Sensor Location Matters When Estimating Player Workload for Baseball Pitching

Abstract

:1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Data Collection and Analysis

2.3. Statistical Analysis

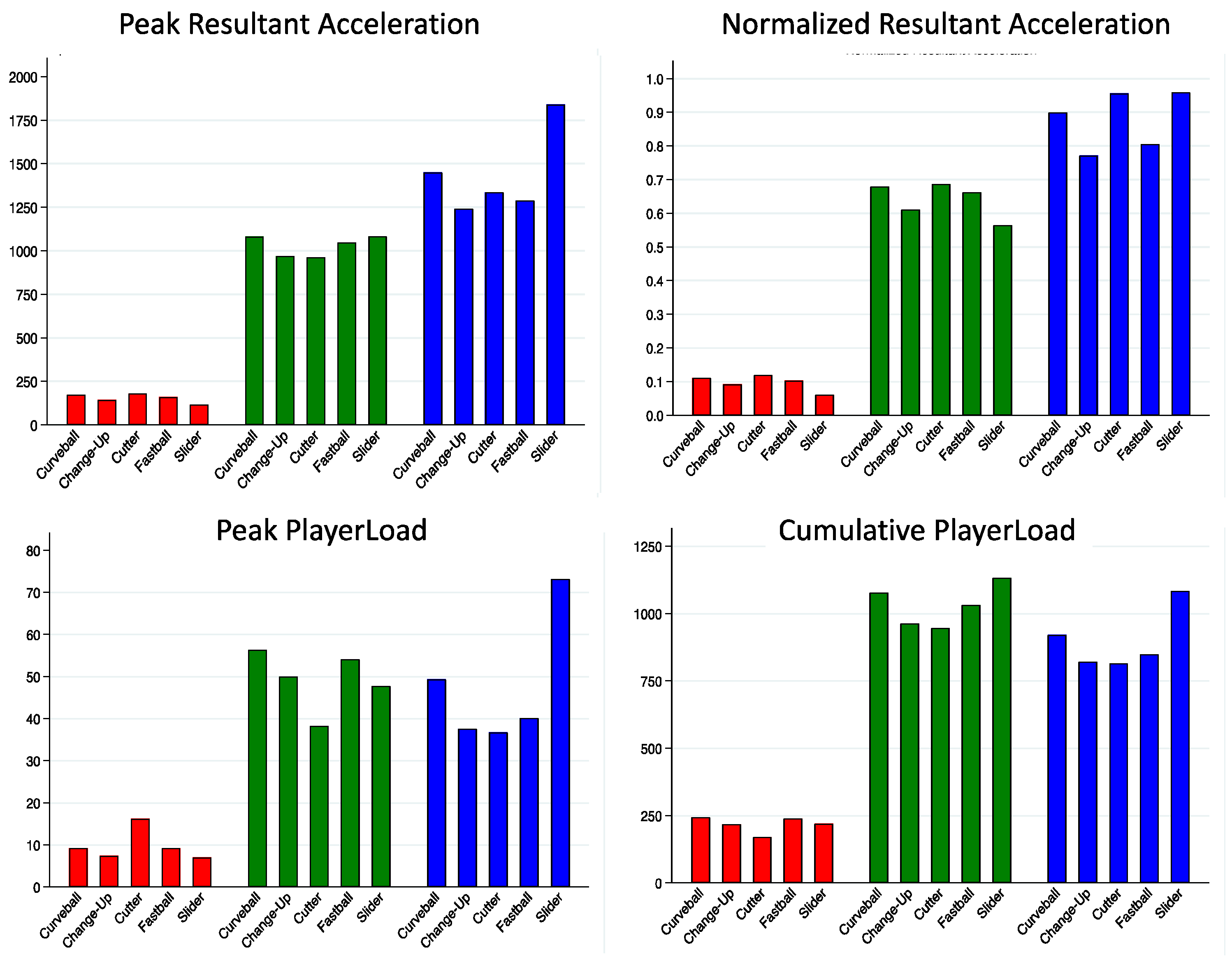

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Solomonow, M. Ligaments: A source of musculoskeletal disorders. J. Bodyw. Mov. Ther. 2009, 13, 136–154. [Google Scholar] [CrossRef] [PubMed]

- Lyman, S.; Fleisig, G.S.; Andrews, J.R.; Osinski, E.D. Effect of pitch type, pitch count, and pitching mechanics on risk of elbow and shoudler pain in youth baseball pitchers. Am. J. Sport. Med. 2002, 30, 463–468. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karakolis, T.; Bhan, S.; Crotin, R.L. Injuries to young professional baseball pitchers cannot be prevented solely by restricting number of innings pitched. J. Sport. Med. Phys. Fit. 2016, 56, 554–559. [Google Scholar]

- Saltzman, B.M.; Mayo, B.C.; Higgins, J.D.; Gowd, A.K.; Cabarcas, B.C.; Leroux, T.S.; Basques, B.A.; Nicholson, G.P.; Bush-Joseph, C.A.; Romeo, A.A.; et al. How many innings can we throw: Does workload influence injury risk in Major League Baseball? An analysis of professional starting pitchers between 2010 and 2015. J. Shoulder Elb. Surg. 2018, 27, 1386–1392. [Google Scholar] [CrossRef] [PubMed]

- Black, G.M.; Gabbett, T.J.; Cole, M.H.; Naughton, G. Monitoring Workload in Throwing-Dominant Sports: A Systematic Review. Sport. Med. 2016, 46, 1503–1516. [Google Scholar] [CrossRef]

- Mehta, S. Relationship between workload and throwing injury in varsity baseball players. Phys. Ther. Sport 2019, 40, 66–70. [Google Scholar] [CrossRef] [PubMed]

- Reinold, M.M.; Macrina, L.C.; Fleisig, G.S.; Aune, K.; Andrews, J.R. Effect of a 6-Week Weighted Baseball Throwing Program on Pitch Velocity, Pitching Arm Biomechanics, Passive Range of Motion, and Injury Rates. Sport. Health 2018, 10, 327–333. [Google Scholar] [CrossRef] [PubMed]

- Makhni, E.C.; Lizzio, V.A.; Meta, F.; Stephens, J.P.; Okoroha, K.R.; Moutzouros, V. Assessment of Elbow Torque and Other Parameters During the Pitching Motion: Comparison of Fastball, Curveball, and Change-up. Arthroscopy 2018, 34, 816–822. [Google Scholar] [CrossRef] [PubMed]

- Okoroha, K.R.; Lizzio, V.A.; Meta, F.; Ahmad, C.S.; Moutzouros, V.; Makhni, E.C. Predictors of Elbow Torque among Youth and Adolescent Baseball Pitchers. Am. J. Sport. Med. 2018, 46, 2148–2153. [Google Scholar] [CrossRef] [PubMed]

- Camp, C.L.; Tubbs, T.G.; Fleisig, G.S.; Dines, J.S.; Dines, D.M.; Altchek, D.W.; Dowling, B. The Relationship of Throwing Arm Mechanics and Elbow Varus Torque: Within-Subject Variation for Professional Baseball Pitchers Across 82,000 Throws. Am. J. Sport. Med. 2017, 45, 3030–3035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bullock, G.S.; Schmitt, A.C.; Chasse, P.; Little, B.A.; Diehl, L.H.; Butler, R.J. Differences in PlayerLoad and pitch type in collegiate baseball players. Sport. Biomech. 2019, 20, 938–946. [Google Scholar] [CrossRef] [PubMed]

- Fleisig, G.S.; Andrews, J.R.; Dillman, C.J.; Escamilla, R.F. Kinetics of baseball pitching with implications about injury mechanisms. Am. J. Sport. Med. 1995, 23, 233–239. [Google Scholar] [CrossRef]

- Gabbett, T.J.; Hulin, B.T.; Blanch, P.; Whiteley, R. High training workloads alone do not cause sports injuries: How you get there is the real issue. Br. J. Sport. Med. 2016, 50, 444–445. [Google Scholar] [CrossRef]

- Hulin, B.T.; Gabbett, T.J.; Blanch, P.; Chapman, P.; Bailey, D.; Orchard, J.W. Spikes in acute workload are associated with increased injury risk in elite cricket fast bowlers. Br. J. Sport. Med. 2014, 48, 708–712. [Google Scholar] [CrossRef] [PubMed]

- Bredt, S.; Chagas, M.H.; Peixoto, G.H.; Menzel, H.J.; de Andrade, A.G.P. Understanding Player Load: Meanings and Limitations. J. Hum. Kinet. 2020, 71, 5–9. [Google Scholar] [CrossRef] [Green Version]

- Aguinaldo, A.L.; Buttermore, J.; Chambers, H. Effects of upper trunk rotatin on shoulder joint torque among baseball pitchers of various levels. J. Appl. Biomech. 2007, 23, 42–51. [Google Scholar] [CrossRef] [Green Version]

- Aguinaldo, A.; Escamilla, R. Segmental Power Analysis of Sequential Body Motion and Elbow Valgus Loading During Baseball Pitching: Comparison between Professional and High School Baseball Players. Orthop. J. Sport. Med. 2019, 7, 2325967119827924. [Google Scholar] [CrossRef] [Green Version]

- Hirashima, M.; Yamane, K.; Nakamura, Y.; Ohtsuki, T. Kinetic chain of overarm throwing in terms of joint rotations revealed by induced acceleration analysis. J. Biomech. 2008, 41, 2874–2883. [Google Scholar] [CrossRef] [PubMed]

- Gabbett, T.J. GPS analysis of elite women’s field hockey training and competition. J. Strength Cond. Res. 2010, 24, 1321–1324. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnston, R.J.; Watsford, M.L.; Pine, M.J.; Spurrs, R.W.; Murphy, A.; Pruyn, E.C. Movement demands and match performance in professional Australian football. Int. J. Sport. Med. 2012, 33, 89–93. [Google Scholar] [CrossRef]

- Wilson, R.P.; White, C.R.; Quintana, F.; Halsey, L.G.; Liebsch, N.; Martin, G.R.; Butler, P.J. Moving towards acceleration for estimates of activity-specific metabolic rate in free-living animals: The case of the cormorant. J. Anim. Ecol. 2006, 75, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Driggers, A.R.; Bingham, G.E.; Bailey, C.A. The Relationship of Throwing Arm Mechanics and Elbow Varus Torque: Letter to the Editor. Am. J. Sport. Med. 2019, 47, NP1–NP5. [Google Scholar] [CrossRef]

- Boddy, K.J.; Marsh, J.A.; Caravan, A.; Lindley, K.E.; Scheffey, J.O.; O’Connell, M.E. Exploring wearable sensors as an alternative to marker based motion capture in the pitching delivery. PeerJ 2019, 7, e6365. [Google Scholar] [CrossRef]

- McGinnis, R.S.; Hough, J.; Perkins, N.C. Accuracy of Wearable Sensors for Estimating Joint Reactions. J. Comput. Nonlinear Dyn. 2017, 12, 041010. [Google Scholar] [CrossRef]

- Greenwood, D.T. Principles of Dynamics; Prentice-Hall: Englewood Cliffs, NJ, USA, 1988. [Google Scholar]

- Saha, S.; Lakes, R. The effect of soft tissue on wave-propagation and vibration tests for determining the in vivo properties of bone. J. Biomech. 1077, 10, 393–401. [Google Scholar] [CrossRef]

- Escamilla, R.F.; Fleisig, G.S.; Groeschner, D.; Akizuki, K. Biomechanical Comparisons among Fastball, Slider, Curveball, and Changeup Pitch Types and between Balls and Strikes in Professional Baseball Pitchers. Am. J. Sport. Med. 2017, 45, 3358–3367. [Google Scholar] [CrossRef] [PubMed]

- Fleisig, G.S.; Kingsley, D.S.; Loftice, J.W.; Dinnen, K.P.; Ranganathan, R.; Dun, S.; Escamilla, R.F.; Andrews, J.R. Kinetic comparison among the fastball, curveball, change-up, and slider in collegiate baseball pitchers. Am. J. Sport. Med. 2006, 34, 423–430. [Google Scholar] [CrossRef] [PubMed]

| Player | Warm-Up Throws | Fastballs | Change-Ups | Curveballs | Sliders | Cutters | Total |

|---|---|---|---|---|---|---|---|

| 1 | 25 | 18 | 7 | 10 | - | - | 60 |

| 2 | 17 | 21 | 13 | 16 | - | - | 67 |

| 3 | 20 | 19 | 7 | 6 | 5 | - | 57 |

| 4 | 17 | 19 | 7 | 10 | - | - | 53 |

| 5 | 12 | 17 | 7 | 10 | - | - | 46 |

| 6 | 20 | 18 | 7 | 9 | - | - | 54 |

| 7 | 8 | 18 | 7 | 10 | - | - | 43 |

| 8 | 16 | 17 | 7 | 6 | - | 4 | 50 |

| 9 | 24 | 19 | 7 | 8 | - | 2 | 60 |

| 10 | 17 | 18 | 7 | 10 | - | - | 52 |

| Peak Resultant Acceleration (WL1) | Peak PlayerLoad (WL2) | Cumulative PlayerLoad (WL3) | Normalized Resultant Acceleration (WL4) | |

|---|---|---|---|---|

| Trunk | ||||

| Fastball | 160.5 ± 113.4 | 9.2 ± 12.3 | 238.6 ± 87.6 | 0.10 ± 0.08 |

| Change-Up | 143.3 ± 84.1 | 7.4 ± 8.7 | 217.3 ± 85.2 | 0.09 ± 0.06 |

| Curveball | 172.6 ± 118.0 | 9.2 ± 11.9 | 243.8 ± 87.9 | 0.11 ± 0.08 |

| Slider | 17.2 ± 102.8 | 7.0 ± 6.8 | 219.7 ± 201.3 | 0.06 ± 0.05 |

| Cutter | 180.2 ± 266.2 | 16.2 ± 25.3 | 170.7 ± 230.9 | 0.12 ± 0.18 |

| p = 0.34 | p = 0.57 | p = 0.73 | p = 0.34 | |

| Upper Arm | ||||

| Fastball | 1046.6 ± 184.0 | 54.1 ± 17.0 | 1031.4 ± 166.5 | 0.66 ± 0.14 |

| Change-Up | 969.8 ± 209.6 | 50.0 ± 20.8 | 963.5 ± 186.8 * | 0.61 ± 0.15 |

| Curveball | 1082.5 ± 194.4 | 56.3 ± 23.5 | 1077.8 ± 157.3 ** | 0.68 ± 0.12 |

| Slider | 1082.9 ± 45.2 | 47.8 ± 3.2 | 1132.6 ± 69.0 | 0.56 ± 0.02 |

| Cutter | 961.9 ± 123.5 | 38.2 ± 10.1 | 945.7 ± 59.4 | 0.69 ± 0.04 |

| p = 0.36 | p = 0.65 | p = 0.04 | p = 0.51 | |

| Forearm | ||||

| Fastball | 1288.7 ± 184.1 | 40.1 ± 12.1 | 848.9 ± 97.0 | 0.81 ± 0.08 |

| Change-Up | 1241.3 ± 190.6 | 37.6 ± 12.3 | 820.8 ± 126.5 | 0.77 ± 0.07 |

| Curveball | 1450.9 ± 243.5 *,** | 49.4 ± 17.1 *,** | 921.2 ± 104.8 *,** | 0.90 ± 0.05 *,** |

| Slider | 1840.5 ± 82.0 *,** | 73.2 ± 5.1 *,**,*** | 1083.3 ± 56.7 *,**,*** | 0.96 ± 0.04 *,**,*** |

| Cutter | 1336.3 ± 116.2 **** | 36.7 ± 6.1 **** | 814.9 ± 81.8 **** | 0.96 ± 0.03 **** |

| p < 0.001 | p = 0.05 | p = 0.008 | p < 0.001 |

| Fastball | Change-Up | Curveball | Slider | Cutter | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WL1 | WL2 | WL3 | WL4 | WL1 | WL2 | WL3 | WL4 | WL1 | WL2 | WL3 | WL4 | WL1 | WL2 | WL3 | WL4 | WL1 | WL2 | WL3 | WL4 | |

| WL1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |||||||||||||||

| WL2 | 0.86 | 1.00 | 0.78 | 1.00 | 0.92 | 1.00 | −0.03 | 1.00 | 0.89 | 1.00 | ||||||||||

| WL3 | 0.59 | 0.54 | 1.00 | 0.66 | 0.63 | 1.00 | 0.72 | 0.73 | 1.00 | 0.36 | −0.56 | 1.00 | 0.96 | 0.94 | 1.00 | |||||

| WL4 | 0.24 | 0.06 | 0.26 | 1.00 | 0.33 | 0.10 | 0.44 | 1.00 | 0.41 | 0.31 | 0.31 | 1.00 | 1.00 | −0.03 | 0.36 | 1.00 | 0.74 | 0.43 | 0.56 | 1.00 |

| Speed (mph) | Spin (rpm) | True Spin (rpm) | Spin Efficiency | Horizontal Break | Vertical Break | |

|---|---|---|---|---|---|---|

| Fastball | 83.4 ± 4.4 | 1339.9 ± 956.9 | 1174.0 ± 849.8 | 58.7 ± 41.8 | −0.22 ± 8.9 | 9.45 ± 8.4 |

| Change-Up | 76.6 ± 5.3 | 1171.6 ± 752.5 | 1009.9 ± 674.2 | 62.2 ± 39.8 | 0.39 ± 11.2 | 7.65 ± 6.1 |

| Curveball | 72.7 ± 4.3 | 1531.6 ± 990.0 | 857.0 ± 620.7 | 40.5 ± 29.9 | −1.24 ± 9.2 | −3.63 ± 6.0 |

| Slider | 81.0 ± 1.4 | 2150.0 ± 37.2 | 558.2 ± 57.8 | 26.0 ± 2.8 | −2.82 ± 0.47 | 6.62 ± 1.1 |

| Cutter | 72.3 ± 4.1 | 959.7 ± 1055.1 | 339.5 ± 372.9 | 17.7 ± 19.4 | −0.28 ± 4.3 | 1.75 ± 4.4 |

| Grand Total | 79.0 ± 6.5 | 1359.5 ± 932.6 | 1035.9 ± 765.7 | 53.6 ± 39.3 | −0.39 ± 9.4 | 5.52 ± 9.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agresta, C.; Freehill, M.T.; Zendler, J.; Giblin, G.; Cain, S. Sensor Location Matters When Estimating Player Workload for Baseball Pitching. Sensors 2022, 22, 9008. https://doi.org/10.3390/s22229008

Agresta C, Freehill MT, Zendler J, Giblin G, Cain S. Sensor Location Matters When Estimating Player Workload for Baseball Pitching. Sensors. 2022; 22(22):9008. https://doi.org/10.3390/s22229008

Chicago/Turabian StyleAgresta, Cristine, Michael T. Freehill, Jessica Zendler, Georgia Giblin, and Stephen Cain. 2022. "Sensor Location Matters When Estimating Player Workload for Baseball Pitching" Sensors 22, no. 22: 9008. https://doi.org/10.3390/s22229008

APA StyleAgresta, C., Freehill, M. T., Zendler, J., Giblin, G., & Cain, S. (2022). Sensor Location Matters When Estimating Player Workload for Baseball Pitching. Sensors, 22(22), 9008. https://doi.org/10.3390/s22229008