossRef]

- Shankaran, V.P.; Azid, S.I.; Mehta, U.; Fagiolini, A. Improved Performance in Quadrotor Trajectory Tracking Using MIMO PIλ-D Control. IEEE Access 2022, 10, 110646–110660. [Google Scholar] [CrossRef]

- Jiang, G.; Voyles, R.M.; Choi, J.J. Precision fully-actuated uav for visual and physical inspection of structures for nuclear decommissioning and search and rescue. In Proceedings of the 2018 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Philadelphia, PA, USA, 6–8 August 2018; pp. 1–7. [Google Scholar]

- Song, P.; Yu, Y.; Zhang, X. A tutorial survey and comparison of impedance control on robotic manipulation. Robotica 2019, 37, 801–836. [Google Scholar] [CrossRef]

- Jiao, R.; Rashad, R.; Bicego, D.; Chou, W.; Stramigioli, S. Observer-based Geometric Impedance Control of a Fully-Actuated Hexarotor for Physical Sliding Interaction with Unknown Generic Surfaces. J. Intell. Robot. Syst. 2021, 102, 1–18. [Google Scholar] [CrossRef]

- Rashad, R.; Bicego, D.; Zult, J.; Sanchez-Escalonilla, S.; Jiao, R.; Franchi, A.; Stramigioli, S. Energy aware impedance control of a flying end-effector in the port-hamiltonian framework. IEEE Trans. Robot. 2022, 38, 3936–3955. [Google Scholar] [CrossRef]

- Hallworth, B. Adaptive Impedance Control for Physical Human-Robot Interaction with a Tethered UAV. Master’s Thesis, ETH Zurich, Zurich, Switzerland, 2023. [Google Scholar]

- Marković, L.; Car, M.; Orsag, M.; Bogdan, S. Adaptive stiffness estimation impedance control for achieving sustained contact in aerial manipulation. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 117–123. [Google Scholar]

- Ryll, M.; Muscio, G.; Pierri, F.; Cataldi, E.; Antonelli, G.; Caccavale, F.; Bicego, D.; Franchi, A. 6D interaction control with aerial robots: The flying end-effector paradigm. Int. J. Robot. Res. 2019, 38, 1045–1062. [Google Scholar] [CrossRef]

- Cataldi, E.; Muscio, G.; Trujillo, M.A.; Rodr´ıguez, Y.; Pierri, F.; Antonelli, G.; Caccavale, F.; Viguria, A.; Chiaverini, S.; Ollero, A. Impedance control of an aerial-manipulator: Preliminary results. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 3848–3853. [Google Scholar]

- Bodie, K.; Brunner, M.; Pantic, M.; Walser, S.; Pfändler, P.; Angst, U.; Siegwart, R.; Nieto, J. An omnidirectional aerial manipulation platform for contact-based inspection. arXiv 2019, arXiv:1905.03502. [Google Scholar]

- Bodie, K.; Brunner, M.; Pantic, M.; Walser, S.; Pfändler, P.; Angst, U.; Siegwart, R.; Nieto, J. Active Interaction Force Control for Omnidirectional Aerial Contact-Based Inspection. arXiv 2020, arXiv:2003.09516. [Google Scholar]

- Manzoor, T.; Sun, Z.; Xia, Y.; Ma, D. MPC based compound flight control strategy for a ducted fan aircraft. Aerosp. Sci. Technol. 2020, 107, 106264. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, Z.; Li, Y. Fuzzy adaptive nonlinear information fusion model predictive attitude control of unmanned rotorcrafts. Aerosp. Sci. Technol. 2020, 98, 105686. [Google Scholar] [CrossRef]

- Brunner, M.; Bodie, K.; Kamel, M.; Pantic, M.; Zhang, W.; Nieto, J.; Siegwart, R. Trajectory tracking nonlinear model predictive control for an overactuated mav. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 5342–5348. [Google Scholar]

- Bicego, D.; Mazzetto, J.; Carli, R.; Farina, M.; Franchi, A. Nonlinear model predictive control with enhanced actuator model for multi-rotor aerial vehicles with generic designs. J. Intell. Robot. Syst. 2020, 100, 1213. [Google Scholar] [CrossRef]

- Kocer, B.B.; Tjahjowidodo, T.; Seet, G.G.L. Model predictive uav-tool interaction control enhanced by external forces. Mechatronics 2019, 58, 47–57. [Google Scholar] [CrossRef]

- Kocer, B.B.; Tjahjowidodo, T.; Pratama, M.; Seet, G.G.L. Inspection-while-flying: An autonomous contact-based nondestructive test using UAV-tools. Autom. Constr. 2019, 106, 102895. [Google Scholar] [CrossRef]

- Bednarczyk, M.; Omran, H.; Bayle, B. Model Predictive Impedance Control. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 4702–4708. [Google Scholar]

- Nava, G.; Sablé, Q.; Tognon, M.; Pucci, D.; Franchi, A. Direct Force Feedback Control and Online Multi-task Optimization for Aerial Manipulators. IEEE Robot. Autom. Lett. 2019, 5, 331. [Google Scholar] [CrossRef]

- Emami, S.A.; Banazadeh, A. Simultaneous trajectory tracking and aerial manipulation using a multi-stage model predictive control. Aerosp. Sci. Technol. 2021, 112, 106573. [Google Scholar] [CrossRef]

- Tomi´c, T.; Lutz, P.; Schmid, K.; Mathers, A.; Haddadin, S. Simultaneous contact and aerodynamic force estimation (s-CAFE) for aerial robots. Int. J. Robot. Res. 2020, 39, 688. [Google Scholar] [CrossRef]

- Guo, K.; Jia, J.; Yu, X.; Guo, L.; Xie, L. Multiple observers based anti-disturbance control for a quadrotor UAV against payload and wind disturbances. Control Eng. Pract. 2020, 102, 104560. [Google Scholar] [CrossRef]

- dos Santos, W.M.; Siqueira, A.A. Optimal impedance via model predictive control for robot-aided rehabilitation. Control Eng. Pract. 2019, 93, 104177. [Google Scholar] [CrossRef]

- Taherian, S.; Halder, K.; Dixit, S.; Fallah, S. Autonomous collision avoidance using MPC with LQR-based weight transformation. Sensors 2021, 21, 4296. [Google Scholar] [CrossRef]

- Zhang, B.; Zong, C.; Chen, G.; Zhang, B. Electrical vehicle path tracking based model predictive control with a laguerre function and exponential weight. IEEE Access 2019, 7, 17082–17097. [Google Scholar] [CrossRef]

- Parra, A.; Tavernini, D.; Gruber, P.; Sorniotti, A.; Zubizarreta, A.; Perez, J. On nonlinear model predictive control for energy-efficient torque-vectoring. IEEE Trans. Veh. Technol. 2020, 70, 173–188. [Google Scholar] [CrossRef]

- Meier, L.; Honegger, D.; Pollefeys, M. PX4: A node-based multithreaded open source robotics framework for deeply embedded platforms. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 6235–6240. [Google Scholar]

- Ferreau, H.J.; Kirches, C.; Potschka, A.; Bock, H.G.; Diehl, M. qpOASES: A parametric active-set algorithm for quadratic programming. Math. Program. Comput. 2014, 6, 327–363. [Google Scholar] [CrossRef]

| Control Input | Parameter | Constraint Variable | Description |

|---|---|---|---|

| , , | Force around the x axis | ||

| , , | Force around the y axis | ||

| , , | Force around the z axis | ||

| , , | Torque around the x axis | ||

| , , | Torque around the y axis | ||

| , , | Torque around the z axis |

| Parameter | Value | Unit |

|---|---|---|

| m | 1.8 | Kg |

| 0.05 | ||

| 0.05 | ||

| 0.09 | ||

| l | 0.34 | m |

| d | 0.04 | m |

| deg | ||

| 0.014 | m | |

| L | 0.7 | m |

| Parameter | Value |

|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, R.; Li, J.; Rong, Y.; Hou, T. Nonlinear Model Predictive Impedance Control of a Fully Actuated Hexarotor for Physical Interaction. Sensors 2023, 23, 5231. https://doi.org/10.3390/s23115231

Jiao R, Li J, Rong Y, Hou T. Nonlinear Model Predictive Impedance Control of a Fully Actuated Hexarotor for Physical Interaction. Sensors. 2023; 23(11):5231. https://doi.org/10.3390/s23115231

Chicago/Turabian StyleJiao, Ran, Jianfeng Li, Yongfeng Rong, and Taogang Hou. 2023. "Nonlinear Model Predictive Impedance Control of a Fully Actuated Hexarotor for Physical Interaction" Sensors 23, no. 11: 5231. https://doi.org/10.3390/s23115231

APA StyleJiao, R., Li, J., Rong, Y., & Hou, T. (2023). Nonlinear Model Predictive Impedance Control of a Fully Actuated Hexarotor for Physical Interaction. Sensors, 23(11), 5231. https://doi.org/10.3390/s23115231