A Self-Referenced Refractive Index Sensor Based on Gold Nanoislands

Abstract

1. Introduction

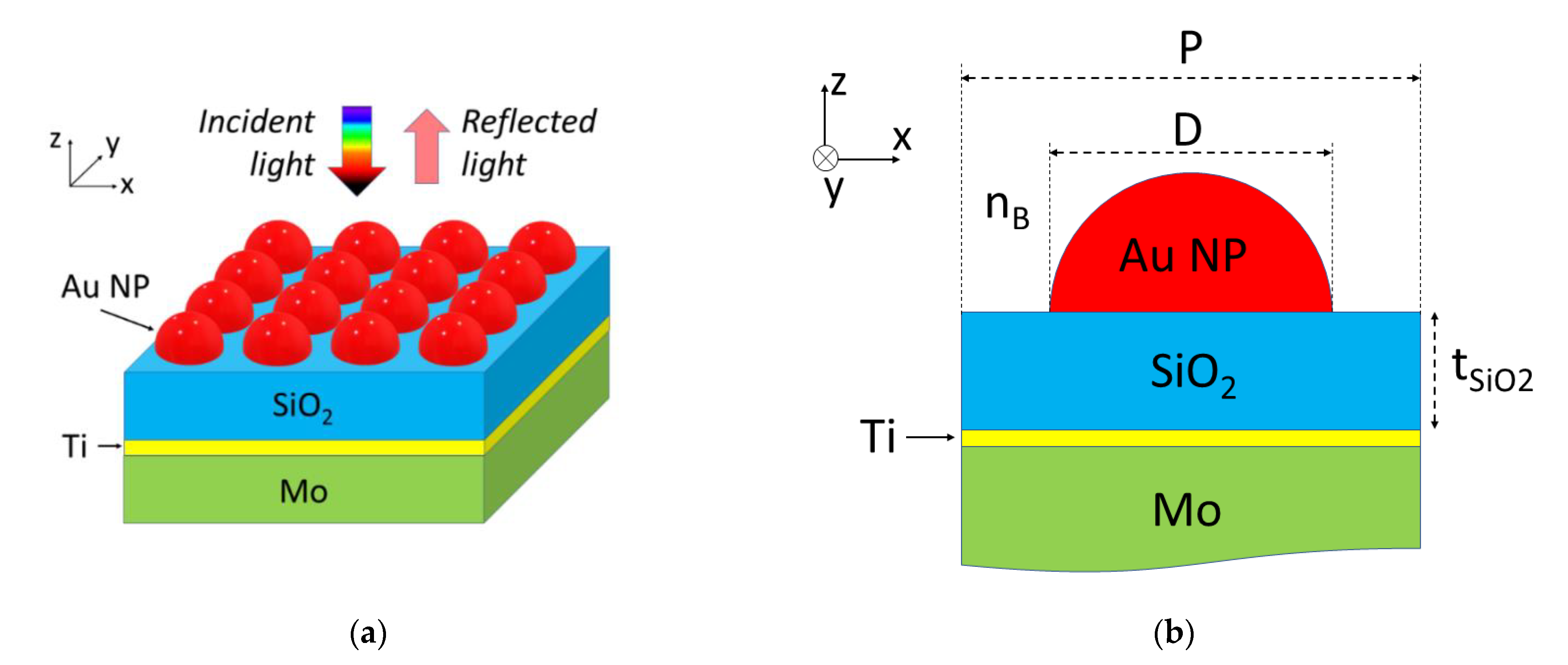

2. Experimental Section

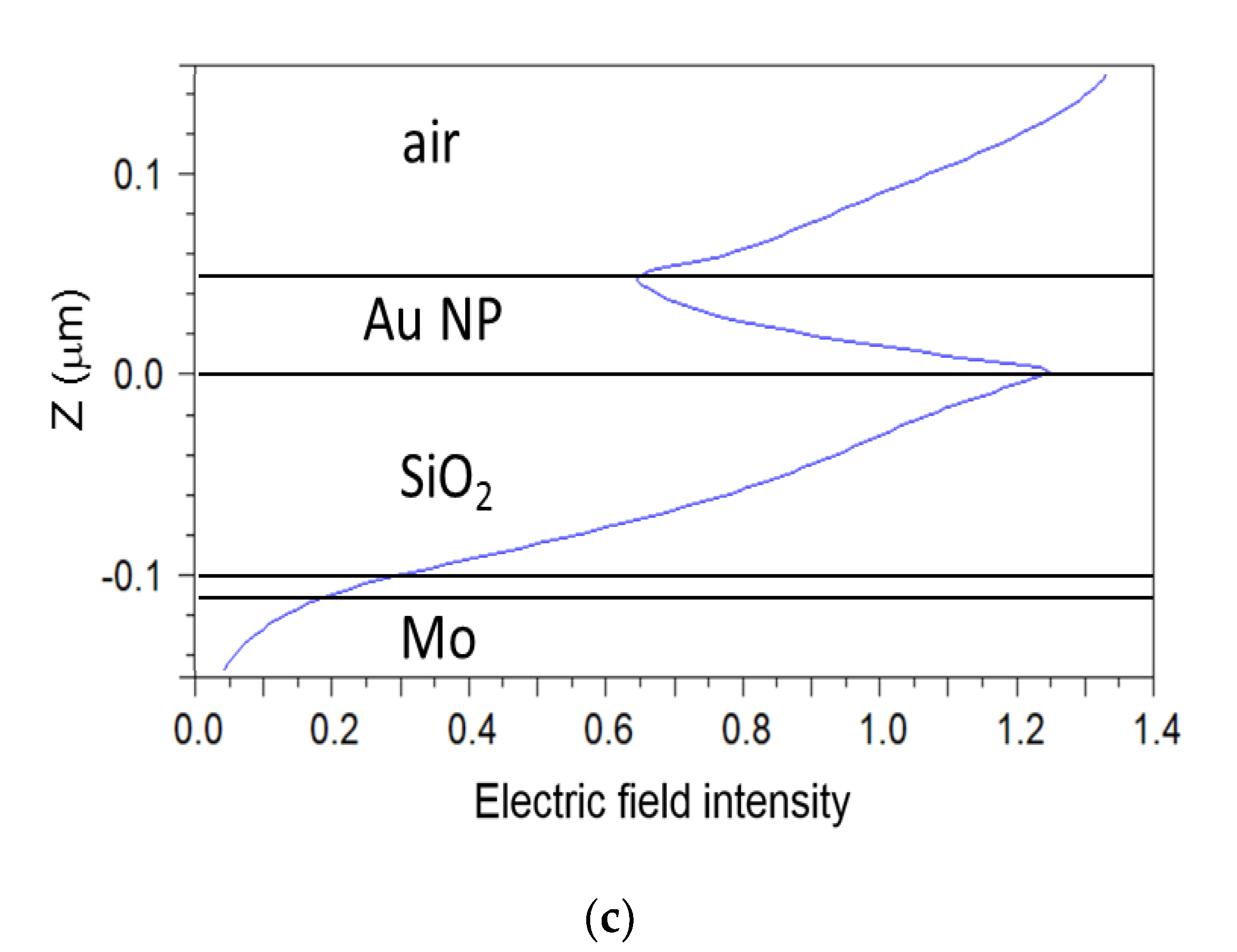

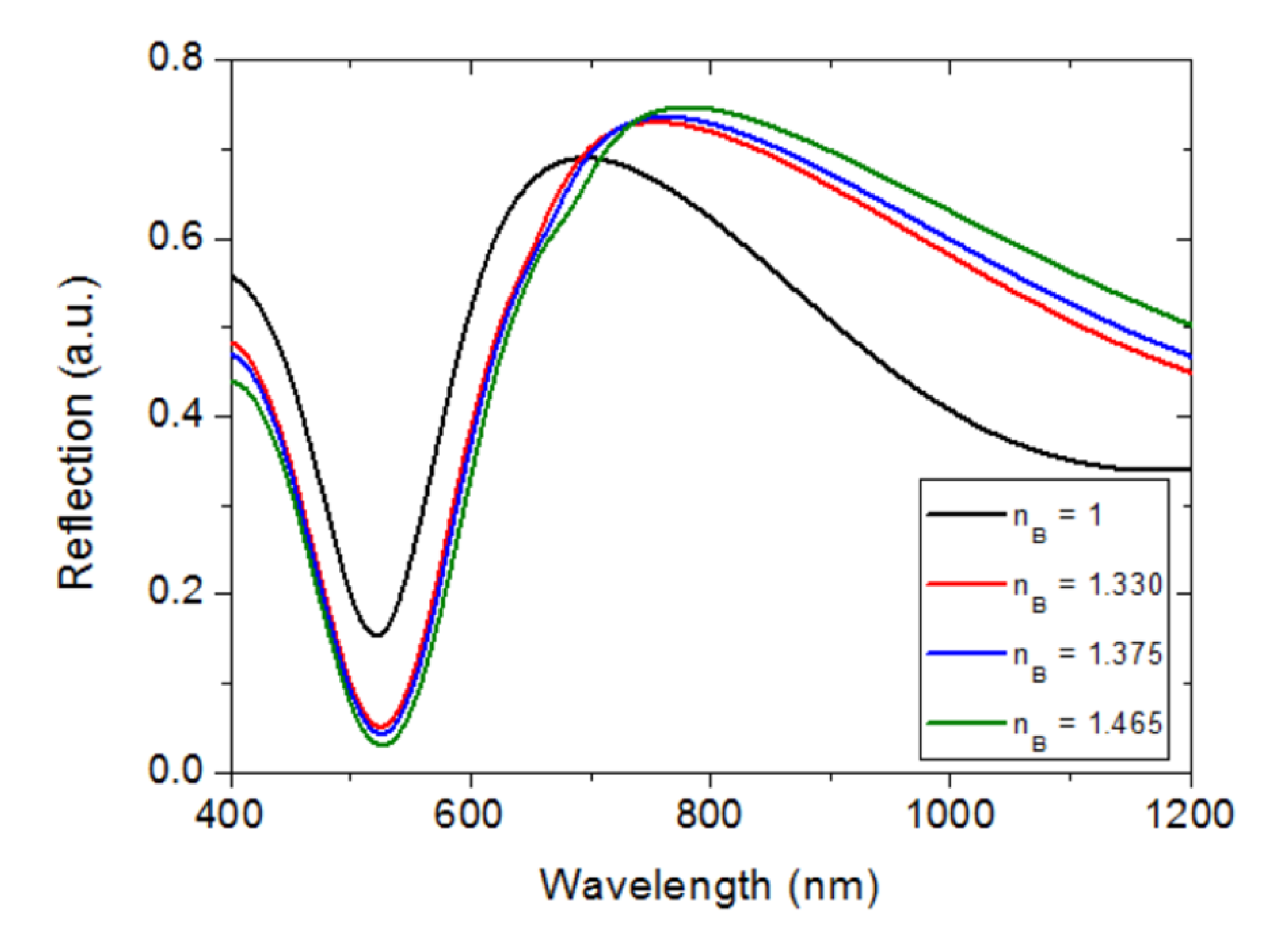

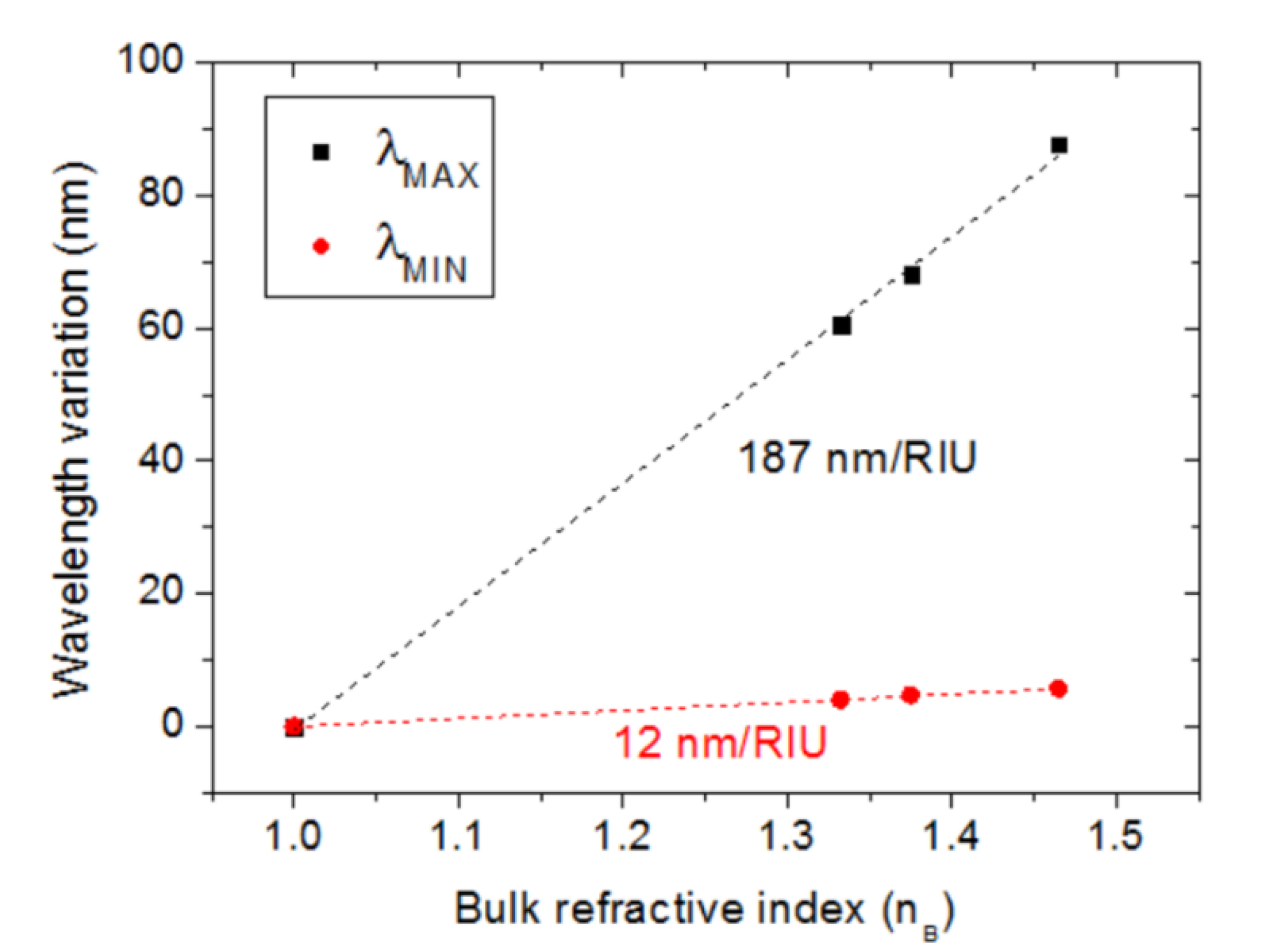

3. Optical Simulations

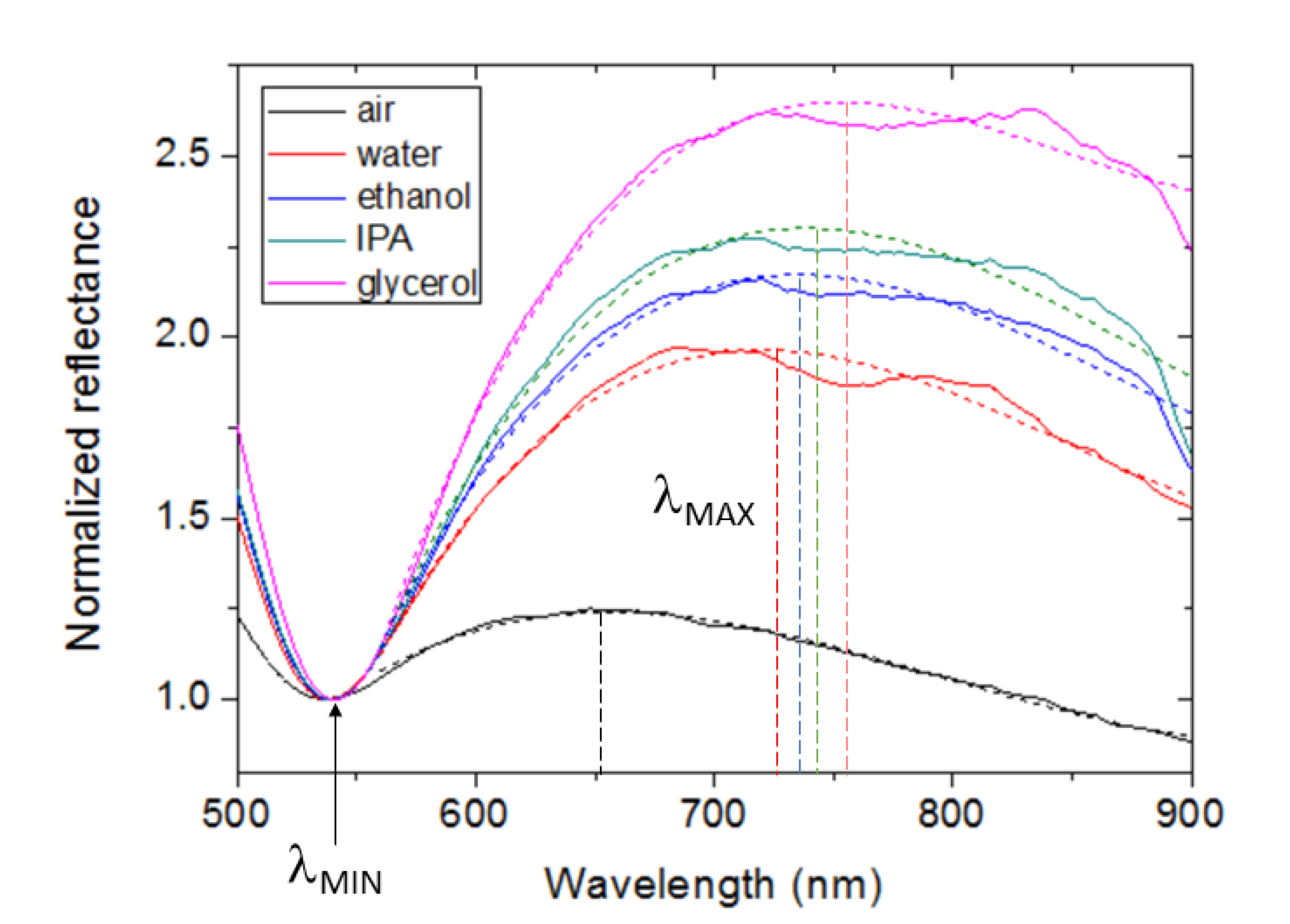

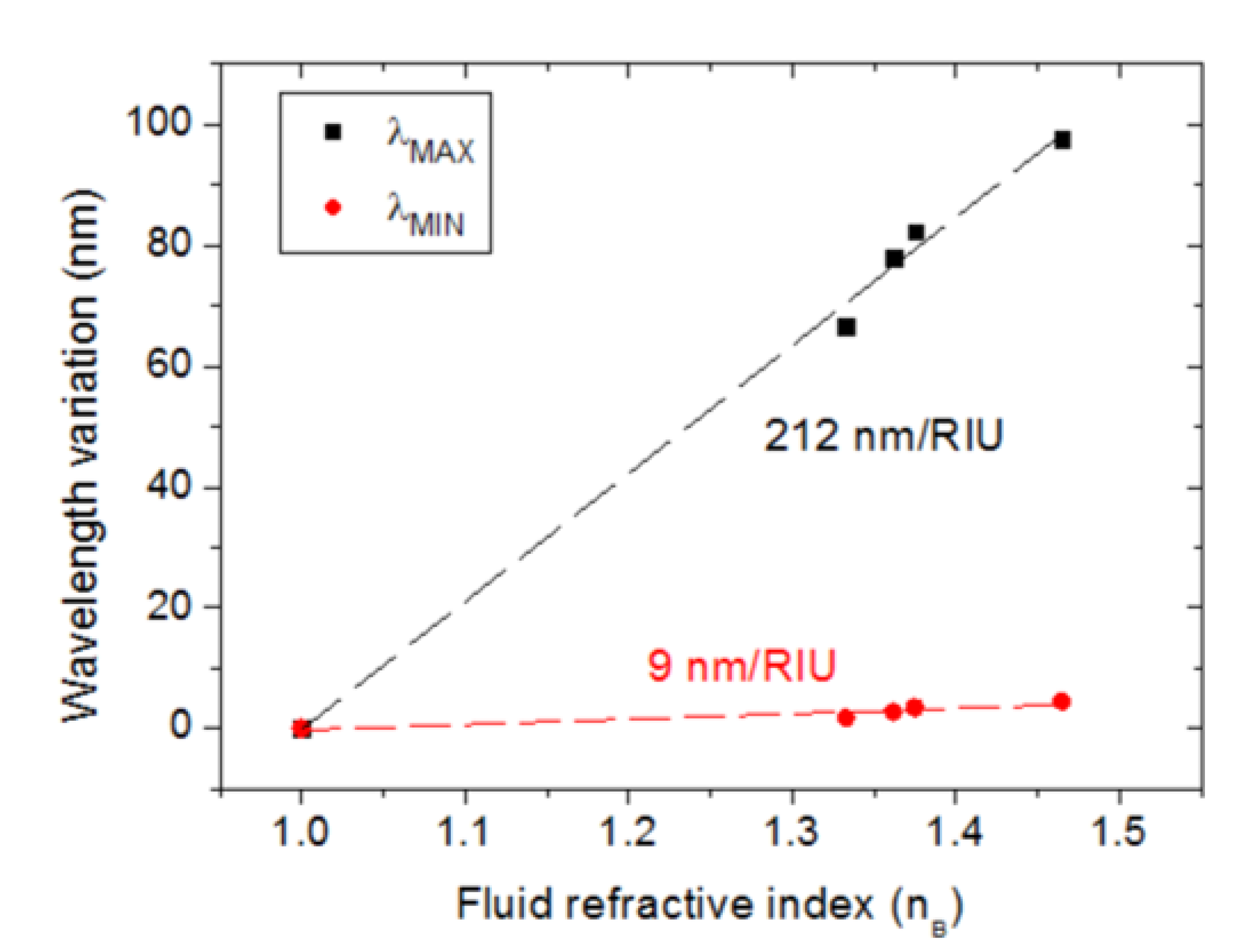

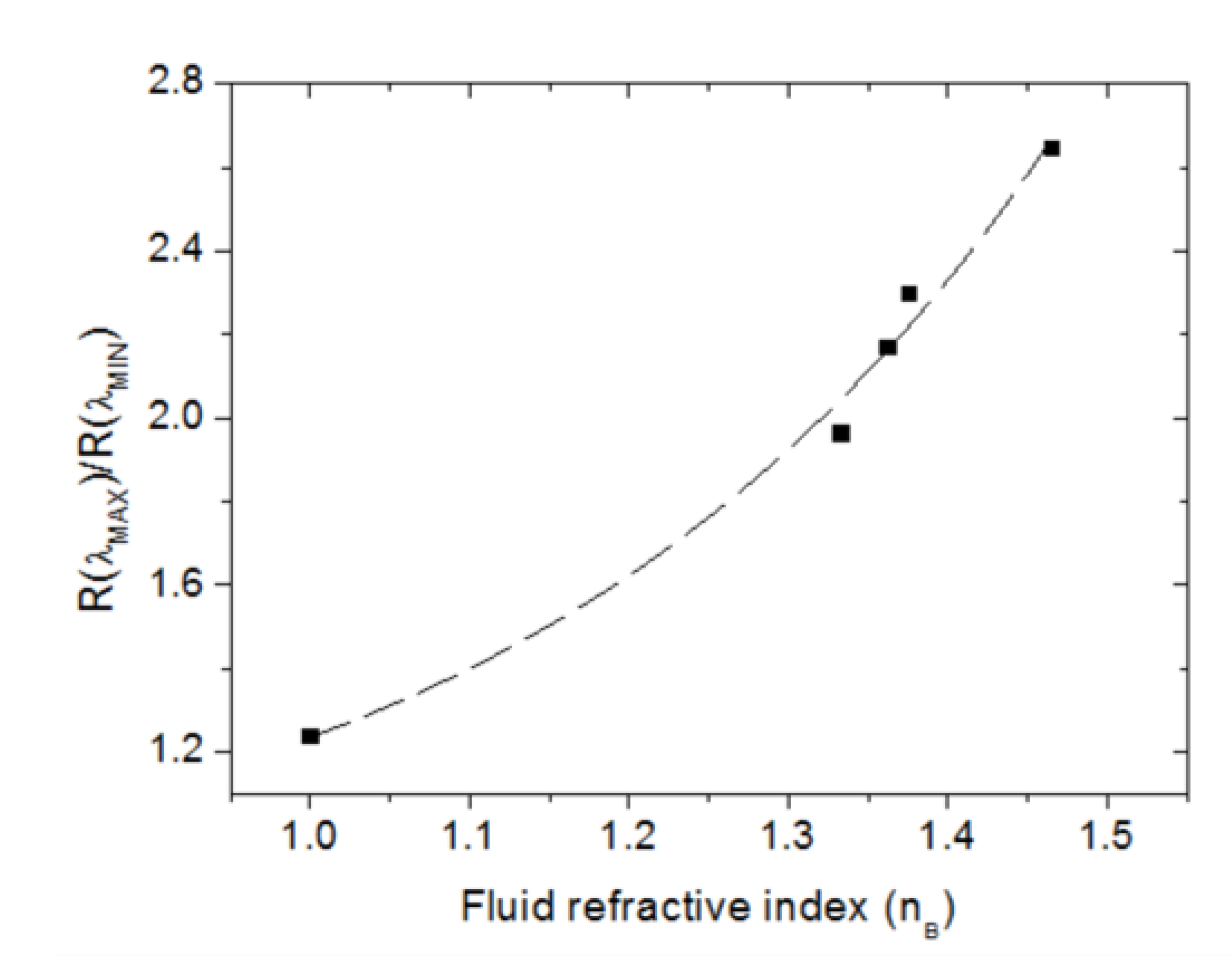

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Homola, J. Present and future of surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2003, 377, 528–539. [Google Scholar] [CrossRef] [PubMed]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; van Duyne, R.P. Biosensing with plasmonic nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar] [CrossRef] [PubMed]

- Piliarik, M.; Vaisocherová, H.; Homola, J. Surface Plasmon Resonance Biosensing. In Biosensors and Biodetection. Methods in Molecular Biology; Rasooly, A., Herold, K.E., Eds.; Humana Press: Totowa, NJ, USA, 2009; Volume 503, pp. 65–88. [Google Scholar] [CrossRef]

- Hill, R.T. Plasmonic biosensors. WIREs Nanomed. Nanobiotechnol. 2014, 7, 152–168. [Google Scholar] [CrossRef] [PubMed]

- Mejía-Salazar, J.R.; Oliveira, J.O.N. Plasmonic Biosensing. Chem. Rev. 2018, 118, 10617–10625. [Google Scholar] [CrossRef]

- Hamza, M.E.; Othman, M.A.; Swillam, M.A. Plasmonic Biosensors: Review. Biology 2022, 11, 621. [Google Scholar] [CrossRef]

- Homola, J. Surface Plasmon Resonance Based Sensors; Springer: Berlin/Heidelberg, Germany, 2006; pp. 26–29. [Google Scholar]

- Piliarik, M.; Homola, J. Surface plasmon resonance (SPR) sensors: Approaching their limits? Opt. Express 2009, 17, 16505–16517. [Google Scholar] [CrossRef]

- Park, J.-H.; Cho, Y.-W.; Kim, T.-H. Recent Advances in Surface Plasmon Resonance Sensors for Sensitive Optical Detection of Pathogens. Biosensors 2022, 12, 180. [Google Scholar] [CrossRef]

- Harris, R.; Wilkinson, J. Waveguide surface plasmon resonance sensors. Sensors Actuators B Chem. 1995, 29, 261–267. [Google Scholar] [CrossRef]

- Cullen, D.; Brown, R.; Lowe, C.R. Detection of immuno-complex formation via surface plasmon resonance on gold-coated diffraction gratings. Biosensors 1988, 3, 211–225. [Google Scholar] [CrossRef]

- Jory, M.; Vukusic, P.; Sambles, J. Development of a prototype gas sensor using surface plasmon resonance on gratings. Sensors Actuators B Chem. 1994, 17, 203–209. [Google Scholar] [CrossRef]

- Rossi, S.; Gazzola, E.; Capaldo, P.; Borile, G.; Romanato, F. Grating-Coupled Surface Plasmon Resonance (GC-SPR) Optimization for Phase-Interrogation Biosensing in a Microfluidic Chamber. Sensors 2018, 18, 1621. [Google Scholar] [CrossRef] [PubMed]

- Kedem, O.; Vaskevich, A.; Rubinstein, I. Critical Issues in Localized Plasmon Sensing. J. Phys. Chem. C 2014, 118, 8227–8244. [Google Scholar] [CrossRef]

- Unser, S.; Bruzas, I.; He, J.; Sagle, L. Localized Surface Plasmon Resonance Biosensing: Current Challenges and Approaches. Sensors 2015, 15, 15684–15716. [Google Scholar] [CrossRef] [PubMed]

- Haes, A.; Van Duyne, R.P. A unified view of propagating and localized surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2004, 379, 920–930. [Google Scholar] [CrossRef] [PubMed]

- Lereu, A.L.; Farahi, R.H.; Tetard, L.; Enoch, S.; Thundat, T.; Passian, A. Plasmon assisted thermal modulation in nanoparticles. Opt. Express 2013, 21, 12145–12158. [Google Scholar] [CrossRef] [PubMed]

- Mayer, K.M.; Hafner, J.H. Localized Surface Plasmon Resonance Sensors. Chem. Rev. 2011, 111, 3828–3857. [Google Scholar] [CrossRef] [PubMed]

- Cinel, N.A.; Bütün, S.; Özbay, E. Electron beam lithography designed silver nano-disks used as label free nano-biosensors based on localized surface plasmon resonance. Opt. Express 2012, 20, 2587–2597. [Google Scholar] [CrossRef]

- Lee, S.-W.; Lee, K.-S.; Ahn, J.; Lee, J.-J.; Kim, M.-G.; Shin, Y.-B. Highly Sensitive Biosensing Using Arrays of Plasmonic Au Nanodisks Realized by Nanoimprint Lithography. ACS Nano 2011, 5, 897–904. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, T.; Yamaguchi, I.; Kobayashi, T. Local plasmon sensor with gold colloid monolayers deposited upon glass substrates. Opt. Lett. 2000, 25, 372–374. [Google Scholar] [CrossRef]

- Nazri, N.A.A.; Azeman, N.H.; Abu Bakar, M.H.; Mobarak, N.N.; Luo, Y.; Arsad, N.; Aziz, T.H.T.A.; Zain, A.R.M.; Bakar, A.A.A. Localized Surface Plasmon Resonance Decorated with Carbon Quantum Dots and Triangular Ag Nanoparticles for Chlorophyll Detection. Nanomaterials 2021, 12, 35. [Google Scholar] [CrossRef] [PubMed]

- Ryu, K.R.; Kim, G.W.; Ha, J.W. Localized surface plasmon resonance inflection points for improved detection of chemisorption of 1-alkanethiols under total internal reflection scattering microscopy. Sci. Rep. 2021, 11, 12902. [Google Scholar] [CrossRef] [PubMed]

- Bin Jeon, H.; Tsalu, P.; Ha, J.W. Shape Effect on the Refractive Index Sensitivity at Localized Surface Plasmon Resonance Inflection Points of Single Gold Nanocubes with Vertices. Sci. Rep. 2019, 9, 13635. [Google Scholar] [CrossRef] [PubMed]

- Thompson, C.V. Solid-State Dewetting of Thin Films. Annu. Rev. Mater. Res. 2012, 42, 399–434. [Google Scholar] [CrossRef]

- Ozhikandathil, J.; Badilescu, S.; Packirisamy, M. Gold nanoisland structures integrated in a lab-on-a-chip for plasmonic detection of bovine growth hormone. J. Biomed. Opt. 2012, 17, 077001. [Google Scholar] [CrossRef] [PubMed]

- Jia, K.; Bijeon, J.-L.; Adam, P.-M.; Ionescu, R.E. Large Scale Fabrication of Gold Nano-Structured Substrates Via High Temperature Annealing and Their Direct Use for the LSPR Detection of Atrazine. Plasmonics 2013, 8, 143–151. [Google Scholar] [CrossRef]

- Ozhikandathil, J.; Packirisamy, M. Simulation and Implementation of a Morphology-Tuned Gold Nano-Islands Integrated Plasmonic Sensor. Sensors 2014, 14, 10497–10513. [Google Scholar] [CrossRef]

- Bhalla, N.; Jain, A.; Lee, Y.; Shen, A.Q.; Lee, D. Dewetting Metal Nanofilms—Effect of Substrate on Refractive Index Sensitivity of Nanoplasmonic Gold. Nanomaterials 2019, 9, 1530. [Google Scholar] [CrossRef]

- Chung, T.; Lee, Y.; Ahn, M.-S.; Lee, W.; Bae, S.-I.; Hwang, C.S.H.; Jeong, K.-H. Nanoislands as plasmonic materials. Nanoscale 2019, 11, 8651–8664. [Google Scholar] [CrossRef]

- Hastings, J.T.; Guo, J.; Keathley, P.D.; Kumaresh, P.B.; Wei, Y.; Law, S.; Bachas, L. Optimal self-referenced sensing using long- and short- range surface plasmons. Opt. Express 2007, 15, 17661–17672. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Verma, R.; Gupta, B.D. Theoretical modeling of a self-referenced dual mode SPR sensor utilizing indium tin oxide film. Opt. Commun. 2016, 369, 131–137. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, C.; Li, H.; Gong, Q.; Chen, J. Self-reference plasmonic sensors based on double Fano resonances. Nanoscale 2017, 9, 11085–11092. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Pandey A., K. Self-referenced plasmonic sensor with TiO2 grating on thin Au layer: simulated performance analysis in optical communication band. J. Opt. Soc. Am. B 2019, 36, F25–F31. [Google Scholar] [CrossRef]

- Sun, P.; Zhou, C.; Jia, W.; Wang, J.; Xiang, C.; Xie, Y.; Zhao, D. Self-referenced refractive index sensor based on hybrid mode resonances in 2D metal-dielectric grating. J. Phys. D Appl. Phys. 2019, 53, 145101. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, J.; Zhang, Y.; Ge, M.; Zhang, P.; Shen, J.; Li, C. Self-referenced refractive index sensor based on double-dips method with bimetal-dielectric and double-groove grating. Opt. Express 2022, 30, 8376. [Google Scholar] [CrossRef] [PubMed]

- Rakić, A.D.; Djurišić, A.B.; Elazar, J.M.; Majewski, M.L. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef]

- Technical Note. Drude Dispersion Model. Horiba. Available online: https://www.horiba.com/fileadmin/uploads/Scientific/Downloads/OpticalSchool_CN/TN/ellipsometer/Drude_Dispersion_Model.pdf (accessed on 5 May 2022).

- Rsoft Photonic Device Tools. Available online: https://www.synopsys.com/photonic-solutions/rsoft-photonic-device-tools.html (accessed on 21 December 2022).

- Huang, K.; Pan, W.; Zhu, J.F.; Li, J.C.; Gao, N.; Liu, C.; Ji, L.; Yu, E.T.; Kang, J. Asymmetric light reflectance from metal nanoparticle arrays on dielectric surfaces. Sci. Rep. 2015, 5, 18331. [Google Scholar] [CrossRef]

- Sun, Z.; Fang, Y. Fabry-Pérot Interference Cavity Length Tuned by Plasmonic Nanoparticle Metasurface for Nanophotonic Device Design. ACS Appl. Nano Mater. 2020, 3, 10732–10738. [Google Scholar] [CrossRef]

- Hägglund, C.; Zeltzer, G.; Ruiz, R.; Wangperawong, A.; Roelofs, K.E.; Bent, S.F. Strong Coupling of Plasmon and Nanocavity Modes for Dual-Band, Near-Perfect Absorbers and Ultrathin Photovoltaics. ACS Photonics 2016, 3, 456–463. [Google Scholar] [CrossRef]

- Ferhan, A.R.; Jackman, J.A.; Cho, N.-J. Integration of Quartz Crystal Microbalance-Dissipation and Reflection-Mode Localized Surface Plasmon Resonance Sensors for Biomacromolecular Interaction Analysis. Anal. Chem. 2016, 88, 12524–12531. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrios, C.A.; Mirea, T.; Represa, M.H. A Self-Referenced Refractive Index Sensor Based on Gold Nanoislands. Sensors 2023, 23, 66. https://doi.org/10.3390/s23010066

Barrios CA, Mirea T, Represa MH. A Self-Referenced Refractive Index Sensor Based on Gold Nanoislands. Sensors. 2023; 23(1):66. https://doi.org/10.3390/s23010066

Chicago/Turabian StyleBarrios, Carlos Angulo, Teona Mirea, and Miguel Huerga Represa. 2023. "A Self-Referenced Refractive Index Sensor Based on Gold Nanoislands" Sensors 23, no. 1: 66. https://doi.org/10.3390/s23010066

APA StyleBarrios, C. A., Mirea, T., & Represa, M. H. (2023). A Self-Referenced Refractive Index Sensor Based on Gold Nanoislands. Sensors, 23(1), 66. https://doi.org/10.3390/s23010066