1. Introduction

In the past years, sensor systems have become important parts of our daily life. Sensors can be wearable devices and used for many applications, such as motion intention detection, real-time signal measurement, and a medical aid system. With peripherals, sensor systems can measure, detect, record and even analyze further health conditions of humans, which can also help more accurate diagnoses. Several types of sensors have been developed, including capacitive sensors [

1,

2,

3,

4], piezoresistive sensors [

5,

6], and piezoelectric sensors [

7,

8]. The linearity between the input and output, the hysteresis effect of signal feedback, and temperature sensitivity are important specifications regarding the performance of sensors. Furthermore, the size of the sensing area and the sensing range of pressure have been improved by previous studies [

9]. The piezoelectric materials can be categorized into the main items: thin films, single crystals, ceramic, compound, and polymer.

Among the piezoelectric materials, Polyvinylidene fluoride (PVDF), zinc oxide, lead zirconate titanate (PZT) and aluminum nitride have high mutual conversion efficiency between electrical energy and mechanical energy. These piezoelectric materials are very sensitive to any small amount of strain, giving them excellent applicability in sensors. Although zinc oxide and aluminum nitride are easy to make into micro-nano-scale thin-film, the poor ductility and low piezoelectric coefficient of the materials will cause deflection and long-term deformation, making their application in the energy-harvesting sector very limited. PZT material has the advantages of good piezoelectric properties, but the material is brittle and cannot be used for long-term deformation. Furthermore, PZT material contains heavy-metal toxicity (lead), which is harmful to the human body. PVDF is a potential piezoelectric material in polymers. PVDF has the following advantages: light weight, low price, flexibility, decent piezoelectric coefficient, high response frequency and no elements of pollution by heavy metals, making it be selected as one of the main materials in this study.

Graphene, achieved by delamination of layered graphene, was developed at the University of Manchester in 2004. It was exfoliated from high-regularity, high-temperature pyrolysis graphite [

10], and it was found in subsequent experiments that the single-layer graphene has excellent electrical conductivity. Single-layer graphene is a six-ring plane graphite structure and carbon atoms are composed of

chains. In appearance, the side length of single-layer graphene is about 2 to 5 μm and the thickness is 1 nm. It can be found that carbon nanocapsule (CNC), carbon nanotube (CNT) and monolayer graphene are all composed of carbon atoms linked by

, in a 0–2 dimensional structure. However, the aspect ratios, surface-to-volume ratios, and the shapes among them are very different. Owing to the excellent electrical conductivity of graphene, it can be mixed with polymer materials to form composite materials and applied to electronic components such as supercapacitors [

11,

12], electromagnetic interference shielding (EMI) [

13], dye-sensitized solar cells [

14] and flexible optoelectronic films [

15].

Electrospinning technology is an unsophisticated way to transform polymer materials into nano-scale fibers [

16]. When the strength of the electric field increases, the electrostatic forces on the original surface overcome the surface tension, and the stretched polymer solution is ejected from the conical tip to form micron- to nanometer-slender fibers on the collector [

17,

18]. However, for PVDF fibers produced by traditional far-field electrospinning, the distance between the needle and the collecting plate is usually more than 10 cm. The polymer solution, which is easily affected by the electric field, will randomly spray the fibers, which will be deposited on the collection plate without order. This phenomenon weakens the piezoelectricity of the fiber. In addition, to spin out the fibers, a high voltage (hundreds of thousands of volts) is required [

19,

20].

Baumgarten et al. [

21] presented the electrospinning process with methyl methacrylate (PMMA). The 1 µm width fiber was fabricated successfully. Reneker et al. [

22] produced polymer fibers with diameters ranging from 40–2000 nm by electrospinning. These small fibers can support arrays of nanomachines and connect integrated arrays of nanomachines to larger-scale systems. Sun et al. [

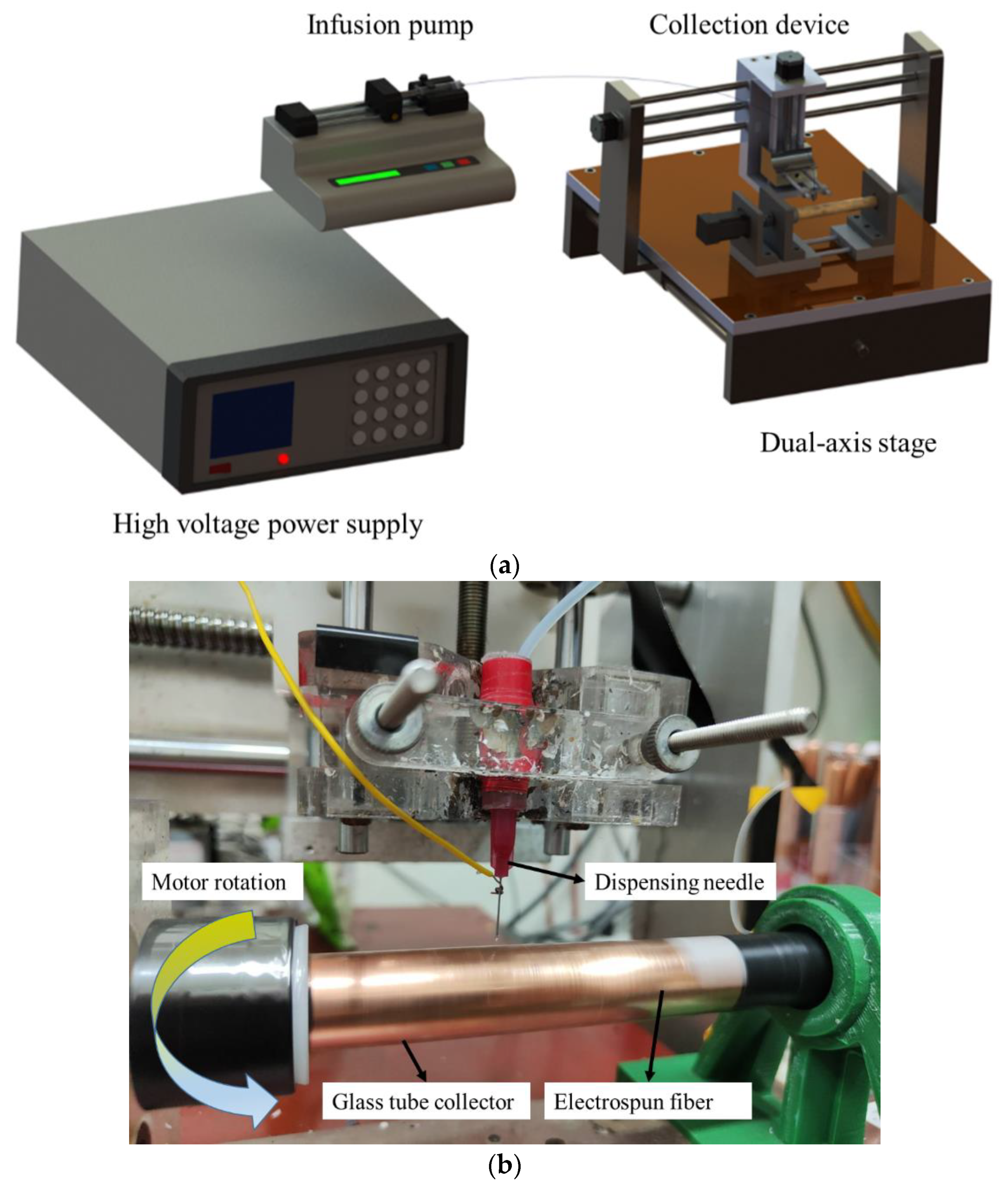

23] proposed the near-field electrospinning technology. It used 600 volts, and the distance between the needle and the collecting plate is only 500 µm during the electrospinning process. This technology successfully produces piezoelectric fibers in good order of 50–500 um in diameter and reduces the energy wasted.

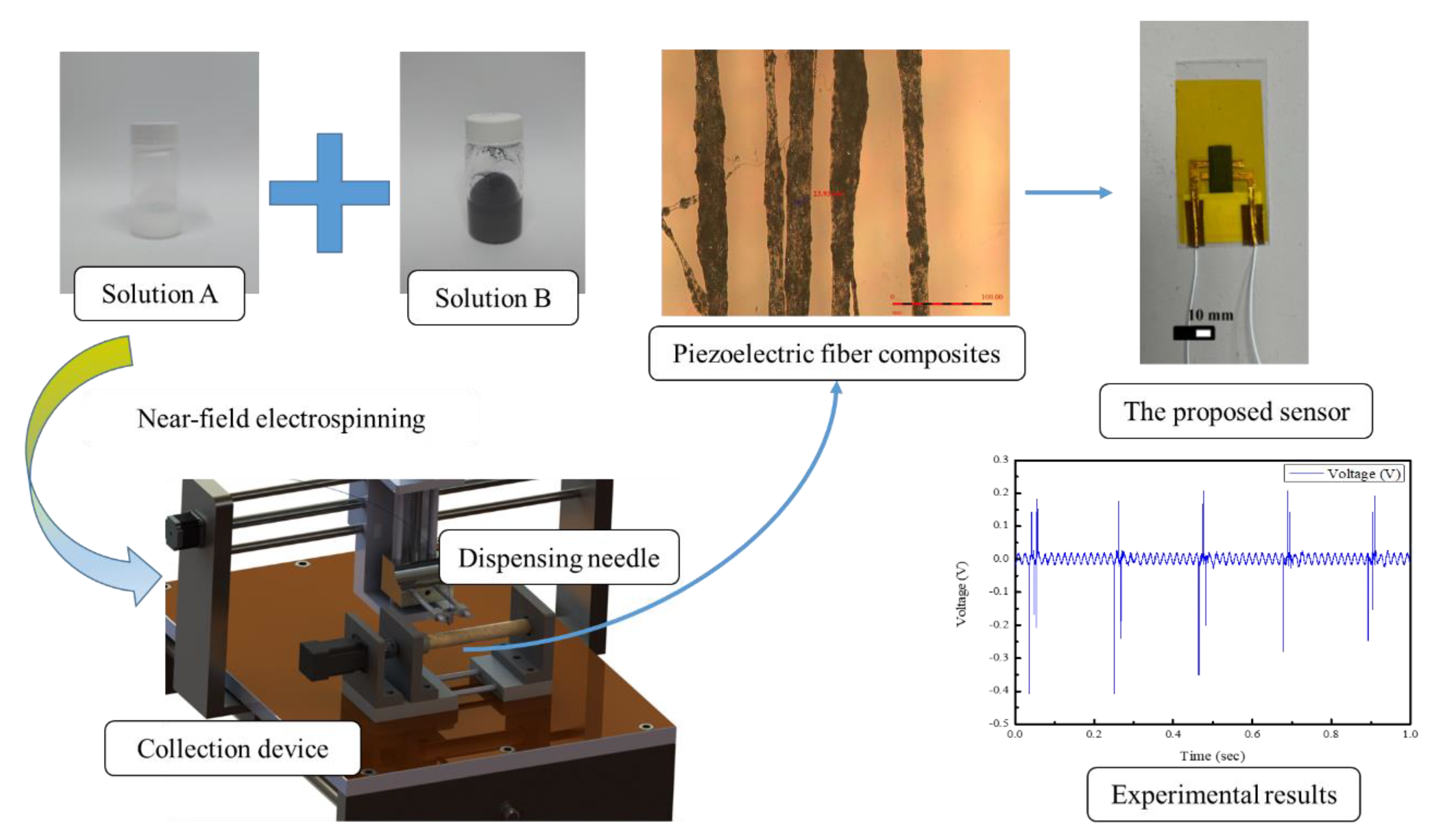

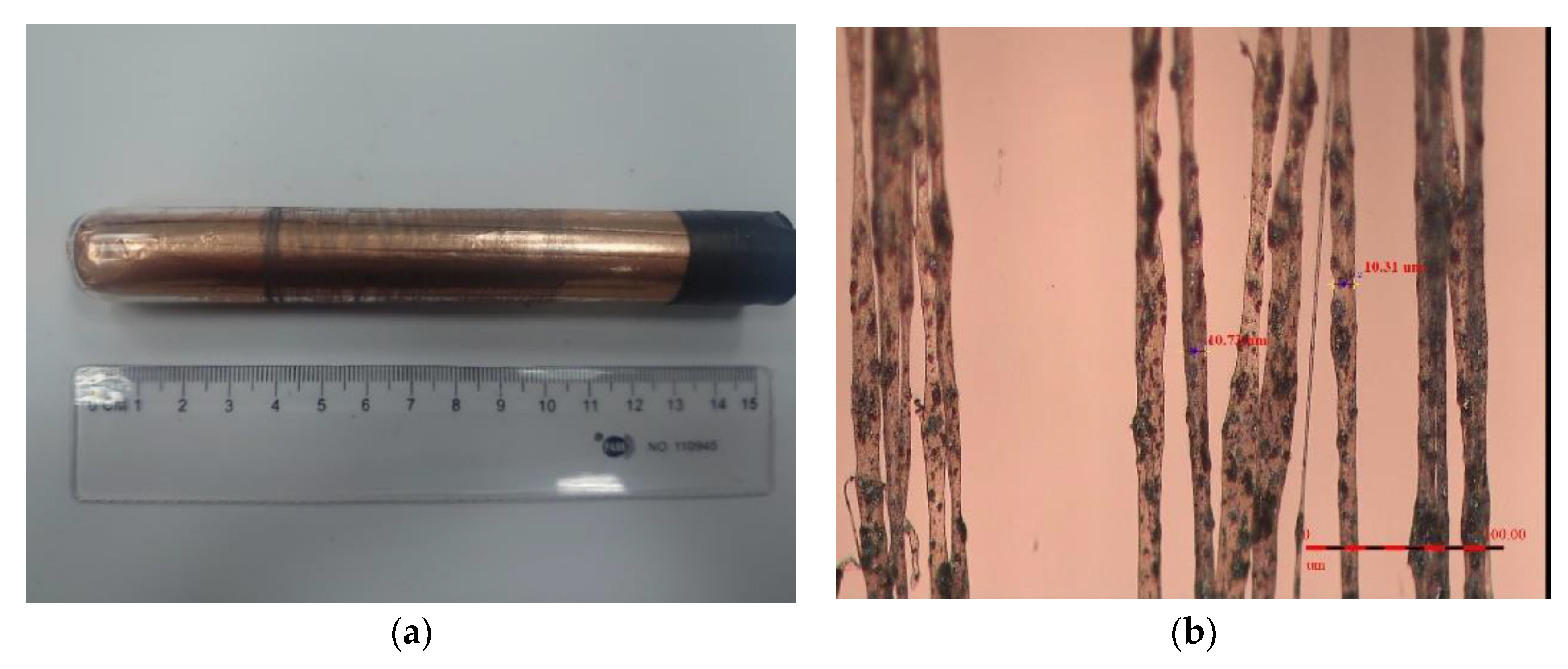

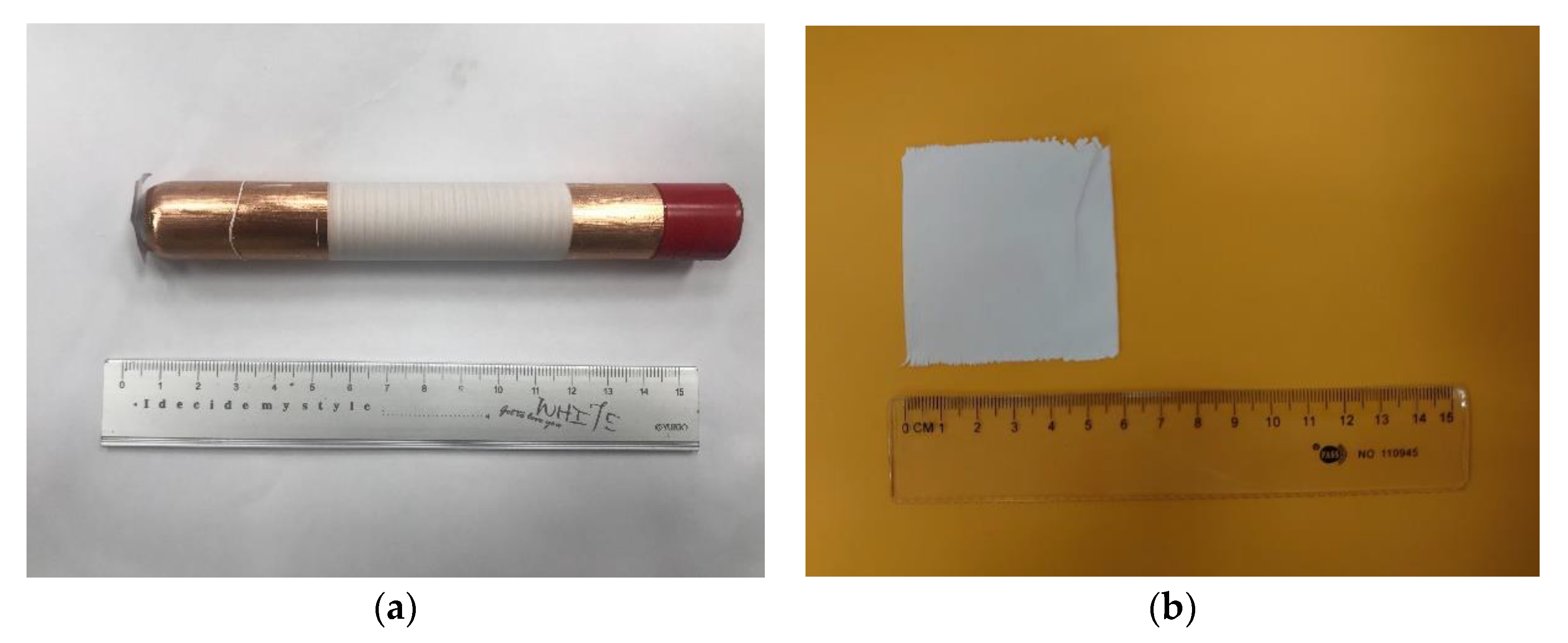

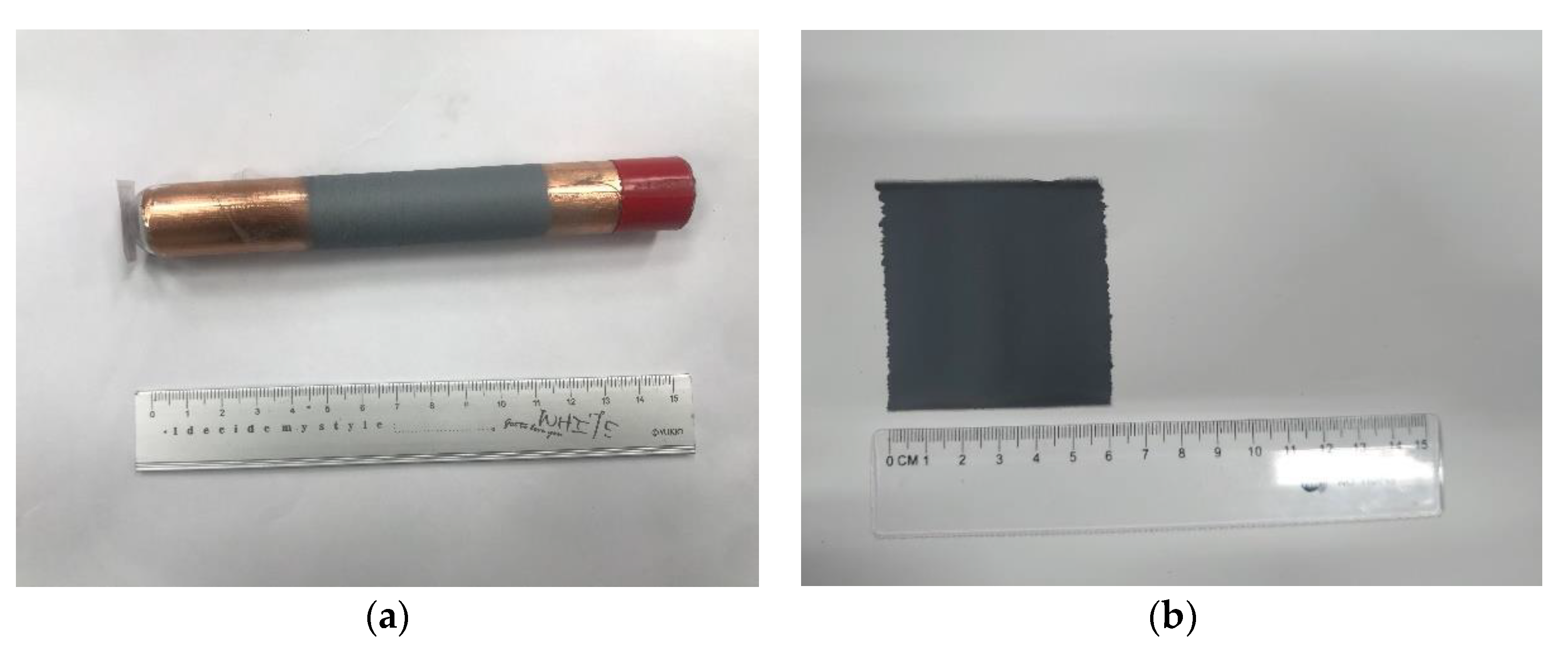

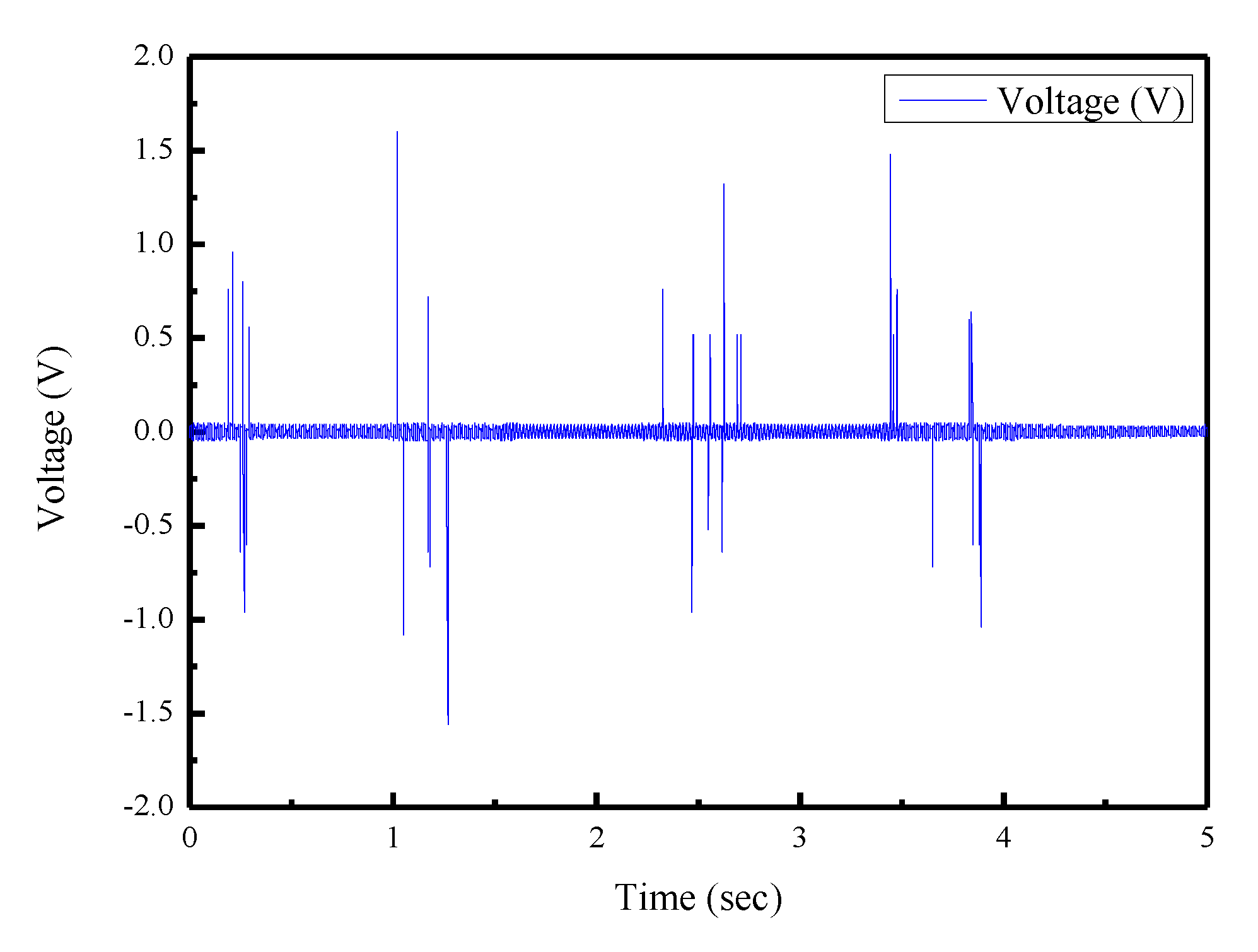

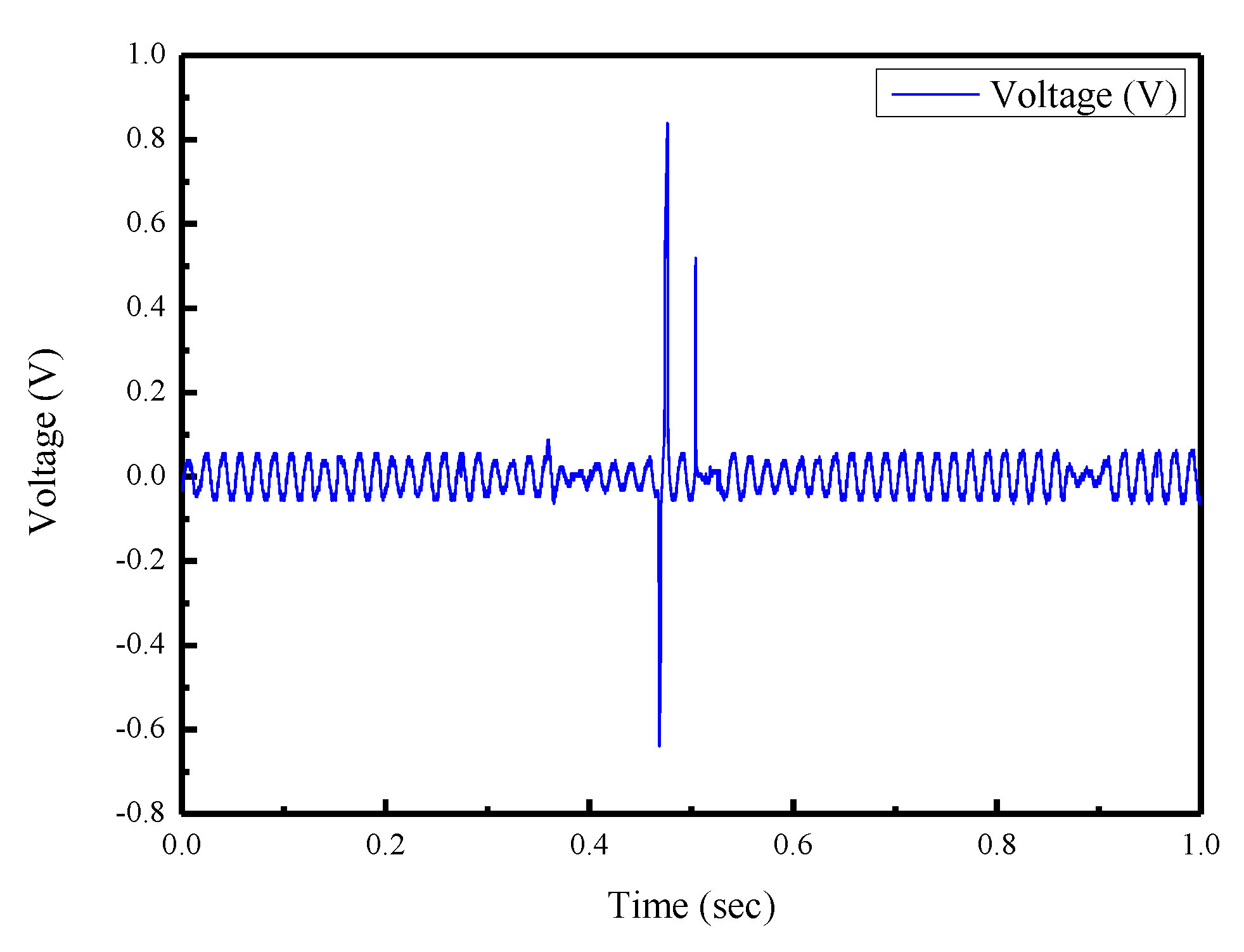

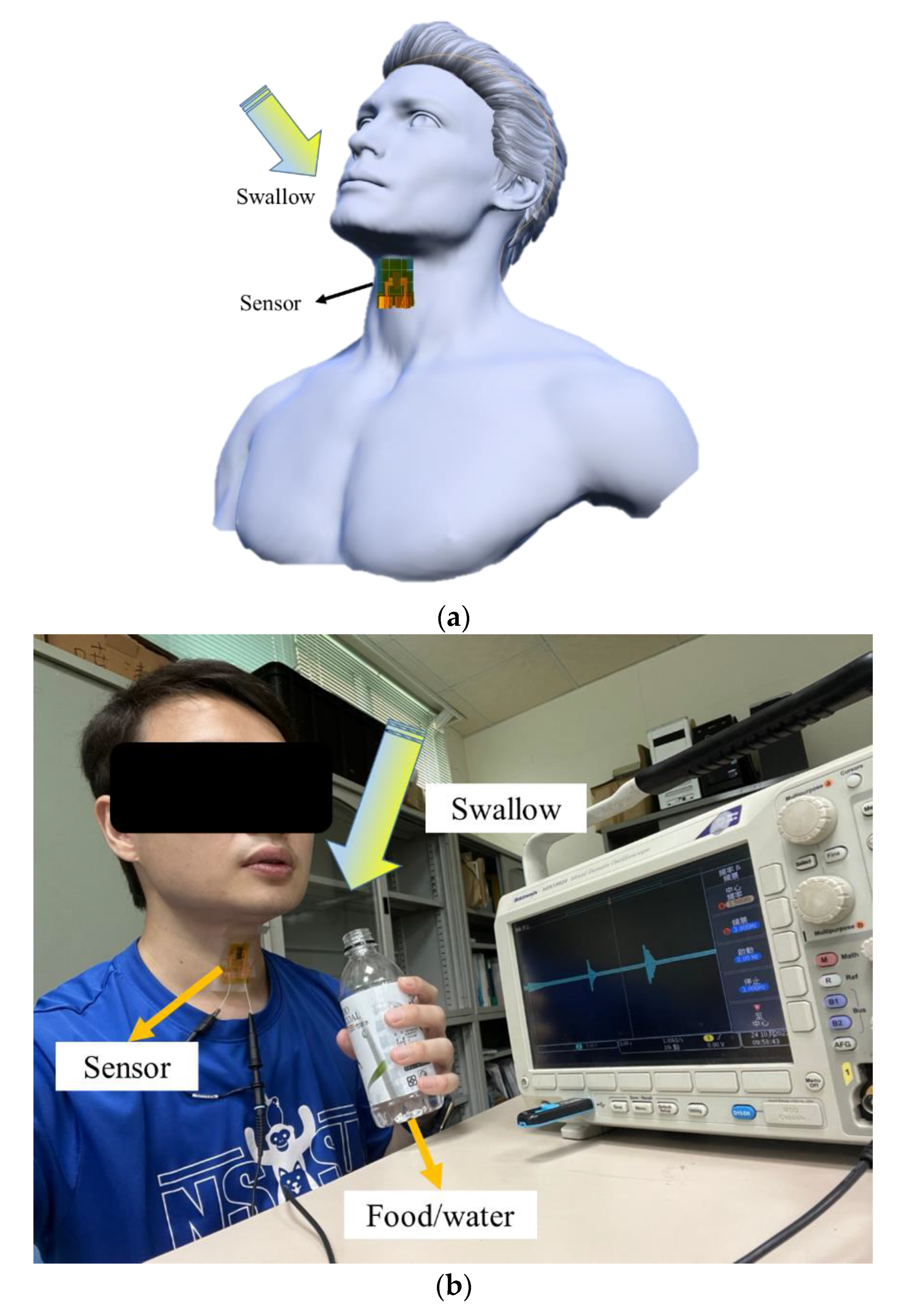

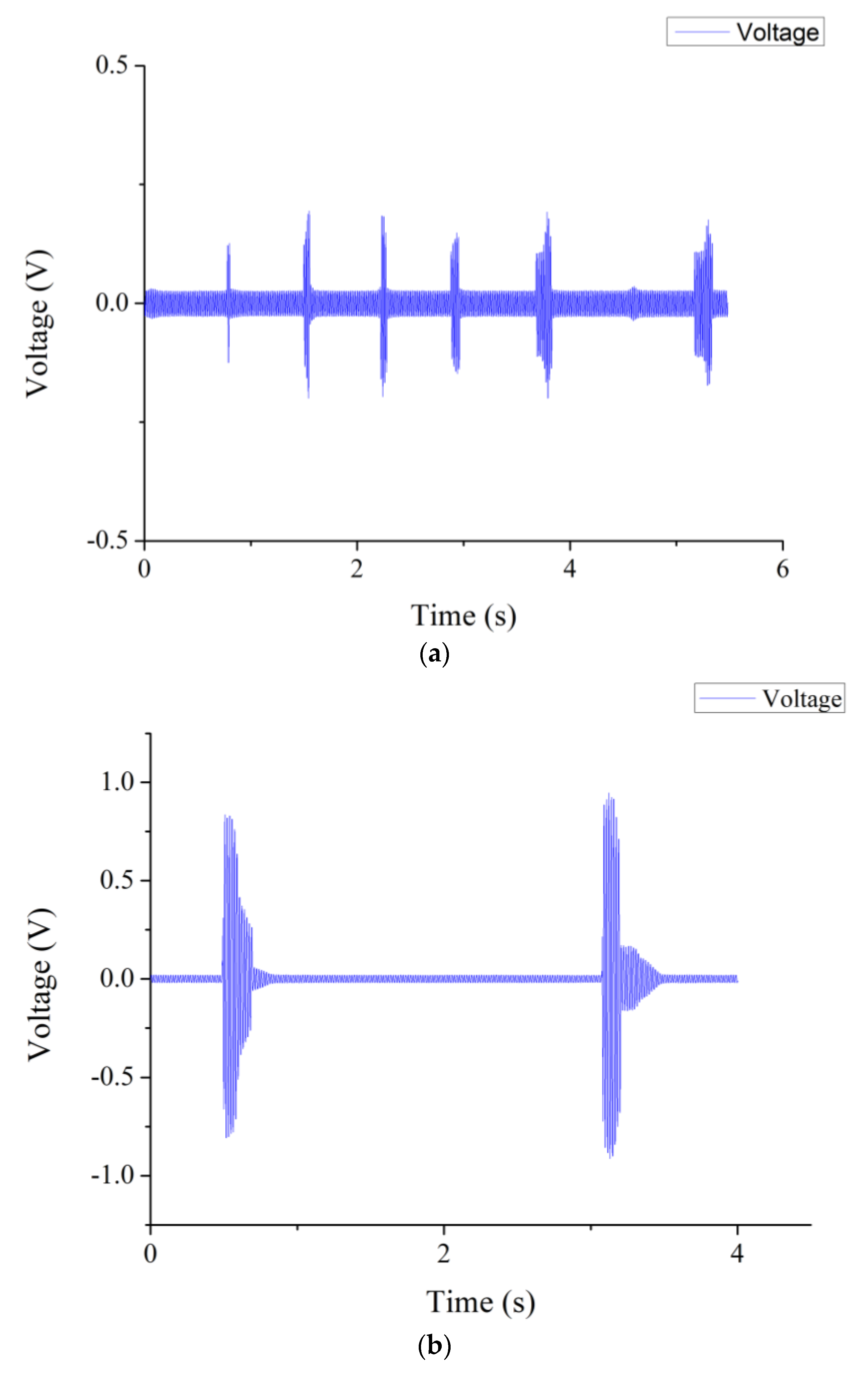

Previous research presented the non-invasive measurement of the swallowing function with developed sensors or sensor-based monitoring during the swallowing events [

24,

25,

26,

27,

28,

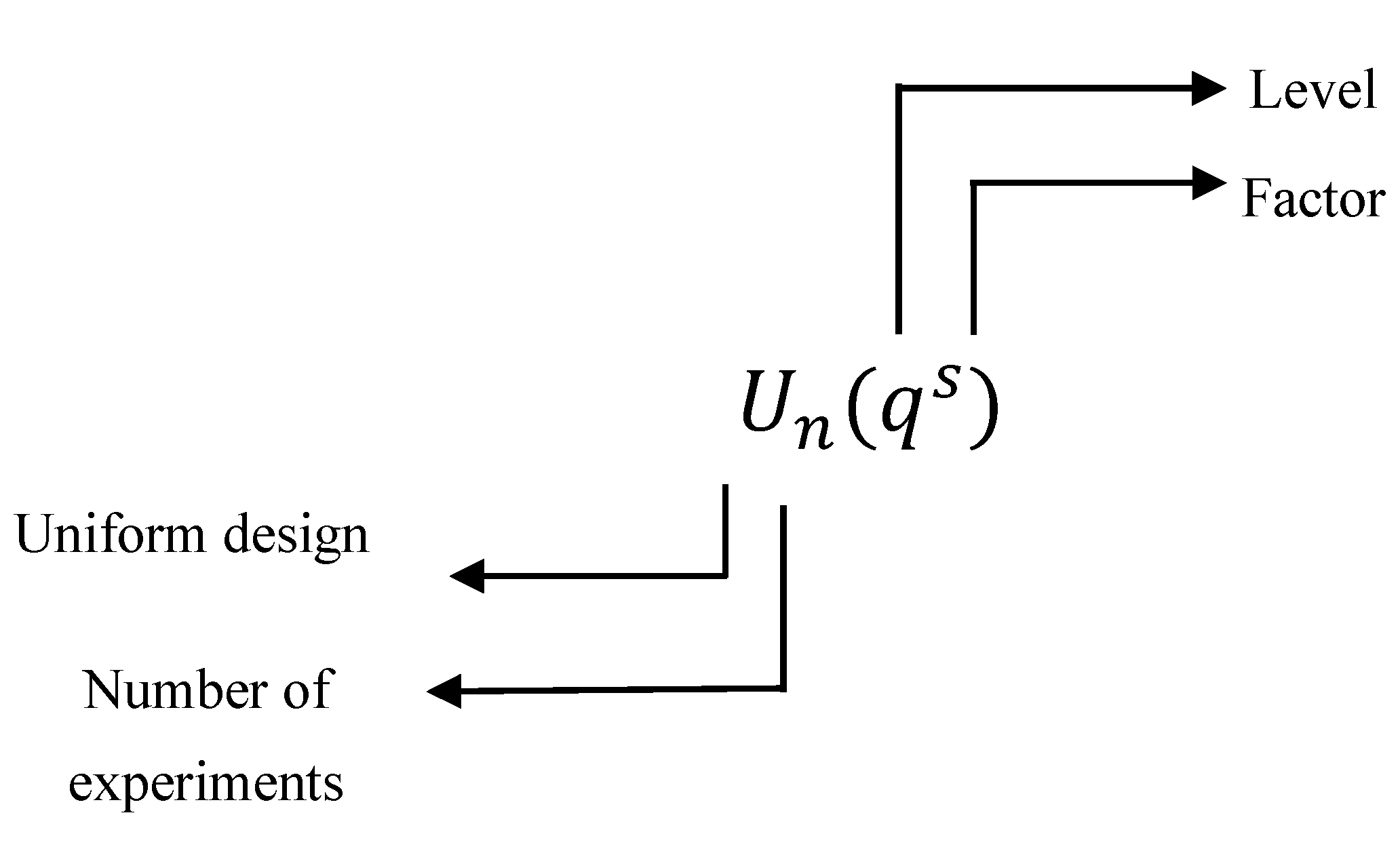

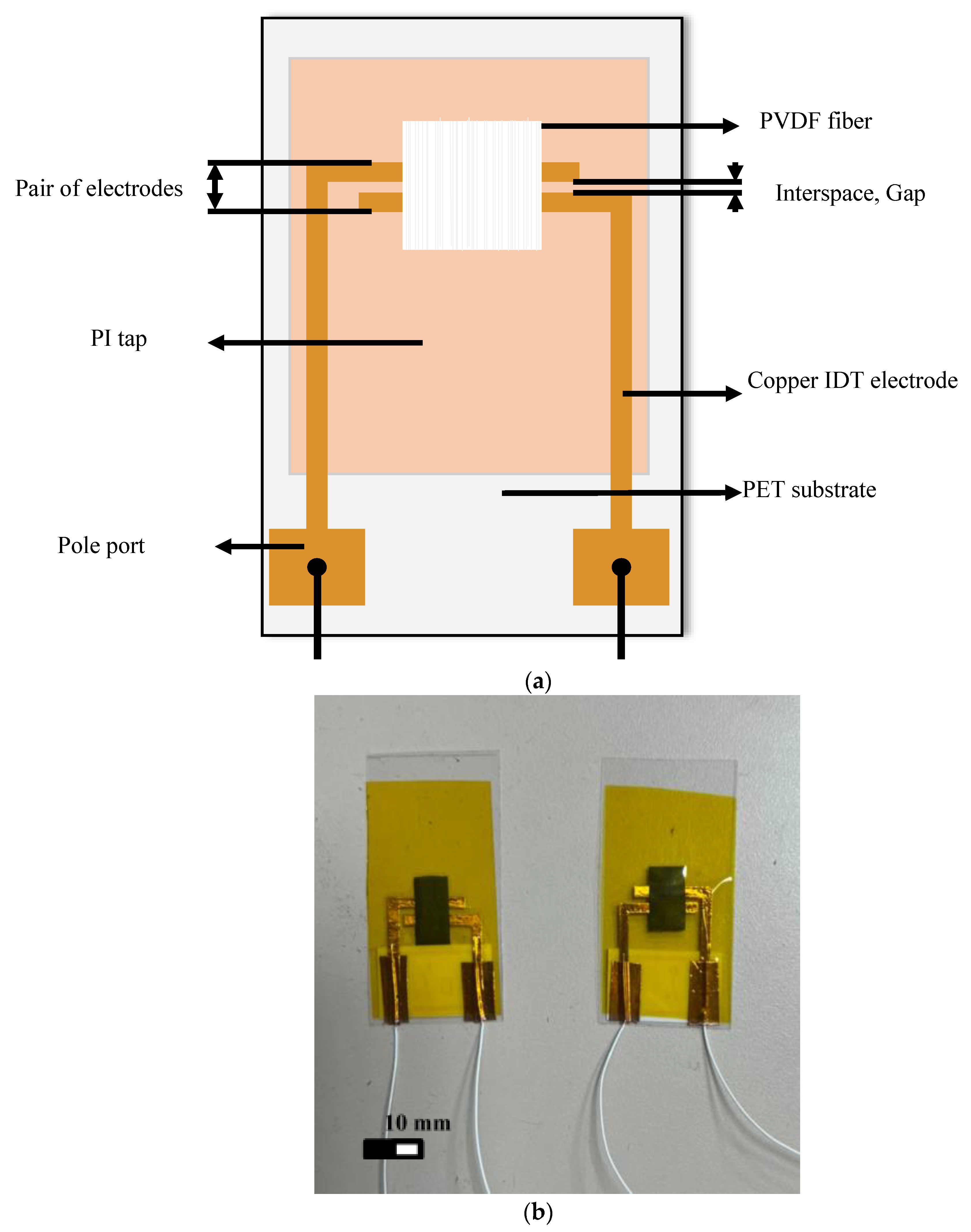

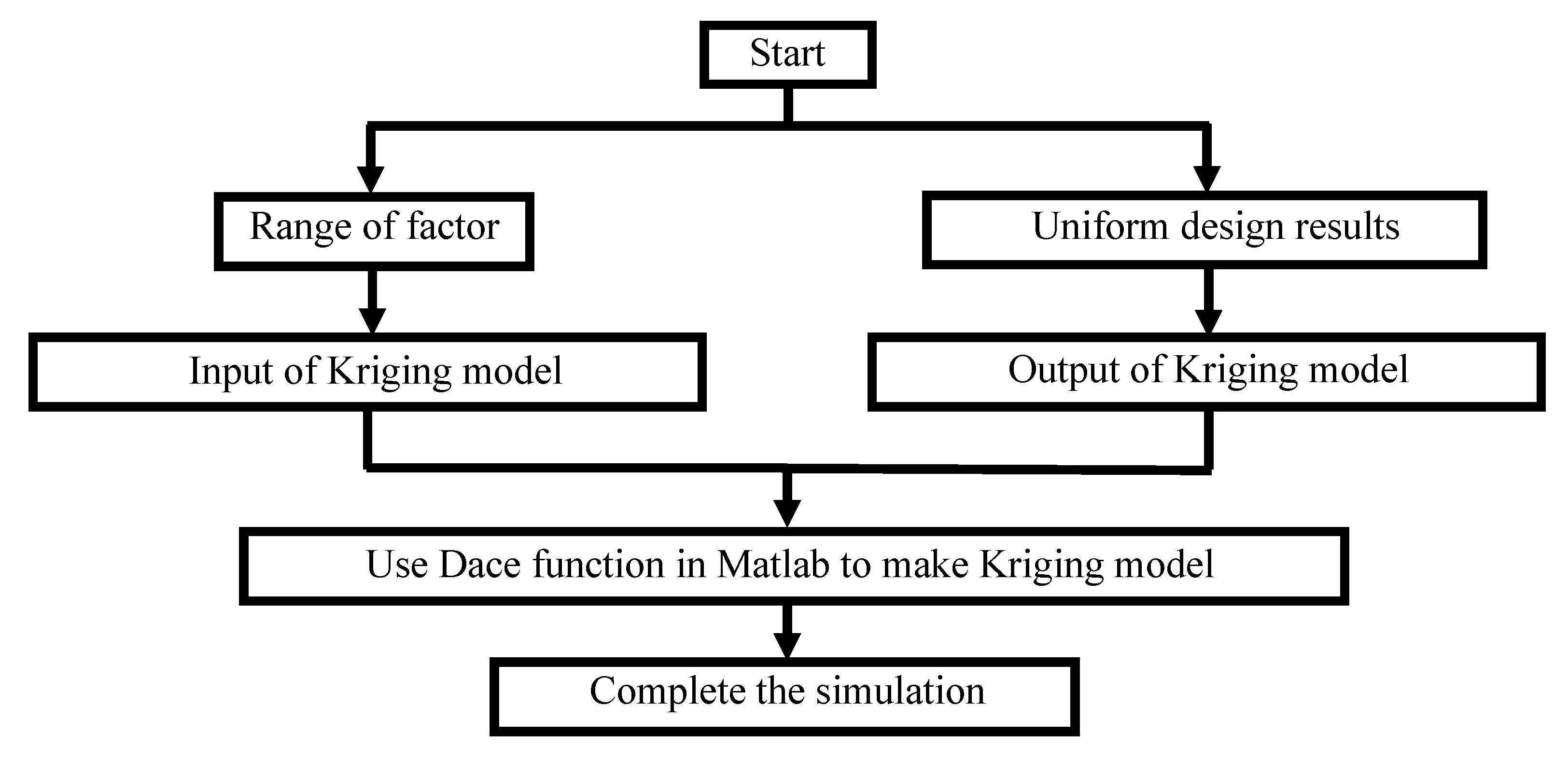

29]. In this study, the proposed sensor was developed by the near-field electrospinning technique. The piezoelectric fiber sensor was produced by adding graphene nanoparticles to the PVDF solution by the near-field electrospinning process with a cylinder collection to make the piezoelectric fibers orderly. The electrospinning process was performed by different weight percentages of additives and related experimental parameters by the uniform experimental design method. The finished sensor was packaged by the interdigitated electrode (IDT), PET substrate, and polydimethylsiloxane (PDMS).

4. Conclusions

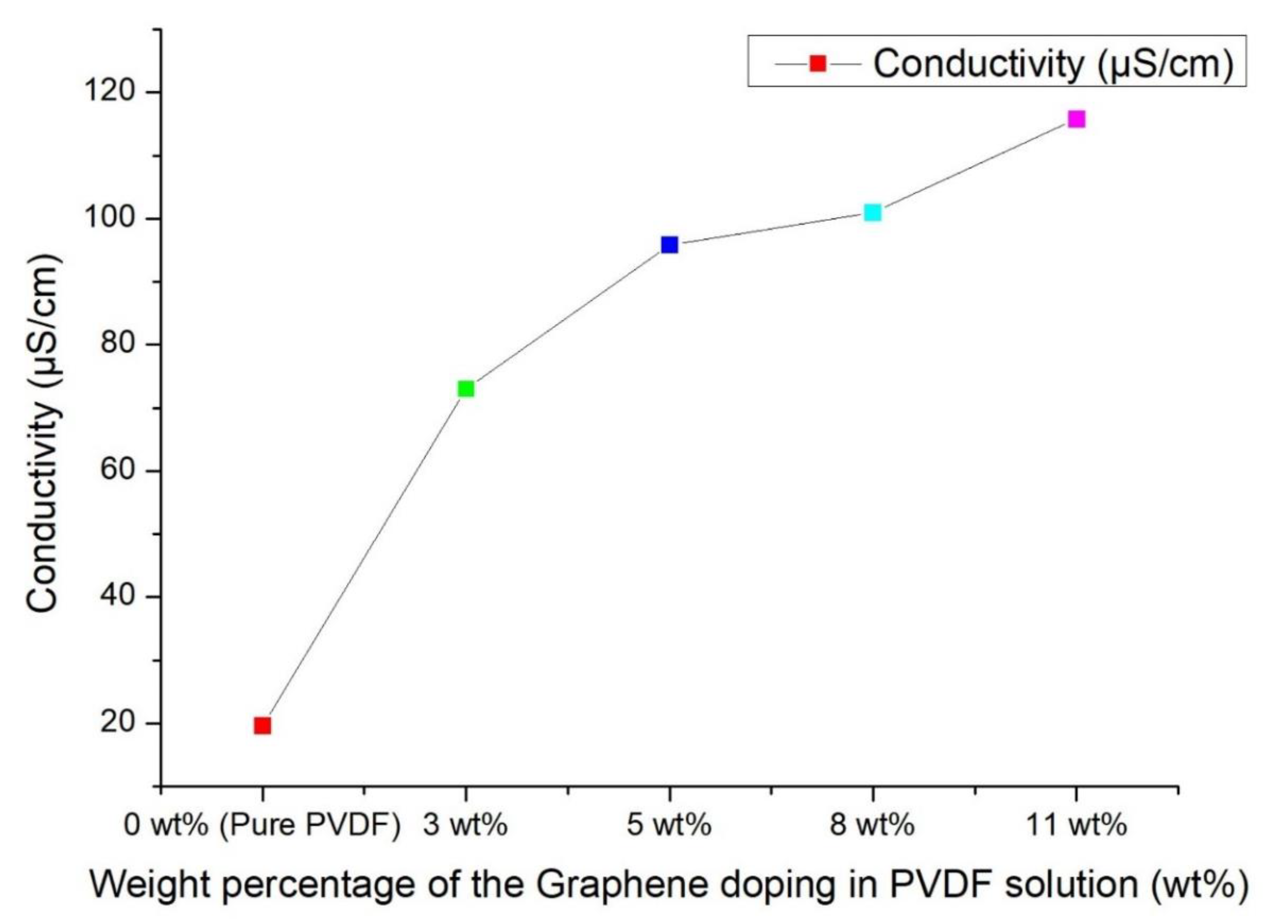

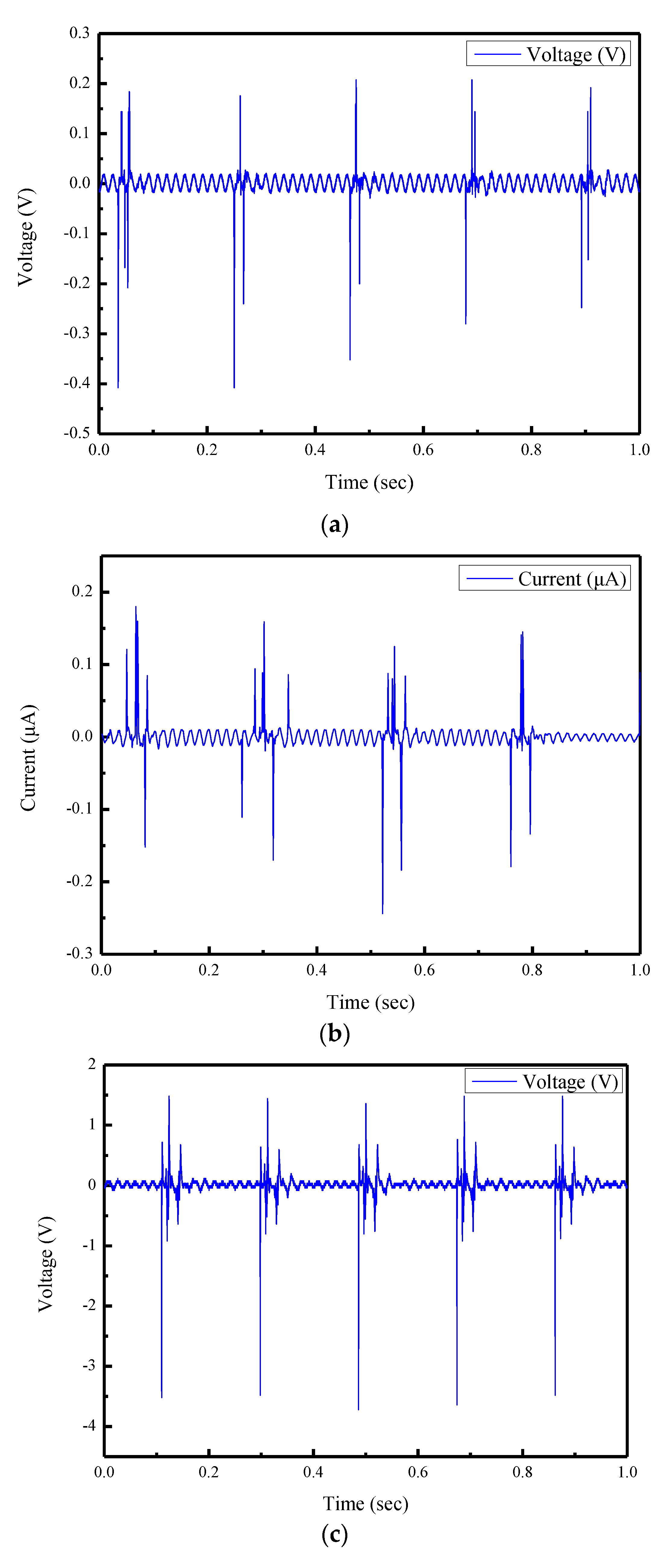

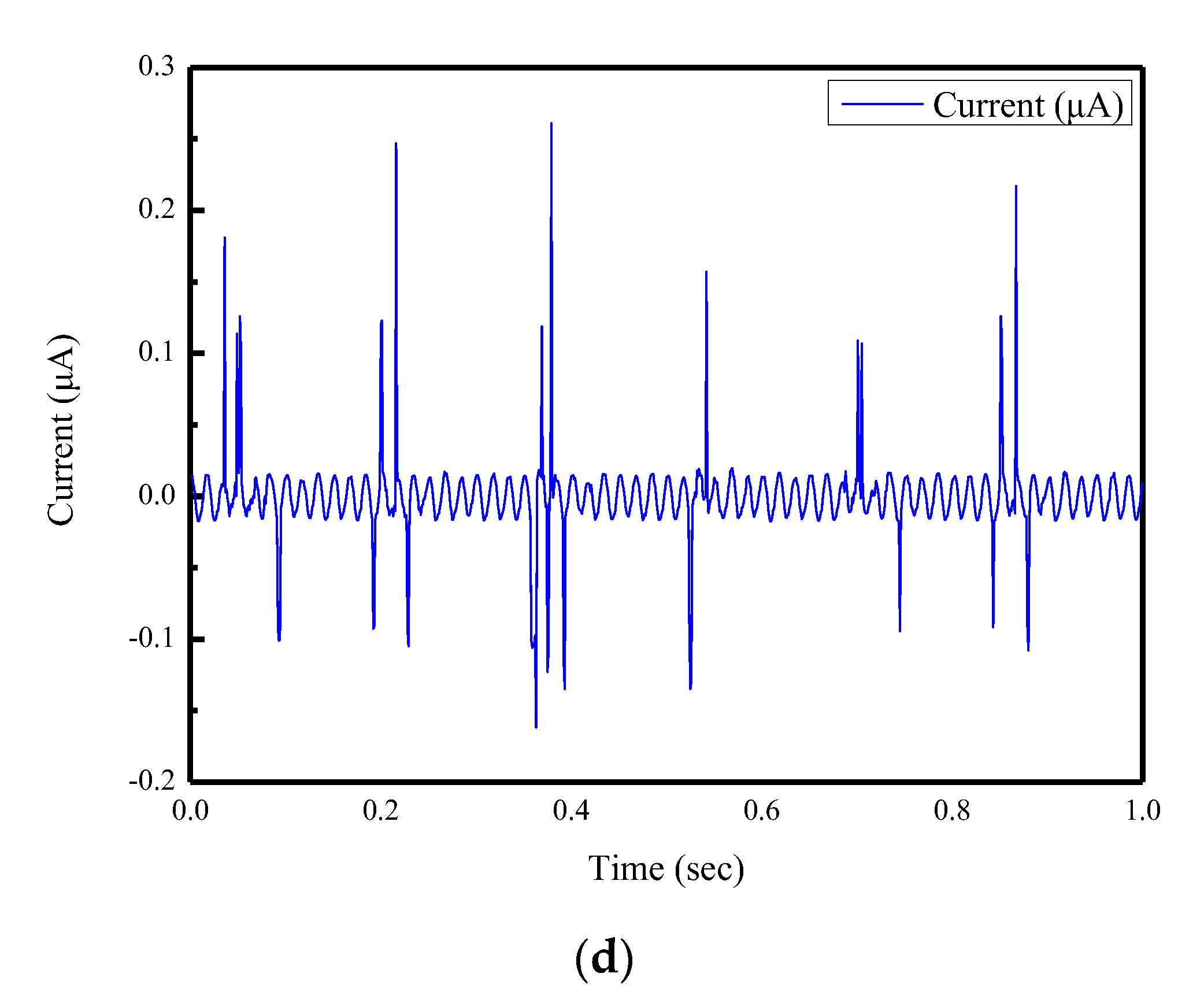

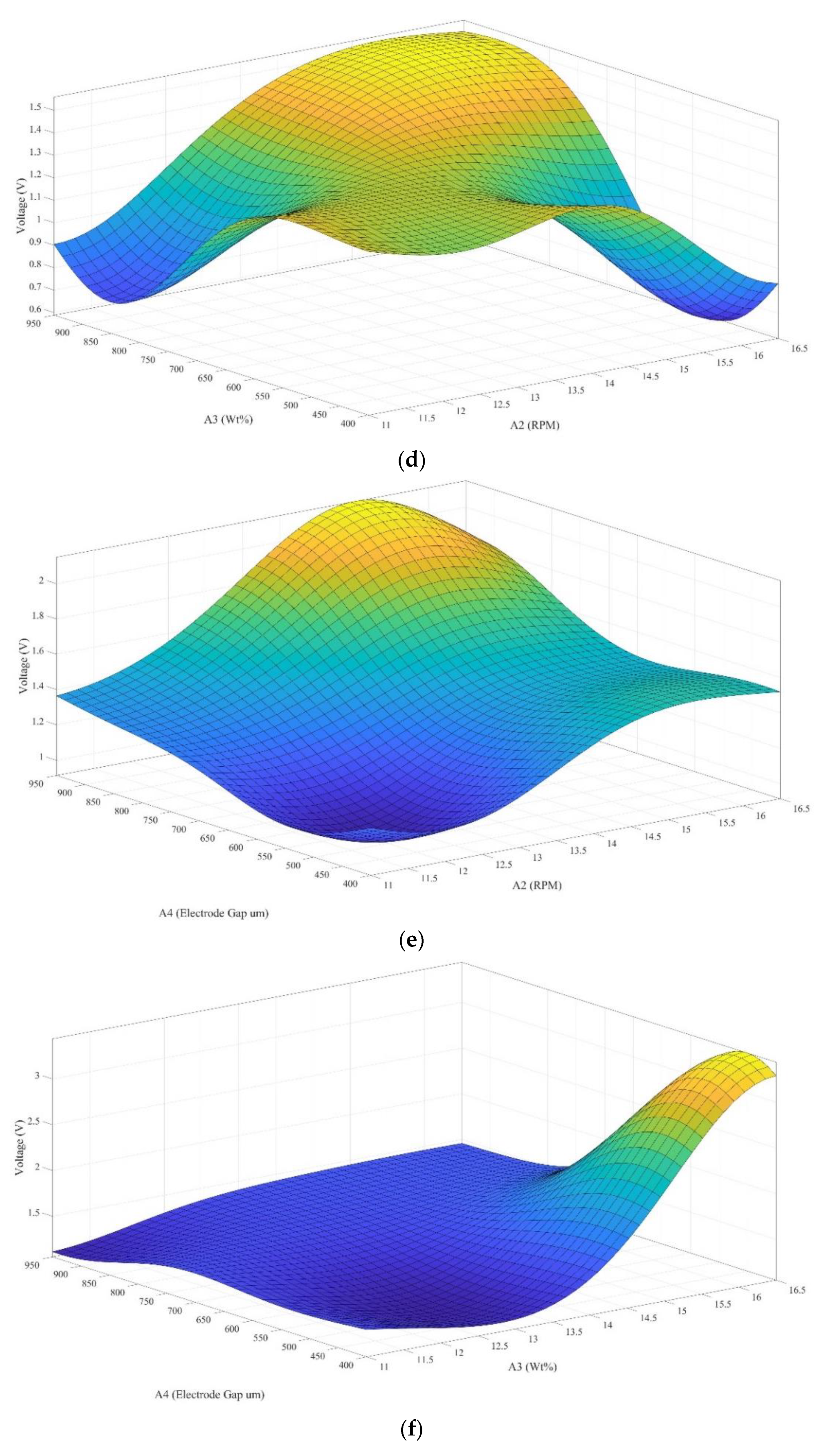

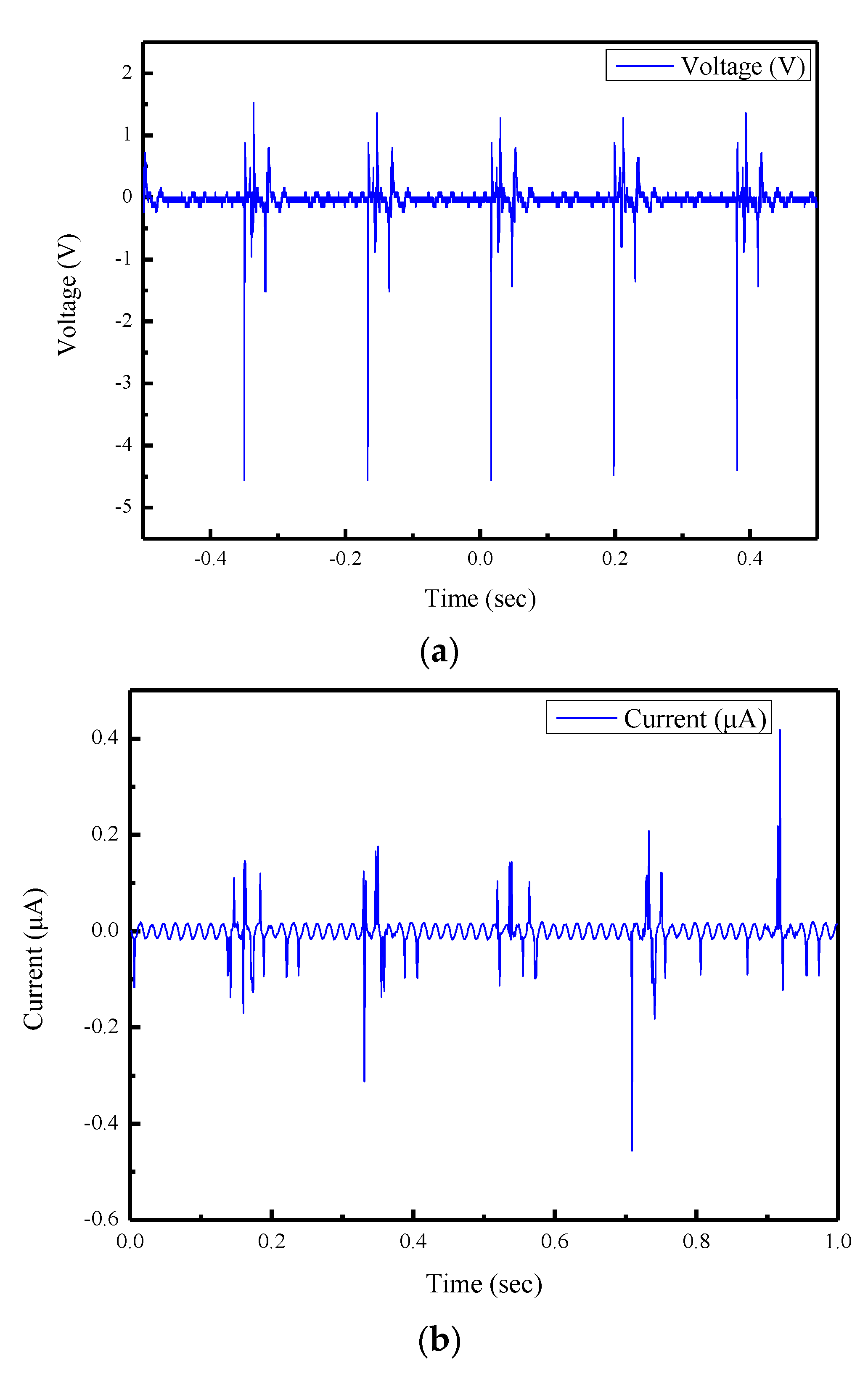

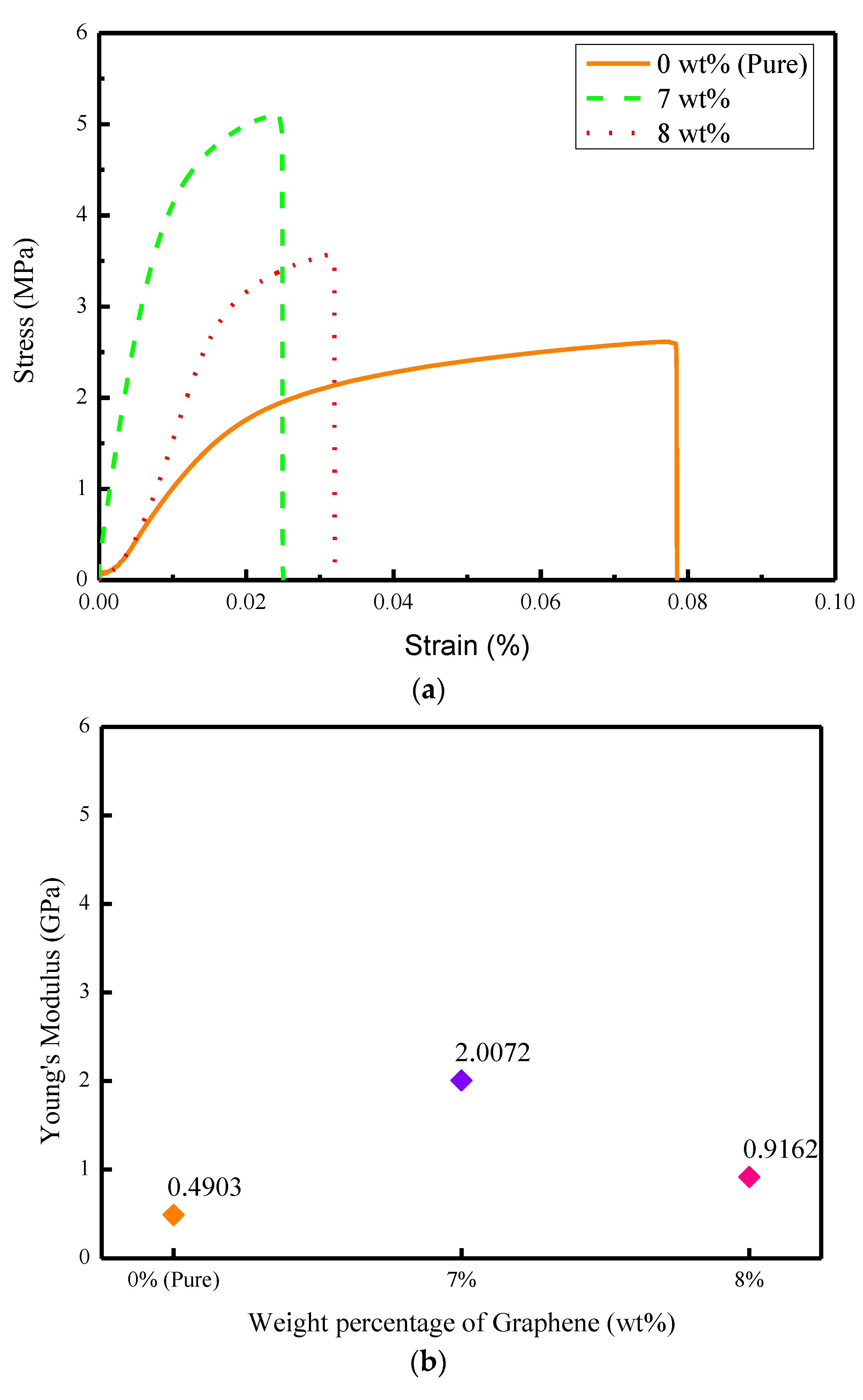

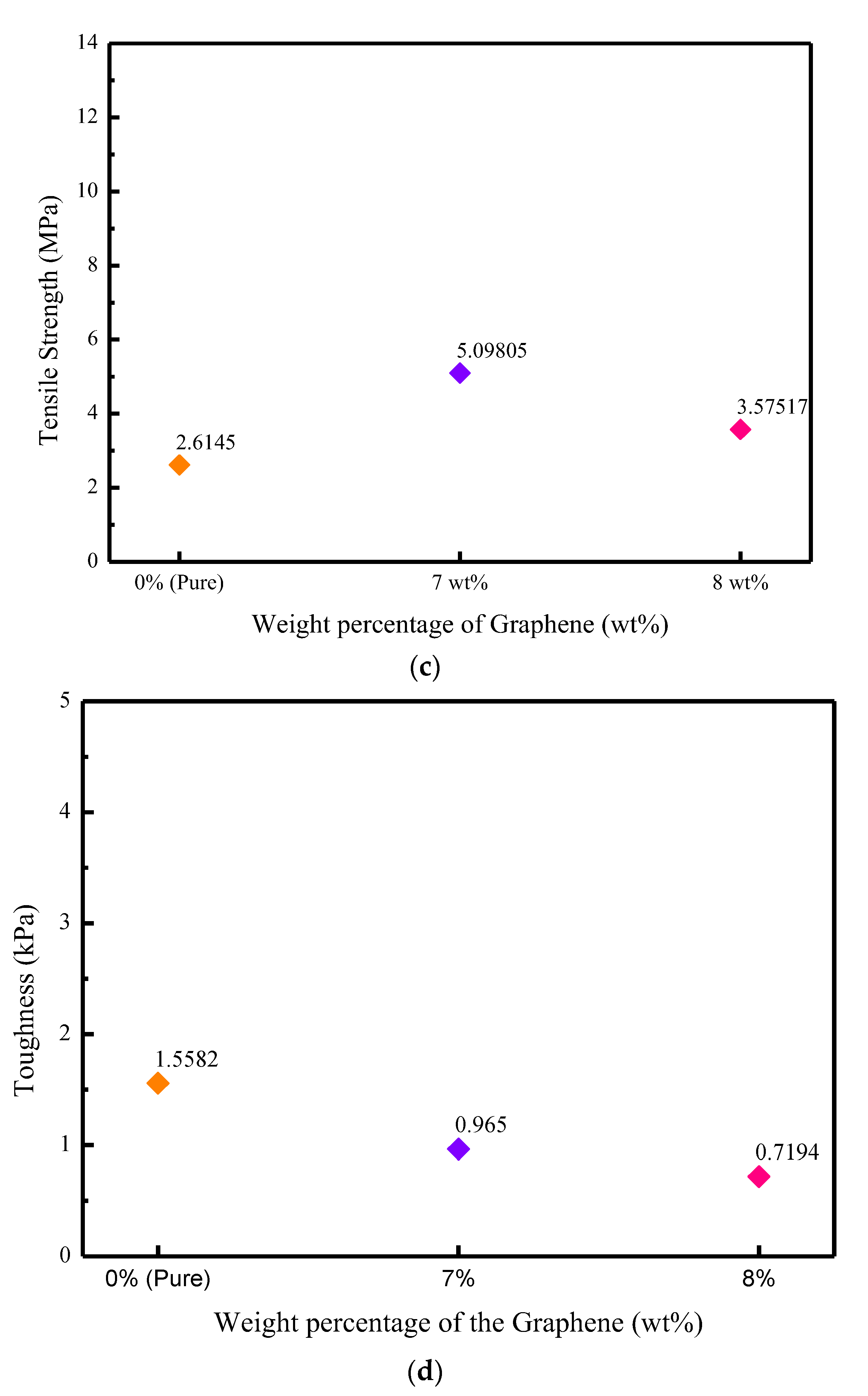

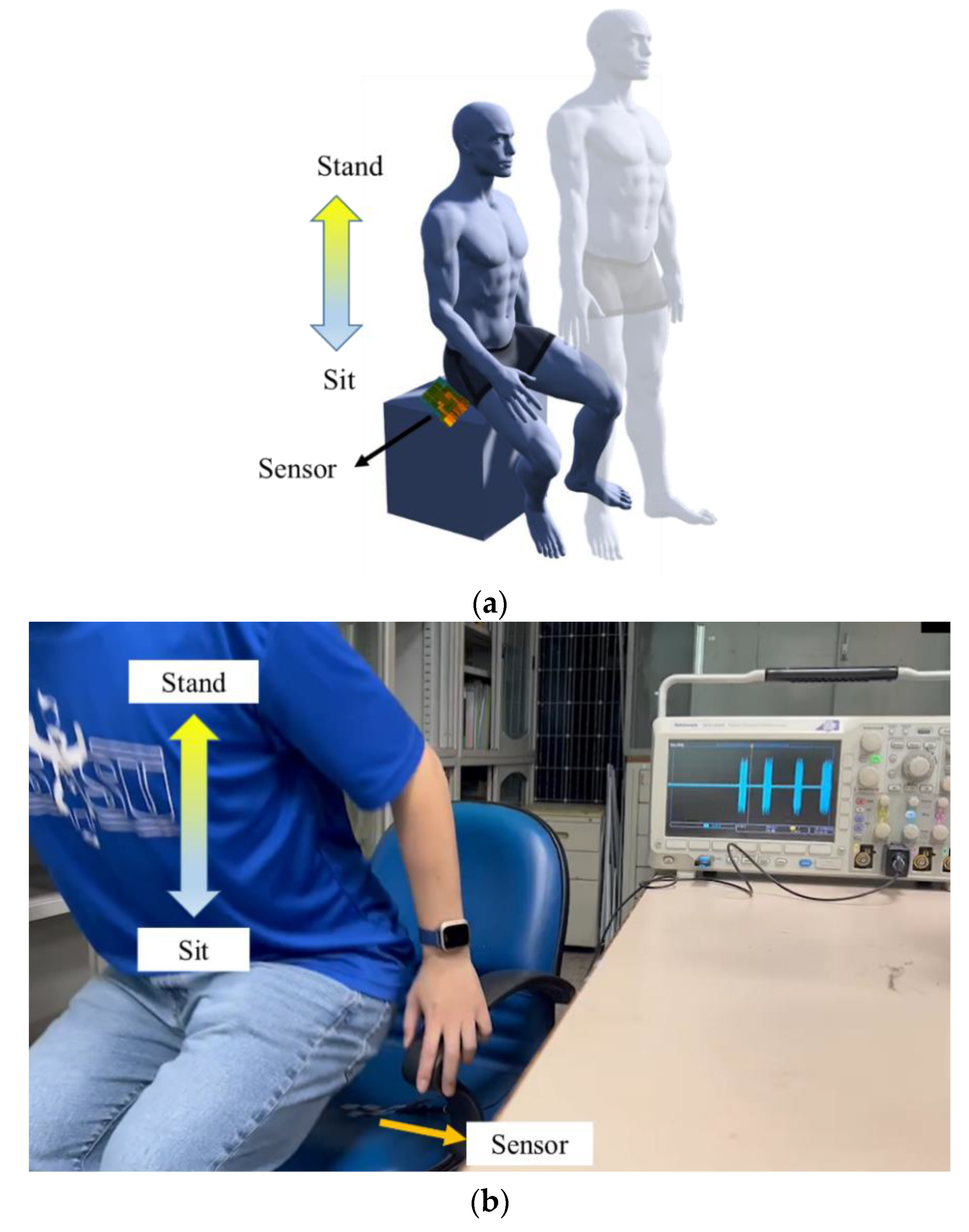

In this study, a novel PVDF/graphene piezoelectric fiber sensor was developed using the near-field electrospinning technology. The applied voltage in electrospinning, rotational speed of the drum collector, weight percentage of graphene, and sensor electrode gap were process parameters. When the weight percentage of the graphene doping ratio was 11 wt%, the conductivity reached 115.3 μS/cm, which was 5.9 times that of the pure PVDF solution. From tapping tests, the output voltage of the 7 wt% doping ratio PVDF/graphene sensor was 3.672 V, which was 9.37 times that of the pure PVDF sensor, indicating that adding graphene to PVDF could improve the piezoelectric effect. Optimized by the uniform experimental design method and Kriging model, the optimal parameters were determined. The maximum output voltage was 4.56 V at 5 wt% graphene doping ratio in PVDF fibers, which was 11.54 times that of the pure PVDF sensors, indicating that the PVDF/graphene sensors were expected to provide a better piezoelectric effect. Through the mechanical property tests, it was observed that the tensile strengths of PVDF/graphene fibers at 7 wt% and 8 wt% doping ratio were 5.1 MPa and 3.6 MPa, which were larger than those of the pure PVDF fibers. Preliminary applications of the proposed sensor, such as the detections of the wrist extension/flexion and stand–sit movement intentions, were carried out. Furthermore, swallowing, such as saliva-swallowing, drinking and eating, were detected by the proposed sensor. The experimental results showed that the proposed sensor had the potential to be used to detect dysphagia and swallowing dysfunction. The PVDF/graphene piezoelectric fiber sensor made by the near-field electrospinning had the characteristics of ductility of PVDF polymer and piezoelectricity of graphene, which increases the possibility of practical applications.