Secure and Reliable Big-Data-Based Decision Making Using Quantum Approach in IIoT Systems

Abstract

1. Introduction

2. Related Work

2.1. Existing Studies

2.2. Key Considerations

- Scalability: Smart factories and industries, in general, rely on big data collected from different sectors. The heterogeneity of the data contributes to the complexity of the system. The more data there is to be processed, the more time it will take to classify and the more complex the system will be. Thus, creating a scalable computational system for smart factories and industries to use is required to maintain the fast-growing needs of smart factories, and quantum algorithms can surely ensure that.

- Efficiency: The efficiency of the big data processing phase is another condemnatory demand for developed smart factories. Yet, the large amount of data facing smart factories is not allowing the system to be efficient enough. Smart factories should be able to classify the acquired data efficiently in order to process it and extract the required information for smart factory development. The current solutions using classical computers and algorithms are struggling to manage these data, which leads to more processing time and less effective results. To this end, we believe that quantum computers and quantum-based algorithms can be a suitable solution for today and future smart factories.

- Integrity: Currently, data breaches are the most critical problem facing the security of smart factories around the world. Mostly, data theft and breaches happen during the processing phase at the server level, where smart factory-related data, such as product information or personalized customer information, are stored [8,9]. Moreover, data manipulation can cause severe losses to smart factories. Surprisingly, even tech giants such as Facebook have been through this issue, and it costs them millions of dollars to gain the trust of their clients back. In the case of the finance industry, such as banks, data theft and breaches can be critical as they can lead to the exposure of sensitive information, such as monetary transactions and credit card information, to the public. Using quantum-based cryptography, we can enhance the security of smart factories and ensure the privacy and security of their data during the processing phase.

- Availability: Smart factories should be able to access their data and results anywhere and at any time; ensuring the availability of information and data is critical to various smart factories and industries. To this end, securing smart factory servers from cyberattacks such as DDoS is essential [10,11].

3. Proposed Quantum Approach for Secure Decision Making in IIoT-Based Smart Factory System

3.1. General System Overview

- Device layer: The first layer of our proposed system is the device layer; The first layer of our proposed system is the device layer; it holds different IoT devices and data sources that smart factories are using to collect data based on their needs. These data include personal information and customers, such as name, gender, IP address, and identification number. The second type of collected data is engagement and behavioral data. These data help smart factories to understand their clients and personalize unique products and commercials for them, which is regarded as the most essential information that almost every smart factory relies on in the era of social platforms. Another type of data that can be collected is regarding the smart factory itself, such as data related to production collected from manufacturers or related to products, logistics, and shipping.

- Edge Layer: The second layer in the proposed system is the edge layer. In this layer, we implement quantum terminals, which are small quantum processors with a minimum of one qubit size that are capable of converting classical bits representing data obtained from the device layer into qubits that are understandable by the quantum cloud server at the cloud layer. This method eliminates the need for quantum programmers or quantum specialists and automatically performs the required quantum computations at the cloud layer for optimized and efficient smart factory decision making. The deployed method at this layer has been proved previously in our published paper [4].

- Edge Layer: At the edge layer, we implement a hybrid quantum–classical model, which is capable of performing hybrid computations; that is, if a certain operation does not require quantum processing, it can immediately perform using classical machine learning methods, which contributes to a much faster and more scalable system. Moreover, the proposed model can be used in quantum machine learning in order to optimize performance. More details about this model are discussed below when we discuss the case study of QNN.

- Cloud Layer: The final layer in the proposal is the cloud layer where the quantum server resides. The quantum server at the cloud layer is powered by quantum machines to perform all sorts of requested computations from the smart factory client. The requested analyses are executed exponentially faster, are scalable, and are more efficient than any classical computer.

3.2. Quantum Application for Smart Factory Development

4. Case Study and Evaluation

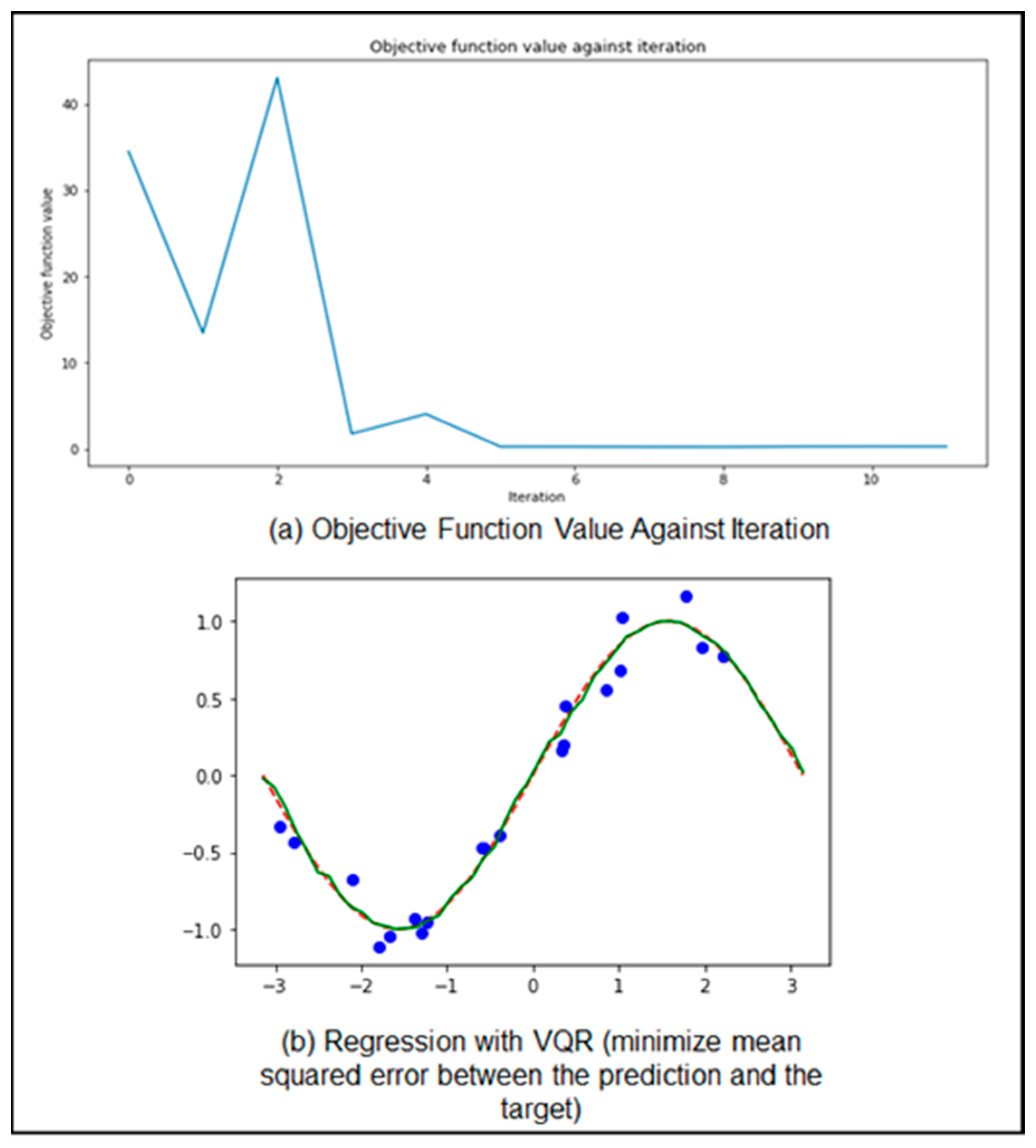

4.1. QNN-Based Financial Forecast in Smart Factory

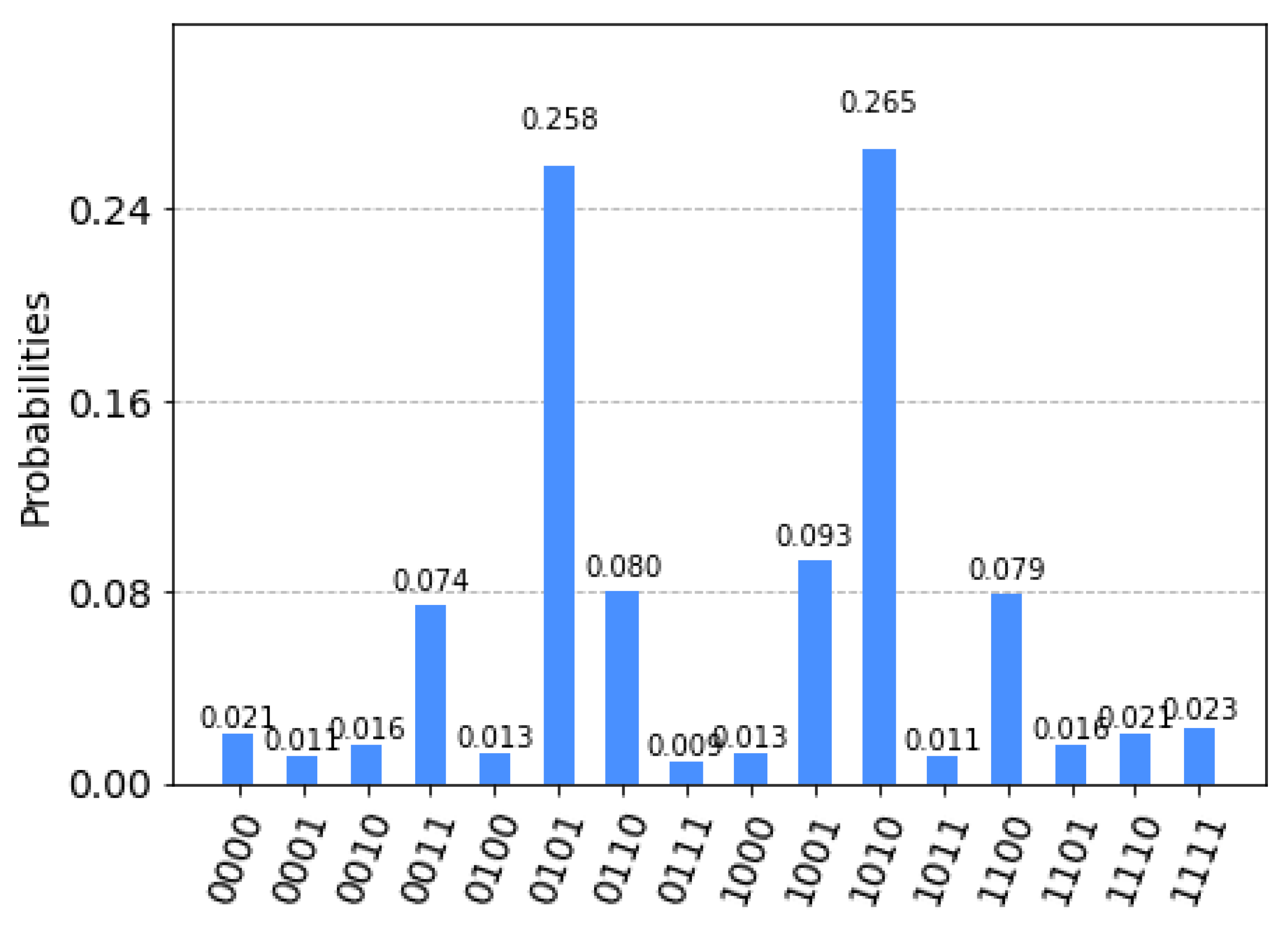

4.2. Quantum Machine Learning for Optimized Route Selection in Smart Logistics

5. Open Research Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | Description |

| QIS | Quantum Information System |

| QA | Quantum Annealing |

| AE | Amplitude Estimation |

| QAE | Quantum Amplitude Estimation |

| M | Number of Quantum samples |

| QAOA | Quantum Approximate Optimization Algorithm |

| QNN | Quantum Neural Network |

| QRG | Quantum Rotation Gate |

| VQC | Variational Quantum Classifier |

| QMT | Quantum Machine Terminal |

| Hamiltonian problem | |

| Mixer Hamiltonian | |

| U | Unitary Gate |

| Pauli-Z Gate | |

| Identity Matrix | |

| Pauli-X Gate |

References

- Industrial Revolution. The Editora of Encyclopedia Britannica. Available online: https://www.britannica.com/event/Industrial-Revolution (accessed on 12 March 2023).

- Chen, H.; Chiang, R.H.; Storey, V.C. Smart factory intelligence and analytics: From big data to big impact. MIS Q. 2012, 36, 1165–1188. [Google Scholar] [CrossRef]

- What Is Quantum Computing? Definition, Industry Trends, & Benefits Explained. CB Insight, Research Report. 7 January 2021. Available online: https://www.cbinsights.com/research/report/quantum-computing/ (accessed on 12 March 2023).

- Azzaoui, A.E.L.; Sharma, P.K.; Park, J.H. Blockchain-based delegated Quantum Cloud architecture for medical big data security. J. Netw. Comput. Appl. 2022, 198, 103304. [Google Scholar] [CrossRef]

- Luckow, A.; Klepsch, J.; Pichlmeier, J. Quantum computing: Towards industry reference problems. Digit. Welt 2021, 5, 38–45. [Google Scholar] [CrossRef]

- Yarkoni, S.; Raponi, E.; Bäck, T.; Schmitt, S. Quantum annealing for industry applications: Introduction and review. Rep. Prog. Phys. 2022, 85, 104001. [Google Scholar] [CrossRef]

- Egger, D.J.; Gambella, C.; Marecek, J.; McFaddin, S.; Mevissen, M.; Raymond, R.; Simonetto, A.; Woerner, S.; Yndurain, E. Quantum computing for finance: State-of-the-art and future prospects. IEEE Trans. Quantum Eng. 2020, 1, 1–24. [Google Scholar] [CrossRef]

- Sen, P.; Bhatia, A.S.; Bhangu, K.S.; Elbeltagi, A. Variational quantum classifiers through the lens of the Hessian. PLoS ONE 2022, 17, e0262346. [Google Scholar] [CrossRef]

- Azzaoui, A.E.; Kim, T.W.; Pan, Y.; Park, J.H. A Quantum Approximate Optimization Algorithm Based on Blockchain Heuristic Approach for Scalable and Secure Smart Logistics Systems. Hum.-Cent. Comput. Inf. Sci. 2021, 11, 46. [Google Scholar]

- Mammeri, Z. Reinforcement Learning Based Routing in Networks: Review and Classification of Approaches. IEEE Access 2019, 7, 55916–55950. [Google Scholar] [CrossRef]

- Shao, Y.; Rezaee, A.; Liew, S.C.; Chan, V.W.S. Significant Sampling for Shortest Path Routing: A Deep Reinforcement Learning Solution. IEEE J. Sel. Areas Commun. 2020, 38, 2234–2248. [Google Scholar] [CrossRef]

- Gilyén, A.; Arunachalam, S.; Wiebe, N. Optimizing quantum optimization algorithms via faster quantum gradient computation. In Proceedings of the Thirtieth Annual ACM-SIAM Symposium on Discrete Algorithms. Society for Industrial and Applied Mathematics, San Diego, CA, USA, 6–9 January 2019. [Google Scholar]

- Lacroix, N.; Hellings, C.; Andersen, C.K.; Di Paolo, A.; Remm, A.; Lazar, S.; Krinner, S.; Norris, G.J.; Gabureac, M.; Heinsoo, J.; et al. Improving the performance of deep quantum optimization algorithms with continuous gate sets. PRX Quantum 2020, 1, 110304. [Google Scholar] [CrossRef]

- Stilck França, D.; Garcia-Patron, R. Limitations of optimization algorithms on noisy quantum devices. Nat. Phys. 2021, 17, 1221–1227. [Google Scholar] [CrossRef]

- Willsch, M.; Willsch, D.; Jin, F.; De Raedt, H.; Michielsen, K. Benchmarking the quantum approximate optimization algorithm. Quantum Inf. Process. 2020, 19, 197. [Google Scholar] [CrossRef]

- Bravyi, S.; Kliesch, A.; Koenig, R.; Tang, E. Obstacles to variational quantum optimization from symmetry protection. Phys. Rev. Lett. 2020, 125, 260505. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.J.; El Azzaoui, A.; Park, J.H. MetaQ: A Quantum Approach for Secure and Optimized Metaverse Environment. Hum.-Cent. Comput. Inf. Sci. 2022, 12, 42. [Google Scholar]

- Almodfer, R.; Mudhsh, M.; Chelloug, S.; Shehab, M.; Abualigah, L.; Abd Elaziz, M. Quantum mutation reptile search algorithm for global optimization and data clustering. Hum.-Cent. Comput. Inf. Sci. 2022, 12, 30. [Google Scholar]

- Silvestrini, P.; Amato, U.; Vettoliere, A.; Silvestrini, S.; Ruggiero, B. Rate equation leading to hype-type evolution curves: A mathematical approach in view of analysing technology development. Technol. Forecast. Soc. Chang. 2017, 116, 1–12. [Google Scholar] [CrossRef]

- Bi, J.; Sarpong, D.; Botchie, D.; Rao-Nicholson, R. From imitation to innovation: The discursive processes of knowledge creation in the Chinese space industry. Technol. Forecast. Soc. Chang. 2017, 120, 261–270. [Google Scholar] [CrossRef]

- Streif, M.; Leib, M. Training the quantum approximate optimization algorithm without access to a quantum processing unit. Quantum Sci. Technol. 2020, 5, 034008. [Google Scholar] [CrossRef]

- Crooks, G.E. Performance of the quantum approximate optimization algorithm on the maximum cut problem. arXiv 2018, arXiv:1811.08419. [Google Scholar]

- Li, L.; Fan, M.; Coram, M.; Riley, P.; Leichenauer, S. Quantum optimization with a novel gibbs objective function and ansatz architecture search. Phys. Rev. Res. 2020, 2, 023074. [Google Scholar] [CrossRef]

- Farhi, E.; Gamarnik, D.; Gutmann, S. The quantum approximate optimization algorithm needs to see the whole graph: A typical case. arXiv 2020, arXiv:2004.09002. [Google Scholar]

- Maheshwari, D.; Ullah, U.; Marulanda, P.A.O.; Jurado, A.G.O.; Gonzalez, I.D.; Merodio, J.M.O.; Garcia-Zapirain, B. Quantum Machine Learning Applied to Electronic Healthcare Records for Ischemic Heart Disease Classification. Hum.-Cent. Comput. Inf. Sci. 2023, 13, 06. [Google Scholar]

| Paper | Year | Scalability | Efficiency | Integrity | Availability |

|---|---|---|---|---|---|

| EL Azzaoui et al. [4] | 2022 | X | O | O | O |

| Luckow et al. [5] | 2021 | O | O | X | X |

| Yarkoni et al. [6] | 2022 | O | X | X | O |

| Egger et al. [7] | 2020 | O | O | X | X |

| Our contribution | 2023 | O | O | O | O |

| Task | Performance |

|---|---|

| Route Optimization Computing Latency | 8.6 (s) |

| Route Optimization Decision Latency | 5 (ms) |

| Successful Optimized Route Probability | 91% |

| System Scalability Improvement | 23% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

EL Azzaoui, A.; Salim, M.M.; Park, J.H. Secure and Reliable Big-Data-Based Decision Making Using Quantum Approach in IIoT Systems. Sensors 2023, 23, 4852. https://doi.org/10.3390/s23104852

EL Azzaoui A, Salim MM, Park JH. Secure and Reliable Big-Data-Based Decision Making Using Quantum Approach in IIoT Systems. Sensors. 2023; 23(10):4852. https://doi.org/10.3390/s23104852

Chicago/Turabian StyleEL Azzaoui, Abir, Mikail Mohammed Salim, and Jong Hyuk Park. 2023. "Secure and Reliable Big-Data-Based Decision Making Using Quantum Approach in IIoT Systems" Sensors 23, no. 10: 4852. https://doi.org/10.3390/s23104852

APA StyleEL Azzaoui, A., Salim, M. M., & Park, J. H. (2023). Secure and Reliable Big-Data-Based Decision Making Using Quantum Approach in IIoT Systems. Sensors, 23(10), 4852. https://doi.org/10.3390/s23104852

_Park.png)