Damage Detection for Conveyor Belt Surface Based on Conditional Cycle Generative Adversarial Network

Abstract

:1. Introduction

2. Related Work

2.1. Belt Surface Damage Detection Methods

2.2. Generative Adversarial Networks

2.3. Discussion

3. Materials and Methods

3.1. Basic Theory of Generative Adversarial Networks

3.2. The Framework of the Multi-Classification Conditional CycleGAN

3.3. The Detailed Improvements of the Proposed MCC-CycleGAN

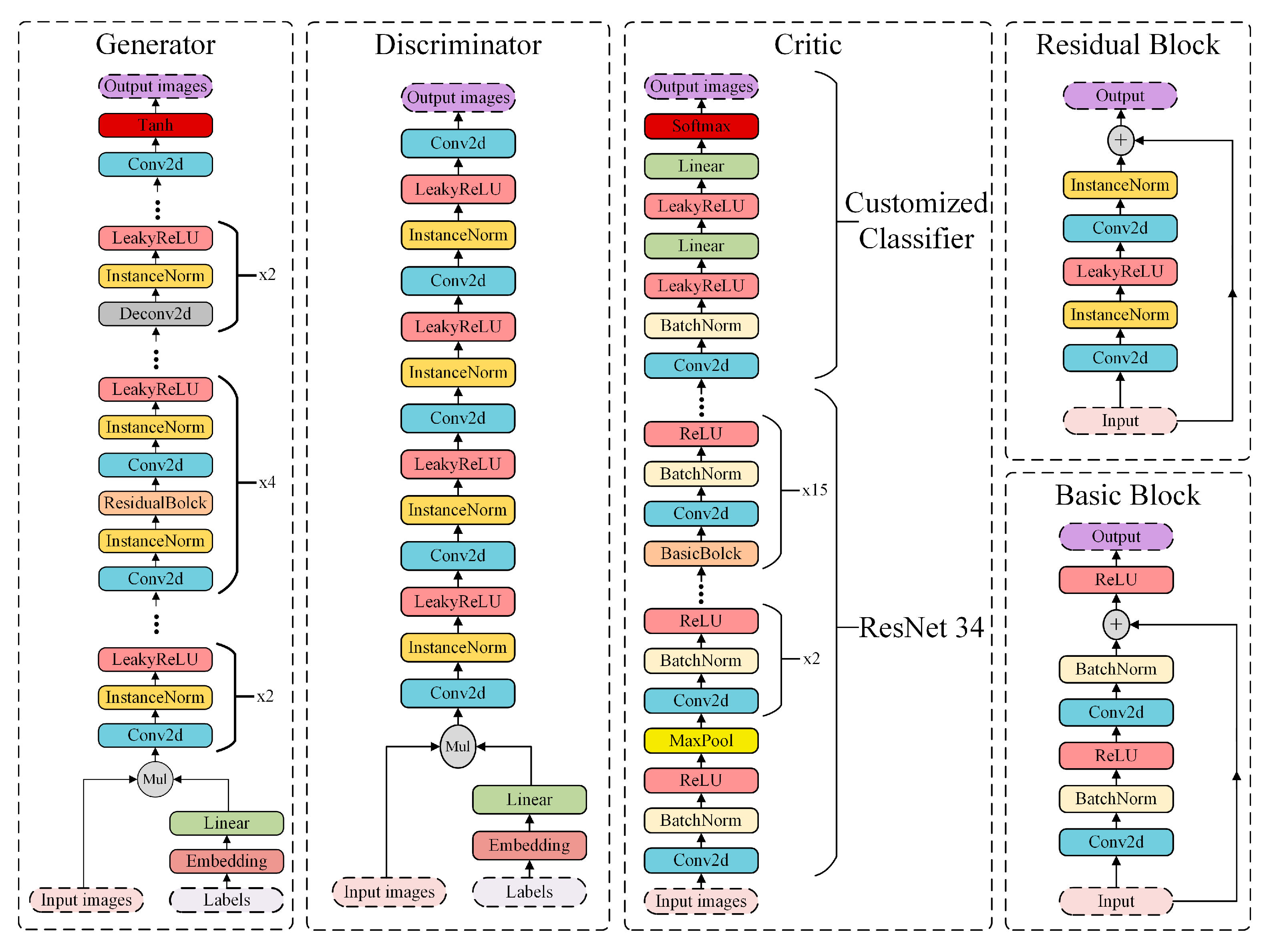

3.3.1. The Network Architectures of the MCC-CycleGAN

3.3.2. The Improved MCC-CycleGAN Loss Function

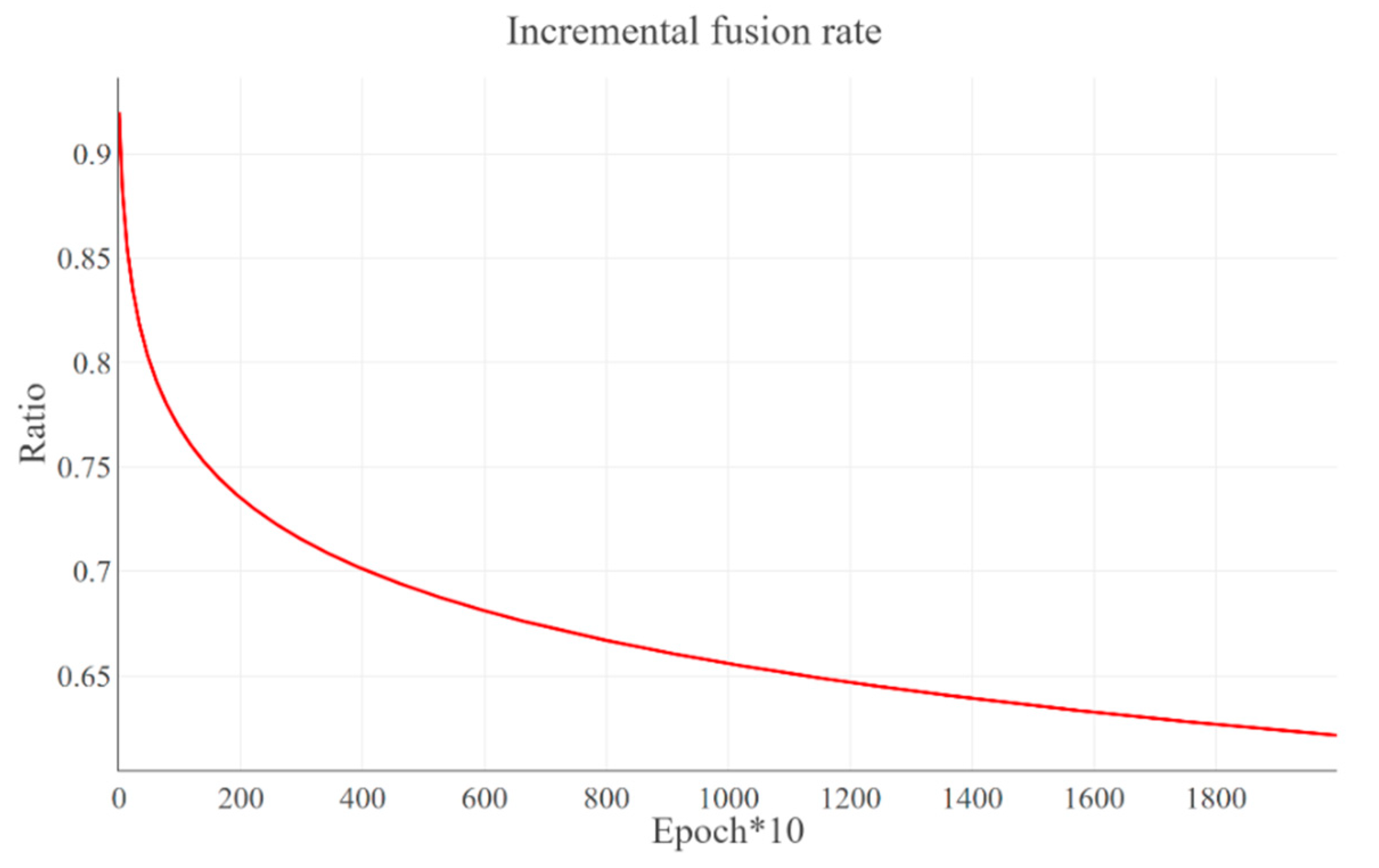

3.3.3. The Image Fusion Strategy of the MCC-CycleGAN

3.3.4. Feature Based Transfer Learning and Fine-Tuning

3.4. The Training Procedure of the MCC-CycleGAN

| Algorithm 1. MCC-CycleGAN training process. The pseudocode of the proposed network training process. | |

| 1: | Input:), location of dataset A and B |

| 2: | , setup optimizer: Adam, |

| 3: | For to do |

| 4: | For to do |

| 5: | Train , generate fake images |

| based | |

| based on Equation (3), then update parameters of | |

| 6: | end for |

| 7: | Train , generate fake images |

| based on | |

| 8: | Train based on Equation (8), feed |

| based on Equation (4), then update parameters | |

| 9: | end for |

4. Results

4.1. The Hardware Framework of the Conveyor Belt Damage Detection System

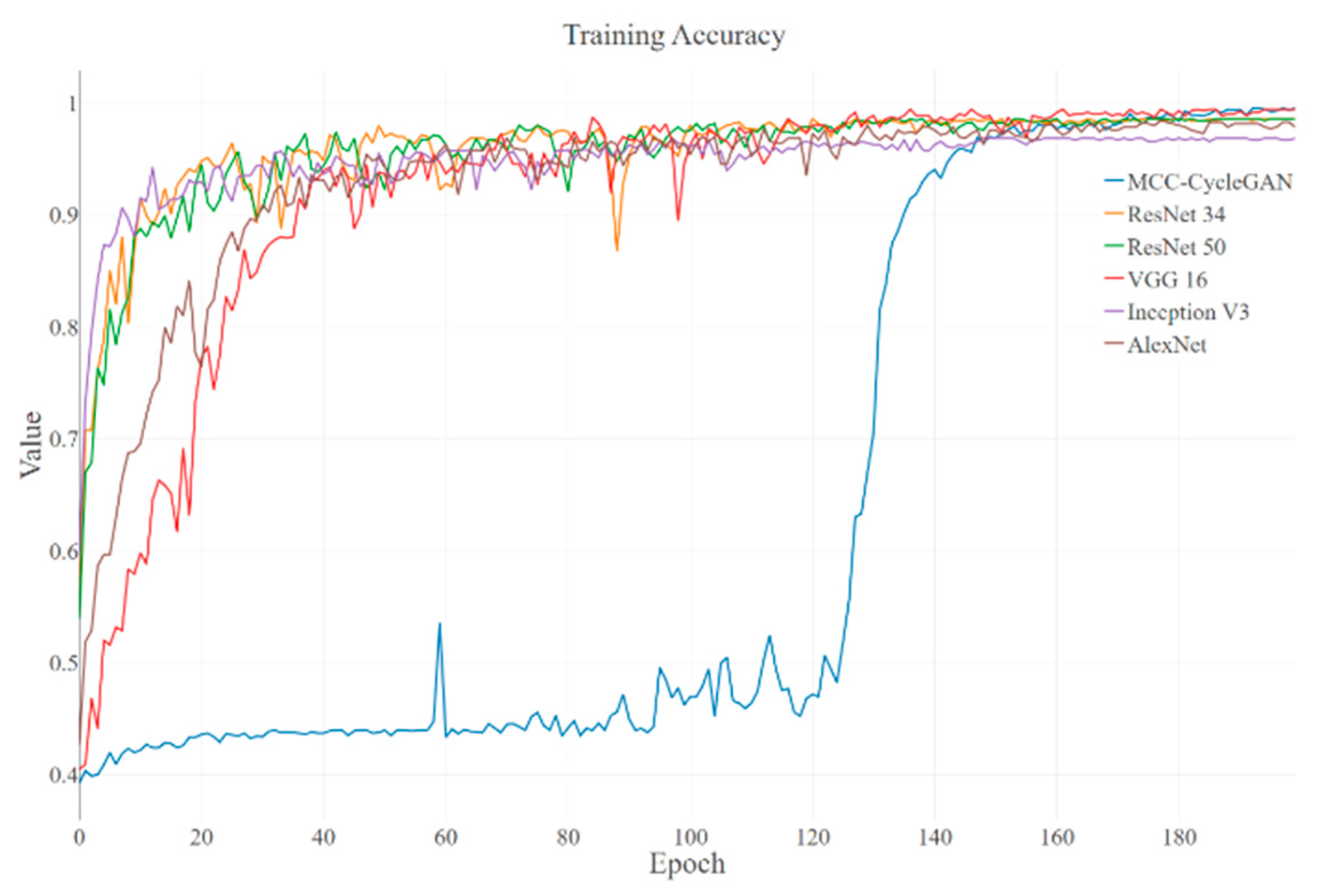

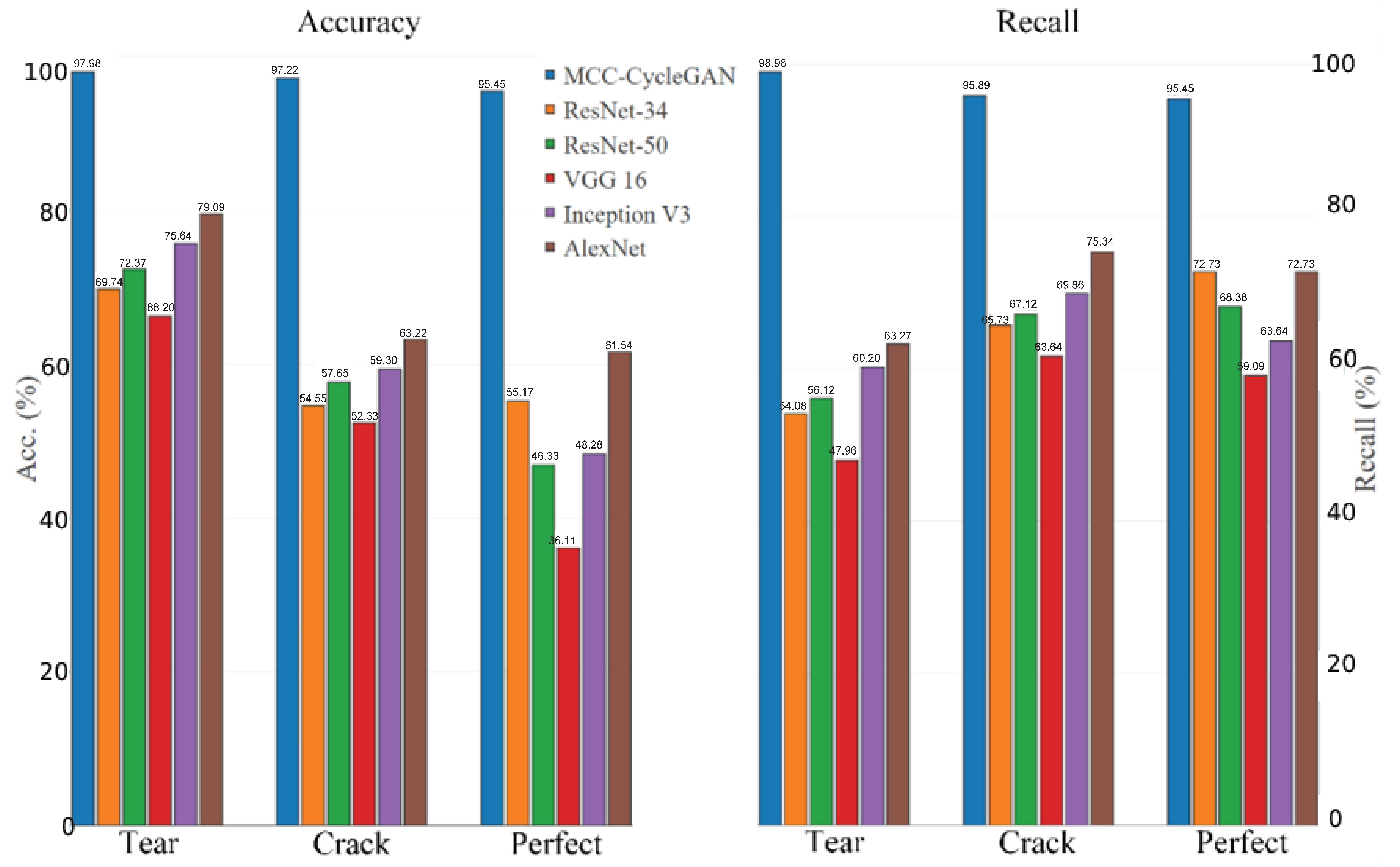

4.2. The Experimental Results and Comparisons

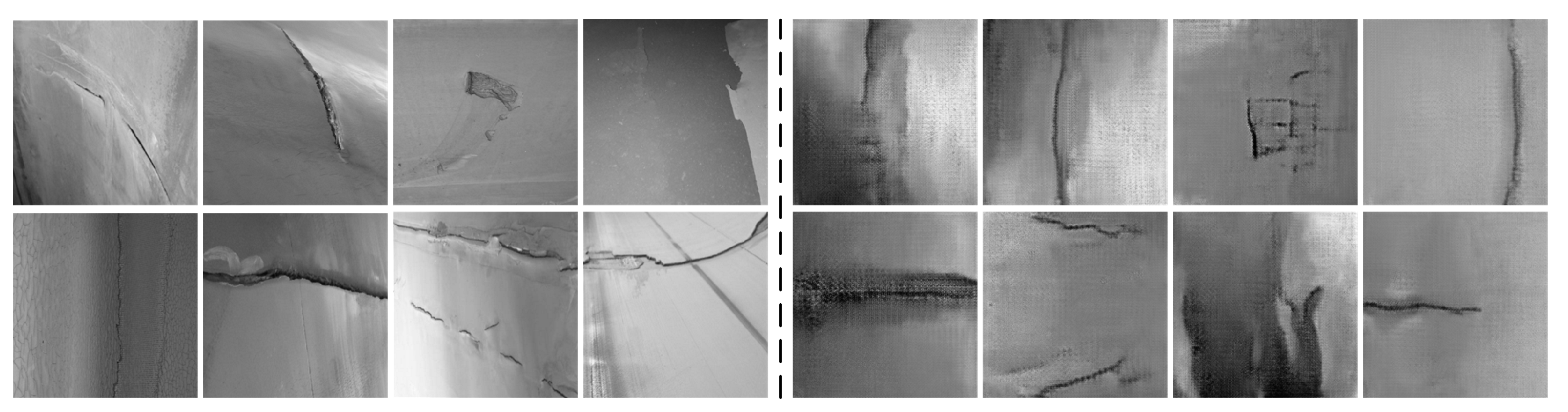

4.3. Application of the Proposed MCC-GAN

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hakami, F.; Pramanik, A.; Ridgway, N.; Basak, A.K. Developments of rubber material wear in conveyer belt system. Tribol. Int. 2017, 111, 148–158. [Google Scholar] [CrossRef] [Green Version]

- Vöth, S.; Zakharov, A.; Geike, B.; Grigoryev, A.; Zakharova, A.; Cehlár, M.; Janocko, J.; Straka, M.; Nuray, D.; Szurgacz, D.; et al. Analysis of Devices to Detect Longitudinal Tear on Conveyor Belts. E3S Web Conf. 2020, 174, 03006. [Google Scholar] [CrossRef]

- Zhu, J.; Park, T.; Isola, P.; Efros, A.A. Unpaired Image-to-Image Translation Using Cycle-Consistent Adversarial Networks. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017; pp. 2242–2251. [Google Scholar]

- Mirza, M.; Osindero, S. Conditional Generative Adversarial Nets. arXiv 2014, arXiv:1411.1784. [Google Scholar]

- Guo, X.; Liu, X.; Zhou, H.; Stanislawski, R.; Królczyk, G.; Li, Z. Belt Tear Detection for Coal Mining Conveyors. Micromachines 2022, 13, 449. [Google Scholar] [CrossRef]

- Błażej, R.; Jurdziak, L.; Kozłowski, T.; Kirjanów, A. The use of magnetic sensors in monitoring the condition of the core in steel cord conveyor belts–Tests of the measuring probe and the design of the DiagBelt system. Measurement 2018, 123, 48–53. [Google Scholar] [CrossRef]

- Kozłowski, T.; Błażej, R.; Jurdziak, L.; Kirjanów-Błażej, A. Magnetic methods in monitoring changes of the technical condition of splices in steel cord conveyor belts. Eng. Fail. Anal. 2019, 104, 462–470. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Z. Researching on the linear X-ray detector application of in the field of steel-core belt conveyor inspection system. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering, Wuhan, China, 15–17 April 2011; pp. 701–704. [Google Scholar]

- Wang, Y. Study on Mechanical Automation with X-Ray Power Conveyor Belt Nondestructive Detection System Design. Adv. Mater. Res. 2013, 738, 256–259. [Google Scholar] [CrossRef]

- Yang, R.; Qiao, T.; Pang, Y.; Yang, Y.; Zhang, H.; Yan, G. Infrared spectrum analysis method for detection and early warning of longitudinal tear of mine conveyor belt. Measurement 2020, 165, 107856. [Google Scholar] [CrossRef]

- Qiao, Z.J.; Shu, X.D. Coupled neurons with multi-objective optimization benefit incipient fault identification of machinery. Chaos Solitons Fractals 2021, 145, 110813. [Google Scholar] [CrossRef]

- Qiao, Z.J.; Liu, J.; Xu, X.; Yin, A.; Shu, X. Nonlinear resonance decomposition for weak signal detection. Rev. Sci. Instrum. 2021, 92, 105102. [Google Scholar] [CrossRef]

- Qiao, Z.; Elhattab, A.; Shu, X.; He, C. A second-order stochastic resonance method enhanced by fractional-order derivative for mechanical fault detection. Nonlinear Dyn. 2021, 106, 707–723. [Google Scholar] [CrossRef]

- Li, J.; Miao, C. The conveyor belt longitudinal tear on-line detection based on improved SSR algorithm. Optik-Int. J. Light Electron Opt. 2016, 127, 8002–8010. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, L.; Sun, H.; Zhu, C. Longitudinal tear detection of conveyor belt under uneven light based on Haar-AdaBoost and Cascade algorithm. Measurement 2021, 168, 108341. [Google Scholar] [CrossRef]

- Hao, X.; Liang, H. A multi-class support vector machine real-time detection system for surface damage of conveyor belts based on visual saliency. Measurement 2019, 146, 125–132. [Google Scholar] [CrossRef]

- Li, W.; Li, C.; Yan, F. Research on belt tear detection algorithm based on multiple sets of laser line assistance. Measurement 2021, 174, 109047. [Google Scholar] [CrossRef]

- Lv, Z.; Zhang, X.; Hu, J.; Lin, K. Visual detection method based on line lasers for the detection of longitudinal tears in conveyor belts. Measurement 2021, 183, 109800. [Google Scholar] [CrossRef]

- Qiao, T.; Chen, L.; Pang, Y.; Yan, G.; Miao, C. Integrative binocular vision detection method based on infrared and visible light fusion for conveyor belts longitudinal tear. Measurement 2017, 110, 192–201. [Google Scholar] [CrossRef]

- Yu, B.; Qiao, T.; Zhang, H.; Yan, G. Dual band infrared detection method based on mid-infrared and long infrared vision for conveyor belts longitudinal tear. Measurement 2018, 120, 140–149. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Zeng, C.; Zhang, W.; Li, J. Edge Detection for Conveyor Belt Based on the Deep Convolutional Network. In Proceedings of the 2018 Chinese Intelligent Systems Conference, Wenzhou, China, 13–14 October 2018; pp. 275–283. [Google Scholar]

- Zhang, M.; Shi, H.; Zhang, Y.; Yu, Y.; Zhou, M. Deep learning-based damage detection of mining conveyor belt. Measurement 2021, 175, 109130. [Google Scholar] [CrossRef]

- Qu, D.; Qiao, T.; Pang, Y.; Yang, Y.; Zhang, H. Research On ADCN Method for Damage Detection of Mining Conveyor Belt. IEEE Sens. J. 2021, 21, 8662–8669. [Google Scholar] [CrossRef]

- Zeng, C.; Junfeng, Z.; Li, J. Real-Time Conveyor Belt Deviation Detection Algorithm Based on Multi-Scale Feature Fusion Network. Algorithms 2019, 12, 205. [Google Scholar] [CrossRef] [Green Version]

- Goodfellow, I.J.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative Adversarial Nets. In Proceedings of the 28th Conference on Neural Information Processing Systems (NIPS), Montreal, QC, Canada, 8–13 December 2014; pp. 2672–2680. [Google Scholar]

- Pan, Z.Q.; Yu, W.J.; Yi, X.K.; Khan, A.; Yuan, F.; Zheng, Y.H. Recent Progress on Generative Adversarial Networks (GANs): A Survey. IEEE Access 2019, 7, 36322–36333. [Google Scholar] [CrossRef]

- Ledig, C.; Theis, L.; Huszár, F.; Caballero, J.; Cunningham, A.; Acosta, A.; Aitken, A.; Tejani, A.; Totz, J.; Wang, Z.; et al. Photo-Realistic Single Image Super-Resolution Using a Generative Adversarial Network. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 105–114. [Google Scholar]

- Isola, P.; Zhu, J.Y.; Zhou, T.H.; Efros, A.A. Image-to-Image Translation with Conditional Adversarial Networks. In Proceedings of the 30th IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2016; pp. 5967–5976. [Google Scholar]

- Zhang, H.; Goodfellow, I.; Metaxas, D.; Odena, A. Self-Attention Generative Adversarial Networks. In Proceedings of the 36th International Conference on Machine Learning (ICML), Long Beach, CA, USA, 9–15 June 2019. [Google Scholar]

- Yu, L.T.; Zhang, W.N.; Wang, J.; Yu, Y. SeqGAN: Sequence Generative Adversarial Nets with Policy Gradient. In Proceedings of the 31st AAAI Conference on Artificial Intelligence, San Francisco, CA, USA, 4–9 February; pp. 2852–2858.

- Hao, X.L.; Meng, X.J.; Zhang, Y.Q.; Xue, J.D.; Xia, J.Y. Conveyor-Belt Detection of Conditional Deep Convolutional Generative Adversarial Network. CMC-Comput. Mater. Contin. 2021, 69, 2671–2685. [Google Scholar] [CrossRef]

- Tran, N.T.; Tran, V.H.; Nguyen, N.B.; Nguyen, T.K.; Cheung, N.M. On Data Augmentation for GAN Training. IEEE Transac. Image Process. 2021, 30, 1882–1897. [Google Scholar] [CrossRef]

- Zhuang, F.; Qi, Z.; Duan, K.; Xi, D.; Zhu, Y.; Zhu, H.; Xiong, H.; He, Q. A Comprehensive Survey on Transfer Learning. Proc. IEEE 2021, 109, 43–76. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

| Network | Input Size | Output Size | Trainable Parameters | Pretrained |

|---|---|---|---|---|

| G-A | (Batch size, 1, 256, 256) | Identical to input | 9,523,319 | No |

| G-B | Identical to input | No | ||

| D-A | (Batch size, 1) | 6,721,426 | No | |

| D-B | (Batch size, 1) | No | ||

| C-net | (Batch size, 3) | 15,279,936 | Partial |

| Dataset | Image Size | Capacity | Ratio | Color Image | Annotation |

|---|---|---|---|---|---|

| A | (256, 256) | 1532 | 4:2:4 (Tear: Crack: Scratch) | Yes | Yes |

| B | (256, 256) | 468 | 5:3:2 (Tear: Crack: Perfect) | No | Annotated manually |

| MCC-CycleGAN | ResNet-34 | ResNet-50 | VGG 16 | Inception v3 | AlexNet | |

|---|---|---|---|---|---|---|

| Loss | 0.01367 | 0.00078 | 0.00079 | 0.00265 | 0.00098 | 0.01571 |

| Acc. | 99.53% | 98.56% | 98.56% | 99.42% | 96.83% | 97.84% |

| Time consumption for training (hour) | 12.6 h | 4.2 h | 5.4 h | 4.6 h | 6.1 h | 7.8 h |

| Test FPS | 44.3 | 47.5 | 41.6 | 31.3 | 37.4 | 40.1 |

| Evaluation | Proposed | ResNet-34 | ResNet-50 | VGG 16 | Inception v3 | AlexNet |

|---|---|---|---|---|---|---|

| mAP | 0.969 | 0.598 | 0.590 | 0.515 | 0.611 | 0.681 |

| Macro-F1 | 0.968 | 0.611 | 0.603 | 0.524 | 0.620 | 0.686 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Liu, X.; Królczyk, G.; Sulowicz, M.; Glowacz, A.; Gardoni, P.; Li, Z. Damage Detection for Conveyor Belt Surface Based on Conditional Cycle Generative Adversarial Network. Sensors 2022, 22, 3485. https://doi.org/10.3390/s22093485

Guo X, Liu X, Królczyk G, Sulowicz M, Glowacz A, Gardoni P, Li Z. Damage Detection for Conveyor Belt Surface Based on Conditional Cycle Generative Adversarial Network. Sensors. 2022; 22(9):3485. https://doi.org/10.3390/s22093485

Chicago/Turabian StyleGuo, Xiaoqiang, Xinhua Liu, Grzegorz Królczyk, Maciej Sulowicz, Adam Glowacz, Paolo Gardoni, and Zhixiong Li. 2022. "Damage Detection for Conveyor Belt Surface Based on Conditional Cycle Generative Adversarial Network" Sensors 22, no. 9: 3485. https://doi.org/10.3390/s22093485

APA StyleGuo, X., Liu, X., Królczyk, G., Sulowicz, M., Glowacz, A., Gardoni, P., & Li, Z. (2022). Damage Detection for Conveyor Belt Surface Based on Conditional Cycle Generative Adversarial Network. Sensors, 22(9), 3485. https://doi.org/10.3390/s22093485