Respiratory Monitoring by Ultrafast Humidity Sensors with Nanomaterials: A Review

Abstract

1. Introduction

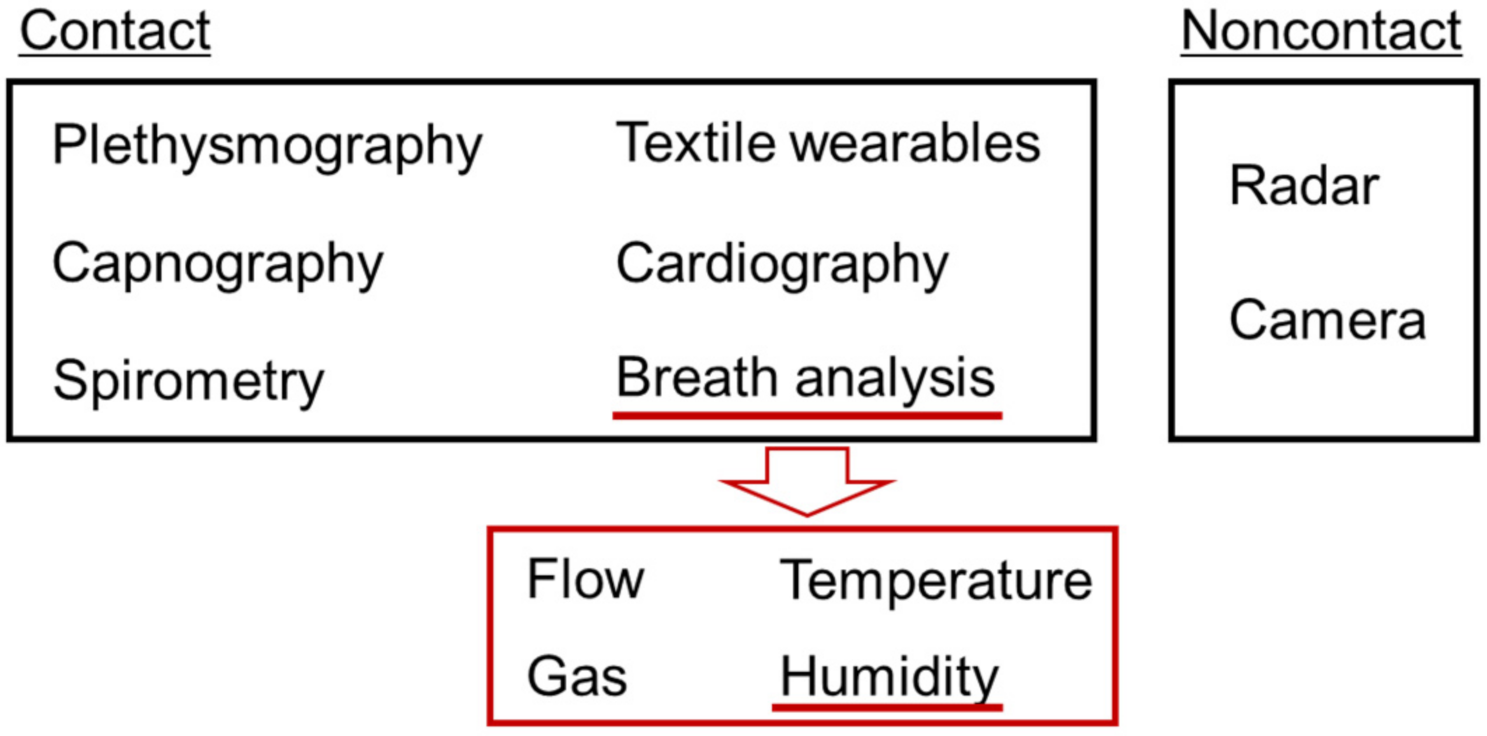

2. Respiration Measured by Humidity Sensor

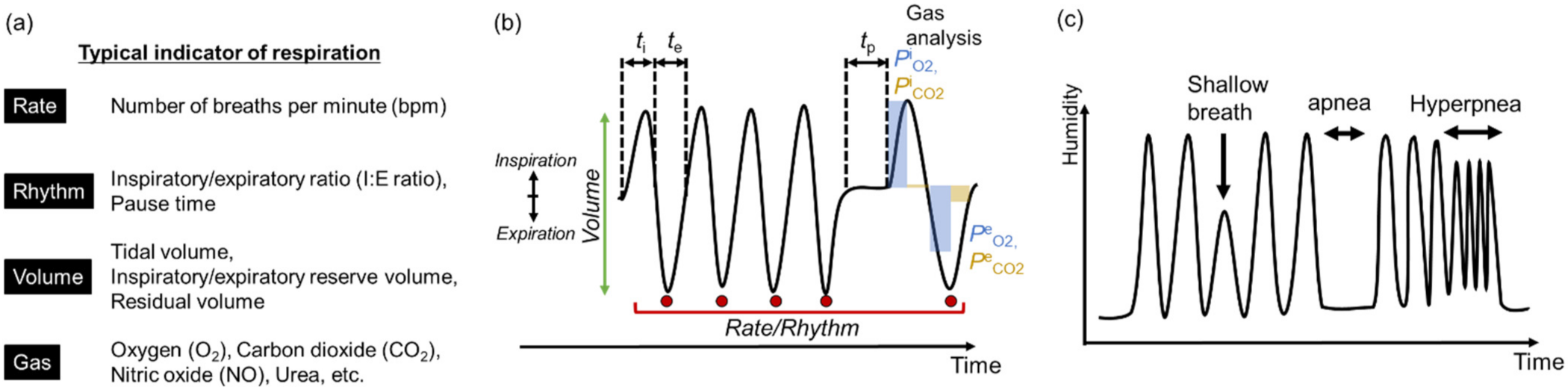

2.1. Indicators of Respiration

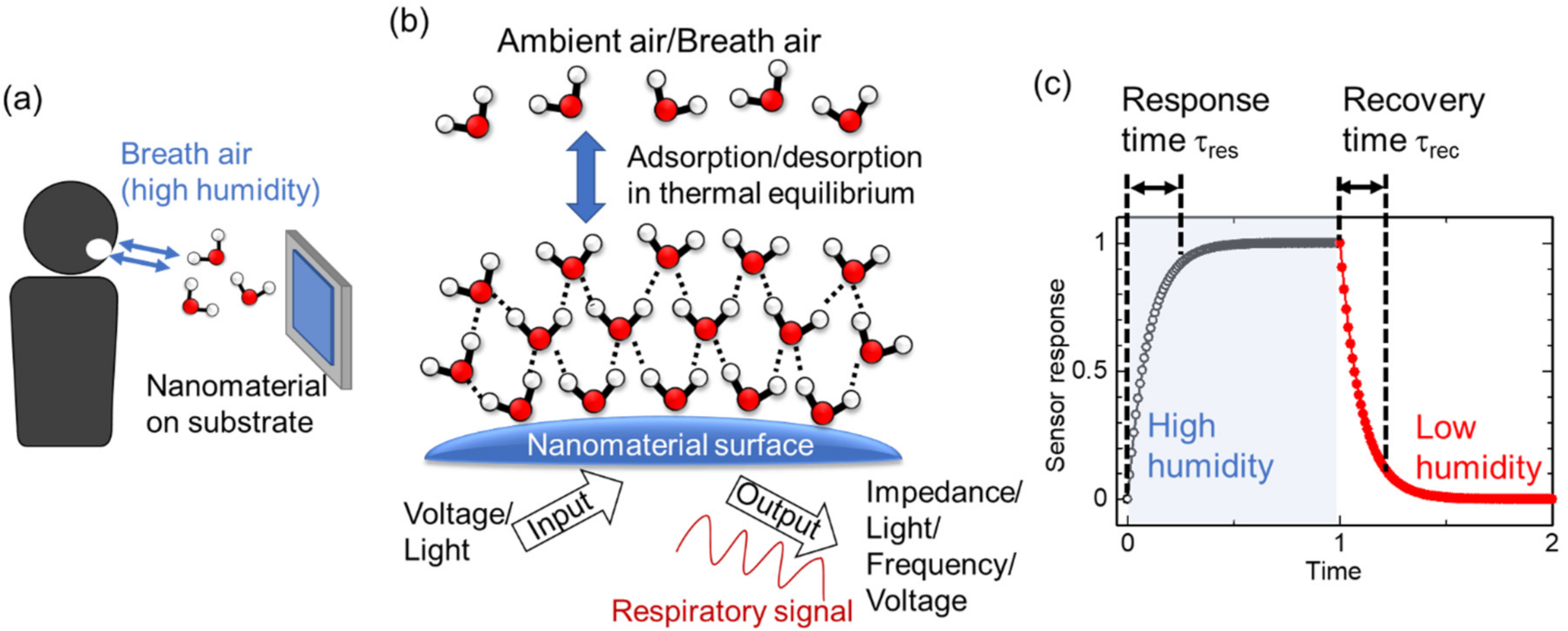

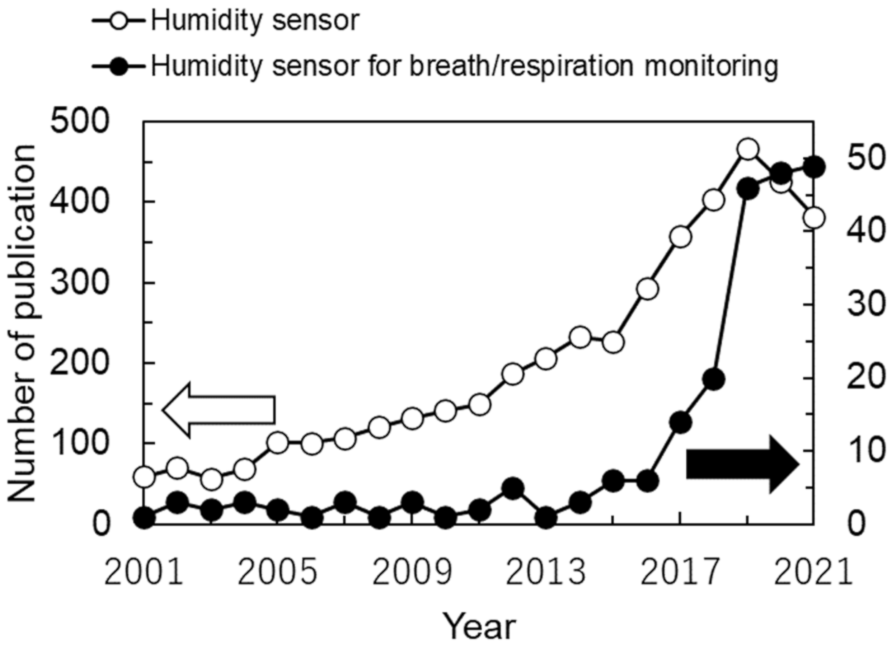

2.2. Concept to Monitor Respiration with Humidity-Sensitive Nanomaterial

2.3. Early Works of Respiratory Monitoring by Humidity Sensors

3. Types of Fast-Response Humidity Sensor

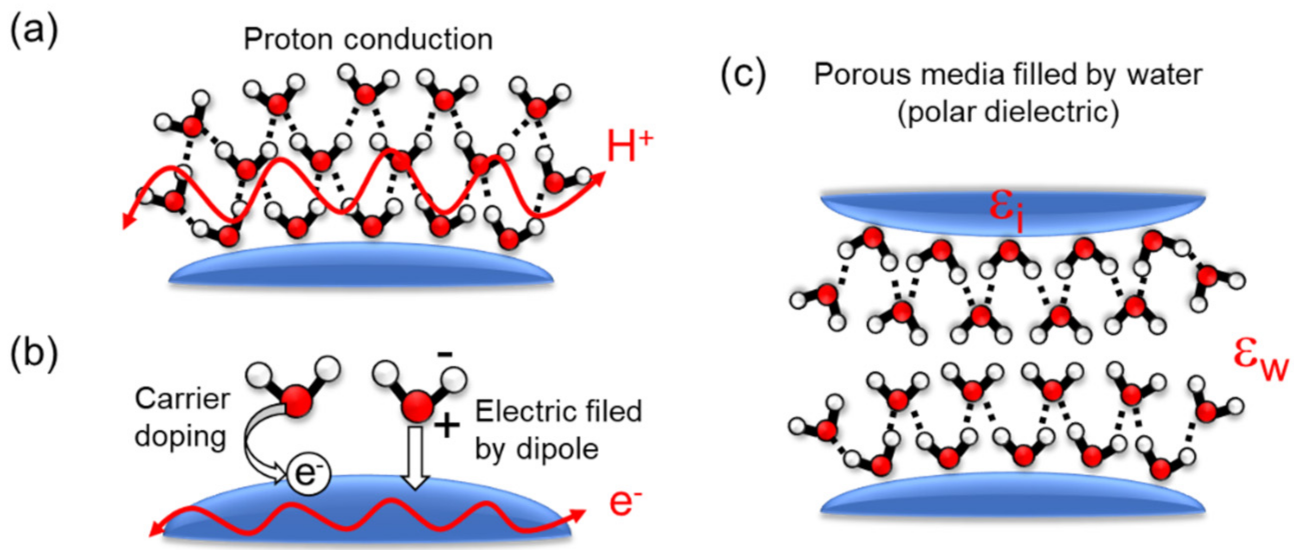

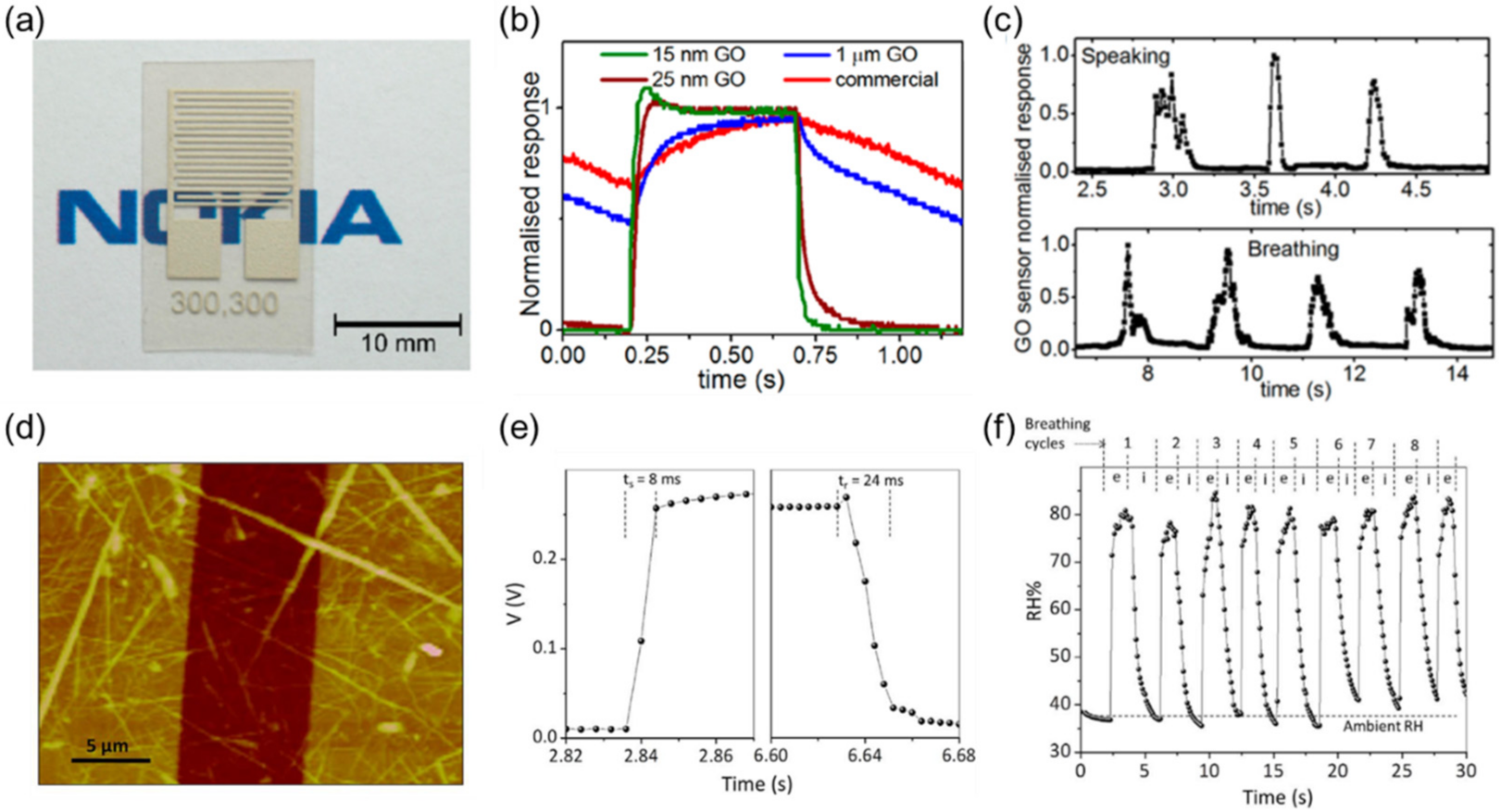

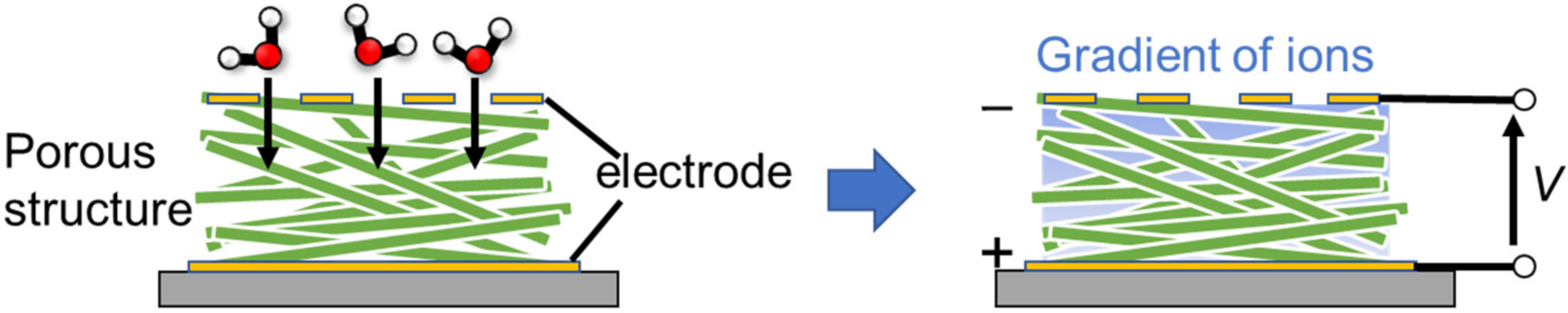

3.1. Impedance-Based Humidity Sensor

3.2. Optical Humidity Sensor

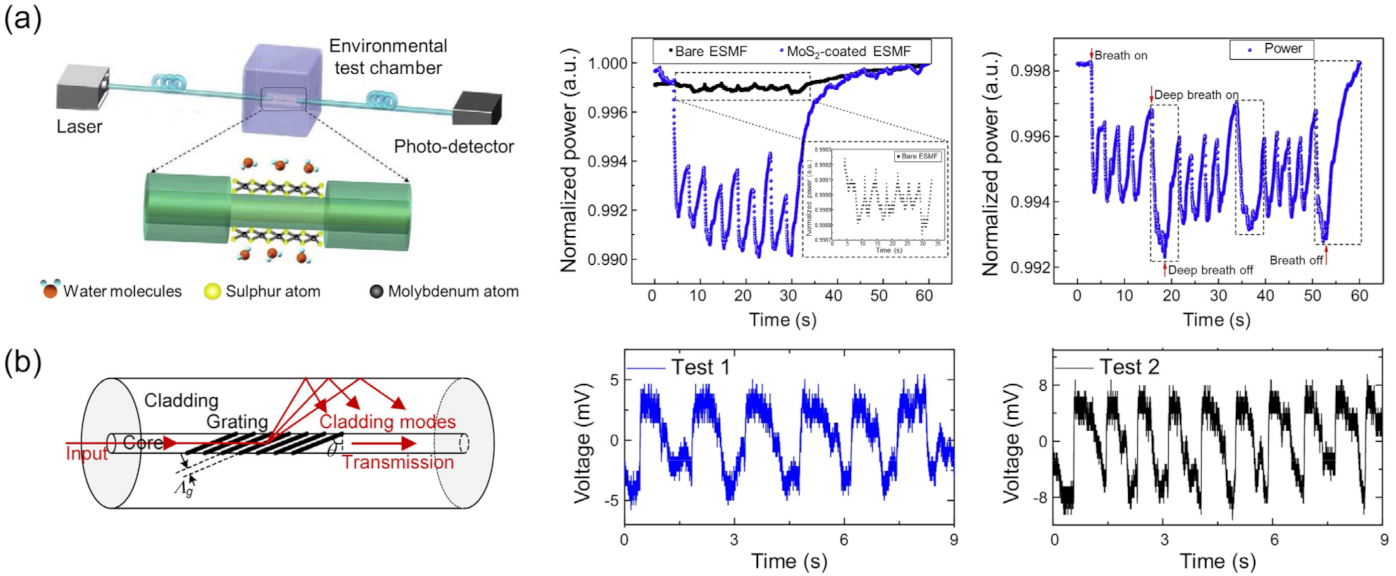

3.2.1. Optical Fiber Humidity Sensors

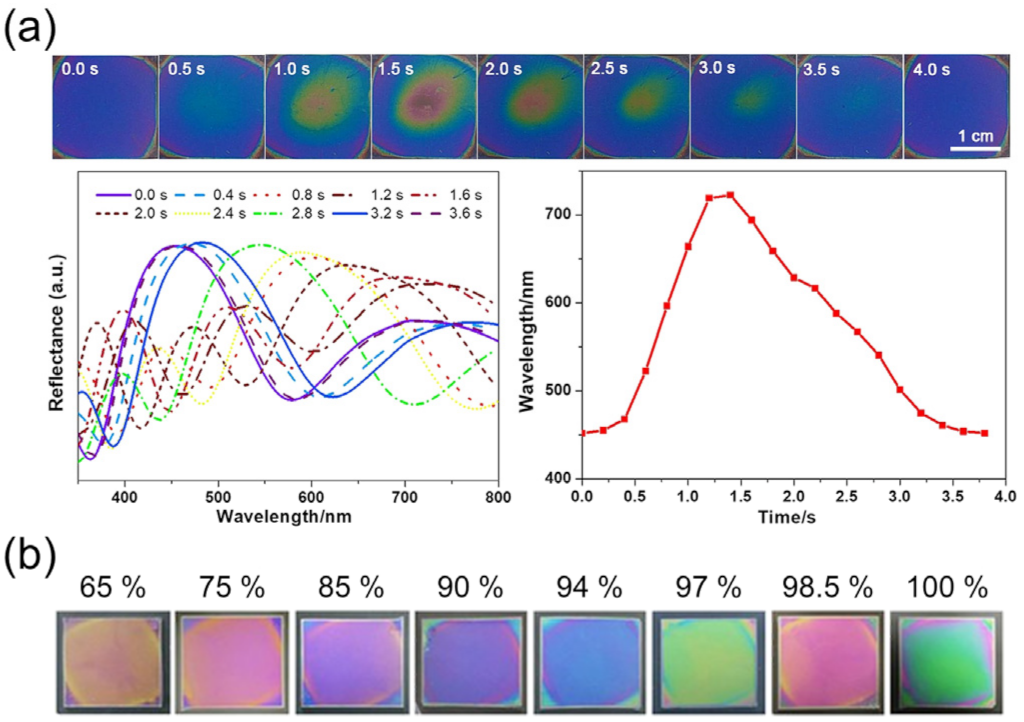

3.2.2. Colorimetric Optical Humidity Sensors

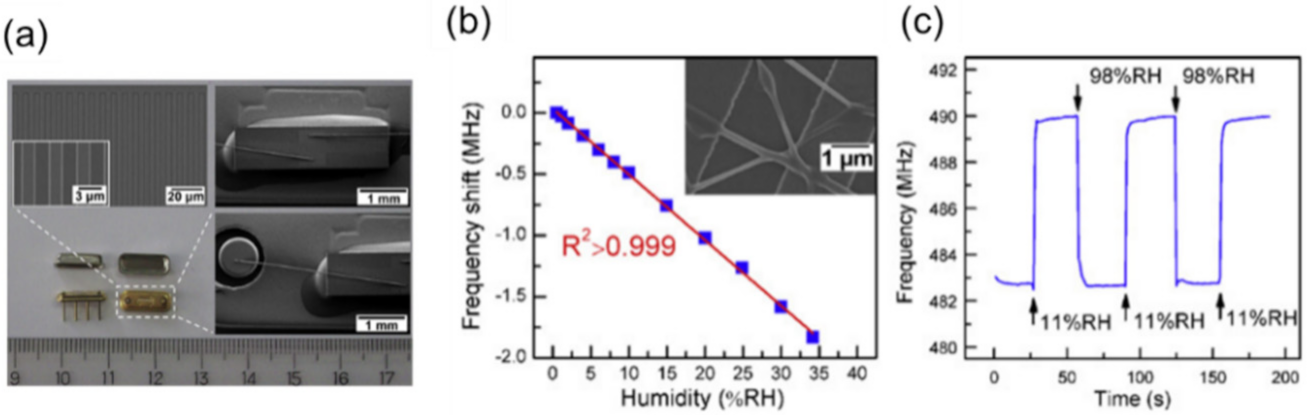

3.3. Frequency-Based Humidity Sensor

3.4. Self-Powered Humidity Sensor

4. Response and Recovery of Reported Fast-Response Humidity Sensors

4.1. Comparison of Response/Recovery Time

4.2. Design Strategy of Nanostructure to Achieve Ultrafast Response and Recovery

5. Benefits of Respiratory Monitoring Using Humidity Sensor

6. Other Application for Physiological Monitoring

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Yuan, G.; Drost, A.N.; Mclvor, R.A. Respiratory Rate and Breathing Pattern. McMaster Univ. Med. J. 1990, 10, 23–25. [Google Scholar]

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395. [Google Scholar] [CrossRef] [PubMed]

- Cretikos, M.A.; Bellomo, R.; Hillman, K.; Chen, J.; Finfer, S.; Flabouris, A. Respiratory rate: The neglected vital sign. Med. J. Aust. 2008, 188, 657–659. [Google Scholar] [CrossRef]

- Nicolò, A.; Massaroni, C.; Schena, E.; Sacchetti, M. The importance of respiratory rate monitoring: From healthcare to sport and exercise. Sensors 2020, 20, 6396. [Google Scholar] [CrossRef] [PubMed]

- McMurray, R.G.; Ahlborn, S.W. Respiratory responses to running and walking at the same metabolic rate. Respir. Physiol. 1982, 47, 257–265. [Google Scholar] [CrossRef]

- Homma, I.; Masaoka, Y. Breathing rhythms and emotions. Exp. Physiol. 2008, 93, 1011–1021. [Google Scholar] [CrossRef] [PubMed]

- Boiten, F.A.; Frijda, N.H.; Wientjes, C.J.E. Emotions and respiratory patterns: Review and critical analysis. Int. J. Psychophysiol. 1994, 17, 103–128. [Google Scholar] [CrossRef]

- Bendixen, H.H.; Smith, G.M.; Mead, J. Pattern of Ventilation in Young Adults. J. Appl. Physiol. 1964, 19, 195–198. [Google Scholar] [CrossRef]

- Vlemincx, E.; Taelman, J.; De Peuter, S.; Van Diest, I.; Van Den Bergh, O. Sigh rate and respiratory variability during mental load and sustained attention. Psychophysiology 2011, 48, 117–120. [Google Scholar] [CrossRef]

- Yilmaz, T.; Foster, R.; Hao, Y. Detecting vital signs with wearable wireless sensors. Sensors 2010, 10, 10837–10862. [Google Scholar] [CrossRef]

- Al-Khalidi, F.Q.; Saatchi, R.; Burke, D.; Elphick, H.; Tan, S. Respiration rate monitoring methods: A review. Pediatr. Pulmonol. 2011, 46, 523–529. [Google Scholar] [CrossRef] [PubMed]

- Massaroni, C.; Nicolò, A.; Lo Presti, D.; Sacchetti, M.; Silvestri, S.; Schena, E. Contact-Based Methods for Measuring Respiratory Rate. Sensors 2019, 19, 908. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Allen, J.; Zheng, D.; Chen, F. Recent development of respiratory rate measurement technologies. Physiol. Meas. 2019, 40. [Google Scholar] [CrossRef] [PubMed]

- Mercuri, M.; Lorato, I.R.; Liu, Y.-H.; Wieringa, F.; van Hoof, C.; Torfs, T. Vital-sign monitoring and spatial tracking of multiple people using a contactless radar-based sensor. Nat. Electron. 2019, 2, 252–262. [Google Scholar] [CrossRef]

- Sharma, P.; Hui, X.; Zhou, J.; Conroy, T.B.; Kan, E.C. Wearable radio-frequency sensing of respiratory rate, respiratory volume, and heart rate. NPJ Digit. Med. 2020, 3, 1–10. [Google Scholar] [CrossRef]

- Kano, S.; Mekaru, H. Nonporous Inorganic Nanoparticle-Based Humidity Sensor: Evaluation of Humidity Hysteresis and Response Time. Sensors 2020, 20, 3858. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Tai, H. Recent advances in humidity sensors for human body related humidity detection. J. Mater. Chem. C 2021, 9, 14963–14980. [Google Scholar] [CrossRef]

- Hooker, E.A.; O’Brien, D.J.; Danzl, D.F.; Barefoot, J.A.C.; Brown, J.E. Respiratory rates in emergency department patients. J. Emerg. Med. 1989, 7, 129–132. [Google Scholar] [CrossRef]

- Folke, M.; Cernerud, L.; Ekström, M.; Hök, B. Critical review of non-invasive respiratory monitoring in medical care. Med. Biol. Eng. Comput. 2003, 41, 377–383. [Google Scholar] [CrossRef]

- Braun, S.R. Respiratory Rate and Pattern. In Clinical Methods: The History, Physical, and Laboratory Examinations; Walker, H.K., Hall, W.D., Hurst, J.W., Eds.; Butterworths: Boston, MA, USA, 1990; pp. 226–230. ISBN 040990077X. [Google Scholar]

- Jin, H.; Abu-Raya, Y.S.; Haick, H. Advanced Materials for Health Monitoring with Skin-Based Wearable Devices. Adv. Healthc. Mater. 2017, 6, 1700024. [Google Scholar] [CrossRef]

- Iliff, A.; Lee, V.A. Pulse rate, respiratory rate, and body temperature of children between two months and eighteen years of age. Child Dev. 1952, 23, 237–245. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.; Wang, L.; Jiang, K.; Wei, Z.; Shen, G. Reviews of wearable healthcare systems: Materials, devices and system integration. Mater. Sci. Eng. R Rep. 2020, 140, 100523. [Google Scholar] [CrossRef]

- Sundkvist, G.; Almér, L.O.; Lilja, B. Respiratory influence on heart rate in diabetes mellitus. Br. Med. J. 1979, 1, 924–925. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Hall, J.E. Guyton and Hall Textbook of Medical Physiology, 13th ed.; Elsevier: Philadelphia, PA, USA, 2016. [Google Scholar]

- Su, Y.; Chen, G.; Chen, C.; Gong, Q.; Xie, G.; Yao, M.; Tai, H.; Jiang, Y.; Chen, J. Self-Powered Respiration Monitoring Enabled By a Triboelectric Nanogenerator. Adv. Mater. 2021, 33, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Risby, T.H.; Solga, S.F. Current status of clinical breath analysis. Appl. Phys. B Lasers Opt. 2006, 85, 421–426. [Google Scholar] [CrossRef]

- Yao, S.; Swetha, P.; Zhu, Y. Nanomaterial-Enabled Wearable Sensors for Healthcare. Adv. Healthc. Mater. 2018, 7, 1700889. [Google Scholar] [CrossRef]

- Muto, S.; Sato, H.; Hosaka, T. Optical Humidity Sensor Using Fluorescent Plastic Fiber and Its Application to Breathing-Condition Monitor. Jpn. J. Appl. Phys. 1994, 33, 6060–6064. [Google Scholar] [CrossRef]

- Tatara, T.; Tsuzaki, K. An Apnea monitor using a rapid-response hygrometer. J. Clin. Monit. 1997, 13, 5–9. [Google Scholar] [CrossRef]

- Laville, C.; Deletage, J.Y.; Pellet, C. Humidity sensors for a pulmonary function diagnostic microsystem. Sens. Actuators B Chem. 2001, 76, 304–309. [Google Scholar] [CrossRef]

- Kuban, P.; Berg, J.M.; Dasgupta, P.K. Durable Microfabricated High-Speed Humidity Sensors. Anal. Chem. 2004, 76, 2561–2567. [Google Scholar] [CrossRef]

- Miyoshi, Y.; Miyajima, K.; Saito, H.; Kudo, H.; Takeuchi, T.; Karube, I.; Mitsubayashi, K. Flexible humidity sensor in a sandwich configuration with a hydrophilic porous membrane. Sens. Actuators B Chem. 2009, 142, 28–32. [Google Scholar] [CrossRef]

- Regtien, P.P.L. Solid-state humidity sensors. Sens. Actuators 1981, 2, 85–95. [Google Scholar] [CrossRef]

- Yamazoe, N.; Shimizu, Y. Humidity sensors: Principles and applications. Sens. Actuators 1986, 10, 379–398. [Google Scholar] [CrossRef]

- Jachowicz, R.S.; Senturia, S.D. A thin-film capacitance humidity sensor. Sens. Actuators 1981, 2, 171–186. [Google Scholar] [CrossRef]

- Agmon, N. The Grotthuss mechanism. Chem. Phys. Lett. 1995, 244, 456–462. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity Sensors: A Review of Materials and Mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Seo, M.-H.; Yang, H.-H.; Choi, K.-W.; Lee, J.-S.; Yoon, J.-B. A simple breathing rate-sensing method exploiting a temporarily condensed water layer formed on an oxidized surface. Appl. Phys. Lett. 2015, 106, 053701. [Google Scholar] [CrossRef]

- Asay, D.B.; Kim, S.H. Evolution of the Adsorbed Water Layer Structure on Silicon Oxide at Room Temperature. J. Phys. Chem. B 2005, 109, 16760–16763. [Google Scholar] [CrossRef]

- Wang, L.; Duan, X.; Xie, W.; Li, Q.; Wang, T. Highly chemoresistive humidity sensing using poly(ionic liquid)s. Chem. Commun. 2016, 52, 8417–8419. [Google Scholar] [CrossRef]

- Dai, J.; Zhao, H.; Lin, X.; Liu, S.; Liu, Y.; Liu, X.; Fei, T.; Zhang, T. Ultrafast Response Polyelectrolyte Humidity Sensor for Respiration Monitoring. ACS Appl. Mater. Interfaces 2019. [Google Scholar] [CrossRef]

- Dai, J.; Zhao, H.; Lin, X.; Liu, S.; Fei, T.; Zhang, T. Design strategy for ultrafast-response humidity sensors based on gel polymer electrolytes and application for detecting respiration. Sens. Actuators B Chem. 2020, 304, 127270. [Google Scholar] [CrossRef]

- Dai, J.; Guan, X.; Zhao, H.; Liu, S.; Fei, T.; Zhang, T. In Situ Preparation of Porous Humidity Sensitive Composite via a One-Stone-Two-Birds Strategy. Sens. Actuators B Chem. 2020, 316, 128159. [Google Scholar] [CrossRef]

- Liu, X.; Fu, T.; Ward, J.; Gao, H.; Yin, B.; Woodard, T.; Lovley, D.R.; Yao, J. Multifunctional Protein Nanowire Humidity Sensors for Green Wearable Electronics. Adv. Electron. Mater. 2020, 6, 2000721. [Google Scholar] [CrossRef]

- Guan, X.; Hou, Z.; Wu, K.; Zhao, H.; Liu, S.; Fei, T.; Zhang, T. Flexible humidity sensor based on modified cellulose paper. Sens. Actuators B Chem. 2021, 339, 129879. [Google Scholar] [CrossRef]

- Wang, C.-T.; Wu, C.-L.; Chen, I.-C.; Huang, Y.-H. Humidity sensors based on silica nanoparticle aerogel thin films. Sens. Actuators B Chem. 2005, 107, 402–410. [Google Scholar] [CrossRef]

- Su, P.G.; Huang, L.N. Humidity sensors based on TiO2 nanoparticles/polypyrrole composite thin films. Sens. Actuators B Chem. 2007, 123, 501–507. [Google Scholar] [CrossRef]

- Su, P.G.; Tseng, J.Y.; Huang, Y.C.; Pan, H.H.; Li, P.C. Novel fully transparent and flexible humidity sensor. Sens. Actuators B Chem. 2009, 137, 496–500. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Wang, Z.; Yan, Q.; Hui, S. Humidity sensing behavior of silicon nanowires with hexamethyldisilazane modification. Sens. Actuators B Chem. 2011, 156, 631–636. [Google Scholar] [CrossRef]

- Zhang, M.; Wei, S.; Ren, W.; Wu, R. Development of High Sensitivity Humidity Sensor Based on Gray TiO2/SrTiO3 Composite. Sensors 2017, 17, 1310. [Google Scholar] [CrossRef]

- Kano, S.; Fujii, M. All-Painting Process To Produce Respiration Sensor Using Humidity-Sensitive Nanoparticle Film and Graphite Trace. ACS Sustain. Chem. Eng. 2018, 6, 12217–12223. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, H.; Zhang, J. Synthesis of high response gold/titanium dioxide humidity sensor and its application in human respiration. Ceram. Int. 2021, 47, 30880–30887. [Google Scholar] [CrossRef]

- Borini, S.; White, R.; Wei, D.; Astley, M.; Haque, S.; Spigone, E.; Harris, N.; Kivioja, J.; Ryhänen, T. Ultrafast Graphene Oxide Humidity Sensors. ACS Nano 2013, 7, 11166–11173. [Google Scholar] [CrossRef] [PubMed]

- Rathi, K.; Pal, K. Impact of Doping on GO: Fast Response-Recovery Humidity Sensor. ACS Omega 2017, 2, 842–851. [Google Scholar] [CrossRef]

- Xu, L.; Zhai, H.; Chen, X.; Liu, Y.; Wang, M.; Liu, Z.; Umar, M.; Ji, C.; Chen, Z.; Jin, L.; et al. Coolmax/graphene-oxide functionalized textile humidity sensor with ultrafast response for human activities monitoring. Chem. Eng. J. 2021, 412. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, Z.; Yang, Z.; Song, X. High-performance flexible self-powered tin disulfide nanoflowers/reduced graphene oxide nanohybrid-based humidity sensor driven by triboelectric nanogenerator. Nano Energy 2020, 67, 104251. [Google Scholar] [CrossRef]

- Wu, J.; Sun, Y.-M.; Wu, Z.; Li, X.; Wang, N.; Tao, K.; Wang, G.P. Carbon Nanocoil-Based Fast-Response and Flexible Humidity Sensor for Multifunctional Applications. ACS Appl. Mater. Interfaces 2019, 11, 4242–4251. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Ou, H.; Kuang, Y.; Hao, L.; Diao, J.; Chen, G. Cellulose Nanofiber/Carbon Nanotube Dual Network-Enabled Humidity Sensor with High Sensitivity and Durability. ACS Appl. Mater. Interfaces 2020, 12, 33229–33238. [Google Scholar] [CrossRef]

- An, H.; Habib, T.; Shah, S.; Gao, H.; Patel, A.; Echols, I.; Zhao, X.; Radovic, M.; Green, M.J.; Lutkenhaus, J.L. Water Sorption in MXene/Polyelectrolyte Multilayers for Ultrafast Humidity Sensing. ACS Appl. Nano Mater. 2019, 2, 948–955. [Google Scholar] [CrossRef]

- Li, X.; Lu, Y.; Shi, Z.; Liu, G.; Xu, G.; An, Z.; Xing, H.; Chen, Q.; Han, R.P.S.; Liu, Q. Onion-inspired MXene/chitosan-quercetin multilayers: Enhanced response to H2O molecules for wearable human physiological monitoring. Sens. Actuators B Chem. 2021, 329, 129209. [Google Scholar] [CrossRef]

- Yamazoe, N.; Fuchigami, J.; Kishikawa, M.; Seiyama, T. Interactions of tin oxide surface with O2, H2O and H2. Surf. Sci. 1979, 86, 335–344. [Google Scholar] [CrossRef]

- Itoh, E.; Yuan, Z. Comparative study of all-printed polyimide humidity sensors with single-and multiwalled carbon nanotube gas-permeable top electrodes. Jpn. J. Appl. Phys. 2017, 56, 05EC03. [Google Scholar] [CrossRef]

- Mogera, U.; Sagade, A.A.; George, S.J.; Kulkarni, G.U. Ultrafast response humidity sensor using supramolecular nanofibre and its application in monitoring breath humidity and flow. Sci. Rep. 2014, 4, 4103. [Google Scholar] [CrossRef] [PubMed]

- Zhen, Z.; Li, Z.; Zhao, X.; Zhong, Y.; Zhang, L.; Chen, Q.; Yang, T.; Zhu, H. Formation of Uniform Water Microdroplets on Wrinkled Graphene for Ultrafast Humidity Sensing. Small 2018, 14, 1703848. [Google Scholar] [CrossRef]

- Guan, Y.; Song, Y.; Li, H.; Ye, L.; Lu, B.; Zang, J.; Yu, Y. A universal respiration sensing platform utilizing surface water condensation. J. Mater. Chem. C 2019, 7, 2853–2864. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, L.; Yu, P.; Mao, L. Sensitive and Fast Humidity Sensor Based on A Redox Conducting Supramolecular Ionic Material for Respiration Monitoring. Anal. Chem. 2017, 89, 996–1001. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, Y.; Yang, H.; Wang, W.; Dai, Y.Z.; Niu, L.G.; Lv, C.; Xia, H.; Liu, T. Fast-response humidity sensor based on laser printing for respiration monitoring. RSC Adv. 2020, 10, 8910–8916. [Google Scholar] [CrossRef]

- Kano, S.; Mekaru, H. Capillary-condensed water in nonporous nanoparticle films evaluated by impedance analysis for nanoparticle devices. Nanotechnology 2020, 31, 455701. [Google Scholar] [CrossRef]

- Kano, S.; Kim, K.; Fujii, M. Fast-Response and Flexible Nanocrystal-Based Humidity Sensor for Monitoring Human Respiration and Water Evaporation on Skin. ACS Sensors 2017, 2, 828–833. [Google Scholar] [CrossRef]

- Kano, S.; Fujii, M. Battery-powered wearable respiration sensor chip with nanocrystal thin film. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; pp. 1293–1295. [Google Scholar]

- Kano, S.; Dobashi, Y.; Fujii, M. Silica Nanoparticle-Based Portable Respiration Sensor for Analysis of Respiration Rate, Pattern, and Phase During Exercise. IEEE Sens. Lett. 2018, 2, 1–4. [Google Scholar] [CrossRef]

- Kano, S.; Yamamoto, A.; Ishikawa, A.; Fujii, M. Respiratory Rate on Exercise Measured by Nanoparticle-Based Humidity Sensor. In Proceedings of the 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, 23–27 July 2019; pp. 3567–3570. [Google Scholar]

- Kano, S.; Mekaru, H. Preliminary comparison of respiratory signals using acceleration on neck and humidity in exhaled air. Microsyst. Technol. 2021, 27, 1–9. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.T.V. Optical fibre-based sensor technology for humidity and moisture measurement: Review of recent progress. Measurement 2013, 46, 4052–4074. [Google Scholar] [CrossRef]

- Sikarwar, S.; Yadav, B.C. Opto-electronic humidity sensor: A review. Sens. Actuators A Phys. 2015, 233, 54–70. [Google Scholar] [CrossRef]

- Vegfors, M.; Lindberg, L.-G.; Pettersson, H.; Öberg, P.Å. Presentation and evaluation of a new optical sensor for respiratory rate monitoring. Int. J. Clin. Monit. Comput. 1994, 11, 151–156. [Google Scholar] [CrossRef] [PubMed]

- Larsson, C.; Davidsson, L.; Lundin, P.; Gustafsson, G.; Vegfors, M. Respiratory monitoring during MR imaging: The clinical value of a new fibre-optical monitor. Acta Radiol. 1999, 40, 33–36. [Google Scholar] [CrossRef]

- Hernandez, F.U.; Morgan, S.P.; Hayes-Gill, B.R.; Harvey, D.; Kinnear, W.; Norris, A.; Evans, D.; Hardman, J.G.; Korposh, S. Characterization and use of a fiber optic sensor based on PAH/SiO2 film for humidity sensing in ventilator care equipment. IEEE Trans. Biomed. Eng. 2016, 63, 1985–1992. [Google Scholar] [CrossRef]

- Favero, F.C.; Villatoro, J.; Pruneri, V. Microstructured optical fiber interferometric breathing sensor. J. Biomed. Opt. 2012, 17, 037006. [Google Scholar] [CrossRef]

- Yi, Y.; Jiang, Y.; Zhao, H.; Brambilla, G.; Fan, Y.; Wang, P. High-performance ultrafast humidity sensor based on microknot resonator-assisted Mach–Zehnder for monitoring human breath. ACS Sens. 2020, 5, 3404–3410. [Google Scholar] [CrossRef]

- Bao, W.; Chen, F.; Lai, H.; Liu, S.; Wang, Y. Wearable breath monitoring based on a flexible fiber-optic humidity sensor. Sens. Actuators B Chem. 2021, 349, 130794. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Recent developments in fiber optics humidity sensors. Sensors 2017, 17, 893. [Google Scholar] [CrossRef]

- Lopez-Torres, D.; Elosua, C.; Villatoro, J.; Zubia, J.; Rothhardt, M.; Schuster, K.; Arregui, F.J. Photonic crystal fiber interferometer coated with a PAH/PAA nanolayer as humidity sensor. Sens. Actuators B Chem. 2017, 242, 1065–1072. [Google Scholar] [CrossRef]

- Li, D.; Lu, H.; Qiu, W.; Dong, J.; Guan, H.; Zhu, W.; Yu, J.; Luo, Y.; Zhang, J.; Chen, Z. Molybdenum disulfide nanosheets deposited on polished optical fiber for humidity sensing and human breath monitoring. Opt. Express 2017, 25, 28407–28416. [Google Scholar] [CrossRef]

- Du, B.; Yang, D.; She, X.; Yuan, Y.; Mao, D.; Jiang, Y.; Lu, F. MoS2-based all-fiber humidity sensor for monitoring human breath with fast response and recovery. Sens. Actuators B Chem. 2017, 251, 180–184. [Google Scholar] [CrossRef]

- Jiang, B.; Bi, Z.; Hao, Z.; Yuan, Q.; Feng, D.; Zhou, K.; Zhang, L.; Gan, X.; Zhao, J. Graphene oxide-deposited tilted fiber grating for ultrafast humidity sensing and human breath monitoring. Sens. Actuators B Chem. 2019, 293, 336–341. [Google Scholar] [CrossRef]

- Du, B.; Yang, D.; Ruan, Y.; Jia, P.; Ebendorff-Heidepriem, H. Compact plasmonic fiber tip for sensitive and fast humidity and human breath monitoring. Opt. Lett. 2020, 45, 985. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.; Ruan, H.; Wang, Y.; Arregui, F.J.; Matias, I.R.; Claus, R.O. Nanostructured optical fibre sensors for breathing airflow monitoring. Meas. Sci. Technol. 2006, 17, 1207. [Google Scholar] [CrossRef]

- Tian, E.; Wang, J.; Zheng, Y.; Song, Y.; Jiang, L.; Zhu, D. Colorful humidity sensitive photonic crystal hydrogel. J. Mater. Chem. 2008, 18, 1116–1122. [Google Scholar] [CrossRef]

- Barry, R.A.; Wiltzius, P. Humidity-sensing inverse opal hydrogels. Langmuir 2006, 22, 1369–1374. [Google Scholar] [CrossRef]

- Kim, S.; Han, S.G.; Koh, Y.G.; Lee, H.; Lee, W. Colorimetric humidity sensor using inverse opal photonic gel in hydrophilic ionic liquid. Sensors 2018, 18, 1357. [Google Scholar] [CrossRef]

- Kou, D.; Ma, W.; Zhang, S.; Lutkenhaus, J.L.; Tang, B. High-Performance and Multifunctional Colorimetric Humidity Sensors Based on Mesoporous Photonic Crystals and Nanogels. ACS Appl. Mater. Interfaces 2018, 10, 41645–41654. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Xie, J.; Li, C.; Li, Y.; Liang, S.; Tian, Z.; Wang, T.; Zhang, H.; Li, H.; et al. Bioinspired water-vapor-responsive organic/inorganic hybrid one-dimensional photonic crystals with tunable full-color stop band. Adv. Funct. Mater. 2010, 20, 3784–3790. [Google Scholar] [CrossRef]

- Szendrei-Temesi, K.; Sanchez-Sobrado, O.; Betzler, S.B.; Durner, K.M.; Holzmann, T.; Lotsch, B.V. Lithium tin sulfide—A high-refractive-index 2D material for humidity-responsive photonic crystals. Adv. Funct. Mater. 2018, 28, 1705740. [Google Scholar] [CrossRef]

- Szendrei, K.; Ganter, P.; Sànchez-Sobrado, O.; Eger, R.; Kuhn, A.; Lotsch, B.V. Touchless Optical Finger Motion Tracking Based on 2D Nanosheets with Giant Moisture Responsiveness. Adv. Mater. 2015, 27, 6341–6348. [Google Scholar] [CrossRef] [PubMed]

- Pavlichenko, I.; Exner, A.T.; Guehl, M.; Lugli, P.; Scarpa, G.; Lotsch, B.V. Humidity-enhanced thermally tunable TiO2/SiO2 Bragg stacks. J. Phys. Chem. C 2012, 116, 298–305. [Google Scholar] [CrossRef]

- Kang, H.S.; Han, S.W.; Park, C.; Lee, S.W.; Eoh, H.; Baek, J.; Shin, D.G.; Park, T.H.; Huh, J.; Lee, H.; et al. 3D touchless multiorder reflection structural color sensing display. Sci. Adv. 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Kim, E.; Kim, S.Y.; Jo, G.; Kim, S.; Park, M.J. Colorimetric and resistive polymer electrolyte thin films for real-time humidity sensors. ACS Appl. Mater. Interfaces 2012, 4, 5179–5187. [Google Scholar] [CrossRef]

- Momtaz, M.; Chen, J. High-Performance Colorimetric Humidity Sensors Based on Konjac Glucomannan. ACS Appl. Mater. Interfaces 2020, 12, 54104–54116. [Google Scholar] [CrossRef]

- Yu, L.; Xu, H.; Monro, T.M.; Lancaster, D.G.; Xie, Y.; Zeng, H.; Chen, G.Y.; Liu, X. Ultrafast colorimetric humidity-sensitive polyelectrolyte coating for touchless control. Mater. Horiz. 2017, 4, 72–82. [Google Scholar] [CrossRef]

- Bi, H.; Yin, K.; Xie, X.; Ji, J.; Wan, S.; Sun, L.; Terrones, M.; Dresselhaus, M.S. Ultrahigh humidity sensitivity of graphene oxide. Sci. Rep. 2013, 3, 2714. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, X.; Guo, H.; Wu, Z. Graphene oxide thin film coated quartz crystal microbalance for humidity detection. Appl. Surf. Sci. 2011, 257, 7778–7782. [Google Scholar] [CrossRef]

- Zhang, L.; Tan, Q.; Wang, Y.; Fan, Z.; Lin, L.; Zhang, W.; Xiong, J. Wirelessly powered multi-functional wearable humidity sensor based on RGO-WS2 heterojunctions. Sens. Actuators B Chem. 2021, 329, 129077. [Google Scholar] [CrossRef]

- Chi, H.; Liu, Y.J.; Wang, F.; He, C. Highly sensitive and fast response colorimetric humidity sensors based on graphene oxides film. ACS Appl. Mater. Interfaces 2015, 7, 19882–19886. [Google Scholar] [CrossRef] [PubMed]

- García, P.D.; Sapienza, R.; Blanco, Á.; López, C. Photonic glass: A novel random material for light. Adv. Mater. 2007, 19, 2597–2602. [Google Scholar] [CrossRef]

- García, P.D.; Sapienza, R.; López, C. Photonic glasses: A step beyond white paint. Adv. Mater. 2010, 22, 12–19. [Google Scholar] [CrossRef]

- Fu, Y.; Tippets, C.A.; Donev, E.U.; Lopez, R. Structural colors: From natural to artificial systems. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2016, 8, 758–775. [Google Scholar] [CrossRef]

- Baek, K.; Kim, Y.; Mohd-Noor, S.; Hyun, J.K. Mie Resonant Structural Colors. ACS Appl. Mater. Interfaces 2020, 12, 5300–5318. [Google Scholar] [CrossRef] [PubMed]

- Mohd-Noor, S.; Jang, H.; Baek, K.; Pei, Y.-R.; Alam, A.-M.; Kim, Y.H.; Kim, I.S.; Choy, J.-H.; Hyun, J.K. Ultrafast humidity-responsive structural colors from disordered nanoporous titania microspheres. J. Mater. Chem. A 2019, 7, 10561–10571. [Google Scholar] [CrossRef]

- Jarulertwathana, N.; Mohd-Noor, S.; Hyun, J.K. Mesoporous Solid and Yolk-Shell Titania Microspheres as Touchless Colorimetric Sensors with High Responsivity and Ultrashort Response Times. ACS Appl. Mater. Interfaces 2021, 13, 44786–44796. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, M.; Machoke, A.G.; Schwieger, W. Catalytic test reactions for the evaluation of hierarchical zeolites. Chem. Soc. Rev. 2016, 45, 3313–3330. [Google Scholar] [CrossRef]

- Berger, C.M.; Henderson, C.L. The effect of humidity on water sorption in photoresist polymer thin films. Polymer 2003, 44, 2101–2108. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, N.B.; Huang, X.H.; Yao, Y.; Jin, Y.R.; Pan, W.; Liu, D. Humidity-Sensing Properties of a BiOCl-Coated Quartz Crystal Microbalance. ACS Omega 2020, 5, 18818–18825. [Google Scholar] [CrossRef]

- Rimeika, R.; Čiplys, D.; Poderys, V.; Rotomskis, R.; Shur, M.S. Fast-response surface acoustic wave humidity sensor based on hematoporphyrin film. Sens. Actuators B Chem. 2009, 137, 592–596. [Google Scholar] [CrossRef]

- Lin, Q.; Li, Y.; Yang, M. Highly sensitive and ultrafast response surface acoustic wave humidity sensor based on electrospun polyaniline/poly (vinyl butyral) nanofibers. Anal. Chim. Acta 2012, 748, 73–80. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Gao, H.; Ward, J.E.; Liu, X.; Yin, B.; Fu, T.; Chen, J.; Lovley, D.R.; Yao, J. Power generation from ambient humidity using protein nanowires. Nature 2020, 578, 550–554. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Cheng, H.; Zhang, Z.; Jiang, L.; Qu, L. Direct Power Generation from a Graphene Oxide Film under Moisture. Adv. Mater. 2015, 27, 4351–4357. [Google Scholar] [CrossRef] [PubMed]

- Komazaki, Y.; Kanazawa, K.; Nobeshima, T.; Hirama, H.; Watanabe, Y.; Suemori, K.; Uemura, S. Energy harvesting by ambient humidity variation with continuous milliampere current output and energy storage. Sustain. Energy Fuels 2021, 5, 3570–3577. [Google Scholar] [CrossRef]

- Shen, D.; Xiao, M.; Zou, G.; Liu, L.; Duley, W.W.; Zhou, Y.N. Self-Powered Wearable Electronics Based on Moisture Enabled Electricity Generation. Adv. Mater. 2018, 30, 1705925. [Google Scholar] [CrossRef]

- Li, X.; Sun, Q.; Kan, Y.; Zhu, Y.; Pang, Z.; Li, M.; Jin, Y. Self-Powered Humidity Sensor Based on Polypyrrole/Melamine Aerogel for Real-Time Humidity Monitoring. IEEE Sens. J. 2021, 21, 2604–2609. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1–25. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, T.; Qi, R.; Dai, J.; Liu, S.; Fei, T.; Lu, G. Humidity sensor based on solution processible microporous silica nanoparticles. Sens. Actuators B Chem. 2018, 266, 131–138. [Google Scholar] [CrossRef]

- Gawli, Y.; Badadhe, S.; Basu, A.; Guin, D.; Shelke, M.V.; Ogale, S. Evaluation of n-type ternary metal oxide NiMn2O4 nanomaterial for humidity sensing. Sens. Actuators B Chem. 2014, 191, 837–843. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, Q.; Wang, S.; Yuan, Z.; Zhang, Y.; Li, X.; Wu, Y.; Jiang, Y.; Tai, H. Novel application of attapulgite on high performance and low-cost humidity sensors. Sens. Actuators B Chem. 2020, 305, 127534. [Google Scholar] [CrossRef]

- Cheng, B.; Tian, B.; Xie, C.; Xiao, Y.; Lei, S. Highly sensitive humidity sensor based on amorphous Al2O3 nanotubes. J. Mater. Chem. 2011, 21, 1907–1912. [Google Scholar] [CrossRef]

- Zampetti, E.; Pantalei, S.; Pecora, A.; Valletta, A.; Maiolo, L.; Minotti, A.; Macagnano, A.; Fortunato, G.; Bearzotti, A. Design and optimization of an ultra thin flexible capacitive humidity sensor. Sens. Actuators B Chem. 2009, 143, 302–307. [Google Scholar] [CrossRef]

- Kubota, Y.; Mishra, V.L.; Ando, T.; Sakamoto, Y.; Kawakita, J. Micro/nano galvanic-coupled arrays for early and initial detection and prediction of dew condensation. Sens. Actuators A Phys. 2020, 303, 111838. [Google Scholar] [CrossRef]

- Steele, J.J.; Taschuk, M.T.; Brett, M.J. Response time of nanostructured relative humidity sensors. Sens. Actuators B Chem. 2009, 140, 610–615. [Google Scholar] [CrossRef]

- Wang, X.; Deng, Y.; Chen, X.; Jiang, P.; Cheung, Y.K.; Yu, H. An ultrafast-response and flexible humidity sensor for human respiration monitoring and noncontact safety warning. Microsyst. Nanoeng. 2021, 7, 99. [Google Scholar] [CrossRef]

- Güder, F.; Ainla, A.; Redston, J.; Mosadegh, B.; Glavan, A.; Martin, T.J.; Whitesides, G.M. Paper-Based Electrical Respiration Sensor. Angew. Chem. Int. Ed. 2016, 55, 5727–5732. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, K.; Zhong, Y.; Liu, P.; Li, Z.; Pan, J.; Long, Y.; Huang, M.; Brakat, A.; Zhu, H. Hydrophobic ionic liquid-in-polymer composites for ultrafast, linear response and highly sensitive humidity sensing. Nano Res. 2021, 14, 1202–1209. [Google Scholar] [CrossRef]

- Smith, A.D.; Elgammal, K.; Niklaus, F.; Delin, A.; Fischer, A.C.; Vaziri, S.; Forsberg, F.; Råsander, M.; Hugosson, H.; Bergqvist, L.; et al. Resistive graphene humidity sensors with rapid and direct electrical readout. Nanoscale 2015, 7, 19099–19109. [Google Scholar] [CrossRef]

- Wang, Q.; Tong, J.; Wang, N.; Chen, S.; Sheng, B. Humidity sensor of tunnel-cracked nickel@polyurethane sponge for respiratory and perspiration sensing. Sens. Actuators B Chem. 2021, 330, 129322. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, A.; Varma, G.D. Ultrafast resistive-type γ-Fe2O3–rGO nanohybrid-based humidity sensor–A respiratory monitoring tool. J. Mater. Chem. C 2021, 9, 8002–8010. [Google Scholar] [CrossRef]

- Gao, N.; Li, H.-Y.; Zhang, W.; Zhang, Y.; Zeng, Y.; Zhixiang, H.; Liu, J.; Jiang, J.; Miao, L.; Yi, F.; et al. QCM-based humidity sensor and sensing properties employing colloidal SnO2 nanowires. Sens. Actuators B Chem. 2019, 293, 129–135. [Google Scholar] [CrossRef]

- Yu, S.; Chen, C.; Zhang, H.; Zhang, J.; Liu, J. Design of high sensitivity graphite carbon nitride/zinc oxide humidity sensor for breath detection. Sens. Actuators B Chem. 2021, 332, 129536. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Neri, G.; Pinna, N. Nanostructured Materials for Room-Temperature Gas Sensors. Adv. Mater. 2016, 28, 795–831. [Google Scholar] [CrossRef]

- Vogel, N.; Retsch, M.; Fustin, C.-A.; del Campo, A.; Jonas, U. Advances in Colloidal Assembly: The Design of Structure and Hierarchy in Two and Three Dimensions. Chem. Rev. 2015, 115, 6265–6311. [Google Scholar] [CrossRef]

- Fisher, L.R.; Israelachvili, J.N. Direct experimental verification of the Kelvin equation for capillary condensation. Nature 1979, 277, 548–549. [Google Scholar] [CrossRef]

- Fisher, L.R.; Gamble, R.A.; Middlehurst, J. The Kelvin equation and the capillary condensation of water. Nature 1981, 290, 575–576. [Google Scholar] [CrossRef]

- Adamson, A.W.; Gast, A.P. Physical Chemistry of Surfaces, 6th ed.; John Wiley&Sons, Inc.: Hoboken, NJ, USA, 1990; ISBN 978-0-471-14873-9. [Google Scholar]

- Gan, X.; Zhao, C.; Yuan, Q.; Fang, L.; Li, Y.; Yin, J.; Ma, X.; Zhao, J. High performance graphene oxide-based humidity sensor integrated on a photonic crystal cavity. Appl. Phys. Lett. 2017, 110, 151107. [Google Scholar] [CrossRef]

- Pang, J.; Le, X.; Pang, K.; Xu, Z.; Gao, C.; Xie, J. Specific Sensing Mechanism Investigation of Surface Acoustic Wave Humidity Sensors Coated with Uniform Graphene Oxide Membrane. J. Microelectromechanical Syst. 2020, 29, 348–356. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Aoyagi, E.; Ogawa, S.; Watanabe, A. Laser Direct Writing of a High-Performance All-Graphene Humidity Sensor Working in a Novel Sensing Mode for Portable Electronics. ACS Appl. Mater. Interfaces 2018, 10, 23987–23996. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Z.; Li, Y.; Yang, M. Single-sided and integrated polyaniline/poly (vinylidene fluoride) flexible membrane with micro/nanostructures as breathable, nontoxic and fast response wearable humidity sensor. J. Colloid Interface Sci. 2022, 607, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Mukhopadhyay, S.C. Wearable Sensors for Human Activity Monitoring: A Review. IEEE Sens. J. 2015, 15, 1321–1330. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, Stretchable Sensors for Wearable Health Monitoring: Sensing Mechanisms, Materials, Fabrication Strategies and Features. Sensors 2018, 18, 645. [Google Scholar] [CrossRef] [PubMed]

- Atalay, O.; Kennon, W.R.; Demirok, E. Weft-Knitted Strain Sensor for Monitoring Respiratory Rate and Its Electro-Mechanical Modeling. IEEE Sens. J. 2015, 15, 110–122. [Google Scholar] [CrossRef]

- Atalay, A.; Atalay, O.; Husain, M.D.; Fernando, A.; Potluri, P. Piezofilm yarn sensor- integrated knitted fabric for healthcare applications. J. Ind. Text. 2017, 47, 505–521. [Google Scholar] [CrossRef]

- Atalay, O.; Atalay, A.; Gafford, J.; Wang, H.; Wood, R.; Walsh, C. A Highly Stretchable Capacitive-Based Strain Sensor Based on Metal Deposition and Laser Rastering. Adv. Mater. Technol. 2017, 1700081, 1–8. [Google Scholar] [CrossRef]

- Min, S.D.; Yun, Y.; Shin, H. Simplified Structural Textile Respiration Sensor Based on Capacitive Pressure Sensing Method. IEEE Sens. J. 2014, 14, 3245–3251. [Google Scholar] [CrossRef]

- Merritt, C.R.; Nagle, H.T.; Grant, E. Textile-Based Capacitive Sensors for Respiration Monitoring. IEEE Sens. J. 2009, 9, 71–78. [Google Scholar] [CrossRef]

- Yamamoto, A.; Nakamoto, H.; Bessho, Y.; Watanabe, Y.; Oki, Y.; Ono, K.; Fujimoto, Y.; Terada, T.; Ishikawa, A. Monitoring respiratory rates with a wearable system using a stretchable strain sensor during moderate exercise. Med. Biol. Eng. Comput. 2019, 57, 2741–2756. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Kim, Y.; Lu, J.; Shih, B.; Gharibans, A.; Zou, Z.; Matsuno, K.; Aguilera, R.; Han, Y.; Meek, A.; Xiao, J.; et al. Scalable Manufacturing of Solderable and Stretchable Physiologic Sensing Systems. Adv. Mater. 2017, 29, 1701312. [Google Scholar] [CrossRef] [PubMed]

- Bates, A.; Ling, M.J.; Mann, J.; Arvind, D.K. Respiratory Rate and Flow Waveform Estimation from Tri-axial Accelerometer Data. In Proceedings of the 2010 International Conference on Body Sensor Networks, Singapore, 7–9 June 2010; pp. 144–150. [Google Scholar]

- Liu, G.-Z.; Guo, Y.-W.; Zhu, Q.-S.; Huang, B.-Y.; Wang, L. Estimation of Respiration Rate from Three-Dimensional Acceleration Data Based on Body Sensor Network. Telemed. e-Health 2011, 17, 705–711. [Google Scholar] [CrossRef] [PubMed]

- Karacocuk, G.; Hoflinger, F.; Zhang, R.; Reindl, L.M.; Laufer, B.; Moller, K.; Roell, M.; Zdzieblik, D. Inertial Sensor-Based Respiration Analysis. IEEE Trans. Instrum. Meas. 2019, 68, 4268–4275. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Ichiki, M. MEMS-based sensor for simultaneous measurement of pulse wave and respiration rate. Sensors 2019, 19, 4942. [Google Scholar] [CrossRef] [PubMed]

- Terazawa, M.; Karita, M.; Kumagai, S.; Sasaki, M. Respiratory Motion Sensor Measuring Capacitance Constructed across Skin in Daily Activities. Micromachines 2018, 9, 543. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Yan, M.; Wang, S.; Yuan, Z.; Zhao, Q.; Sun, P.; Xie, G.; Du, X.; Tai, H. Facile, Flexible, Cost-Saving, and Environment-Friendly Paper-Based Humidity Sensor for Multifunctional Applications. ACS Appl. Mater. Interfaces 2019, 11, 21840–21849. [Google Scholar] [CrossRef]

- Lu, L.; Jiang, C.; Hu, G.; Liu, J.; Yang, B. Flexible Noncontact Sensing for Human–Machine Interaction. Adv. Mater. 2021, 33, 1–10. [Google Scholar] [CrossRef]

- Tai, H.; Wang, S.; Duan, Z.; Jiang, Y. Evolution of breath analysis based on humidity and gas sensors: Potential and challenges. Sens. Actuators B Chem. 2020, 128104. [Google Scholar] [CrossRef]

- Li, N.; Jiang, Y.; Xiao, Y.; Meng, B.; Xing, C.; Zhang, H.; Peng, Z. A fully inkjet-printed transparent humidity sensor based on a Ti3C2/Ag hybrid for touchless sensing of finger motion. Nanoscale 2019, 11, 21522–21531. [Google Scholar] [CrossRef]

- Nilsson, G.E. Measurement of water exchange through skin. Med. Biol. Eng. Comput. 1977, 15, 209–218. [Google Scholar] [CrossRef]

- Grice, K.; Sattar, H.; Baker, H. The effect of ambient humidity on transepidermal water loss. J. Investig. Dermatol. 1972, 58, 343–346. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Lan, C.; Zhou, Z.; Sun, P.; Wei, D.; Li, C. Transparent, flexible, and stretchable WS 2 based humidity sensors for electronic skin. Nanoscale 2017, 9, 6246–6253. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Xu, K.; Yang, M.Q.; Tang, S.Y.; Yang, T.Y.; Fujita, Y.; Honda, S.; Arie, T.; Akita, S.; Chueh, Y.L.; et al. Highly stable Pd/HNb3O8-based flexible humidity sensor for perdurable wireless wearable applications. Nanoscale Horiz. 2021, 6, 260–270. [Google Scholar] [CrossRef]

- Li, T.; Li, L.; Sun, H.; Xu, Y.; Wang, X.; Luo, H.; Liu, Z.; Zhang, T. Porous Ionic Membrane Based Flexible Humidity Sensor and its Multifunctional Applications. Adv. Sci. 2017, 4, 1600404. [Google Scholar] [CrossRef] [PubMed]

- Yamamura, T.; Masaki, H.; Sakon, K.; Suzuki, K.; Tezuka, T. Simple monochromatic refractometer for trans-epidermal water loss (TEWL). J. Dermatol. Sci. 1990, 1, 201–206. [Google Scholar] [CrossRef]

| Breath Info | Breath Rate | Breath Rhythm | Breath Volume | Portability |

|---|---|---|---|---|

| Airflow | ✓ | ✓ | ✓ | |

| Temperature | ✓ | ✓ | ||

| Gas | ✓ | ✓ | ✓ | |

| Humidity | ✓ | ✓ | ✓ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kano, S.; Jarulertwathana, N.; Mohd-Noor, S.; Hyun, J.K.; Asahara, R.; Mekaru, H. Respiratory Monitoring by Ultrafast Humidity Sensors with Nanomaterials: A Review. Sensors 2022, 22, 1251. https://doi.org/10.3390/s22031251

Kano S, Jarulertwathana N, Mohd-Noor S, Hyun JK, Asahara R, Mekaru H. Respiratory Monitoring by Ultrafast Humidity Sensors with Nanomaterials: A Review. Sensors. 2022; 22(3):1251. https://doi.org/10.3390/s22031251

Chicago/Turabian StyleKano, Shinya, Nutpaphat Jarulertwathana, Syazwani Mohd-Noor, Jerome K. Hyun, Ryota Asahara, and Harutaka Mekaru. 2022. "Respiratory Monitoring by Ultrafast Humidity Sensors with Nanomaterials: A Review" Sensors 22, no. 3: 1251. https://doi.org/10.3390/s22031251

APA StyleKano, S., Jarulertwathana, N., Mohd-Noor, S., Hyun, J. K., Asahara, R., & Mekaru, H. (2022). Respiratory Monitoring by Ultrafast Humidity Sensors with Nanomaterials: A Review. Sensors, 22(3), 1251. https://doi.org/10.3390/s22031251