Numerical Simulation and Experimental Study of the Drop Impact for a Multiphase System Formed by Two Immiscible Fluids

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiments

- ρ—liquid density (kg∙m−3),

- σ—surface tension for a fluid–air interface (N∙m−1),

- d—diameter of the drop (m),

- v—velocity of the drop (m∙s−1),

- g—acceleration of gravity (m∙s−2).

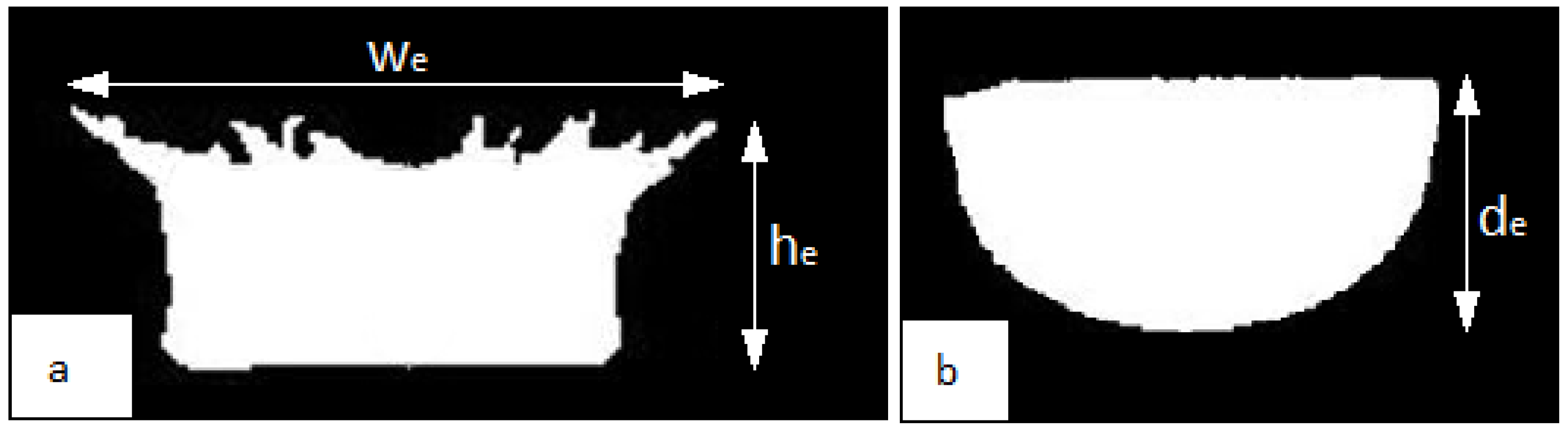

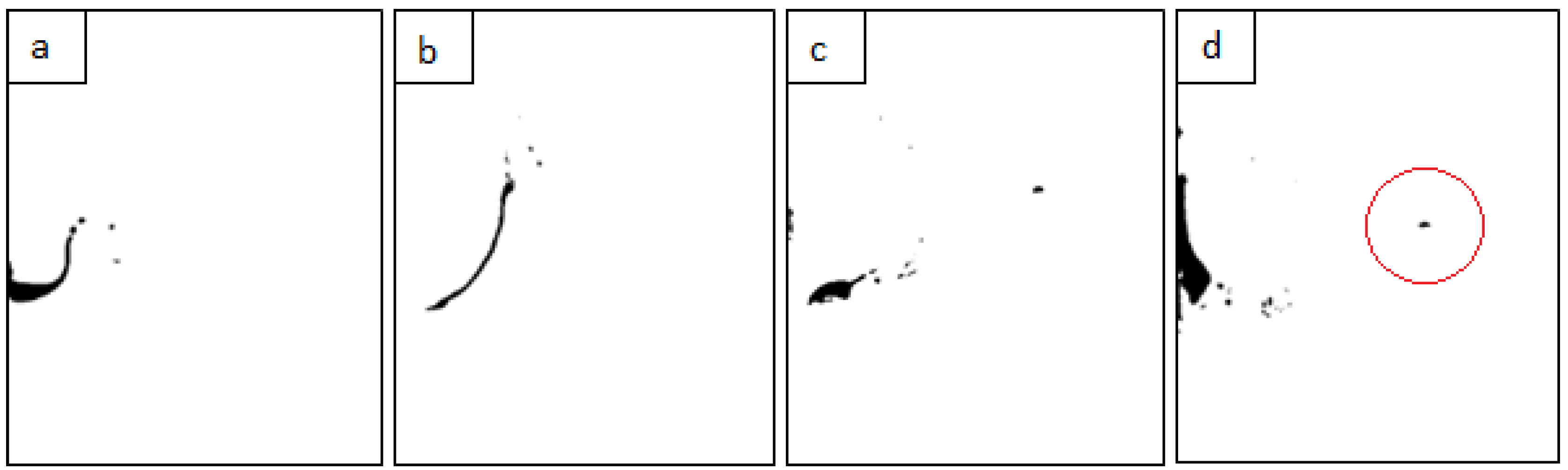

2.2. Image Analysis—Real (Experimental) Splash Phenomenon

- the experimental crown height (he)—measured from the liquid surface to the highest of the crown spikes;

- the experimental external width of the crown (we)—measured at the height of the crown spikes at their maximum spread;

- the experimental depth of the cavity below the water surface (de)—measured from the liquid surface to the deepest point below the surface.

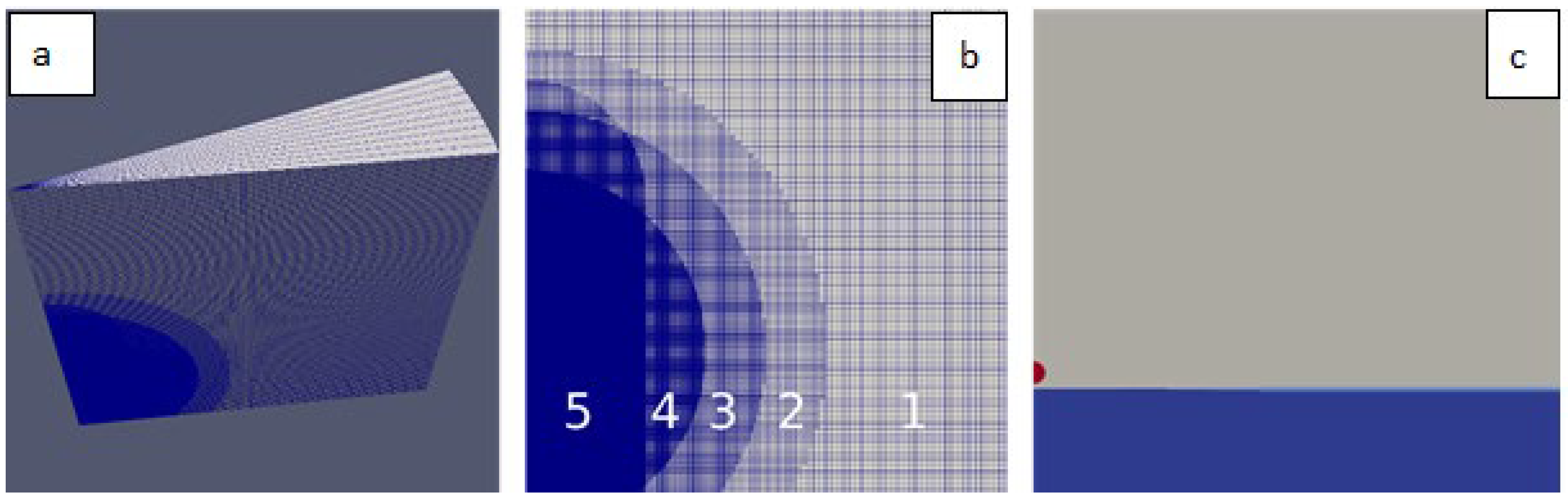

2.3. Numerical Simulations

- liquid properties (Table 1);

- properties of the drop, i.e., its size and impact velocity.

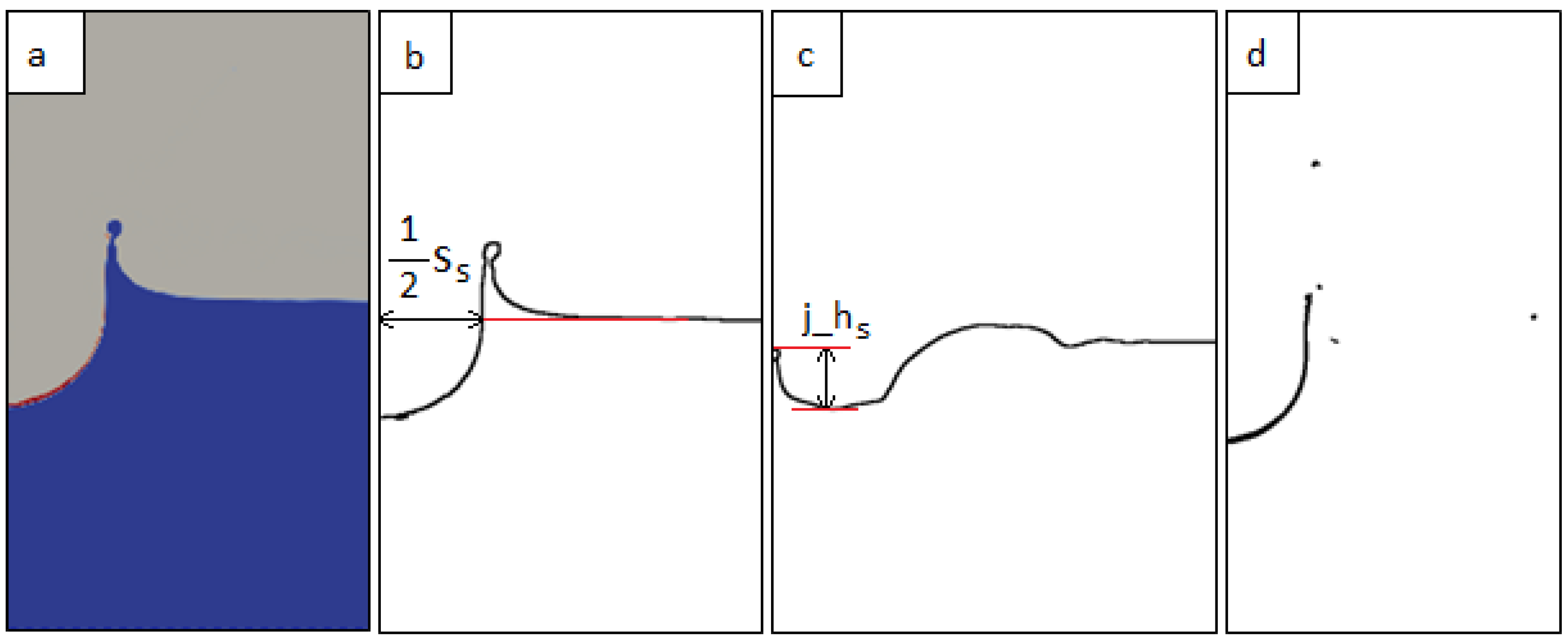

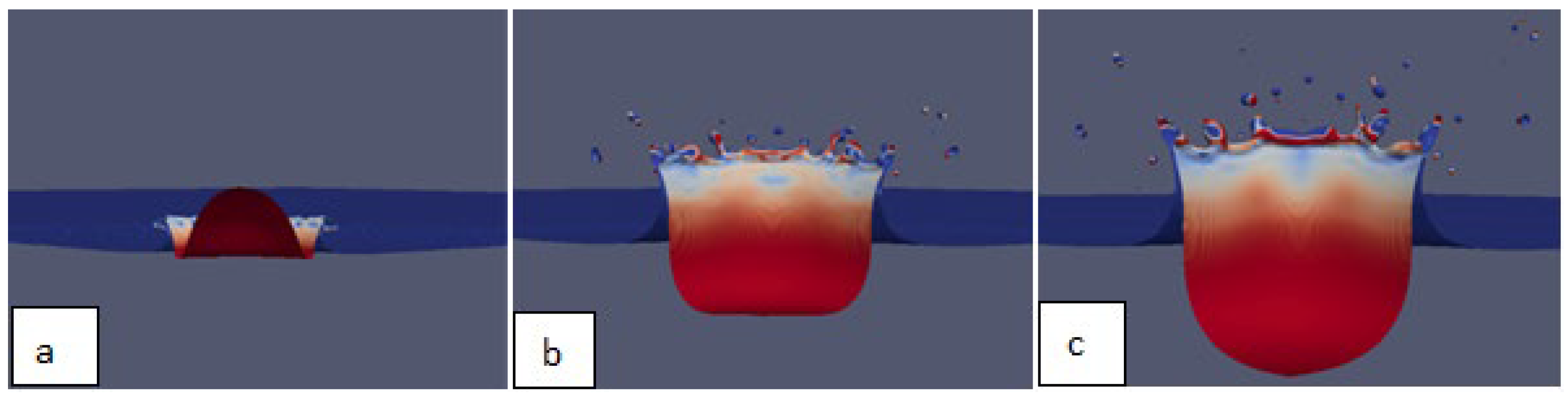

2.4. Image Analysis—Simulation of the Splash Phenomenon

- the simulated crown height (hs);

- the simulated external width of the crown (ws);

- the simulated depth of the cavity below the water surface (ds);

- the simulated spread of the cavity (ss), measured on the liquid level (Figure 3b);

- the simulated jet height (j_hs), measured from the bottom of the cavity (Figure 3c).

- the difference between the height of the experimental crown and its simulation (∆h);

- the difference between the external width of the experimental crown and its simulation (∆w);

- the difference between the depth of the experimental cavity and its simulation (∆d).

3. Results

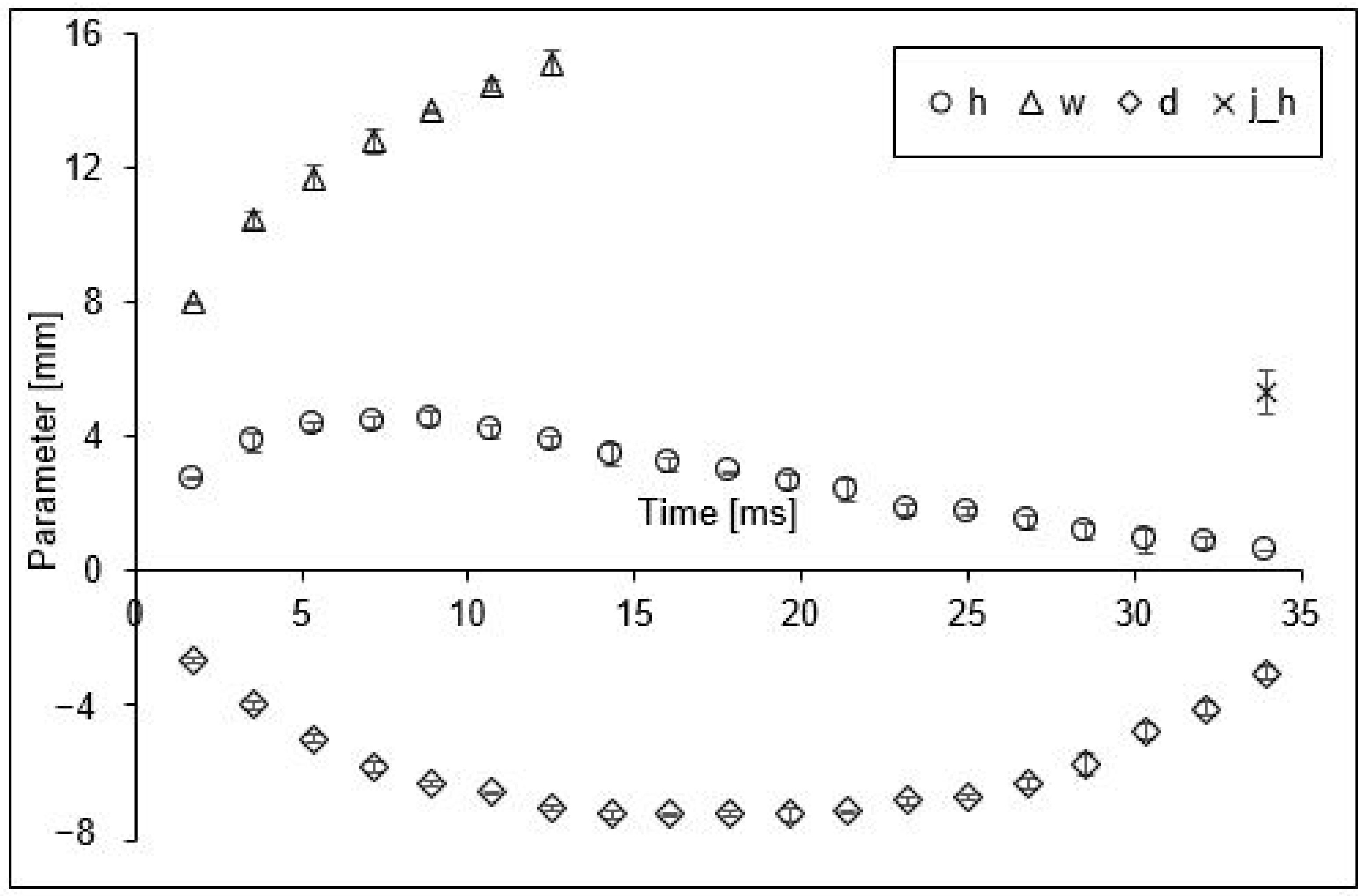

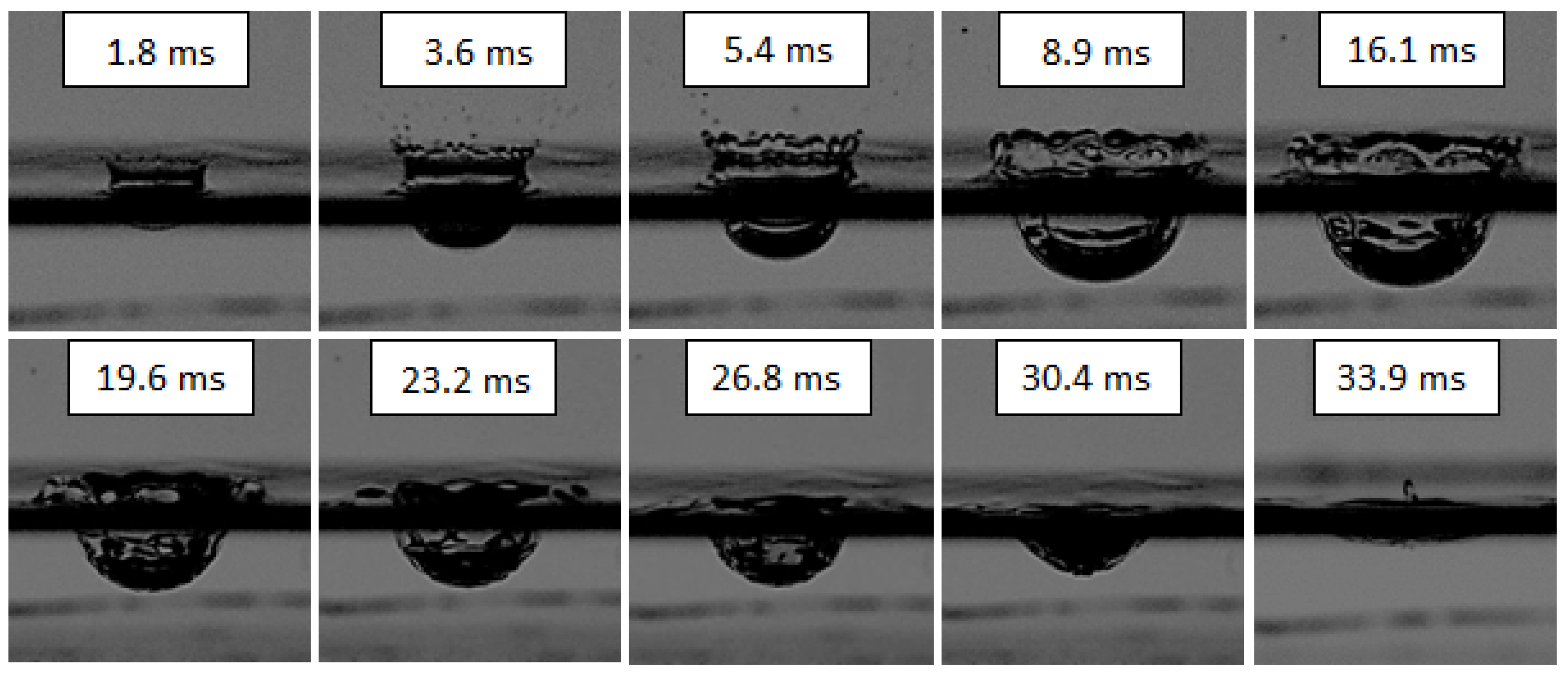

3.1. Results of the Experiment

3.2. Results of Simulations

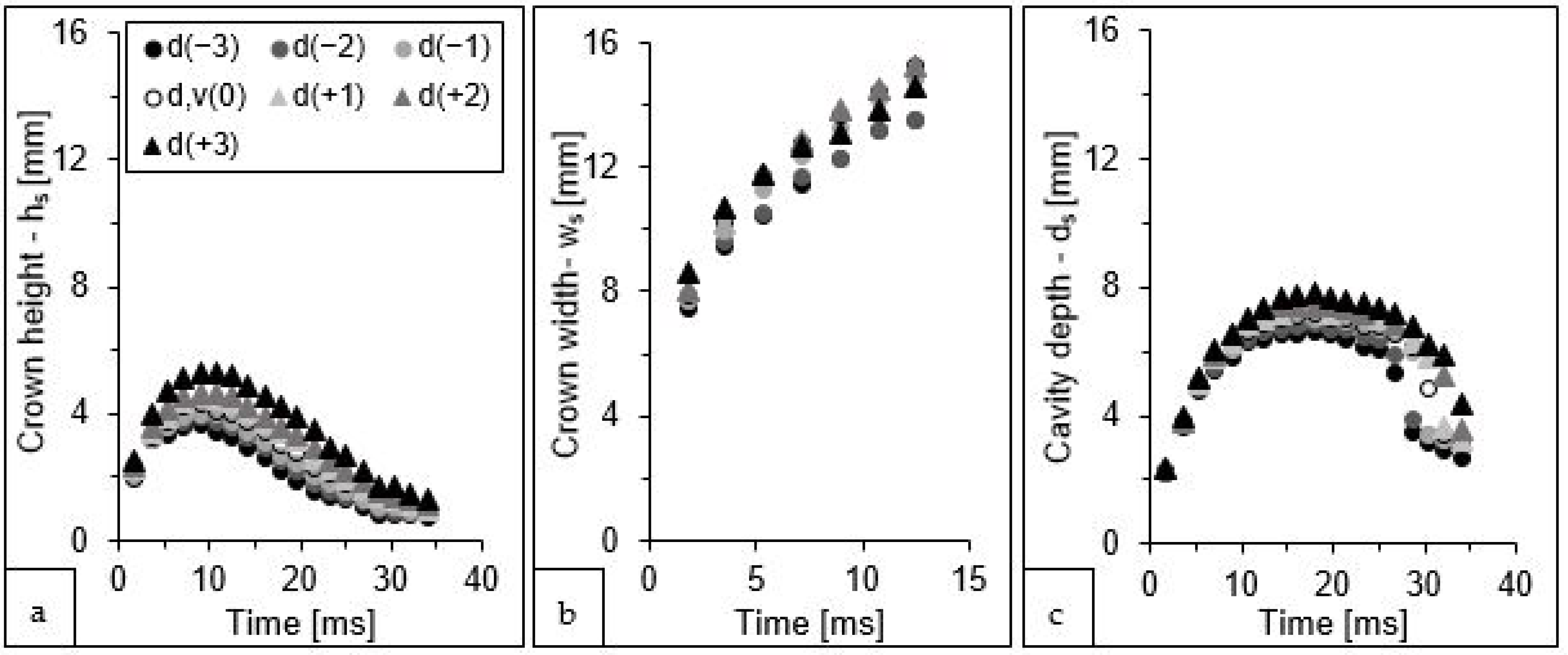

3.2.1. Effect of Drop Size

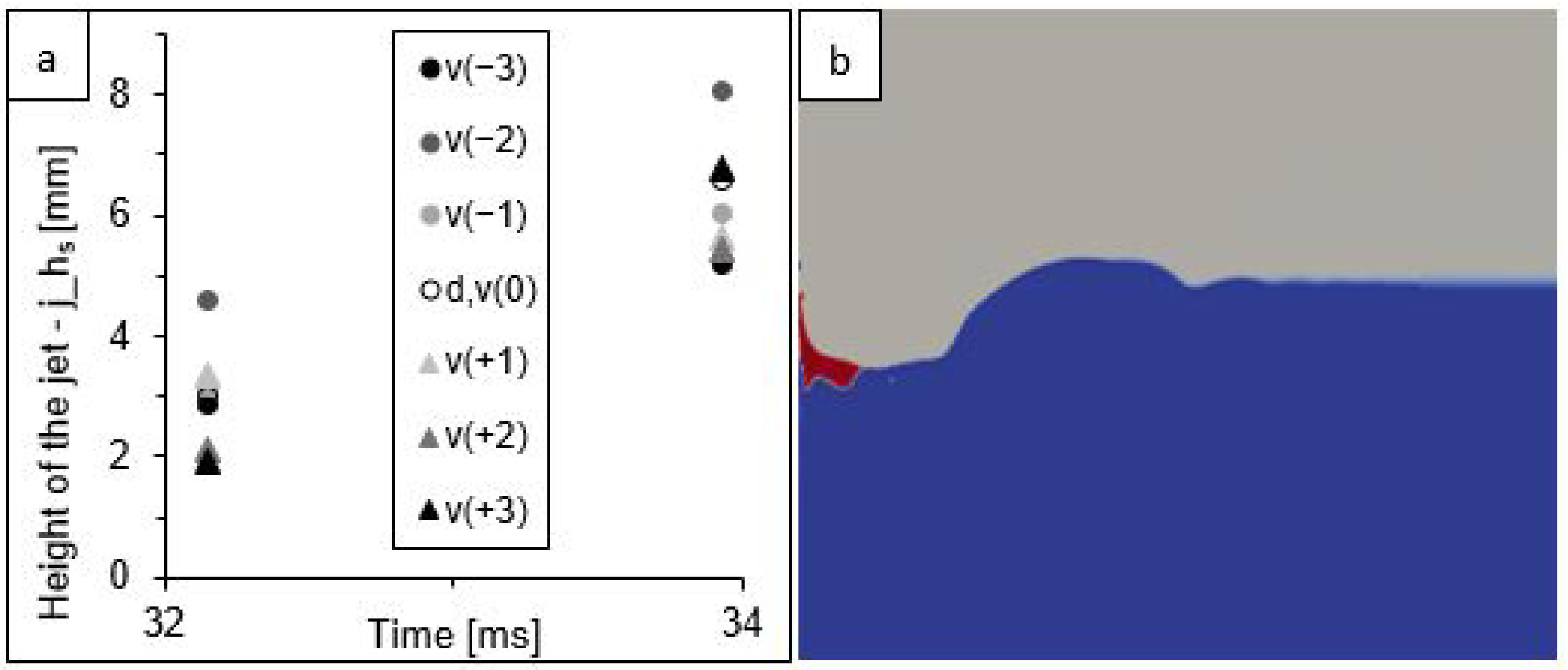

3.2.2. Effect of Drop Velocity

3.3. Model Validation

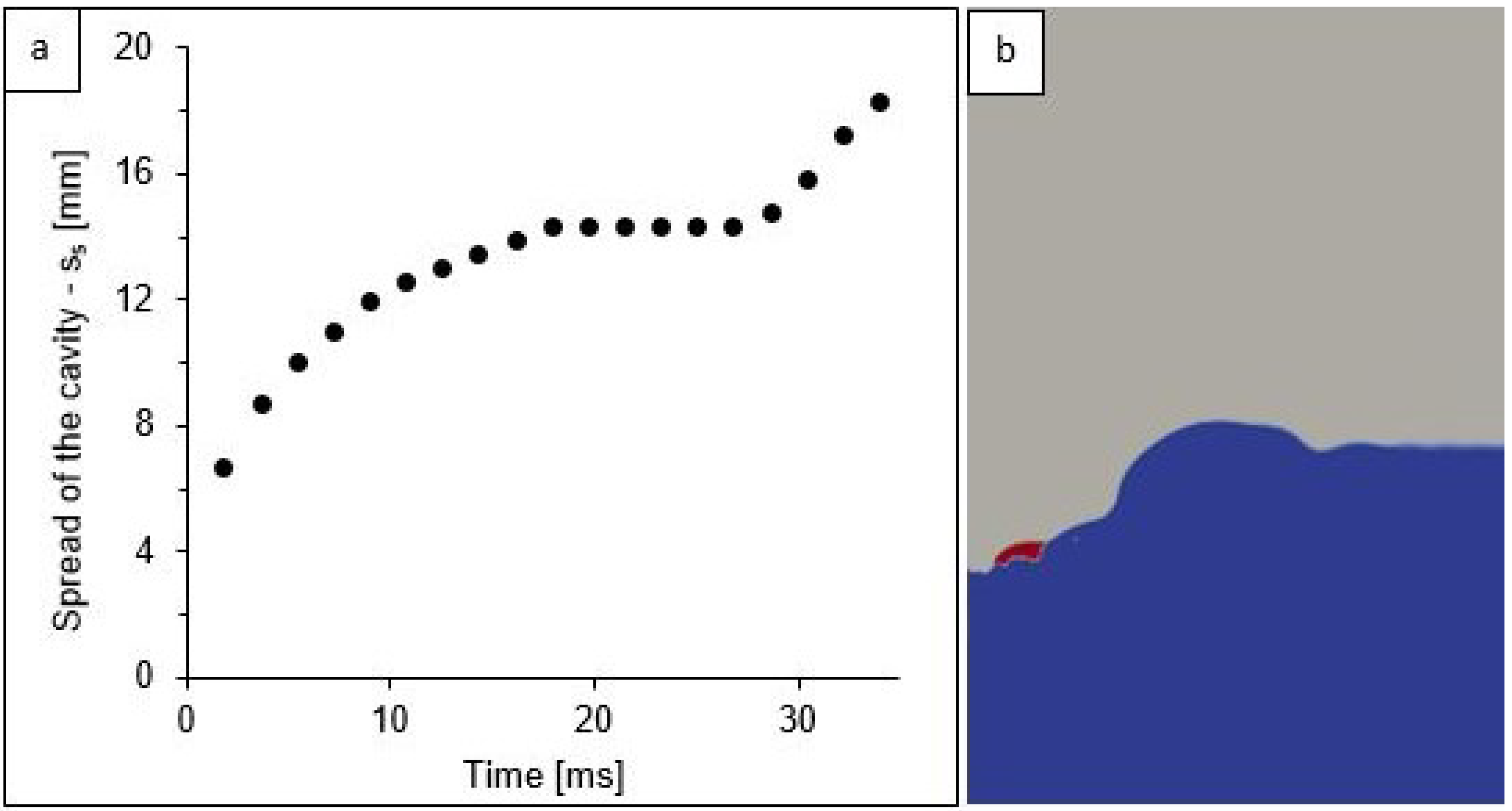

3.4. Stratification of Liquids

4. Discussion

4.1. Analysis of the Resulting Forms

4.2. Analysis of the Simulation of Changes in the Size of the Drop and Its Impact Velocity

4.3. Validation of the Model

4.4. Description of the Behaviour of Both Liquids (Petrol and Water) during a Splash

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Gilet, T.; Bush, W.M. Droplets bouncing on a wet, inclined surface. Phys. Fluids 2012, 24, 122103. [Google Scholar] [CrossRef]

- Lau, K.K.S.; Bico, J.; Teo, K.B.K.; Chhowalla, M.; Amaratunga, G.A.J.; Milne, W.I.; McKinley, G.H.; Gleason, K.K. Superhydrophobic carbon nanotube forests. Nanoletters 2003, 3, 1701–1705. [Google Scholar] [CrossRef] [Green Version]

- Yarin, A.L. Drop impact dynamics: Splashing, spreading, receding, bouncing…. Annu. Rev. Fluid Mech. 2006, 38, 159–192. [Google Scholar] [CrossRef]

- Ray, B.; Biswas, G.; Sharma, A. Generation of secondary droplets in coalescence of a drop at a liquid-liquid interface. J. Fluid Mech. 2010, 655, 72–104. [Google Scholar] [CrossRef]

- Rein, M. The transitional regime between coalescing and splashing drops. J. Fluid Mech. 1996, 306, 145–165. [Google Scholar] [CrossRef]

- Tran, T.; de Maleprade, H.; Sun, C.; Lohse, D. Air entrainment during impact of droplets on liquid surfaces. J. Fluid Mech. 2013, 726, R3. [Google Scholar] [CrossRef] [Green Version]

- Fedorchenko, A.I.; Wang, A.B. On some common features of drop impact on liquid surfaces. Phys. Fluids 2004, 16, 1349–1365. [Google Scholar] [CrossRef]

- Gielen, M.V.; Sleutel, P.; Benschop, J.; Riepen, M.; Voronina, V.; Visser, C.W.; Lohse, D.; Snoeijer, J.H.; Versluis, M.; Gelderblom, H. Oblique drop impact onto a deep liquid pool. Phys. Rev. Fluids 2017, 2, 083602. [Google Scholar] [CrossRef] [Green Version]

- Liow, J.L. Splash formation by spherical drops. J. Fluid Mech. 2001, 427, 73–105. [Google Scholar] [CrossRef]

- Lhuissier, H.; Sun, C.; Prosperetti, A.; Lohse, D. Drop Fragmentation at Impact onto a Bath of an Immiscible Liquid. Phys. Rev. Lett. 2013, 110, 264503. [Google Scholar] [CrossRef] [Green Version]

- Murphy, D.W.; Li, C.; d’Albignac, V.; Morra, D.; Katz, J. Splash behavior and oily marine aerosol production by raindrops impacting oil slicks. J. Fluid Mech. 2015, 780, 536–577. [Google Scholar] [CrossRef]

- Bisighini, A.; Cossali, G.E. High-speed visualization of interface phenomena: Single and double drop impacts onto a deep liquid layer. J. Vis. 2011, 14, 103–110. [Google Scholar] [CrossRef]

- Sochan, A.; Beczek, M.; Mazur, R.; Ryzak, M.; Bieganowski, A. The shape and dynamics of the generation of the splash forms in single-phase systems after drop hitting. Phys. Fluids 2018, 30, 027103. [Google Scholar] [CrossRef]

- Morton, D.; Rudman, M.; Jong-Leng, L. An investigation of the flow regimes resulting from splashing drops. Phys. Fluids 2000, 12, 747–763. [Google Scholar] [CrossRef]

- Zou, J.; Ji, C.; Yuan, B.; Ren, Y.; Ruan, X.; Fu, X. Large bubble entrapment during drop impacts on a restricted liquid surface. Phys. Fluids 2012, 24, 057101. [Google Scholar] [CrossRef]

- Castillo-Orozco, E.; Davanlou, A.; Choudhury, P.; Kumar, R. Droplet impact on deep liquid pools: Rayleigh jet to formation of secondary droplets. Phys. Rev. E 2015, 92, 053022. [Google Scholar] [CrossRef]

- Walker, T.W.; Logia, A.N.; Fuller, G.G. Multiphase flow of miscible liquids: Jets and drops. Exp. Fluids 2015, 56, 106. [Google Scholar] [CrossRef]

- Agbaglah, G.; Thoraval, M.-J.; Thoroddsen, S.T.; Zhang, L.V.; Fezzaa, K.; Deegan, R.D. Drop impact into a deep pool: Vortex shedding and jet formation. J. Fluid Mech. 2015, 764, R1. [Google Scholar] [CrossRef] [Green Version]

- Santini, M.; Fest-Santini, S.; Cossali, G.E. Experimental study of vortices and cavities from single and double drop impacts onto deep pools. Eur. J. Mech. B Fluids 2017, 62, 21–31. [Google Scholar] [CrossRef]

- Guilizzoni, M.; Santini, M.; Fest-Santini, S. Synchronized multiple drop impacts into a deep pool. Fluids 2019, 4, 141. [Google Scholar] [CrossRef] [Green Version]

- Liang, G.; Guo, Y.; Shen, S.; Yang, Y. Crown behavior and bubble entrainment during a drop impact on a liquid film. Theor. Comput. Fluid Dyn. 2014, 28, 159–170. [Google Scholar] [CrossRef]

- Yakhshi-Tafti, E.; Cho, H.J.; Kumar, R. Impact of drops on the surface of immiscible liquids. J. Colloid Interface Sci. 2010, 350, 373–376. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, X. Experimental study of drop impact on deep-water surface in the presence of wind. J. Phys. Oceanogr. 2018, 48, 329–341. [Google Scholar] [CrossRef]

- Fernández-Raga, M.; Cabeza-Ortega, M.; González-Castro, V.; Peters, P.; Commelin, M.; Campo, J. The use of high-speed cameras as a tool for the characterization of raindrops in splash laboratory studies. Water 2021, 13, 2851. [Google Scholar] [CrossRef]

- Fernández-Raga, M.; Fraile, R.; Keizer, J.J.; Varela Teijeiro, M.E.; Castro, A.; Palencia, C.; Calvo, A.I.; Koenders, J.; Da Costa Marques, R.L. The kinetic energy of rain measured with an optical disdrometer: An application to splash erosion. Atmos. Res. 2010, 96, 225–240. [Google Scholar] [CrossRef]

- Marzen, M.; Iserloh, T. Chapter 15—Processes of raindrop splash and effects on soil erosion. In Precipitation: Earth Surface Responses and Processes; Rodrigo-Comino, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 351–371. ISBN 9780128226995. [Google Scholar] [CrossRef]

- Doria, A.; Fanti, G.; Filipi, G.; Moro, F. Development of a novel piezoelectric harvester excited by raindrops. Sensors 2019, 19, 3653. [Google Scholar] [CrossRef] [Green Version]

- Hao, G.; Dong, X.; Li, Z.; Liu, X. Dynamic response of PVDF cantilever due to droplet impact using and electromechanical model. Sensors 2020, 20, 5764. [Google Scholar] [CrossRef]

- Helseth, L.E.; Wen, H.Z. Evaluation of the energy generation potential of rain cells. Energy 2017, 119, 472–482. [Google Scholar] [CrossRef]

- Basu, S. Computational characterization of inhaled droplet transport to the nasopharynx. Sci. Rep. 2021, 11, 6652. [Google Scholar] [CrossRef]

- Bourouiba, L. The Fluid Dynamics of Disease Transmission. Annu. Rev. Fluid Mech. 2021, 53, 473–508. [Google Scholar] [CrossRef]

- De Oliveira, P.M.; Mesquita, L.C.C.; Gkantonas, S.; Giusti, A.; Mastorakos, E. Evolution of spray and aerosol from respiratory releases: Theoretical estimates for insight on viral transmission. Proc. R. Soc. A Math. Phys. Eng. Sci. 2021, 477, 20200584. [Google Scholar] [CrossRef] [PubMed]

- Mügler, C.; Ribolzi, O.; Viguier, M.; Janeau, J.-L.; Jardé, E.; Latsachack, K.; Henry-Des-Tureaux, T.; Thammahacksa, C.; Valentin, C.; Sengtaheuanghoung, O.; et al. Experimental and modelling evidence of splash effects on manure borne Escherichia coli washoff. Environ. Sci. Pollut. Res. 2021, 28, 33009–33020. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Wilson, L.L.; Madden, L.V.; Ellis, M.A. Rain splash dispersal of Colletotrichum acutatum from infected strawberry fruit. Phytopathology 1990, 80, 590–595. [Google Scholar] [CrossRef]

- Deising, D.; Marschall, H.; Bothe, D. A unified single-field model framework for Volume-Of-Fluid simulations of interfacial species transfer applied to bubbly flows. Chem. Eng. Sci. 2016, 139, 173–195. [Google Scholar] [CrossRef]

- Hoang, D.A.; van Steijn, V.; Portela, L.M.; Kreutzer, M.T.; Kleijn, C.R. Benchmark numerical simulations of segmented two-phase flows in microchannels using the Volume of Fluid method. Comput. Fluids 2013, 86, 28–36. [Google Scholar] [CrossRef]

- Reijers, S.A.; Liu, B.; Lohse, D.; Gelderblom, H. Oblique droplet impact onto a deep liquid pool. arXiv 2019, arXiv:1903.08978. [Google Scholar]

- Rieber, M.; Frohn, A. A numerical study on the mechanism of splashing. Int. J. Heat Fluid Flow 1999, 20, 455–461. [Google Scholar] [CrossRef]

- Erwee, M.W.; Reynolds, Q.G.; Zietsman, J.H.; Bezuidenhout, P.J.A. Multiphase flow modelling of lancing of furnace tap-holes: Validation of multiphase flow simulated in OpenFOAM®. J. S. Afr. Inst. Min. Metall. 2019, 119, 551–556. [Google Scholar] [CrossRef]

- Luo, M.; Xue, M.-A.; Yuan, X.; Zhang, F.; Xu, Z. Experimental and Numerical Study of Stratified Sloshing in a Tank under Horizontal Excitation. Shock Vib. 2021, 2021, 6639223. [Google Scholar] [CrossRef]

- EN ISO 12185:1996; Crude Petroleum and Petroleum Products—Determination of Density—Oscillating U-Tube Method. International Organization for Standardization: Geneva, Switzerland, 1996.

- EN ISO 3104:1996; Petroleum and Its Products—Kinematic Viscosity—Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. International Organization for Standardization: Geneva, Switzerland, 2020.

- Beczek, M.; Ryżak, M.; Sochan, A.; Mazur, R.; Polakowski, C.; Hess, D.; Bieganowski, A. Methodological aspects of using high-speed cameras to quantify soil splash phenomenon. Geoderma 2020, 378, 114592. [Google Scholar] [CrossRef]

- Sochan, A.; Łagodowski, A.; Nieznaj, E.; Beczek, M.; Ryżak, M.; Mazur, R.; Bobrowski, A.; Bieganowski, A. Splash of solid particles as a stochastic point proces. J. Geophys. Res. Earth 2019, 124, 2475–2490. [Google Scholar] [CrossRef]

- Beczek, M.; Ryżak, M.; Sochan, A.; Mazur, R.; Bieganowski, A. The mass ratio of splashed particles during raindrop splash phenomenon on soil surface. Geoderma 2019, 347, 40–48. [Google Scholar] [CrossRef]

- GIMP. Available online: https://www.gimp.org/ (accessed on 3 January 2022).

- OpenFOAM v.2.1.1. Available online: http://www.openfoam.com (accessed on 3 January 2022).

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Deshpande, S.S.; Anumolu, L.; Trujillo, M.F. Evaluating the performance of the two-phase flow solver interFoam. Comput. Sci. Discov. 2012, 5, 014016. [Google Scholar] [CrossRef]

- ParaView. Available online: https://www.paraview.org/ (accessed on 3 January 2022).

- Cheng, M.; Lou, J. A numerical study on splash of oblique drop impact on wet walls. Comput. Fluids 2015, 115, 11–24. [Google Scholar] [CrossRef]

- Beczek, M.; Ryżak, M.; Sochan, A.; Mazur, R.; Polakowski, C.; Bieganowski, A. The differences in crown formation during the splash on the thin water layers formed on the saturated soil surface and model surface. PLoS ONE 2017, 12, e0181974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vander Wal, R.L.; Berger, G.M. Droplets splashing upon films of the same fluid of various depths. Exp. Fluids 2006, 40, 33–52. [Google Scholar] [CrossRef]

- Rioboo, R.; Bauthier, C.; Conti, J.; Voue, M.; De Coninck, J. Experimental investigation of splash and crown formation during single drop impact on wetted surfaces. Exp. Fluids 2003, 35, 648–652. [Google Scholar] [CrossRef]

- Krechetnikov, R.; Homsy, G.M. Crown-forming instability phenomena in the drop splash problem. J. Colloid Interface Sci. 2009, 331, 555–559. [Google Scholar] [CrossRef]

- Bouwhuis, W.; Huang, X.; Chan, C.U.; Frommhold, P.E.; Ohl, C.D.; Lohse, D.; Snoeijer, J.H.; van der Meer, D.J. Impact of a high-speed train of microdrops on a liquid pool. Fluid Mech. 2016, 792, 850–868. [Google Scholar] [CrossRef] [Green Version]

- Kittel, H.M.; Roisman, I.V.; Tropea, C. Splash of a drop impacting onto a solid substrate wetted by a thin film of another liquid. Phys. Rev. Fluids 2018, 3, 073601. [Google Scholar] [CrossRef]

- Saylor, J.R.; Bounds, G.D. Experimental study of the role of the Weber and capillary numbers on Mesler entrainment. AIChE J. 2012, 58, 3841–3851. [Google Scholar] [CrossRef]

- Chen, X.; Mandre, S.; Feng, J.J. Partial coalescence between a drop and a liquid-liquid interface. Phys. Fluids 2006, 18, 051705. [Google Scholar] [CrossRef] [Green Version]

- Thoroddsen, S.T.; Takehara, K. The coalescence cascade of a drop. Phys. Fluids 2000, 12, 1265. [Google Scholar] [CrossRef]

| Fluid Property (in 20 °C) | Water | Petrol | Air |

|---|---|---|---|

| Density (kg∙m−3) | 998.2 | 748.0 | 1.2 |

| Kinematic viscosity (m2∙s−1) | 1.0 × 10−6 | 0.4 × 10−6 | 14.9 × 10−6 |

| Surface tension for a fluid-air interface (mN∙m−1) | 72.94 | 28.42 | - |

| Interfacial tension (mN∙m−1) | 35.0 | ||

| Modelling Variant | Drop Properties | ||

|---|---|---|---|

| Diameter (d) (mm) | Velocity (v) (m∙s−1) | ||

| d(−3) | −3 pixels | 3.00 | 3.37 |

| d(−2) | −2 pixels | 3.10 | |

| d(−1) | −1 pixel | 3.20 | |

| d,v(0) | Read from the recorded frame | 3.30 | |

| d(+1) | +1 pixel | 3.40 | |

| d(+2) | +2 pixels | 3.50 | |

| d(+3) | +3 pixels | 3.60 | |

| v(−3) | −3 pixels | 3.30 | 3.29 |

| v(−2) | −2 pixels | 3.32 | |

| v(−1) | −1 pixel | 3.34 | |

| d,v(0) | Read from the recorded frame | 3.37 | |

| v(+1) | +1 pixel | 3.39 | |

| v(+2) | +2 pixels | 3.42 | |

| v(+3) | +3 pixels | 3.44 | |

| Drop Size Variants | |||||||

| d(−3) | d(−2) | d(−1) | d,v(0) | d(+1) | d(+2) | d(+3) | |

| crown height | 0.20 | 0.15 | 0.10 | −0.03 | −0.14 | −0.22 | −0.43 |

| crown width | 0.10 | 0.09 | 0.04 | 0.00 | −0.01 | −0.01 | 0.01 |

| cavity depth | 0.10 | 0.06 | 0.03 | 0.01 | −0.02 | −0.03 | −0.06 |

| Drop Velocity Variants | |||||||

| v(−3) | v(−2) | v(−1) | d,v(0) | v(+1) | v(+2) | v(+3) | |

| crown height | 0.05 | −0.03 | −0.03 | −0.03 | −0.06 | −0.07 | −0.08 |

| crown width | 0.04 | 0.02 | 0.02 | 0.00 | 0.01 | 0.01 | 0.01 |

| cavity depth | 0.02 | 0.03 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sochan, A.; Lamorski, K.; Bieganowski, A. Numerical Simulation and Experimental Study of the Drop Impact for a Multiphase System Formed by Two Immiscible Fluids. Sensors 2022, 22, 3126. https://doi.org/10.3390/s22093126

Sochan A, Lamorski K, Bieganowski A. Numerical Simulation and Experimental Study of the Drop Impact for a Multiphase System Formed by Two Immiscible Fluids. Sensors. 2022; 22(9):3126. https://doi.org/10.3390/s22093126

Chicago/Turabian StyleSochan, Agata, Krzysztof Lamorski, and Andrzej Bieganowski. 2022. "Numerical Simulation and Experimental Study of the Drop Impact for a Multiphase System Formed by Two Immiscible Fluids" Sensors 22, no. 9: 3126. https://doi.org/10.3390/s22093126

APA StyleSochan, A., Lamorski, K., & Bieganowski, A. (2022). Numerical Simulation and Experimental Study of the Drop Impact for a Multiphase System Formed by Two Immiscible Fluids. Sensors, 22(9), 3126. https://doi.org/10.3390/s22093126