A Model-Agnostic Meta-Baseline Method for Few-Shot Fault Diagnosis of Wind Turbines

Abstract

:1. Introduction

2. Few-Shot Learning and Meta-Learning

2.1. Few-Shot Learning Based on Meta-Learning

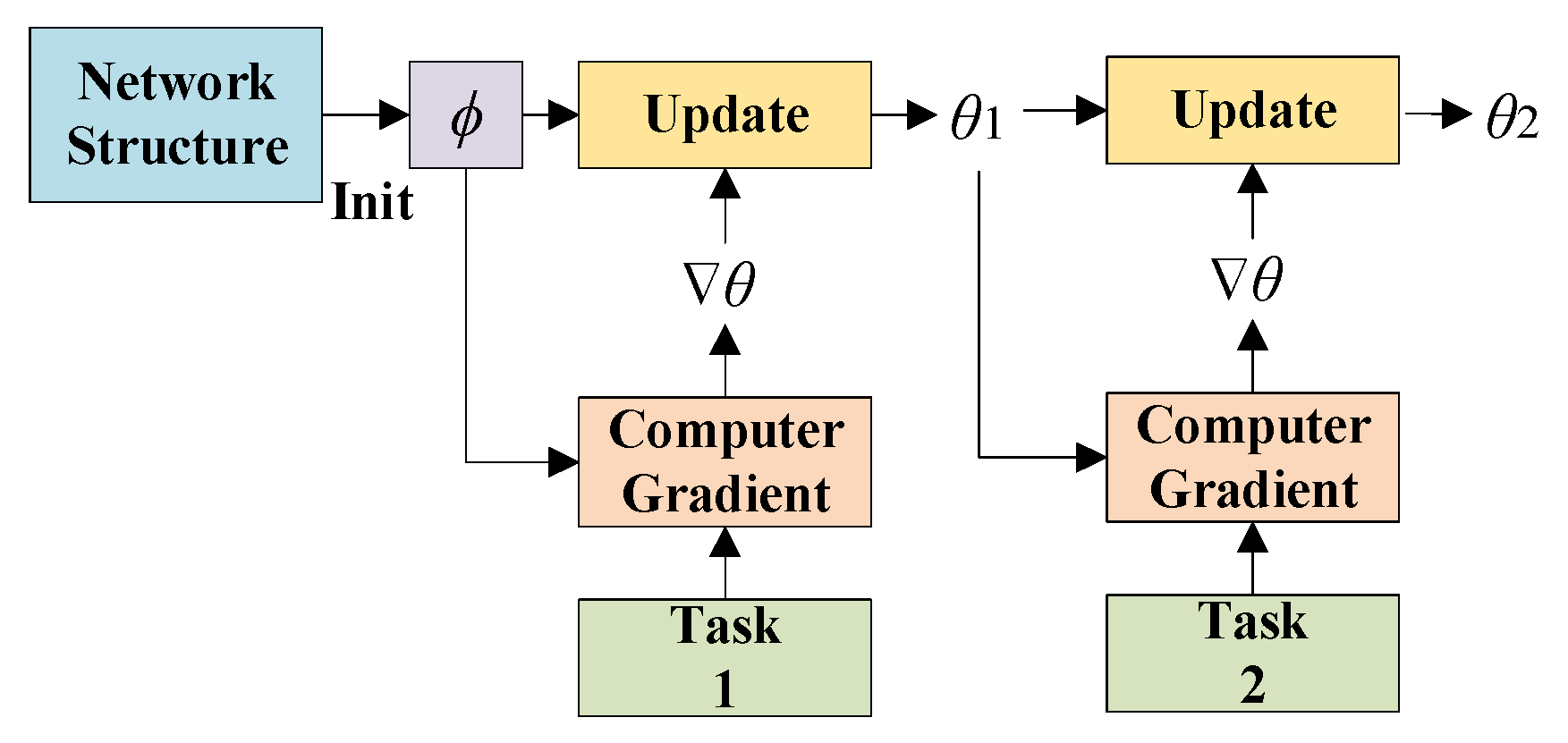

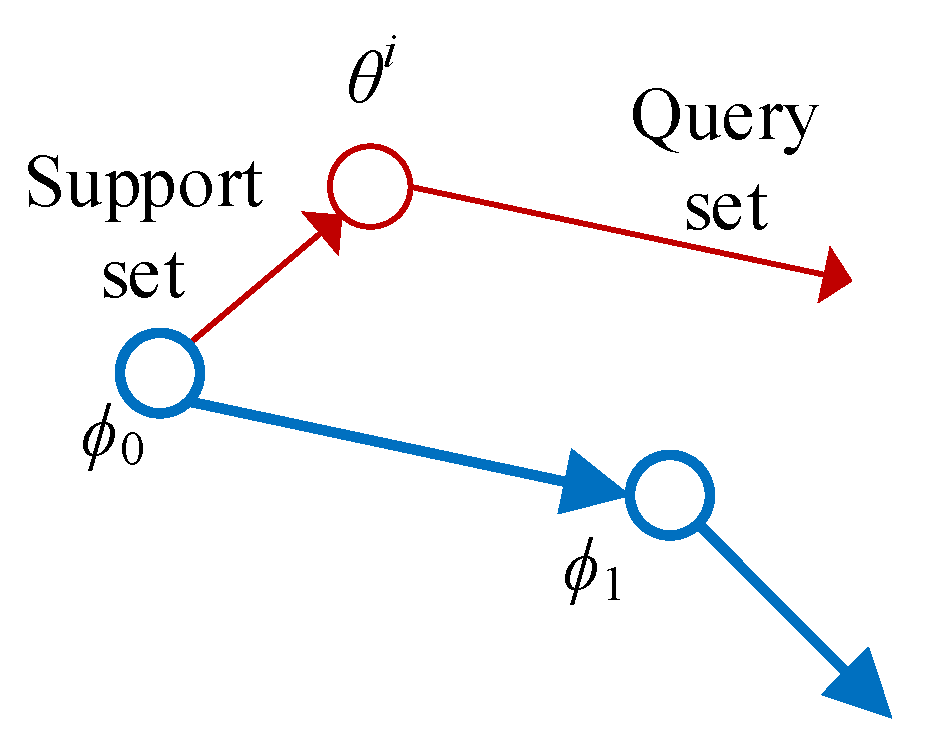

2.2. Model-Agnostic Meta-Learning

2.3. Fine-Tuning the Model

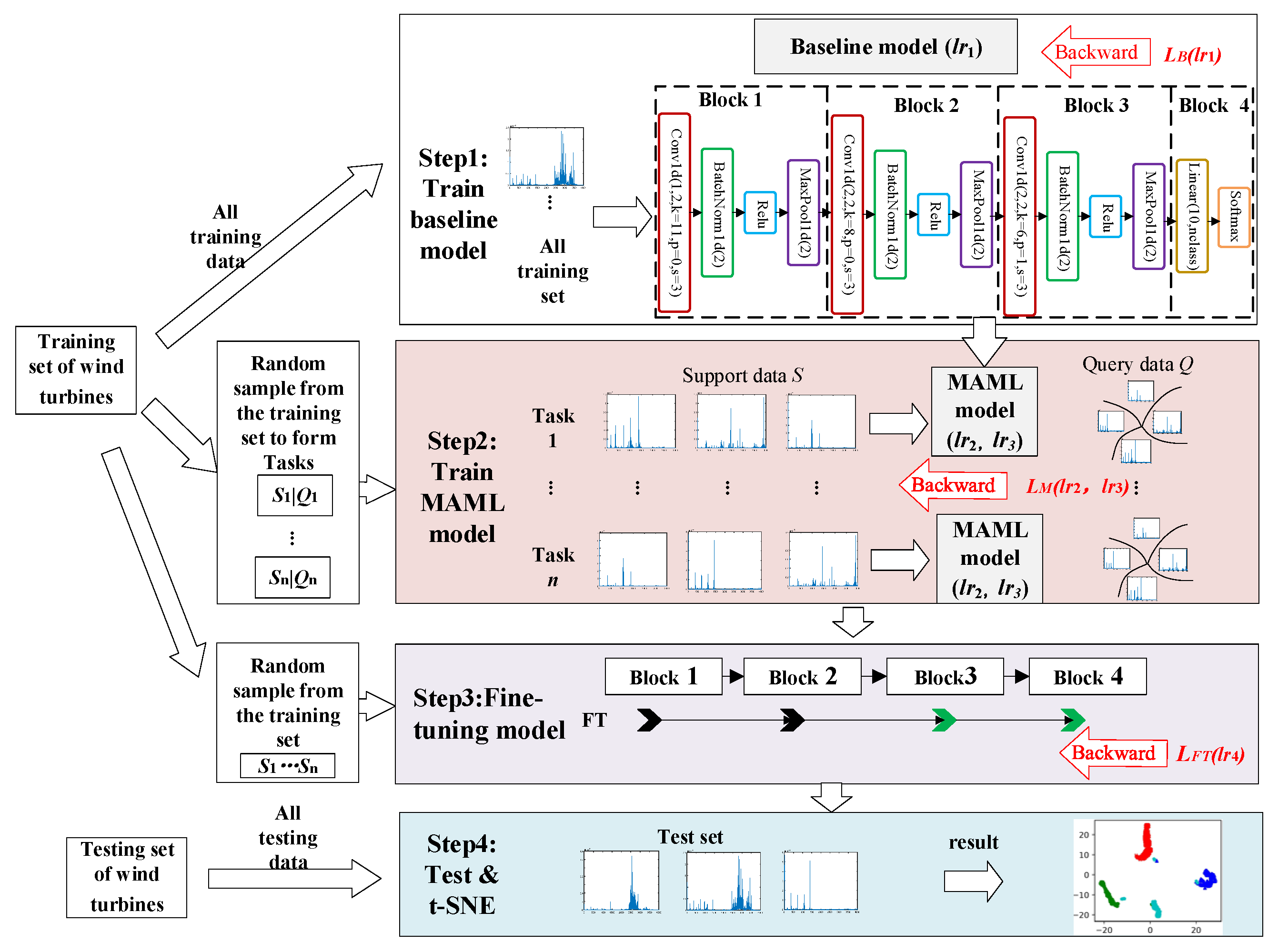

3. Proposed MAMB for Few-Shot Fault Diagnosis

| Algorithm 1. few-shot (c-way-k-shot) fault diagnosis based on MAMB. |

| Input: Input training data , testing data , classified model f, model parameters ϕ, meta-learning model task parameters θ, updated learning rate lr2 of task θ, updated learning rate lr3 of model ϕ, updated learning rate lr4 of fine-tuning. ########################(1) Pre-training baseline models #################### 1: For each training epoch, do: 2: For each batch, do: 3: ci = fϕ(xi) 4: Backward propagation (with the learning rate as lr1): 5: end ########################(2) train MAML models ############################ 6: Randomly draw data from Tr to form N tasks, each task containing k support sets and q query sets, to form 7: For each training, do: 8: For each batch, do: 9: ci = fθ (Si), l = yilogci +(1 − yi)log(1 − ci) 10: Update parameters 11: cqi = fθ (Qi) 12: ln(ϕ)= yilogcqi +(1 − yi)log(1 − cqi) 13: Calculate , Backward Propagation: 14: end ###################### (3) Fine-tuned meta-learning model ################## 15: Randomly draw data Si from Tr 16: For each training, do: 17: ci = fϕ (Si) 18: Backward Propagation: 19: end ###################### (4) testing results and t-SNE ######################### 20: For the test set, calculate cTi = fϕ (Tei), calculate the accuracy, and draw the t-SNE diagram. Output: optimized meta-learning model and testing results. |

4. Case Analysis

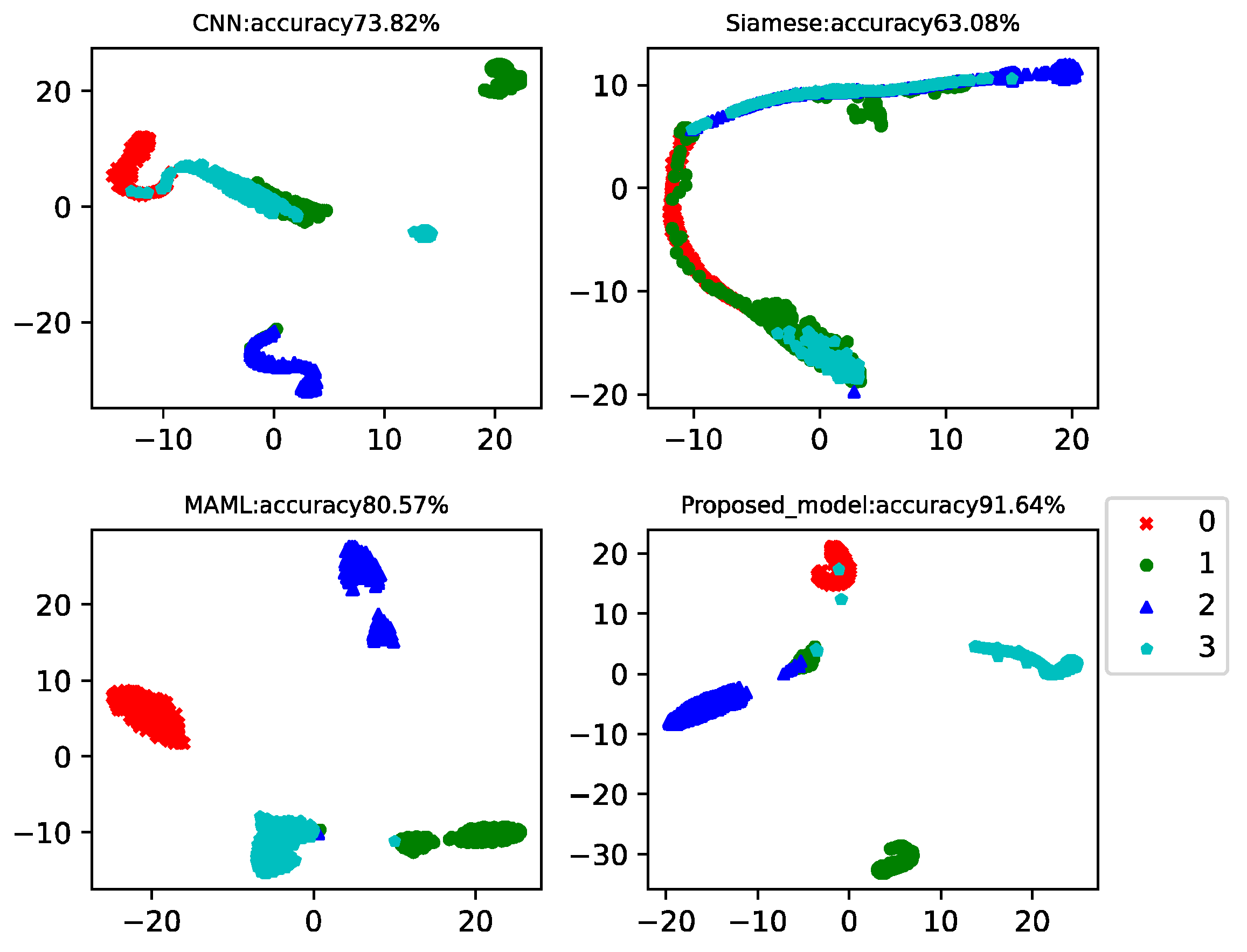

4.1. Case 1: Fault Diagnosis of CWRU Datasets

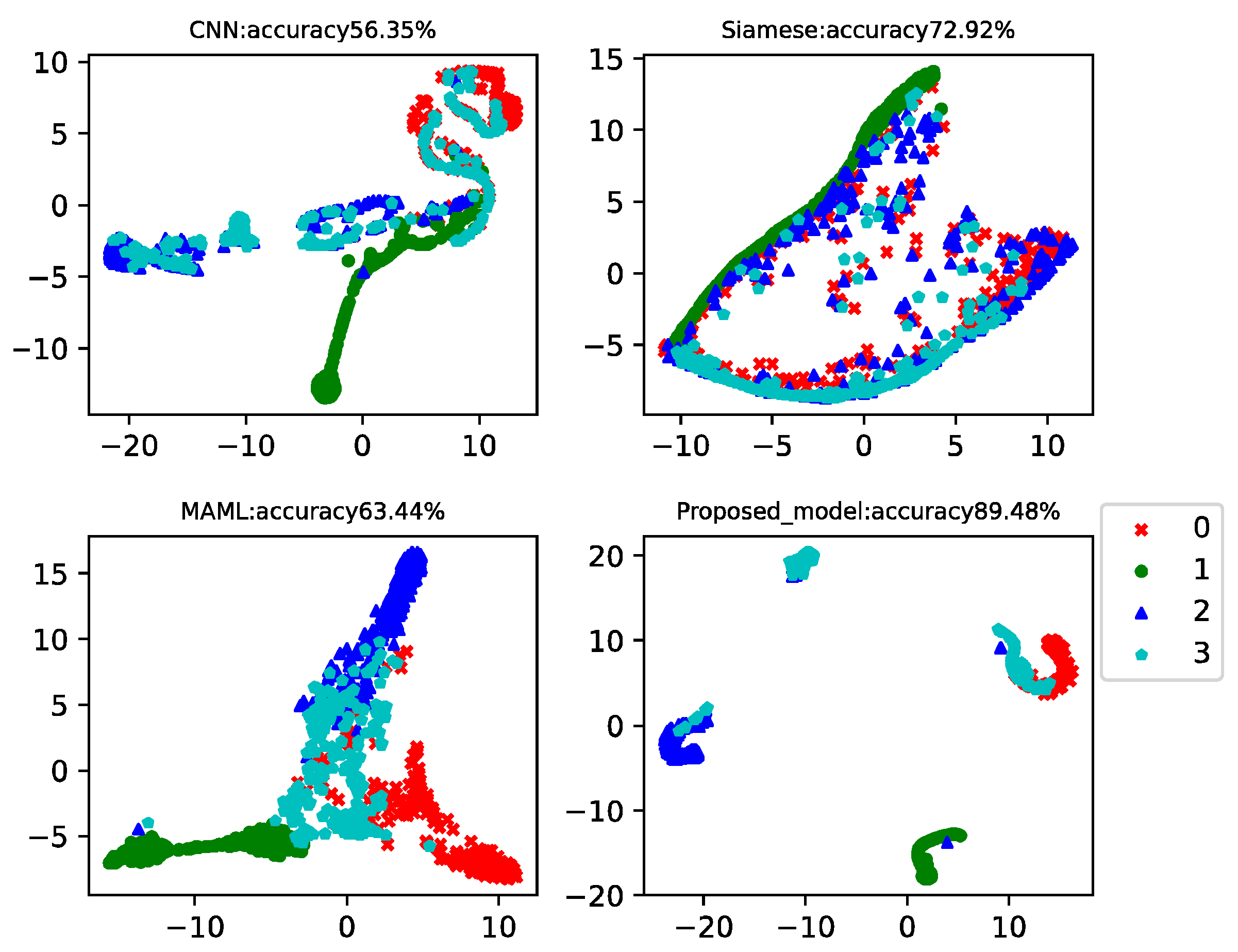

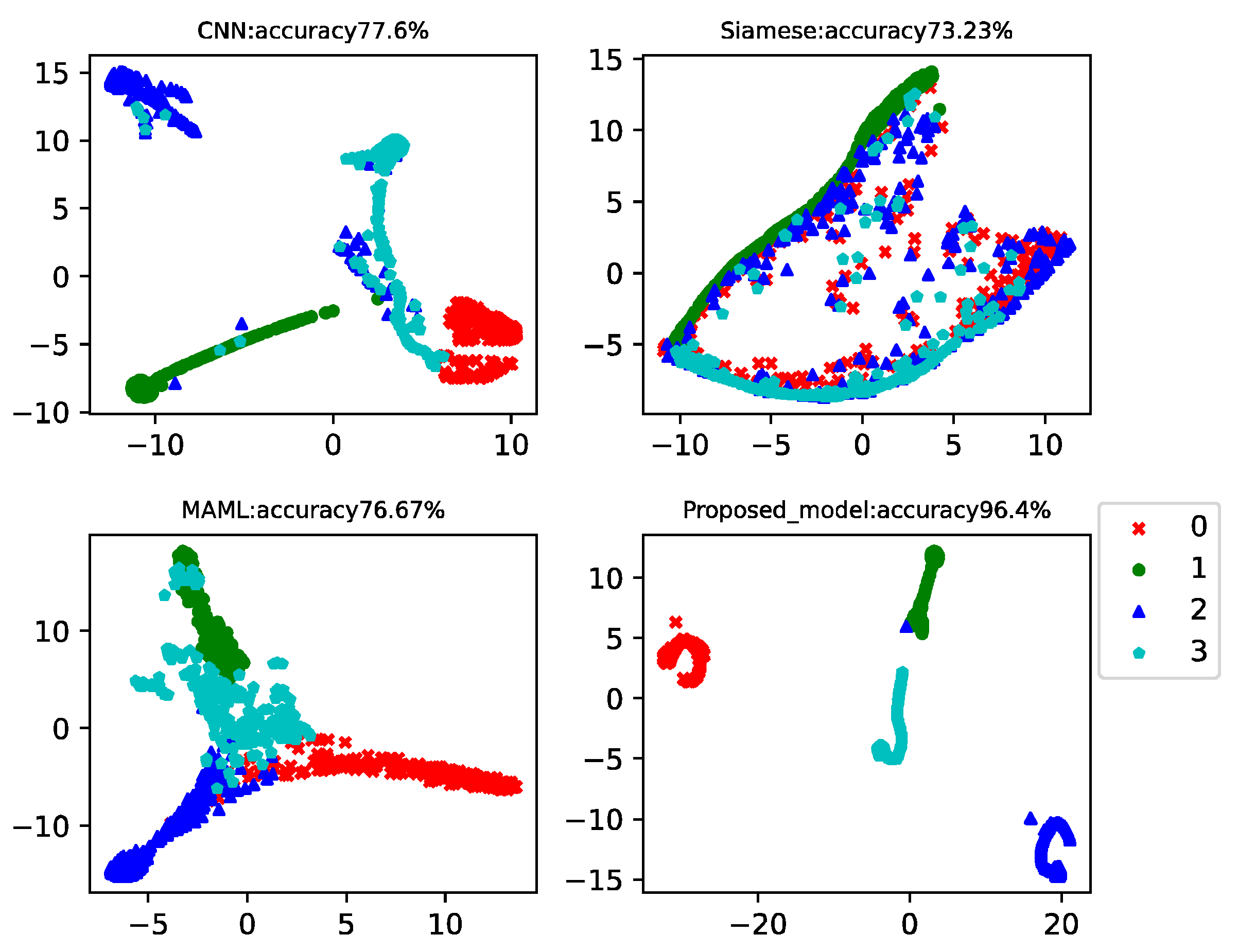

4.2. Case 2: Fault Diagnosis of Generator Bearings for Wind Turbines

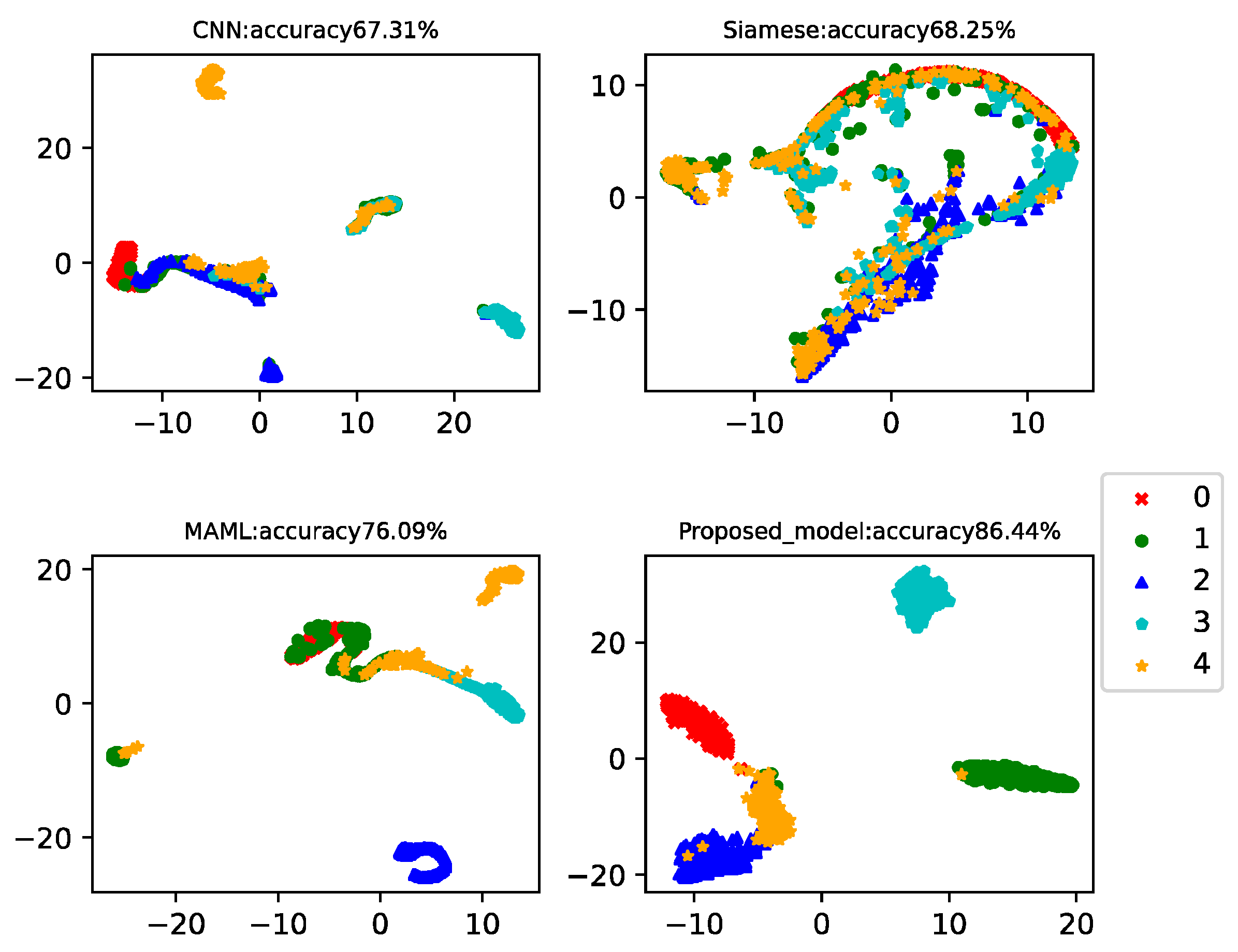

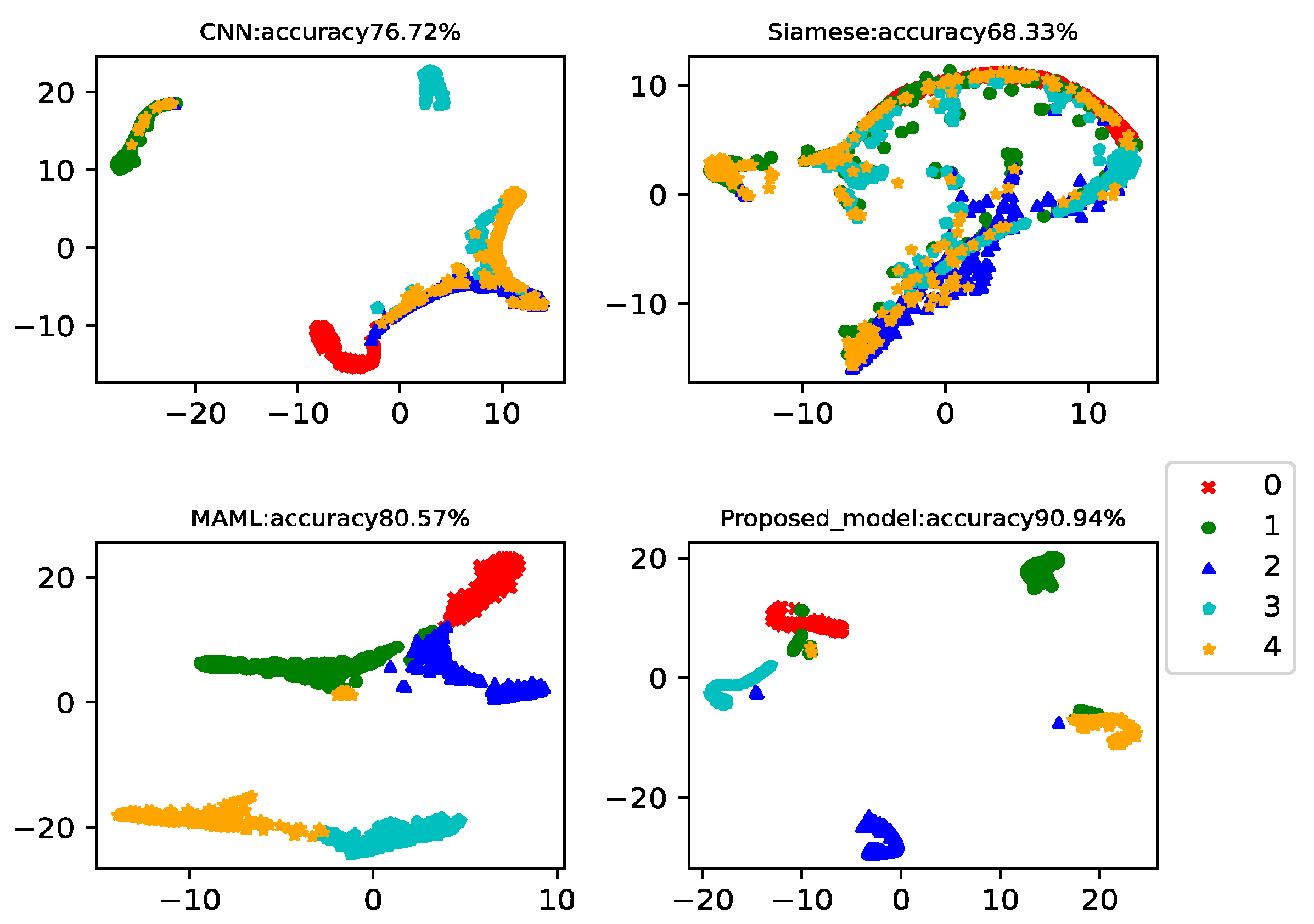

4.3. Case 3: Fault Diagnosis of Wind Turbine Gearbox

4.4. The Impact of the Number of Training Data on the Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nie, Y.; Zamzamb, A.S.; Brandt, A. Resampling and data augmentation for short-term PV output prediction based on an imbalanced sky images dataset using convolutional neural networks. Sol. Energy 2021, 224, 341–354. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Q.; Kwok, J.T.; Ni, L.M. Generalizing from a few examples: A survey on few-shot learning. ACM Comput. Surv. 2020, 53, 1–34. [Google Scholar] [CrossRef]

- Hu, T.; Tang, T.; Lin, R.; Chen, M.; Han, S.; Wu, J. A simple data augmentation algorithm and a self-adaptive convolutional architecture for few-shot fault diagnosis under different working conditions. Measurement 2020, 156, 107539. [Google Scholar] [CrossRef]

- Zheng, T.; Song, L.; Wang, J.; Teng, W.; Xu, X.; Ma, C. Data synthesis using dual discriminator conditional generative adversarial networks for imbalanced fault diagnosis of rolling bearings. Measurement 2020, 158, 107741. [Google Scholar] [CrossRef]

- Ren, Z.; Zhu, Y.; Yan, K.; Chen, K.; Kang, W.; Yue, Y.; Gao, D. A novel model with the ability of few-shot learning and quick updating for intelligent fault diagnosis. Mech. Syst. Signal Process. 2020, 138, 106608. [Google Scholar] [CrossRef]

- Koch, G.; Zemel, R.; Salakhutdinov, R. Siamese Neural Networks for One-Shot Image Recognition. In Proceedings of the 32th International Conference on Machine Learning, Lille, France, 7–9 July 2015; Volume 37, pp. 1–8. [Google Scholar]

- Zhang, A.; Li, S.; Cui, Y.; Yang, W.; Dong, R.; Hu, J. Limited data rolling bearing fault diagnosis with few-shot learning. IEEE Access 2019, 7, 110895–110904. [Google Scholar] [CrossRef]

- Cai, Q.; Pan, Y.; Yao, T.; Yan, C.; Mei, T. Memory matching networks for one-shot image recognition. In Proceedings of the 2018 IEEE CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–22 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 4080–4088. [Google Scholar]

- Vinyals, O.; Blundell, C.; Lillicrap, T.; Kavukcuoglu, K.; Wierstra, D. Matching networks for one-shot learning. arXiv 2016, arXiv:1606.04080. [Google Scholar]

- Sung, F.; Yang, Y.; Zhang, L.; Xiang, T.; Torr, P.H.S.; Hospedales, T.M. Learning to compare: Relation network for few-shot learning. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–23 June 2018. [Google Scholar]

- Garcia, V.; Bruna, J. Few-shot learning with graph neural networks. arXiv 2017, arXiv:1711.04043. [Google Scholar]

- Hospedales, T.M.; Antoniou, A.; Micaelli, P.; Storkey, A.J. Meta-learning in neural networks: A survey. IEEE Trans. Pattern Anal. Mach. Intell. 2021, 1–20, 3079209. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, X.; Liu, Z.; Xu, H. A new meta-baseline for few-shot learning. arXiv 2020, arXiv:2003.04390. [Google Scholar]

- Chen, Y.; Liu, Z.; Xu, H.; Darrell, T.; Wang, X. Meta-baseline: Exploring simple meta-learning for few-shot learning. In Proceedings of the 2021 IEEE/CVF International Conference on Computer Vision (ICCV), Montreal, QC, Canada, 10–17 October 2021. [Google Scholar]

- Soh, J.W.; Cho, S.; Cho, N.I. Meta-transfer learning for zero-shot super-resolution. In Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Hsu, K.; Levine, S.; Finn, C. Unsupervised learning via meta-learning. arXiv 2018, arXiv:1810.02334. [Google Scholar]

- Wu, J.; Zhao, Z.; Sun, C.; Yan, R.; Chen, X. Few-shot transfer learning for intelligent fault diagnosis of machine. Measurement 2020, 166, 108202. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Xu, Y.; Lu, W.; Yang, J.; Zhang, T. Metric-based meta-learning model for few-shot fault diagnosis under multiple limited data conditions. Mech. Syst. Signal Process. 2021, 155, 107510. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, J.; Zhang, T.; He, S.; Xu, E.; Zhou, Z. Semi-supervised meta-learning networks with squeeze-and-excitation attention for few-shot fault diagnosis. ISA Trans. 2021, 120, 383–401. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Xiang, L.; Hu, A.; Xu, Y.; Yang, X. A novel method based on meta-learning for bearing fault diagnosis with small sample learning under different working conditions. Mech. Syst. Signal Process. 2022, 169, 108765. [Google Scholar] [CrossRef]

- Wang, S.; Wang, D.; Kong, D.; Wang, J.; Li, W.; Zhou, S. Few-shot rolling bearing fault diagnosis with metric-based meta learning. Sensors 2020, 20, 6437. [Google Scholar] [CrossRef] [PubMed]

- Encalada-Dávila, N.; Puruncajas, B.; Tutivén, C.; Vidal, Y. Wind turbine main bearing fault prognosis based solely on SCADA data. Sensors 2021, 21, 2228. [Google Scholar] [CrossRef] [PubMed]

- Castellani, F.; Garibaldi, L.; Daga, A.P.; Astolfi, D.; Natili, F. Diagnosis of faulty wind turbine bearings using tower vibration measurements. Energies 2020, 13, 1474. [Google Scholar] [CrossRef] [Green Version]

- Meyer, A. Vibration Fault Diagnosis in Wind Turbines Based on Automated Feature Learning. Energies 2022, 15, 1514. [Google Scholar] [CrossRef]

- Artigao, E.; Honrubia-Escribano, A.; Gómez-Lázaro, E. In-service wind turbine DFIG diagnosis using current signature analysis. IEEE Trans. Ind. Electron. 2019, 67, 2262–2271. [Google Scholar] [CrossRef]

- Rahimilarki, R.; Gao, Z.; Jin, N.; Zhang, A. Convolutional neural network fault classification based on time-series analysis for benchmark wind turbine machine. Renew. Energy 2021, 185, 916–931. [Google Scholar] [CrossRef]

- Miele, E.S.; Bonacina, F.; Corsini, A. Deep anomaly detection in horizontal axis wind turbines using graph convolutional autoencoders for multivariate time series. Energy AI 2022, 8, 100145. [Google Scholar] [CrossRef]

- Zhan, J.; Wu, C.; Ma, X.; Yang, C.; Miao, Q.; Wang, S. Abnormal vibration detection of wind turbine based on temporal convolution network and multivariate coefficient of variation. Mech. Syst. Signal Process. 2022, 174, 109082. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, P.; Yang, X.; Hu, A.; Su, H. Fault detection of wind turbine based on SCADA data analysis using CNN and LSTM with attention mechanism. Measurement 2021, 175, 109094. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.; Wang, K.; Zuo, M.J.; Heyns, S.; Baggerohr, S. A threshold self-setting condition monitoring scheme for wind turbine generator bearings based on deep convolutional generative adversarial networks. Measurement 2020, 167, 108234. [Google Scholar] [CrossRef]

- Liu, X.; Teng, W.; Wu, S.; Wu, X.; Liu, Y.; Ma, Z. Sparse dictionary learning based adversarial variational auto-encoders for fault identification of wind turbines. Measurement 2021, 183, 109810. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, X. Time-series data-driven online prognosis of wind turbine faults in presence of SCADA data loss. IEEE Trans. Sustain. Energy 2020, 12, 1289–1300. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Z. Wind turbine gearbox failure detection based on SCADA data: A deep learning based approach. IEEE Trans. Instrum. Meas. 2020, 70, 1–11. [Google Scholar] [CrossRef]

- He, Q.; Pang, Y.; Jiang, G.; Xie, P. A spatio-temporal multiscale neural network approach for wind turbine fault diagnosis with imbalanced SCADA data. IEEE Trans. Ind. Inform. 2020, 17, 6875–6884. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Zhang, X.; Liu, Y.; Ma, Z. Multi-fault detection and failure analysis of wind turbine gearbox using complex wavelet transform. Renew. Energy 2016, 93, 591–598. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Zhang, Y.; Liu, Y.; Ma, Z.; Kusiak, A. Application of cyclic coherence function to bearing fault detection in a wind turbine generator under electromagnetic vibration-ScienceDirect. Mech. Syst. Signal Process. 2017, 87, 279–293. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Cheng, H.; Liu, Y.; Mu, H. Compound faults diagnosis and analysis for a wind turbine gearbox via a novel vibration model and empirical wavelet transform. Renew. Energy 2019, 136, 393–402. [Google Scholar] [CrossRef]

- Teng, W.; Liu, Y.; Huang, Y.; Song, L.; Ma, Z. Fault detection of planetary subassemblies in a wind turbine gearbox using TQWT based sparse representation. J. Sound Vib. 2020, 490, 115707. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Tang, S.; Xu, J.; Shi, B.; Liu, Y. Vibration Analysis for Fault Detection of Wind Turbine Drivetrains—A Comprehensive Investigation. Sensors 2021, 21, 1686. [Google Scholar] [CrossRef] [PubMed]

- Finn, C.; Abbeel, P.; Levine, S. Model-agnostic meta-learning for fast adaptation of deep networks. In Proceedings of the 34th International Conference on Machine Learning, Sydney, Australia, 6–11 August 2017. [Google Scholar]

- Ren, M.; Triantafillou, E.; Ravi, S.; Snell, J.; Swersky, K.; Tenenbaum, J.B.; Larochelle, H.; Zemel, R.S. Meta-learning for semi-supervised few-shot classification. arXiv 2018, arXiv:1803.00676. [Google Scholar]

- Xu, H. Cross-domain adaptation of crowd counting with model-agnostic meta-learning. Appl. Sci. 2021, 11, 12037. [Google Scholar]

- Ma, N.; Bu, J.; Yang, J.; Zhang, Z.; Yao, C.; Yu, Z. Few-shot graph classification with model agnostic meta-learning. arXiv 2020, arXiv:2003.08246. [Google Scholar]

- Kang, J.; Liu, R.; Li, L.; Cai, Y.; Wang, D.; Zheng, T.F. Domain-invariant speaker vector projection by model-agnostic meta-learning. In Proceedings of the Interspeech 2021, Brno, Czech Republic, 30 August–3 September 2021; pp. 1–5. [Google Scholar]

- Indurthi, S.; Han, H.; Lakumarapu, N.K.; Beomseok, L. Data efficient direct speech-to-text translation with modality agnostic meta-learning. arXiv 2019, arXiv:1911.04283. [Google Scholar]

- Fallah, A.; Mokhtari, A.; Ozdaglar, A. Provably convergent policy gradient methods for model-agnostic meta-reinforcement learning. arXiv 2020, arXiv:2002.05135. [Google Scholar]

- Howard, J.; Ruder, S. Universal language model fine-tuning for text classification. In Proceedings of the 56th Annual Meeting of the Association for Computational Linguistics, Melbourne, Australia, 15–20 July 2018. [Google Scholar]

- Nakamura, A.; Harada, T. Revisiting fine-tuning for few-shot learning. arXiv 2019, arXiv:1910.00216. [Google Scholar]

- Gao, T.; Fisch, A.; Chen, D. Making pre-trained language models better few-shot learners. arXiv 2020, arXiv:2012.15723. [Google Scholar]

- Chua, K.; Lei, Q.; Lee, J.D. How fine-tuning allows for effective meta-learning. Adv. Neural Inf. Process. Syst. 2021, 34, 1–34. [Google Scholar]

| Fault Type | Label | Number of Samples from the Training Set | Number of Samples from the Testing Set |

|---|---|---|---|

| Healthy | 0 | 100 | 240 |

| Outer Race 6 | 1 | 15 | 240 |

| Inner Race | 2 | 15 | 240 |

| Rolling fault | 3 | 15 | 240 |

| Algorithms | 4-Way-1-Shot | 4-Way-5-Shot | 4-Way-10-Shot | Average |

|---|---|---|---|---|

| CNN | 73.82% | 79.81% | 87.67% | 80.43% |

| Siamese net [7] | 63.08% | 63.0% | 62.92% | 63% |

| MAML [40] | 80.57% | 86.4% | 89.27% | 85.41% |

| MAMB (proposed model) | 91.64% | 95.78% | 97.21% | 94.88% |

| Fault Type | Label | Number of Samples from the Training Set | Number of Samples from the Testing Set | |

|---|---|---|---|---|

| Healthy | No faults | 0 | 100 | 240 |

| Fault 1 | Outer ring failure | 1 | 15 | 240 |

| Fault 2 | Inner ring failure + Outer ring failure | 2 | 15 | 240 |

| Fault 3 | Inner ring failure + Rolling failure + Cage failure | 3 | 15 | 240 |

| Algorithms | 4-Way-1-Shot | 4-Way-5-Shot | 4-Way-10-Shot | Average |

|---|---|---|---|---|

| CNN | 56.35% | 74.9% | 77.6% | 69.62% |

| Siamese net [7] | 72.92% | 73.02% | 73.23% | 73.06% |

| MAML [40] | 63.44% | 74.38% | 76.67% | 71.5% |

| MAMB (proposed model) | 89.48% | 95.73% | 96.4% | 93.87% |

| Fault Type | Label | Number of Samples from the Training Set | Number of Samples from the Testing Set | |

|---|---|---|---|---|

| Healthy | No faults | 0 | 100 | 240 |

| Fault 1 | Spalling of gears in the intermediate shaft | 1 | 15 | 240 |

| Fault 2 | Broken teeth of gears in the intermediate and high-speed shaft | 2 | 15 | 240 |

| Fault 3 | Broken teeth of gears in the high-speed shaft | 3 | 15 | 240 |

| Fault 4 | Broken teeth of gears in the intermediate shaft | 4 | 15 | 240 |

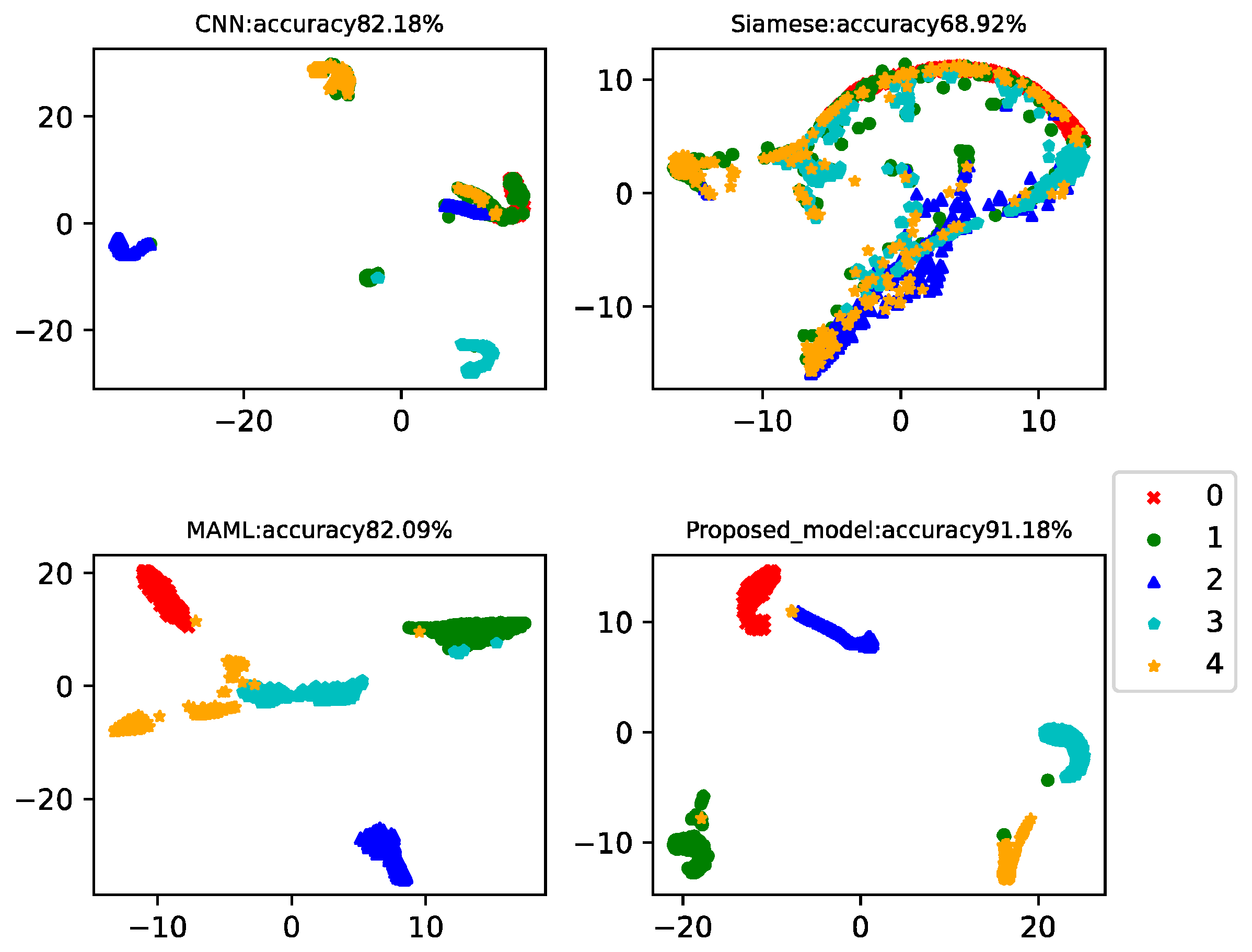

| Algorithms | 5-Way-1-Shot | 5-Way-5-Shot | 5-Way-10-Shot | Average |

|---|---|---|---|---|

| CNN | 67.31% | 76.72% | 82.18% | 75.4% |

| Siamese net [7] | 68.25% | 68.33% | 68.92% | 68.5% |

| MAML [40] | 76.09% | 80.57% | 82.09% | 79.58% |

| MAMB (proposed model) | 86.44% | 90.94% | 91.18% | 89.52% |

| No. of Shot | 1-Shot | 5-Shot | 10-Shot | |||

|---|---|---|---|---|---|---|

| No. of Train Data | 15 | 20 | 15 | 20 | 15 | 20 |

| Bearing (4-way) | 89.48% | 90.02% | 95.73% | 96.08% | 96.4% | 97.2% |

| Gearbox (5-way) | 86.44% | 88.25% | 90.94% | 92.0% | 91.18% | 92.09% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Teng, W.; Liu, Y. A Model-Agnostic Meta-Baseline Method for Few-Shot Fault Diagnosis of Wind Turbines. Sensors 2022, 22, 3288. https://doi.org/10.3390/s22093288

Liu X, Teng W, Liu Y. A Model-Agnostic Meta-Baseline Method for Few-Shot Fault Diagnosis of Wind Turbines. Sensors. 2022; 22(9):3288. https://doi.org/10.3390/s22093288

Chicago/Turabian StyleLiu, Xiaobo, Wei Teng, and Yibing Liu. 2022. "A Model-Agnostic Meta-Baseline Method for Few-Shot Fault Diagnosis of Wind Turbines" Sensors 22, no. 9: 3288. https://doi.org/10.3390/s22093288

APA StyleLiu, X., Teng, W., & Liu, Y. (2022). A Model-Agnostic Meta-Baseline Method for Few-Shot Fault Diagnosis of Wind Turbines. Sensors, 22(9), 3288. https://doi.org/10.3390/s22093288